Barriers of and Possibilities for Recycling of Single-Use Take-Away Food and Beverage Packaging: Evidence from Lithuanian Market

Abstract

:1. Introduction

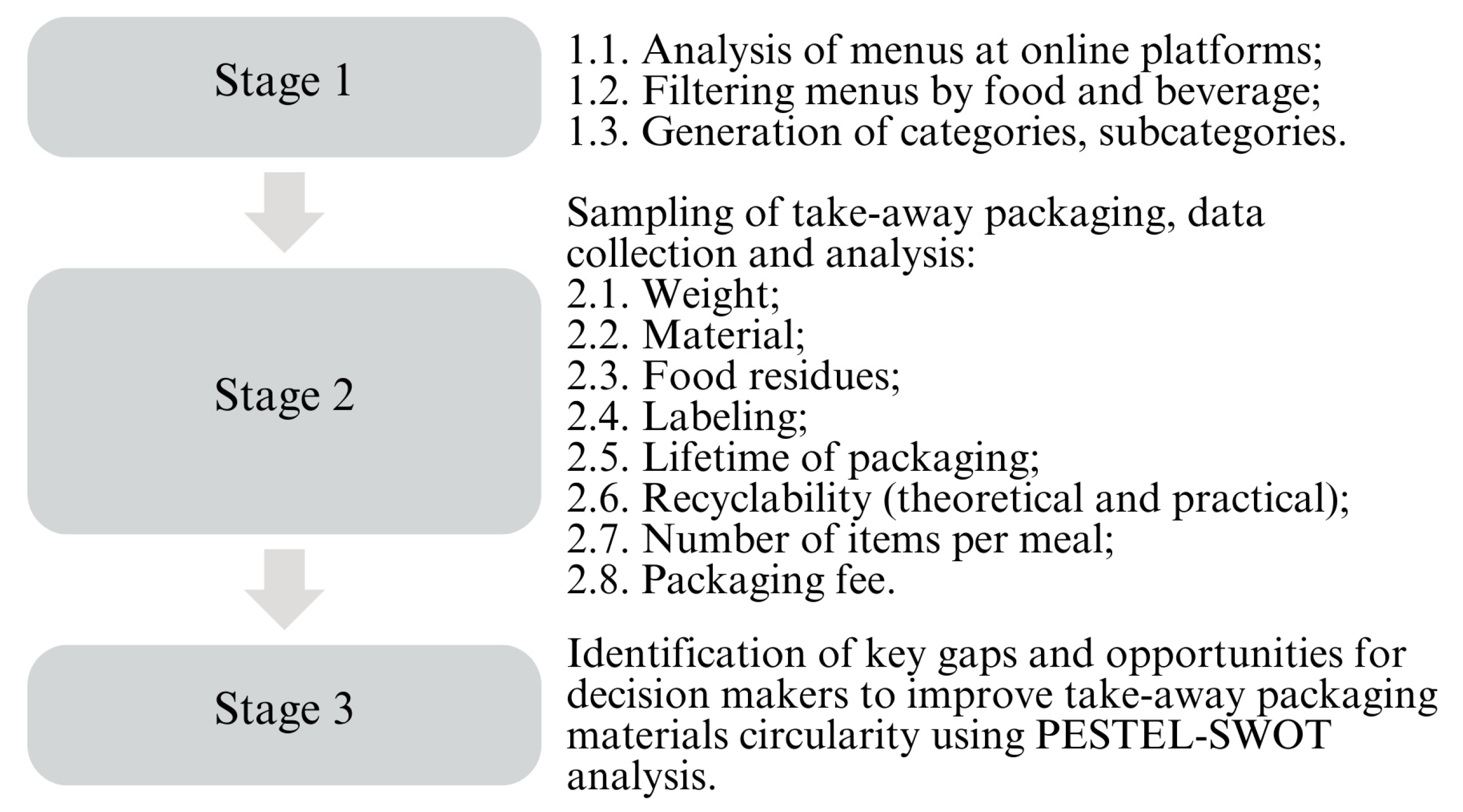

2. Materials and Methods

- (1)

- The selection of food and beverages from menus and assigning them to certain categories and subcategories, with reference to the packaging requirements for each category and subcategory.

- (2)

- An analysis of take-away packaging samples—packaging materials, sizes, weight, dirt, labelling, and potential recyclability. Packaging samples were gathered from the different restaurants on online platforms, ordering meals and beverages that were identified as the most popular meals and beverages at the first stage of the research. 10 orders per one popular meal and beverage were performed, e.g., 10 zeppelinas, 10 burgers, 10 coffees, etc. Sampling was performed to collect primary packaging samples and to register the data. Labelling was assessed from the user perspective. At the EoL stage, the waste manager identified the theoretical and practical recyclability of the collected packaging samples.The average time of use of packaging was assessed to understand how long single-use take-away packaging performs its main function, from confirming that the order was ready to be picked up by a courier to the final delivery at the door. Packaging fees were measured, analysing what part of the business provided free-of-charge packaging, how many of businesses applied a packaging fee, and also whether the packaging fee correlates with environmental benefits (the packaging was sustainable, was from consciously sourced materials, the fee supported the company’s environmental practices, etc.).

