Vendor Partnerships in Sustainable Supply Chains in the Indian Electric Two-Wheeler Industry—A Systematic Review of the Literature

Abstract

1. Introduction

2. Sources and Classification of the Literature

2.1. Need and Scope

2.2. Barriers to EV Adoption

2.3. Policy

2.4. Environmental Aspects

2.4.1. Sustainability

2.4.2. Sustainable SCM (SSCM) & Green SCM (GSCM)

2.4.3. SSCM & GSCM in the Indian Automobile Industry

2.5. Green Energy and Manufacturing

2.6. Economic Perspective and Profitability

2.7. Social Perspective

2.8. Supply Chain Practices

2.8.1. SCM in the Automobile Industry

2.8.2. Logistics/Industry 4.0 Concepts

2.9. Vendor Management

Vendor Partnerships in the Indian Automobile Industry

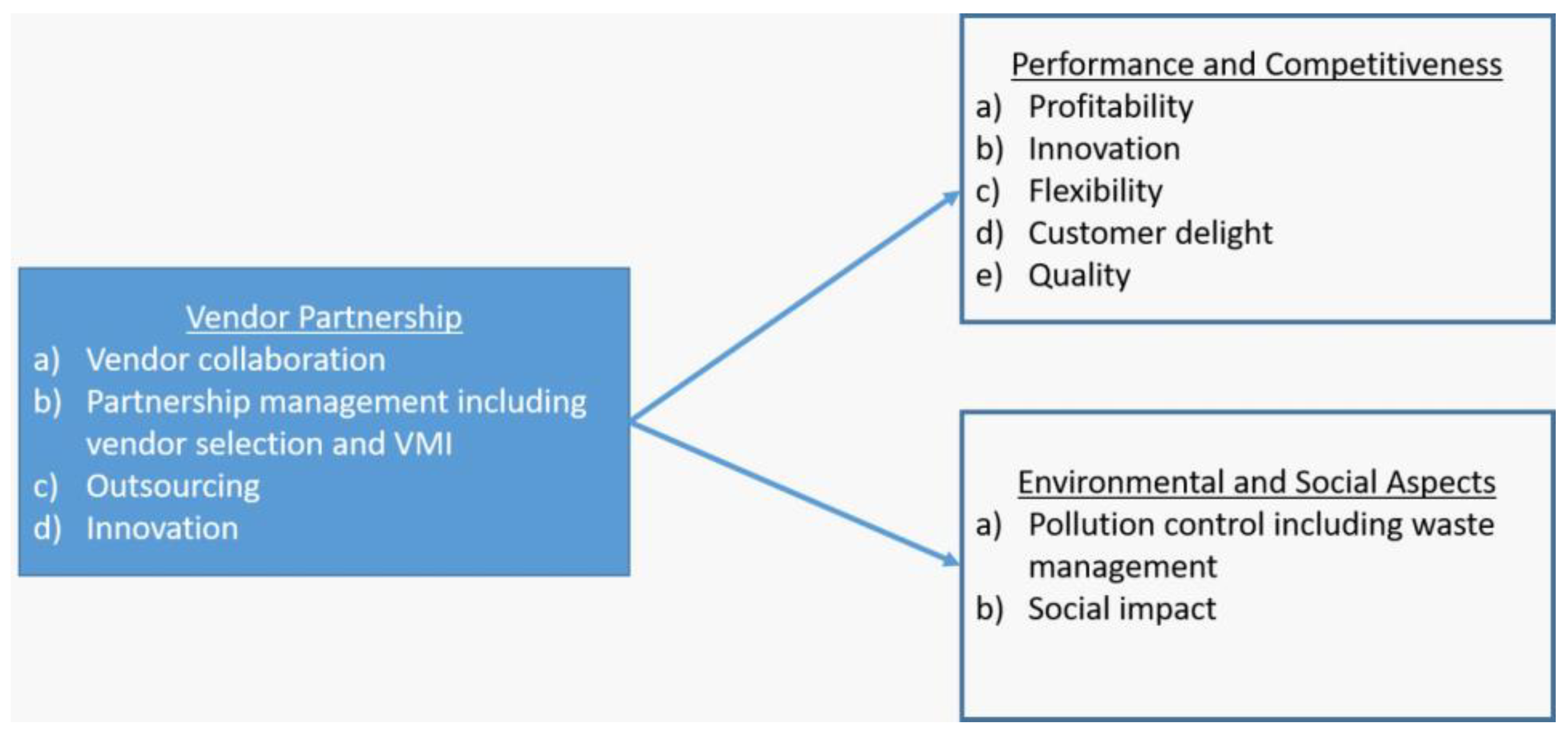

3. The Conceptual Framework

- Need for study specific to EVs in India rather than generic to the automobile sector or industry.

- Need for India-specific study on E2Ws.

- Need for specific topics of research to consider developing country like India.

- Need to incorporate and integrate social issues in SSCM performance.

- Need to further research on vendors/suppliers’ partnership or collaboration on sustainable supply chain performance.

- Need to focus investigation of SSCM performance to a particular type of industry to have consistency in results, which in this case would be the EV sector in India and specifically E2W sector.

- Assessment of critical factors of suppliers’ partnership influencing industry’s performance.

- Evolve suitable sustainable supply chain practices to tap significant opportunities expected in the EV/E2W industry in future.

- Assessment of GoI support for the E2W industry, and influence of State Government’s policies on the development of ecosystem, especially for undertaking E2W manufacture.

- A framework for further research on investigation of other variables like technology, human resources, investment, operations, vis à vis industries’ performance.

- Creating awareness among the E2W industry on the opportunities existing and also solutions for the supply chain challenges related to E2W work packages.

- Academic institutions collaboration for E2W research and development activities.

- The current study is expected to help practitioners of not only the E2W industry but also other manufacturing industries for overcoming supply chain challenges.

