Abstract

Infrastructure expansion considerably contributes to greenhouse gas emissions causing the critical global issue of climate change. In recent years, submerged floating tunnels (SFTs) have thus been developed as a sustainable and efficient solution for crossing large water bodies instead of resource-demanding superstructures (e.g., cable stayed bridges). This research delves into a comparative analysis of two SFT design alternatives: SFTs with pontoons and SFTs with tethers centered on environmental sustainability and long-term viability. By incorporating life-cycle assessments and quantitative risk analysis methodologies, our study aims to ascertain the optimal SFT design for real-world application. Our study embarks on detailed investigations into SFTs and then gathers data on material quantities and LCA studies, identifying potential hazards and comparing life cycle performance. Our new findings highlight the significant advantage of the SFT with a tethered design, which has a lower dependency on materials, particularly steels, resulting in lower CO2 emissions. Additionally, in terms of risk, the SFT with tethers has a lower risk profile in general, especially in situations, including environmental elements, like rising water levels, potential tsunamis, and storms. This design is a promising solution for sustainable and resilient infrastructure development, coinciding with global objectives to cut down carbon emissions and enrich potential benefits in the face of increasing climatic uncertainties. Not only does this study scrutinize the risk and environmental aspects of both SFT designs, but it also opens the path for future infrastructure projects that emphasize engineering robustness and environmental sustainability.

1. Introduction

Climate change driven by rising greenhouse gas emissions (GHGs) is a major global issue with far-reaching consequences for the planet [1]. A study co-published by UNOPS, UNEP, and the University of Oxford emphasized the urgent need for countries to prioritize sustainable infrastructure as a crucial sector for climate action, highlighting how infrastructure is responsible for 79% of all GHGs [2]. Moreover, amongst all the greenhouse gases, CO2 is the most common and impactful gas contributing to 39% of emissions [3]. Thus, its reduction is at the heart of the global climate goal, as outlined in the Paris agreement [4]. While sustainability has predominantly centered on buildings, civil infrastructure, especially tunnels, has received comparatively less attention. The construction of these structures is resource- and energy-intensive, which has a significant negative impact on the environment [5]. Thus, adopting sustainable practices, like environmental assessments early in the planning process, might have long-lasting benefits. Emerging within this context, submerged floating tunnels, commonly known as SFTs, are a new and innovative concept in the construction industry [6]. In addition, according to Martire [7], the construction cost of SFTs comes out to be the lowest compared to other waterway crossings, such as suspension bridges (SBs) [7]. Thus, this concept is chosen by many countries to cross waterways as the SFTs cost 1/3 of the SBs. The two primary design alternatives, SFTs with pontoons and tethers, are at the forefront of this exploration. As countries like Norway, China, and USA are considering it for major infrastructure projects, understanding their environmental and risk implications becomes crucial [8,9]. To assess the environmental implications of such infrastructures, a life-cycle assessment (LCA) stands out as a robust tool for benchmarking, which is recommended by ISO 14040 [10]. Also, it is internationally accepted, and it provides a standardized technique for quantifying possible environmental consequences across the whole life cycle of a product or service, including raw material extraction, production, usage, and the disposal stage [3]. However, certain components of these standards lack an explicit definition, resulting in differences in the LCA methodologies [11]. Furthermore, the European Programme for Critical Infrastructure Protection (EPCIP) underscores the significance of a comprehensive approach to infrastructure protection, emphasizing hazard identification and its analysis [3]. Yet, the specific resilience and risk analysis for the SFT alternatives remain unexplored [12]. Based on the critical literature review, a key research question remains: what could be the implications of adopting different SFT designs on infrastructure resilience and sustainability in the face of climate change and other future uncertainties? This is the key knowledge gap that demands our research on which to embark.

Our study aims to assess and compare the environmental impact and risk profiles of the submerged floating tunnel design alternatives, emphasizing on carbon emissions and long-term viability. The investigations will help engineers by understanding the concept of the life cycle and sustainability in the context of SFTs; identifying threats for the construction of an SFT in the context of uncertainties; systemically breaking down and compare each stage of the life cycle, which could be quantified for raw material production, construction installation, and end of life; and finally, providing appropriate recommendations for the most sustainable and viable SFT proposal based on the LCA and risk analysis. As the 21st century unfolds, integrating sustainable practices in infrastructure development, such as SFTs, supported by thorough risk assessment methods, will lay the foundation for resilient future infrastructure.

2. Literature Review

2.1. Previous Studies on SFTs

Research by Bolin et al. [13] conducted a comparative analysis of SFTs with SBs for the crossing of the Qiongzhou Strait, China [13]. As per his study, SFTs represented a better alternative due to benefits, such as a shorter distance, cost-effectiveness, and reduced environmental and navigational impacts. ANSYS/Fluent software-based numerical simulations indicated that SFTs are feasible. However, comprehensive assessments are crucial to ensure safety [13]. A study undertaken by Martire [7] focused on the various design options of SFTs and developed solutions by analyzing different parameters of design and structural stability [7]. The study not only offered unique solutions but also drew a critical comparison between SFTs and standard SBs by analyzing design and structural stability criteria [7]. This comparison, especially in terms of cost and stability, offered a new dimension to our understanding of SFTs, emphasizing their potential advantages over traditional frameworks. However, the lack of an extensive environmental effect analysis in Martire’s work presents a gap in knowing the whole sustainability profile of SFTs, a vital issue that must be addressed. Further, research by Ostlid [14] elaborated on different SFT design alternatives, i.e., SFTs with pontoons, SFTs with tethers, SFTs with column support, and unanchored SFTs, examining their advantages and disadvantages [14]. However, the two major design alternatives proposed by the Norwegian Ministry of Transport and communications happens to be with the pontoons and tethers [15].

- (a)

