Numerical Analysis on Heat Collecting Performance of Novel Corrugated Flat Plate Solar Collector Using Nanofluids

Abstract

:1. Introduction

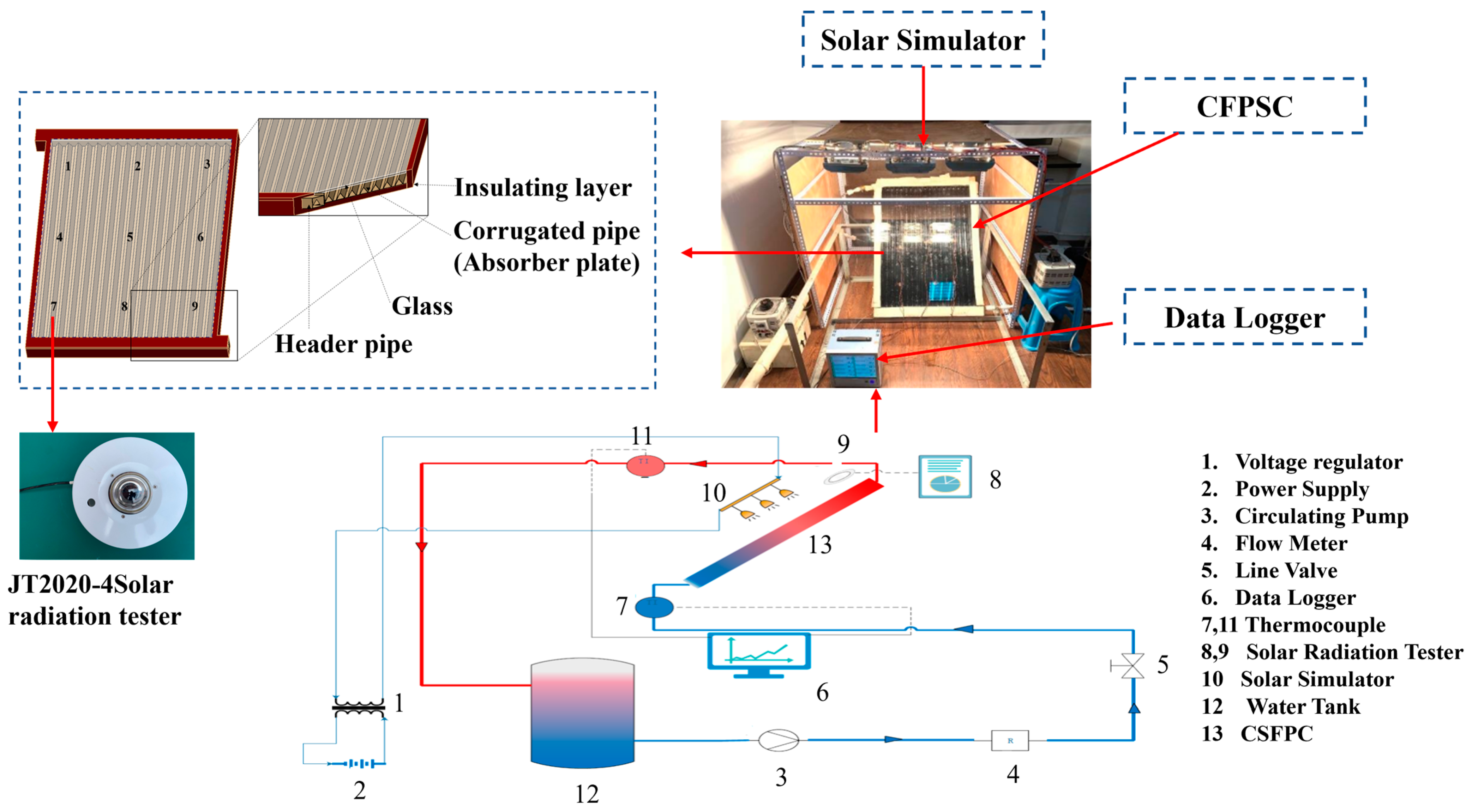

2. Description of Experiment Test Bench

3. Numerical Analysis Model of CFPSC Using Nanofluid

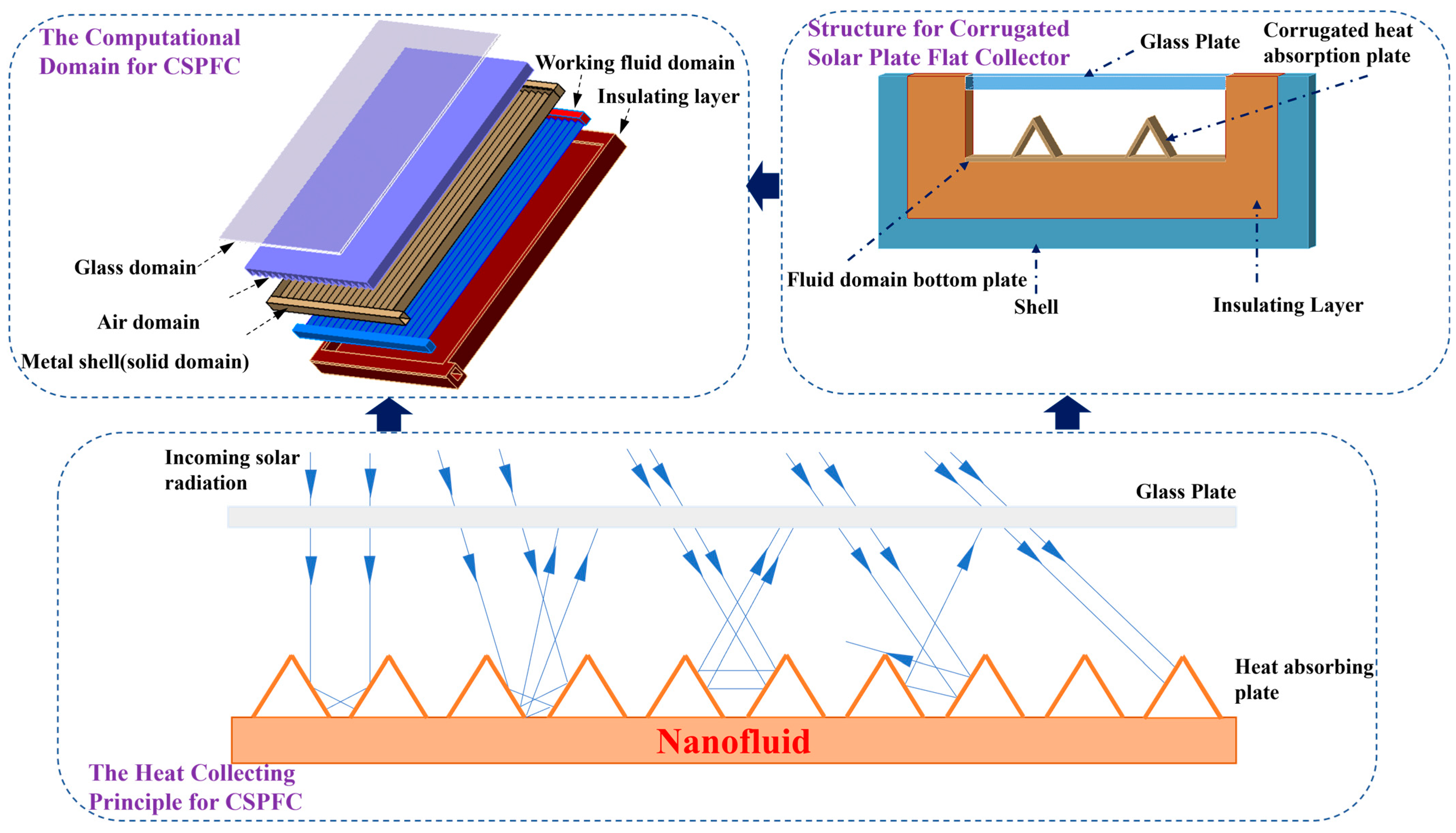

3.1. Computational Domain

3.2. Theoretical Governing Equations and Boundary Conditions

3.3. Physical Properties of Nanofluids

3.4. Grid Independence Verification

3.5. Verification and Analysis

4. Results and Analysis

4.1. Effect of X-Water Nanofluids on Heat Collection Performance

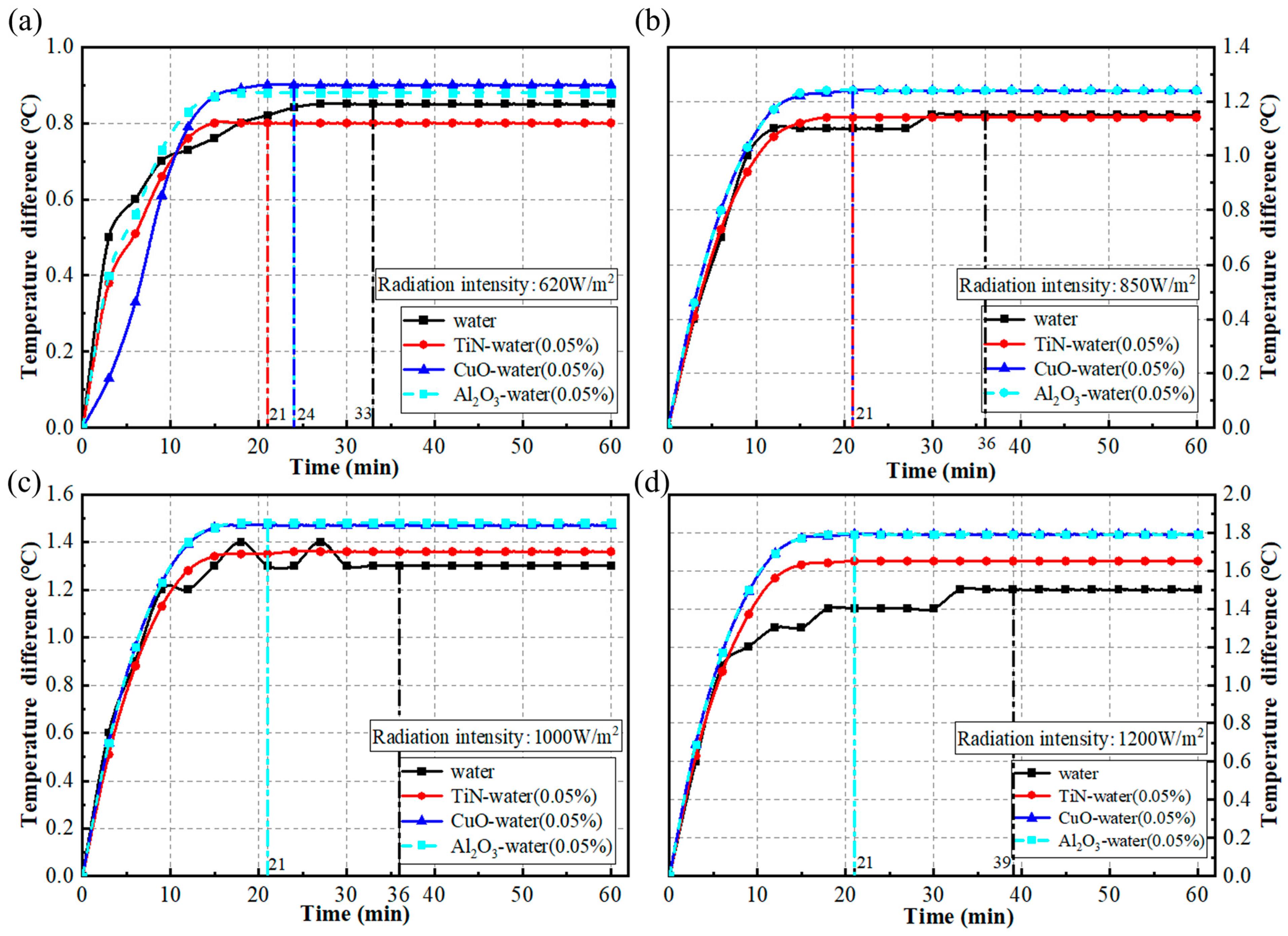

4.1.1. Effect of X-Water Nanofluids on the Stabilization Time of Heat Collection

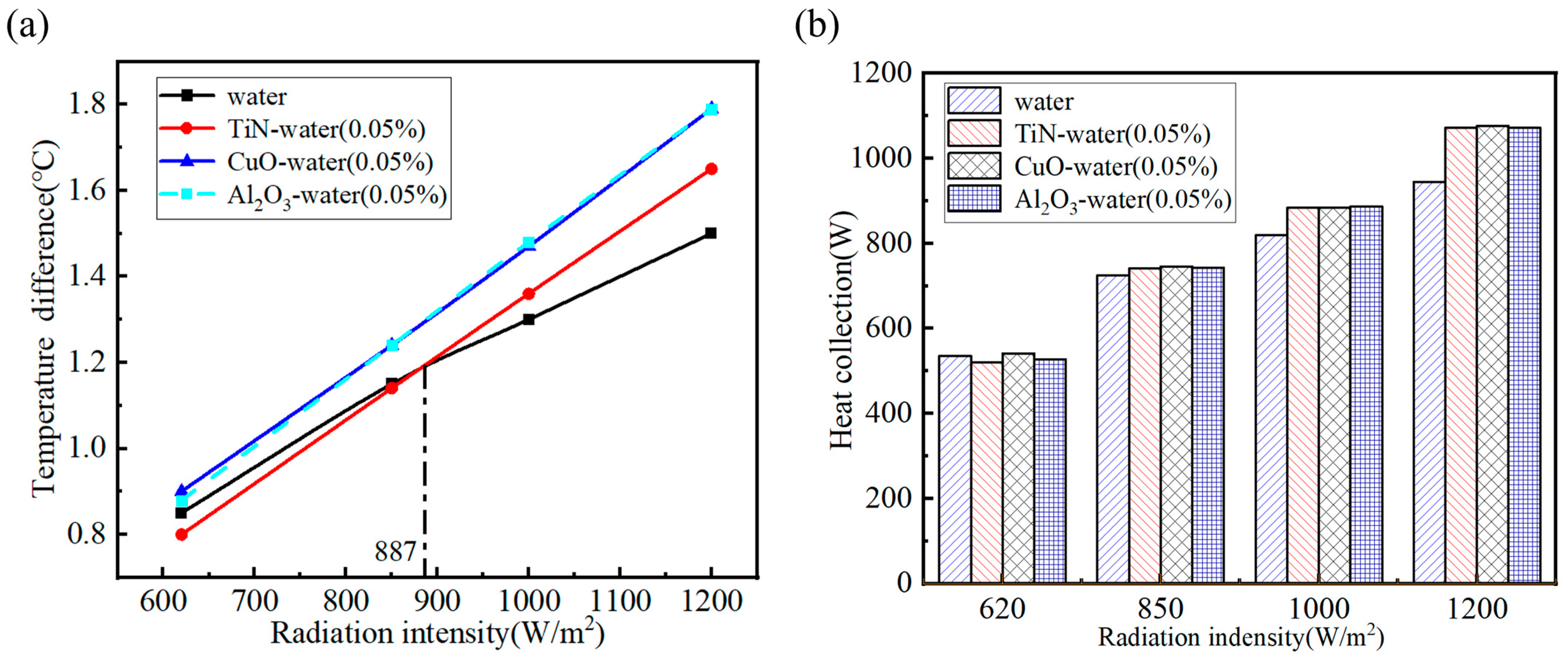

4.1.2. Effect of X-Water Nanofluids on Temperature Difference and Heat Collection

4.1.3. Effect of X-Water Nanofluids on Heat Collection Efficiency

4.2. Effect of CuO-X Nanofluids on Heat Collection Performance

4.2.1. Effect of CuO-X Nanofluids on the Stabilization Time of Heat Collection

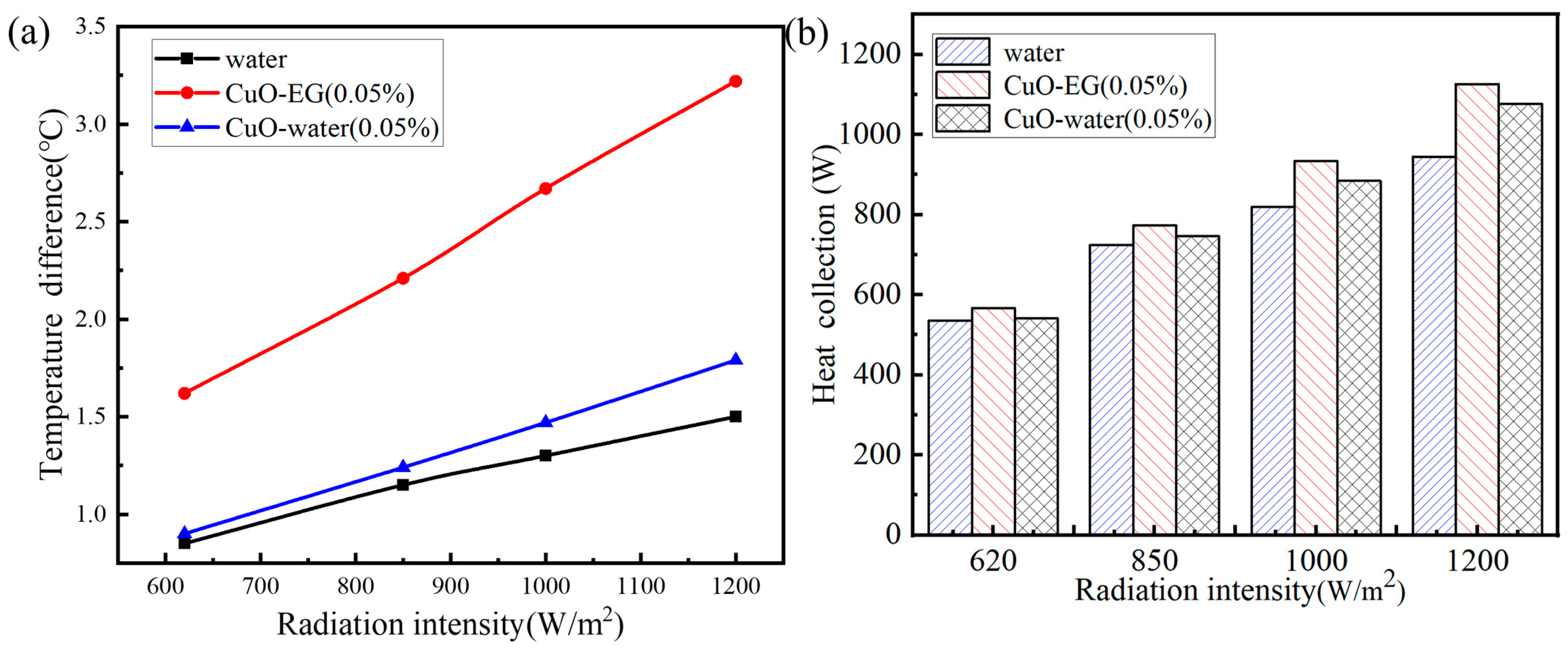

4.2.2. Effect of CuO-X Nanofluids on the Temperature Difference and Heat Collection

4.2.3. Effect of CuO-X Nanofluids on Heat Collection Efficiency

4.3. Effect of X-EG Nanofluids on Heat Collection Performance

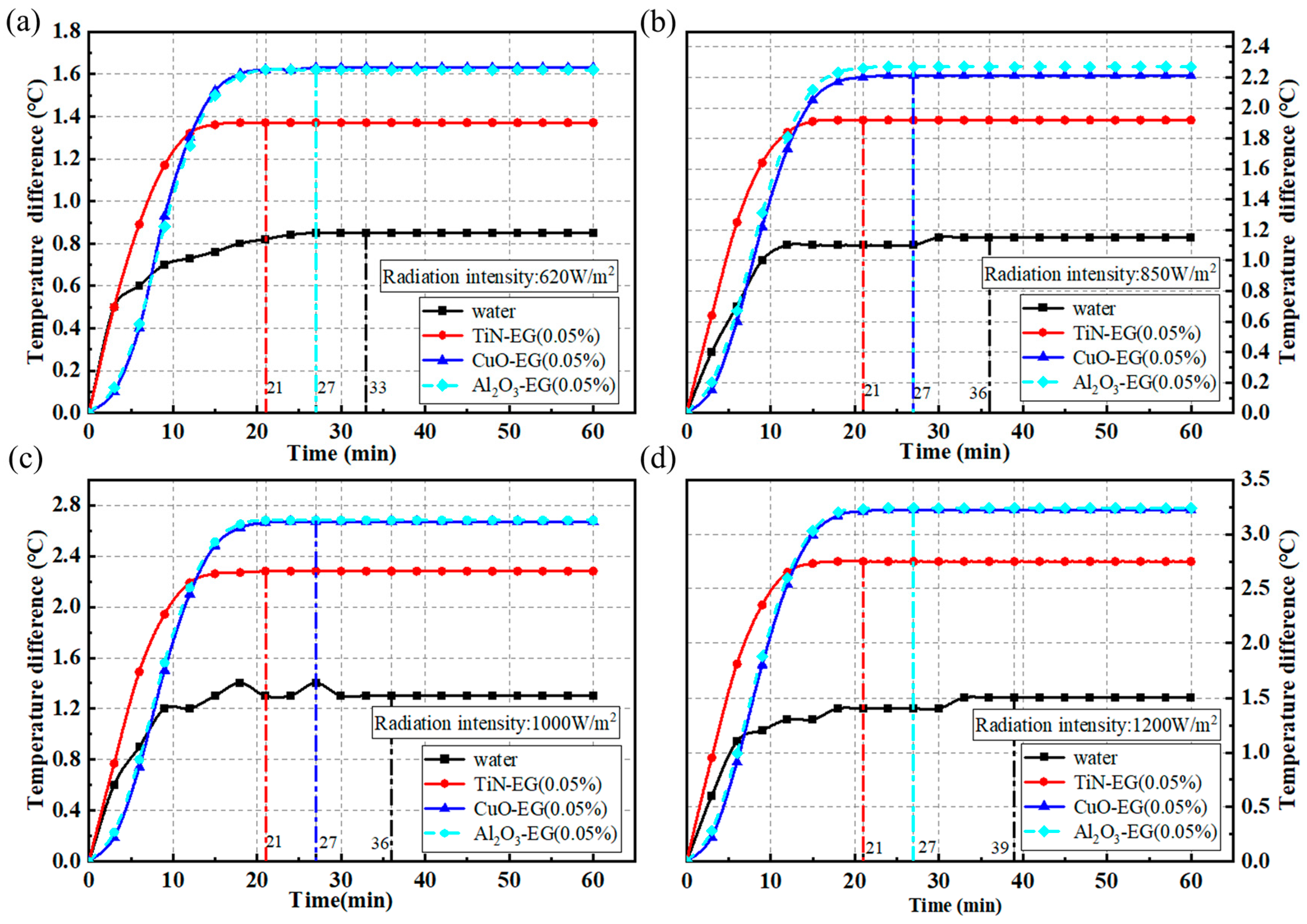

4.3.1. Effect of X-EG Nanofluids on the Stabilization Time of Heat Collection

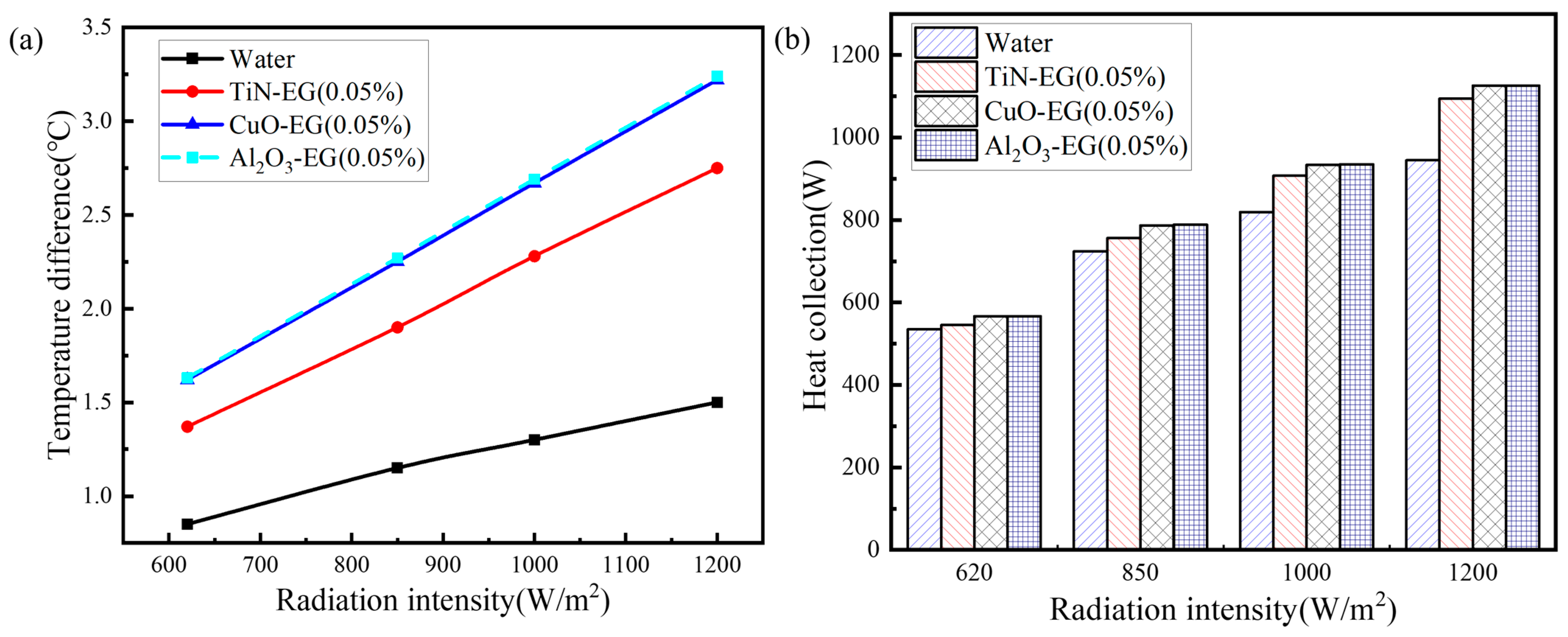

4.3.2. Effect of X-EG Nanofluids on Temperature Difference and Heat Collection

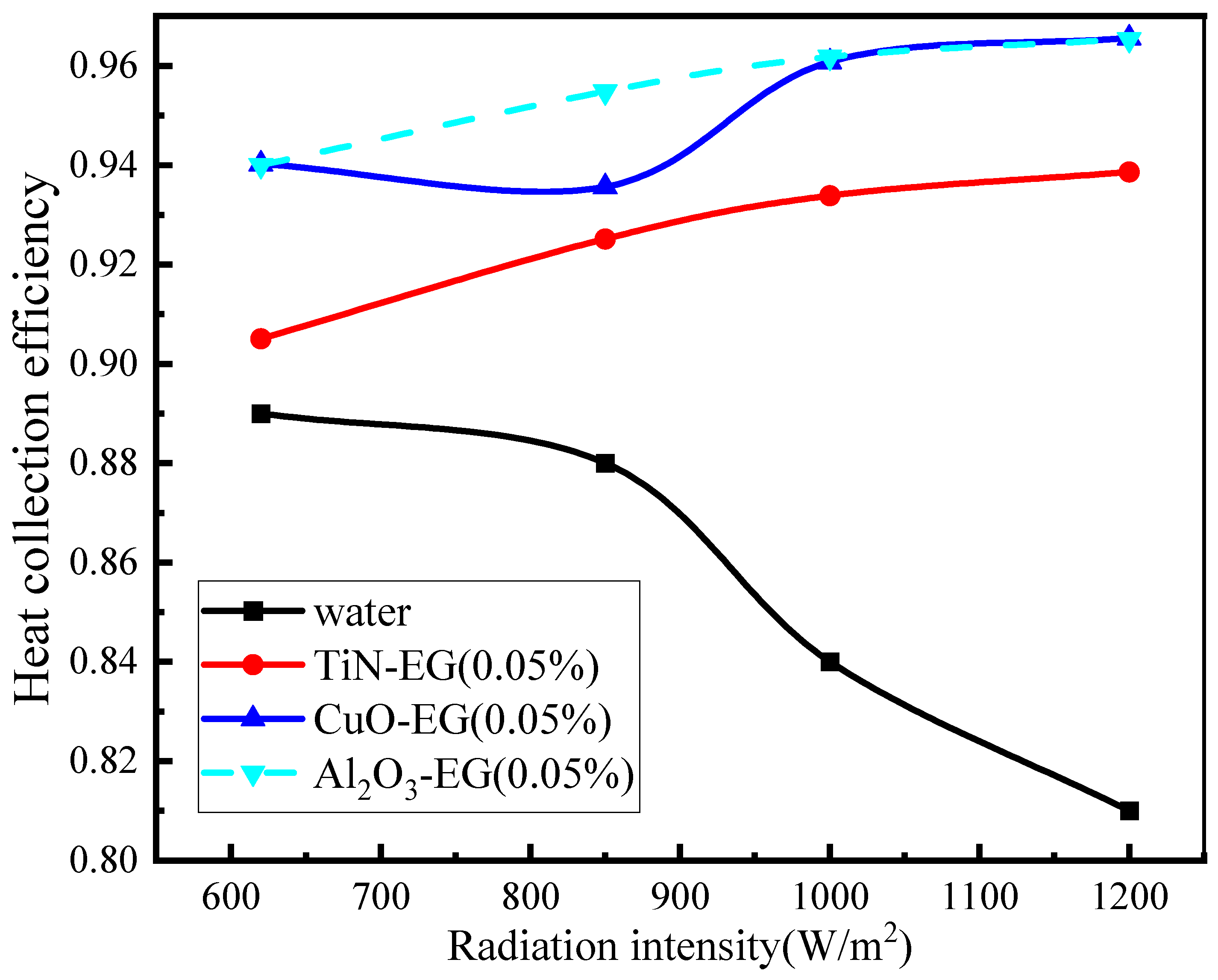

4.3.3. Effect of X-EG Nanofluids on Heat Collection Efficiency

4.4. Effect of Nanofluids of Different Volume Fractions on Heat Collection Performance

4.4.1. Effect of Nanofluids of Different Volume Fractions on the Stabilization Time of Heat Collection

4.4.2. Effect of Different Volume Fractions of Nanofluids on Temperature Difference and Heat Collection Amount

4.4.3. Effect of Nanofluids of Different Volume Fractions on Heat Collection Efficiency

5. Conclusions

- (1)

- The heat stabilization time of nanofluid was less than that of water. The heat stabilization time of TiN-X nanofluid was 18~24 min. Both CuO-X nanofluids and Al2O3-X nanofluids had the same heat stabilization time, which was 24 min, and the variation of volume fraction had no obvious effect on the heat collection stabilization time of CuO-X nanofluids and Al2O3-X nanofluids.

- (2)

- The heat collection performance of nanofluids whose base fluid is EG was higher than that of nanofluids whose base fluid is water. On the one hand, when the base fluid was water, the temperature differences of CuO-water nanofluids under different radiation intensities were 1.1%, 3%, 8%, and 13.9% higher than that of water; when the base fluid was EG, the temperature differences of CuO-EG nanofluid under different radiation intensities were 5.8%, 6.7%, 14%, and 19.2% higher than that of water.

- (3)

- The heat collection performance of CuO-water (EG) nanofluids and Al2O3-water (EG) nanofluids was better than that of TiN-water (EG) nanofluids, but there was no significant difference in temperature difference and heat collection between CuO-water (EG) nanofluids and Al2O3-water (EG) nanofluids. When the basefluid was EG, the heat collections of CuO-EG nanofluid were only 3.8%, 4%, 2.9%, and 2.9% higher than that of TiN-EG nanofluid at different radiation intensities. The maximum heat efficiency of CuO-EG nanofluids and Al2O3-EG nanofluids was 96.5%, while the maximum heat efficiency of Tin-EG nanofluids was lower, at 93.8%.

- (4)

- The temperature difference of TiN-EG nanofluids decreased with the increase in the volume fraction of nanoparticles. However, the variation of volume fraction had no significant effect on the temperature difference and heat collection amount of CuO-EG nanofluids and Al2O3-EG nanofluids. When the volume fraction of TiN-EG nanofluid was 0.075%, the heat collection efficiency was the highest. However, when the volume fraction was 0.05%, the heat collection efficiency was the lowest. The heat collection efficiency of CuO-EG nanofluids increased with the increase in the volume fraction. The heat collection efficiencies of CuO-EG (0.075%) nanofluid under