Enhancing Sustainable Supply Chain Management through Digital Transformation: A Comparative Case Study Analysis

Abstract

:1. Introduction

2. Theoretical Background

2.1. Sustainable Development and Supply Chain Management

2.2. Digital Transformation

- Data collection and monitoring [40].

- Supplier assessment and compliance [41].

- Inventory and demand management [42].

- Transport optimization [43].

- Waste reduction [44].

- Carbon footprint monitoring [45].

- Product traceability [15].

- Stakeholder communication [15].

- Decision-making [46].

- Continuous improvement and adaptation [47].

2.3. Supply Chain Management Resources and Capabilities

2.4. Business Performance, Sustainable Impact, and Business Excellence

2.5. Sustainable Strategies

- The sustainable technology development strategy, which aims to develop IT capabilities that can contribute to sustainable development through innovation.

- The networking strategy, which aims to develop collaborative skills within the company and between all stakeholders.

- The sustainability strategy, which includes investments in feasibility-related technologies and aims to provide financial incentives for employees to propose and implement innovative ideas.

- The sustainable product marketing and promotion strategy, which aims to develop marketing and promote the benefits of sustainable products to customers in order to increase demand for products and services.

- The research and development strategy, which aims to develop research units within the company in order to improve products and processes.

- The sustainable skills and competencies development strategy, which aims to create an enabling environment for employees to develop green and sustainable skills.

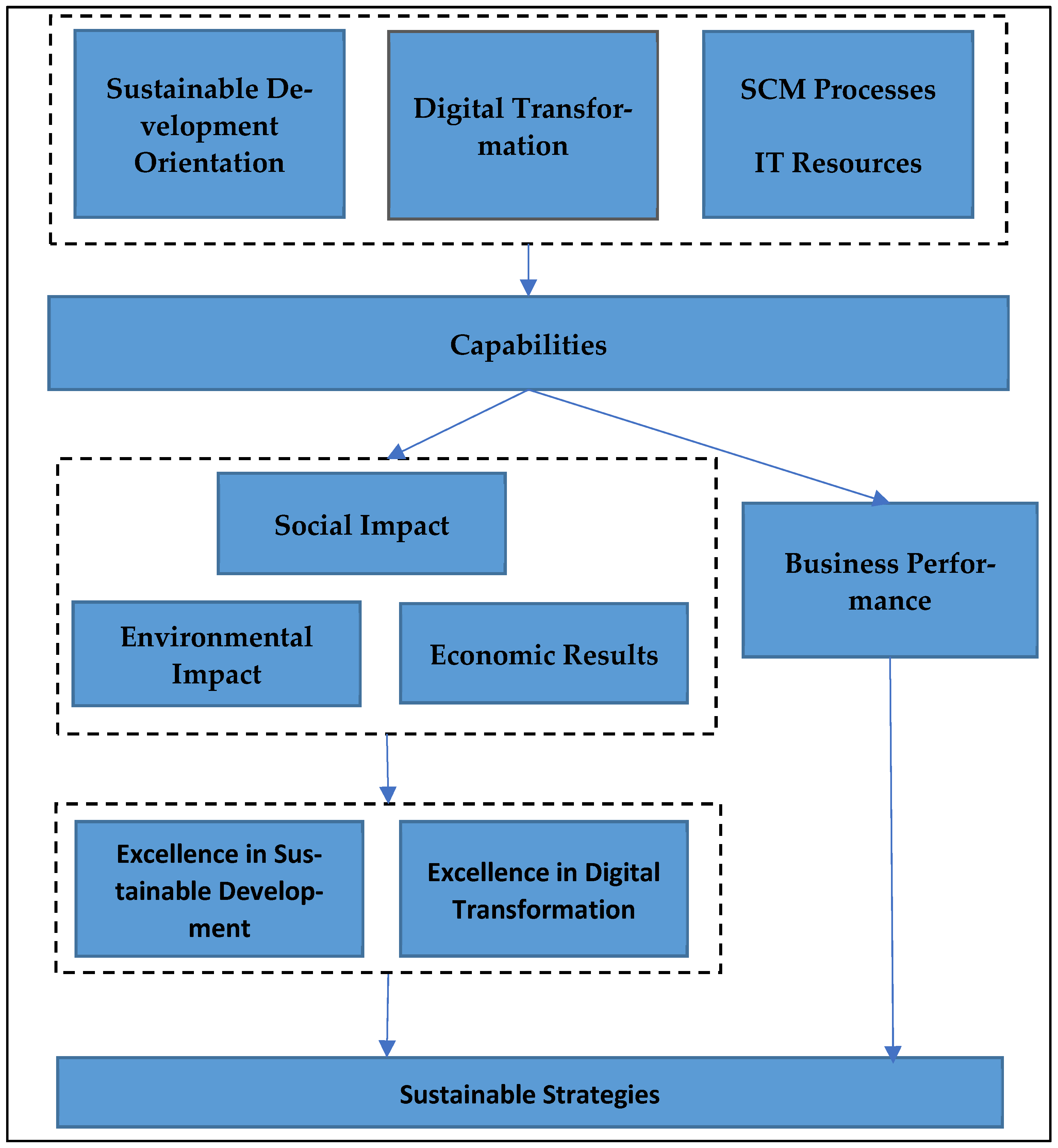

2.6. Conceptual Framework

3. Research Method

3.1. Research Design

3.2. Case Selection

3.3. Data Collection Procedures

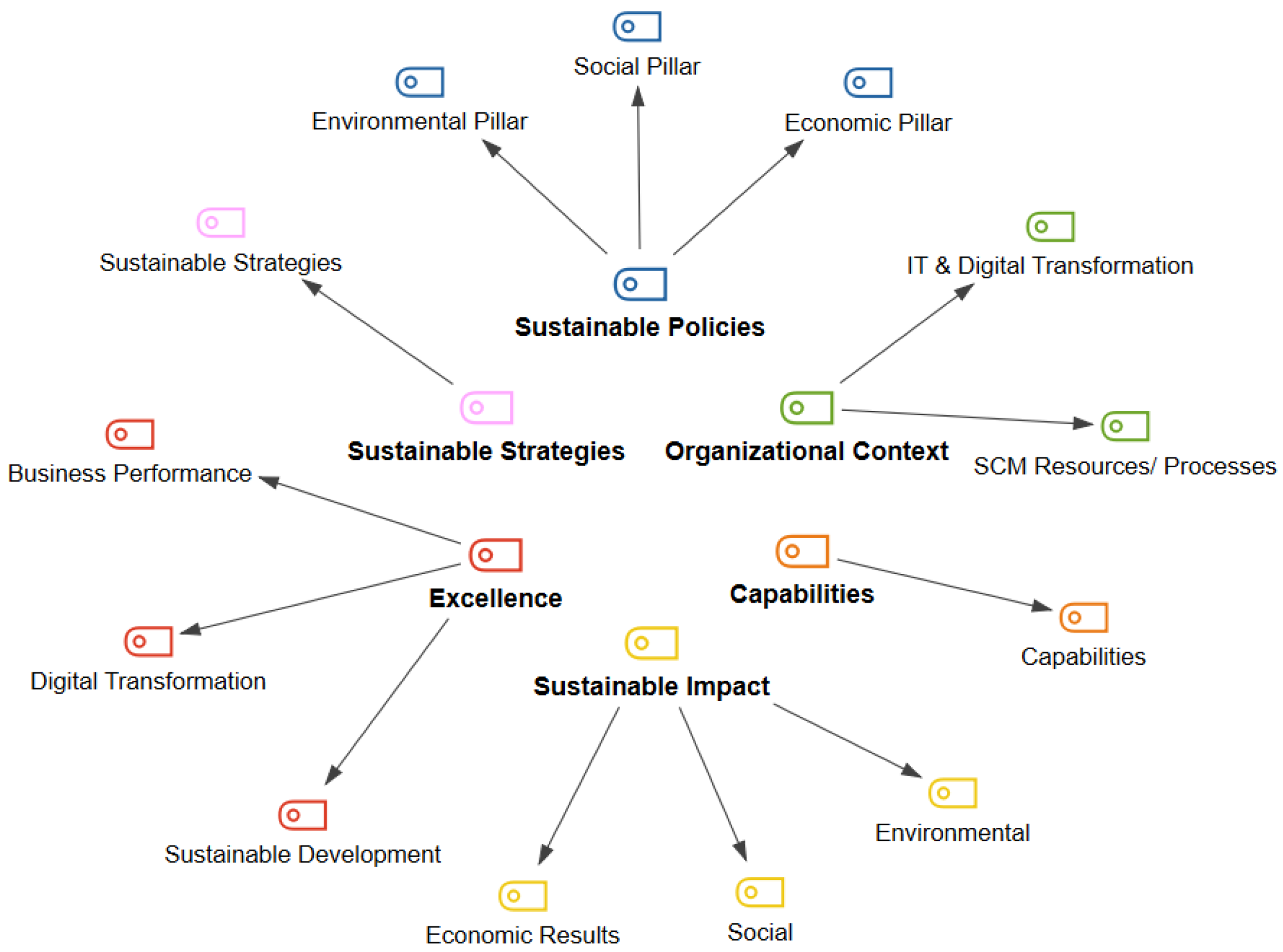

3.4. Data Coding and Analysis

4. Case Studies’ Description and Findings

4.1. Case Study—3PL Company

4.1.1. Resources and Capabilities

- Efficient warehouse management through the “Mantis WMS”, which enabled the company to automate and effectively manage its processes, achieving accuracy and speed in the storage and preparation of orders.

- Automation, quick product identification, and information management through the use of “barcode” labels on each product and pallet and connection to wireless terminals, allowing operators to quickly access and alter information.

- Employee development through investment in staff training.

4.1.2. Sustainable Impact

4.1.3. Business Performance, Excellence and Sustainable Strategies

4.2. Case Study—Retailer

4.2.1. Resources and Capabilities

- Driver information.

- Location at all times.

- Temperature in storage areas for the better and safer transport and monitoring of products.

4.2.2. Sustainable Impact

4.2.3. Business Performance, Excellence and Sustainable Strategies

4.3. Case Study—Producer

4.3.1. Resources

- Financial Supply Chain Management (FSCM);

- Logistics Execution (LE).

4.3.2. Capabilities and Sustainable Impact

- Commitment to sustainability.

- Resilience in financial performance.

- Social contribution and community support.

- Digital transformation.

- Ethics and compliance training.

- Effective management of distribution centers.

4.3.3. Sustainable Strategies

- Research and development.

- Networking.

- Marketing and promotion.

5. Results and Discussion

- Increasing productivity.

- Reducing operating costs.

- Efficient management of supply chain processes.

- Automation.

- Knowledge transfer and training.

- Customer satisfaction and loyalty.

- Commitment to sustainability.

- Digital transformation.

5.1. Theoretical Implications

5.2. Managerial Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Dong, J.Q.; Fabian, N.; Haenlein, M. Digital Transformation: A Multidisciplinary Reflection and Research Agenda. J. Bus. Res. 2021, 122, 889–901. [Google Scholar] [CrossRef]

- Gao, P.; Wu, W.; Yang, Y. Discovering Themes and Trends in Digital Transformation and Innovation Research. J. Theor. Appl. Electron. Commer. Res. 2022, 17, 1162–1184. [Google Scholar] [CrossRef]

- Schmidt, C.G.; Wagner, S.M. Blockchain and Supply Chain Relations: A Transaction Cost Theory Perspective. J. Purch. Supply Manag. 2019, 25, 100552. [Google Scholar] [CrossRef]

- Farahani, P.; Meier, C.; Wilke, J. Digital Supply Chain Management Agenda for the Automotive Supplier Industry. In Shaping the Digital Enterprise; Oswald, G., Kleinemeier, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 157–172. ISBN 978-3-319-40966-5. [Google Scholar]

- Duong Thi Binh, A.; Akbari, M.; Le Thi Cam, H.; Nguyen Canh, L.; Truong Quang, H. Forging Pathways to Circular Economy Excellence: Integrating Industry 4.0 with Quality Management. Sustainability 2024, 16, 3053. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, L.; Sun, Q.; Dong, H. Impact of Novel Information Technology on IT Alignment and Sustainable Supply Chain Performance: Evidence from Chinese Manufacturing Industry. J. Bus. Ind. Mark. 2022, 37, 461–473. [Google Scholar] [CrossRef]

- Ahmed, Z.; Ahmad, M.; Alvarado, R.; Sinha, A.; Shah, M.I.; Abbas, S. Towards Environmental Sustainability: Do Financial Risk and External Conflicts Matter? J. Clean. Prod. 2022, 371, 133721. [Google Scholar] [CrossRef]

- Nozari, H.; Fallah, M.; Szmelter-Jarosz, A. A Conceptual Framework of Green Smart IoT-Based Supply Chain Management. Int. J. Res. Ind. Eng. 2021, 10, 22–34. [Google Scholar]

- Birkel, H.; Müller, J.M. Potentials of Industry 4.0 for Supply Chain Management within the Triple Bottom Line of Sustainability–A Systematic Literature Review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Papadopoulos, T.; Hazen, B.; Dubey, R. Supply Chain Social Sustainability for Developing Nations: Evidence from India. Resour. