A Social Assessment Framework to Derive a Social Score for Green Material Selection: A Case Study from the Sri Lankan Cement Industry

Abstract

:1. Introduction

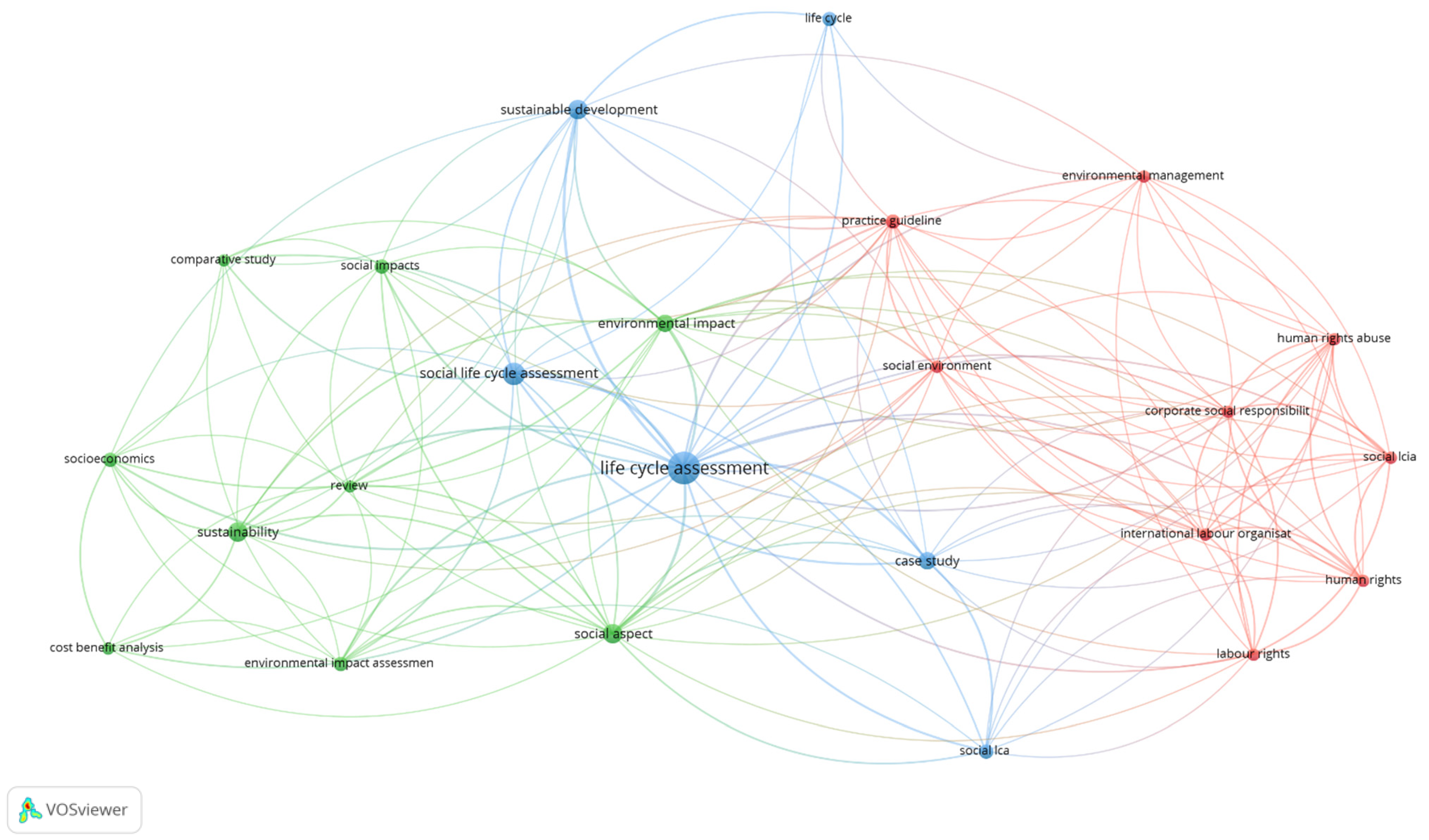

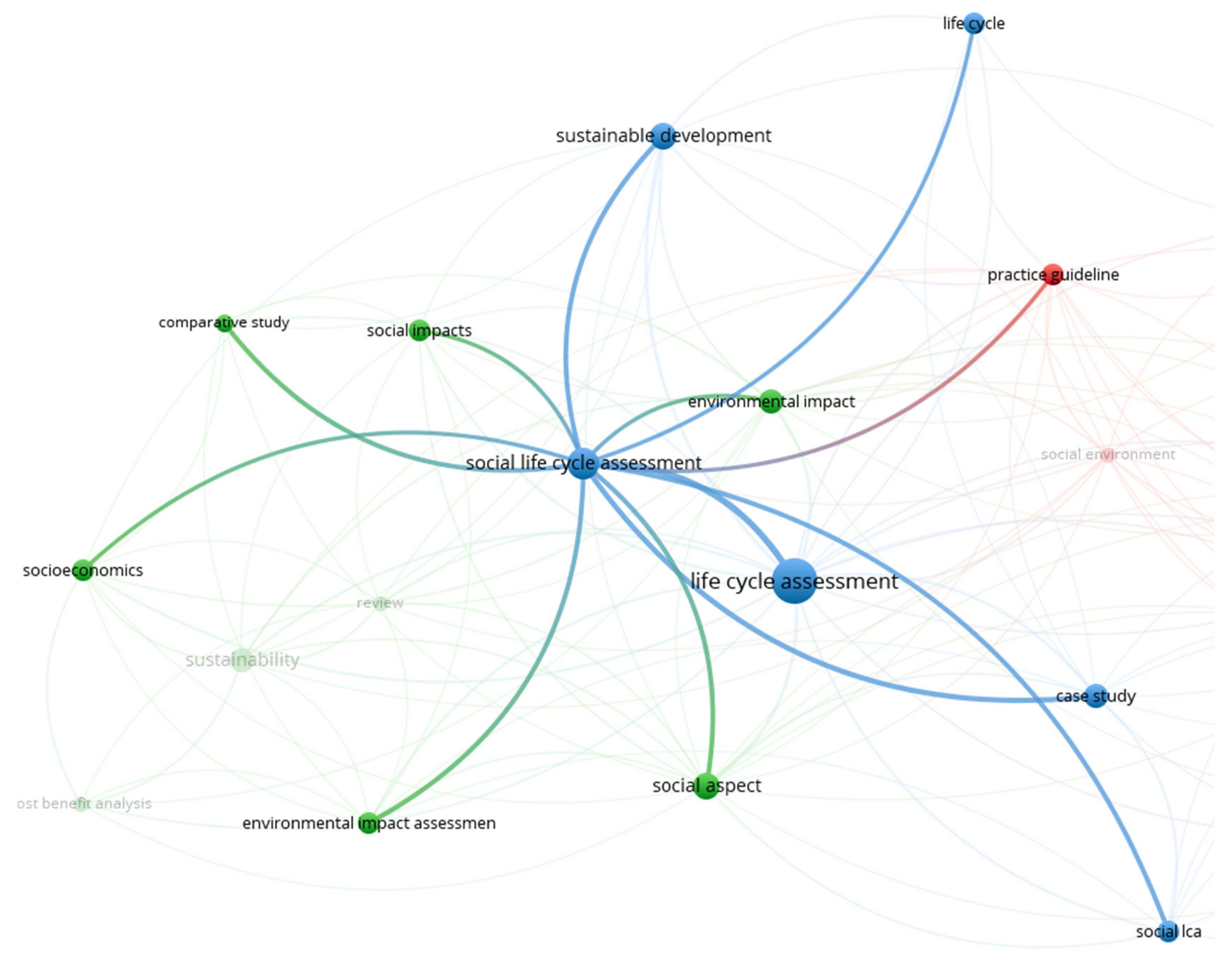

2. Theoretical Background

2.1. Need for a Social Assessment Framework

2.2. Social Assessment Criteria and Indicators

3. Research Methodology

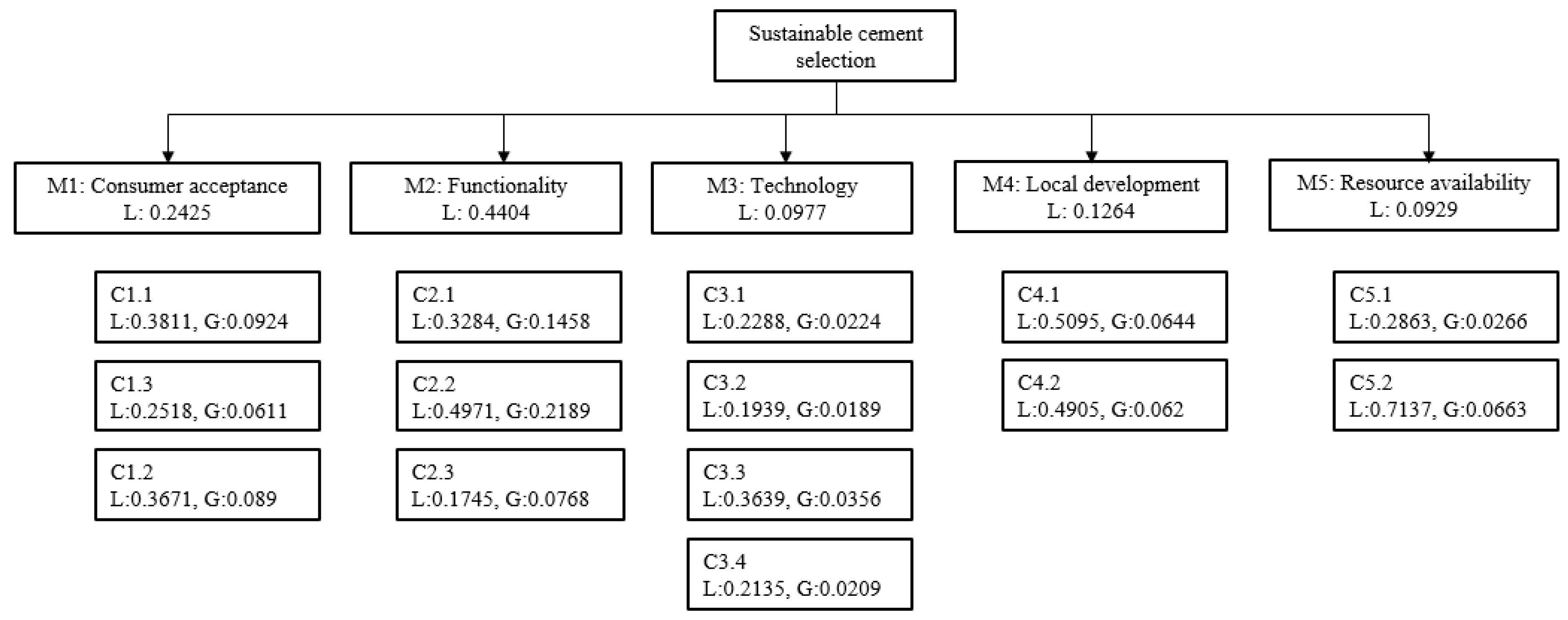

3.1. Weighing of Criteria

3.2. Scoring System

3.3. Alternatives for Ranking

4. Results

4.1. Sample Characteristics

4.2. Relative Importance of Social Criteria

4.3. Scoring and Ranking of Alternatives

5. Discussion

6. Conclusions

- The research demonstrates that social aspects, such as consumer acceptance, local development, and resource availability play a significant role in shaping the sustainability of cement materials. This highlights the need for a more comprehensive approach to material selection that encompasses these social dimensions;

- The observed variation in weightage decisions highlights the need for a multidisciplinary approach to cement sustainability. Industry practitioners’ practical insights are crucial for ensuring that sustainability measures are feasible and effective in real-world scenarios. Academics, on the other hand, play a vital role in advancing sustainable technologies and conducting research that aid industry practices;

