Continuous Ozonation Coupled with UV-C Irradiation for a Sustainable Post-Harvest Processing of Vaccinium macrocarpon Ait. Fruits to Reduce Storage Losses

Abstract

:1. Introduction

2. Materials and Methods

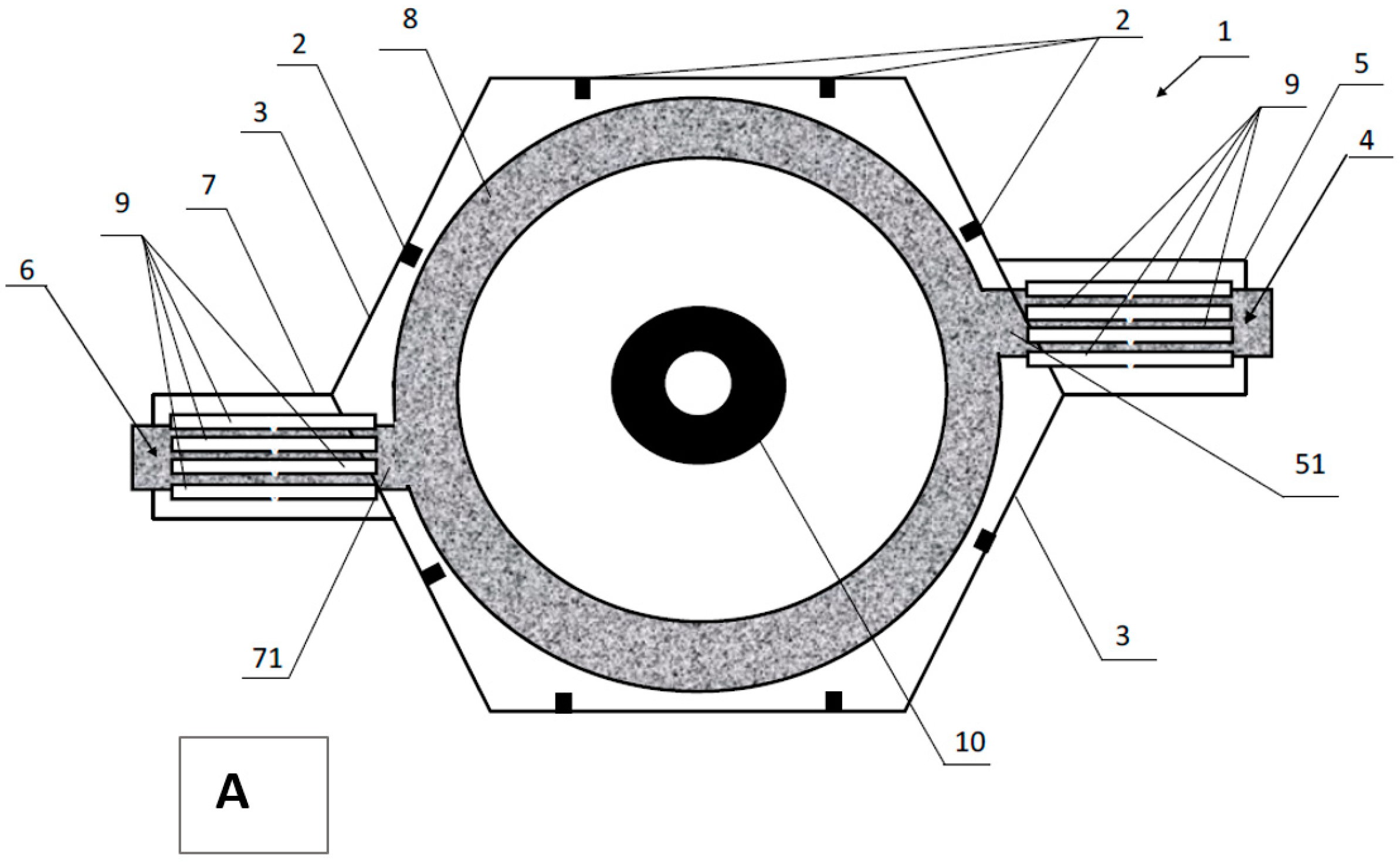

2.1. Construction of a System for Continuous Ozonation and UV Exposure

2.2. Research Material

2.3. Determination of Microbiological Load

2.4. Determination of Water Content in Fruit

