Modification of Coconut Fibers through Impregnation with Eco-Friendly Wood Based Isolate as a Method to Increase the Sustainability of Dessert Raspberries Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrates Variants

- ▪

- W0—substrate consisting only of coconut fibers (control).

- ▪

- W1—substrate consisting of coconut fibers impregnated with activated for polymerization isolate (100%). The substrate was prepared according to the procedure described in Section 2.2.

- ▪

- W2—substrate consisting of coconut fibers impregnated with activated for polymerization isolate (90% by weight) with an admixture of pelleted biochar from sunflower husks (10% by weight). The substrate was prepared in a ribbon mixer using 9 kg of W1 substrate and 1 kg of pelleted biochar prepared according to the procedure described in Section 2.3. The mixing process was continued until the biochar pellets were evenly distributed in the mass of the impregnated coconut fibers.

2.2. The Process of Producing Substrates and Their Impregnation

2.3. Production of a Pelleted Biochar

2.4. Analysis of Selected Physical Properties of the Obtained Substrates

2.4.1. Specific Density

2.4.2. Bulk Density

2.4.3. General Porosity

2.4.4. Susceptibility to Compaction

2.4.5. Water Properties of the Obtained Substrates

2.5. Production Experiment

2.6. Assessment of Selected Physiological Properties of Raspberry Plants Grown on the Developed Substrates

2.7. The Degree of Substrate Degradation during Plant Production

2.7.1. Substrate Shrinkage

2.7.2. Root Mass Fraction

2.8. Fruit Yield Siz

2.9. Statistical Analysis of the Results

3. Results and Discussion

3.1. Physical Properties of the Obtained Substrates

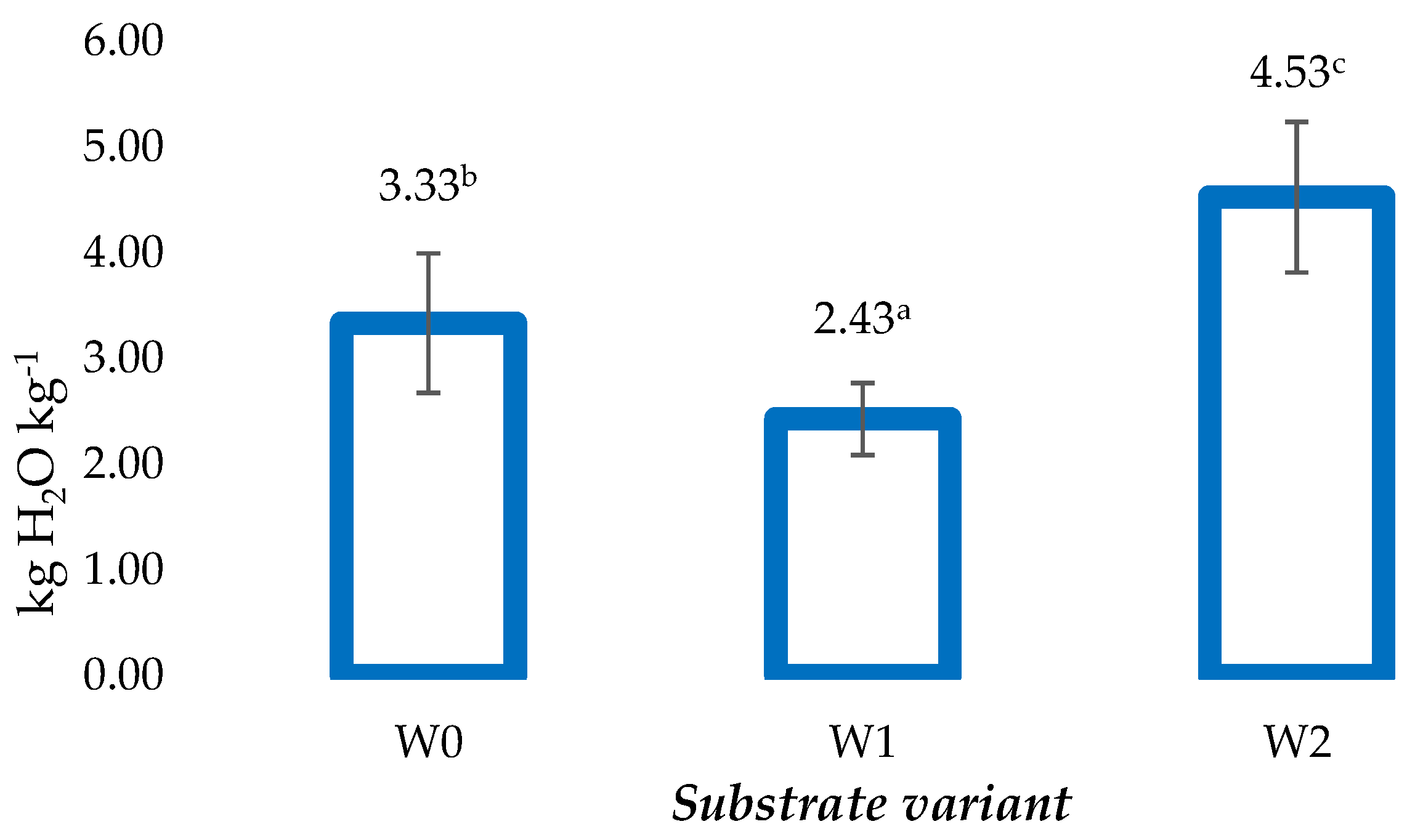

3.2. The Retention of Water Ability of the Obtained Substrates

3.3. Evaluating the Suitability of the Produced Substrates for Plant Production: A Case Study of Raspberries

3.3.1. Chlorophyll Content in Raspberry Leaves and Selected Chlorophyll Fluorescence Parameters

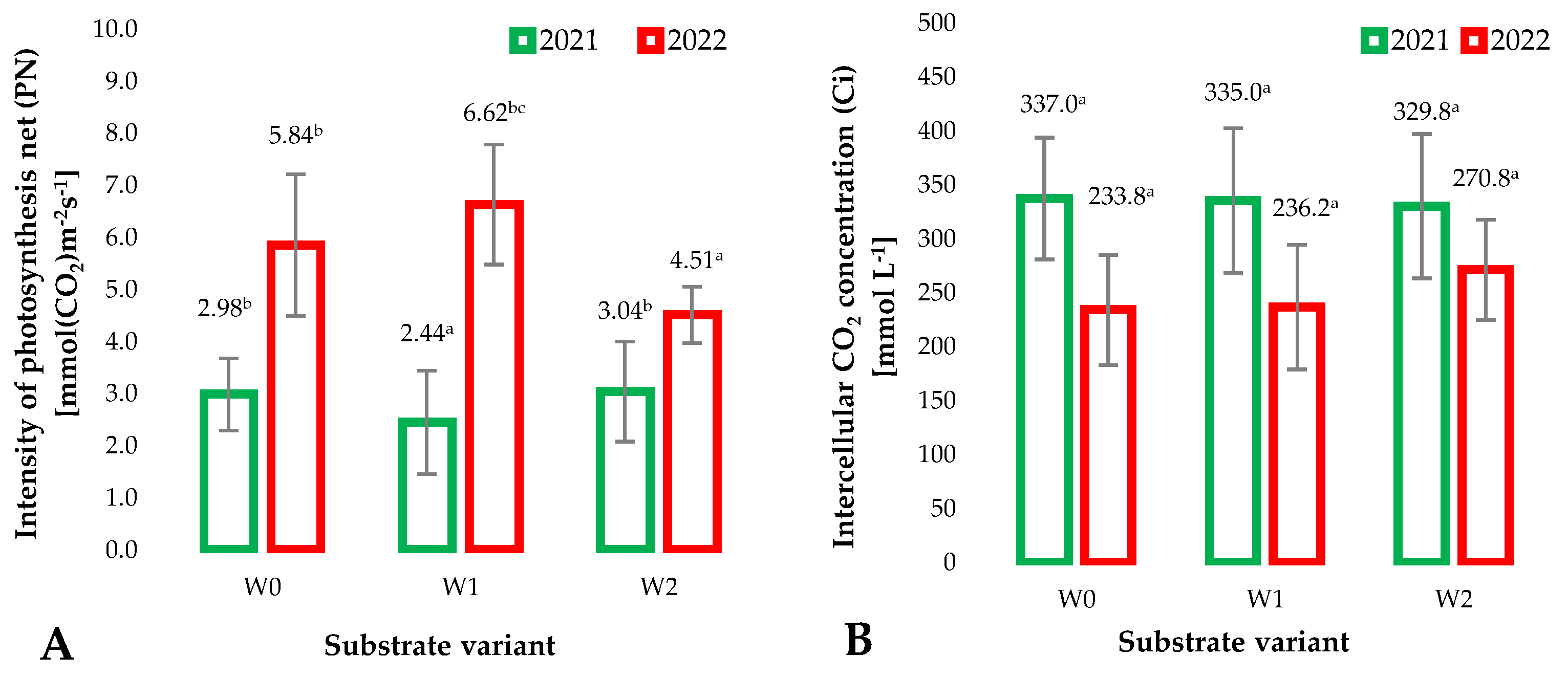

3.3.2. Parameters of Plant Gas Exchange and Photosynthesis Intensity

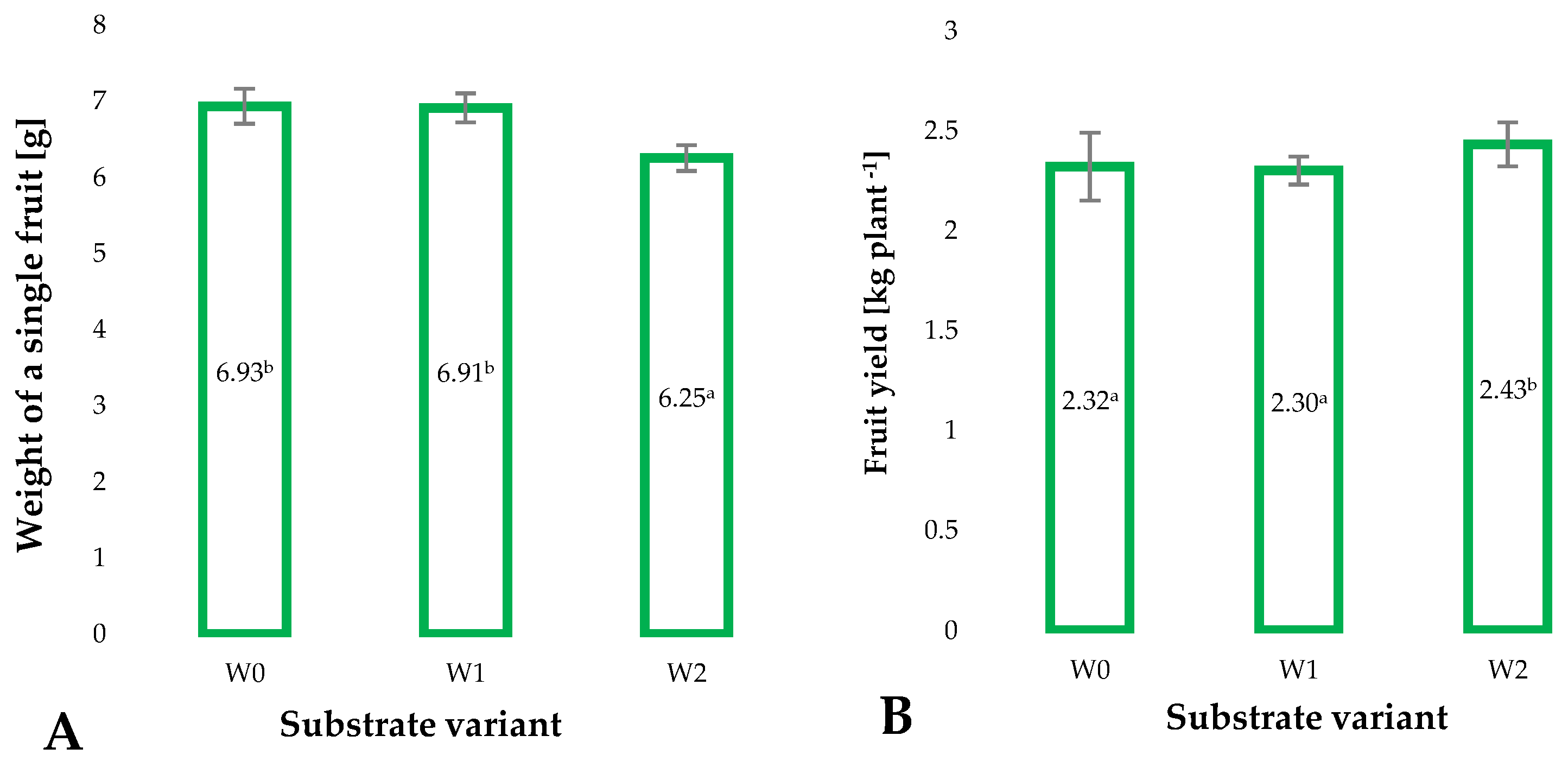

3.4. Productivity of Raspberry Plants Grown on Developed Substrates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Treder, J.; Nowak, J. Cocopeat as growing medium in bedding plant production. Zesz. Probl. Postep. Nauk. Rol. 2002, 485, 351–358. (In Polish) [Google Scholar]

