Development and Performance Study of Composite Protein Foaming Agent Based on Human Hair Residue

Abstract

:1. Introduction

2. Materials Development and Experimental Method

2.1. Selection of Foaming Agents

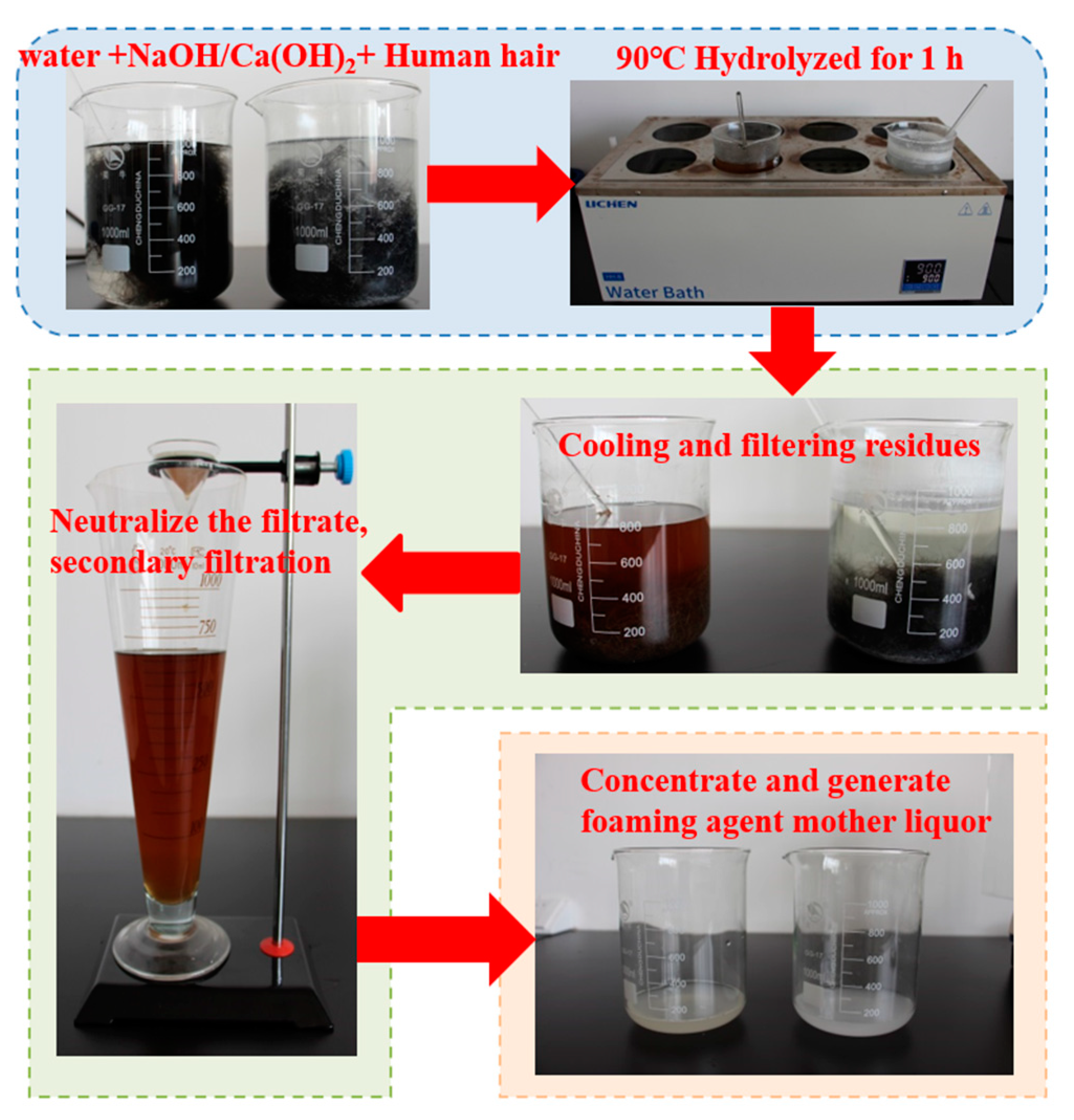

2.2. Preparation of Foaming Agent Mother Liquor

2.3. Modification and Compounding of Foaming Agents

- (1)

- The concentration of the protein mother liquor foaming agent was fixed, and the best concentration was determined to be 2.0 g/L.

- (2)

- Four 30 mL foaming agent aqueous solutions with a mixed concentration of 2.0 g/L were poured into five 1000 mL empty beakers, respectively, and K12, LAS, AOS, and SLS were added successively to make their concentrations 0.8, 0.9, 1.0, 1.5, 2.0, 2.5 and 3.0 g/L, respectively, for the compound experiment.

- (3)

- The data were recorded, and the optimal surfactant and its concentration were determined according to the foam volume and foam settling distance.