2.5. Mechanical Properties of Fruit

2.6. Determining the Extent of Fruit Losses

2.7. Statistical Analysis

3. Results and Discussion

3.1. Modification of the Post-Harvest Processing Technology for Wet-Harvested Cranberries

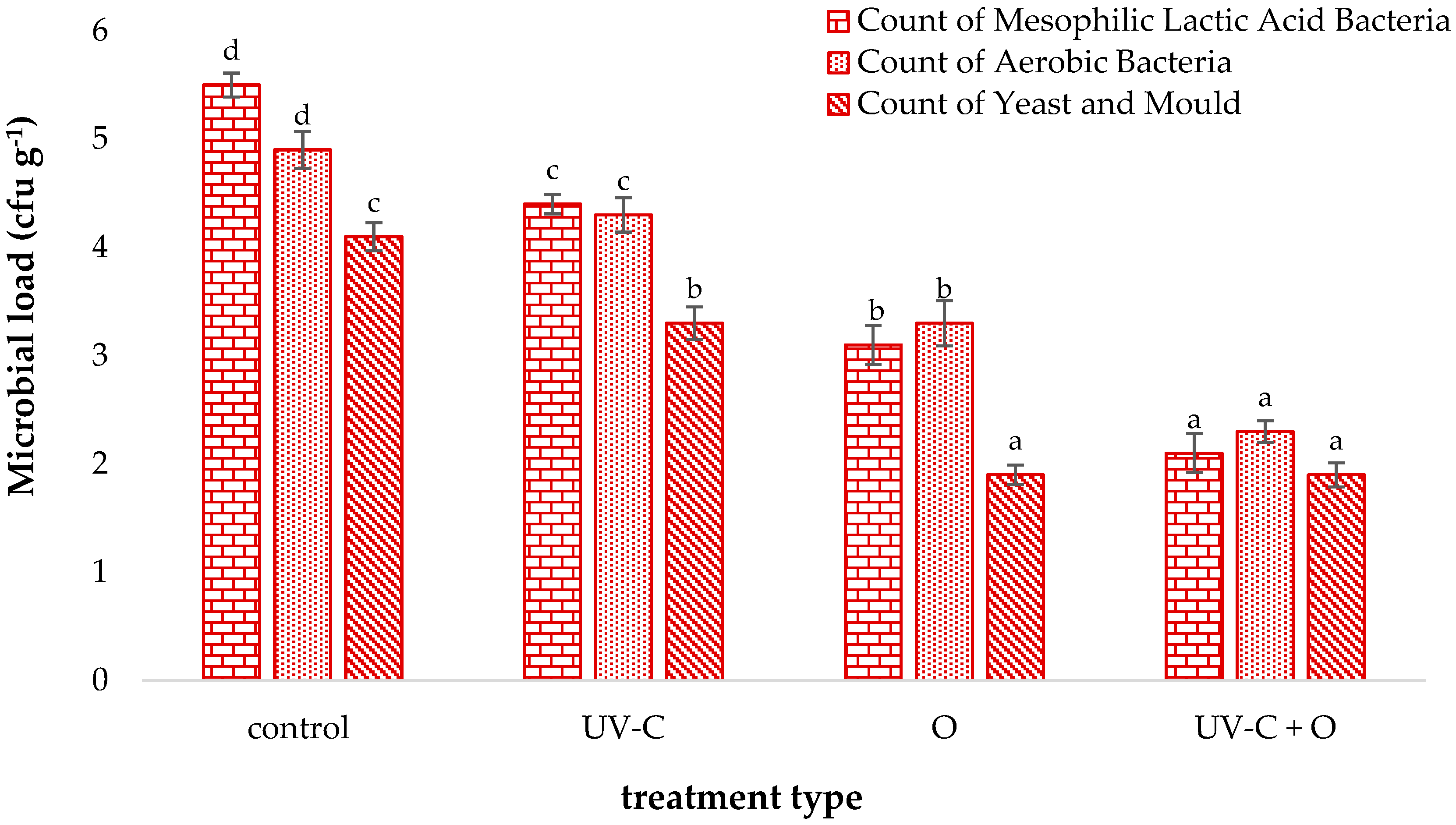

3.2. Reducing the Microbiological Load on Large Fruit

3.3. Cranberry Fruit Texture Analysis

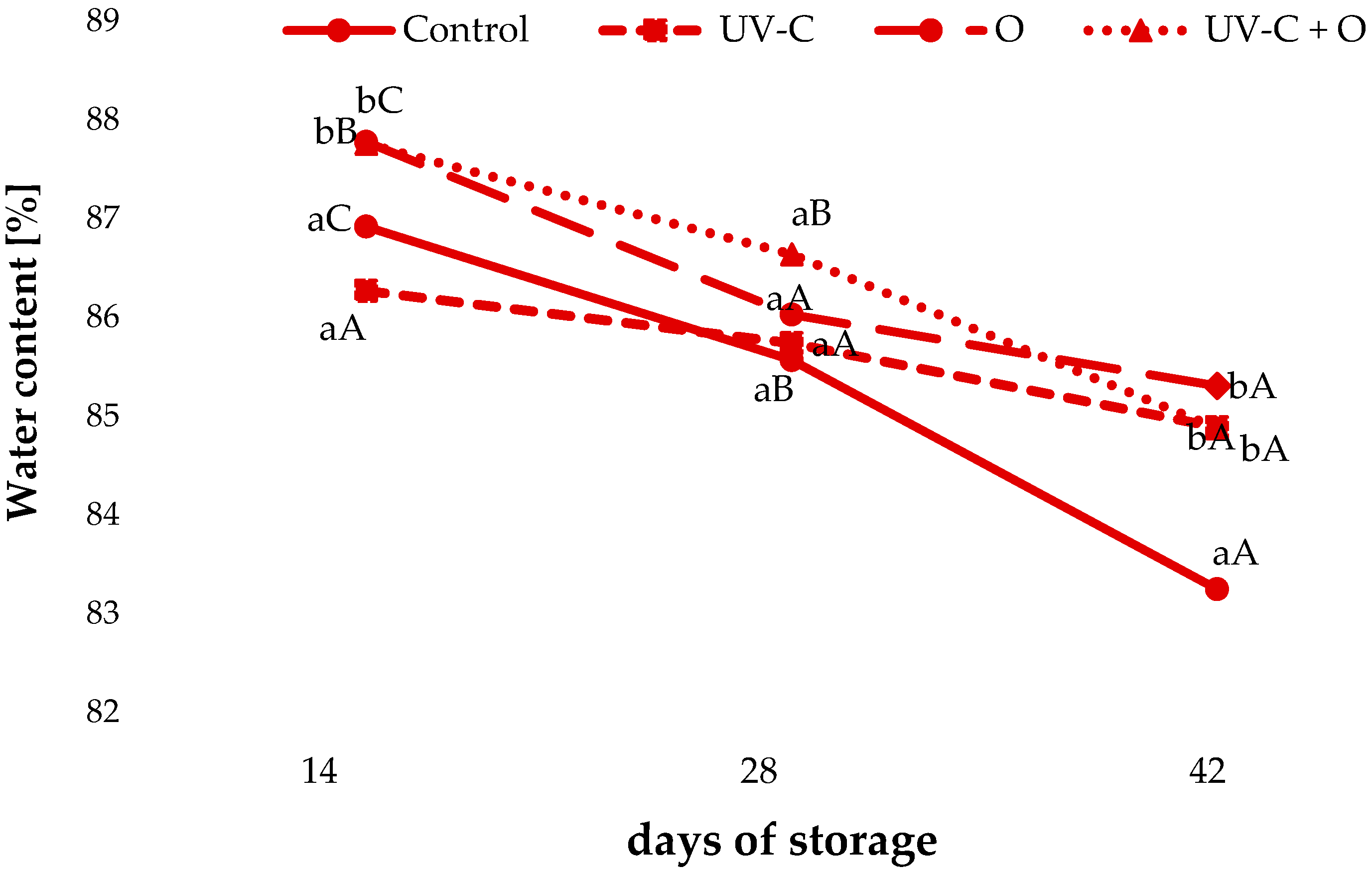

3.3.1. Water Content