- Sawicka, B.; Barbaś, P.; Skiba, D.; Krochmal-Marczak, B.; Pszczółkowski, P. Evaluation of the Quality of Raspberries (Rubus idaeus L.) Grown in Balanced Fertilization Conditions. Commodities 2023, 2, 220–245. [Google Scholar] [CrossRef]

- Qiu, C.P.; Xu, Q.H.; Gaudreau, L.; Gosselin, A.; Gauthier, L.; Van Sterthem, A.; Desjardins, Y. Yield improvement of red raspberry by soilless cultivation with two propagation methods under northern Canadian climate. Acta Hortic. 2016, 1133, 195–200. [Google Scholar] [CrossRef]

- Verdonk, O. Reviewing, and evaluation of new materials used as substrates. Acta Hortic. 1984, 150, 467–473. [Google Scholar] [CrossRef]

- Mariotti, B.; Martini, S.; Raddi, S.; Tani, A.; Jacobs, D.F.; Oliet, J.A.; Maltoni, A. Coconut Coir as a Sustainable Nursery Growing Media for Seedling Production of the Ecologically Diverse Quercus Species. Forests 2020, 11, 522. [Google Scholar] [CrossRef]

- Nawrocka-Grześkowiak, U. Influence of coir on the rooting of Calluna vulgaris L. cuttings. Zesz. Probl. Postępów Nauk. Rol. 2005, 504, 479–486. (In Polish) [Google Scholar]