4. Future Research and Conclusions

4.1. Limitations

4.2. Discussion

4.2.1. Theoretical

4.2.2. Managerial

4.2.3. Areas for Future Research

- Research on E2W penetration, proliferation in India and globally, including studying its role in expediting the shift from ICE. Further analysis on buyer behavior towards EV purchase and barriers.

- Research on alternate elements for future batteries with corresponding impact on geopolitics, including geopolitical aspects of dependence on lithium., e.g., research on materials like sodium for batteries. Research will also focus on other propulsion technologies like hydrogen and solar driven.

- For balance, future research can also explore the negative impact of EVs on society, environment, industry, supply chain, etc. Examples include disposal of existing ICE vehicles, and EV batteries, which will be a logistics and environmental nightmare.

- More in-depth analysis of the social impacts of EV industries.

- Research on supply chain of automobile ICE industries vis à vis the EV industry, and changes necessitated. Supply chain involved in the eventual and perhaps inevitable re-purposing of ICE automobile factories into EV production lines, and the consequent evolving of vendors for this change, could be studied.

- The supply chain and logistics aspects that determine the choice of location for setting up an EV plant.

4.3. Summary

Funding

Conflicts of Interest

References

- Seethalakshmi, S.; Shyamala, K. India two Wheelers Go Electric-Setting Stage for the E-Revolution. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 751–756. [Google Scholar] [CrossRef]

- Cornet, A.; Conzade, J.; Schaufuss, P.; Schenk, S.; Tschiesner, A.; Laufenberg, K.; von Hensley, R.; Hertzke, P.; Heuss, R.; Moller, T. Why the Automotive Future is Electric; 2021. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/why-the-automotive-future-is-electric#/ (accessed on 13 May 2024).

- Ritchie, H. Cars, planes, trains: Where do CO2 emissions from transport come from? Our World in Data, 6 October 2020. [Google Scholar]

- Paladugula, A.L.; Kholod, N.; Chaturvedi, V.; Ghosh, P.P.; Pal, S.; Clarke, L.; Evans, M.; Kyle, P.; Koti, P.N.; Parikh, K.; et al. A multi-model assessment of energy and emissions for India’s transportation sector through 2050. Energy Policy 2018, 116, 10–18. [Google Scholar] [CrossRef]

- Anand, A.; Sagar, S.R.; Kumar, C. How India Is Able to Control Inflation During the Russia-Ukraine War. In Cases on the Resurgence of Emerging Businesses; IGI Global: Hershey, PA, USA, 2023; pp. 237–251. [Google Scholar] [CrossRef]

- ANI. India tops Japan to become world’s 3rd largest auto market. Fortune India, 9 January 2023.

- SIAM. Automobile Domestic Sales Trends. Society of Indian Automobile Manufacturers (SIAM). 2022. Available online: https://www.siam.in/statistics.aspx?mpgid=8&pgidtrail=14 (accessed on 13 May 2024).

- Sripad, S.; Mehta, T.; Srivastava, A.; Viswanathan, V. The Future of Vehicle Electrification in India May Ride on Two Wheels. ACS Energy Lett. 2019, 4, 2691–2694. [Google Scholar] [CrossRef]

- Jacob, C. India is learning to love electric vehicles—But they’re not cars. Available online: https://www.cnbc.com/ (accessed on 13 May 2024).

- Khande, M.S.; Patil, A.S.; Andhale, G.C.; Shirsat, R.S. Design and Development of Electric Scooter. Int. Res. J. Eng. Technol. (IRJET) 2020, 7, 359–364. [Google Scholar]

- Dhaked, D.K.; Birla, D. Microgrid Designing for Electrical Two-Wheeler Charging Station Supported by Solar PV and Fuel Cell. Indian J. Sci. Technol. 2021, 14, 2517–2525. [Google Scholar] [CrossRef]

- Indu, K.; Kumar, M.A. Electric Vehicle Research: Need, Opportunities, and Challenges. In Handbook of Sustainable Development Through Green Engineering and Technology, 1st ed.; Imprint CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Sheorey, P.; Gandhi, A. Antecedents of green consumer behaviour: A study of consumers in a developing country like India. Int. J. Public Sect. Perform. Manag. 2019, 5, 278. [Google Scholar] [CrossRef]

- Satya Sai Surya Varun, D.; Halder, T.; Basak, A.; Chakravarty, D. A Brief Review of Current Smart Electric Mobility Facilities and Their Future Scope. In Robotics, Control and Computer Vision; Lecture Notes in Electrical Engineering; Springer: Singapore, 2023; pp. 541–566. [Google Scholar] [CrossRef]

- Hema, R.; Venkatarangan, M. Adoption of EV: Landscape of EV and opportunities for India. Meas. Sens. 2022, 24, 100596. [Google Scholar] [CrossRef]

- Sreeram, K.; Preetha, P.K.; Poornachandran, P. Electric Vehicle Scenario in India: Roadmap, Challenges and Opportunities. In Proceedings of the 2019 IEEE International Conference on Electrical, Computer and Communication Technologies (ICECCT), Coimbatore, India, 20–22 February 2019. [Google Scholar] [CrossRef]

- Kesari, J.P.; Sharma, Y.; Goel, C. Opportunities and Scope for Electric Vehicles in India. Int. J. Mech. Eng. 2019, 6, 1–8. [Google Scholar] [CrossRef]

- Ravi, K.; Naveenchandran, P. Automobile manufacturing in India by 2050—War on EV. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Prajeesh, C.B.; Pillai, A.S. Indian smart mobility ecosystem—Key visions and missions. In Proceedings of the Innovations in Computational and Computer Techniques: ICACCT-2021, Virtual Conference, 6–7 May 2021; p. 050005. [Google Scholar]