3. Results and Analysis

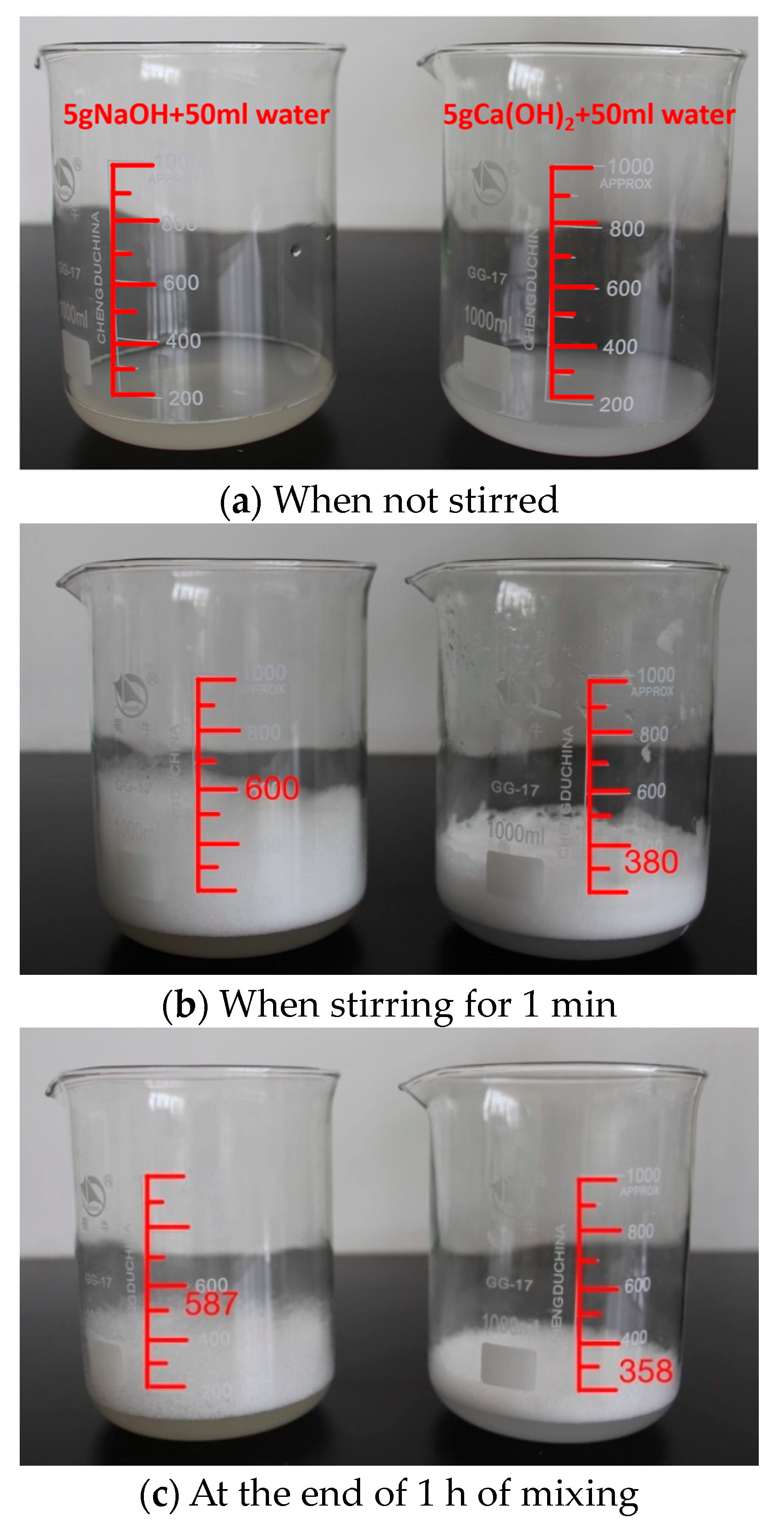

3.1. Selection of Hydrolysis Drugs

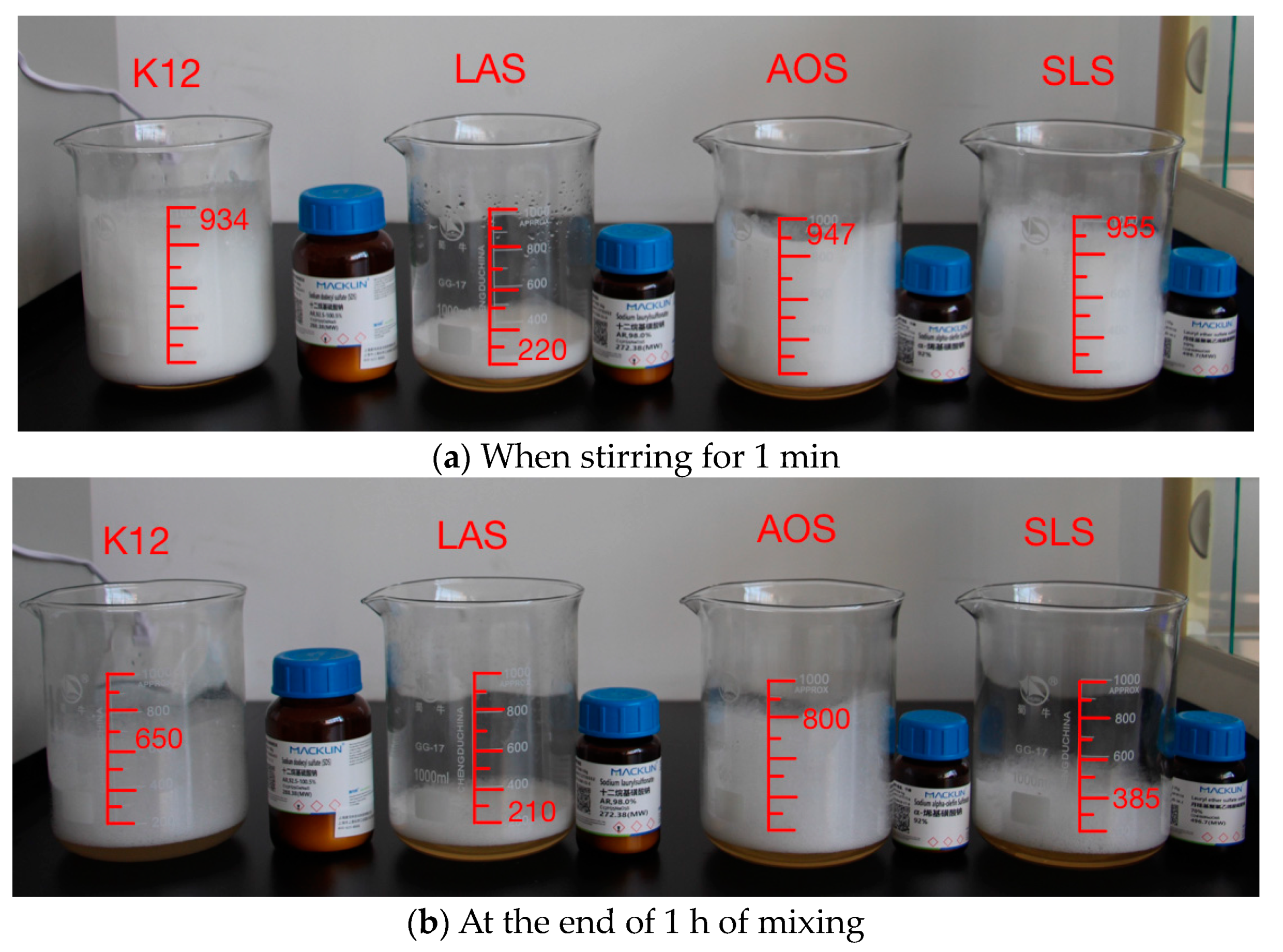

3.2. The Selection and Dosage of the Active Agent Is Determined