- Dyśko, J.; Kaniszewski, S.; Kowalczyk, W.; Dziedziczak, K.; Kowalski, B.; Moraczewski, A.; Podsiedlik, W.; Wojtysiak, J. Ecological fibrous soilless substrates for greenhouse cultivation. Probl. Eksploat. 2012, 2, 37–56. (In Polish) [Google Scholar]

- Balawejder, M.; Matłok, N.; Piechowiak, T.; Szostek, M.; Kapusta, I.; Niemiec, M.; Komorowska, M.; Wróbel, M.; Mudryk, K.; Szeląg-Sikora, A.; et al. The Modification of Substrate in the Soilless Cultivation of Raspberries (Rubus Idaeus L.) as a Factor Stimulating the Biosynthesis of Selected Bioactive Compounds in Fruits. Molecules 2023, 28, 118. [Google Scholar] [CrossRef]

- Mishra, L.; Basu, G. 8—Coconut fibre: Its structure, properties and applications. In Woodhead Publishing Series in Textiles, Handbook of Natural Fibres, 2nd ed.; Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; Woodhead Publishing: Sawston, UK, 2020; pp. 231–255. ISBN 9780128183984. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Odutuga, O.L.; Effiong, J.U.; De Jesus Silvera Sarmiento, A.; Mortazavi, S.J.; Hu, J.W. Development of Fibre-Reinforced Cementitious Mortar with Mineral Wool and Coconut Fibre. Materials 2022, 15, 4520. [Google Scholar] [CrossRef] [PubMed]