- SFTs with Pontoons

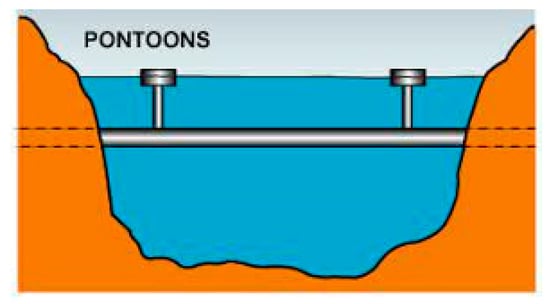

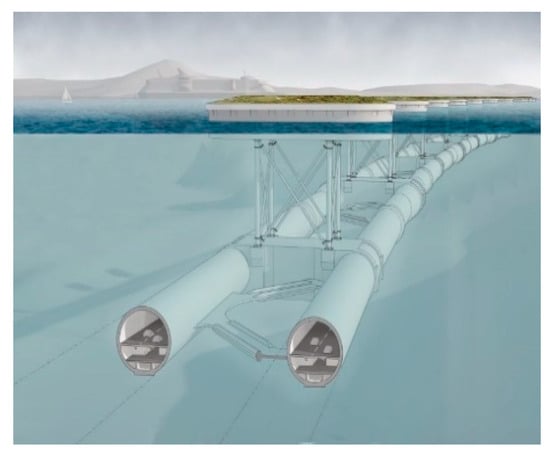

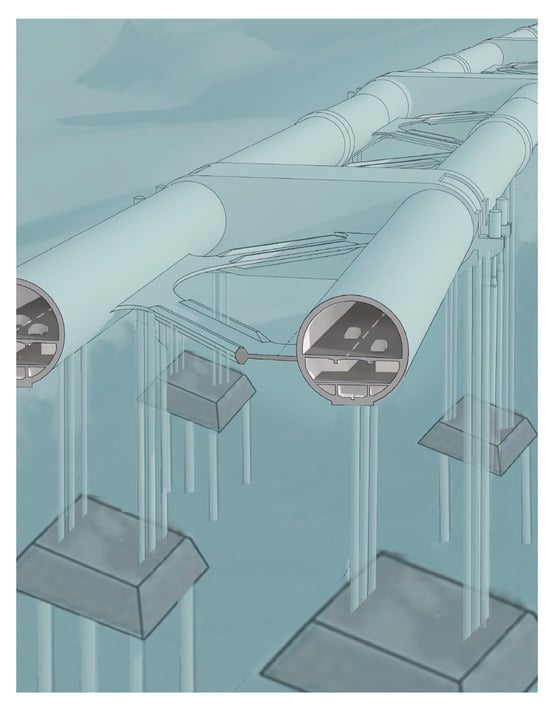

Pontoons are buoyant structures used as a support for maintaining the tunnel’s depth beneath the water surface as shown in Figure 1. The pontoons ensure tunnel stability against external forces, and they are generally made out of concrete or steel [14].

Figure 1.

SFTs with pontoons.

Based on this concept, a feasibility study by Fjeld [16] provided a foundational understanding of an SFT with pontoons design proposal in Norway, offering an in-depth look at the design, scope, risk factors, load calculations, and construction methodology [16]. While this study provided useful insights into the SFT concept, particularly in the context of pontoons, it also identified areas of uncertainty within the fjord concepts, emphasizing the need for additional refinement and research.

- (b)

- SFTs with Tethers

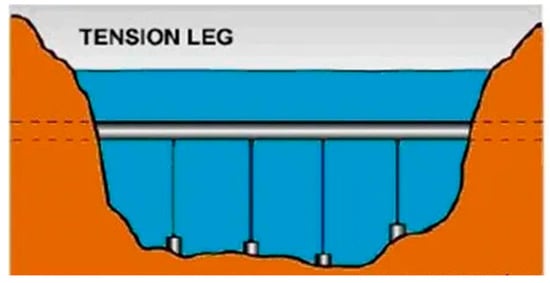

Unlike pontoons, these SFTs do not rely on buoyancy as shown in Figure 2. Instead, they are anchored to the seabed using tethers, typically composed of steel and noncorrosive material. They provide flexibility in terms of positioning and depth adjustments [17]. Additionally, the concrete piles below the seabed offer extra stability to the structure [7].

Figure 2.

SFT with tethers.

2.2. Life-Cycle Assessment

2.2.1. Methodologies

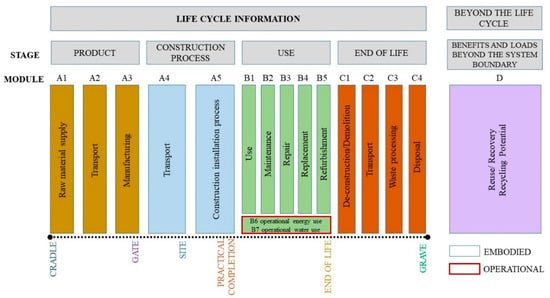

The life-cycle assessment (LCA), which incorporates life-cycle stages and impact categories, is frequently a useful tool to enhance decision-making since it can identify instances of problem shifting [18]. To analyze the environmental loads of processes and products throughout their life cycle, four stages must be undertaken: goal and scope identification, life-cycle inventory (LCI), life-cycle impact assessment (LCIA), and an interpretation [19]. The two international standards based on LCA are ISO 14040:2006 and ISO 14044:2006 [10]. The guide of LCA by Gibbons and Orr [19], published by the Institute of Structural Engineers (IStructE), offers a defined methodology that corresponds to the ISO standards and builds upon the guidance recommendations provided by the Royal Institution of Chartered Surveyors (RICS), as Figure 3 shows.

Figure 3.

LCA stages of SFT infrastructures.

Previous research by Kohler an Moffatt [20], Dossche et al. [11], identified severe challenges in the application of LCA methodologies. Difficulties in analyzing specific local consequences at specific places, variances in the complexity of different models, uncertainty connected with long-term forecasts, and concerns linked to the design of indoor environments in buildings were among the hurdles. Although, the application of LCA in the field of civil engineering has become increasingly vital, there have not been many studies conducted on the environmental impacts of SFTs because of their uniqueness.

2.2.2. LCA Studies

A study undertaken by Iversen [21] highlighted the point of the massive GHG emissions connected with the road infrastructure and how it must be taken into account while planning road corridors and developing concepts for Fjord crossings to effectively meet Norway’s carbon emission reduction goals. Moreover, Iversen [21] compared the new floating tunnel concept with the traditional bridge concept in terms of the environmental impact and concluded that a traditional bridge is the most emission-intensive structure, whereas a floating bridge has the lowest GHG emissions according to the analysis [21]. Lastly, the study’s recommendation showcased the need for a joint and in-depth analysis for obtaining comparable results of the Fjord infrastructure solutions.

2.3. Risk Assessment

A conference proceeding reported by Kumar and Bhowmik [22] revealed that SFTs are still developing and need materials that are strong and resistant to corrosion, water, and potential risks. The researchers called attention to creating norms of practice for design, safety, and maintenance as accidents inside the tunnel or the wearing of tethers/pontoons can be disastrous because the idea of such structures is still relatively new. Moreover, a study undertaken by Xiang et al. [23] suggested that taking a risk assessment at an early stage could save unpredictable costs in later stages of the life cycle. They categorized life cycles for risk management into six stages: planning, feasibility studies, design, tendering, construction, and operation, and gave a feasible risk management workflow for SFTs. However, the report lacks the mitigation of the potential risks discussed.