- (3)

- The identification of key gaps and opportunities for take-away packaging circularity applying the PESTEL-SWOT matrix as a tool. This tool was selected due to the complexity of this research area, which was influenced by a number of internal and external factors. The PESTEL-SWOT matrix provided a great structure for the proper evaluation of certain influences for single-use take-away food and beverage packaging circularity and recyclability improvement. In this part of the research, all data and information gathered from Stage 1 and Stage 2 practices were assessed and analysed, through political, economic, environmental, technological, legal, and social strengths, weaknesses, opportunities, and threats. This framework allows one to distinguish the enablers and the main obstacles to be overcome [35].

2.1. Categorization of Food and Beverages Regarding Packaging Needs

2.2. Analysis of Take-Away Packaging Materials, Sizes, Weight, Dirt, Labelling and Potential Recyclability

2.2.1. Packaging Time of Use, Number of Items per Meal, and Packaging Pricing

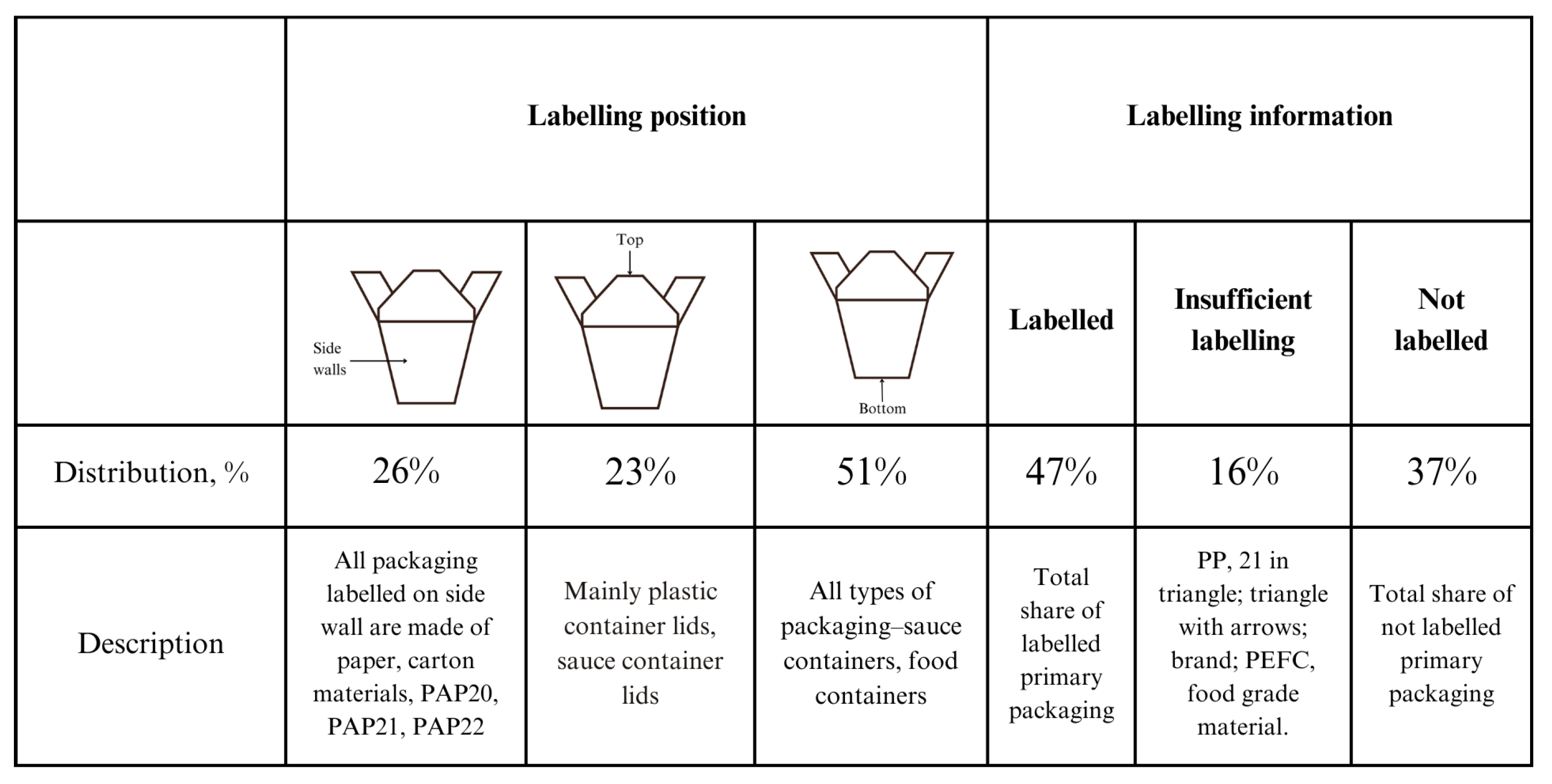

2.2.2. Labelling, Packaging Materials, and Weight Identification

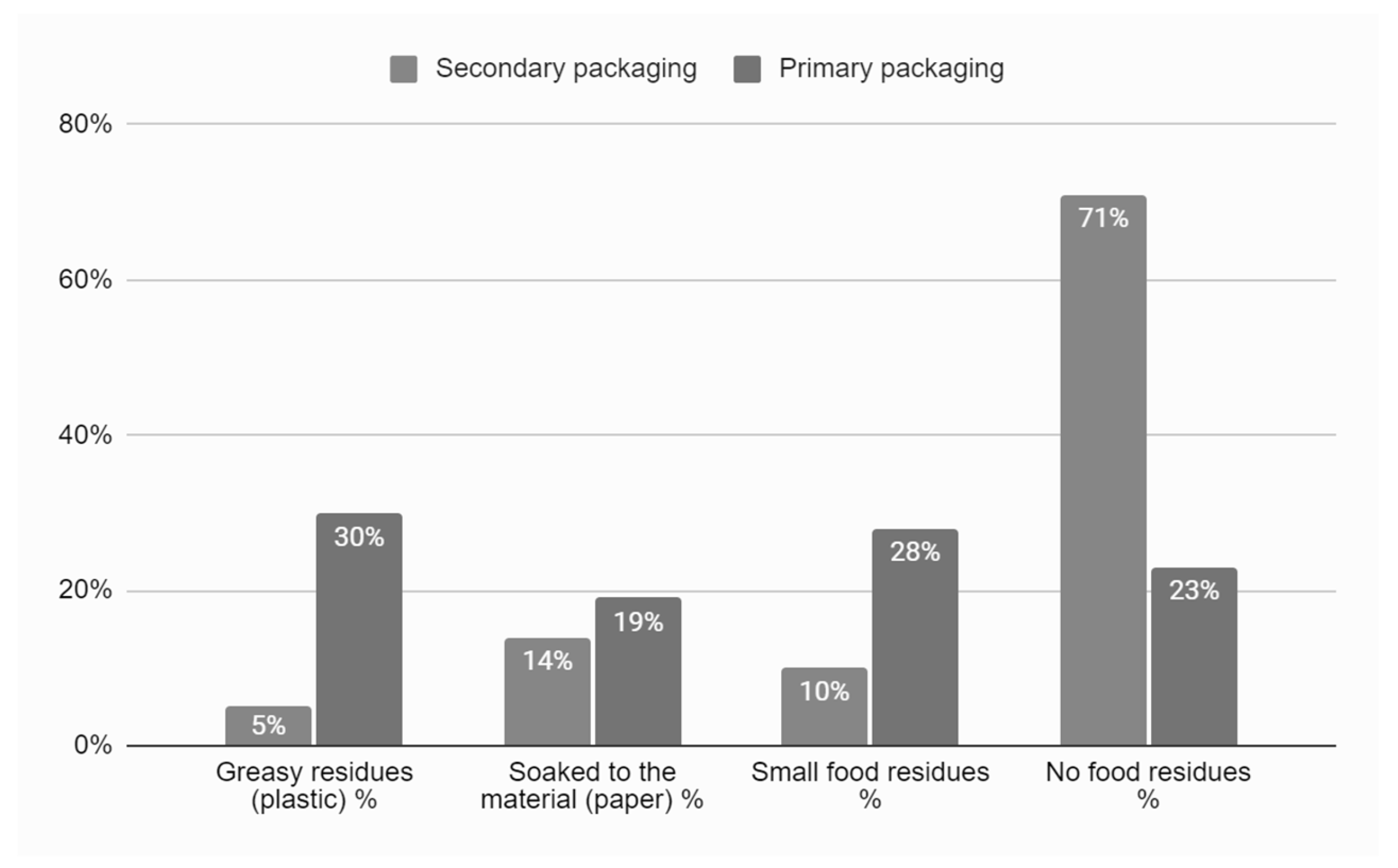

2.2.3. Food Residue Level, and Recyclability

- Can the package be prescribed to a certain waste stream according to the labelling?

- Can the package be recycled according to the material (layers, printing inks, barriers, etc.) and current recycling infrastructure?

- Can theoretically recyclable packaging (when infrastructure is in place and materials are suitable for recycling) be recycled with the current levels of food residues?

2.3. Identification of Key Gaps and Opportunities for Take-Away Packaging Circularity

3. Results and Discussions