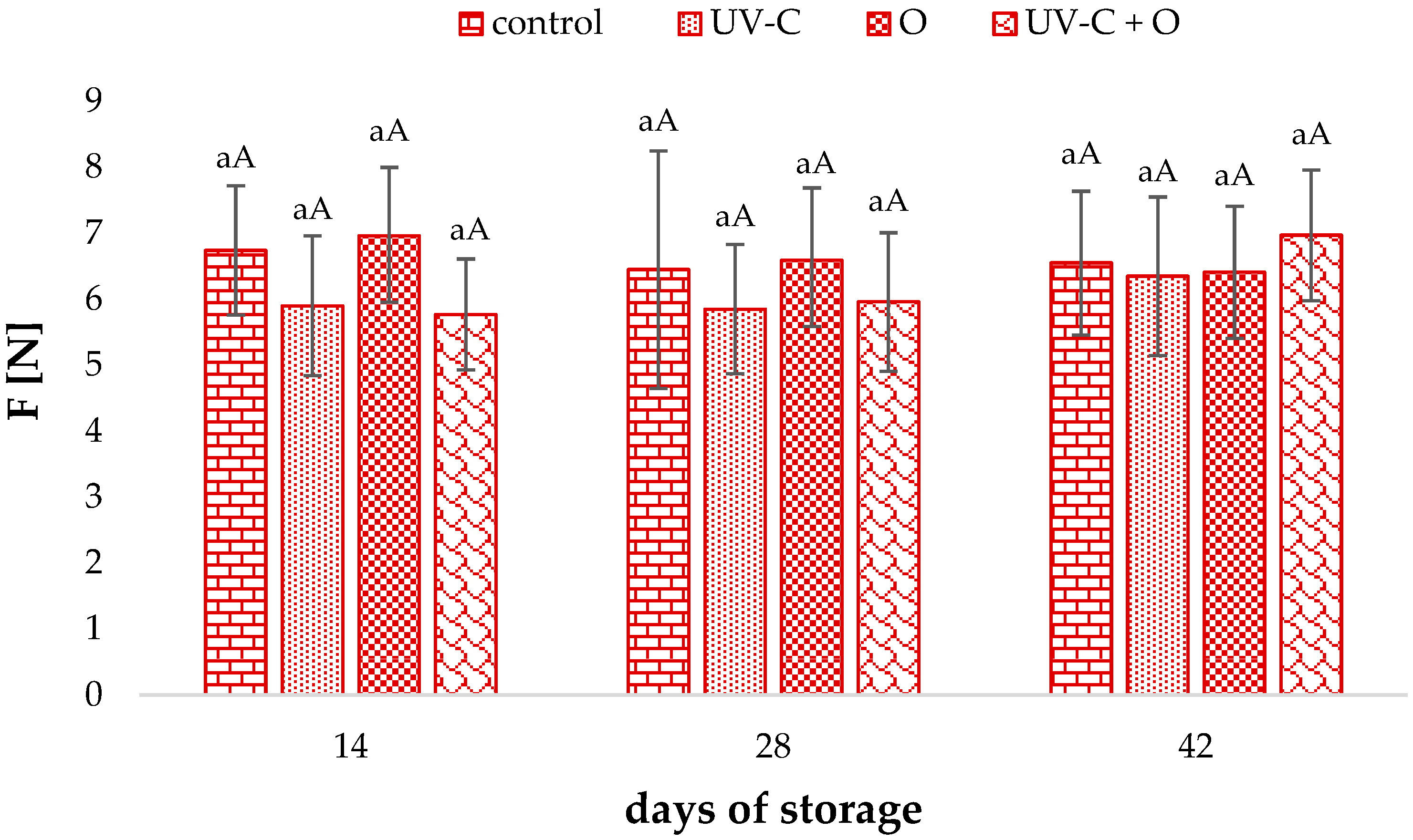

3.3.2. Mechanical Properties of Cranberry Fruits

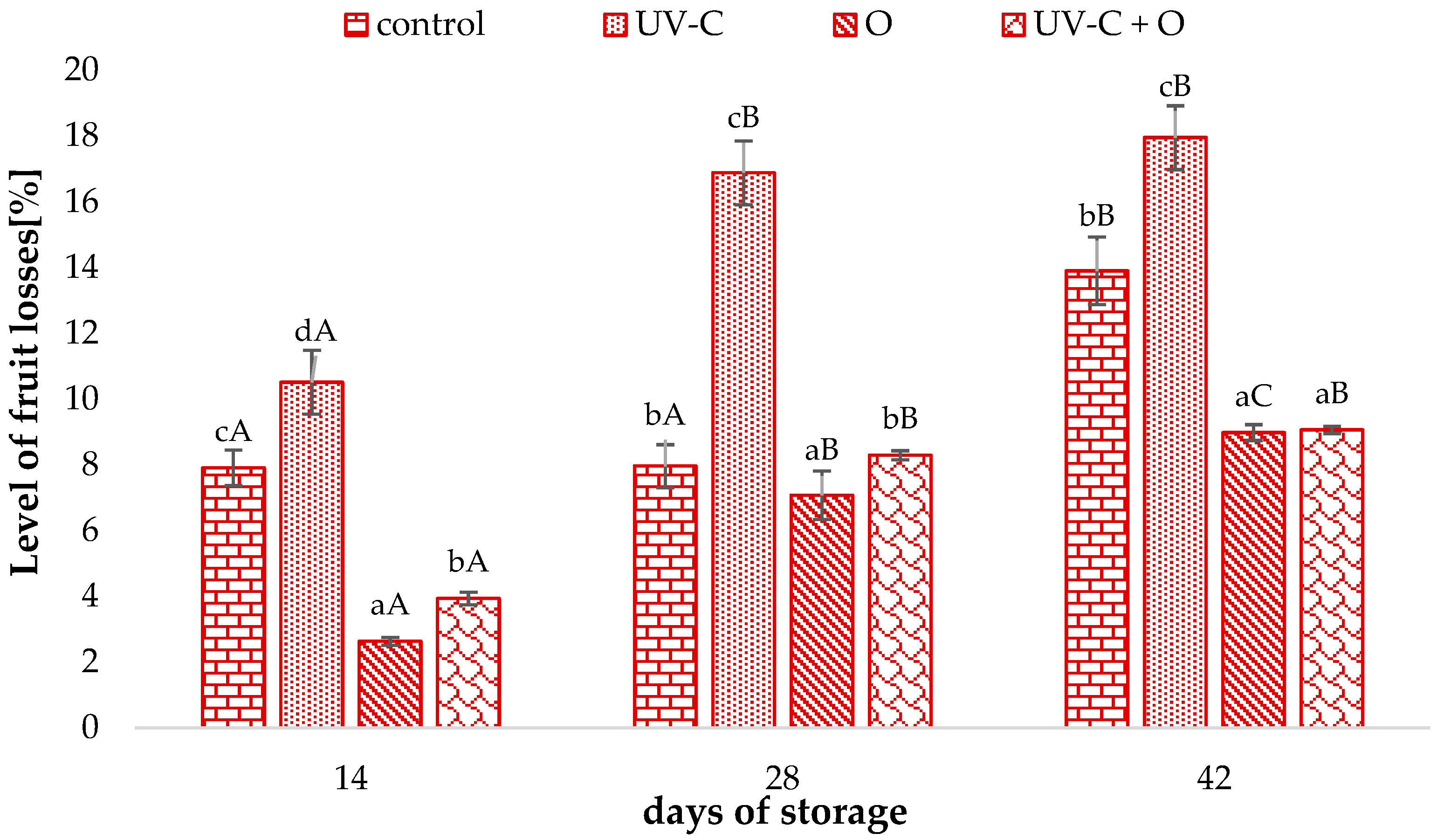

3.3.3. Reduction in the Level and Value of Fruit Losses of Cranberries

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Majeed, M.; Nagabhushanam, K.; Arumugam, S.; Natarajan, S.; Majeed, S.; Pande, A.; Beede, K.; Ali, F. Cranberry seed fibre: A promising prebiotic fibre and its fermentation by the probiotic Bacillus coagulans MTCC 5856. Int. J. Food Sci. Technol. 2018, 53, 1640–1647. [Google Scholar] [CrossRef]

- Kennedy, C.D. Hydrologic and nutrient response of groundwater to flooding of cranberry farms in southeastern Massachusetts, USA. J. Hydrol. 2015, 525, 441–449. [Google Scholar] [CrossRef]

- Negri, C.; Chiaradia, E.; Rienzner, M.; Mayer, A.; Gandolfi, C.; Romani, M.; Facchi, A. On the effects of winter flooding on the hydrological balance of rice areas in northern Italy. J. Hydrol. 2020, 590, 125401. [Google Scholar] [CrossRef]

- Rasool, M.; Malik, A.; Abdul Basit Ashraf, M.; Mubbin, R.; Ayyaz, U.; Waquar, S.; Asif, M.; Umar, M.; Hua, G.S.; Iqbal, Z.; et al. Phytochemical analysis and protective effects of Vaccinium macrocarpon (cranberry) in rats (Rattus norvegicus) following ethylene oxide-induced oxidative insult. Bioengineered 2021, 12, 4593–4604. [Google Scholar] [CrossRef]