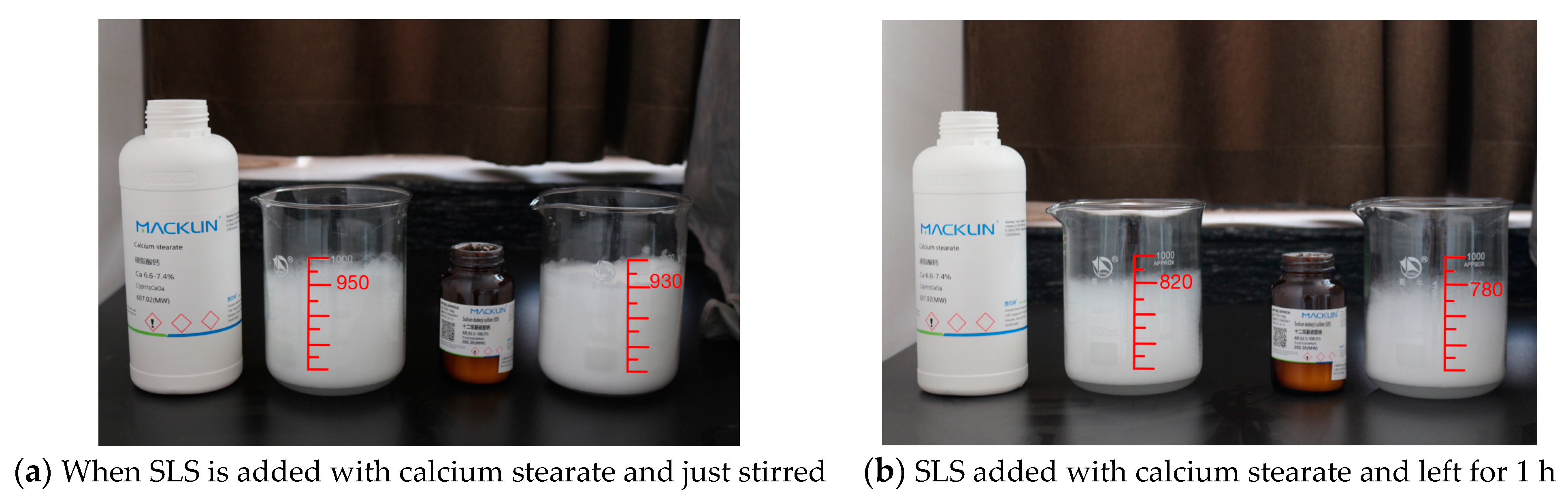

3.3. Selection and Determination of Dosage of Foaming Stabilizers

3.4. Study on Performance of Foamed Concrete Based on Human Hair Slag Composite Foaming Agent

- (1)