3.1. Categorization of Food and Beverages with Regard to Packaging Needs

3.2. Analysis of Take-Away Packaging

3.2.1. Packaging Time of Use, Number of Items per Meal, and Packaging Pricing

3.2.2. Packaging Materials, Weight, and Labelling Identification

- Material composition

- Weight

- Labelling

- Material composition and labelling of HD and CD categories

3.2.3. Food Residue Level and Recyclability

3.3. PESTEL-SWOT Analysis

- Political (strengths, weakness, opportunities, and threats)

- Economical (strengths, weakness, opportunities, and threats)

- Social (strengths, weakness, opportunities, and threats)

- Technological (strengths, weakness, opportunities, and threats)

- Environmental (strengths, weakness, opportunities, and threats)

- Legal (strengths, weakness, opportunities, and threats)

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ada, E.; Kazancoglu, Y.; Gozacan-Chase, N.; Altin, O. Challenges for circular food packaging: Circular resources utilization. Appl. Food Res. 2023, 3, 100310. [Google Scholar] [CrossRef]

- Wu, F.; Misra, M.; Mohanty, A.K. Challenges and new opportunities on barrier performance of biodegradable polymers for sustainable packaging. Prog. Polym. Sci. 2021, 117, 101395. [Google Scholar] [CrossRef]

- Kearney. No Silver Bullet. Why the Right Mix of Solutions Will Achieve Circularity in Europe’s Informal Eating Out (IEO) Sector. Available online: https://nosilverbullet.eu/wp-content/uploads/2023/02/No-silver-bullet%E2%80%93why-a-mix-of-solutions-is-required-to-achieve-circularity-in-Europe.pdf (accessed on 12 March 2024).

- Statista. Restaurant Delivery—Lithuania. Available online: https://www.statista.com/outlook/dmo/online-food-delivery/meal-delivery/restaurant-delivery/lithuania (accessed on 23 March 2024).