- Thimóteo, N.S.B.; Iryioda, T.M.V.; Alfieri, D.F.; Rego, B.E.F.; Scavuzzi, B.M.; Fatel, E.; Lozovoy, M.A.B.; Simão, A.N.C.; Dichi, I. Cranberry juice decreases disease activity in women with rheumatoid arthritis. Nutrition 2019, 60, 112–117. [Google Scholar] [CrossRef]

- Karboune, S.; Davis, E.J.; Fliss, I.; Spadoni Andreani, E. In-vitro digestion and fermentation of cranberry extracts rich in cell wall oligo/polysaccharides. J. Funct. Foods 2022, 92, 105039. [Google Scholar] [CrossRef]

- Khairnar, M.R.; Karibasappa, G.N.; Dodamani, A.S.; Vishwakarma, P.; Naik, R.G.; Deshmukh, M.A. Comparative assessment of cranberry and chlorhexidine mouthwash on streptococcal colonization among dental students: A randomized parallel clinical trial. Contemp. Clin. Dent. 2015, 6, 35–39. [Google Scholar] [CrossRef] [PubMed]

- Oszmiański, J.; Lachowicz, S.; Gorzelany, J.; Matłok, N. The effect of different maturity stages on phytochemical composition and antioxidant capacity of cranberry cultivars. Eur. Food Res. Technol. 2018, 244, 705–719. [Google Scholar] [CrossRef]

- Del Rio, D.; Rodriguez-Mateos, A.; Spencer, J.P.E.; Tognolini, M.; Borges, G.; Crozier, A. Dietary (Poly)phenolics in Human Health: Structures, Bioavailability, and Evidence of Protective Effects Against Chronic Diseases. Antioxid. Redox Signal. 2013, 18, 1818–1892. [Google Scholar] [CrossRef] [PubMed]

- Forney, C.F. Postharvest Issues in Blueberry and Cranberry and Methods to Improve Market-Life. Acta Hortic. 2009, 810, 785–798. [Google Scholar] [CrossRef]

- Gu, G.; Bolten, S.; Mowery, J.; Luo, Y.; Gulbronson, C.; Nou, X. Susceptibility of foodborne pathogens to sanitizers in produce rinse water and potential induction of viable but non-culturable state. Food Control 2020, 112, 107138. [Google Scholar] [CrossRef]

- Fundo, J.F.; Miller, F.A.; Mandro, G.F.; Tremarin, A.; Brandão, T.R.S.; Silva, C.L.M. UV-C light processing of Cantaloupe melon juice: Evaluation of the impact on microbiological, and some quality characteristics, during refrigerated storage. LWT 2019, 103, 247–252. [Google Scholar] [CrossRef]

- Abdul Karim Shah, N.N.; Shamsudin, R.; Abdul Rahman, R.; Adzahan, N.M. Fruit Juice Production Using Ultraviolet Pasteurization: A Review. Beverages 2016, 2, 22. [Google Scholar] [CrossRef]

- Miller, F.A.; Silva, C.L.M.; Brandão, T.R.S. A Review on Ozone-Based Treatments for Fruit and Vegetables Preservation. Food Eng. Rev. 2013, 5, 77–106. [Google Scholar] [CrossRef]

- Tchonkouang, R.D.; Lima, A.R.; Quintino, A.C.; Cristofoli, N.L.; Vieira, M.C. UV-C Light: A Promising Preservation Technology for Vegetable-Based Nonsolid Food Products. Foods 2023, 12, 3227. [Google Scholar] [CrossRef]

- Sarron, E.; Gadonna-Widehem, P.; Aussenac, T. Ozone Treatments for Preserving Fresh Vegetables Quality: A Critical Review. Foods 2021, 10, 605. [Google Scholar] [CrossRef]

- Mrozek-Szetela, A.; Rejda, P.; Wińska, K. A Review of Hygienization Methods of Herbal Raw Materials. Appl. Sci. 2020, 10, 8268. [Google Scholar] [CrossRef]

- Gidado, M.J.; Gunny, A.; Gopinath, C.B.; Ali, A.; Chalermchai, W.; Salleh, N. Challenges of postharvest water loss in fruits: Mechanisms, influencing factors, and effective control strategies—A comprehensive review. J. Agric. Food Res. 2024, 17, 101249. [Google Scholar] [CrossRef]

- Benkeblia, N.; Tennant, D.P.F.; Jawandha, S.K.; Gill, P.S. Preharvest and harvest factors influencing the postharvest quality of tropical and subtropical fruits. In Woodhead Publishing Series in Food Science, Technology and Nutrition, Postharvest Biology and Technology of Tropical and Subtropical Fruits; Elsevier: Amsterdam, The Netherlands, 2011; pp. 112–142. [Google Scholar] [CrossRef]