3. Methodology

The framework for the LCA given in the ISO 14040 British Standard Institution [10] has been incorporated for the sustainability assessment for the SFTs, along with a quantitative risk analysis breakdown of the design, construction, and operations stages for better clarity. The following steps portray the methodology adopted in this study:

3.1. Step 1: Goal Identification for Conceptual Analysis

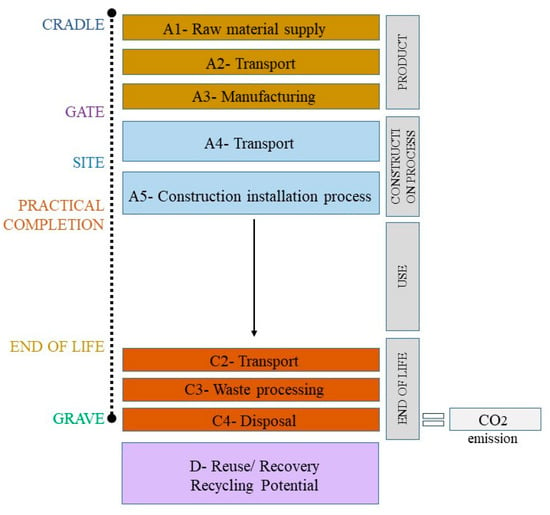

The purpose of this stage is to define the scope of analysis as it is important to consider the purpose of the analysis and what it is attempting to cover before conducting it directly [21]. Figure 4 shows the chosen stages to calculate the CO2 emissions.

Figure 4.

Chosen LCA stages.

3.2. Step 2: Data Collection and Inventory Analysis

This stage can be divided into two parts for a better comparison as follows:

3.2.1. Quantification of Materials Based on Technical Design Drawings

In this, a detailed study of the design drawing for both the SFTs has been conducted to identify the materials. Data have been collected from the chosen case study reports, specifically focusing on the companies that are directly involved with the design, construction, and management of the SFT. This method ensures that the materials acquired are both relevant and authoritative, laying the groundwork for the analysis. Further, the quantities of the major materials are calculated in volume (m3) and further converted to kg considering the average design of material, i.e., 2400 kg/m3 for concrete and 7850 kg/m3 for steel [24].

3.2.2. Quantification of Environmental Impacts Based on the Materials

As per Figure 3, this stage can be broken down accordingly for calculations. As suggested by Gibbons and Orr [25], general existing material databases are used for the embodied carbon calculations [25]. Moreover, since the SFTs comprise a new prototype and have not been built before, there are no operational data available for the maintenance scenarios of the use stage. Thus, both the SFT designs are compared accordingly based on CO2 emissions.

3.3. Step 3: Environmental Impact Assessment for Both Proposals

Embodied carbon for both the design alternatives can be calculated using the carbon factors specified for each stage and the material quantities calculated in step 2. CO2 emissions can be calculated using Equation (1) [5].

∑ [Material Quantity (kg) × Embodied Carbon Factor (ECF) (kgCO2e/kg)] = Embodied Carbon (kgCO2e)

3.4. Step 4: Life-Cycle Analysis

The findings from the environmental impact assessment conducted in step 3 are critically evaluated and integrated into the LCA results. A comparative analysis is then performed on the LCA results from the two different SFT designs, specifically the pontoons and tethers. The comparison delves into each design’s environmental impact, taking into account the many life stages, from raw material extraction to disposal. This method provides a thorough understanding of the environmental implications of each design alternative, allowing for informed decision-making for long-term growth.

3.5. Step 5: Threat Identification and Risk Assessment for Both SFTs

Analyzing hazards and uncertainties that can affect the success of a project or an organization is crucial for the business’s long-term viability [26]. In this paper, the qualitative method of risk analysis was adopted. However, for complex projects, like the E-39 route, the adoption of the quantitative method (Event Tree Analysis, Fault Tree Analysis) could provide a more thorough and in-depth scenario involving computer modeling of a single or combination of events leading to a failure or event.

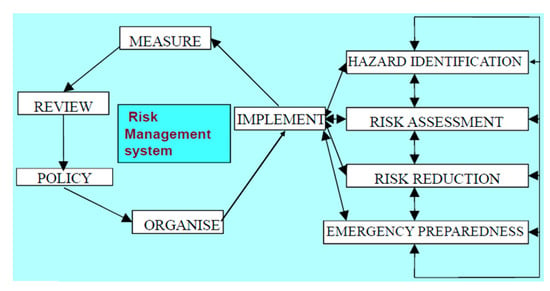

This stage was based on a comprehensive review of the existing literature, patents, and studies related to SFTs. The process followed the four key elements of the Risk Management Framework (RMF): hazard identification, risk assessment, risk response, and emergency preparedness, as Figure 5 shows [26]. The identification was performed according to the 3 project stages: design, construction, and operations. Hazard identification involved recognizing potential risks for both the SFT alternatives. Further, through a qualitative analysis, the possibility and impact of hazards were assessed by giving the consequence (C) and likelihood (L) score, which was showcased through the risk matrix. Additionally, a risk-response plan was developed to improve their C and L score to mitigate the risks.

Figure 5.

Risk analysis framework.

3.6. Step 6: Communicating the Combined Results

This stage was more comprehensive and showed an integrated approach. This stage combined the insights from both the LCA and risk assessment to recommend one design alternative. By combining the insights, the methodology provided a detailed understanding of the environmental risk, associated hazards, and uncertainties associated with the two SFT design possibilities by combining insights from the LCA and risk assessment.

4. Case Study

4.1. Project Description

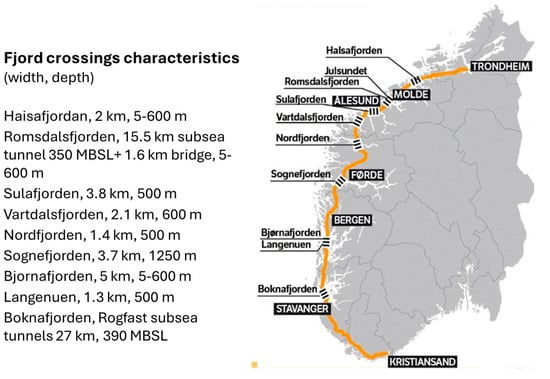

For a fair comparison between the two alternatives, the Sognefjord SFT location, part of the E-39 coastal highway in Norway was chosen in particular, as shown in Figure 6 [15]. This particular fjord crossing stands out as the most challenging water crossing within the E-39 project, reported as the deepest fjord with a water depth of 1250 m [16].

Figure 6.

Coastal Highway E-39 fjord crossing.