- Kim, Y.T.; Min, B.; Kim, K.W. General Characteristics of Packaging Materials for Food System. In Innovations in Food Packaging, 2nd ed.; Academic Press: San Diego, CA, USA, 2014; pp. 13–35. ISBN 9780123946010. [Google Scholar] [CrossRef]

- Dany, H.; Utami, F.; Sulistiyono, N.; Latuheru, P.; Negeri, P.; Kreatif, M.; Pendidikan, U.; Transportasi, P.; Danau, S.; Palembang, P.; et al. Characterization Physical, Chemical, Mechanical and Optical Properties of Paper on the Market for Dry Food Packaging Applications. In Proceedings of the First Jakarta International Conference on Multidisciplinary Studies Towards Creative Industries, JICOMS 2022, Jakarta, Indonesia, 16 November 2022. [Google Scholar] [CrossRef]

- Agarwal, A.; Shaida, B.; Rastogi, M.; Singh, N.B. Food Packaging Materials with Special Reference to Biopolymers-Properties and Applications. Chem. Afr. 2022, 6, 117–144. [Google Scholar] [CrossRef]

- Molina-Besch, K.; Wikström, F.; Williams, H. The environmental impact of packaging in food supply chains—Does life cycle assessment of food provide the full picture? Int. J. Life Cycle Assess. 2019, 24, 37–50. [Google Scholar] [CrossRef]

- Eurostat. Eurostat Statistics Explained: Packaging Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Packaging_waste_statistics#:~:text=In%20both%202020%20and%202021,each%20following%20year%20until%202020 (accessed on 12 March 2024).

- Environmental Protection Agency. Packaging Waste. Available online: https://aaa.lrv.lt/lt/veiklos-sritys/atliekos/atlieku-apskaita/atlieku-apskaitos-duomenys/pakuociu-atliekos/ (accessed on 12 March 2024). (In Lithuanian).

- Zhuo, Y.; He, J.T.; Li, W.; Deng, J.; Lin, Q.L. A review on takeaway packaging waste: Types, ecological impact, and disposal route. Environ. Pollut. 2023, 337, 122518. [Google Scholar] [CrossRef]

- Caspers, J.; Süßbauer, E.; Coroama, V.C.; Finkbeiner, M. Life Cycle Assessments of Takeaway Food and Beverage Packaging: The Role of Consumer Behavior. Sustainability 2023, 15, 4315. [Google Scholar] [CrossRef]

- Packaging Today. Available online: https://www.packagingtoday.co.uk/features/featurecommunicating-with-consumers-through-packaging-4673481/ (accessed on 27 February 2024).

- Klaiman, K.; Ortega, D.L.; Garnache, C. Consumer preferences and demand for packaging material and recyclability. Resour. Conserv. Recycl. 2016, 115, 1–8. [Google Scholar] [CrossRef]

- Kimberly, K.; David, O.; Cloe, G. Perceived barriers to food packaging recycling: Evidence from a choice experiment of US consumers. Food Control 2016, 73, 291–299. [Google Scholar] [CrossRef]

- Otto, S.; Strenger, M.; Maier-Nöth, A.; Schmid, M. Food packaging and sustainability—Consumer perception vs. correlated scientific facts: A review. J. Clean. Prod. 2021, 298, 126733. [Google Scholar] [CrossRef]

- Boz, Z.; Korhonen, V.; Koelsch Sand, C. Consumer Considerations for the Implementation of Sustainable Packaging: A Review. Sustainability 2020, 12, 2192. [Google Scholar] [CrossRef]

- Kozik, N. Sustainable packaging as a tool for global sustainable development. SHS Web Conf. 2020, 74, 04012. [Google Scholar] [CrossRef]

- Clubzero. Available online: https://www.clubzero.co/ (accessed on 25 February 2024).

- Recup. Available online: https://recup.de/ (accessed on 25 February 2024).

- RingoEco. Available online: https://ringo.eco/ (accessed on 25 February 2024).

- Recircle. Available online: https://www.recircle.eu/europa/ (accessed on 25 February 2024).

- CupCup. Available online: https://cupcup.lt/ (accessed on 25 February 2024).

- Vytal. Available online: https://en.vytal.org/ (accessed on 25 February 2024).

- Deliverzero. Available online: https://www.deliverzero.com/ (accessed on 25 February 2024).

- Return. Available online: https://returnr.org/ (accessed on 25 February 2024).

- Ozarka. Available online: https://ozarka.biz/?lang=en (accessed on 25 February 2024).

- Simply Cups. Available online: https://www.simplycups.com.au/ (accessed on 25 February 2024).

- The Cup Collective. Available online: https://thecupcollective.eu/about.html (accessed on 25 February 2024).

- Norton, V.; Oloyede, O.O.; Lignou, S.; Wang, Q.J.; Vásquez, G.; Alexi, N. Understanding consumers’ sustainability knowledge and behaviour towards food packaging to develop tailored consumer-centric engagement campaigns: A Greece and the United Kingdom perspective. J. Clean. Prod. 2023, 408, 137169. [Google Scholar] [CrossRef]

- Nemat, B.; Razzaghi, M.; Bolton, K.; Rousta, K. The Role of Food Packaging Design in Consumer Recycling Behavior—A Literature Review. Sustainability 2019, 11, 4350. [Google Scholar] [CrossRef]

- Gallego Schmid, A.; Mendoza, J.M.F.; Azapagic, A. Environmental impacts of takeaway food containers. J. Clean. Prod. 2018, 211, 417–427. [Google Scholar] [CrossRef]