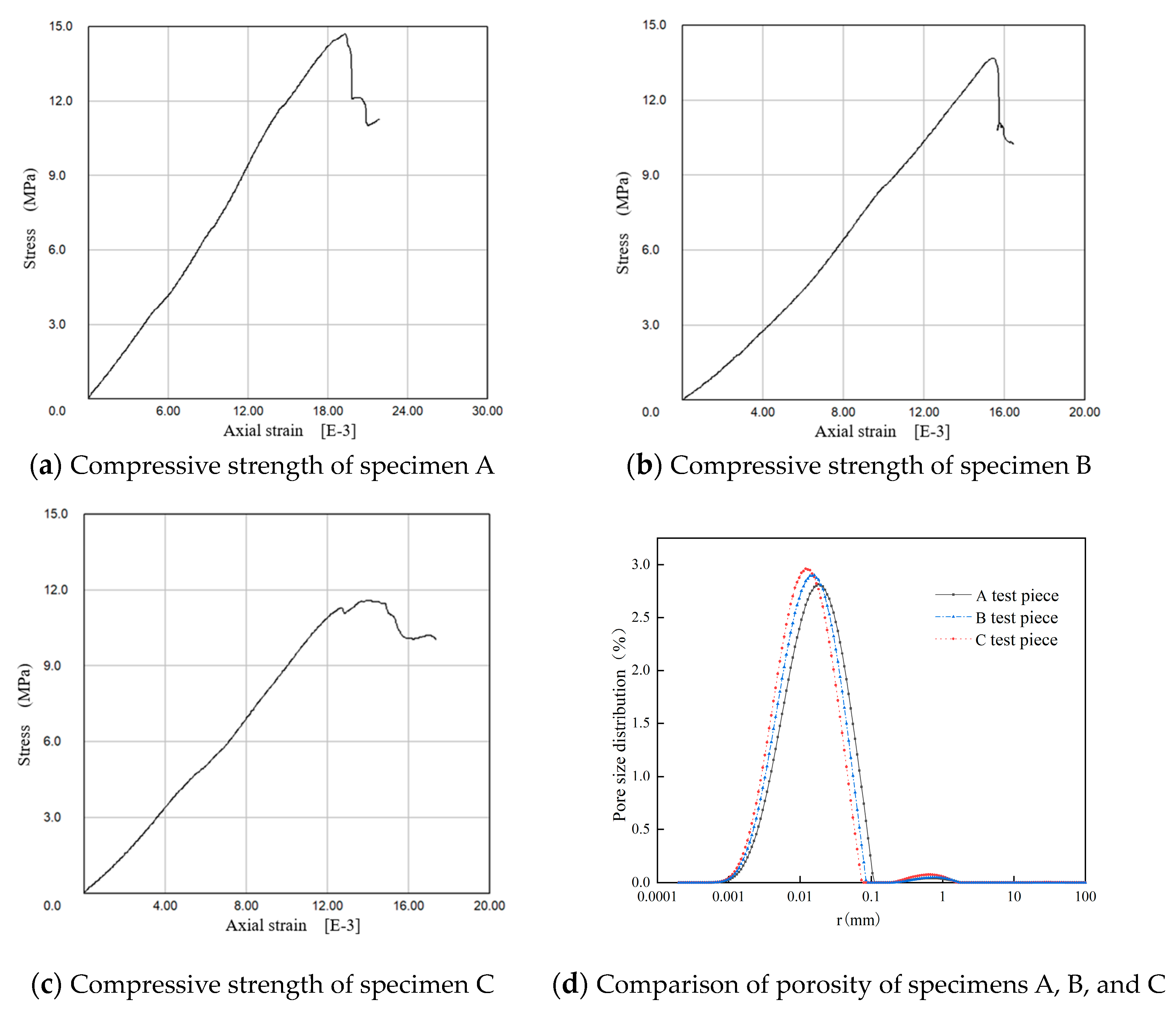

- In terms of porosity, the higher the foam content, the smaller the pore size of the foamed concrete because the increase in foam content can generate more and smaller bubbles. These small bubbles can fill the gaps between cement and sand particles, thereby restricting the formation of larger bubbles and making the overall pore size distribution more uniform. As the foam content increased, the foamed concrete formed more pore structures, leading to an increase in porosity.

- (2)

