Application of Guar Gum Treatment of Basalt Residual-Soil Shallow Slope in Early Ecological Restoration

Abstract

:1. Introduction

2. Materials and Methods

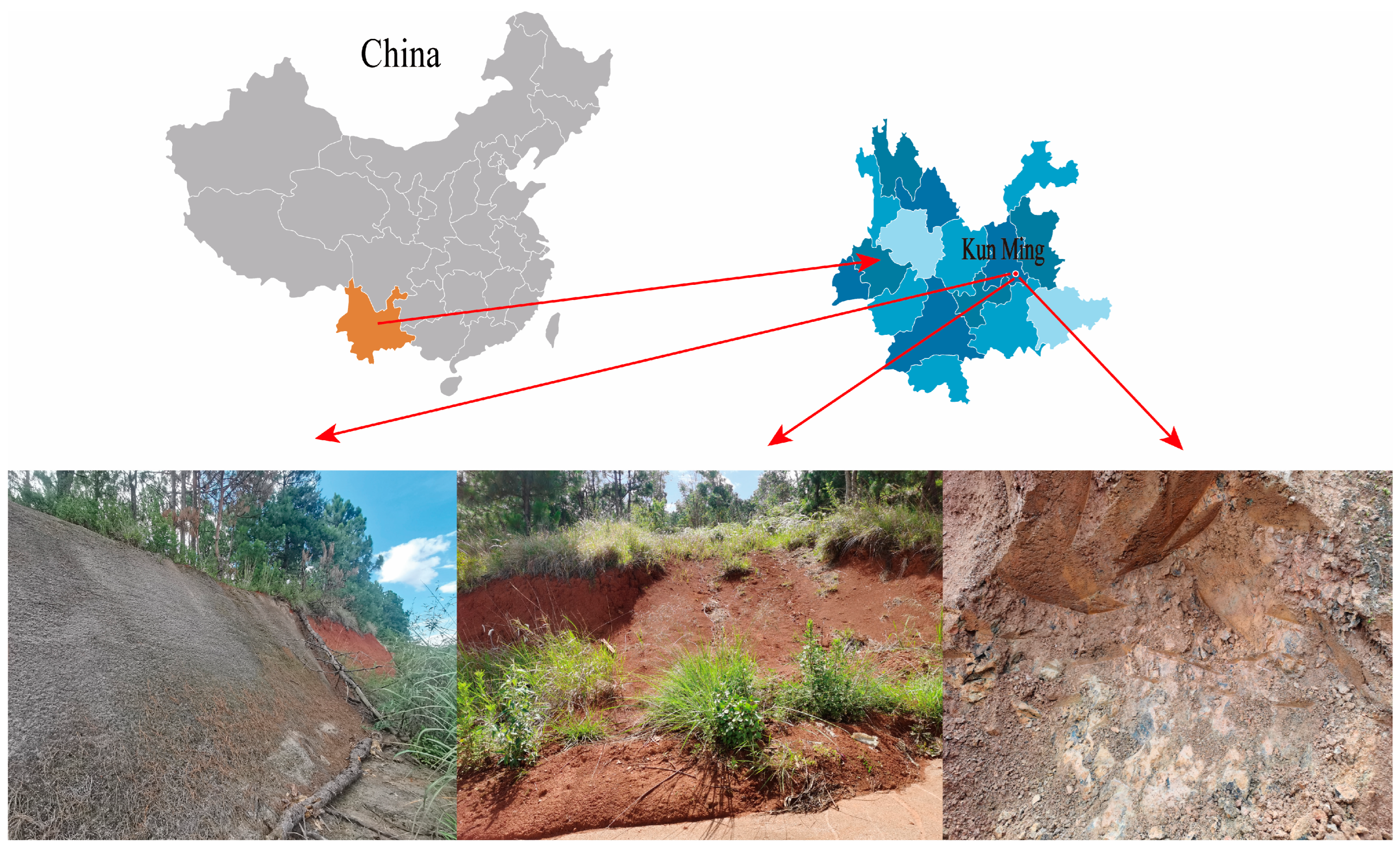

2.1. Material

2.2. Test Methods

