The Impact of Desert Regions on Solar Energy Production with the Evaluation of Groundwater for Maintenance: A Case Study in Morocco

Abstract

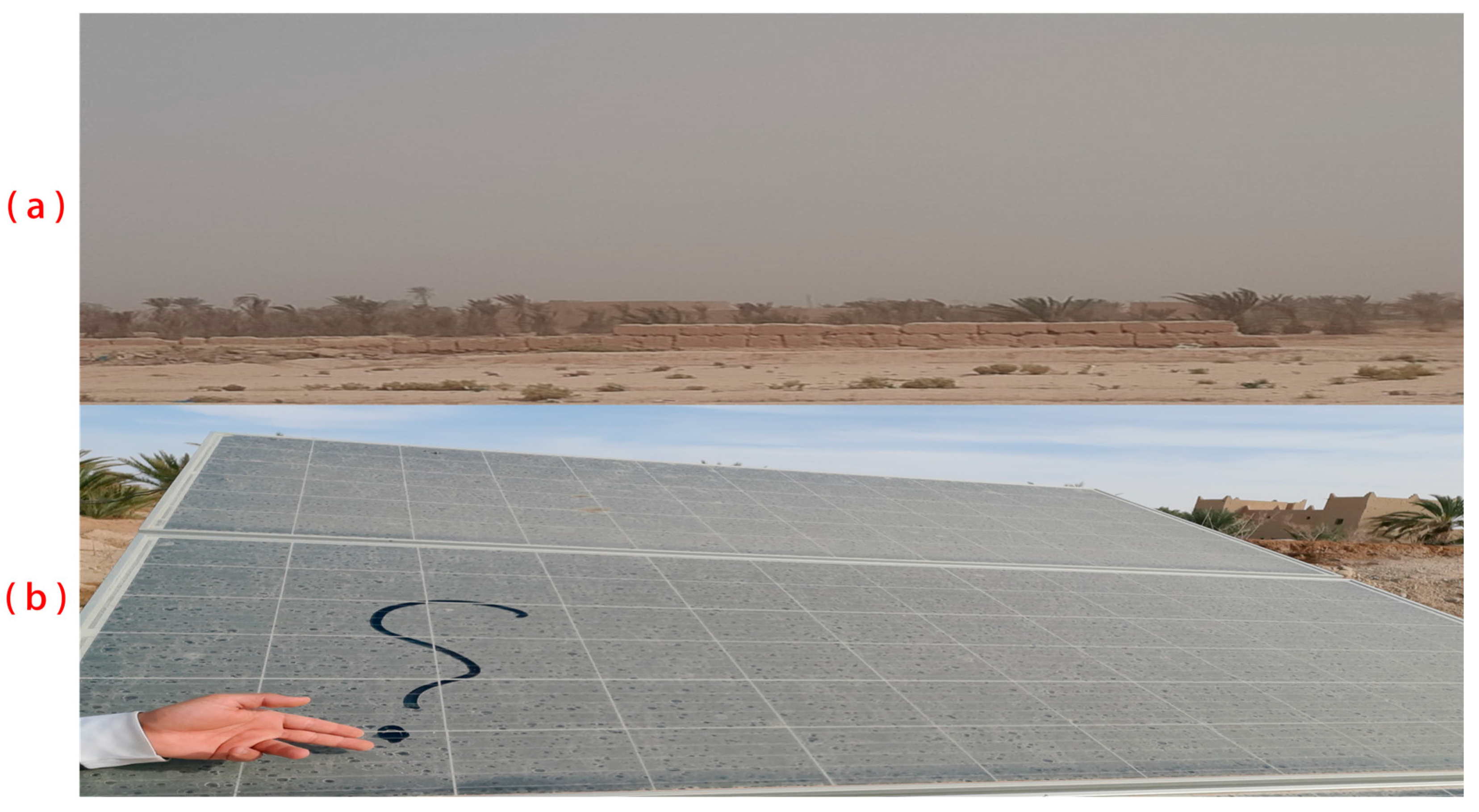

:1. Introduction

2. Materials and Methods

2.1. Geographic Context of the Study Area

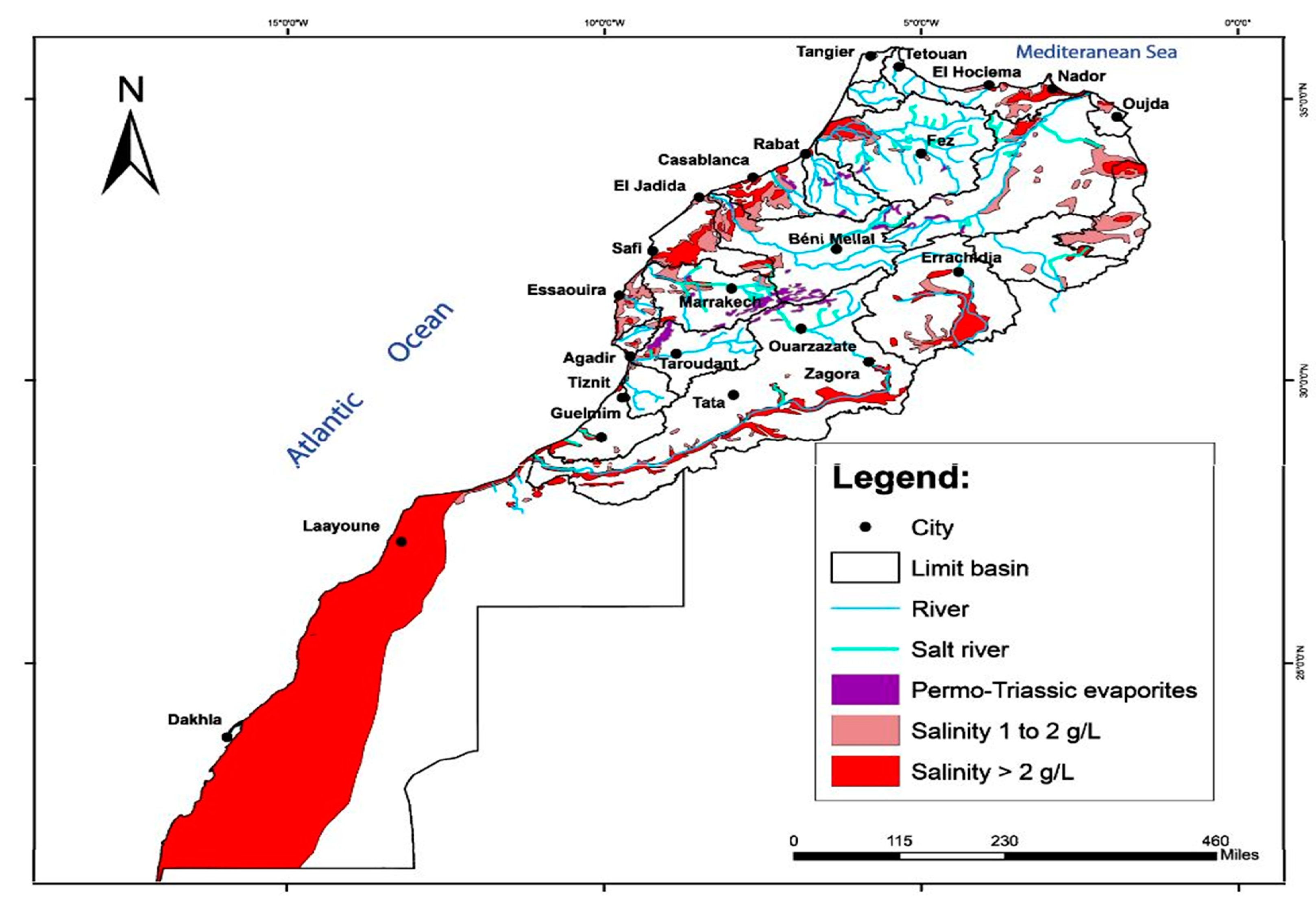

2.2. Hydrological Context

2.2.1. Water Surfaces

2.2.2. The gheris Watershed

2.2.3. The ziz Watershed

2.2.4. Groundwater

- –

- A portion of water used for consumption by palm trees, most of which are not irrigated directly but draw water from the aquifer;

- –

- Water from the shallow water table, which rises by capillary action and evaporates on bare soil.