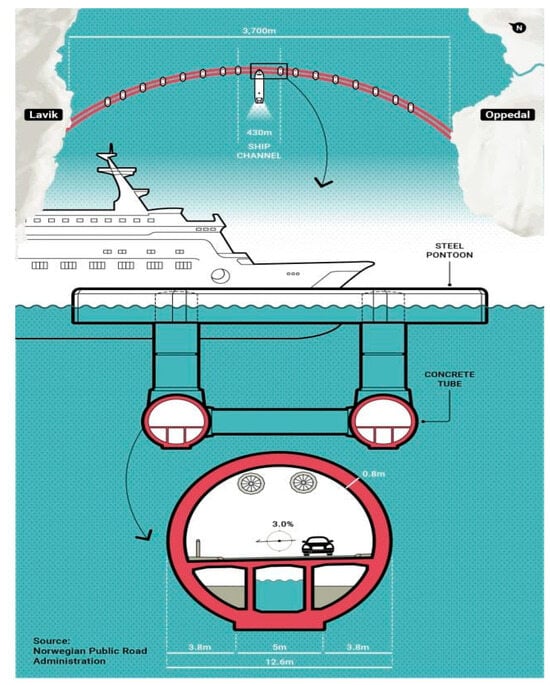

This SFT would link the Norwegian cities of Lavik and Oppedal as shown in Figure 7 and would be the first floating tunnel in the world, measuring more than 3.7 km long and 392 m beneath the water surface [27].

Figure 7.

Location of the Sognefjord SFT.

The two principal design possibilities are investigated for the Submerged Floating Tunnel (SFT) proposals in Norway [15]. The proposal outlines the construction of two parallel tunnels, each spanning the arched length of 4083 m, connected with steel shafts and bracings [28].

4.1.1. SFT with Pontoons

This SFT incorporates two tunnel tubes running parallel, supported by 16 pontoons with dimensions of 26 × 80 × 8 m to carry the load. The construction techniques involve assembling and placing pontoons, tubes, and associated components. The tunnels are interconnected to the pontoons using concrete bracings and steel shafts (horizontal and vertical connection) to keep the tunnel’s structure intact, as shown in Figure 8 [28]. Pontoons are strategically utilized to provide buoyancy and stability to the tunnel structure underneath it, allowing it to float at a controlled depth [29]. The cross section of the SFT can be seen in Figure 9.

Figure 8.

SFT with pontoon design.

Figure 9.

Schematic section of SFT.

4.1.2. SFT with Tethers

Similarly, instead of pontoons, this SFT features concrete footings on the seabed, to which six steel tethers are anchored, to keep the structure stable. The height of the tether is the same as the water depth. Moreover, each foundation is reinforced with four concrete piles under the seabed, as shown in Figure 10. There are a total of 32 foundations to hold the two tunnel tubes.

Figure 10.

SFT with tether anchorage design.

For a fair and objective comparison, the same design specifications as for the Sognefjord SFT with pontoons are assumed for the SFT with tethers. This method enables a targeted study based on carbon emissions, giving a consistent foundation for assessing the environmental impact of each design.

4.2. Project Scope

The scope of our research will focus on evaluating the CO2 emissions of each asset for the LCA of SFT alternatives. Our study will take into account all four life-cycle stages of the product, construction, usage, and end of life for the LCA assessment and three stages, design, construction, and operations, for the risk assessment. Environmental risks for the two design options would be assessed separately for a better comparison.

4.3. LCA Analysis Inputs

4.3.1. Product Stage

For the production stage, it is assumed that the whole tunnel is made up of concrete wherein in reality there are four layers, two layers of foam, and two layers of concrete. For both the SFT options, the concrete is suggested to be of class C45/55 due to potential corrosive effects from the surrounding environment, and thus, the same grade of concrete is chosen for the analysis [30]. Note that C45/55 refers to the compressive strength class of concrete (cylinder strength of 45 MPa; or cube strength of 45 MPa). The bill of quantities is evaluated through the structural drawings and specifications for both the SFTs. Carbon factors for the specific grade of concrete and steel were taken to calculate the raw material supply, transport, and manufacturing CO2 emissions [25].

4.3.2. Construction Stage

The construction of the SFT elements will be carried out in a dry dock, specifically utilizing the existing nearby ‘Lutelandet Offshore AS dock’ [16]. As a result, the towing distance is assumed to be 50 km for all pre-cast concrete structures, while for steel transport, it is assumed to be 300 km on an average as recommended by [25,31]. Therefore, carbon factors for the A4 stage were calculated as shown in Equation (2). Also, it is assumed that all transport is via road. The A5w emissions factor accounts for the CO2 emissions via the disposal of waste material during the production and transportation, which was calculated as shown in Equation (3) [25].

where ECF—embodied carbon factor, TD—transport distance, and TEF—transport mode emission factor.

ECFA4 = ∑ mode (TD mode × TEF mode)

Therefore, for concrete, 50 km × 0.10650 gCO2e/kg/km = 0.005 kgCO2/kg

And for steel, 300 km × 0.10650 gCO2e/kg/km = 0.032 kgCO2/kg

where WF is the waste factor.

A5w = WF × (A13 + A4 + C2 + C34)

4.3.3. Use Stage

The SFT design assumes that the main structural elements, such as the tunnel tube, shafts, bracings, and tethers, do not need to be completely changed throughout the structure’s lifetime [32]. Moreover, the design life of the whole structure is given to be 120 years [16]. Also, it is considered that the structural maintenance is minimal [25,31], and this stage could be neglected.

4.3.4. End of Life (EoL)

A study highlights the advantages of SFTs; because of their inherent buoyancy, it allows for an easy relocation [14]. Thus, the SFTs can be segmented into manageable sections, which can then be transported to other destinations for reuse or safe disposal. However, recommendations by Gibbons and Orr [25] were used to evaluate the landfill carbon data, with the given ECF of 0.013 kgCO2e/kg for C3–C4 for waste and 0.005 kgCO2e/kg for the stage C2 in the LCA.

4.4. Risk Inputs

To perform an appropriate risk analysis, the qualitative method of risk analysis, i.e., the risk matrix technique, has been used as discussed in the methodology with the following inputs.

4.4.1. Hazard Identification

The hazard identification and risk analysis in this study has been conducted based on relevant information gathered from the articles and authoritative reports published by the project officials and independent researchers, as well as newsletters. To enable hazard classification, the core principles and understanding of the scale covered in the class lecture are inferred to create a realistic assumption [26].