- Dybka-Stępień, K.; Antolak, H.; Kmiotek, M.; Piechota, D.; Koziróg, A. Disposable Food Packaging and Serving Materials—Trends and Biodegradability. Polymers 2021, 13, 3606. [Google Scholar] [CrossRef]

- Zeng, L.; Zhou, Y.; Zhang, H.; Cai, Y.; Yang, Z. Driving factors and their interactions of takeaway packaging waste generation in China. Resour. Conserv. Recycl. 2022, 185, 106467. [Google Scholar] [CrossRef]

- Rim, B.; Said, M. Investigating the Viability of Implementing Electric Freight Vehicles in Morocco: Using an Integrated SWOT PESTEL Analysis in Combination with Analytic Hierarchy Process. In Optimization and Decision-Making in the Renewable Energy Industry; Publisher IGI Global: Hershey, PA, USA, 2022; pp. 126–152. [Google Scholar] [CrossRef]

- Liu, G.; Agostinho, F.; Duan, H.; Song, G.; Wang, X.; Giannetti, B.F.; Santagata, R.; Casazza, M.; Lega, M. Environmental impacts characterization of packaging waste generated by urban food delivery services. A big-data analysis in Jing-Jin-Ji region (China). Waste Manag. 2020, 117, 157–169. [Google Scholar] [CrossRef]

- Basil, F.F.A.; Tamyez, P.F.M.; Zahari, A.R.; Yao, L.; Ahmarofi, A.A. Packaging waste generation by households: A mixed method study. Int. J. Environ. Stud. 2023, 80, 964–977. [Google Scholar] [CrossRef]

- Foodservice Packaging Institute. Food Residue Study. Available online: https://static1.squarespace.com/static/5e8221dbc8b11929c3f7eef7/t/64c125732fe366528d9d1123/1690379636000/FPI+Food+Residue+Study+2022.pdf (accessed on 24 January 2024).

- Aarnio, T.; Hämäläinen, A. Challenges in packaging waste management in the fast food industry. Resour. Conserv. Recycl. 2008, 52, 612–621. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food Packaging—Roles, Materials, and Environmental Issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front. Nutr. 2018, 5, 121. [Google Scholar] [CrossRef]

- Du Rietz, S.; Kremel, A. Consumer Behavior as a Challenge and Opportunity for Circular Food Packaging—A Systematic Literature Review. Circ. Econ. Sustain. 2023, 4, 413–438. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Liu, Y. Barriers to circular food supply chains in China. Supply Chain Manag. 2019, 24, 677–696. [Google Scholar] [CrossRef]

- Carvalho de Sousa, G.; Castañeda-Ayarza, J.A. PESTEL analysis and the macro-environmental factors that influence the development of the electric and hybrid vehicles industry in Brazil. Case Stud. Transp. Pol. 2022, 10, 686–699. [Google Scholar] [CrossRef]

- Thakur, V. Framework for PESTEL dimensions of sustainable healthcare waste management: Learnings from COVID-19 outbreak. J. Clean. Prod. 2021, 287, 125562. [Google Scholar] [CrossRef] [PubMed]

- Loizia, P.; Voukkali, I.; Zorpas, A.A.; Pedreño, J.N.; Chatziparaskeva, G.; Inglezakis, V.J.; Vardopoulos, I.; Doula, M. Measuring the level of environmental performance in insular areas, through key performed indicators, in the framework of waste strategy development. Sci. Total Environ. 2021, 753, 141974. [Google Scholar] [CrossRef]

- Helsinki Region Environmental Services (HSY). Carton and Cardboard. Available online: https://www.hsy.fi/en/waste-and-recycling/waste-guide/sorting/carton-and-cardboard/ (accessed on 14 March 2024).

- Allahvaisi, S. Polypropylene in the Industry of Food Packaging. In Polypropylene; Dogan, F., Ed.; IntechOpen: London, UK, 2012; pp. 3–22. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Chemical Safety Facts. Polystyrene. Available online: https://www.chemicalsafetyfacts.org/chemicals/polystyrene/ (accessed on 14 March 2024).

- Nisticò, R. Polyethylene terephthalate (PET) in the packaging industry. Polym. Test. 2020, 90, 106707. [Google Scholar] [CrossRef]

- Benyathiar, P.; Kumar, P.; Carpenter, G.; Brace, J.; Mishra, D.K. Polyethylene Terephthalate (PET) Bottle-to-Bottle Recycling for the Beverage Industry: A Review. Polymers 2022, 14, 2366. [Google Scholar] [CrossRef]

- Ecomatters. Environmental Life Cycle Assessment. Available online: https://www.ecomatters.nl/services/lca-epd/life-cycle-assessment/environmental-lca-claims/ (accessed on 23 March 2024).

- Eur-lex. Proposal for a Directive of the European Parliament and of the Council Amending Directive 2008/98/EC on Waste COM/2023/420 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52023PC0420&qid=1707729490112 (accessed on 25 March 2024).

- VMI. Tax for Environmental Pollution. Available online: https://www.vmi.lt/evmi/mokestis-uz-aplinkos-tersima1 (accessed on 21 February 2024).

- Lithuanian Ministry of Environment. Classification of Packaging as Recyclable/Non-Recyclable/Taxation of Non-Recyclable Packaging. Available online: https://am.lrv.lt/lt/veiklos-sritys-1/atlieku-politika/atliekos/pakuociu-priskyrimas-perdirbamoms-neperdirbamoms-neperdirbamu-pakuociu-apmokestinimas/pakuociu-priskyrimas-perdirbamoms-neperdirbamoms/ (accessed on 23 March 2024). (In Lithuanian).