2.3. Climatological Context

2.3.1. Temperature

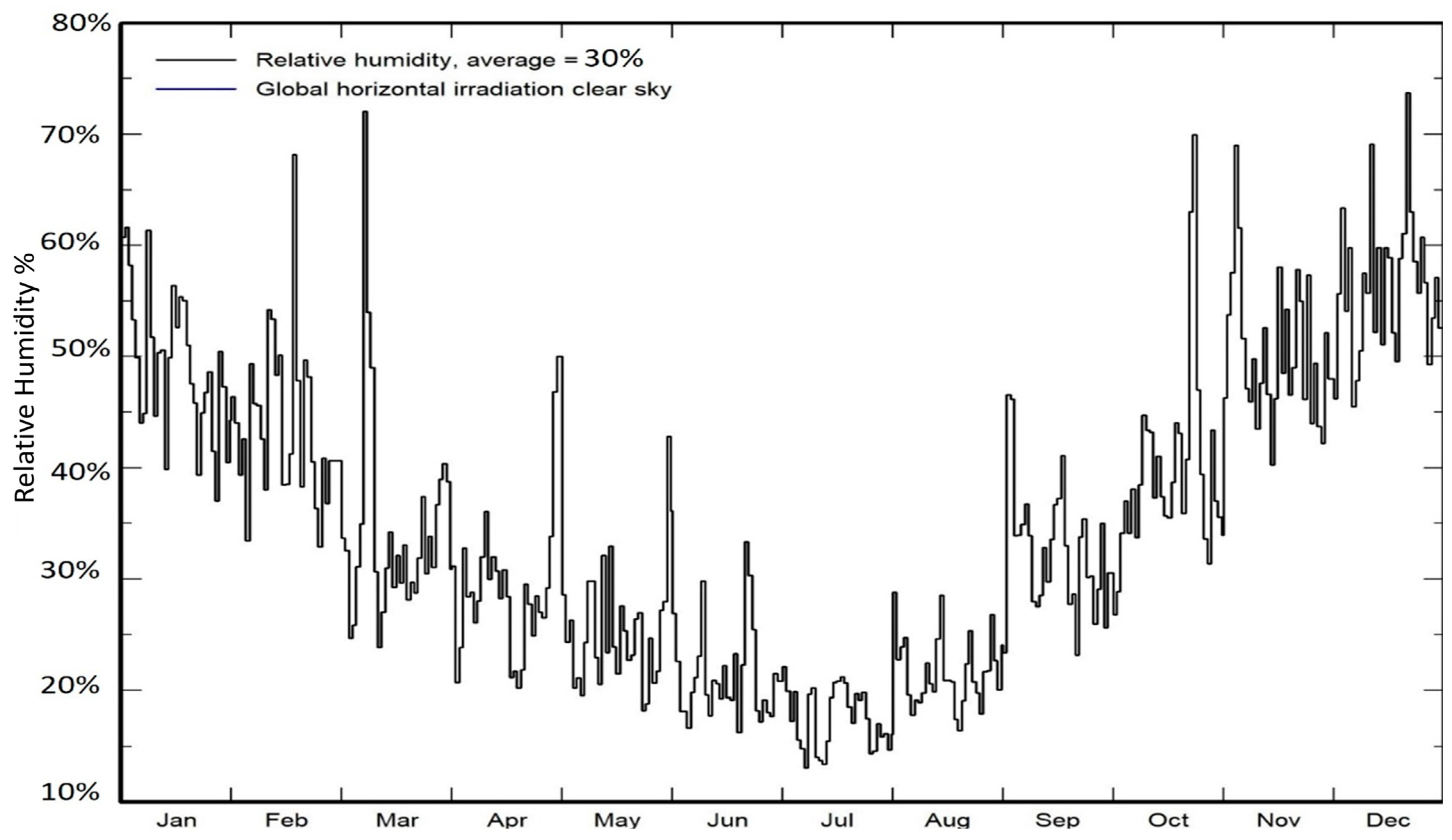

2.3.2. Relative Humidity

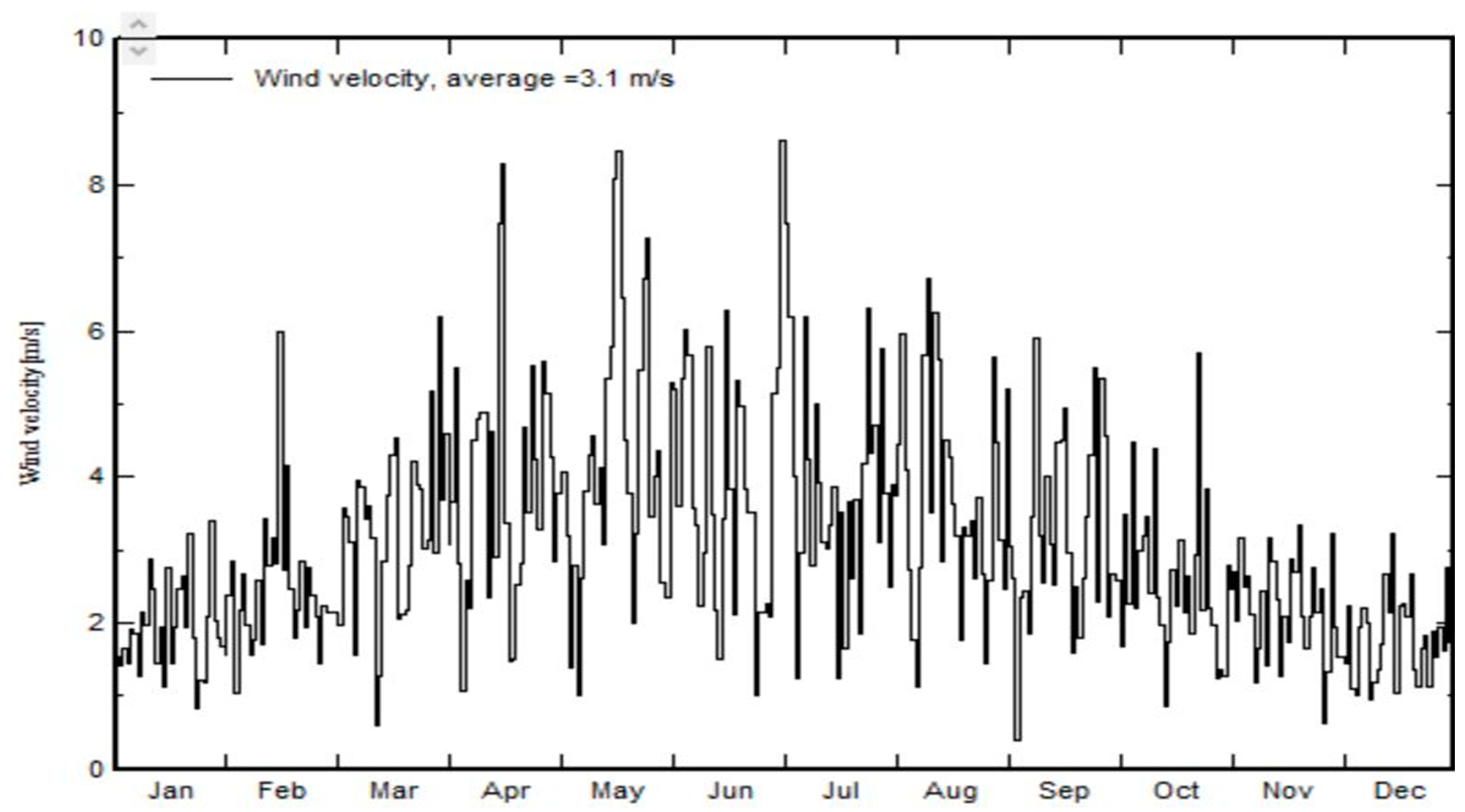

2.3.3. The Wind

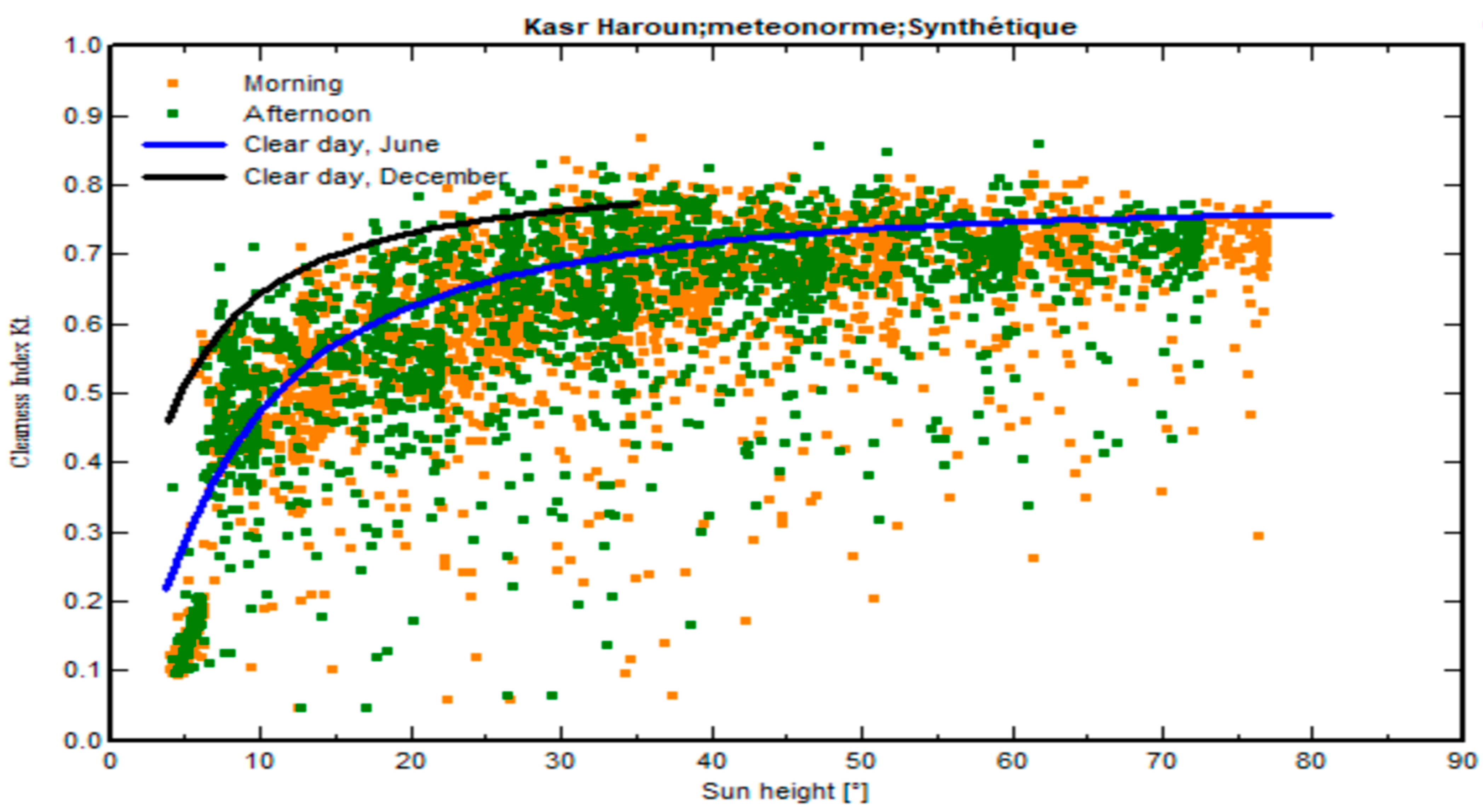

2.3.4. Solar Irradiation

2.4. Environment MATLAB-Simulink

2.5. Effect of Scale Deposits in Dust on Transmission

2.6. Impact of Dust and Limestone on Solar Irradiance

2.7. Moroccan Drinking Water Treatment Standard

- All water intended for drinking, whatever the method of production and distribution Water used for the preparation, packaging, storage, and/or conservation of foodstuffs intended for the public [34].