2.2.1. Direct Shear Test

2.2.2. Water Retention and Water Absorption Test

2.2.3. Disintegration Test

2.2.4. Vegetation Growth Test

2.2.5. Simulated Rainfall Erosion Test

3. Results and Discussion

3.1. Effect of Guar Gum Content and Curing Time on Shear Strength Parameters

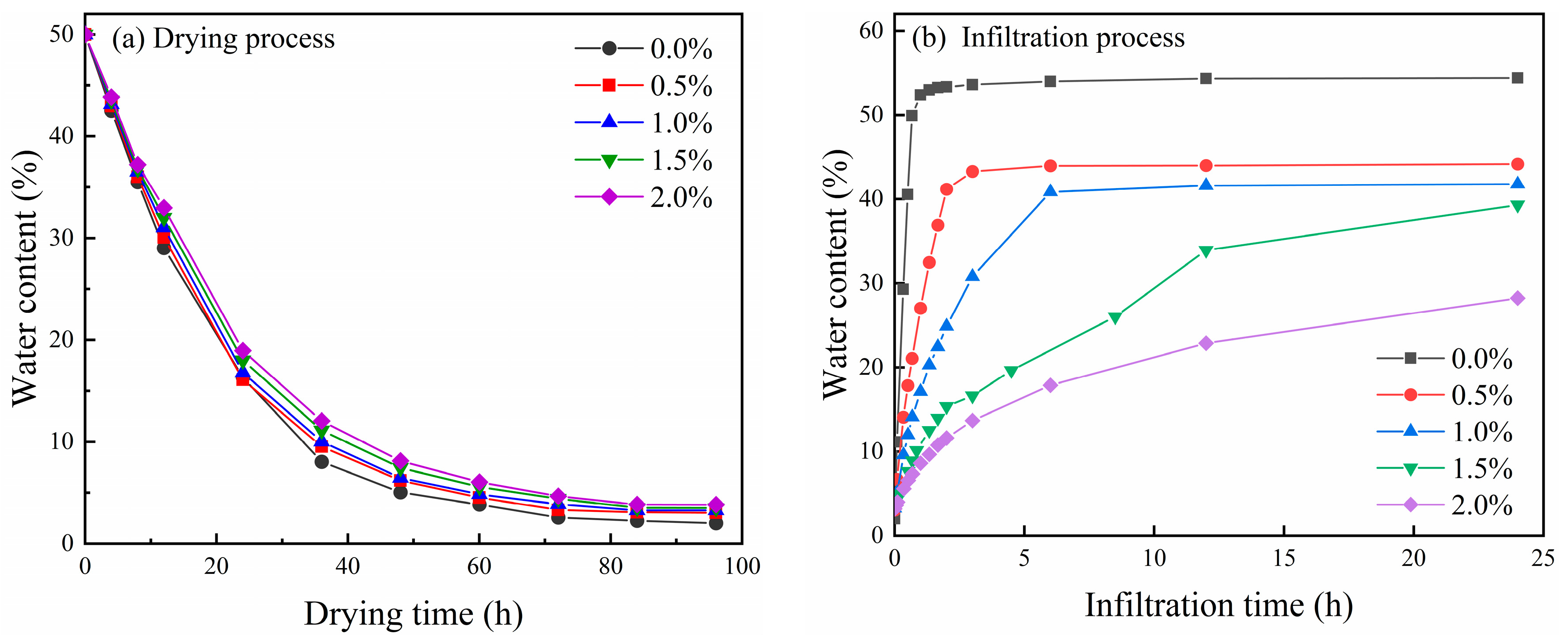

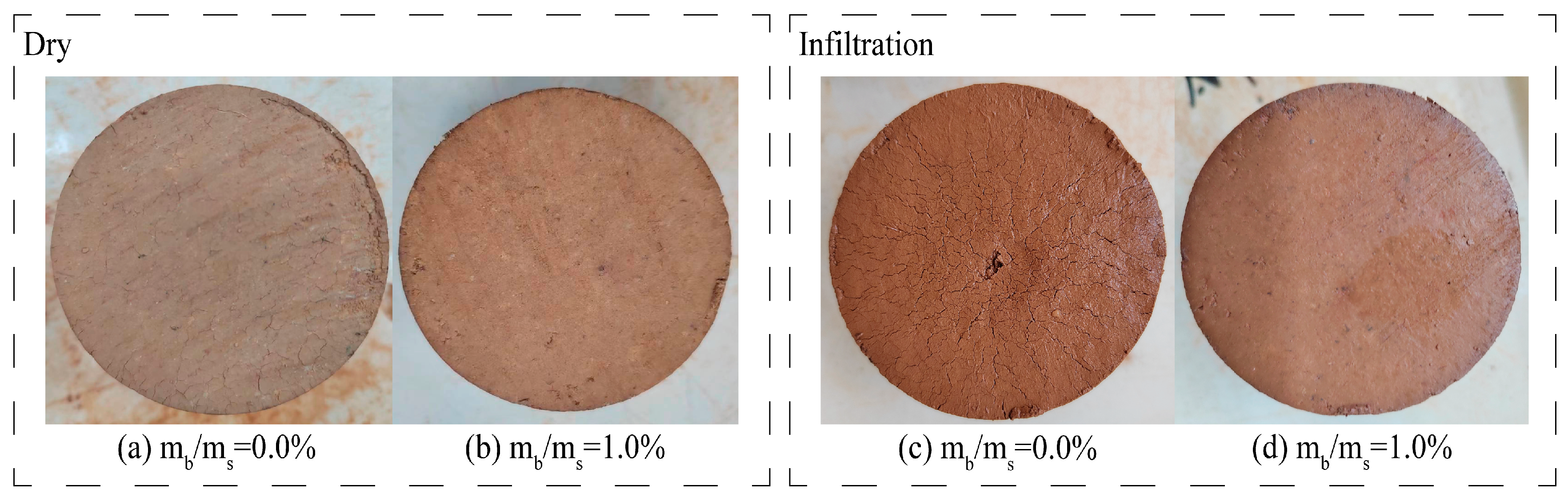

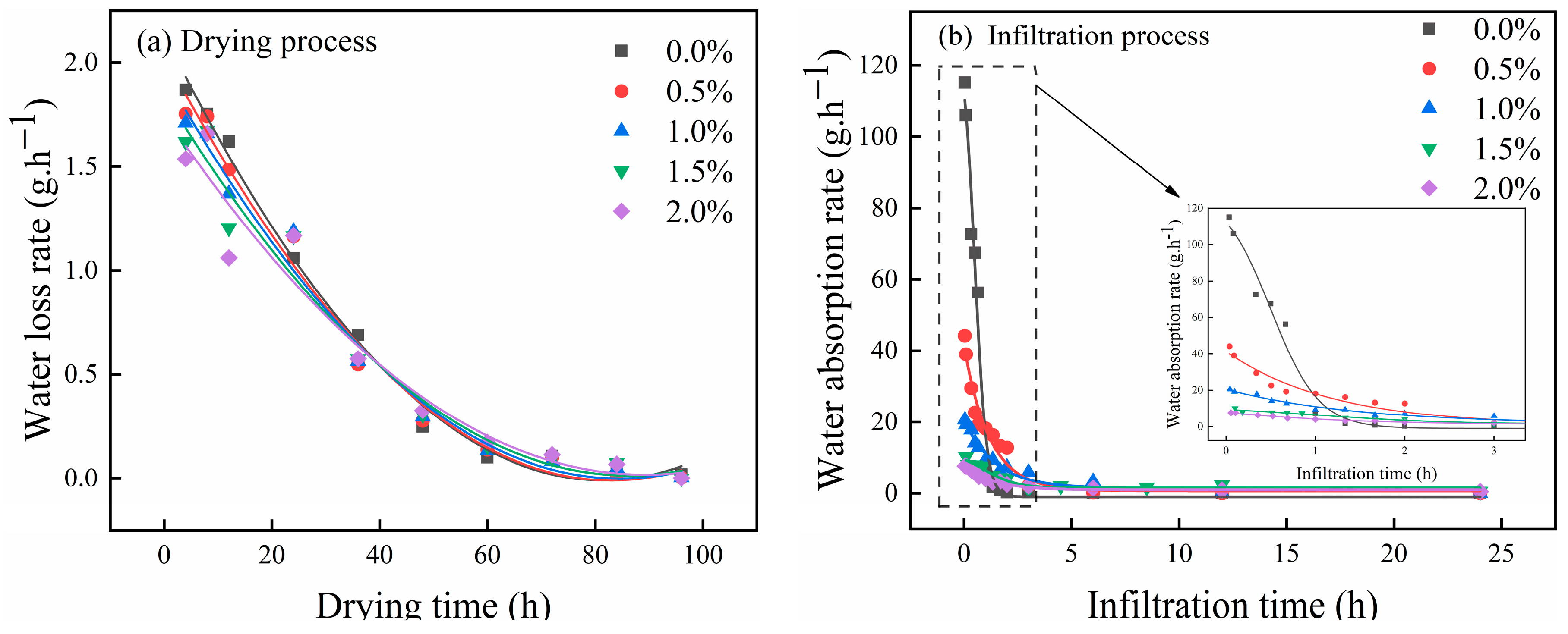

3.2. Effect of Guar Gum Content on Water Retention and Water Absorption