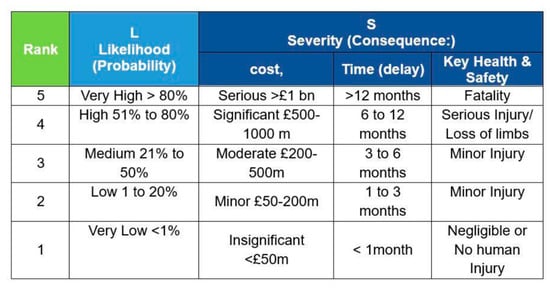

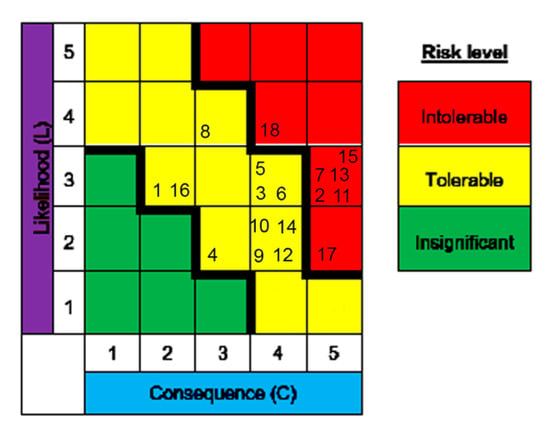

4.4.2. Risk Analysis

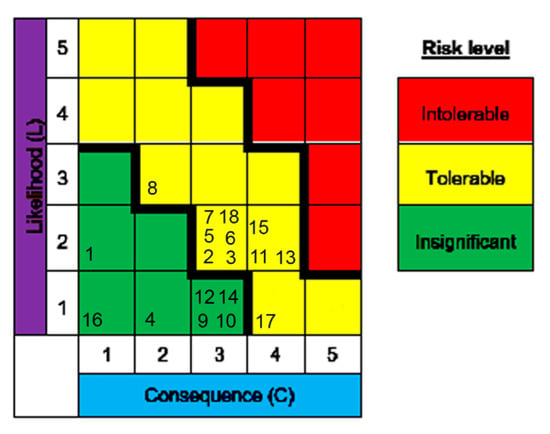

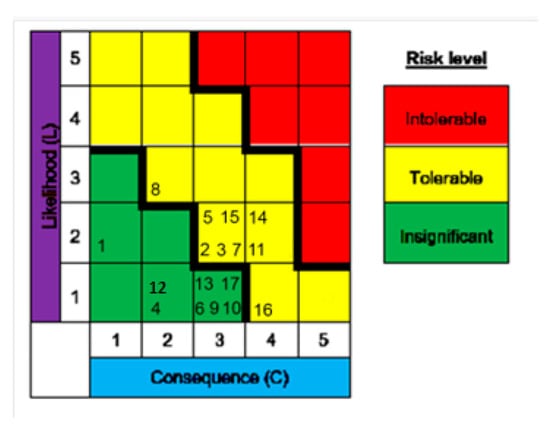

The risk matrix technique has been used for the classification of hazards. The likelihood (L) and consequence (C) are classified based on their scale in accordance with project costs. Figure 11 is used for the pre-management of the risk classification matrix.

Figure 11.

Risk classification scheme (with the scale and risk response).

Furthermore, the risk management plan has been prepared for the reduction of identified intolerable risks, and their change for (C) and (L) can be scaled. Finally, the post-management classification matrix created displays the improvement in minimizing the depicted risks for both the SFTs.

5. Results and Analysis

5.1. LCA

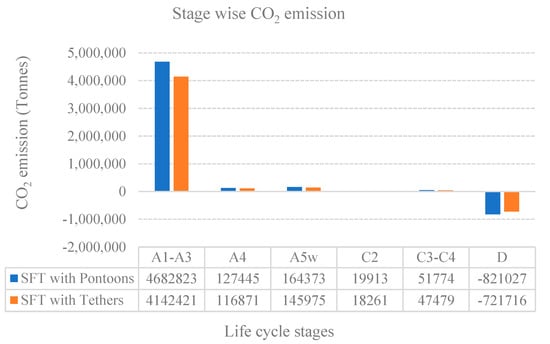

Figure 12 shows the total CO2 emissions (tCO2e) for each stage of the life cycle, except for the use stage, which is not being considered in this study, as discussed in the methodology. The results indicate that the production stage is the largest contributor to CO2 emissions for both of the SFT alternatives, whereas C2, representing transport at the EoL stage, contributes the least amount of CO2 emissions.

Figure 12.

Total CO2 emissions at each stage of the life cycle.

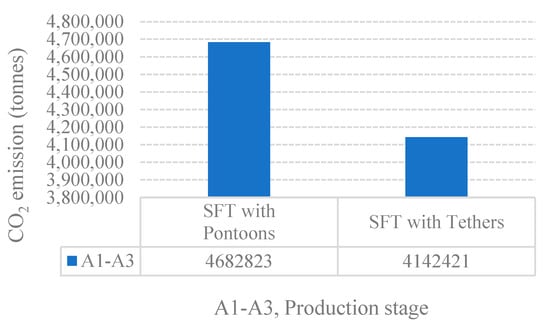

5.1.1. Production Stage

To delve into more details, Figure 13 shows a detailed comparison of carbon emissions at the production stage (A1, A2, A3), focusing on the concrete and steel quantities. The data highlight that the SFT with pontoons accounts for 4,682,823 tonnes of CO2 emissions, whereas the SFT with tethers contributes 4,142,421 tonnes of CO2. This reduced amount of carbon emissions is related to the SFT with tethers’ design features, which adopt lesser amount of materials. Since steel, which has a higher carbon coefficient than other materials, makes up a large portion of the SFT with pontoons, it produces more carbon emissions.

Figure 13.

CO2 emissions at the production stage.

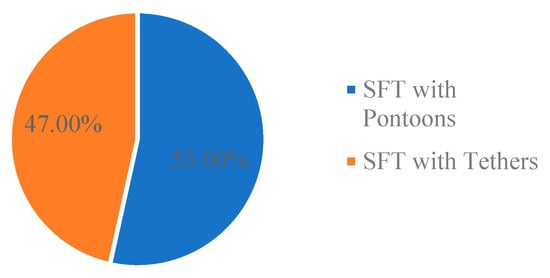

Clearly, steel is a primary material for SFT construction, which is responsible for about 95% of the total CO2e due to its higher ECF compared to any other material utilized in SFTs. A closer examination of the carbon emission by steel reveals that the SFT with pontoons contributes 54%, whereas the SFT with tethers accounts for 47% of the total CO2e of steel, as depicted in Figure 14.

Figure 14.

Carbon emissions caused by steel.

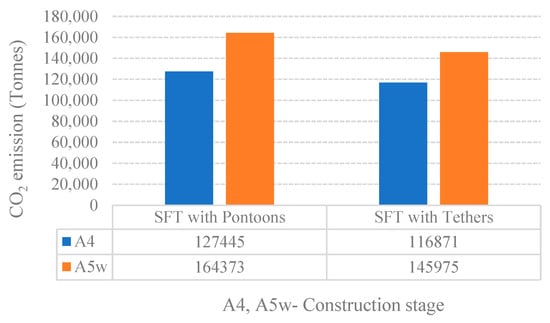

5.1.2. Construction Stage

For the construction stage, the carbon emissions produced by the waste (Aw) is higher for both the SFTs than the emissions caused by the transportation (A4). The disposal of waste material carbon emissions is calculated using Equation (2). However, the carbon emitted attributed to wastage by SFTs with tethers is 6% lower than compared to pontoons as demonstrated in Figure 15.

Figure 15.

CO2 emissions at the construction stage.