- This diversity of perspectives can lead to a more comprehensive and balanced approach to sustainable cement production. Collaboration between academia and industry can bridge these differences and foster innovation, leading to more sustainable and socially responsible cement products;

- Industry specialists put more focus on consumer acceptance. On the other hand, academics, while recognizing the importance of consumer acceptance, prioritize other research areas such as technology or sustainability assessment. This divergence in priorities suggests that academics prioritize broader research areas, including green technology assessment and sustainable production methods. They bring attention to the long-term sustainability and environmental implications of cement materials. In addition, it shows that factors such as practical experience, research interests, and the context in which these experts operate influence this decision-making.

- One notable area of convergence among both industry practitioners and academics is functionality criteria. The consensus on the importance of material strength, durability, and visual quality underscores the universal significance of these functional attributes in cement materials. Cement types that excel in functionality are well-positioned to meet construction project requirements effectively.

- The overall weighting of the criteria functionality emerged as the most important criteria, with the highest weightage (44.04%), followed by consumer acceptance (24.25%), local development (12.64%), technology (9.77%), and resource availability (9.29%).

- The consistency checks in this research, yielding consistency ratios well within the established threshold, attested to the soundness of the methodological approach adopted. By ensuring that the experts’ pairwise comparisons aligned with a high degree of consistency, the study effectively mitigated the potential for subjectivity or inconsistencies in the data.

- The study ranked the cement types according to the overall social sustainability scores. CEM II/B-M took the top position, followed by CEM IV/A, CEM II/A-S, CEM II/A-V, CEM I, and CEM II/A-L. These rankings serve as a valuable guide for stakeholders in the cement industry, enabling them to make informed decisions that align with sustainability principles.