- Strano, M.C.; Altieri, G.; Allegra, M.; Di Renzo, G.C.; Paterna, G.; Matera, A.; Genovese, F. Postharvest Technologies of Fresh Citrus Fruit: Advances and Recent Developments for the Loss Reduction during Handling and Storage. Horticulturae 2022, 8, 612. [Google Scholar] [CrossRef]

- Botondi, R.; Barone, M.; Grasso, C. A Review into the Effectiveness of Ozone Technology for Improving the Safety and Preserving the Quality of Fresh-Cut Fruits and Vegetables. Foods 2021, 10, 748. [Google Scholar] [CrossRef]

- Darré, M.; Vicente, A.R.; Cisneros-Zevallos, L.; Artés-Hernández, F. Postharvest Ultraviolet Radiation in Fruit and Vegetables: Applications and Factors Modulating Its Efficacy on Bioactive Compounds and Microbial Growth. Foods 2022, 11, 653. [Google Scholar] [CrossRef] [PubMed]

- Tzortzakis, N.; Chrysargyris, A. Postharvest ozone application for the preservation of fruits and vegetables. Food Rev. Int. 2016, 33, 270–315. [Google Scholar] [CrossRef]

- Khadre, M.A.; Yousef, A.E.; Kim, J.-G. Microbiological Aspects of Ozone Applications in Food: A Review. J. Food Sci. 2001, 66, 1242–1252. [Google Scholar] [CrossRef]

- Kim, J.G.; Yousef, A.E.; Dave, S. Application of ozone for enhancing the microbiological safety and quality of foods: A review. J. Food Prot. 1999, 62, 1071–1087. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, D.R.; Chaves, A.R.; Rodríguez, S.D.C. Use of UV-C and Gaseous Ozone as Sanitizing Agents for Keeping the Quality of Fresh-Cut Rocket (Eruca sativa mill). J. Food Process. Preserv. 2017, 41, e12968. [Google Scholar] [CrossRef]

- Martínez-Hernández, G.B.; Artés-Hernández, F.; Gómez, P.A.; Formica, A.C.; Artés, F. Combination of electrolysed water, UV-C and superatmospheric O2 packaging for improving fresh-cut broccoli quality. Postharvest Biol. Technol. 2013, 76, 125–134. [Google Scholar] [CrossRef]

- Matłok, N.; Piechowiak, T.; Zardzewiały, M.; Gorzelany, J.; Balawejder, M. Effects of Ozone Treatment on Microbial Status and the Contents of Selected Bioactive Compounds in Origanum majorana L. Plants. Plants 2020, 9, 1637. [Google Scholar] [CrossRef] [PubMed]

- Zapałowska, A.; Matłok, N.; Zardzewiały, M.; Piechowiak, T.; Balawejder, M. Effect of Ozone Treatment on the Quality of Sea Buckthorn (Hippophae rhamnoides L.). Plants 2021, 10, 847. [Google Scholar] [CrossRef] [PubMed]

- Matłok, N.; Lachowicz, S.; Gorzelany, J.; Balawejder, M. Influence of Drying Method on Some Bioactive Compounds and the Composition of Volatile Components in Dried Pink Rock Rose (Cistus creticus L.). Molecules 2020, 25, 2596. [Google Scholar] [CrossRef]

- Laichmanová, M.; Sedláček, I. Fungal species associated with fruit and vegetables transported to the J.G. Mendel station and the influence of UV-C treatment on their fungal community. Czech Polar Rep. 2019, 9, 78–87. [Google Scholar] [CrossRef]

- Ziyaina, M.; Rasco, B. Inactivation of microbes by ozone in the food industry: A review. Afr. J. Food Sci. 2021, 15, 113–120. [Google Scholar] [CrossRef]

- Pisani Gareau, T.L.; Gao, L.; Gareau, B.J. The enduring nature of cranberry production in a changing climate: The interplay of extreme weather, knowledge networks, and adaptation. PLoS Clim. 2024, 3, e0000350. [Google Scholar] [CrossRef]