- Dutt, D. Exploring multi-level interactions in electric vehicle niche evolution in India. Transp. Res. Part D Transp. Environ. 2023, 114, 103538. [Google Scholar] [CrossRef]

- Dixit, S.K.; Singh, A.K. Predicting Electric Vehicle (EV) Buyers in India: A Machine Learning Approach. Rev. Socionetwork Strat. 2022, 16, 221–238. [Google Scholar] [CrossRef]

- Kumar, R.; Bangwal, D. An assessment of sustainable supply chain initiatives in Indian automobile industry using PPS method. Environ. Dev. Sustain. 2022, 25, 9703–9729. [Google Scholar] [CrossRef]

- Tarei, P.K.; Chand, P.; Gupta, H. Barriers to the adoption of electric vehicles: Evidence from India. J. Clean. Prod. 2021, 291, 125847. [Google Scholar] [CrossRef]

- Patyal, V.S.; Kumar, R.; Kushwah, S. Modeling barriers to the adoption of electric vehicles: An Indian perspective. Energy 2021, 237, 121554. [Google Scholar] [CrossRef]

- Virmani, N.; Agarwal, V.; Karuppiah, K.; Agarwal, S.; Raut, R.D.; Paul, S.K. Mitigating barriers to adopting electric vehicles in an emerging economy context. J. Clean. Prod. 2023, 414, 137557. [Google Scholar] [CrossRef]

- Javanmardi, E.; Hoque, M.; Tauheed, A.; Umar, M. Evaluating the Factors Affecting Electric Vehicles Adoption Considering the Sustainable Development Level. World Electr. Veh. J. 2023, 14, 120. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Pradhan, S. Shabbiruddin Barriers in Replacement of Conventional Vehicles by Electric Vehicles in India. Int. J. Decis. Support Syst. Technol. 2023, 15, 1–20. [Google Scholar] [CrossRef]

- Mishra, S.; Verma, S.; Chowdhury, S.; Gaur, A.; Mohapatra, S.; Dwivedi, G.; Verma, P. A Comprehensive Review on Developments in Electric Vehicle Charging Station Infrastructure and Present Scenario of India. Sustainability 2021, 13, 2396. [Google Scholar] [CrossRef]

- Saw, K.; Kedia, A. Estimating the adoption of electric vehicles: A case study of four Indian states. Competition Regul. Netw. Ind. 2023, 24, 120–135. [Google Scholar] [CrossRef]

- Digalwar, A.K.; Rastogi, A. Assessments of social factors responsible for adoption of electric vehicles in India: A case study. Int. J. Energy Sect. Manag. 2023, 17, 251–264. [Google Scholar] [CrossRef]

- Chawla, U.; Mohnot, R.; Mishra, V.; Singh, H.V.; Singh, A.K. Factors Influencing Customer Preference and Adoption of Electric Vehicles in India: A Journey towards More Sustainable Transportation. Sustainability 2023, 15, 7020. [Google Scholar] [CrossRef]

- Kumar, R.R.; Alok, K. Adoption of electric vehicle: A literature review and prospects for sustainability. J. Clean. Prod. 2020, 253, 119911. [Google Scholar] [CrossRef]

- Singh, V.; Singh, V.; Vaibhav, S. Analysis of electric vehicle trends, development and policies in India. Case Stud. Transp. Policy 2021, 9, 1180–1197. [Google Scholar] [CrossRef]

- Das, P.K.; Bhat, M.Y. Global electric vehicle adoption: Implementation and policy implications for India. Environ. Sci. Pollut. Res. 2022, 29, 40612–40622. [Google Scholar] [CrossRef]

- Mordor Intelligence. India Electric Vehicle Market-Size, Share, COVID-19 Impact & Forecasts up to 2028. 2023. Available online: https://www.mordorintelligence.com/ (accessed on 13 May 2024).

- Dhawan, R.; Gupta, S.; Hensley, R.; Huddar, N.; Iyer, B.; Mangaleswaran, R. The Future of Mobility in India: Challenges & Opportunities for the Auto Component Industry; 2017. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/the-future-of-mobility-in-india-challenges-and-opportunities-for-the-auto-component-industry (accessed on 13 May 2024).

- Khurana, A.; Kumar, V.V.R.; Sidhpuria, M. A Study on the Adoption of Electric Vehicles in India: The Mediating Role of Attitude. Vision J. Bus. Perspect. 2020, 24, 23–34. [Google Scholar] [CrossRef]

- Asokan, V.A.; Teah, H.Y.; Kawazu, E.; Hotta, Y. Ambitious EV policy expedites the e-waste and socio-environmental impacts in India. Resour. Conserv. Recycl. 2023, 190, 106829. [Google Scholar] [CrossRef]

- Mahajan, B.; Singh, M.; Pai, S. Mapping the Evolution of Parliamentary Conversations on Air Pollution: A Focus on India’s National Clean Air Program and Electric Vehicles. 2023. Available online: https://www.swaniti.com/wp-content/uploads/2023/06/Mapping-the-Evolution-of-Parliamentary-conversation-on-air-pollution.pdf (accessed on 13 May 2024).

- Srivastava, A.; Kumar, R.R.; Chakraborty, A.; Mateen, A.; Narayanamurthy, G. Design and selection of government policies for electric vehicles adoption: A global perspective. Transp. Res. Part E Logist. Transp. Rev. 2022, 161, 102726. [Google Scholar] [CrossRef]

- Honna Prabhu Lingegowda, B.M.; Santosh Kumar, A.N. A Conceptual Study of Electric Vehicle Market in India. Int. J. Eng. Manag. Res. 2022, 12, 193–198. [Google Scholar] [CrossRef]

- Shrimali, G. Getting to India’s electric vehicle targets cost-effectively: To subsidize or not, and how? Energy Policy 2021, 156, 112384. [Google Scholar] [CrossRef]

- Soman, A.; Ganesan, K.; Kaur, H. India’s Electric Vehicle Transition Impact on Auto Industry and Building the EV Ecosystem. 2019. Available online: https://shaktifoundation.in/wp-content/uploads/2021/12/Indias-Electric-Vehicle-Transition-Report-PDF.pdf (accessed on 13 May 2024).

