A Green Marketing and Operations Management Decision-Making Approach Based on QFDE for Photovoltaic Systems

Abstract

:1. Introduction

2. Materials and Methods

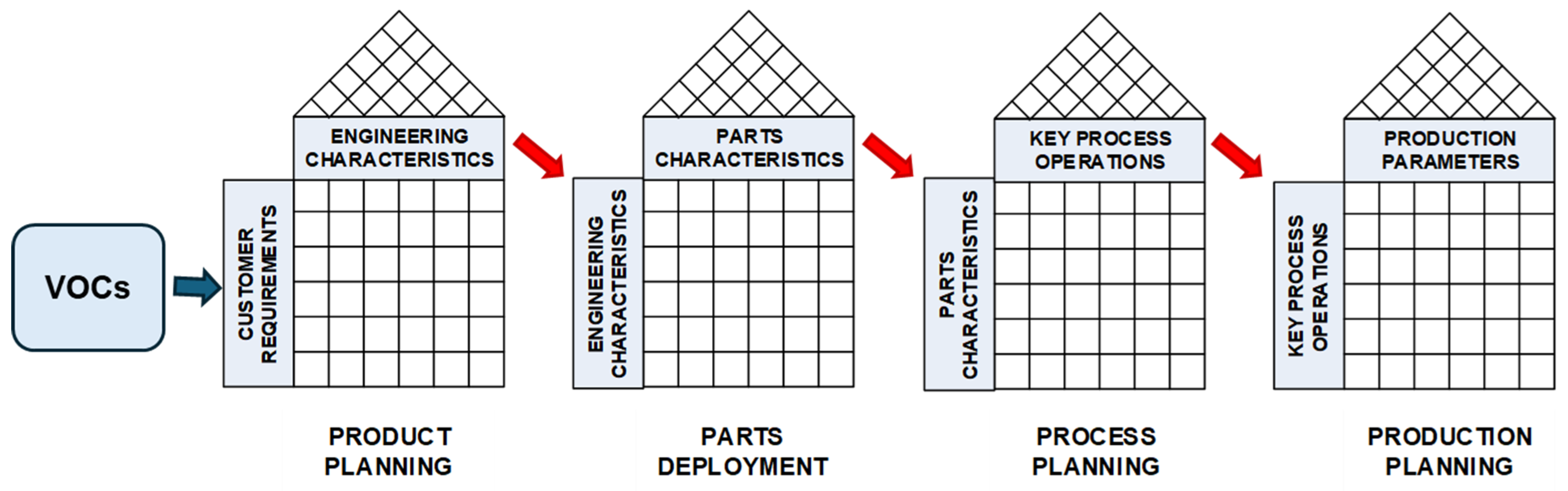

2.1. Quality Function Deployment for the Environment (QFDE)

- Engineering characteristics (ECs) from customer R=requirements (CRs) in the first phase (product planning);