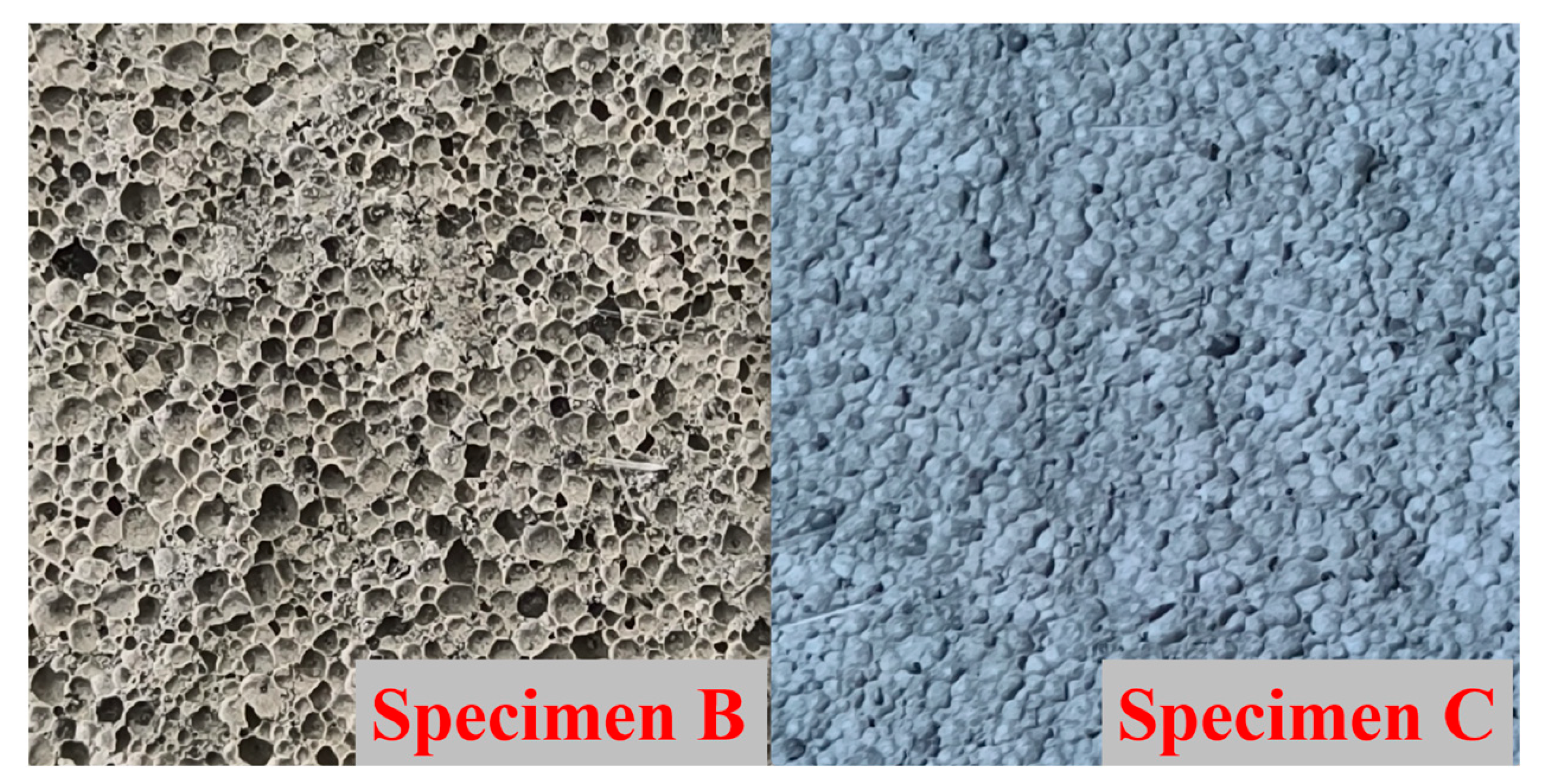

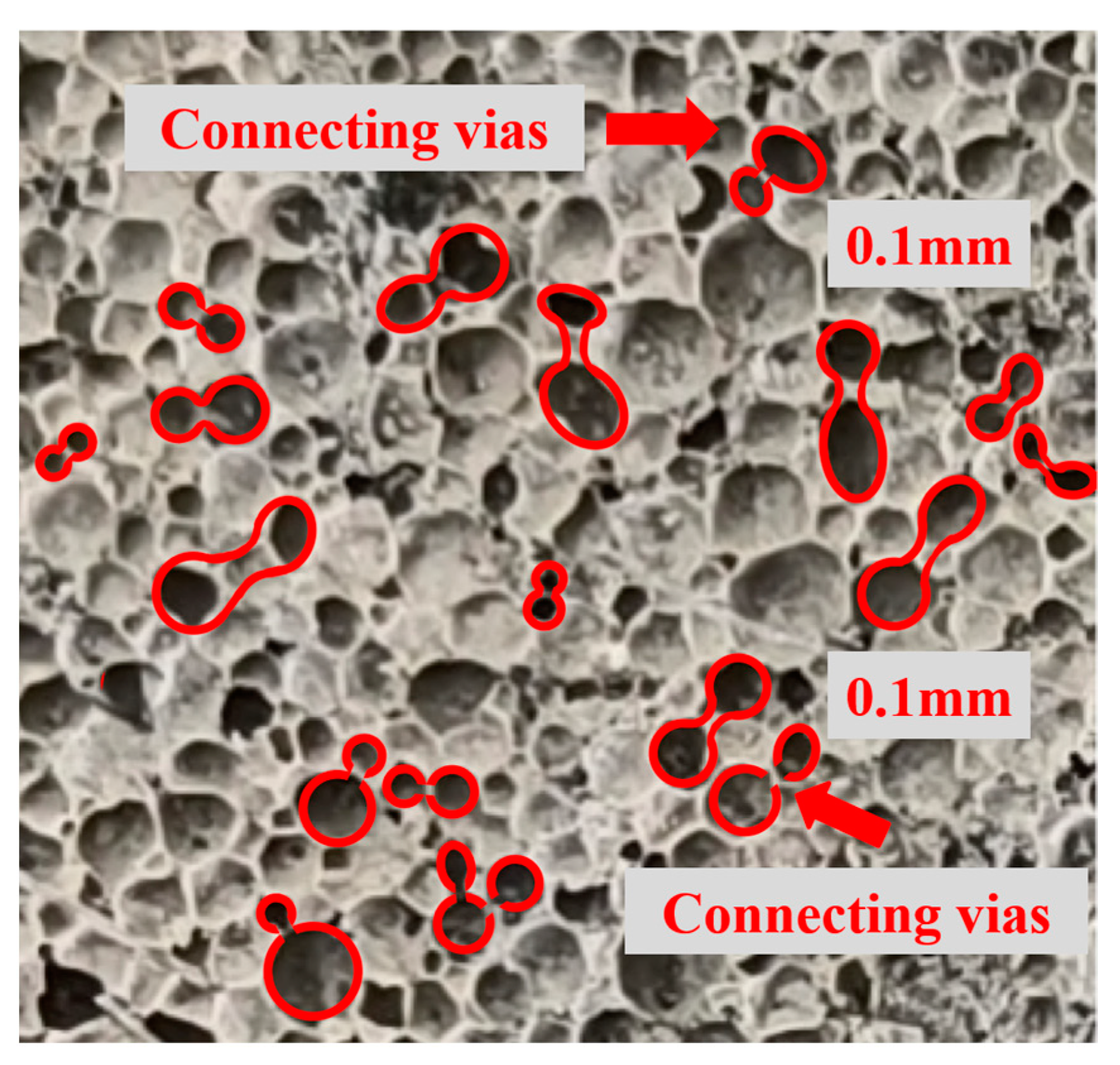

- In terms of permeability, the permeability first increased and then decreased as the amount of foam increased. Among them, specimen A had the lowest permeability, and specimen B had the highest permeability. Adding foam caused the porosity of the concrete to increase, making it easier for gases to penetrate into the concrete. Simultaneously, as the foam content in specimen A was the smallest, its porosity was correspondingly smaller, leading to lower permeability. Specimen B had a moderate amount of foam, correspondingly larger porosity, and more formed interconnected pores, leading to higher permeability. Although the porosity of the C specimen is increased, it is basically small pores and poor connectivity, as shown in Figure 12. When the right amount of foam enters the concrete, some of it bursts, forming a network of interconnected pores. This connected porosity can promote the penetration of moisture and improve the permeability of concrete. However, the dispersion of excess foam in the concrete slows down, and the pores formed at the same time are no longer connected to each other, causing the pores in the concrete to become more isolated and disconnected, which means that the pores in the concrete cannot form a continuous channel, hindering the penetration of moisture and other substances. In this case, the permeability of the concrete will be reduced.

- (3)

- In terms of compressive strength, the larger the amount of foam, the lower the compressive strength of the foamed concrete. Among them, specimen A had the highest compressive strength, and specimen C had the lowest. Adding too much foaming agent foam reduced the density of the concrete, leading to a decrease in compressive strength. Since specimen A had the smallest amount of foam, its porosity was correspondingly smaller, leading to higher compressive strength. In contrast, specimen C, which had the largest amount of foam, had the largest porosity, leading to lower compressive strength. Hence, a negative correlation exists between porosity and compressive strength.

- (4)

- According to Table 3, Yue Wenping et al. [12] found that the compressive strength of foamed concrete prepared with hydrogen peroxide as a chemical foaming agent was generally 14 MPa. Guo Yisong [26] found that the compressive strength of foamed concrete prepared using plant protein as a foaming agent was 1.52 MPa. Gao Zhihan et al. [27] found that the compressive strength of four different density foamed concretes prepared using physical foaming methods was 16 MPa. The compressive strength of the A, B, and C specimens prepared in this study all exceeded 11 MPa, demonstrating excellent support effects. For low-rank coals, the permeability generally ranged from 10−3 to 10−5 MD, while the permeability of high-rank coals ranged from 10−7 to 10−9 MD. The permeability of specimens A, B, and C far exceeded that of coal permeability. An experimental analysis showed