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, M.; Qureshi, M.N.; Mallick, J.; Ben Kahla, N. Selection of Sustainable Supplementary Concrete Materials Using OSM-AHP-TOPSIS Approach. Adv. Mater. Sci. Eng. 2019, 2019, 2850480. [Google Scholar] [CrossRef]

- Arukala, S.R.; Pancharathi, R.K.; Pulukuri, A.R. Evaluation of Sustainable Performance Indicators for the Built Environment Using AHP Approach. J. Inst. Eng. India Ser. A 2019, 100, 619–631. [Google Scholar] [CrossRef]

- Hosseinijou, S.A.; Mansour, S.; Shirazi, M.A. Social Life Cycle Assessment for Material Selection: A Case Study of Building Materials. Int. J. Life Cycle Assess. 2014, 19, 620–645. [Google Scholar] [CrossRef]

- Yasantha Abeysundara, U.G.; Babel, S. A Quest for Sustainable Materials for Building Elements in Sri Lanka: Foundations. Environ. Prog. Sustain. Energy 2010, 29, 370–381. [Google Scholar] [CrossRef]

- Fernando, A.; Siriwardana, C.; Law, D.; Gunasekara, C.; Zhang, K.; Gamage, K. A Scoping Review and Analysis of Green Construction Research: A Machine Learning Aided Approach. SASBE 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Global Cement Report, 14th ed.Tradeship Publications Ltd.: Dorking, UK, 2020.

- Keshani, N.; Sathsara, A.; Asanka, L.; Arachchige, U.; Anjalee, S. Cement Industry in Sri Lanka. JRTE 2020, 1, 16–27. [Google Scholar]

- Wijayasundara, M.; Crawford, R.H.; Mendis, P. Comparative Assessment of Embodied Energy of Recycled Aggregate Concrete. J. Clean. Prod. 2017, 152, 406–419. [Google Scholar] [CrossRef]

- International Cement Review 2022. Available online: https://www.carbonclean.com/hubfs/International%20Cement%20Review/Carbon%20Clean%20-%20International%20Cement%20Review%20September%202022.pdf (accessed on 28 June 2024).

- Yosef, F.A.; Jum’a, L.; Alatoom, M. Identifying and Categorizing Sustainable Supply Chain Practices Based on Triple Bottom Line Dimensions: Evaluation of Practice Implementation in the Cement Industry. Sustainability 2023, 15, 7323. [Google Scholar] [CrossRef]

- Coffetti, D.; Crotti, E.; Gazzaniga, G.; Carrara, M.; Pastore, T.; Coppola, L. Pathways towards Sustainable Concrete. Cem. Concr. Res. 2022, 154, 106718. [Google Scholar] [CrossRef]

- Kulasuriya, C.; Vimonsatit, V.; Dias, W.P.S. Performance Based Energy, Ecological and Financial Costs of a Sustainable Alternative Cement. J. Clean. Prod. 2021, 287, 125035. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life Cycle Greenhouse Gas Emissions of Blended Cement Concrete Including Carbonation and Durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D. Influence of Blended Cements on the Concrete Resistance to Carbonation. In Brittle Matrix Composites 10; Elsevier: Amsterdam, The Netherlands, 2012; pp. 125–134. ISBN 978-0-85709-988-4. [Google Scholar]

- Kulasuriya, C.; Dias, P.; Vimonsatit, V. Investigation of Social Concerns Regarding a Sustainable Cement. J. Eng. 2024, 30, 1–20. [Google Scholar] [CrossRef]

- Ekener-Petersen, E.; Finnveden, G. Potential Hotspots Identified by Social LCA—Part 1: A Case Study of a Laptop Computer. Int. J. Life Cycle Assess. 2013, 18, 127–143. [Google Scholar] [CrossRef]

- Dreyer, L.C.; Hauschild, M.Z.; Schierbeck, J. Characterisation of Social Impacts in LCA: Part 1: Development of Indicators for Labour Rights. Int. J. Life Cycle Assess. 2010, 15, 247–259. [Google Scholar] [CrossRef]

- Dreyer, L.C.; Hauschild, M.Z.; Schierbeck, J. Characterisation of Social Impacts in LCA. Part 2: Implementation in Six Company Case Studies. Int. J. Life Cycle Assess. 2010, 15, 385–402. [Google Scholar] [CrossRef]

- Lopez, A.D.; Razza, F.; Slimani, D.; Ramos, M.H.; Gordillo, P.C.; Pastor, M.C. Report on the Current Situation Analysis: Recyclability, Social and Economic Requirements Evaluation and How It Can Affect New Developments. 2009. [Google Scholar]

- Kruse, S.A.; Flysjö, A.; Kasperczyk, N.; Scholz, A.J. Socioeconomic Indicators as a Complement to Life Cycle Assessment—An Application to Salmon Production Systems. Int. J. Life Cycle Assess. 2009, 14, 8–18. [Google Scholar] [CrossRef]

- Manhart, A. Key Social Impacts of Electronics Production and WEEE-Recycling in China. 2007. [Google Scholar]

- Matos, S.; Hall, J. Integrating Sustainable Development in the Supply Chain: The Case of Life Cycle Assessment in Oil and Gas and Agricultural Biotechnology. J. Oper. Manag. 2007, 25, 1083–1102. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of Construction Materials: Methodologies, Applications and Future Directions for Sustainable Decision-Making. Case Stud. Constr. Mater. 2023, 19, e02326. [Google Scholar] [CrossRef]

- GBCSL. Green Labelling System; GBCSL: Colombo, Sri Lanka, 2012. [Google Scholar]

- GBCSL Green Rating System for Built Environment 2013. Available online: https://www.srilankagbc.org/green-rating-system-for-built-environment/ (accessed on 28 June 2024).