- A number of thermal installations require cleaning and/or cooling with water, and photovoltaic panels in particular. This water must meet certain quality criteria to ensure that the photovoltaic panels function properly:

- Total dissolved solids (TDS) refer to the quantity of organic and inorganic sub-stances contained in a given liquid. They are after the standard (N.M. 03.7.001 ONSSA-MAROC). They are shown in Table 1.

- Conductivity is the opposite of resistivity and refers to the ability of a material to let current through when a potential difference is applied.

2.8. Collects Ground Water for Cooling Purposes

3. Results and Discussion

3.1. Simulation Parameter

3.2. The Effect of Dust and Limestone on the Temperature of Photovoltaic Modules

3.3. Simulation Result in Matlab-Simulink

3.4. Quality of Water

4. Conclusions

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nezami Savojbolaghi, M.; Davodian, E.; Bouich, A.; Tlemçani, M.; Mesbahi, O.; Janeiro, F.M. The Impact of Dust Deposition on PV Panels’ Efficiency and Mitigation Solutions: Review Article. Energies 2023, 16, 8022. [Google Scholar] [CrossRef]

- Alaoui, M.; Maker, H.; Mouhsen, A.; Hihi, H. High Power PV Array Emulator Based on State Feedback Controller Under Uniform and Non-Uniform Insolation. Trans. Electr. Electron. Mater. 2023, 24, 54–64. [Google Scholar] [CrossRef]

- Bugeja, R.; Stagno, L.M.; Niarchos, I. Full-Scale Design, Implementation and Testing of an Innovative Photovoltaic Cooling System (IPCoSy). Sustainability 2023, 15, 16900. [Google Scholar] [CrossRef]

- Saidan, M.; Albaali, A.G.; Alasis, E.; Kaldellis, J.K. Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renew. Energy 2016, 92, 499–505. [Google Scholar] [CrossRef]

- Abderrezek, M.; Fathi, M. Experimental study of the dust effect on photovoltaic panels’ energy yield. Sol. Energy 2017, 142, 308–320. [Google Scholar] [CrossRef]

- Lasfar, S.; Haidara, F.; Mayouf, C.; Abdellahi, F.M.; Elghorba, M.; Wahid, A.; Kane, C.S.E. Study of the influence of dust deposits on photovoltaic solar panels: Case of Nouakchott. Energy Sustain. Dev. 2021, 63, 7–15. [Google Scholar] [CrossRef]

- Mallal, Y.; Sharma, D.K.; El Bahir, L.; Hassboun, T. Temperature prediction-based realistic performance analysis of various electrical configurations of solar PV panels. Sol. Energy 2021, 228, 612–624. [Google Scholar] [CrossRef]

- Sahay, A.; Sethi, V.; Tiwari, A.; Pandey, M. A review of solar photovoltaic panel cooling systems with special reference to Ground coupled central panel cooling system (GC-CPCS). Renew. Sustain. Energy Rev. 2015, 42, 306–312. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlation. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Radziemska, E.; Klugmann, E. Thermally affected parameters of the current–voltage characteristics of silicon photocell. Energy Convers. Manag. 2002, 43, 1889–1900. [Google Scholar] [CrossRef]

- Han, X.; Wang, Y.; Zhu, L. The performance and long-term stability of silicon concentrator solar cells immersed in dielectric liquids. Energy Convers. Manag. 2013, 66, 189–198. [Google Scholar] [CrossRef]

- Mankani, K.L.; Chaudhry, H.N.; Calautit, J.K. Optimization of an air-cooled heat sink for cooling of a solar photovoltaic panel: A computational study. Energy Build. 2022, 270, 112274. [Google Scholar] [CrossRef]

- Li, D.; King, M.; Dooner, M.S.; Guo, S.; Wang, J. Study on the cleaning and cooling of solar photovoltaic panels using compressed airflow. Sol. Energy 2021, 221, 433–444. [Google Scholar] [CrossRef]