that when the amount of foaming agent added was 25 mL, specimen B had the best performance with a compressive strength of 13.665 MPa, a permeability of 2.48 MD, and a porosity of 18.141%. The cross-sectional image of specimen B is shown in Figure 13. The foam size is relatively uniform, the overall shape is spherical, the compressive strength is high, and the pores are well connected with good permeability, demonstrating that it is a new type of high-performance drilling protection material.

4. Conclusions

- (1)

- Human hair waste has not been effectively treated and utilized. As a composite protein foaming agent mother liquor material, human hair waste can be used as a low-cost and environmentally friendly raw material through waste utilization. Comparing the hydrolysis effects of sodium hydroxide and calcium hydroxide, the foaming volume of the foaming agent prepared with sodium hydroxide as the hydrolysis agent was 600 mL, with a foaming ratio of 12, and a 1 h settling distance of 13 mm. The performance of the sodium hydroxide hydrolysis solution was significantly better than that of calcium hydroxide. Therefore, sodium hydroxide was selected as the hydrolysis agent for the protein.

- (2)

- Through the experiment of compounding and improvement, it was found that the foaming capacity was ranked as SLS > AOS > K12 > LAS, and the stabilizing capacity was ranked as AOS > K12 > SLS > LAS. SLS showed the best foaming performance, and AOS showed the best stabilizing performance. LAS did not show significant modification effects. The variations in foaming volume and 1 h settling distance in the four compounding systems followed a roughly inverted “V” shape. The foam volume reached its peak when the surfactant dosage was 2.0 g/L. Comparing the stabilizing agents arabic gum and calcium stearate, calcium stearate as an anionic stabilizing agent showed better results when compounded with anionic surfactants. The optimal compounding scheme for foam performance was determined as 2 g/L sodium lauryl ether sulfate (SLS) + 0.3% calcium stearate.

- (3)

- The foam content showed a negative correlation with compressive strength and a positive correlation with porosity. As the foam content increased, the porosity of the foamed concrete increased, leading to a decrease in compressive strength. The permeability initially increased and then decreased with increasing foam content. A higher foam content generally resulted in a higher porosity and better permeability of the foamed concrete. However, as the foam content continued to increase, the formed pores in the concrete became predominantly closed small pores with poor connectivity. Therefore, when the foam content was 25 mL, the permeability of the foamed concrete reached 2.48 MD, with optimal internal pore connectivity, a compressive strength of 13.665 MPa, and a porosity of 18.141%. This indicates that it is a new type of drilling protection material with high compressive strength, high permeability, and environmental friendliness.