- Escorcia Hernández, J.R.; Torabi Moghadam, S.; Lombardi, P. Sustainability Assessment in Social Housing Environments: An Inclusive Indicators Selection in Colombian Post-Pandemic Cities. Sustainability 2023, 15, 2830. [Google Scholar] [CrossRef]

- Fatourehchi, D.; Zarghami, E. Social Sustainability Assessment Framework for Managing Sustainable Construction in Residential Buildings. J. Build. Eng. 2020, 32, 101761. [Google Scholar] [CrossRef]

- Rashid, K.; Rehman, M.U.; De Brito, J.; Ghafoor, H. Multi-Criteria Optimization of Recycled Aggregate Concrete Mixes. J. Clean. Prod. 2020, 276, 124316. [Google Scholar] [CrossRef]

- Reddy, A.S.; Kumar, P.R.; Raj, P.A. Development of Sustainable Performance Index (SPI) for Self-Compacting Concretes. J. Build. Eng. 2020, 27, 100974. [Google Scholar] [CrossRef]

- Bakhoum, E.S.; Brown, D.C. An Automated Decision Support System for Sustainable Selection of Structural Materials. Int. J. Sustain. Eng. 2015, 8, 80–92. [Google Scholar] [CrossRef]

- Al-Atesh, E.A.; Rahmawati, Y.; Zawawi, N.A.W.A.; Utomo, C. A Decision-Making Model for Supporting Selection of Green Building Materials. Int. J. Constr. Manag. 2023, 23, 922–933. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Valipour, A.; Ismail, M.; Rahmat, A.R. Rank of Green Building Material Criteria Based on the Three Pillars of Sustainability Using the Hybrid Multi Criteria Decision Making Method. J. Clean. Prod. 2018, 173, 82–99. [Google Scholar] [CrossRef]

- Bakhoum, E.S.; Brown, D.C. Developed Sustainable Scoring System for Structural Materials Evaluation. J. Constr. Eng. Manag. 2012, 138, 110–119. [Google Scholar] [CrossRef]

- Hossain, U.; Liu, J.-C.; Xuan, D.; Ng, S.T.; Ye, H.; Abdulla, S.J. Designing Sustainable Concrete Mixes with Potentially Alternative Binder Systems: Multicriteria Decision Making Process. J. Build. Eng. 2022, 45, 103587. [Google Scholar] [CrossRef]

- Figueiredo, K.; Pierott, R.; Hammad, A.W.A.; Haddad, A. Sustainable Material Choice for Construction Projects: A Life Cycle Sustainability Assessment Framework Based on BIM and Fuzzy-AHP. Build. Environ. 2021, 196, 107805. [Google Scholar] [CrossRef]

- AL-Nassar, F.; Ruparathna, R.; Chhipi-Shrestha, G.; Haider, H.; Hewage, K.; Sadiq, R. Sustainability Assessment Framework for Low Rise Commercial Buildings: Life Cycle Impact Index-Based Approach. Clean Technol. Environ. Policy 2016, 18, 2579–2590. [Google Scholar] [CrossRef]

- Wang Chen, H.M.; Chou, S.-Y.; Luu, Q.D.; Yu, T.H.-K. A Fuzzy MCDM Approach for Green Supplier Selection from the Economic and Environmental Aspects. Math. Probl. Eng. 2016, 2016, 8097386. [Google Scholar] [CrossRef]

- Hagerty, M.R.; Land, K.C. Constructing Summary Indices of Quality of Life: A Model for the Effect of Heterogeneous Importance Weights. Sociol. Methods Res. 2007, 35, 455–496. [Google Scholar] [CrossRef]

- Saaty, T.L.; Özdemir, M.S. How Many Judges Should There Be in a Group? Ann. Data. Sci. 2014, 1, 359–368. [Google Scholar] [CrossRef]

- Kurda, R.; De Brito, J.; Silvestre, J.D. A Comparative Study of the Mechanical and Life Cycle Assessment of High-Content Fly Ash and Recycled Aggregates Concrete. J. Build. Eng. 2020, 29, 101173. [Google Scholar] [CrossRef]