The construction stage is critical in defining the project’s overall environmental impact, and utilizing innovative technologies can help to significantly reduce CO2 emissions. For the SFT with pontoons, the construction process involves utilizing innovative construction methods, such as prefabrication, modular construction, etc. Emphasis is placed on the use of advanced technologies, including Building Information Modeling (BIM) and robotic construction, which have been demonstrated to minimize carbon footprints during construction. These technologies aim to optimize material usage, enhance construction efficiency, and reduce energy consumption, collectively contributing to a more sustainable construction process.

Similarly, for the SFT with tethers, construction techniques can be prioritized. The incorporation of cutting-edge technology, including autonomous construction trucks, can be applied to demonstrate their potential for reducing CO2 emissions related to the construction phase. We anticipate that implementing these innovations will improve the project’s overall environmental performance [33].

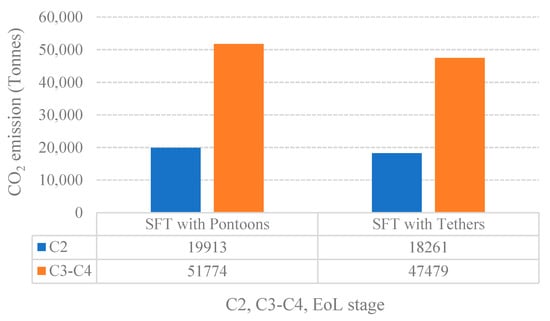

5.1.3. End of Life (EoL)

For both types of the SFTs, the end of life stage’s transport, waste processing, and disposal (C2, C3 and C4) contribute minimal amounts of carbon emissions compared to other stages, as Figure 16 displays. However, as demonstrated, the SFTs with the tether alternative showcases 5% lower total carbon emissions than the pontoon alternative at the EoL stage.

Figure 16.

CO2 emissions at the EoL (end-of-life stage).

5.2. Risk Assessment

Our study carefully follows the standardized concepts indicated in ISO 31000—risk management, which are widely recognized as the best practices in risk management. The entire risk management methodology used to examine SFTs includes a risk evaluation, risk treatment, and monitoring and review, adapted to the specific context of these infrastructure projects.

Risk evaluation begins during hazard identification and covers all stages of the SFT life cycle, including the design, construction, use, and operations. Hazards can be found methodically through a thorough study of the current literature, patents, design documentation, and investigations of SFTs. Each hazard receives a qualitative investigation, and scores for likelihood (L) and consequence (C) are assigned. The risk matrix technique, shown in Figure 11, is used to classify and prioritize the detected dangers. This matrix provides a structured approach for assessing and categorizing hazards based on their potential impact.

After evaluating risks, a response plan has been created to mitigate them. This strategy attempts to improve the consequence and likelihood scores for unbearable and severe hazards. Specific mitigation techniques are designed to lessen the likelihood and severity of hazards. The post-management risk matrices demonstrate the efficacy of risk treatment options in reducing and managing the identified hazards. It is important to highlight that, in some circumstances, emergency preparedness plans can be advised, particularly for dangers with high consequence scores.

Risk management is a dynamic process that adapts to changing circumstances. Our study recognizes the value of ongoing monitoring and occasional evaluations. As SFT projects proceed through various stages, continuous risk assessment and management activities are required. This includes reviewing the risk matrices, revising the risk response plan as necessary, and incorporating lessons learned from comparable projects or emerging industry best practices.

In summary, our study adheres to ISO 31000 standards by including a systematic approach to risk management that is customized to the unique problems of submerged floating tunnels [33].

5.2.1. SFT with Pontoons

Hazards are identified in Table 1 below.

Table 1.

Hazard identification for SFT with pontoons.

Figure 17 presents the matrix, which classifies hazards according to the pre-management assessment. According to the matrix, hazard numbers 2, 7, 11, 13, 15, and 17 can be identified as intolerable.

Figure 17.

Pre-management risk matrix for SFT with Pontoons.

Furthermore, according to risk responses, the matrix in Figure 18 shows the post-management classification indicating the improvements in mitigating the highlighted risks.

Figure 18.

Post-management risk matrix for SFT with Pontoons.

Thus, all the dangers can become less likely as a result of the mitigation measures that are planned and implemented. However, hazards No. 11, 13, and 15, although being in the tolerable zone, show high scores of consequence, necessitating an emergency preparedness plan as they are highlighted in orange in Table 1. Moreover, hazard 13 (pontoon and ship collision) is a critical concern affecting complete stability of the structure and human safety, which calls for a detailed risk analysis [35,39,40,41,42,43,44,45,46,47,48,49,50,51].

5.2.2. SFT with Tethers

Similarly, Table 2 shows the hazards identified for the SFT with tethers.

Table 2.

Hazard identification for SFT with tethers.

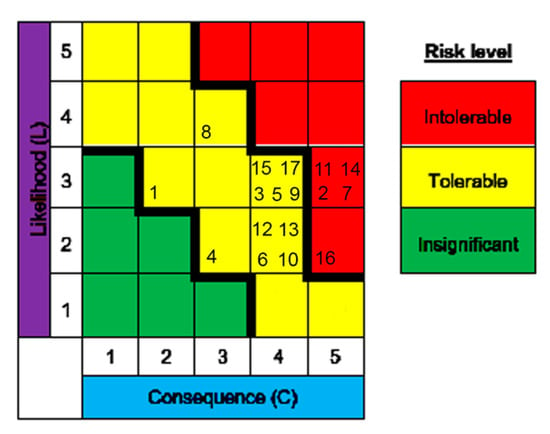

Figure 19 shows the matrix with classified hazards according to the pre-management assessment.

Figure 19.

Pre-management risk matrix for SFT with Tethers.

This matrix displays risks no. 2, 7, 11, 14, and 16 in the intolerable zone. According to mitigation, the matrix in Figure 20 shows the post-management classification, indicating the improvements in reducing the highlighted risks of the SFT with tethers.

Figure 20.

Post-management risk matrix for SFT with Tethers.

Thus, all the risks are insignificant and tolerable. However, hazards no. 11 and 14 (being in the tolerable zone) cannot be depicted by their high consequence rating and should be taken care of as highlighted with orange in Table 2 above.

From the comparison made through the post classification matrixes and the environmental risk comparison shown in Table 3, it becomes evident that the SFT with tethers presents fewer risks than the SFT with pontoons.

Table 3.

Environmental risk comparison.

6. Discussion

As per Norwegian Ministry of Transport and Communications [15,25], the specific SFT project is still in the planning phase, which yields an appropriate opportunity to assess the LCA and risk profiles of both projects. Our results reveal consistent findings across all LCA stages for benchmarking.