- (1)

- The steps of preparing compound protein blowing agents are too complicated, and the site is not easy to construct, which needs to be further optimized. In the future, it can be considered to optimize the process flow of hydrolyzed protein, reduce cumbersome operations and steps, and achieve a more efficient and simplified hydrolyzed human hair process by controlling reaction conditions. As for the compound foaming agent, the price of the improved compound drugs and foam stabilizers is high, which leads to high production costs. In the formulation design of compound foaming agents, alternative drugs and foam stabilizers can be sought to reduce costs and maintain performance.

- (2)

- Currently, commonly used grouting materials mainly include concrete, polymer materials, etc. Future research can explore new materials, such as high-strength fiber materials, composite materials, etc., to improve strength and durability. Future research can explore a more efficient and accurate grouting process, including the optimization of injection pressure and speed control, in order to improve the grouting effect and construction efficiency. Combined with intelligent technology, such as sensors and data acquisition and analysis, real-time monitoring and an evaluation of the screen and grouting collaborative protection system is carried out to achieve dynamic monitoring and early warning of borehole stability and improve the safety of the protection system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Wang, H.; Yang, M.; Wang, P.; Han, L. Research and application of the impact mechanism of instability and collapse of drainage boreholes on gas extraction. J. Coal Ind. 2023, 48, 3102–3115. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, J. Research on deformation and instability characteristics of extraction boreholes in deep mining of soft coal seams. China Sci. Technol. Work. Saf. 2017, 13, 152–158. [Google Scholar]

- Ye, D.; Liu, G.; Wang, F.; Gao, F.; Yang, T.; Zhu, J. Fractal hydrological-thermal-mechanical analysis of unconventional reservoir: A fracture-matrix structure model for gas extraction. Int. J. Heat Mass Transf. 2023, 202, 123670. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Ma, T.; Cheng, G.; Fan, S.; Yang, T. The mechanics of frost heave with stratigraphic microstructure evolution. Eng. Geol. 2023, 319, 107119. [Google Scholar] [CrossRef]

- Peng, R.; Xue, D.; Sun, H.; Zhou, H. Exploration of Strong Disturbance Characteristics in Deep Mining. J. Coal Sci. 2019, 44, 1359–1368. [Google Scholar]

- Cheng, Y.; Liu, H.; Guo, P.; Pan, R.; Wang, L. Theoretical model for permeability evolution and unloading permeability enhancement of deep gas bearing coal bodies. J. Coal Sci. 2014, 39, 1650–1658. [Google Scholar]

- Wang, Y.; Sun, Y.; Wang, Z.; Song, W. Mechanical characteristics of drilling blockage in soft and protruding coal seams. J. Coal Sci. 2015, 40, 119–125. [Google Scholar]

- Zhang, Q.; Wang, C.; Wang, S. Application Test of Screen Tube Hole Protection Technology and Research on Gas Extraction Effect. Coal Technol. 2016, 35, 162–164. [Google Scholar] [CrossRef]

- Yang, J.; Du, M.; Yang, X.; Yu, C. Study on the preparation of high-performance Foam concrete from coal gangue in Weibei. Appl. Chem. Ind. 2018, 47, 1838–1840. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, P.; Li, S.; Liu, C.; Cheng, R.; Chang, J. Experimental study and field application of anti collapse support materials for gas drainage borehole sealing section. J. Min. Saf. Eng. 2021, 38, 199–205. [Google Scholar] [CrossRef]

- Liu, R.; Ou, Y.; Yang, Y.; Qi, W. The relationship between frost resistance and pore characteristics of hydrogen peroxide foamed Foam concrete. J. Silic. 2014, 42, 1055–1063+1069. [Google Scholar]

- Yue, W.; Ling, W.; Liu, C. Study on the influence of different foaming agents on the performance of Foam concrete for hole protection of extraction boreholes. Coal Mine Saf. 2020, 51, 25–28+33. [Google Scholar] [CrossRef]

- Li, T.; Huang, F.; Li, L.; Zhu, J.; Jiang, X.; Huang, Y. Preparation and properties of sulphoaluminate cement-based foamed concrete with high performance. Constr. Build. Mater. 2020, 263, 120945. [Google Scholar] [CrossRef]

- Hou, L.; Li, J.; Lu, Z.; Niu, Y. Influence of foaming agent on cement and foam concrete. Constr. Build. Mater. 2021, 280, 122399. [Google Scholar] [CrossRef]

- Sahu, S.S.; Gandhi, I.S.R. Evaluation of performance of foam produced with different methodologies for use in foam concrete production. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 17–19 May 2019; IOP Publishing: Bristol, UK, 2019; Volume 652, p. 012050. [Google Scholar]

- Compaore, A.; Sawadogo, M.; Sawadogo, Y.; Ouedraogo, M.; Sorgho, B.; Seynou, M.; Blanchart, P.; Zerbo, L. Preparation and characterization of foamed concrete using a foaming agent and local mineral resources from Burkina Faso. Results Mater. 2023, 17, 100365. [Google Scholar] [CrossRef]

- Hashim, M.; Tantray, M. Comparative study on the performance of protein and synthetic-based foaming agents used in foamed concrete. Case Stud. Constr. Mater. 2021, 14, e00524. [Google Scholar] [CrossRef]