different radiation intensities were 0.94, 0.956, 0.961, and 0.966, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Liu, X.; Xin, J.; Zhang, Y.; Wen, L.; Liang, Q.; Miao, Z. Dual Function of the Third Component in Ternary Organic Solar Cells: Broaden the Spectrum and Optimize the Morphology. Small 2024, 20, e2308863. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Yang, M.; Shi, L.; Hou, Z.; Xu, S.; Sun, C.; Tang, X.; Yang, M.; Shi, L.; Hou, Z.; et al. Adaptive state-of-health temperature sensitivity characteristics for durability improvement of PEM fuel cells. Chem. Eng. J. 2024, 491, 151951. [Google Scholar] [CrossRef]

- Xin, J.; Zhao, C.; Geng, Z.; Xue, W.; Chen, Z.; Song, C.; Yan, H.; Liang, Q.; Miao, Z.; Ma, W.; et al. Elucidate the Thermal Degradation Mechanism of Y6-Based Organic Solar Cells by Establishing Structure-Property Correlation. Adv. Energy Mater. 2024, 2401433. [Google Scholar] [CrossRef]

- Rashid, F.L.; Aljibori, H.S.; Mohammed, H.I.; Ameen, A.; Ahmad, S.; Ben Hamida, M.B.; Al-Rubaye, A.H. Recent advances and developments of the application of hybrid nanofluids in parabolic solar collector energy systems and guidelines for future prospects. J. Eng. Res. 2024, in press. [CrossRef]

- Sharma, H.K.; Kumar, S.; Verma, S.K. Comparative performance analysis of flat plate solar collector having circular &trapezoidal corrugated absorber plate designs. Energy 2022, 253, 124137. [Google Scholar] [CrossRef]

- Gao, M.; Fan, J.; Furbo, S.; Xiang, Y. Energy and exergy analysis of a glazed solar preheating collector wall with non-uniform perforated corrugated plate. Renew. Energy 2022, 196, 1048–1063. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, H.; You, S.; Fan, M.; Wang, Y.; Wu, Z. Dynamic performance modeling and operation strategies for a v-corrugated flat-plate solar collector with movable cover plate. Appl. Therm. Eng. 2021, 197, 117374. [Google Scholar] [CrossRef]

- Tong, Y.; Chi, X.; Kang, W.; Cho, H. Comparative investigation of efficiency sensitivity in a flat plate solar collector according to nanofluids. Appl. Therm. Eng. 2020, 174, 115346. [Google Scholar] [CrossRef]

- Sharma, H.K.; Kumar, S.; Kumar, S.; Verma, S.K. Performance investigation of flat plate solar collector with nanoparticle enhanced integrated thermal energy storage system. J. Energy Storage 2022, 55, 105681. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, C.; Jin, Y.; Ma, S. Heat collection performance analysis of corrugated flat plate collector: An experimental study. Renew. Energy 2022, 181, 1–9. [Google Scholar] [CrossRef]

- Anirudh, K.; Dhinakaran, S. Performance improvement of a flat-plate solar collector by inserting intermittent porous blocks. Renew. Energy 2020, 145, 428–441. [Google Scholar] [CrossRef]

- Gao, M.; Wang, D.; Liu, Y.; Wang, Y.; Zhou, Y. A study on thermal performance of a novel glazed transpired solar collector with perforating corrugated plate. J. Clean. Prod. 2020, 257, 120443. [Google Scholar] [CrossRef]

- Esmaeili, Z.; Akbarzadeh, S.; Rashidi, S.; Valipour, M.S. Effects of hybrid nanofluids and turbulator on efficiency improvement of parabolic trough solar collectors. Eng. Anal. Bound. Elem. 2023, 148, 114–125. [Google Scholar] [CrossRef]

- Geovo, L.; Ri, G.D.; Kumar, R.; Verma, S.K.; Roberts, J.J.; Mendiburu, A.Z. Theoretical model for flat plate solar collectors operating with nanofluids: Case study for Porto Alegre, Brazil. Energy 2023, 263, 125698. [Google Scholar] [CrossRef]

- Alawi, O.A.; Kamar, H.M.; Mallah, A.; Mohammed, H.A.; Kazi, S.; Sidik, N.A.C.; Najafi, G. Nanofluids for flat plate solar collectors: Fundamentals and applications. J. Clean. Prod. 2021, 291, 125725. [Google Scholar] [CrossRef]

- Balakin, B.V.; Struchalin, P.G. Eco-friendly and low-cost nanofluid for direct absorption solar collectors. Mater. Lett. 2023, 330, 133323. [Google Scholar] [CrossRef]

- Aissa, A.; Qasem, N.A.; Mourad, A.; Laidoudi, H.; Younis, O.; Guedri, K.; Alazzam, A. A review of the enhancement of solar thermal collectors using nanofluids and turbulators. Appl. Therm. Eng. 2023, 220, 119663. [Google Scholar] [CrossRef]

- Almanassra, I.W.; Manasrah, A.D.; Al-Mubaiyedh, U.A.; Al-Ansari, T.; Malaibari, Z.O.; Atieh, M.A. An experimental study on stability and thermal conductivity of water/CNTs nanofluids using different surfactants: A comparison study. J. Mol. Liq. 2020, 304, 111025. [Google Scholar] [CrossRef]

- Sahin, A.Z.; Uddin, M.A.; Yilbas, B.S.; Al-Sharafi, A. Performance enhancement of solar energy systems using nanofluids: An updated review. Renew. Energy 2020, 145, 1126–1148. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, S.; Arshad, A.; Hu, Y.; He, Y.; Yan, Y. Thermo-physical properties prediction of carbon-based magnetic nanofluids based on an artificial neural network. Renew. Sustain. Energy Rev. 2021, 149, 111341. [Google Scholar] [CrossRef]

- Ali, B.; Siddique, I.; Ahmadian, A.; Senu, N.; Ali, L.; Haider, A. Significance of Lorentz and Coriolis forces on dynamics of water based silver tiny particles via finite element simulation. Ain Shams Eng. J. 2022, 13, 101572. [Google Scholar] [CrossRef]

- Rehman, S.U.; Fatima, N.; Ali, B.; Imran, M.; Ali, L.; Shah, N.A.; Chung, J.D. The Casson Dusty Nanofluid: Significance of Darcy–Forchheimer Law, Magnetic Field, and Non-Fourier Heat Flux Model Subject to Stretch Surface. Mathematics 2022, 10, 2877. [Google Scholar] [CrossRef]

- Choi, S. Enhancing thermal conductivity of fluids with nanoparticles, developments and applications of non-Newtonian flows. ASME FED 1995, 105, 231. [Google Scholar]

- Dharmakkan, N.; Srinivasan, P.M.; Muthusamy, S.; Jomde, A.; Shamkuwar, S.; Sonawane, C.; Sharma, K.; Alrubaie, A.J.; El Shafay, A.; Panchal, H. A case study on analyzing the performance of microplate heat exchanger using nanofluids at different flow rates and temperatures. Case Stud. Therm. Eng. 2023, 44, 102805. [Google Scholar] [CrossRef]

- Deshmukh, K.; Karmare, S.; Patil, P. Experimental investigation of convective heat transfer performance of TiN nanofluid charged U-pipe evacuated tube solar thermal collector. Appl. Therm. Eng. 2023, 225, 120199. [Google Scholar] [CrossRef]

- Shojaeizadeh, E.; Veysi, F.; Goudarzi, K. Heat transfer and thermal efficiency of a lab-fabricated ferrofluid-based single-ended tube solar collector under the effect of magnetic field: An experimental study. Appl. Therm. Eng. 2020, 164, 114510. [Google Scholar] [CrossRef]

- Akram, N.; Montazer, E.; Kazi, S.; Soudagar, M.E.M.; Ahmed, W.; Zubir, M.N.M.; Afzal, A.; Muhammad, M.R.; Ali, H.M.; Márquez, F.P.G.; et al. Experimental investigations of the performance of a flat-plate solar collector using carbon and metal oxides based nanofluids. Energy 2021, 227, 120452. [Google Scholar] [CrossRef]

- Mirzaei, M.; Hosseini, S.M.S.; Kashkooli, A.M.M. Assessment of Al2O3 nanoparticles for the optimal operation of the flat plate solar collector. Appl. Therm. Eng. 2018, 134, 68–77. [Google Scholar] [CrossRef]