- Juríková, T.; Mlček, J.; Balla, Š.; Ondrášová, M.; Dokoupil, L.; Sochor, J.; Ďurišová, L.; Eliáš, P., Jr.; Adámková, A.; Baroň, M.; et al. The Elucidation of Total Polyphenols, Individual Phenolic Compounds, Antioxidant Activity of Three Underutilized Fruit Species—Black Crowberry, Honeyberry, European Cranberry with Their Accumulation. Agronomy 2021, 11, 73. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Munekata, P.E.; Dominguez, R.; Pateiro, M.; Saraiva, J.A.; Franco, D. Main Groups of Microorganisms of Relevance for Food Safety and Stability: General Aspects and Overall Description. In Innovative Technologies for Food Preservation; Academic Press: Cambridge, MA, USA, 2018; pp. 53–107. [Google Scholar] [CrossRef]

- Nawkar, G.M.; Maibam, P.; Park, J.H.; Sahi, V.P.; Lee, S.Y.; Kang, C.H. UV-Induced cell death in plants. Int. J. Mol. Sci. 2013, 14, 1608–1628. [Google Scholar] [CrossRef] [PubMed]

- Çavuşoğlu, K.; Kalefetoğlu Macar, T.; Macar, O.; Çavuşoğlu, D.; Yalçın, E. Comparative investigation of toxicity induced by UV-A and UV-C radiation using Allium test. Environ. Sci. Pollut. Res. Int. 2022, 29, 33988–33998. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.selinawamucii.com/insights/prices/poland/cranberries/ (accessed on 15 May 2024).

- Available online: https://openknowledge.fao.org/server/api/core/bitstreams/12a578c2-47c3-4095-9ab3-c95126878d7d/content (accessed on 15 May 2024).

- Pandiselvam, R.; Mayookha, V.P.; Kothakota, A.; Sharmila, L.; Ramesh, S.V.; Bharathi, C.P.; Gomathy, K.; Srikanth, V. Impact of Ozone Treatment on Seed Germination—A Systematic Review. Ozone Sci. Eng. 2020, 42, 331–346. [Google Scholar] [CrossRef]

- Promyou, S. Effect of ultraviolet-C (UV-C) illumination on postharvest quality and bioactive compounds in yellow bell pepper fruit (Capsicum annuum L.) during storage. Afr. J. Agric. Res. 2012, 7, 4084–4096. [Google Scholar] [CrossRef]

- Vicente, A.R.; Pineda, C.; Lemoine, L.; Civello, P.M.; Martinez, G.A.; Chaves, A.R. UV-C treatments reduce decay, retain quality and alleviate chilling injury in pepper. Postharvest Biol. Technol. 2005, 35, 69–78. [Google Scholar] [CrossRef]

- Barka, E.A.; Kalantari, S.; Makhlouf, J.; Arul, J. Impact of UV-C Irradiation on the Cell Wall-Degrading Enzymes during Ripening of Tomato (Lycopersicon esculentum L.) Fruit. J. Agric. Food Chem. 2000, 48, 667–671. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matłok, N.; Piechowiak, T.; Zardzewiały, M.; Saletnik, B.; Balawejder, M. Continuous Ozonation Coupled with UV-C Irradiation for a Sustainable Post-Harvest Processing of Vaccinium macrocarpon Ait. Fruits to Reduce Storage Losses. Sustainability 2024, 16, 5420. https://doi.org/10.3390/su16135420

Matłok N, Piechowiak T, Zardzewiały M, Saletnik B, Balawejder M. Continuous Ozonation Coupled with UV-C Irradiation for a Sustainable Post-Harvest Processing of Vaccinium macrocarpon Ait. Fruits to Reduce Storage Losses. Sustainability. 2024; 16(13):5420. https://doi.org/10.3390/su16135420

Chicago/Turabian StyleMatłok, Natalia, Tomasz Piechowiak, Miłosz Zardzewiały, Bogdan Saletnik, and Maciej Balawejder. 2024. "Continuous Ozonation Coupled with UV-C Irradiation for a Sustainable Post-Harvest Processing of Vaccinium macrocarpon Ait. Fruits to Reduce Storage Losses" Sustainability 16, no. 13: 5420. https://doi.org/10.3390/su16135420

APA StyleMatłok, N., Piechowiak, T., Zardzewiały, M., Saletnik, B., & Balawejder, M. (2024). Continuous Ozonation Coupled with UV-C Irradiation for a Sustainable Post-Harvest Processing of Vaccinium macrocarpon Ait. Fruits to Reduce Storage Losses. Sustainability, 16(13), 5420. https://doi.org/10.3390/su16135420