- Consilium. Proposal for a Regulation of the European Parlament and of the Council on Packaging and Packaging Waste, Amending Regulation (EU) 2019/1020 and Directive (EU) 2019/904, and Repealing Directive 94/62/EC. Available online: https://data.consilium.europa.eu/doc/document/ST-16946-2023-INIT/en/pdf (accessed on 22 January 2024).

- Environment.ec. EU Restrictions on Certain Single-Use Plastics. Available online: https://environment.ec.europa.eu/topics/plastics/single-use-plastics/eu-restrictions-certain-single-use-plastics_en#:~:text=From%203%20July%202021%2C%20single,made%20of%20oxo%2Ddegradable%20plastic (accessed on 23 March 2024).

- Cruz, N.F.; Simões, P.; Marques, R.C. Economic cost recovery in the recycling of packaging waste: The case of Portugal. J. Clean. Prod. 2012, 37, 8–18. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, X.; Sun, Q. The influence of economic incentives on residents’ intention to participate in online recycling: An experimental study from China. Resour. Conserv. Recycl. 2021, 169, 105497. [Google Scholar] [CrossRef]

- European Commission. InvestEU: EIF Invests €50 Million to Support Circular Plastics. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_4309 (accessed on 23 March 2024).

- Oloyede, O.O.; Lignou, S. Sustainable Paper-Based Packaging: A Consumer’s Perspective. Foods 2021, 10, 1035. [Google Scholar] [CrossRef] [PubMed]

- Jäger, J.K.; Piscicelli, L. Collaborations for circular food packaging: The set-up and partner selection process. Sustain. Prod. Consum. 2021, 26, 733–740. [Google Scholar] [CrossRef]

- Xueqing, M.; Lise, M.; Ruth, M. Switching to reuse? An exploration of consumers’ perceptions and behavior towards reusable packaging systems. Resour. Conserv. Recycl. 2023, 193, 106972. [Google Scholar] [CrossRef]

- Open Ideo. NextGen Challenge Top Ideas. Available online: https://www.openideo.com/content/nextgen-challenge-top-ideas (accessed on 23 March 2024).

- Vibrantz. Promoting Recyclability with Near-Infrared Pigments. Available online: https://vibrantz.com/vibrantz-edge/promoting-recyclability-with-near-infrared-pigments/ (accessed on 23 March 2024).

- Hakola, L.; Hakola, E.; Palola, S.; Tenhunen-Lunkka, A.; Lahtinen, J. Durable and sustainable smart tags for identity management and condition monitoring: Case study for reusable packaging and recyclable data carriers. Packag. Technol. Sci. 2024, 37, 107–121. [Google Scholar] [CrossRef]

- Kroell, N.; Chen, X.; Greiff, K.; Feil, A. Optical sensors and machine learning algorithms in sensor-based material flow characterization for mechanical recycling processes: A systematic literature review. Waste Manag. 2022, 149, 259–290. [Google Scholar] [CrossRef]

- Recyclass. Available online: https://recyclass.eu/ (accessed on 23 March 2024).

- Paper. About Papercycle. Available online: https://paper.org.uk/Papercycle/Papercycle/About-Papercycle.aspx?hkey=0f50bb9f-4de7-4fe1-a3ce-dbd336d3d56c (accessed on 23 March 2024).

- Circular Economy. Chemical Recycling in Circular Perspective. Available online: https://circulareconomy.europa.eu/platform/sites/default/files/2023-08/Chemical%20Recycling%20in%20Circular%20Perspective.pdf (accessed on 23 March 2024).

- Kim, S.Y.; Kang, D.H.; Charoensri, K.; Ryu, J.R.; Shin, Y.J.; Park, H.J. Comparative Life Cycle Assessment of Reusable and Disposable Distribution Packaging for Fresh Food. Sustainability 2023, 15, 16448. [Google Scholar] [CrossRef]

- Beckline, M.; Sun, Y.; Eric, Z.; Samuel, M. Paper Consumption and Environmental Impact in an Emerging Economy. J. Energy Environ. Chem. Eng. 2016, 1, 13–18. [Google Scholar] [CrossRef]