- Ge, Z.; Xiang, Q.; Li, J.; Zhang, S.; Wang, Z.; Xie, J.; Xie, Z.; Yang, F. Thermo-economic analysis of organic Rankine cycle using a new two-stage solar collector with nanofluids. Int. J. Heat Fluid Flow 2024, 107, 109393. [Google Scholar] [CrossRef]

- Struchalin, P.G.; Zhao, Y.; Balakin, B.V. Field study of a direct absorption solar collector with eco-friendly nanofluid. Appl. Therm. Eng. 2024, 243, 122652. [Google Scholar] [CrossRef]

- Alawi, O.A.; Kamar, H.M.; Mallah, A.; Kazi, S.; Sidik, N.A.C. Thermal efficiency of a flat-plate solar collector filled with Pentaethylene Glycol-Treated Graphene Nanoplatelets: An experimental analysis. Sol. Energy 2019, 191, 360–370. [Google Scholar] [CrossRef]

- Sathish, T.; Giri, J.; Saravanan, R.; Ubaidullah, M.; Shangdiar, S.; Iikela, S.; Sithole, T.; Amesho, K.T. Amplifying thermal performance of solar flat plate collector by Al2O3/Cu/MWCNT/SiO2 mono and hybrid nanofluid. Appl. Therm. Eng. 2024, 252, 123692. [Google Scholar] [CrossRef]

- Aytaç, I.; Tuncer, A.D.; Khanlari, A.; Variyenli, H.I.; Mantıcı, S.; Güngör, L.; Ünvar, S. Investigating the effects of using MgO-CuO/water hybrid nanofluid in an evacuated solar water collector: A comprehensive survey. Therm. Sci. Eng. Prog. 2023, 39, 101688. [Google Scholar] [CrossRef]

- Choudhary, S.; Sachdeva, A.; Kumar, P. Investigation of the stability of MgO nanofluid and its effect on the thermal performance of flat plate solar collector. Renew. Energy 2020, 147 Pt 1, 1801–1814. [Google Scholar] [CrossRef]

- Khanafer, K.; Vafai, K. A critical synthesis of thermophysical characteristics of nanofluids. Int. J. Heat Mass Transf. 2011, 54, 4410–4428. [Google Scholar] [CrossRef]

- Xuan, Y.; Roetzel, W. Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 2000, 43, 3701–3707. [Google Scholar] [CrossRef]

- Chon, C.H.; Kihm, K.D.; Lee, S.P.; Choi, S.U.S. Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3) thermal conductivity enhancement. Appl. Phys. Lett. 2005, 87, 153107. [Google Scholar] [CrossRef]

| Component | Param. | Unit | Value |

|---|---|---|---|

| CFPSC | Length | mm | 1060 |

| Width | mm | 823 | |

| Height | mm | 50 | |

| Absorber | Length | mm | 1000 |

| Edge length | mm | 27 | |

| Thickness | mm | 1 | |

| Thermal conductivity | 397 | ||

| Quantity | - | 18 | |

| Absorptivity | - | 0.98 | |

| Insulating layer | Thickness | mm | 55 |

| Thermal conductivity | 0.034 | ||

| Glass cover | Length | mm | 1400 |

| Width | mm | 1200 | |

| Thickness | mm | 4 | |

| Transmittance | - | 0.92 |

| Boundary Name | Boundary Condition |

|---|---|

| Inlet | mass flow inlet |

| Outlet | pressure outlet |

| Glass | Semi-transparnet, transmissivity: 0.92 Absorptivity: 0.02 |

| Absorber | coupled Absorptivity: 0.96 Emissivity: 0.8 |

| Insulation layer | Adiabatic |

| X-Water Nanofluids | CuO-X Nanofluids | X-EG Nanofluids | |||

|---|---|---|---|---|---|

| Nanoparticles | base fluid | nanoparticle | base fluids | nanoparticles | base fluid |

| CuO/Al2O3/TiN | water | CuO | water/EG | CuO/Al2O3/TiN | EG |

| N | Number | Temperature Difference (K) | Error () |

|---|---|---|---|

| 1 | 1,756,665 | 0.882 | — |

| 2 | 2,306,644 | 0.903 | 2.3% |

| 3 | 3,261,324 | 0.931 | 3.1% |

| 4 | 4,659,290 | 0.935 | 0.4% |

| 5 | 5,925,766 | 0.934 | 0.1% |

| Solar Irradiance (W/m2) | Experimental Value (K) | Simulated Value (K) | Error () |

|---|---|---|---|

| 620 | 0.85 | 0.93 | 9.4% |

| 850 | 1.15 | 1.25 | 8.7% |

| 1000 | 1.34 | 1.49 | 9.7% |

| 1200 | 1.54 | 1.68 | 9.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.; Tan, C.; Liu, Y.; Sun, C.; Xu, S. Numerical Analysis on Heat Collecting Performance of Novel Corrugated Flat Plate Solar Collector Using Nanofluids. Sustainability 2024, 16, 5924. https://doi.org/10.3390/su16145924

Tang X, Tan C, Liu Y, Sun C, Xu S. Numerical Analysis on Heat Collecting Performance of Novel Corrugated Flat Plate Solar Collector Using Nanofluids. Sustainability. 2024; 16(14):5924. https://doi.org/10.3390/su16145924

Chicago/Turabian StyleTang, Xingwang, Chenchen Tan, Yan Liu, Chuanyu Sun, and Sichuan Xu. 2024. "Numerical Analysis on Heat Collecting Performance of Novel Corrugated Flat Plate Solar Collector Using Nanofluids" Sustainability 16, no. 14: 5924. https://doi.org/10.3390/su16145924

APA StyleTang, X., Tan, C., Liu, Y., Sun, C., & Xu, S. (2024). Numerical Analysis on Heat Collecting Performance of Novel Corrugated Flat Plate Solar Collector Using Nanofluids. Sustainability, 16(14), 5924. https://doi.org/10.3390/su16145924