- Tian, M.-W.; Khetib, Y.; Yan, S.-R.; Rawa, M.; Sharifpur, M.; Cheraghian, G.; Melaibari, A.A. Energy, exergy and economics study of a solar/thermal panel cooled by nanofluid. Case Stud. Therm. Eng. 2021, 28, 101481. [Google Scholar] [CrossRef]

- Ibrahim, T.; Akrouch, M.A.; Hachem, F.; Ramadan, M.; Ramadan, H.S.; Khaled, M. Cooling Techniques for Enhanced Efficiency of Photovoltaic Panels—Comparative Analysis with Environmental and Economic Insights. Energies 2024, 17, 713. [Google Scholar] [CrossRef]

- Jidhesh, P.; Arjunan, T.; Gunasekar, N.; Mohanraj, M. Experimental thermodynamic performance analysis of semi-transparent photovoltaic-thermal hybrid collectors using nanofluids. Proc. Inst. Mech.Eng. Part E J. Process Mech. Eng. 2021, 235, 1639–1651. [Google Scholar] [CrossRef]

- Al Aboushi, A.; Abdelhafez, E.; Hamdan, M. Finned PV Natural Cooling Using Water-Based TiO2 Nanofluid. Sustainability 2022, 14, 12987. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Hammad, W.; Al-Dhaifallah, M.; Rezk, H. Performance enhancement of grid-tied PV system through proposed design cooling techniques: An experimental study and comparative analysis. Sol. Energy 2020, 211, 1110–1127. [Google Scholar] [CrossRef]

- Jafari Khoushehmehr, R.; Erkılıç, K.T.; Uğurer, D.; Kanbur, Y.; Yıldız, M.Ö.; Ayhan, E.B. Enhanced photovoltaic panel energy by minichannel cooler and natural geothermal system. Int. J. Energy Res. 2021, 45, 13646–13656. [Google Scholar] [CrossRef]

- Hussien, A.A.; Eltayesh, A.; El-Batsh, H.M. Experimental and numerical investigation for PV cooling by forced convection. Alex. Eng. J. 2022, 64, 427–440. [Google Scholar] [CrossRef]

- Nižetić, S.; Čoko, D.; Yadav, A.; Grubišić-Čabo, F. Water spray cooling technique applied on a photovoltaic panel: The performance response. Energy Convers. Manag. 2016, 108, 287–296. [Google Scholar] [CrossRef]

- Maatallah, T.; Houcine, A.; Saeed, F.; Khan, S.; Ali, S. Simulated Performance Analysis of a Hybrid Water-Cooled Photovoltaic/Parabolic Dish Concentrator Coupled with Conical Cavity Receiver. Sustainability 2024, 16, 544. [Google Scholar] [CrossRef]

- Shah, A.H.; Alraeesi, A.; Hassan, A.; Laghari, M.S. A Novel Photovoltaic Panel Cleaning and Cooling Approach through Air Conditioner Condensate Water. Sustainability 2023, 15, 15431. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Okulu, D.; Öztop, H.F. Photovoltaic Thermal Management by Combined Utilization of Thermoelectric Generator and Power-Law-Nanofluid-Assisted Cooling Channel. Sustainability 2023, 15, 5424. [Google Scholar] [CrossRef]

- Gesteira, L.G.; Uche, J.; Cappiello, F.L.; Cimmino, L. Thermoeconomic Optimization of a Polygeneration System Based on a Solar-Assisted Desiccant Cooling. Sustainability 2023, 15, 1516. [Google Scholar] [CrossRef]

- Candra, O.; Kumar, N.B.; Dwijendra, N.K.A.; Patra, I.; Majdi, A.; Rahardja, U.; Kosov, M.; Guerrero, J.W.G.; Sivaraman, R. Energy Simulation and Parametric Analysis of Water Cooled Thermal Photovoltaic Systems: Energy and Exergy Analysis of Photovoltaic Systems. Sustainability 2022, 14, 15074. [Google Scholar] [CrossRef]