- Goyal, S.; Routroy, S.; Singhal, A. Analyzing Environment Sustainability Enablers Using Fuzzy DEMATEL for an Indian Steel Manufacturing Company. J. Eng. Des. Technol. 2019, 17, 300–329. [Google Scholar] [CrossRef]

- Franciosi, C.; Di Pasquale, V.; Iannone, R.; Miranda, S. Multi-Stakeholder Perspectives on Indicators for Sustainable Maintenance Performance in Production Contexts: An Exploratory Study. J. Qual. Maint. Eng. 2020. ahead-of-print. [Google Scholar] [CrossRef]

- Brescia-Norambuena, L.; González, M.; Avudaiappan, S.; Saavedra Flores, E.I.; Grasley, Z. Improving Concrete Underground Mining Pavements Performance through the Synergic Effect of Silica Fume, Nanosilica, and Polypropylene Fibers. Constr. Build. Mater. 2021, 285, 122895. [Google Scholar] [CrossRef]

- Kubler, S.; Robert, J.; Derigent, W.; Voisin, A.; Le Traon, Y. A State-of the-Art Survey & Testbed of Fuzzy AHP (FAHP) Applications. Expert Syst. Appl. 2016, 65, 398–422. [Google Scholar] [CrossRef]

- Odu, G. Weighting Methods for Multi-Criteria Decision Making Technique. J. Appl. Sci. Environ. Manag. 2019, 23, 1449. [Google Scholar] [CrossRef]

- Kabir, G. Comparative analysis of ahp and fuzzy ahp models for multicriteria inventory classification. Int. J. Fuzzy Log. Syst. 2011, 1, 1–16. [Google Scholar]

- Liu, Y.; Eckert, C.M.; Earl, C. A Review of Fuzzy AHP Methods for Decision-Making with Subjective Judgements. Expert Syst. Appl. 2020, 161, 113738. [Google Scholar] [CrossRef]

- Saaty, R.W. The Analytic Hierarchy Process—What It Is and How It Is Used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Peng, G.; Han, L.; Liu, Z.; Guo, Y.; Yan, J.; Jia, X. An Application of Fuzzy Analytic Hierarchy Process in Risk Evaluation Model. Front. Psychol. 2021, 12, 715003. [Google Scholar] [CrossRef] [PubMed]

- Vafaei, N.; Ribeiro, R.A.; Camarinha-Matos, L.M. Normalization Techniques for Multi-Criteria Decision Making: Analytical Hierarchy Process Case Study. In Technological Innovation for Cyber-Physical Systems; Camarinha-Matos, L.M., Falcão, A.J., Vafaei, N., Najdi, S., Eds.; Springer International Publishing: Cham, Switzerland, 2016; Volume 470, pp. 261–269. ISBN 978-3-319-31164-7. [Google Scholar]

- Saaty, T.L. Decision Making with the Analytic Hierarchy Process. IJSSCI 2008, 1, 83. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M. Perception of User Criteria in the Context of Sustainability of Modern Methods of Construction Based on Wood. Sustainability 2018, 10, 116. [Google Scholar] [CrossRef]

- Kayani, S.A.; Warsi, S.S.; Liaqait, R.A. A Smart Decision Support Framework for Sustainable and Resilient Supplier Selection and Order Allocation in the Pharmaceutical Industry. Sustainability 2023, 15, 5962. [Google Scholar] [CrossRef]

- Lee, W.J.; Mwebaza, R. The Role of the Climate Technology Centre and Network as a Climate Technology and Innovation Matchmaker for Developing Countries. Sustainability 2020, 12, 7956. [Google Scholar] [CrossRef]

- Suchith Reddy, A.; Anand Raj, P. Developing a Material Sustainable Performance Score (MSPS) to Select an Alternative Cementitious Material. Cem. Wapno Beton 2019, 24, 68–76. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Gnanavelbabu, A.; Lokesh Prabhuraj, B. A Sustainable Assessment Model for Material Selection in Construction Industries Perspective Using Hybrid MCDM Approaches. JAMR 2019, 16, 234–259. [Google Scholar] [CrossRef]

- De Luca, P.; Carbone, I.; Nagy, J.B. Green building materials: A review of state of the art studies of innovative materials. J. Green Build. 2017, 12, 141–161. [Google Scholar] [CrossRef]

- Akadiri, P.O.; Olomolaiye, P.O. Development of Sustainable Assessment Criteria for Building Materials Selection. Eng. Constr. Arch. Manag. 2012, 19, 666–687. [Google Scholar] [CrossRef]