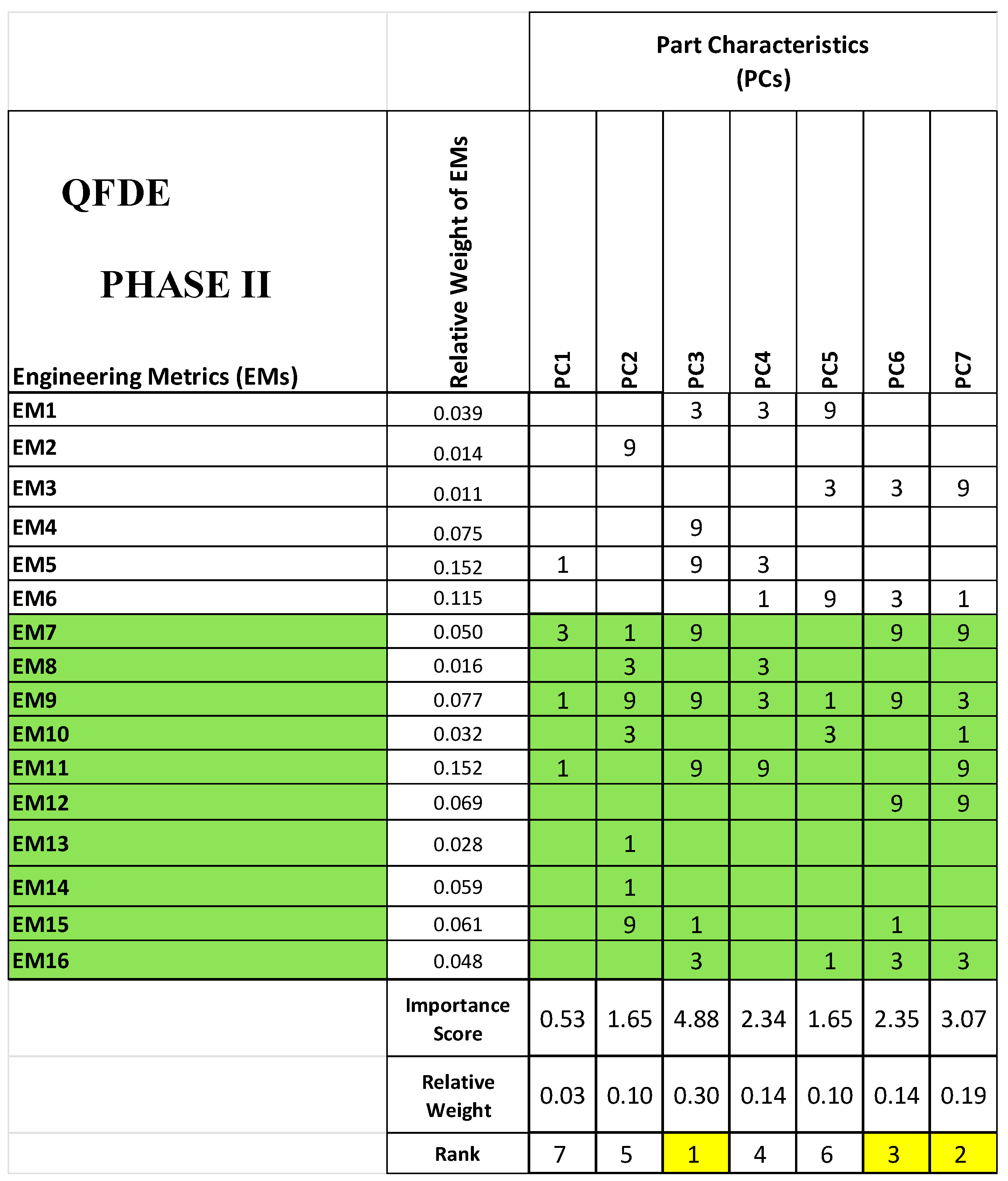

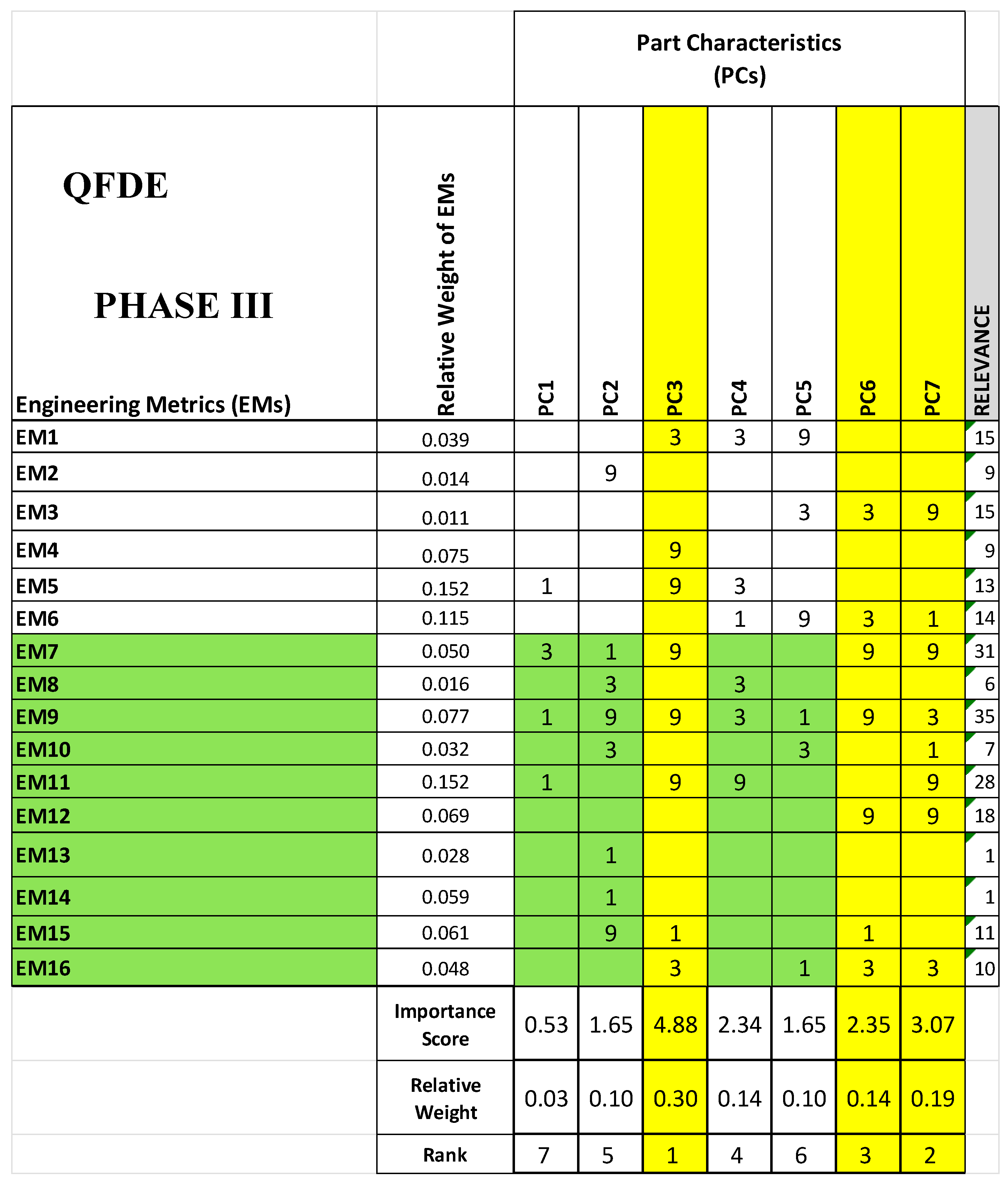

- Part Characteristics (PCs) from engineering characteristics (ECs) in the second phase (parts deployment);

- Process Operations (POs) from Part Characteristics (PCs) in the third phase (process planning);

- Production Requirements (PRs) from Process Operations (POs) in the fourth phase (production/quality control).

2.2. Analytic Hierarchy Process (AHP)

- The definition of the goal of the analysis (i.e., the decision-making problem);

- The definition of the hierarchy of the elements to be evaluated;

- The construction of a set of pairwise comparison matrices;

- The computation of the final priorities.

2.3. Strengths, Weaknesses, Opportunities, and Threats (SWOT) Analysis

2.4. Threats, Opportunities, Weaknesses, and Strengths (TOWS) Matrix

- (a)

- Strengths–opportunities (SO), which follows a “maxi-maxi” approach including strategies that use strengths to maximize opportunities;

- (b)

- Strengths–threats (ST) that is based on a “maxi-mini” approach, i.e., strengths are used to minimize threats;

- (c)

- Weaknesses–opportunities (WO), which follows a “mini-maxi” approach where the minimization of weaknesses is used to maximize opportunities;

- (d)

- Weaknesses–threats (WT), which fosters a “mini-mini” approach aimed at minimizing weaknesses and avoiding threats.