- Carbon Emissions

Data from Figure 11 reveal that both SFT options have a pronounced carbon footprint, particularly during the production stage (A1-A3). The findings clearly show that construction materials, particularly steel, have a major environmental impact on the carbon footprint of SFTs, accounting for 95% of total CO2e in the production phase, while concrete accounts for 5% of the total CO2e. By comparing both SFT alternatives, it is seen that there is a notable decrease in carbon emissions from 5,046,330 tonnes CO2e for the SFT with pontoons to 4,471,009 tonnes CO2e for the SFT with tethers, highlighting the sustainability of the former design. This is an important observation that aligns with global initiatives to reduce carbon emissions from infrastructure developments.

- Risk Assessment

Our new findings derived from the risk assessment indicate several vulnerabilities associated with each SFT alternative. While each design has its own set of challenges, the SFT with tethers appears to be more resistant to environmental hazards, such as rising sea levels, tsunamis, storms, ice formation, and landslides.

While this study provides valuable insights into the life-cycle analysis and risk assessment of SFTs, it is important to note that the project is still in the design phase, and the material data are based on the existing literature and available design information. The limitation of the study is based on the estimation of costs, which may be changed at a later stage. However, our LCA models can be adaptive to assess any potential changes required in the future. Recognizing the dynamic nature of material breakthroughs and changing industry practices, future research efforts will attempt to perform a comprehensive sensitivity analysis that includes the most recent data on materials, construction procedures, and environmental factors. This will ensure that the life-cycle analysis remains current and reflects the most up-to-date information, helping in the continual improvement and accuracy of evaluations in the field of resilient infrastructure construction [38,39].

7. Conclusions

This research has comprehensively compared two SFT designs: an SFT with pontoons and SFT with tethers, focusing on their life cycle carbon emissions and potential risk at the design, construction, and operation stages, as well environmental hazards for future uncertainties. The life-cycle assessments (LCAs) in this study have revealed the possibility for large reductions in carbon emissions by carefully selecting the SFT design. The SFT with tethers appears as a more sustainable and resilient design option. Its low carbon footprint, combined with its adaptability to environmental hazards, makes it an appealing option for future infrastructure development. However, given the potential severity of certain hazards it is critical to approach its adoption with comprehensive risk-management measures. The new insights derived from our study are especially important, considering the growing worldwide emphasis on sustainable and resilient infrastructure as a critical component of climate action. Our study exhibits that life-cycle perspectives should be fully adopted for infrastructure asset management. The perspectives can help decision-makers to strike a balance among cost, the carbon footprint, risks, and vulnerability of the built environment. While our study focuses on the reduction in CO2 emissions, we recognize the significance of a cost–benefit analysis for informed decision-making in infrastructure projects for a sustainable future.

Author Contributions

Data collection, conceptualization, methodology, simulation, and writing—original draft preparation, S.V., J.S. and S.K.; supervision, project administration, and funding acquisition, S.K.; conceptualization, methodology, and writing—review and editing, S.V., J.S. and S.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the European Commission for the financial sponsorship of the H2020-RISE Project No. 691135. The APC is sponsored by MDPI’s Invited Paper Initiative.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data can be made available upon reasonable request to the corresponding author.

Acknowledgments

The authors are also sincerely grateful to the European Commission for the financial sponsorship of the H2020-RISE Project No. 691135 “RISEN: Rail Infrastructure Systems Engineering Network”, which enables a global research network that tackles the grand challenge of railway infrastructure resilience and advanced sensing in extreme environments. The corresponding author wishes to thank the Australian Academy of Science and the Japan Society for the Promotion of Sciences for his Invitation Research Fellowship (Long-term), Grant No. JSPS-L15701, at the Railway Technical Research Institute and The University of Tokyo, Japan.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IPCC. Climate change 2021—The Physical Science Basis. In Working Group I Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; United Nation: Geneva, Switzerland, 2021. [Google Scholar]

- UN Climate Change Conference. COP26 Goals. 2021. Available online: https://webarchive.nationalarchives.gov.uk/ukgwa/20230311034236/https://ukcop26.org/cop26-goals/ (accessed on 30 May 2023).

- European Commission. Energy Efficient Buildings. 2018. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings_en (accessed on 1 July 2023).

- World Green Building Council. World Green Building Week 2019. Available online: https://worldgbc.org/ (accessed on 10 June 2023).

- Kaewunruen, S.; Sresakoolchai, J.; Yu, S. Global Warming Potentials Due to Railway Tunnel Construction and Maintenance. Appl. Sci. 2020, 10, 6459. [Google Scholar] [CrossRef]

- Moan, T.; Eidem, M.E. Floating Bridges and Submerged Tunnels in Norway—The History and Future Outlook; Springer: Singapore, 2019. [Google Scholar]

- Martire, G. The Development of Submerged Floating Tunnels as an Innovative Solution for Waterway Crossing; University of Naples Federico II Faculty of Engineering: Naples, Italy, 2010. [Google Scholar]

- Ministry of Transport. Norwegian Public Road Administration. 2008. Available online: https://www.regjeringen.no/en/dep/sd/organisation/subordinate-agencies-and-enterprises/norwegian-public-roads-administration/id443412/ (accessed on 4 August 2023).

- Baravalle, M.; Köhler, J. Risk and reliability based calibration of design codes for submerged floating tunnels. Procedia Eng. 2016, 166, 247–254. [Google Scholar] [CrossRef]

- BS EN ISO 14040:2006+A1:2020; Environmental Management—Life Cycle Assessment—Principles and Framework. BSI Standards Limited: Singpaore, 2020.

- Dossche, C.; Boel, V.; De Corte, W. Use of life cycle assessment in the construction sector: Critical review. Procedia Eng. 2017, 171, 302–311. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission on a Euprpean Programme for Critical Infrastructure Protection; Commission of the European Communities: Brussels, Belgium, 2006. [Google Scholar]

- Jiang, B.; Liang, B.; Wu, S. Feasibility study on the submerged floating tunnel in Qiongzhou strait, China. Pol. Marit. Res. 2018, 25, 4–11. [Google Scholar] [CrossRef]

- Østlid, H. When is SFT competitive? Procedia Eng. 2010, 4, 3–11. [Google Scholar] [CrossRef]

- Norwegian Ministry of Transport and Communications. National Transport Plan 2018–2029: A Targeted and Historic Commitment to the Norwegian Transport Sector; Storting (White Paper): Oslo, Norway, 2016. [Google Scholar]

- Fjeld, A. Feasibility Study for Crossing Sognefjorden-Submerged Floating Tunnel; Reinertsen Olav Olsen Group: Trondheim, Norway, 2012. [Google Scholar]

- Xu, W.; Ma, Y.; Liu, G.; Li, M.; Li, A.; Jia, M.; He, Z.; Du, Z. A review of research on tether type submerged floatin tunnel. Appl. Ocean Res. 2023, 134, 103525. [Google Scholar] [CrossRef]

- DByrne, M.; Lohman, H.A.C.; Cook, S.M.; Peters, G.M.; Guest, J.S. Life cycle assessment (LCA) of urban water infrastructure: Emerging approaches to balance objectives and inform comprehensive decision-making. Environ. Sci. Water Res. Technol. 2017, 3, 1002–1014. [Google Scholar]