3.3. Effect of Guar Gum Content on Disintegration Properties

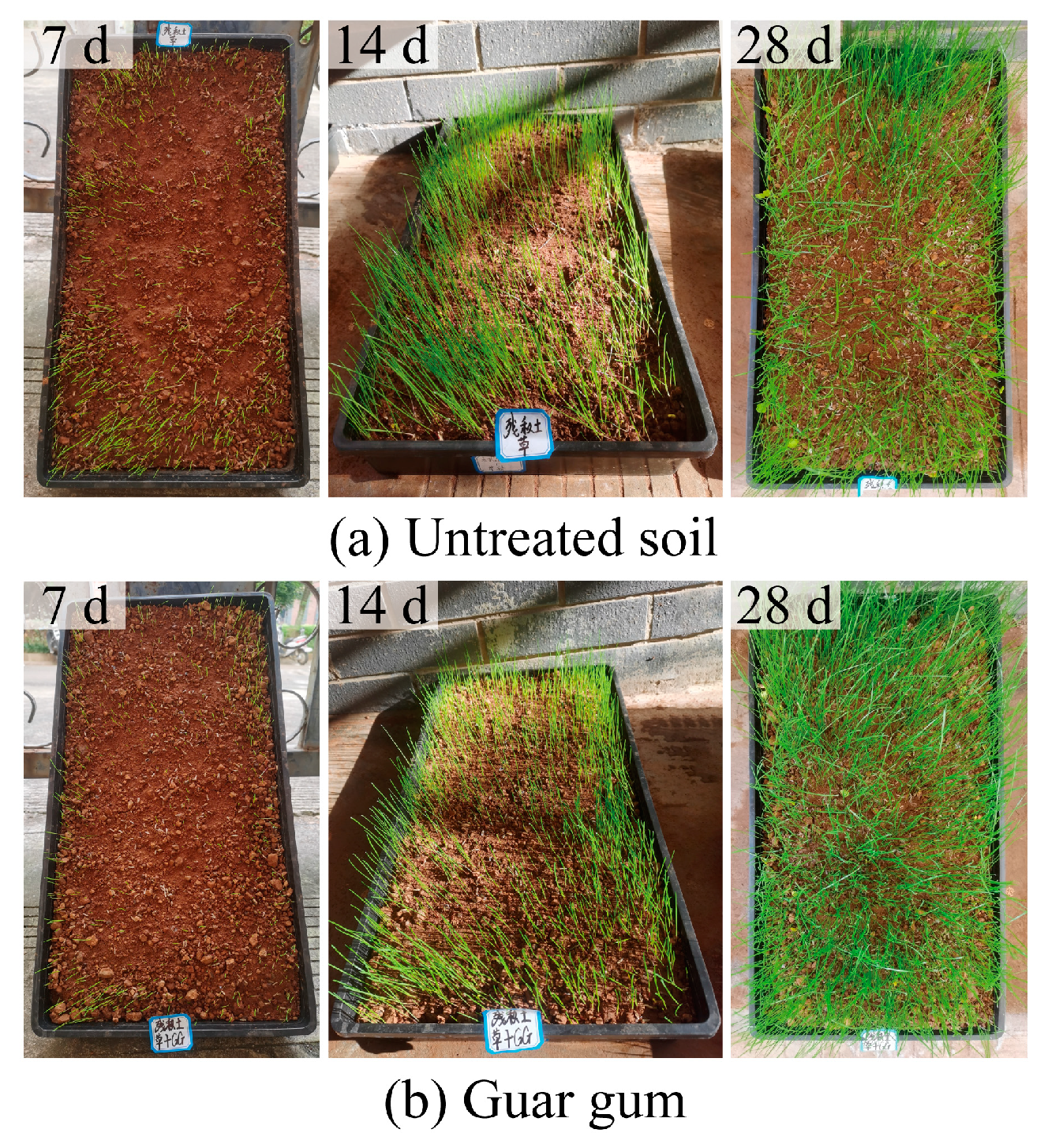

3.4. Effect of Guar Gum on Vegetation Growth

3.5. Effect of Guar Gum on the Erosion Resistance of Slopes

4. Conclusions

- (1)

- The incorporation of guar gum into the soil effectively enhances its shear strength. As the concentration of guar gum increases and the curing time extends, the cohesion of the soil specimens exhibits a trend of initial increase followed by a decrease or gradual increase. Meanwhile, the internal friction angle remains within a range of 21° to 26°, with the magnitude of change being less than 5°. Notably, after a curing period of 3 days, the cohesion and internal friction angle of the soil treated with 1.0% guar gum increased by 61.18% and 16.59%, respectively, compared to untreated soil.

- (2)

- The presence of guar gum effectively fills the voids between soil particles, thereby reducing the speed of water flow. This, in turn, prevents water evaporation and infiltration, significantly improving the cracking phenomenon on the surface layer of the soil specimens. The disintegration rate of the guar gum-treated soil is significantly lower. After 3 days of testing, the volume of the specimen remains stable with minimal expansion, maintaining its original shape without damage. The disintegration rate is only approximately 2%.

- (3)

- During the early stages of vegetation growth, the application of guar gum significantly improves the water retention and stability of the soil, creating a favorable environment for plant growth. Under the influence of rainwater leaching, splashing, and runoff scouring, the synergistic action of guar gum and the vegetation root system forms a protective layer on the slope surface. This protective layer enhances the stability of the slope and effectively shields the roots of the vegetation, ensuring their healthy growth.

- (4)

- Under the action of rainfall erosion, the slopes treated with guar gum exhibit a significant reduction in the amount of soil particles taken away by the erosion process. This reduction is due to the unique properties of guar gum, which effectively binds the soil particles together, enhancing the overall stability of the slope. As a result, the overall structure of the slope is able to remain intact, and the erosion characteristics are not as prominent as on untreated slopes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, J.; Yu, P.; Wei, H.; Meng, Q. Slaking behaviour of weathered basalt residual soil in Guizhou. J. Eng. Geol. 2011, 19, 778–783. [Google Scholar]

- Wang, C.; Lei, X.; Meng, Q. Experimental study on soil strength of ochre weathered basalt in Guizhou and Yunnan Province. Yangtze Riv. 2012, 43, 47–50. [Google Scholar] [CrossRef]

- Wu, D.; Liu, H.; Wang, G. Laboratory experimental study of slaking characteristics of red-bed soft rock. Chin. J. Rock Mech. Eng. 2010, 29, 4173–4179. [Google Scholar]

- Abad, S.; Tugrul, A.; Gokceoglu, C.; Armaghani, D.J. Characteristics of weathering zones of granitic rocks in Malaysia for geotechnical engineering design. Eng. Geol. 2016, 200, 94–103. [Google Scholar] [CrossRef]

- Pradhan, A.M.S.; Kim, Y.T. Application and comparison of shallow landslide susceptibility models in weathered granite soil under extreme rainfall events. Environ. Earth Sci. 2015, 73, 5761–5771. [Google Scholar] [CrossRef]

- Yang, G. Development and new challenges of deep excavation supporting engineering in Guangdong province. Chin. J. Rock Mech. Eng. 2012, 31, 2276–2284. [Google Scholar]

- Xu, R.; Li, X.C.; Yang, W.; Jiang, C.; Rabiei, M. Use of local plants for ecological restoration and slope stability: A possible application in Yan’an, Loess Plateau, China. Geomat. Nat. Hazards Risk 2019, 10, 2106–2128. [Google Scholar] [CrossRef]

- Stokes, A.; Sotir, R.; Chen, W.; Chestem, M. Soil bio- and eco-engineering in China: Past experience and future priorities Preface. Ecol. Eng. 2010, 36, 247–257. [Google Scholar] [CrossRef]

- Tran, A.T.P.; Chang, I.; Cho, G.C. Soil water retention and vegetation survivability improvement using microbial biopolymers in drylands. Geomech. Eng. 2019, 17, 475–483. [Google Scholar] [CrossRef]