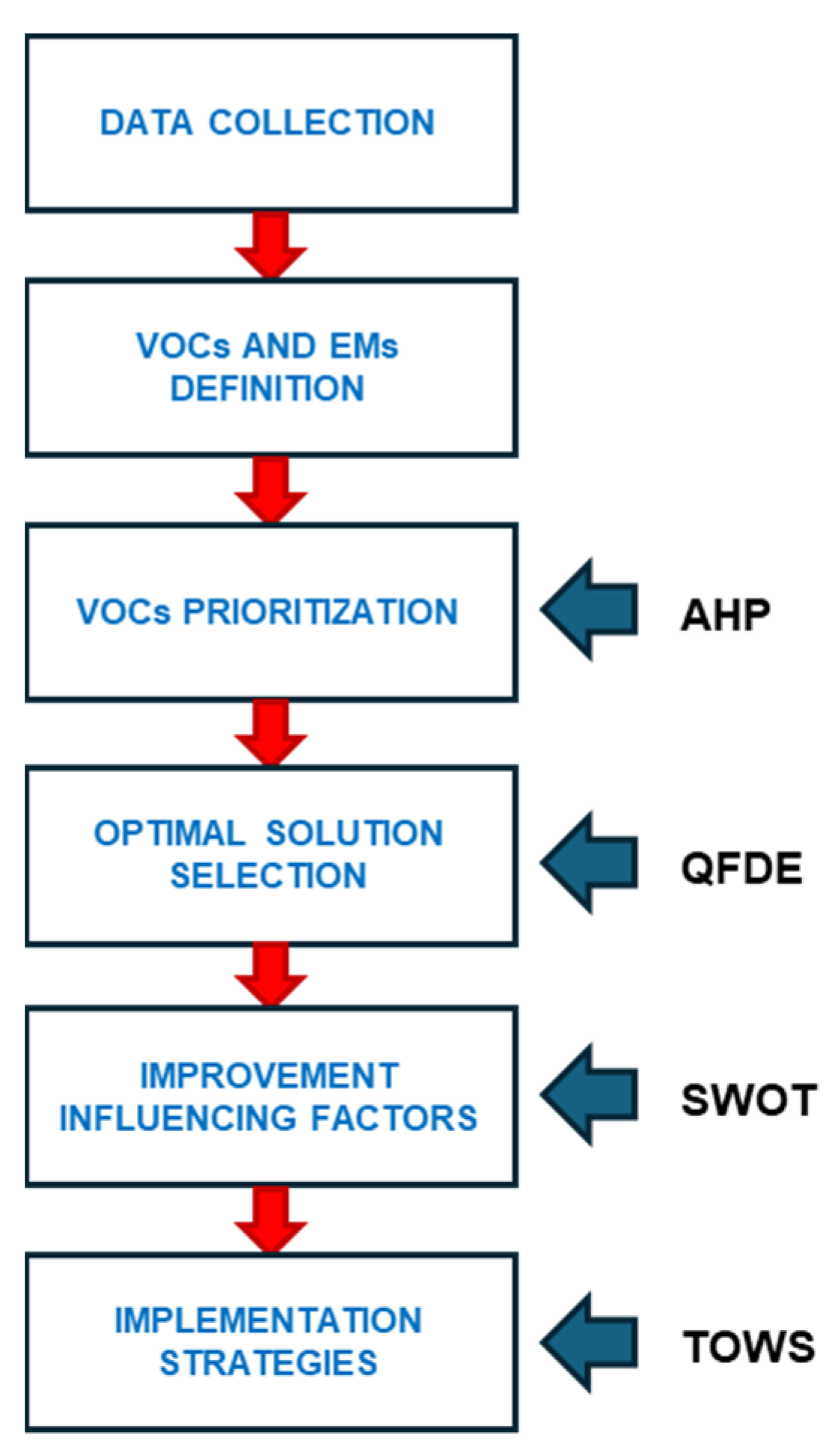

2.5. Research Approach

- The definition of VOCs and EMs: together with a team of experts belonging both to the marketing and technical departments of the company, a set of VOCs and engineering metrics was defined.

- The application of the AHP to prioritize VOCs through a survey among customers.

- The implementation of the QFDE’s four phases based on the AHP output.

- The SWOT analysis of the QFDE output.

- The implementation of the TOWS matrix to address the company’s marketing strategies.

3. The Results of the Research

3.1. Case Study Context

3.2. Data Collection and VOCs-EMs’ Definition

3.3. Prioritization of VOCs

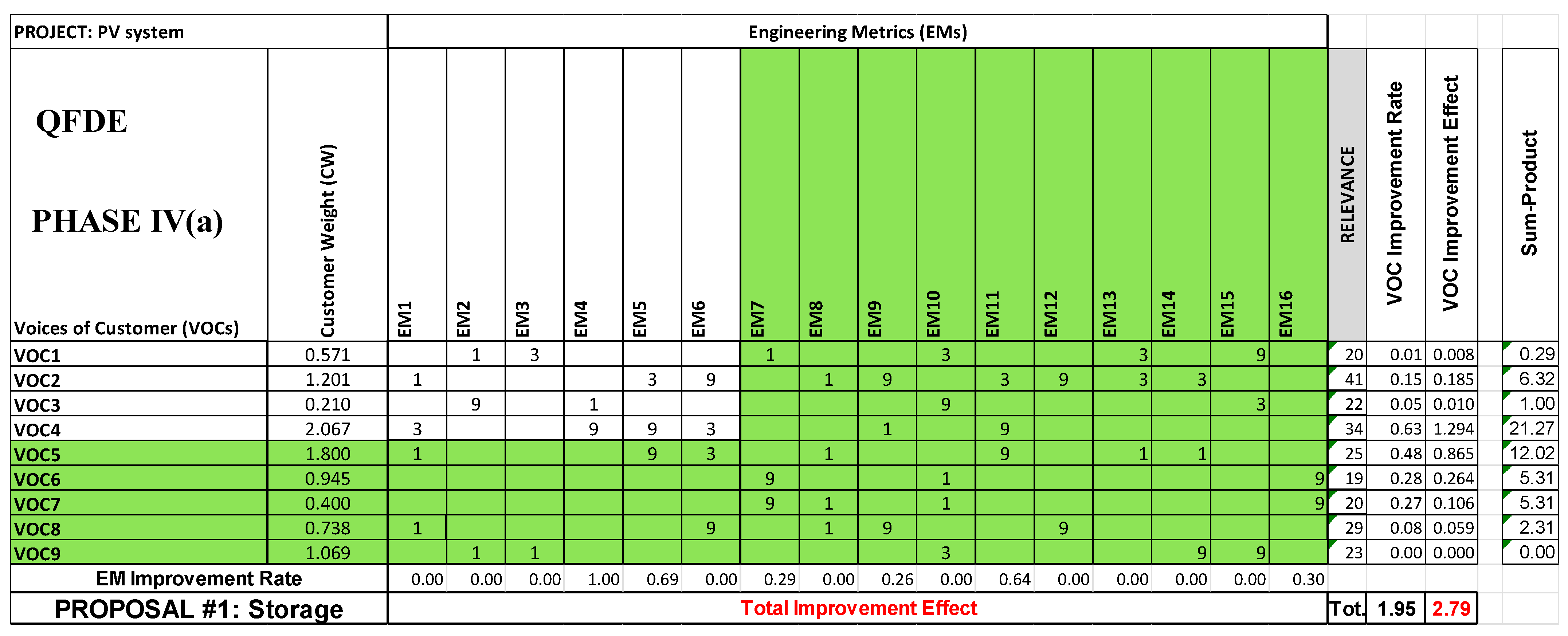

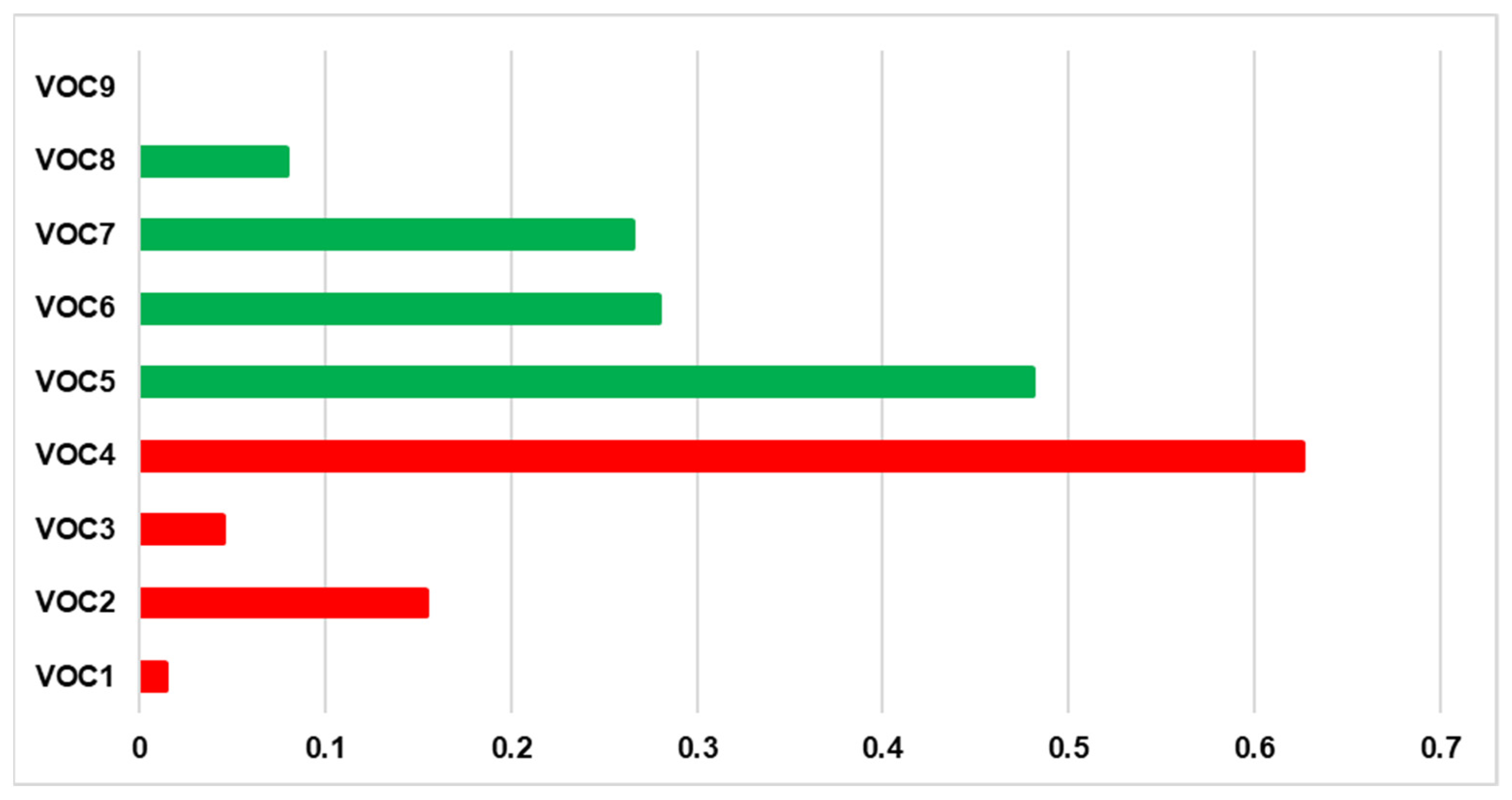

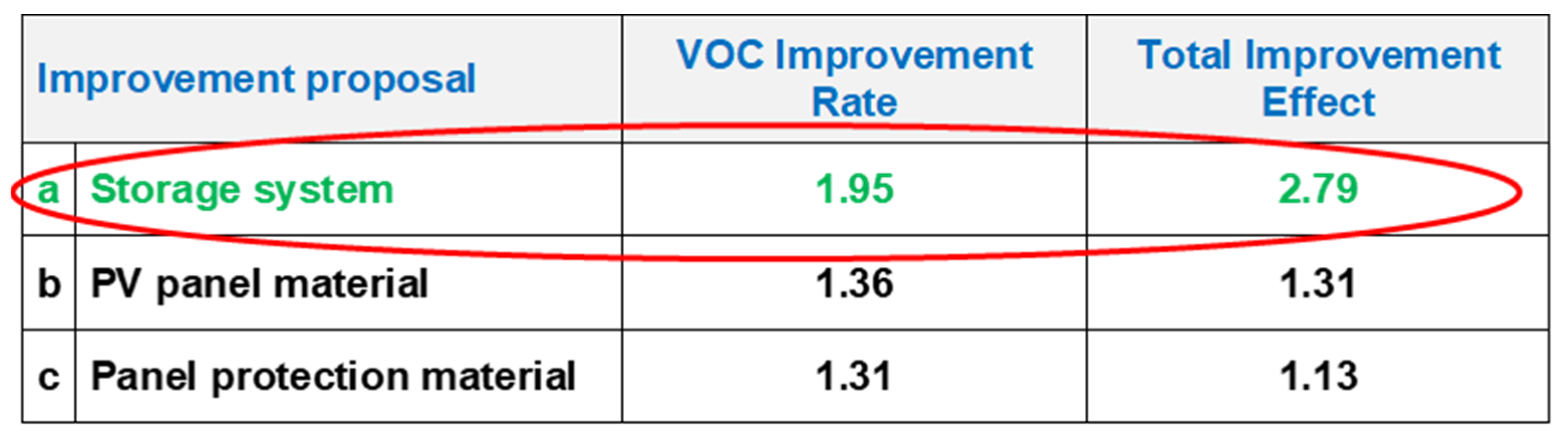

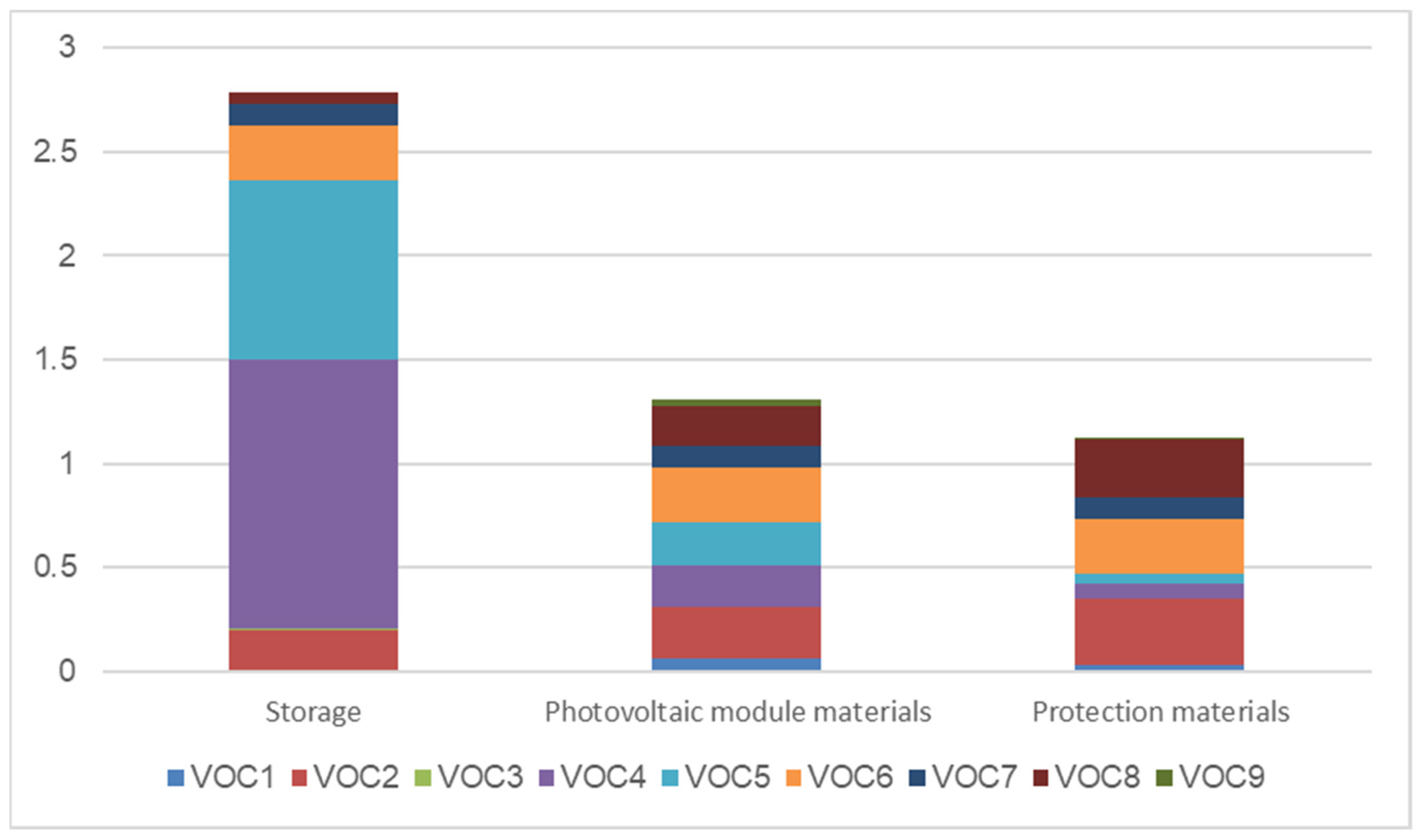

3.4. QFDE Application

- Phase III(a) for the proposal of PC3 (storage unit) improvement;

- Phase III(b) for the proposal of PC6 (solar panel) improvement;

- Phase III(c) for the proposal of PC7 (panel protection system) improvement.

3.5. SWOT Analysis

3.6. TOWS Matrix Strategic Planning

4. Discussion

- (1)

- From the technical point of view, the search for better components and modular products can allow the company to offer a system with increased efficiency and easier installation and maintenance operations.

- (2)

- From the environmental point of view, the implementation of the PSS approach can allow the company to better manage both maintenance and EoL activities.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mukonza, C.; Swarts, I. The Influence of Green Marketing Strategies on Business Performance and Corporate Image in the Retail Sector. Bus. Strateg. Environ. 2020, 29, 838–845. [Google Scholar] [CrossRef]

- Fargnoli, M.; Haber, N. A QFD-based approach for the development of smart product-service systems. Eng. Rep. 2023, 5, e12665. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 13 March 2024).

- European Commission. Ecodesign for Sustainable Products Regulation. Available online: https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/ecodesign-sustainable-products-regulation_en (accessed on 13 March 2024).

- European Union. JRC Science for Policy Report, Ecodesign for Sustainable Products Regulation—Preliminary Study on New Product Priorities. Available online: https://susproc.jrc.ec.europa.eu/product-bureau/sites/default/files/2023-01/Preliminary%20ESPR%20WP%20Report_MERGED_CLEAN_.pdf (accessed on 13 March 2024).

- Kim, C.H.; Kuah, A.T.; Thirumaran, K. Morphology for circular economy business models in the electrical and electronic equipment sector of Singapore and South Korea: Findings, implications, and future agenda. Sustain. Prod. Consum. 2022, 30, 829–850. [Google Scholar] [CrossRef]

- Arai, R.; Calisto Friant, M.; Vermeulen, W.J. The Japanese Circular Economy and Sound Material-Cycle Society Policies: Discourse and Policy Analysis. Circ. Econ. Sustain. 2024, 4, 619–650. [Google Scholar] [CrossRef]

- Nekmahmud, M.; Fekete-Farkas, M. Why Not Green Marketing? Determinates of Consumers’ Intention to Green Purchase Decision in a New Developing Nation. Sustainability 2020, 12, 7880. [Google Scholar] [CrossRef]

- Martínez, M.P.; Cremasco, C.P.; Filho, L.G.; Junior, S.S.B.; Bednaski, A.V.; Quevedo-Silva, F.; Correa, C.M.; Da Silva, D.; Padgett, R.C.M.L.; Gabriel, C.P.C. Fuzzy inference system to study the behavior of the green consumer facing the perception of greenwashing. J. Clean. Prod. 2020, 242, 116064. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Vocalelli, D. “Green marketing”: An analysis of definitions, strategy steps, and tools through a systematic review of the literature. J. Clean. Prod. 2017, 165, 1263–1279. [Google Scholar] [CrossRef]

- García-Salirrosas, E.E.; Escobar-Farfán, M.; Gómez-Bayona, L.; Moreno-López, G.; Valencia-Arias, A.; Gallardo-Canales, R. Influence of environmental awareness on the willingness to pay for green products: An analysis under the application of the theory of planned behavior in the Peruvian market. Front. Psychol. 2024, 14, 282383. [Google Scholar] [CrossRef] [PubMed]

- Kaur, B.; Gangwar, V.P.; Dash, G. Green Marketing Strategies, Environmental Attitude, and Green Buying Intention: A Multi-Group Analysis in an Emerging Economy Context. Sustainability 2022, 14, 6107. [Google Scholar] [CrossRef]

- Cronin, J.J.; Smith, J.S.; Gleim, M.R.; Ramirez, E.; Martinez, J.D. Green marketing strategies: An examination of stakeholders and the opportunities they present. J. Acad. Mark. Sci. 2010, 39, 158–174. [Google Scholar] [CrossRef]

- Mestre, A.; Cooper, T. Circular Product Design. A Multiple Loops Life Cycle Design Approach for the Circular Economy. Des. J. 2017, 20, S1620–S1635. [Google Scholar] [CrossRef]

- Spreafico, C. An analysis of design strategies for circular economy through life cycle assessment. Environ. Monit. Assess. 2022, 194, 180. [Google Scholar] [CrossRef] [PubMed]

- Hapuwatte, B.M.; Jawahir, I.S. Closed-loop sustainable product design for circular economy. J. Ind. Ecol. 2021, 25, 1430–1446. [Google Scholar] [CrossRef]

- Acerbi, F.; Taisch, M. A literature review on circular economy adoption in the manufacturing sector. J. Clean. Prod. 2020, 273, 123086. [Google Scholar] [CrossRef]