- Butle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction section: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar]

- Kohler, N.; Moffatt, S. Life cycle analysis of the built environment. Ind. Environ. 2003, 26, 17–21. [Google Scholar]

- Iversen, O.M.K. Early-Phase Life Cycle Assessment of New Concepts for Fjord Crossings along Coastal Highway Route E39; Norwegian University of Science and Technology: Trondheim, Norway, 2014. [Google Scholar]

- Kumar, R.; Bhowmik, R. Submerged floating tunnels: State-of-the-art on design and challenges. In Proceedings of the Indian Geotechnical Conference IGC 2022, Kochi, Indian, 15–17 December 2022. [Google Scholar]

- Xiang, Y.; Liu, C.; Zhang, K.; Wu, Q. Risk analysis and management of submerged floating tunnel and its application. Procedia Eng. 2010, 4, 107–116. [Google Scholar] [CrossRef][Green Version]

- The Constructor. Density of Construction Materials in kg/m3 and lb/ft3. 2016. Available online: https://theconstructor.org/building/density-construction-materials/13531/ (accessed on 30 July 2023).

- OGibbons, P.; Orr, J.J. How to Calculate Embodied Carbon. 2020. Available online: https://www.istructe.org/IStructE/media/Public/Resources/istructe-how-to-calculate-embodied-carbon.pdf (accessed on 20 June 2023).

- Hawwash, R. Safety, Risk and Hazard; University of Birmingham: Birmingham, UK, 2023. [Google Scholar]

- Dunham, K.K. Coastal Highway Route E39—Extreme crossings. Transp. Res. Procedia 2016, 14, 494–498. [Google Scholar] [CrossRef][Green Version]

- Vegvesen, S. Feasibility Study for Crossing the Sognefjord; Region West: Trondheim, Norway, 2012. [Google Scholar]

- Ayyad, S.M. Design Criteria for the Floating Walkways and Pontoons Considering the Extreme Climatic Conditions; Amman Arab University: Jordan, Arab, 2020. [Google Scholar]

- Kellenberger, D.; Althaus, H.-J.; Kunniger, T.; Lehmann, M.; Thalmann, P. Life Cycle Inventories of Building Products; Ecoinvent Data, Swiss Centre for Life Cycle Inventories: Geneva, Switzerland, 2007. [Google Scholar]

- RICS. Whole Life Carbon Assessment for the Built Environment. 2017. Available online: https://www.rics.org/globalassets/rics-website/media/news/whole-life-carbon-assessment-for-the--built-environment-november-2017.pdf (accessed on 28 June 2023).

- Haugerud, S.A. Personal Communication Regarding the Construction, Operation and Maintenance of the SFT Claimed Technically Feasible to Cross the Sognefjord. Personal E-mail Communication, 2024. [Google Scholar]

- Gunanandhini, T.; Sivakumar, S.; Sreenivasan, A.; Suresh, M. Green Construction Project Management: A Bibliometric Analysis. In ICT: Smart Systems and Technologies. ICTCS 2023. Lecture Notes in Networks and Systems; Kaiser, M.S., Xie, J., Rathore, V.S., Eds.; Springer: Singapore, 2024; Volume 878. [Google Scholar] [CrossRef]

- ISO 31000; ISO 31000:2018 Risk Management—Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2018.

- Hurlbert, M.; Krishnaswamy, J.; Johnson, F.X.; Rodríguez-Morales, J.E.; Zommers, Z. Risk Management and Decsion Making in Relation to Sustainable Development; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Jakobsen, B. Design of the Submerged Floating Tunnel operating under various conditions. Procedia Eng. 2010, 4, 71–79. [Google Scholar] [CrossRef]

- Amdahl, J.; Ehlers, S.; Leira, B.J. Collison and Grounding of Ships and Offshore Structures; CRC Press: Trondheim, Norway, 2013. [Google Scholar]

- Matejicka, L.; Georgakis, C.T. A review of ice and snow risk mitigation and control measures for bridge cables. Cold Reg. Sci. Technol. 2022, 193, 103429. [Google Scholar] [CrossRef]

- Nadim, F. Landslide Hazard and Risk Assessment; United Nations Office for Risk Reduction (UNISDR): Geneva Switzerland, 2017. [Google Scholar]

- IGBC. IGBC Green New Buildings. 2020. Available online: https://igbc.in/igbc/redirectHtml.htm?redVal=showGreenNewBuildingsnosign (accessed on 10 June 2020).

- Thacker, S.; Adshead, D.; Fantini, C.; Palmer, R.; Ghosal, R.; Adeoti, T.; Morgan, G.; Stratton-Short, S. Infrastructure for Climate Action; UNOPS, UN Environment Programme (UNEP) and University of Oxford: Copenhagen, Denmark, 2021. [Google Scholar]

- Gijzel, D.; Bosch-Rekveldt, M.; Schraven, D.; Hertogh, M. Integrating Sustainability into Major Infrastructure Projects: Four Perspectives on Sustainable Tunnel Development. Sustainability 2019, 12, 6. [Google Scholar] [CrossRef]

- Hammervold, J.; Reenaas, M.; Brattebø, H. Environmental Life Cycle Assessment of Bridges. J. Bridg. Eng. 2013, 18, 153–161. [Google Scholar] [CrossRef]

- Mascella, M. Global Analysis of Submerged Floating Tunnels under Hydrodynamic Loading; Norwegian University of Science and Technology: Milano, Italy, 2020. [Google Scholar]

- Lee, H.K. Research Center for Smart Submerged Gloating Tunnel System; Korea Advanced Institute of Science and Technology (KAIST): Daejeon, Republic of Korea, 2018. [Google Scholar]

- Jonsson, D.K. Indirect energy associated with Swedish road transport. Eur. J. Transp. Infrastruct. Res. 2007, 7, 183–200. [Google Scholar] [CrossRef]

- Hoffmann, C.; Hoey, M.V.; Zeumer, B. Decarbonization Challenge for Steel. 3 June 2020. Available online: https://www.mckinsey.com/industries/metals-and-mining/our-insights/decarbonization-challenge-for-steel#/ (accessed on 14 August 2023).

- World Steel Association. World Steel in Figures; World Steel Association: Brussels, Belgium, 2023. [Google Scholar]

- Lunniss, R.; Baber, J. Immersed Tunnels, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 1–483. [Google Scholar]

- Swaalf, F. Reliability Analysis of Submerged Floating Tunnels; Delft University of Technology: Delft, The Netherlands, 2020. [Google Scholar]

- Civil Engineering Seminar. Submerged Floating Tunnel. 2016. Available online: http://civilenggseminar.blogspot.com/2016/06/submerged-floating-tunnel.html (accessed on 15 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).