- Lisowska, A.; Filipek-Mazur, B.; Komorowska, M.; Niemiec, M.; Bar-Michalczyk, D.; Kuboń, M.; Tabor, S.; Gródek-Szostak, Z.; Szeląg-Sikora, A.; Sikora, J.; et al. Environmental and production aspects of using fertilizers based on waste elemental sulfur and organic materials. Materials 2022, 15, 3387. [Google Scholar] [CrossRef] [PubMed]

- Mog, L. Smartphone-Operated Smart Farm Watering System Using Long-Range Communication Technology. Agric. Eng. 2023, 27, 59–74. [Google Scholar] [CrossRef]

- Opstad, N.; Sønsteby, A.; Espelien, H.G.; Myrheim, U. Fertigation timing and fertilizer composition affects growth and yield in raspberry long cane and field production. Acta Hortic. 2012, 946, 361–366. [Google Scholar] [CrossRef]

- Klimek-Kopyra, A.; Sadowska, U.; Kuboń, M.; Gliniak, M.; Sikora, J. Sunflower husk biochar as a key agrotechnical factor enhancing sustainable soybean production. Agriculture 2021, 11, 305. [Google Scholar] [CrossRef]

- Wyzińska, M.; Berbeć, A.K.; Grabiński, J. Impact of Biochar Dose and Origin on Winter Wheat Grain Quality and Quantity. Agriculture 2023, 14, 39. [Google Scholar] [CrossRef]

- Ghorbani, M.; Konvalina, P.; Neugschwandtner, R.W.; Soja, G.; Bárta, J.; Chen, W.-H.; Amirahmadi, E. How do different feedstocks and pyrolysis conditions effectively change biochar modification scenarios? A critical analysis of engineered biochars under H2O2 oxidation. Energy Convers. Manag. 2024, 300, 117924. [Google Scholar] [CrossRef]

- Altland, J.E.; Locke, J. Biochar affects macronutrient leaching from soilless substrate. HortScience 2012, 47, 1136–1140. [Google Scholar] [CrossRef]

- Graber, E.R.; Meller Harel, Y.; Kolton, M.; Cytryn, E.; Silber, A.; David, D.R.; Tsechansky, L.; Borenshtein, M.; Elad, Y. Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 2010, 337, 481–496. [Google Scholar] [CrossRef]

- Shi, R.; Liu, W.; Lian, Y.; Wang, Q.; Zeb, A.; Tang, J. Phytotoxicity of polystyrene, polyethylene and polypropylene microplastics on tomato (Lycopersicon esculentum L.). J. Environ. Manag. 2022, 317, 115441. [Google Scholar] [CrossRef] [PubMed]

- PN-EN ISO 17828_2016-02E; Solid Biofuels—Determination of Bulk Density. Polish Committee for Standardization: Warszawa, Poland, 2015.

- Matlok, N.; Szostek, M.; Antos, P.; Gajdek, G.; Gorzelany, J.; Bobrecka-Jamro, D.; Balawejder, M. Effect of Foliar and Soil Fertilization with New Products Based on Calcinated Bones on Selected Physiological Parameters of Maize Plants. Appl. Sci. 2020, 10, 2579. [Google Scholar] [CrossRef]

- Xing, X.; Fan, F.; Jiang, W. Characteristic of biochar pellets from corn straw under different pyrolisis temperatures. R. Soc. Open Sci. 2018, 5, 172346. [Google Scholar] [CrossRef]

- Lynch, J.; Marschner, P.; Rengel, Z. Chapter 13—Effect of Internal and External Factors on Root Growth and Development. In Marschner’s Mineral Nutrition of Higher Plants, 3rd ed.; Marschner, P., Ed.; Academic Press: Cambridge, MA, USA, 2012; pp. 331–346. ISBN 9780123849052. [Google Scholar] [CrossRef]

- Moore, J.A.M.; Sulman, B.N.; Mayes, M.; Patterson, C.M.; Classen, A.T. Plant root stimulate the decomposition of complex, but not simple, soil carbon. Funct. Ecol. 2019, 34, 899–910. [Google Scholar] [CrossRef]

- Nowak, J.S. Air-Water properties of growing media. Zesz. Probl. Postępów Nauk. Rolniczych 2005, 504, 175–184. (In Polish) [Google Scholar]