- Guo, Z. Research on the Application of High Slope Measures in Expressway Subgrade. Constr. Des. Eng. 2023, 20, 21–23. [Google Scholar] [CrossRef]

- Song, X.Y.; Huang, Y.H.; Fu, J.Y.; Jiang, D.; Tian, G.J. Spatial Variability and Ecological Effects of Anthropogenic Activities in a Nature Reserve: A Case Study in the Baijitan National Nature Reserve, China. Sustainability 2017, 9, 239. [Google Scholar] [CrossRef]

- Fatehi, H.; Ong, D.E.L.; Yu, J.; Chang, I. Biopolymers as Green Binders for Soil Improvement in Geotechnical Applications: A Review. Geosciences 2021, 11, 291. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.D.; Cho, G.C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2015, 253, 39–47. [Google Scholar] [CrossRef]

- Dehghan, H.; Tabarsa, A.; Latifi, N.; Bagheri, Y. Use of xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 2019, 21, 155–165. [Google Scholar] [CrossRef]

- Sulaiman, H.; Taha, M.R.; Abd Rahman, N.; Taib, A.M. Performance of soil stabilized with biopolymer materials-xanthan gum and guar gum. Phys. Chem. Earth 2022, 128, 103276. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.H.; Aziz, M.; Ijaz, N.; Fang, C.F.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Salman, M. Geotechnical properties of problematic expansive subgrade stabilized with guar gum biopolymer. Clean Technol. Environ. Policy 2023, 25, 1699–1719. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Saisree, S. Geotechnical behaviour of guar gum-treated soil. Soils Found. 2019, 59, 2155–2166. [Google Scholar] [CrossRef]

- Wang, S.W.; Zhao, X.X.; Zhang, J.R.; Jiang, T.; Wang, S.K.; Zhao, J.D.; Meng, Z.H. Water retention characteristics and vegetation growth of biopolymer-treated silt soils. Soil Tillage Res. 2023, 225, 105544. [Google Scholar] [CrossRef]

- Kumar, S.A.; Sujatha, E.R.; Pugazhendi, A.; Jamal, M.T. Guar gum-stabilized soil: A clean, sustainable and economic alternative liner material for landfills. Clean Technol. Environ. Policy 2023, 25, 323–341. [Google Scholar] [CrossRef]

- Sharma, G.; Sharma, S.; Kumar, A.; Al-Muhtaseb, A.H.; Naushad, M.; Ghfar, A.A.; Mola, G.T.; Stadler, F.J. Guar gum and its composites as potential materials for diverse applications: A review. Carbohydr. Polym. 2018, 199, 534–545. [Google Scholar] [CrossRef]

- Wang, T.; Wang, L.; Liu, S.; Zhang, S.; Wang, O. Experimental Study on Mechanical Properties of Expansive Soil Improved by Xanthan Gum and Guar Gum. China Railw. Sci. 2023, 44, 1–10. [Google Scholar]

- Fu, H.; Zha, H.; Pan, H.; Zeng, L.; Liu, J. Experimental study on water stability and scour resistance of biopolymer modified disintegrated carbonaceous mudstone. J. Cent. South Univ. 2022, 53, 2633–2644. [Google Scholar] [CrossRef]

- Bao, H.; Liu, C.Q.; Lan, H.X.; Yan, C.G.; Li, L.P.; Zheng, H.; Dong, Z.G. Time-dependency deterioration of polypropylene fiber reinforced soil and guar gum mixed soil in loess cut-slope protecting. Eng. Geol. 2022, 311, 106895. [Google Scholar] [CrossRef]

- Yang, W.; Shi, Y.; Mu, P.; Jia, Z.; Cao, Y. An experimental study of the engineering properties and erosion resistance of guar gum-reinforced loess. Hydroge Eng. Geol. 2022, 49, 117–124. [Google Scholar]

- GB/T 50123-2019; Standard for Geotechnical Test Methods. China Standard Press: Beijing, China, 2019.