- Matschewsky, J.; Kambanou, M.L.; Sakao, T. Designing and providing integrated product-service systems—Challenges, opportunities and solutions resulting from prescriptive approaches in two industrial companies. Int. J. Prod. Res. 2018, 56, 2150–2168. [Google Scholar] [CrossRef]

- Diaz, A.; Schöggl, J.-P.; Reyes, T.; Baumgartner, R.J. Sustainable product development in a circular economy: Implications for products, actors, decision-making support and lifecycle information management. Sustain. Prod. Consum. 2021, 26, 1031–1045. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Schuit, C.S.C.; Kraaijenhagen, C. Experimenting with a circular business model: Lessons from eight cases. Environ. Innov. Soc. Transit. 2018, 28, 79–95. [Google Scholar] [CrossRef]

- Chrispim, M.C.; Mattsson, M.; Ulvenblad, P. The underrepresented key elements of Circular Economy: A critical review of assessment tools and a guide for action. Sustain. Prod. Consum. 2023, 35, 539–558. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Su, D.; Casamayor, J.L.; Xu, X. An integrated approach for eco-design and its application in LED lighting product development. Sustainability 2021, 13, 488. [Google Scholar] [CrossRef]

- Fargnoli, M.; De Minicis, M.; Tronci, M. Product’s life cycle modelling for ecodesigning product-service systems. In Proceedings of the DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; pp. 869–878. [Google Scholar]

- Fargnoli, M.; Kimura, F. Sustainable design of modern industrial products. In Proceedings of the International Conference of Life Cycle Engineering, LCE 2006, Leuven, Belgium, 31 May–2 June 2006; pp. 189–194. [Google Scholar]

- Younesi, M.; Roghanian, E. A framework for sustainable product design: A hybrid fuzzy approach based on Quality Function Deployment for Environment. J. Clean. Prod. 2015, 108, 385–394. [Google Scholar] [CrossRef]

- Perez-Gallardo, J.R.; Azzaro-Pantel, C.; Astier, S. Combining Multi-Objective Optimization, Principal Component Analysis and Multiple Criteria Decision Making for ecodesign of photovoltaic grid-connected systems. Sustain. Energy Technol. Assess. 2018, 27, 94–101. [Google Scholar] [CrossRef]

- Jayal, A.D.; Badurdeen, F.; Dillon, O.W.; Jawahir, I.S. Sustainable Manufacturing: Modeling and Optimization Challenges at the Product, Process and System Levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Jiang, P.; Dieckmann, E.; Han, J.; Childs, P.R.N. A Bibliometric Review of Sustainable Product Design. Energies 2021, 14, 6867. [Google Scholar] [CrossRef]

- Sakao, T.A. QFD-centred design methodology for environmentally conscious product design. Int. J. Prod. Res. 2007, 45, 4143–4162. [Google Scholar] [CrossRef]

- Puglieri, F.N.; Ometto, A.R.; Salvador, R.; Barros, M.V.; Piekarski, C.M.; Rodrigues, I.M.; Diegoli Netto, O. An Environmental and Operational Analysis of Quality Function Deployment-Based Methods. Sustainability 2020, 12, 3486. [Google Scholar] [CrossRef]

- Masui, K.; Sakao, T.; Aizawa, S.; Inaba, A.I. Quality Function Deployment for Environment (QFDE) to Support Design for Environment (DFE). In Proceedings of the ASME 7th Design for Manufacturing Conference, Montreal, QC, Canada, 29 September–2 October 2002; pp. 415–423. [Google Scholar] [CrossRef]

- Saaty, T. Decision-making with the AHP: Why is the principal eigenvector necessary. Eur. J. Oper. Res. 2003, 145, 85–91. [Google Scholar] [CrossRef]

- Weihrich, H. The TOWS matrix—A tool for situation analysis. Long Range Plan 1982, 15, 54–66. [Google Scholar] [CrossRef]

- Ravanavar, G.M.; Charantimath, P.M. Strategic formulation using TOWS matrix—A case study. Int. J. Res. Dev. 2012, 1, 87–90. [Google Scholar]

- Överholm, H. Alliance formation by intermediary ventures in the solar service industry: Implications for product-service systems research. J. Clean. Prod. 2017, 140, 288–298. [Google Scholar] [CrossRef]

- Van Opstal, W.; Smeets, A. Circular economy strategies as enablers for solar PV adoption in organizational market segments. Sustain. Prod. Consum. 2023, 35, 40–54. [Google Scholar] [CrossRef]

- Obaideen, K.; AlMallahi, M.N.; Alami, A.H.; Ramadan, M.; Abdelkareem, M.A.; Shehata, N.; Olabi, A. On the contribution of solar energy to sustainable developments goals: Case study on Mohammed bin Rashid Al Maktoum Solar Park. Int. J. Thermofluid 2021, 12, 100123. [Google Scholar] [CrossRef]

- Aniello, G.; Bertsch, V. Shaping the energy transition in the residential sector: Regulatory incentives for aligning household and system perspectives. Appl. Energy 2023, 333, 120582. [Google Scholar] [CrossRef]

- Seker, S.; Kahraman, C. Socio-economic evaluation model for sustainable solar PV panels using a novel integrated MCDM methodology: A case in Turkey. Socio-Econ. Plan. Sci. 2021, 77, 100998. [Google Scholar] [CrossRef]

- Chan, L.K.; Wu, M.L. Quality function deployment: A literature review. Eur. J. Oper. Res. 2002, 143, 463–497. [Google Scholar] [CrossRef]

- Sivasamy, K.; Arumugam, C.; Devadasan, S.R.; Murugesh, R.; Thilak, V.M.M. Advanced models of quality function deployment: A literature review. Qual. Quant. 2016, 50, 1399–1414. [Google Scholar] [CrossRef]

- Vinayak, K.; Kodali, R. Benchmarking the quality function deployment models. Benchmarking Int. J. 2013, 20, 825–854. [Google Scholar] [CrossRef]

- Fargnoli, M.; Sakao, T. Uncovering differences and similarities among quality function deployment-based methods in Design for X: Benchmarking in different domains. Qual. Eng. 2017, 29, 690–712. [Google Scholar] [CrossRef]

- Akao, Y. Quality Function Deployment: Integrating Customer Requirements into Product Design; Productivity Press: New York, NY, USA, 2004. [Google Scholar]

- Carnevalli, J.A.; Miguel, P.A.C. Review, analysis and classification of the literature on QFD-Types of research, difficulties and benefits. Int. J. Prod. Econ. 2008, 114, 737–754. [Google Scholar] [CrossRef]

- Franceschini, F.; Rossetto, S. QFD: The Problem of Comparing Technical/Engineering Design Requirements. Res. Eng. Des. 1995, 7, 270–278. [Google Scholar] [CrossRef]