- Lovecchio, N.; Shaikh, F.; Rosano, M.; Ceravolo, R.; Biswas, W. Environmental Assessment of Supplementary Cementitious Materials and Engineered Nanomaterials Concrete. AIMS Environ. Sci. 2020, 7, 13–30. [Google Scholar] [CrossRef]

- Rhaouti, Y.; Taha, Y.; Benzaazoua, M. Assessment of the Environmental Performance of Blended Cements from a Life Cycle Perspective: A Systematic Review. Sustain. Prod. Consum. 2023, 36, 32–48. [Google Scholar] [CrossRef]

| Reference | Case Study/Application | |

|---|---|---|

| Simple | Comparative | |

| [16] | A laptop in several countries | |

| [17,18] | Manufacturing processes | |

| [19] | Plastic family materials in EU countries | |

| [20] | Food production system | |

| [21] | Chinese electronics industry | |

| [22] | Oil and gas; agricultural biotechnology | |

| [3] | Concrete and steel as building materials in Iran | |

| Main Criteria | Sub-Criteria |

|---|---|

| M1. Consumer Acceptance (Consumer awareness and acceptance to use the product which determines the viability of the product) | 1.1 Eco-friendliness with Conformity to Standards (is extra assurance for the consumers and is a positive attribute for protecting the environment) |

| 1.2 Market Reputation (Depending on the brand service and brand knowledge, consumers’ preferences differ with the brand and type of cement) | |

| 1.3 Affordability (Price that the users can afford) | |

| M2. Functionality (The role that the product plays for its customers in terms of providing the desired strength and other properties of the product) | 2.1 Ease of Use for the Intended Purpose |

| 2.2 Material Strength and Durability | |

| 2.3 Visual Quality | |

| M3. Technology (Use of green technology assessment is vital) | 3.1 Use of Renewable Energy (Sustainable development needs evaluating the use of renewable resources) |

| 3.2 Use of Alternate Fuel (Sustainable development needs evaluating the use of green technologies) | |

| 3.3 Reuse Content (Industrial/other byproducts used) | |

| 3.4 Environmentally Friendly Production (Quantification of embodied energy) | |

| M4. Local Development (Creation of value to local resources and jobs) | 4.1 Local Material Use (Important for prioritizing purposes given the current economic situation and restrictions on importing products) |

| 4.2 Use of Locally Available Waste Materials (Sustainable development needs evaluating the use of green technologies involving local development) | |

| M5. Resource Availability (Feasibility to produce sustainably) | 5.1 Short-term Resource Availability (confirms the longevity of the product) |

| 5.2 Long-term Resource Availability (Sustainability concerns for future generations) |

| Expert No. | Professional Field | Area of Expertise | Years of Experience |

|---|---|---|---|

| 1 | Lecturer—Structural Engineering | Civil/Structural Engineering | 8 years |

| 2 | Senior Professor/Lecturer— Structural Engineering | Civil/Structural Engineering | 14 years |

| 3 | Head of Products and Solutions—Cement Manufacturing | Concrete and Cement Technology | 38 years |

| 4 | Quality Assurance Manager | Ready-mix Concrete | 10 years |

| 5 | General Manager | Green Certification Green Materials | 6 years |

| 6 | Project Manager | Building Construction | 7 years |

| 7 | Structural Engineer | Building Construction | 15 years |

| 8 | Quality assurance Manager | Building Materials | 8 years |

| 9 | Director | Cement Manufacturing | 20 years |

| 10 | Senior Professor/Lecturer | Civil/Sustainable Engineering | 12 years |

| Saaty Scale | Definitions | Triangular Fuzzy Scale (L,M,U) |

|---|---|---|

| 1 | Equally important | (1,1,1) |

| 3 | Weakly important | (2,3,4) |

| 5 | Fairly important | (4,5,6) |

| 7 | Strongly important | (6,7,8) |

| 9 | Absolutely important | (9,9,9) |

| 2 | Intermittent values between two adjacent scales | (1,2,3) |

| 4 | (3,4,5) | |

| 6 | (5,6,7) | |

| 8 | (7,8,9) |

| Main Criteria | Sub-Criteria | Indicators |

|---|---|---|

| M1. Consumer acceptance | 1.1 Eco-friendliness with conformity to standards | Clinker factor specified, per SLS standards |

| 1.2 Market reputation | 1. Years in business 2. Customer engagement for brand 3. Customer engagement for cement product | |

| 1.3 Affordability | Price | |

| M2. Functionality | 2.1 Ease of use for the intended purpose | 1. Workability of the mix experienced by users 2. Early strength |

| 2.2 Material strength and durability | 1. Expected strength achievement experienced by users 2. Durability properties | |

| 2.3 Visual quality | Color of cement | |

| M3. Technology | 3.1 Use of renewable energy | 1. ≥50% renewable energy (both thermal electrical) 2. ≥30% renewable energy 3. <30% renewable energy |

| 3.2 Use of alternate fuel | 1. % of alternate fuel ≥ 25% of conventional fuel use 2. % of alternate fuel < 25% of conventional fuel use | |

| 3.3 Reuse content | 1. % reused content ≥ 25% of conventional material use 2. %reuse content < 25% of conventional material use | |

| 3.4 Environmentally friendly production | Embodied energy | |

| M4. Local development | 4.1 Local material use | 1. % local material use< 50% conventional raw materials and distance from raw material source to manufacturing facility ≥ 50 km 2. % local material use ≥ 50% conventional raw materials and distance from raw material source to manufacturing facility ≥ 50 km 3. % local material use < 50% conventional raw materials and distance from raw material source to manufacturing facility < 50 km 4. % local material use ≥ 50% conventional raw materials and distance from raw material source to manufacturing facility < 50 km |

| 4.2 Use of locally available waste materials | 1. % alternate material usage < 25% conventional materials 2. % alternate material usage ≥ 25% conventional materials | |

| M5. Resource availability | 5.1 Short-term resource availability | Availability for next 5 years |

| 5.2 Long-term resource availability | Availability for next 50 years |

| Cement Type | Composition % | |||||

|---|---|---|---|---|---|---|

| Designation | BS EN 197-1 Cement Notation | Slag | Fly Ash | Limestone | Gypsum | Clinker |

| Portland cement | CEM I | - | - | - | 5 | 95 |

| Portland slag cement | CEM II/A-S | 5 | - | 21 | 4.5 | 69.5 |

| Portland fly ash cement | CEM II/A-V | - | 18 | 3 | 5 | 74 |

| Portland limestone cement | CEM II/A-L | - | 5 | 18 | 5 | 72 |

| Portland composite cement | CEM II/B-M | 10.5 | 7 | 12 | 4.5 | 66 |

| Pozzolanic cement | CEM IV/A | - | 28.5 | 2 | 4.5 | 65 |

| Participant Category | Academia | Industry | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Participant Number | P1 | P2 | P10 | P3 | P4 | P5 | P6 | P7 | P8 | P9 | |

| Criteria weights(%) | Crit M1 | 7.64 | 15.47 | 32.40 | 41.57 | 39.75 | 12.27 | 13.21 | 16.44 | 38.09 | 50.23 |

| Crit M2 | 54.01 | 56.02 | 29.92 | 41.57 | 28.04 | 62.70 | 57.36 | 54.79 | 22.07 | 20.17 | |

| Crit M3 | 10.74 | 6.79 | 12.02 | 5.68 | 6.06 | 7.46 | 9.99 | 7.09 | 10.86 | 11.18 | |

| Crit M4 | 17.91 | 6.72 | 18.40 | 7.04 | 9.27 | 6.45 | 14.37 | 15.92 | 16.39 | 12.11 | |

| Crit M5 | 9.70 | 15.00 | 7.26 | 4.14 | 16.88 | 11.12 | 5.07 | 5.76 | 12.59 | 6.31 | |

| Main Criteria | Consistency Ratio |

|---|---|

| M1 | 0.00011 |

| M2 | 0.00425 |

| M3 | 0.01027 |

| M4 | 0.00007 |

| M5 | 0.00005 |

| Cement Type | Overall Score | Normalized Score |

|---|---|---|

| CEM I | 2.945 | 0.676 |

| CEM II/A-LL | 2.836 | 0.650 |

| CEM II/A-S | 3.666 | 0.841 |

| CEM II/A-V | 3.567 | 0.818 |

| CEM II/B-M | 4.360 | 1.000 |

| CEM IV/A | 4.099 | 0.940 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernando, A.; Siriwardana, C.; Gunasekara, C.; Law, D.W.; Zhang, G.; Gamage, J.C.P.H. A Social Assessment Framework to Derive a Social Score for Green Material Selection: A Case Study from the Sri Lankan Cement Industry. Sustainability 2024, 16, 6632. https://doi.org/10.3390/su16156632

Fernando A, Siriwardana C, Gunasekara C, Law DW, Zhang G, Gamage JCPH. A Social Assessment Framework to Derive a Social Score for Green Material Selection: A Case Study from the Sri Lankan Cement Industry. Sustainability. 2024; 16(15):6632. https://doi.org/10.3390/su16156632

Chicago/Turabian StyleFernando, Ashani, Chandana Siriwardana, Chamila Gunasekara, David William Law, Guomin Zhang, and J. C. P. H. Gamage. 2024. "A Social Assessment Framework to Derive a Social Score for Green Material Selection: A Case Study from the Sri Lankan Cement Industry" Sustainability 16, no. 15: 6632. https://doi.org/10.3390/su16156632