- Badr, A.; Bruggemann, W. Comparative analysis of drought stress response of maize genotypes using chlorophyll fluorescense measurements and leaf relative water content. Photosynthetica 2020, 58, 638–645. [Google Scholar] [CrossRef]

- Gorbe, E.; Calatayud, A. Applications of chlorophyll fluorescence imaging tecchnique in horticultural reaserch: A review. Sci. Horticulare 2012, 138, 24–35. [Google Scholar] [CrossRef]

- Górny, A.G. Photosynthetic activity of flag leaves in diallel crosses of spring har ley under varied nutrition and soil moisture. Cercal Res. Commun. 2001, 29, 159–166. [Google Scholar] [CrossRef]

- Kalaji, H.M.; Cetner, M.D.; Dąbrowski, P.; Samborska, I.A.; Łukasik, I.; Swoczyna, T.; Pietkiewicz, S.; Bąba, W. Chlorophyll fluorescence measurements in environmental studies. Kosmos 2016, 65, 197–205. [Google Scholar]

- Baker, N.R.; Oxborough, K. Chlorophyll Fluorescence as a Probe of Photosynthetic Productivity. In Chlorophyll a Fluorescence. Advances in Photosynthesis and Respiration; Papageorgiou, G.C., Govindjee, Eds.; Springer: Dordrecht, The Netherlands, 2004; pp. 65–82. [Google Scholar]

- Borowski, E.; Nurzyński, J. Effect of different growing substrates on the photosynthesis parameters and fruit yield of greenhouse-grown tomato. Acta Sci. Pol. Hortorum Cultus 2012, 11, 95–105. [Google Scholar]

| Parameter | Substrate Variant | ||

|---|---|---|---|

| W0 | W1 | W2 | |

| Specific density SD [Mg m−3] | 0.25 a ± 0.02 | 0.32 b ± 0.01 | 0.39 bc ± 0.03 |

| Bulk density BD [Mg m−3] | 0.12 a ± 0.01 | 0.14 b ± 0.02 | 0.16 c ± 0.05 |

| General porosity (%) | 52.12 a | 56.24 ab | 59.15 b |

| Susceptibility to compaction Y [%] | 65.17 a | 64.22 a | 64.14 a |

| Parameter | Substrate Variant | ||

|---|---|---|---|

| W0 | W1 | W2 | |

| Share of the root mass in the mass of the substrate (%) | 39.33 c | 30.78 b | 25.47 a |

| Substrate shrinkage (%) | 8.44 c | 3.56 a | 4.44 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuboń, M.; Matłok, N.; Szostek, M.; Wróbel, M.; Mudryk, K.; Sikora, J.; Marczuk, A.; Saletnik, B.; Balawejder, M. Modification of Coconut Fibers through Impregnation with Eco-Friendly Wood Based Isolate as a Method to Increase the Sustainability of Dessert Raspberries Production. Sustainability 2024, 16, 5878. https://doi.org/10.3390/su16145878

Kuboń M, Matłok N, Szostek M, Wróbel M, Mudryk K, Sikora J, Marczuk A, Saletnik B, Balawejder M. Modification of Coconut Fibers through Impregnation with Eco-Friendly Wood Based Isolate as a Method to Increase the Sustainability of Dessert Raspberries Production. Sustainability. 2024; 16(14):5878. https://doi.org/10.3390/su16145878

Chicago/Turabian StyleKuboń, Maciej, Natalia Matłok, Małgorzata Szostek, Marek Wróbel, Krzysztof Mudryk, Jakub Sikora, Andrzej Marczuk, Bogdan Saletnik, and Maciej Balawejder. 2024. "Modification of Coconut Fibers through Impregnation with Eco-Friendly Wood Based Isolate as a Method to Increase the Sustainability of Dessert Raspberries Production" Sustainability 16, no. 14: 5878. https://doi.org/10.3390/su16145878

APA StyleKuboń, M., Matłok, N., Szostek, M., Wróbel, M., Mudryk, K., Sikora, J., Marczuk, A., Saletnik, B., & Balawejder, M. (2024). Modification of Coconut Fibers through Impregnation with Eco-Friendly Wood Based Isolate as a Method to Increase the Sustainability of Dessert Raspberries Production. Sustainability, 16(14), 5878. https://doi.org/10.3390/su16145878