- Zhou, J.; Shen, Y.; Pantelous, A.A.; Liu, Y. Quality Function Deployment: A Bibliometric-Based Overview. IEEE Trans. Eng. Manag. 2022, 56, 1–22. [Google Scholar] [CrossRef]

- Bereketli, I.; Genevois, M.E. An integrated QFDE approach for identifying improvement strategies in sustainable product development. J. Clean. Prod. 2013, 54, 188–198. [Google Scholar] [CrossRef]

- Wu, Y.; Luo, B.; Li, M. Application of quality function deployment for environment in product eco-design. In Proceedings of the IEEE International Symposium on Assembly and Manufacturing, Seoul, Republic of Korea, 17–20 November 2009; pp. 254–257. [Google Scholar] [CrossRef]

- Popoff, A.; Millet, D. Sustainable life cycle design using constraint satisfaction problems and Quality Function Deployment. Procedia CIRP 2017, 61, 75–80. [Google Scholar] [CrossRef]

- Yu, S.; Yang, Q.; Tao, J.; Xu, X. Incorporating Quality Function Deployment with modularity for the end-of-life of a product family. J. Clean. Prod. 2015, 87, 423–430. [Google Scholar] [CrossRef]

- Vinodh, S.; Kamala, V.; Jayakrishna, K. Integration of ECQFD, TRIZ, and AHP for innovative and sustainable product development. Appl. Math. Model. 2014, 38, 2758–2770. [Google Scholar] [CrossRef]

- Kuo, T.C.; Wu, H.H.; Shieh, J.I. Integrating of environmental considerations in quality function deployment by using fuzzy logic. Expert Syst. Appl. 2009, 36, 7148–7156. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Zhang, C. Green QFD-II: A life cycle approach for environmentally conscious manufacturing by integrating LCA and LCC into QFD matrices. Int. J. Prod. Res. 1999, 37, 1075–1091. [Google Scholar] [CrossRef]

- Bovea, M.D.; Wang, B. Redesign methodology for developing environmentally conscious products. Int. J. Prod. Res. 2007, 45, 4057–4072. [Google Scholar] [CrossRef]

- Mehta, C.; Wang, B. Green quality function deployment III: A methodology for developing environmentally conscious products. J. Des. Manuf. Autom. 2001, 1, 1–16. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Sarkar, B.; Mukherjee, S.K. Integrating AHP with QFD for robot selection under requirement perspective. Int. J. Prod. Res. 2005, 43, 3671–3685. [Google Scholar] [CrossRef]

- Das, D.; Mukherjee, K. Development of an AHP-QFD framework for designing a tourism product. Int. J. Serv. Oper. Manag. 2008, 4, 321–344. [Google Scholar] [CrossRef]

- Phadermrod, B.; Crowder, R.M.; Wills, G.B. Importance-performance analysis based, SWOT analysis. Int. J. Inf. Manag. 2019, 44, 194–203. [Google Scholar] [CrossRef]

- Sammut-Bonnici, T.; Galea, D. SWOT analysis. In Willey Encyclopedia of Management: Volume 12 Strategic Management, 3rd ed.; McGee, J., Sammut-Bonnici, T., Eds.; John Wiley & Sons: Chichister, UK, 2014; pp. 495–502. [Google Scholar] [CrossRef]

- Clegg, B.; Tan, B. Using QFD for e-business planning and analysis in a micro-sized enterprise. Int. J. Qual. Reliab. Manag. 2007, 24, 813–828. [Google Scholar] [CrossRef]

- Saragih, L.L.; Simarmata, E.; Aloina, G.; Tarigan, U.P.; Ramadhani, V.B.; Ginting, S.E. Product development of canned fish using SWOT and quality function deployment (QFD). AIP Conf. Proc. 2020, 2227, 040017. [Google Scholar] [CrossRef]

- Pur, M.M.; Tabriz, A.A. SWOT analysis using of modified fuzzy QFD—A Case study for strategy formulation in Petrokaran film factory. Procedia Soc. Behav. Sci. 2012, 41, 322–333. [Google Scholar] [CrossRef]

- Microsoft Office 365. Available online: https://www.microsoft.com/en-us/microsoft-365 (accessed on 13 March 2024).

- Liu, H.Y.; Skandalos, N.; Braslina, L.; Kapsalis, V.; Karamanis, D. Integrating Solar Energy and Nature-Based Solutions for Climate-Neutral Urban Environments. Solar 2023, 3, 382–415. [Google Scholar] [CrossRef]

- Akrofi, M.M.; Okitasari, M. Integrating solar energy considerations into urban planning for low carbon cities: A systematic review of the state-of-the-art. Urban Gov. 2022, 2, 157–172. [Google Scholar] [CrossRef]

- Sahu, Β.Κ. A study on global solar PV energy developments and policies with special focus on the top ten solar PV power producing countries. Renew. Sustain. Energy Rev. 2015, 43, 621–634. [Google Scholar] [CrossRef]

- Formolli, M.; Croce, S.; Vettorato, D.; Paparella, R.; Scognamiglio, A.; Mainini, A.G.; Lobaccaro, G. Solar Energy in Urban Planning: Lesson Learned and Recommendations from Six Italian Case Studies. Appl. Sci. 2022, 12, 2950. [Google Scholar] [CrossRef]

- Ferreira, A.; Kunh, S.S.; Fagnani, K.C.; De Souza, T.A.; Tonezer, C.; Dos Santos, G.R.; Coimbra-Araújo, C.H. Economic overview of the use and production of photovoltaic solar energy in brazil. Renew. Sustain. Energy Rev. 2018, 81, 181–191. [Google Scholar] [CrossRef]

- Mundaca, L.; Samahita, M. What drives home solar PV uptake? Subsidies, peer effects and visibility in Sweden. Energy Res. Soc. Sci. 2020, 60, 101319. [Google Scholar] [CrossRef]

- El-Bayeh, C.Z.; Alzaareer, K.; Brahmi, B.; Zellagui, M.; Eicker, U. An Original Multi-Criteria Decision-Making Algorithm for Solar Panels Selection in Buildings. Energy 2021, 217, 1–15. [Google Scholar] [CrossRef]

- Balo, F.; Sagbansua, L. The selection of the best solar panel for the photovoltaic system design by using AHP. Energy Procedia 2016, 100, 50–53. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Model of Choice Photovoltaic Panels Considering Customers’ Expectations. Energies 2021, 14, 5977. [Google Scholar] [CrossRef]

- Alaaeddin, M.H.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Al-Oqla, F.M. Photovoltaic Applications: Status and Manufacturing Prospects. Renew. Sustain. Energy Rev. 2019, 102, 318–332. [Google Scholar] [CrossRef]

- Bączkiewicz, A.; Kizielewicz, B.; Shekhovtsov, A.; Yelmikheiev, M.; Kozlov, V.; Sałabun, W. Comparative Analysis of Solar Panels with Determination of Local Significance Levels of Criteria Using the MCDM Methods Resistant to the Rank Reversal Phenomenon. Energies 2021, 14, 5727. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Model to Predict Quality of Photovoltaic Panels Considering Customers’ Expectations. Energies 2022, 15, 1101. [Google Scholar] [CrossRef]

- Franěk, J.; Kresta, A. Judgment Scales and Consistency Measure in AHP. Procedia Econ. Financ. 2014, 12, 164–173. [Google Scholar] [CrossRef]

- MS EXCEL. Available online: https://www.microsoft.com/en-ie/microsoft-365/excel (accessed on 13 March 2024).