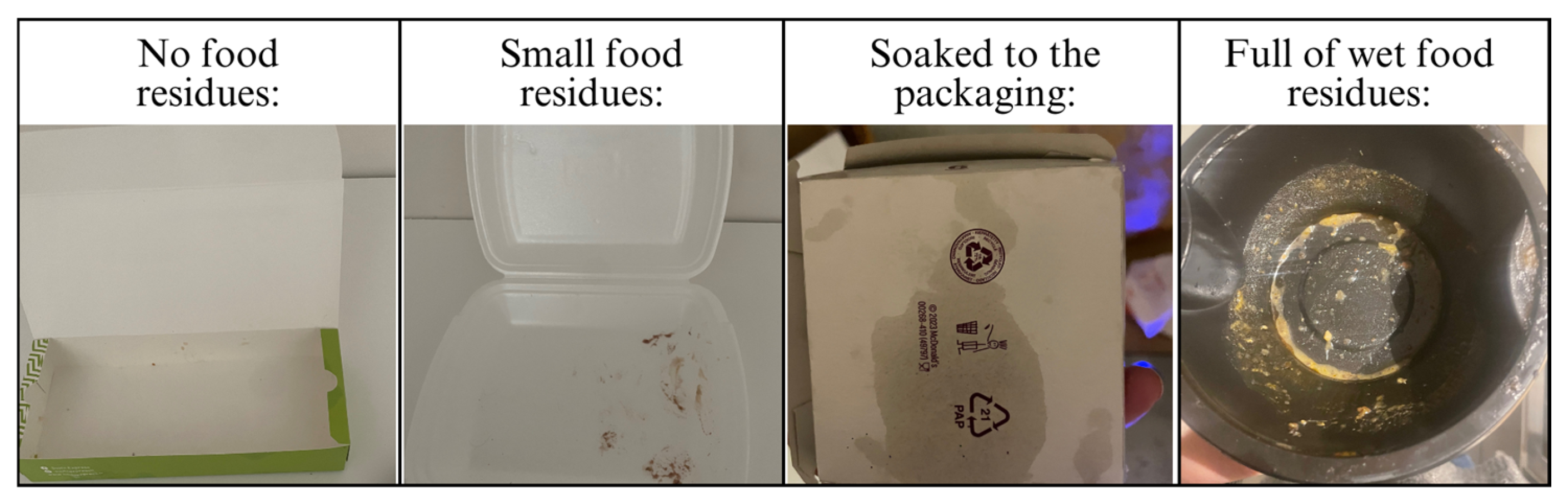

| Food Residues | Features |

|---|---|

| No food residues | Packaging remains clean and unaffected by food or beverage. |

| Small food residues | Some food residues that can be easily removed without affecting packaging material. |

| Soaked into the packaging | Packaging material affected by food residues in the form of grease and cannot be removed from the packaging. |

| Full of wet food residues | Packaging covered by food residues in the form of grease or liquids, can be washed out by rinsing. |

| Category | Meal, Drink | Packaging Properties | Meals Prescribed to Certain Category |

|---|---|---|---|

| CF | Cold food | Barrier from dirt, physical barrier | Sushi, sandwich, salads, ice cream. |

| HF | Hot food | Maintenance of temperature, moisture prevention | Pizza, burgers, kebabs, fish, pasta, steaks, chicken wings, woks, zeppelins, chicken fillets, tortillas, dumplings |

| CD | Cold drinks | Barrier from liquids, leakage insulation | Blended cocktails, fresh drinks |

| HD | Hot drinks | Barrier from liquids, temperature and leakage insulation | Coffee |

| S | Soups | Barrier from liquids, maintenance of temperature, leakage insulation | Soup, ramen, stew |

| G | Groceries | Barrier from dirt and other contamination sources, physical and grease barriers | Chebureki, kibin, doughnuts, waffles, pancakes |

| Subcategory | Food Properties | Specific Characteristics | Packaging Properties | Meals and Beverages Prescribed to Certain Subcategory |

|---|---|---|---|---|

| 1 | Greasy | Has a certain level of fat | Barrier for grease | Pizza, burgers, kebabs, fish, pasta, steaks, chicken wings, woks, zeppelins, chicken fillets, tortillas, dumplings, ice cream, ramen, soup, stew, chebureki, doughnuts, waffles, pancakes |

| 2 | Wet | Usually used with sauce or wet salads | Barrier for liquids, humidity | Salad, pasta, steak, wok, zeppelin, dumpling |

| 3 | Humid (semi-wet) | No sauce used, but the meal itself has humidity | Barrier for humidity | Sushi, burger, kebab, fish, chicken wing |

| 4 | Dry | Has no humidity | Physical barrier | Sandwiches, chebureki, kibins, doughnuts, waffles, pancakes, pizza, tortillas |

| 5 | Liquid | Liquid texture | Barrier for liquids | Ice cream, blended cocktails, fresh drinks, coffee, soup, stew, ramen |

| Packaging Materials for Food Categories | Paper | Composite | Plastic | Plastic Parts (Only Lids, Sauce Containers, Films) | Primary Plastic Packaging (without Lids, Sauce Containers, Films) |

|---|---|---|---|---|---|

| (The share of each material within a food category) | (The share from the whole plastic) | ||||

| CF (cold food) | 33% | 17% | 50% | ||

| HF (hot food) | 67% | 7% | 27% | ||

| S (soup) | 20% | - | 80% | ||

| G (groceries) | 88% | - | 12% | ||

| Share of materials within all categories | 44% | 8% | 48% | 54% | 46% |

| Average weight of primary packaging materials per meal | 19 g | 12 g | 13 g | 6 g | 16 g |

| Packaging Material | Paper | Plastic | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Labelling | C/PAP81 | PAP20 | PAP21 | PAP22 | Not Labelled, Insufficient | PP, 5 | PS, 6 | PET, 1 | Not Labelled |

| 100% | 100% | ||||||||

| Distribution, % | 5% | 7% | 16% | 11% | 61% | 29% | 17% | 21% | 33% |

| Average weight per item, g | 16 g | 81 g | 14 g | 7 g | 22 g | 17 g | 15 g | 13 g | 12 g |