- Gupta, D.; Garg, A. Sustainable development and carbon neutrality: Integrated assessment of transport transitions in India. Transp. Res. Part D Transp. Environ. 2020, 85, 102474. [Google Scholar] [CrossRef]

- IPCC. Summary for Policymakers; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Hossain, S.; Fang, Y.R.; Ma, T.; Huang, C.; Dai, H. The role of electric vehicles in decarbonizing India’s road passenger toward carbon neutrality and clean air: A state-level analysis. Energy 2023, 273, 127218. [Google Scholar] [CrossRef]

- Hossain, M.; Fang, Y.R.; Ma, T.; Huang, C.; Peng, W.; Urpelainen, J.; Hebbale, C.; Dai, H. Narrowing fossil fuel consumption in the Indian road transport sector towards reaching carbon neutrality. Energy Policy 2023, 172, 113330. [Google Scholar] [CrossRef]

- Shyam, H.S.; Shuaib, I.; Pandey, S.P. Exploring the Supply Chain Challenges in the Area of Lithium-Ion Batteries Used in Electric Vehicles. Macromol. Symp. 2023, 407. [Google Scholar] [CrossRef]

- Vidhi, R.; Shrivastava, P. A Review of Electric Vehicle Lifecycle Emissions and Policy Recommendations to Increase EV Penetration in India. Energies 2018, 11, 483. [Google Scholar] [CrossRef]

- Bhosale, A.P.; Mastud, S.A. Comparative Environmental Impact Assessment of Battery Electric Vehicles and Conventional Vehicles: A Case Study of India. Int. J. Eng. 2023, 36, 965–978. [Google Scholar] [CrossRef]

- Gautam, A.; Akhtar, A.; Shah, M.; Soni, U. Carving strategic resilience roadmap for Indian automotive industry using hybrid analytical approach. Int. J. Bus. Contin. Risk Manag. 2023, 13, 115–137. [Google Scholar] [CrossRef]

- Hsieh, I.-Y.L.; Chossière, G.P.; Gençer, E.; Chen, H.; Barrett, S.; Green, W.H. An Integrated Assessment of Emissions, Air Quality, and Public Health Impacts of China’s Transition to Electric Vehicles. Environ. Sci. Technol. 2022, 56, 6836–6846. [Google Scholar] [CrossRef] [PubMed]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Panigrahi, S.S.; Bahinipati, B.; Jain, V. Sustainable supply chain management. Manag. Environ. Qual. Int. J. 2019, 30, 1001–1049. [Google Scholar] [CrossRef]

- Sezen, B.; Çankaya, S.Y. Effects of Green Manufacturing and Eco-innovation on Sustainability Performance. Procedia Soc. Behav. Sci. 2013, 99, 154–163. [Google Scholar] [CrossRef]

- Çankaya, S.Y.; Sezen, B. Effects of green supply chain management practices on sustainability performance. J. Manuf. Technol. Manag. 2019, 30, 98–121. [Google Scholar] [CrossRef]

- Holden, E.; Linnerud, K.; Banister, D. Sustainable development: Our Common Future revisited. Glob. Environ. Chang. 2014, 26, 130–139. [Google Scholar] [CrossRef]

- De Brito, M.P.; Van der Laan, E.A. Supply Chain Management and Sustainability: Procrastinating Integration in Mainstream Research. Sustainability 2010, 2, 859–870. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Zhang, Q. Impact of sustainable practices on sustainable performance: The moderating role of supply chain visibility. J. Manuf. Technol. Manag. 2021, 32, 1421–1443. [Google Scholar] [CrossRef]

- Saqib, Z.A.; Qin, L.; Menhas, R.; Lei, G. Strategic Sustainability and Operational Initiatives in Small- and Medium-Sized Manufacturers: An Empirical Analysis. Sustainability 2023, 15, 6330. [Google Scholar] [CrossRef]

- Fritz, M.M.C. Sustainable Supply Chain Management; Springer Nature Switzerland AG: Berlin/Heidelberg, Germany, 2019; pp. 1–14. [Google Scholar] [CrossRef]

- Hong, J.; Zhang, Y.; Ding, M. Sustainable supply chain management practices, supply chain dynamic capabilities, and enterprise performance. J. Clean. Prod. 2018, 172, 3508–3519. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Najjar, M.; Small, M.H.; Yasin, M.M. Social Sustainability Strategy across the Supply Chain: A Conceptual Approach from the Organisational Perspective. Sustainability 2020, 12, 10438. [Google Scholar] [CrossRef]

- Sánchez-Flores, R.B.; Cruz-Sotelo, S.E.; Ojeda-Benitez, S.; Ramírez-Barreto, M.E. Sustainable Supply Chain Management—A Literature Review on Emerging Economies. Sustainability 2020, 12, 6972. [Google Scholar] [CrossRef]

- Das, D. Development and validation of a scale for measuring Sustainable Supply Chain Management practices and performance. J. Clean. Prod. 2017, 164, 1344–1362. [Google Scholar] [CrossRef]

- Das, D. Sustainable supply chain management in Indian organisations: An empirical investigation. Int. J. Prod. Res. 2018, 56, 5776–5794. [Google Scholar] [CrossRef]

- Chikán, A.; Czakó, E.; Kiss-Dobronyi, B.; Losonci, D. Firm competitiveness: A general model and a manufacturing application. Int. J. Prod. Econ. 2022, 243, 108316. [Google Scholar] [CrossRef]

- Gopal, P.; Thakkar, J. Sustainable supply chain practices: An empirical investigation on Indian automobile industry. Prod. Plan. Control 2016, 27, 49–64. [Google Scholar] [CrossRef]

- Wang, J.; Dai, J. Sustainable supply chain management practices and performance. Ind. Manag. Data Syst. 2018, 118, 2–21. [Google Scholar] [CrossRef]

- Winter, M.; Knemeyer, A.M. Exploring the integration of sustainability and supply chain management. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 18–38. [Google Scholar] [CrossRef]

- Gong, R.; Xue, J.; Zhao, L.; Zolotova, O.; Ji, X.; Xu, Y. A Bibliometric Analysis of Green Supply Chain Management Based on the Web of Science (WOS) Platform. Sustainability 2019, 11, 3459. [Google Scholar] [CrossRef]

- Wong, C.Y.; Wong, C.W.; Boon-Itt, S. Integrating environmental management into supply chains: A systematic literature review and theoretical framework. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 43–68. [Google Scholar] [CrossRef]

- Geng, R.; Mansouri, S.A.; Aktas, E. The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies. Int. J. Prod. Econ. 2017, 183, 245–258. [Google Scholar] [CrossRef]

- Sepehriar, A.; Eslamipoor, R. An economical single-vendor single-buyer framework for carbon emission policies. J. Bus. Econ. 2024, 94, 927–945. [Google Scholar] [CrossRef]

- Eslamipoor, R.; Sepehriyar, A. Promoting green supply chain under carbon tax, carbon cap and carbon trading policies. Bus. Strat. Environ. 2024, 33, 4901–4912. [Google Scholar] [CrossRef]

- Jamwal, A.; Patidar, A.; Agrawal, R.; Sharma, M.; Manupati, V.K. Analysis of Barriers in Sustainable Supply Chain Management for Indian Automobile Industries. Springer: Berlin/Heidelberg, Germany, 2022; pp. 79–89. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Critical success factors of green supply chain management for achieving sustainability in Indian automobile industry. Prod. Plan. Control 2015, 26, 339–362. [Google Scholar] [CrossRef]

- Digalwar, A.K.; Thomas, R.G.; Rastogi, A. Evaluation of Factors for Sustainable Manufacturing of Electric Vehicles in India. Procedia CIRP 2021, 98, 505–510. [Google Scholar] [CrossRef]

- Luthra, S.; Qadri, M.A.; Garg, D.; Haleem, A. Identification of critical success factors to achieve high green supply chain management performances in Indian automobile industry. Int. J. Logist. Syst. Manag. 2014, 18, 170. [Google Scholar] [CrossRef]

- Mathivathanan, D.; Kannan, D.; Haq, A.N. Sustainable supply chain management practices in Indian automotive industry: A multi-stakeholder view. Resour. Conserv. Recycl. 2018, 128, 284–305. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. J. Clean. Prod. 2016, 121, 142–158. [Google Scholar] [CrossRef]

- Sonar, H.; Mukherjee, A.; Gunasekaran, A.; Singh, R.K. Sustainable supply chain management of automotive sector in context to the circular economy: A strategic framework. Bus. Strat. Environ. 2022, 31, 3635–3648. [Google Scholar] [CrossRef]

- Singh, J.; Hamid, A.B.A.; Garza-Reyes, J.A. Supply chain resilience strategies and their impact on sustainability: An investigation from the automobile sector. Supply Chain Manag. Int. J. 2023, 28, 787–802. [Google Scholar] [CrossRef]

- Mishra, R.; Singh, R.K.; Rana, N.P. Developing environmental collaboration among supply chain partners for sustainable consumption & production: Insights from an auto sector supply chain. J. Clean. Prod. 2022, 338, 130619. [Google Scholar] [CrossRef]

- Balakrishnan, A.; Suresh, J. Green supply chain management in Indian automotive sector. Int. J. Logist. Syst. Manag. 2018, 29, 502. [Google Scholar] [CrossRef]

- Liu, Y.; Srai, J.S.; Evans, S. Environmental management: The role of supply chain capabilities in the auto sector. Supply Chain Manag. Int. J. 2016, 21, 1–19. [Google Scholar] [CrossRef]

- Gedam, V.V.; Raut, R.D.; Jabbour, A.B.L.d.S.; Narkhede, B.E.; Grebinevych, O. Sustainable manufacturing and green human resources: Critical success factors in the automotive sector. Bus. Strat. Environ. 2021, 30, 1296–1313. [Google Scholar] [CrossRef]

- Luthra, S.; Haleem, A. Hurdles in Implementing Sustainable Supply Chain Management: An Analysis of Indian Automobile Sector. Procedia Soc. Behav. Sci. 2015, 189, 175–183. [Google Scholar] [CrossRef]

- Ghosh, S.; Mandal, M.C.; Ray, A. Strategic sourcing model for green supply chain management: An insight into automobile manufacturing units in India. Benchmarking Int. J. 2022, 29, 3097–3132. [Google Scholar] [CrossRef]

- Dixon, J.; Andersen, P.B.; Bell, K.; Træholt, C. On the ease of being green: An investigation of the inconvenience of electric vehicle charging. Appl. Energy 2020, 258, 114090. [Google Scholar] [CrossRef]

- Kapustin, N.O.; Grushevenko, D.A. Long-term electric vehicles outlook and their potential impact on electric grid. Energy Policy 2020, 137, 111103. [Google Scholar] [CrossRef]

- Desai, A.; Patel, C.R. The impact of electric vehicle charging infrastructure on the energy demand of a city. Energy Rep. 2023, 9, 814–823. [Google Scholar] [CrossRef]

- Abhyankar, N.; Mohanty, P.; Deorah, S.; Karali, N.; Paliwal, U.; Kersey, J.; Phadke, A. India’s path towards energy independence and a clean future: Harnessing india’s renewable edge for cost-effective energy independence by 2047. Electr. J. 2023, 36, 107273. [Google Scholar] [CrossRef]

- Han, H. Analysis of India’s New and Renewable Energy Market and Policies and Implications for Korea-India Cooperation. SSRN Electron. J. 2023, 13, 3–4. [Google Scholar] [CrossRef]

- Kuppusamy, K.; Bashir, S.; Ramesh, S.; Ramesh, K. Solar cell-integrated energy storage devices for electric vehicles: A breakthrough in the green renewable energy. Ionics 2022, 28, 4065–4081. [Google Scholar] [CrossRef]

- Makeen, P.; Memon, S.; Elkasrawy, M.A.; Abdullatif, S.O.; Ghali, H.A. Smart green charging scheme of centralized electric vehicle stations. Int. J. Green Energy 2022, 19, 490–498. [Google Scholar] [CrossRef]

- Gulzari, A.; Wang, Y.; Prybutok, V. A green experience with eco-friendly cars: A young consumer electric vehicle rental behavioral model. J. Retail. Consum. Serv. 2022, 65, 102877. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, X.; Sun, J.; Lei, Q.; Zhang, Y. Is it worth promoting battery swapping? A social welfare perspective on provider- and consumer-side incentives. J. Environ. Manag. 2023, 330, 117157. [Google Scholar] [CrossRef]

- Varshney, K.; Varshney, P.K.; Gautam, K.; Tanwar, M.; Chaudhary, M. Current trends and future perspectives in the recycling of spent lead acid batteries in India. Mater. Today Proc. 2020, 26, 592–602. [Google Scholar] [CrossRef]

- Ourici, A. Battery Technologies Comparison for Electric Vehicles. Indian J. Sci. Technol. 2023, 16, 1461–1468. [Google Scholar] [CrossRef]

- Eftekhari, A.; Kim, D.-W. Sodium-ion batteries: New opportunities beyond energy storage by lithium. J. Power Sources 2018, 395, 336–348. [Google Scholar] [CrossRef]

- Manivannan, B.; Kathirvelu, P.; Balasubramanian, R. A review on wireless charging methods—The prospects for future charging of EV. Renew. Energy Focus 2023, 46, 68–87. [Google Scholar] [CrossRef]

- Shu, T.; Papageorgiou, D.J.; Harper, M.R.; Rajagopalan, S.; Rudnick, I.; Botterud, A. From coal to variable renewables: Impact of flexible electric vehicle charging on the future Indian electricity sector. Energy 2023, 269, 126465. [Google Scholar] [CrossRef]

- Barman, P.; Dutta, L.; Azzopardi, B. Electric Vehicle Battery Supply Chain and Critical Materials: A Brief Survey of State of the Art. Energies 2023, 16, 3369. [Google Scholar] [CrossRef]

- Shaikh, M.Y.; Shaikh, N.; Shah, T. A Fundamental Analysis of Selected Battery Companies in India. Int. Res. J. Mod. Eng. Technol. Sci. 2023, 5. [Google Scholar] [CrossRef]

- Penn, I.; Lipton, E. The Lithium Gold Rush: Inside the Race to Power Electric Vehicles. The New York Times, 6 May 2021. [Google Scholar]

- Nygaard, A. The Geopolitical Risk and Strategic Uncertainty of Green Growth after the Ukraine Invasion: How the Circular Economy Can Decrease the Market Power of and Resource Dependency on Critical Minerals. Circ. Econ. Sustain. 2022, 3, 1099–1126. [Google Scholar] [CrossRef]

- Li, Y.; Taghizadeh-Hesary, F. The economic feasibility of green hydrogen and fuel cell electric vehicles for road transport in China. Energy Policy 2022, 160, 112703. [Google Scholar] [CrossRef]

- Singh, P.L.; Sindhwani, R.; Sharma, B.P.; Srivastava, P.; Rajpoot, P.; Lalit; Rahul; Kumar, R. Analyse the Critical Success Factor of Green Manufacturing for Achieving Sustainability in Automotive Sector; Springer: Berlin/Heidelberg, Germany, 2022; pp. 79–94. [Google Scholar] [CrossRef]

- Naim, A.; Muniasamy, A.; Clementking, A.; Rajkumar, R. Relevance of Green Manufacturing and IoT in Industrial Transformation and Marketing Management. In Computational Intelligence Techniques for Green Smart Cities. Green Energy and Technology; Springer: Cham, Switzerland, 2022; pp. 395–419. [Google Scholar] [CrossRef]

- Singh, J.; Singh, C.D.; Deepak, D. Green Manufacturing a Modern Era for Indian Manufacturing Industries: A Review. In Recent Trends in Industrial and Production Engineering; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022; pp. 103–107. [Google Scholar] [CrossRef]

- Umar, M.; Khan, S.A.R.; Zia-Ul-Haq, H.M.; Yusliza, M.Y.; Farooq, K. The role of emerging technologies in implementing green practices to achieve sustainable operations. TQM J. 2021, 34, 232–249. [Google Scholar] [CrossRef]

- Pathak, S.K.; Karwasra, K.; Sharma, V.; Sharma, V. Analysis of Barriers to Green Manufacturing Using Hybrid Approach: An Investigatory Case Study on Indian Automotive Industry. Process Integr. Optim. Sustain. 2021, 5, 545–560. [Google Scholar] [CrossRef]

- Sopadang, A.; Wichaisri, S.; Banomyong, R. Sustainable Supply Chain Performance Measurement A Case Study of the Sugar Industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Rabat, Morocco, 11 April 2017. [Google Scholar]

- Kumar, S.; Dutt, A. Interrelating Financial Performance and Inventory Management: Study of Indian Automobile Industry. Seybold Rep. 2022, 17, 1239–1251. [Google Scholar] [CrossRef]