- Alami, A.H. Effects of evaporative cooling on efficiency of photovoltaic modules. Energy Convers. Manag. 2014, 77, 668–679. [Google Scholar] [CrossRef]

- Shen, Y.H. Treatment of Low Turbidity Water by Sweep Coagulation Using Bentonite. J. Chem. Technol. Biotechnol. 2005, 80, 581–586. [Google Scholar] [CrossRef]

- Sanghi, R.; Bhatttacharya, B.; Singh, V. Cassia An-Gustifolia Seed Gum as an Effective Natural Coagulant for Decolourisation of Dye Solutions. Green Chem. 2002, 4, 252–254. [Google Scholar] [CrossRef]

- Šciban, M.; Klašnja, M.; Antov, M.; Škrbic, B. Removal of Water Turbidity by Natural Coagulants Obtained from Chestnut and Acorn. Bioresour. Technol. 2009, 100, 6639–6643. [Google Scholar] [CrossRef] [PubMed]

- El Meknassi Yousoufi, E.; Hammani, A.; Kuper, M.; Bouarfa, S.; Vallée, D. Water accounting in the Berrechid plain (Morocco): A process approach. Irrig. Drain. 2024, 73, 180–197. [Google Scholar] [CrossRef]

- Ministry of Equipment and Water Morocco. Available online: http://www.equipement.gov.mahttps://www.equipement.gov.ma/Pages/accueil.aspx (accessed on 20 May 2023).

- Hssaisoune, M.; Bouchaou, L.; Sifeddine, A.; Bouimetarhan, I.; Chehbouni, A. Moroccan Groundwater Resources and Evolution with Global Climate Changes. Geosciences 2020, 10, 81. [Google Scholar] [CrossRef]

- The National Office of Food Safety Morocco. Available online: https://www.onssa.gov.ma/a-propos-de-lonssa/?lang=en (accessed on 15 April 2024).

| Potential Hydrogen | Units pH | 6.5 < pH < 8.5 | for the disinfection of water by chlorine to be effective, the pH should preferably be <8 |

| Conductivity | S/cm at 20 °C | 2700 |

| S.No | Parameters | Values |

|---|---|---|

| 1 | Maximum power | 400 W |

| 2 | Maximum power Voltage | 39.92 V |

| 3 | Maximum Power Current | 10.02 A |

| 4 | Open Circuit Voltage | 48.6 V |

| 5 | Short Circuit Current | 10.4 A |

| 6 | Total series cells | 72 |

| 7 | Total parallel cells | 1 |

| 8 | Ideality factor of diode | 1.3 |

| 9 | Cell Short circuit currenttemperature coefficient of Isc | +0.06%/°C |

| 10 | Cell Short circuit currenttemperature coefficient of Circuit Voltage | −0.31%/°C |

| 11 | Reference temperature | 25 |

| 12 | Pmax temperature coefficient | 0.396%/°C |

| 13 | Solar Irradiance | 1000 at STC |

| pH | Conductivity (µS/cm) | TDS (mg/L) |

|---|---|---|

| 7.39 | 1422 | 1500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ait Ali, A.; Ouhassan, Y.; Abouyaakoub, M.; Chahboun, M.; Hihi, H. The Impact of Desert Regions on Solar Energy Production with the Evaluation of Groundwater for Maintenance: A Case Study in Morocco. Sustainability 2024, 16, 5476. https://doi.org/10.3390/su16135476

Ait Ali A, Ouhassan Y, Abouyaakoub M, Chahboun M, Hihi H. The Impact of Desert Regions on Solar Energy Production with the Evaluation of Groundwater for Maintenance: A Case Study in Morocco. Sustainability. 2024; 16(13):5476. https://doi.org/10.3390/su16135476

Chicago/Turabian StyleAit Ali, Ali, Youssef Ouhassan, Mohcine Abouyaakoub, Mbarek Chahboun, and Hicham Hihi. 2024. "The Impact of Desert Regions on Solar Energy Production with the Evaluation of Groundwater for Maintenance: A Case Study in Morocco" Sustainability 16, no. 13: 5476. https://doi.org/10.3390/su16135476