- Sakao, T.; Nordholm, A.K. Requirements for a Product Lifecycle Management System Using Internet of Things and Big Data Analytics for Product-as-a-Service. Front. Sustain. 2021, 2, 735550. [Google Scholar] [CrossRef]

- Pandey, A.K.; Kalidasan, B.; Reji Kumar, R.; Rahman, S.; Tyagi, V.V.; Krismadinata; Said, Z.; Salam, P.A.; Juanico, D.E.; Ahamed, J.U.; et al. Solar Energy Utilization Techniques, Policies, Potentials, Progresses, Challenges and Recommendations in ASEAN Countries. Sustainability 2022, 14, 11193. [Google Scholar] [CrossRef]

- Jabeen, G.; Ahmad, M.; Zhang, Q. Perceived critical factors affecting consumers’ intention to purchase renewable generation technologies: Rural-urban heterogeneity. Energy 2021, 218, 119494. [Google Scholar] [CrossRef]

- Setyawati, D. Analysis of perceptions towards the rooftop photovoltaic solar system policy in Indonesia. Energy Policy 2020, 144, 111569. [Google Scholar] [CrossRef]

- Mont, O. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Gräßler, I.; Pottebaum, J. Generic Product Lifecycle Model: A Holistic and Adaptable Approach for Multi-Disciplinary Product–Service Systems. Appl. Sci. 2021, 11, 4516. [Google Scholar] [CrossRef]

- Kesavapanikkar, P.; Amit, R.K.; Ramu, P. Product as a service (PaaS) for traditional product companies: An automotive lease practice evaluation. J. Indian Bus. Res. 2021, 15, 40–54. [Google Scholar] [CrossRef]

- Blüher, T.; Amaral, D.C.; Lindow, K.; Costa, J.M.H.; Stark, R. Research opportunities in PSS design focusing on the potentials of agile approaches. Procedia CIRP 2019, 84, 832–837. [Google Scholar] [CrossRef]

- Golinska-Dawson, P.; Zysnarska, Z.; Pender, A. Assessment of the maturity of product-as-a-service business models for household appliances from the perspective of R strategies in Circular Economy. Procedia CIRP 2024, 122, 1083–1088. [Google Scholar] [CrossRef]

- Hidalgo-Crespo, J.; Riel, A.; Duberg, J.V.; Bunodiere, A.; Golinska-Dawson, P. An exploratory study for product-as-a-service (PaaS) offers development for electrical and electronic equipment. Procedia CIRP 2024, 122, 521–526. [Google Scholar] [CrossRef]

- Sakao, T.; Brambila-Macias, S.A. Do we share an understanding of transdisciplinarity in environmental sustainability research? J. Clean. Prod. 2018, 170, 1399–1403. [Google Scholar] [CrossRef]

- Zhang, X.; Tong, S.; Eres, H.; Wang, K.; Kossmann, M. Towards avoiding the hidden traps in QFD during requirements establishment. J. Syst. Sci. Syst. Eng. 2015, 24, 316–336. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N. A fuzzy-QFD approach for the enhancement of work equipment safety: A case study in the agriculture sector. Int. J. Reliab. Saf. 2018, 12, 306–326. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, N.; Yang, T. Wisdom of crowds: SWOT analysis based on hybrid text mining methods using online reviews. J. Bus. Res. 2024, 171, 114378. [Google Scholar] [CrossRef]

- Benzaghta, M.A.; Elwalda, A.; Mousa, M.; Erkan, I.; Rahman, M. SWOT Analysis Applications: An Integrative Literature Review. J. Glob. Bus. Insights 2021, 6, 55–73. [Google Scholar] [CrossRef]

| Type | Code | VOCs |

|---|---|---|

| Conventional VOCs | VOC1 | Purchase cost |

| VOC2 | Reliability | |

| VOC3 | Dimensions | |

| VOC4 | Profit | |

| Environmental VOCs | VOC5 | Energy efficiency |

| VOC6 | Ease of disassembling and parts sorting | |

| VOC7 | Easy to dispose | |

| VOC8 | Lifespan duration | |

| VOC9 | Installation complexity |

| Type | Code | VOCs |

|---|---|---|

| Conventional EMs | EM1 | Monitoring |

| EM2 | Product size | |

| EM3 | Aesthetics | |

| EM4 | Storage capacity | |

| EM5 | Storage efficiency | |

| EM6 | Maintainability | |

| Environmental EMs | EM7 | Materials recyclability |

| EM8 | Accessibility | |

| EM9 | Durability | |

| EM10 | Product modularity | |

| EM11 | Energy production efficiency | |

| EM12 | Materials resistance | |

| EM13 | Quality of preliminary inspection | |

| EM14 | Quality of installation | |

| EM15 | Reduced number of components | |

| EM16 | Product disposal/recycling |

| Code | PCs |

|---|---|

| PC1 | Connection cables |

| PC2 | Installation system |

| PC3 | Storage unit |

| PC4 | Inverters |

| PC5 | Control system |

| PC6 | Panel protection (materials) |

| PC7 | Panel (materials) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fargnoli, M.; Salvatori, E.; Tronci, M. A Green Marketing and Operations Management Decision-Making Approach Based on QFDE for Photovoltaic Systems. Sustainability 2024, 16, 5941. https://doi.org/10.3390/su16145941

Fargnoli M, Salvatori E, Tronci M. A Green Marketing and Operations Management Decision-Making Approach Based on QFDE for Photovoltaic Systems. Sustainability. 2024; 16(14):5941. https://doi.org/10.3390/su16145941

Chicago/Turabian StyleFargnoli, Mario, Emilio Salvatori, and Massimo Tronci. 2024. "A Green Marketing and Operations Management Decision-Making Approach Based on QFDE for Photovoltaic Systems" Sustainability 16, no. 14: 5941. https://doi.org/10.3390/su16145941

APA StyleFargnoli, M., Salvatori, E., & Tronci, M. (2024). A Green Marketing and Operations Management Decision-Making Approach Based on QFDE for Photovoltaic Systems. Sustainability, 16(14), 5941. https://doi.org/10.3390/su16145941