- Mani, V.; Jabbour, C.J.C.; Mani, K.T. Supply chain social sustainability in small and medium manufacturing enterprises and firms’ performance: Empirical evidence from an emerging Asian economy. Int. J. Prod. Econ. 2020, 227, 107656. [Google Scholar] [CrossRef]

- Badri Ahmadi, H.; Kusi-Sarpong, S.; Rezaei, J. Assessing the social sustainability of supply chains using Best Worst Method. Resour. Conserv. Recycl. 2017, 126, 99–106. [Google Scholar] [CrossRef]

- Zhang, M.; Pawar, K.S.; Bhardwaj, S. Improving supply chain social responsibility through supplier development. Prod. Plan. Control 2017, 28, 500–511. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning, and Operation (Sixth Glob); Pearson Education Ltd.: London, UK, 2016. [Google Scholar]

- Soares, L.O.; Reis, A.d.C.; Vieira, P.S.; Hernández-Callejo, L.; Boloy, R.A.M. Electric Vehicle Supply Chain Management: A Bibliometric and Systematic Review. Energies 2023, 16, 1563. [Google Scholar] [CrossRef]

- Jones, B.; Nguyen-Tien, V.; Elliott, R.J.R. The electric vehicle revolution: Critical material supply chains, trade and development. World Econ. 2023, 46, 2–26. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Gamini, L.; Rajapaksa, P. Impact of Supply Chain Management Practices on Competitive Advantage and Organization Performance: Evidence from the Manufacturing Industry in Sri Lanka. Sri Lanka J. Manag. Stud. 2020, 2, 137–158. [Google Scholar] [CrossRef]

- Mehdikhani, R.; Valmohammadi, C. Strategic collaboration and sustainable supply chain management. J. Enterp. Inf. Manag. 2019, 32, 778–806. [Google Scholar] [CrossRef]

- Khan, M.; Hussain, M.; Saber, H.M. Information sharing in a sustainable supply chain. Int. J. Prod. Econ. 2016, 181, 208–214. [Google Scholar] [CrossRef]

- Liao, S.-H.; Hu, D.-C.; Shih, Y.-S. Supply chain collaboration and innovation capability: The moderated mediating role of quality management. Total. Qual. Manag. Bus. Excel 2021, 32, 298–316. [Google Scholar] [CrossRef]

- Sayed, M.; Hendry, L.C.; Bell, M.Z. Sustainable procurement: Comparing in-house and outsourcing implementation modes. Prod. Plan. Control 2021, 32, 145–168. [Google Scholar] [CrossRef]

- Kähkönen, A.-K.; Lintukangas, K.; Ritala, P.; Hallikas, J. Supplier collaboration practices: Implications for focal firm innovation performance. Eur. Bus. Rev. 2017, 29, 402–418. [Google Scholar] [CrossRef]

- Jermsittiparsert, K.; Rungsrisawa, S. Impact Strategic Sourcing, Supplier Innovativeness, and Information Sharing on Supply Chain Agility. Int. J. Innov. Creat. Change 2019, 5, 397–415. [Google Scholar] [CrossRef]

- Lee, R. The Effect of Supply Chain Management Strategy on Operational and Financial Performance. Sustainability 2021, 13, 5138. [Google Scholar] [CrossRef]

- Bhattacharya, S. Supply Chain Management in Indian Automotive Industry: Complexities, Challenges and Way Ahead. Int. J. Manag. Value Supply Chains 2014, 5, 49–62. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Empirical Analysis of Green Supply Chain Management Practices in Indian Automobile Industry. J. Inst. Eng. (India) Ser. C 2014, 95, 119–126. [Google Scholar] [CrossRef]

- Khot, S.B.; Thiagarajan, S. Resilience and sustainability of supply chain management in the Indian automobile industry. Int. J. Data Netw. Sci. 2019, 3, 339–348. [Google Scholar] [CrossRef]

- Singh, R.K.; Modgil, S. Assessment of Lean Supply Chain Practices in Indian Automotive Industry. Glob. Bus. Rev. 2023, 24, 68–105. [Google Scholar] [CrossRef]

- Mathivathanan, D.; Agarwal, V.; Mathiyazhagan, K.; Saikouk, T.; Appolloni, A. Modeling the pressures for sustainability adoption in the Indian automotive context. J. Clean. Prod. 2022, 342, 130972. [Google Scholar] [CrossRef]

- Ghadge, A.; Mogale, D.; Bourlakis, M.; Maiyar, L.M.; Moradlou, H. Link between Industry 4.0 and green supply chain management: Evidence from the automotive industry. Comput. Ind. Eng. 2022, 169, 108303. [Google Scholar] [CrossRef]

- Fauzdar, C.; Gupta, N.; Goswami, M.; Kumar, R. MICMAC Analysis of Industry 4.0 in Indian Automobile Industry. J. Sci. Ind. Res. 2022, 81, 873–881. [Google Scholar] [CrossRef]

- Agarwal, S.; Saxena, K.K.; Agrawal, V.; Dixit, J.K.; Prakash, C.; Buddhi, D.; Mohammed, K.A. Prioritizing the barriers of green smart manufacturing using AHP in implementing Industry 4.0: A case from Indian automotive industry. TQM J. 2022, 36, 71–89. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Spekman, R.; Davis, E.W. The extended enterprise: A decade later. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 43–61. [Google Scholar] [CrossRef]

- Soosay, C.A.; Hyland, P. A decade of supply chain collaboration and directions for future research. Supply Chain Manag. Int. J. 2015, 20, 613–630. [Google Scholar] [CrossRef]

- Soosay, C.A.; Hyland, P.W.; Ferrer, M. Supply chain collaboration: Capabilities for continuous innovation. Supply Chain Manag. Int. J. 2008, 13, 160–169. [Google Scholar] [CrossRef]

- Shin, N.; Park, S.H.; Park, S. Partnership-Based Supply Chain Collaboration: Impact on Commitment, Innovation, and Firm Performance. Sustainability 2019, 11, 449. [Google Scholar] [CrossRef]