- Shi, X.; Huo, J.; Yin, B.; Yao, G.; Lu, Z. Study on the preparation and performance of protein based concrete foaming agents using pig hoof horn powder. New Build. Mater. 2008, 4, 74–77. [Google Scholar]

- Huang, F.; Deng, D.; Zhang, Y. Research and application of an animal protein foaming agent. Tianjin Chem. Ind. 2014, 28, 16–20. [Google Scholar]

- Bai, Y.; Tian, R.; Wu, J. Experimental study on the performance of surfactant modified animal protein foaming agent. New Build. Mater. 2021, 48, 100–103. [Google Scholar]

- Bai, Y.; Wu, J. Effect of compound modified animal protein on the performance of Foam concrete. Green Sci. Technol. 2021, 23, 213–215+225. [Google Scholar] [CrossRef]

- Yin, S.; Li, Z.; Wang, E.; Niu, Y.; Tian, H.; Li, X.; Li, H.; Yang, C. The infrared thermal effect of coal failure with different impact types and its relationship with bursting liability. Infrared Phys. Technol. 2024, 138, 105263. [Google Scholar] [CrossRef]

- Rong, H.; Zhang, J.; Zhang, L.; Zhang, Y.; Xu, R.; Liu, Z. Development and performance study of bio based foaming agent for Foam concrete. Silic. Bull. 2020, 39, 90–95. [Google Scholar]

- GB/T19274-2011; Geosynthetics Plastic Geocell. National Technical Committee for Standardization of Plastic Products: Chengdu, China, 2011.

- Zhao, C. Experimental Study on Polymer Modified Cement-Based Foam Concrete; Chongqing University: Chongqing, China, 2012. [Google Scholar]

- Guo, Y.; Liu, L.; Chen, J. Experimental study on the preparation of Foam concrete with green foaming agent from camellia oleifera meal. Silic. Bull. 2023, 42, 1226–1232+1241. [Google Scholar] [CrossRef]

- Gao, Z.; Chen, B.; Chen, J.; Yuan, Z. Pore structure and mechanical properties of Foam concrete in freeze-thaw environment. J. Compos. Mater. 2024, 41, 827–838. [Google Scholar] [CrossRef]

| K12 | LAS | AOS | SLS | |||||

|---|---|---|---|---|---|---|---|---|

| Foaming Volume | Subsidence Distance | Foaming Volume | Subsidence Distance | Foaming Volume | Subsidence Distance | Foaming Volume | Subsidence Distance | |

| 0.8 g/L | 476 mL | 7 mm | 201 mL | —— | 582 mL | 9 mm | 831 mL | 32 mm |

| 0.9 g/L | 503 mL | 7 mm | 212 mL | —— | 596 mL | 9 mm | 894 mL | 37 mm |

| 1.0 g/L | 515 mL | 9 mm | 210 mL | —— | 600 mL | 10 mm | 900 mL | 40 mm |

| 1.5 g/L | 800 mL | 15 mm | 211 mL | —— | 710 mL | 13 mm | 920 mL | 51 mm |

| 2.0 g/L | 934 mL | 36 mm | 220 mL | —— | 947 mL | 18 mm | 955 mL | 55 mm |

| 2.5 g/L | 910 mL | 31 mm | 215 mL | —— | 930 mL | 17 mm | 947 mL | 55 mm |

| 3.0 g/L | 887 mL | 29 mm | 210 mL | —— | 820 mL | 17 mm | 942 mL | 53 mm |

| AOS | SLS | |||

|---|---|---|---|---|

| Add Calcium Stearate | Calcium Stearate Is Not Added | Add Calcium Stearate | Calcium Stearate Is Not Added | |

| Foaming volume | 830 mL | 920 mL | 950 mL | 930 mL |

| 1 h Subsidence distance | 7 mm | 19 mm | 9 mm | 17 mm |

| Researcher | Sample | Preparation Method | Foaming Agent | Compressive Strength (MPa) | Permeability (MD) | Porosity (%) |

|---|---|---|---|---|---|---|

| Yue Wenping | —— | Chemical Foaming | H2O2 | 14 | —— | —— |

| Guo Yisong | —— | Chemical Foaming | Plant Protein | 1.52 | —— | —— |

| Gao Zhihan | —— | Physical Foaming | —— | 16 | —— | —— |

| This Study | Sample A | —— | —— | >11 | —— | —— |

| This Study | Sample B | —— | 25 mL Compound Foaming Agent | 13.665 | 2.48 | 18.141 |

| This Study | Sample C | —— | —— | >11 | —— | —— |

| Low-Rank Coal | —— | —— | —— | —— | 10−3~10−5 MD | —— |

| High-Rank Coal | —— | —— | —— | —— | 10−7~10−9 MD | —— |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Du, S.; Han, L.; Feng, X.; Yang, M. Development and Performance Study of Composite Protein Foaming Agent Based on Human Hair Residue. Sustainability 2024, 16, 6608. https://doi.org/10.3390/su16156608

Zhang X, Du S, Han L, Feng X, Yang M. Development and Performance Study of Composite Protein Foaming Agent Based on Human Hair Residue. Sustainability. 2024; 16(15):6608. https://doi.org/10.3390/su16156608

Chicago/Turabian StyleZhang, Xuebo, Shuaiqi Du, Linxiu Han, Xiaojun Feng, and Ming Yang. 2024. "Development and Performance Study of Composite Protein Foaming Agent Based on Human Hair Residue" Sustainability 16, no. 15: 6608. https://doi.org/10.3390/su16156608