| Category | Material | Labelling | Distribution | Average Weight per Item | |

|---|---|---|---|---|---|

| CD (cold drinks) | Paper-based | C/PAP81 | 44% | 100% | 9.2 g |

| Plastic | PET | 43% | 13.2 g | ||

| PP | 13% | 21 g | |||

| HD (hot drinks) | Paper-based | C/PAP81 | 31% | 100% | 13.3 g |

| PAP21 | 13% | ||||

| Not or insufficiently labelled | 56% | ||||

| Category | Material | Labelling | Distribution | Average Weight | |

|---|---|---|---|---|---|

| CD (cold drinks) | Plastic | PET | 50% | 100% | 4 g |

| PS | 25% | 3.5 g | |||

| Not labelled | 25% | 1.5 g | |||

| HD (hot drinks) | Paper | Paper-based | 31% | 100% | 4.4 g |

| Plastic | PS | 56% | 3.8 g | ||

| Biobased | C/PLA | 12% | 3.5 g | ||

| Recyclable | Not Recyclable | Recyclable or Non-Recyclable (Depending on Situation) | |

|---|---|---|---|

| Totally | 100% | ||

| Share of all take-away packaging materials | 43% | 43% | 14% |

| Paper | 59% | 41% | - |

| Plastic | 40% | 30% | 30% |

| Composite | - | 100% | - |

| Packaging Material for Take-Away Food and Beverage | Recycling Technology | Limitations for Recycling | Strategies for Better Materials Recycling |

|---|---|---|---|

| PP black | Chemical recycling (pyrolysis, gasification), mechanical recycling | Black colour is not recognizable by sorting optics | Manual sorting, change colour, plastic pigmentation, improvement in optics |

| PP transparent container | Labelling is hardly visible | Improve visibility of labelling | |

| PS foam containers | Thermal extrusion recycling | Dirt level, lots of space for transportation, low material output | Change packaging material, compressors |

| PS black plastic lid | Mechanical, chemical recycling | Small size may be lost in sorting drum, black colour is not recognizable by sorting optics | Change colour or add pigments, improve sorting optics, separate collection |

| PET containers, cups | Mechanical, chemical, biological recycling | Labelling is hardly visible | Improve visibility of labelling |

| PET sauce containers, lids | Small size of lids may be lost in sorting drum | Attach the lids to the packaging if material is the same | |

| Composite plastic (sealable films) | Incineration, chemical recycling (pyrolysis) | Small size, can be lost during collection and sorting operations, cannot be recycled using mechanical recycling | Change material from composite to monomaterial, chemical recycling |

| C/PLA black lid | Industrial composting | Small size, can be lost during collection and sorting operations, no collection, industrial composting infrastructure, black colour is not recognizable by sorting optics | Create infrastructure for industrial composting, change to paper or plastic material, change colour |

| PLA black lid | Industrial composting | ||

| C/PAP81 PAP20 PAP21 PAP22 | Chemical, mechanical pulping | Barrier coating, high level of food residues, impregnated grease | Alternative coating, recycling innovations, proper packaging–product combination to improve recyclability |

| SWOT/PESTEL | Strengths | Weakness | Opportunities | Threats |

|---|---|---|---|---|

| Political | P1 Paying differentiated taxes for recyclable and non-recyclable packaging | P2 Choosing packaging for recycling or reuse, providing clear labelling is still partial as incentives to do so are still weak | P3 Further involvement of politicians and decision makers | P4 Change in requirements in unexpected direction |

| Economic | E1 Packaging costs fully covered by consumers. The dominant materials have economic value when recovered | E2 Unclear correlation of packaging fee charged to consumers and environmental implications Waste treatment cost for non-recyclable packaging | E3 Increasing market for take-away food and packaging Implementation of deposit-return systems. Consumer agreement to pay for sustainable solutions | E4 Investments in recyclability do not pay off |

| Social | S1 Good product preservation. Growing environmental awareness | S2 Insufficient information regarding packaging materials and packaging waste sorting | S3 Consumer awareness to pay more for sustainable packaging: more alternative packaging business models appear | S4 Collaboration across the value chain is challenging, consumers may refuse to put effort into proper sorting and reuse |

| Technological | T1 Recycling technologies for the most popular packaging materials are available Online platforms ordering system are well designed, easy to use | T2 Technology backlashes to sort out and recycle all types of packaging materials | T3 Innovative materials, technologies (RFID, NFC, etc.), for collection, sorting, and recycling | T4 Technological innovations have no acceptance from businesses and consumers |

| Environmental | EN1 Recyclable secondary packaging, food well preserved | EN2 Resource loss, lots of waste in a short time | EN3 Choice of materials and packaging design for recycling | EN4 Packaging for recycling can have adverse effect on food that will lead to higher environmental impact. Alternative materials and recycling methods might have unexpected negative environmental impacts |

| Legal | L1 Single-Use Plastic Directive (SUPD) | L2 Biodegradable plastics are not differentiated in labelling and accounting | L3 Upcoming Regulation on Packaging and Packaging Waste | L4 Potential gaps in applying PPWR provisions, accounting for challenges—VAT for deposit |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daugėlaitė, V.; Kruopienė, J. Barriers of and Possibilities for Recycling of Single-Use Take-Away Food and Beverage Packaging: Evidence from Lithuanian Market. Sustainability 2024, 16, 5732. https://doi.org/10.3390/su16135732

Daugėlaitė V, Kruopienė J. Barriers of and Possibilities for Recycling of Single-Use Take-Away Food and Beverage Packaging: Evidence from Lithuanian Market. Sustainability. 2024; 16(13):5732. https://doi.org/10.3390/su16135732

Chicago/Turabian StyleDaugėlaitė, Valdonė, and Jolita Kruopienė. 2024. "Barriers of and Possibilities for Recycling of Single-Use Take-Away Food and Beverage Packaging: Evidence from Lithuanian Market" Sustainability 16, no. 13: 5732. https://doi.org/10.3390/su16135732