- Kuzma, E.; Padilha, L.S.; Sehnem, S.; Julkovski, D.J.; Roman, D.J. The relationship between innovation and sustainability: A meta-analytic study. J. Clean. Prod. 2020, 259, 120745. [Google Scholar] [CrossRef]

- Hui, Z.; He-Cheng, W.; Min-Fei, Z. Partnership Management, Supply Chain Collaboration, and Firm Innovation Performance: An Empirical Examination. Int. J. Innov. Sci. 2015, 7, 127–138. [Google Scholar] [CrossRef]

- Hudnurkar, M.; Jakhar, S.; Rathod, U. Factors Affecting Collaboration in Supply Chain: A Literature Review. Procedia Soc. Behav. Sci. 2014, 133, 189–202. [Google Scholar] [CrossRef]

- Ramanathan, U.; Gunasekaran, A. Supply chain collaboration: Impact of success in long-term partnerships. Int. J. Prod. Econ. 2014, 147, 252–259. [Google Scholar] [CrossRef]

- Beheshti, H.M.; Clelland, I.J.; Harrington, K.V. Competitive Advantage with Vendor Managed Inventory. J. Promot. Manag. 2020, 26, 836–854. [Google Scholar] [CrossRef]

- Kwateng, K.O.; Fokuoh, B.; Tetteh, F.K. The relationship between vendor managed inventory and operational performance. Mod. Supply Chain Res. Appl. 2022, 4, 202–222. [Google Scholar] [CrossRef]

- Radzuan, K.; Omar, M.F.; Nawi, M.N.M.; Rahim, M.K.I.A.; Yaakob, M. Vendor Managed Inventory Practices: A case in Manufacturing Companies. Int. J. Supply Chain Manag. 2018, 7, 196–201. [Google Scholar]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

- Sharma, M.; Raut, R.D.; Sahu, A.K.; Sahu, N.K.; Antony, J.; Tortorella, G.L. Decision-making framework for supplier selection using an integrated MCDM approach in a lean-agile-resilient-green environment: Evidence from Indian automotive sector. TQM J. 2022, 35, 964–1006. [Google Scholar] [CrossRef]

- Jain, V.; Sangaiah, A.K.; Sakhuja, S.; Thoduka, N.; Aggarwal, R. Supplier selection using fuzzy AHP and TOPSIS: A case study in the Indian automotive industry. Neural Comput. Appl. 2018, 29, 555–564. [Google Scholar] [CrossRef]

- Sytch, M.; Kim, Y.; Page, S. Supplier-Selection Practices for Robust Global Supply Chain Networks: A Simulation Of The Global Auto Industry. Calif. Manag. Rev. 2022, 64, 119–142. [Google Scholar] [CrossRef]

- Juned, M.; Farooquie, J.A. VMI adoption in automotive industries: Two different perspectives. Int. J. Serv. Oper. Manag. 2022, 43, 227. [Google Scholar] [CrossRef]

- Sharma, H.; Sohani, N. Modelling the leagile enablers of supply chain management in Indian automobile sector. Int. J. Soc. Syst. Sci. 2022, 14, 54. [Google Scholar] [CrossRef]

- Meena, P.L.; Katiyar, R.; Kumar, G. Supplier performance and selection from sustainable supply chain performance perspective. Int. J. Prod. Perform. Manag. 2022, 72, 2420–2445. [Google Scholar] [CrossRef]

- Yu, V.F.; Qiu, M.; Gupta, J.N. Improving supplier capability through training: Evidence from the Chinese Automobile Industry. Comput. Ind. Eng. 2022, 163, 107825. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.; Kumari, M. Impact assessment of logistics management practices on supply chain management performance in the automobile industry in India. Int. J. Logist. Econ. Glob. 2022, 9, 319. [Google Scholar] [CrossRef]

- Kumar, R.; Jha, A.; Damodaran, A.; Bangwal, D.; Dwivedi, A. Addressing the challenges to electric vehicle adoption via sharing economy: An Indian perspective. Manag. Environ. Qual. Int. J. 2020, 32, 82–99. [Google Scholar] [CrossRef]

- Venkatasatish, R.; Dhanamjayulu, C. Reinforcement learning based energy management systems and hydrogen refuelling stations for fuel cell electric vehicles: An overview. Int. J. Hydrogen Energy 2022, 47, 27646–27670. [Google Scholar] [CrossRef]

- Fridrich, M.; Pražanová, A.; Knap, V.; Weinzettel, J. Hydrogen in Automotive: LCA Study. In Proceedings of the 47th International Spring Seminar on Electronics Technology (ISSE), Prague, Czech Republic, 15–19 May 2024; pp. 1–5. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Achal, D.K.; Vijaya, G.S. Vendor Partnerships in Sustainable Supply Chains in the Indian Electric Two-Wheeler Industry—A Systematic Review of the Literature. Sustainability 2024, 16, 6603. https://doi.org/10.3390/su16156603

Achal DK, Vijaya GS. Vendor Partnerships in Sustainable Supply Chains in the Indian Electric Two-Wheeler Industry—A Systematic Review of the Literature. Sustainability. 2024; 16(15):6603. https://doi.org/10.3390/su16156603

Chicago/Turabian StyleAchal, D. K., and G. S. Vijaya. 2024. "Vendor Partnerships in Sustainable Supply Chains in the Indian Electric Two-Wheeler Industry—A Systematic Review of the Literature" Sustainability 16, no. 15: 6603. https://doi.org/10.3390/su16156603

APA StyleAchal, D. K., & Vijaya, G. S. (2024). Vendor Partnerships in Sustainable Supply Chains in the Indian Electric Two-Wheeler Industry—A Systematic Review of the Literature. Sustainability, 16(15), 6603. https://doi.org/10.3390/su16156603