- Thombare, N.; Jha, U.; Mishra, S.; Siddiqui, M.Z. Guar gum as a promising starting material for diverse applications: A review. Int. J. Biol. Macromol. 2016, 88, 361–372. [Google Scholar] [CrossRef] [PubMed]

- Stupp, S.I.; Braun, P.V. Molecular manipulation of microstructures: Biomaterials, ceramics, and semiconductors. Science 1997, 277, 1242–1248. [Google Scholar] [CrossRef] [PubMed]

- Gupta, B.S.; Ako, J.E. Application of guar gum as a flocculant aid in food processing and potable water treatment. Eur. Food Res. Technol. 2005, 221, 746–751. [Google Scholar] [CrossRef]

- Gong, X. Some problems concerning shear strength of soil in soft clay ground. J. Geotech. Eng. 2011, 33, 1596–1600. [Google Scholar]

- Sun, Y.L.; Liu, Q.X.; Xu, H.S.; Wang, Y.X.; Tang, L.S. Influences of different modifiers on the disintegration of improved granite residual soil under wet and dry cycles. Int. J. Min. Sci. Technol. 2022, 32, 831–845. [Google Scholar] [CrossRef]

- Li, J.; Cui, S.; Tian, W. Erosion characteristic of road slope and test of soil disintegration. J. Chang. Univ. 2007, 1, 23–26+49. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, D.; Su, Z.; Dong, Y.; Xue, Y.; Zhang, B.; Li, S. Research Progress of Influence Factors in Soils Anti-scourabillty. World Sci. Technol. R D 2014, 36, 721–725. [Google Scholar] [CrossRef]

- Acharya, R.; Pedarla, A.; Bheemasetti, T.V.; Puppala, A.J. Assessment of Guar Gum Biopolymer Treatment toward Mitigation of Desiccation Cracking on Slopes Built with Expansive Soils. Transp. Res. Rec. 2017, 2657, 78–88. [Google Scholar] [CrossRef]

- He, Z.; Fan, H.; Wang, J.; Liu, G.; Wang, Z.; Yu, J. Experimental study of engineering properties of loess reinforced by lignosulfonate. Rock Soil Mech 2017, 38, 731–739. [Google Scholar] [CrossRef]

- Puppala, A.J.; Pedarla, A. Innovative ground improvement techniques for expansive soils. Innov. Infrastruct. Solutions 2017, 2, 24. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Z. A Review on Effect of Entrapped Air on Soil Permeability. J. China Three Gorges Univ. 2009, 31, 52–56. [Google Scholar]

- Dasberg, S.; Mendel, K. The effect of soil water and aeration on seed germination. J. Exp. Bot. 1971, 22, 992–998. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, D.; Wang, Y.; Sun, M.; Duan, X.; Bai, Y. Reinforcement Mechanism of Soil Slope Surface with Polymer Soil Stabilizer and Its Application. J. Earth Sci. Environ. 2016, 38, 420–426. [Google Scholar]

- Pardo, A.; Amato, M.; Chiarandà, F.Q. Relationships between soil structure, root distribution and water uptake of chickpea (Cicer arietinum L.). Plant growth and water distribution. Eur. J. Agron. 2000, 13, 39–45. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of xanthan gum biopolymer on soil strengthening, Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Ham, S.M.; Chang, I.; Noh, D.H.; Kwon, T.H.; Muhunthan, B. Improvement of surface erosion resistance of sand by microbial biopolymer formation. J. Geotech. Geoenviron. Eng. 2018, 144, 06018004. [Google Scholar] [CrossRef]

| Specific Gravity | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Maximum Dry Density (g·cm−3) | Optimum Water Content (%) |

|---|---|---|---|---|---|

| 2.81 | 58.67 | 31.05 | 27.62 | 1.53 | 36.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, X.; Wang, L.; Pan, X.; Yang, B.; Han, J.; Zhang, L. Application of Guar Gum Treatment of Basalt Residual-Soil Shallow Slope in Early Ecological Restoration. Sustainability 2024, 16, 6676. https://doi.org/10.3390/su16156676

Shen X, Wang L, Pan X, Yang B, Han J, Zhang L. Application of Guar Gum Treatment of Basalt Residual-Soil Shallow Slope in Early Ecological Restoration. Sustainability. 2024; 16(15):6676. https://doi.org/10.3390/su16156676

Chicago/Turabian StyleShen, Xianfei, Lina Wang, Xuemin Pan, Bijin Yang, Jiayuan Han, and Lianxing Zhang. 2024. "Application of Guar Gum Treatment of Basalt Residual-Soil Shallow Slope in Early Ecological Restoration" Sustainability 16, no. 15: 6676. https://doi.org/10.3390/su16156676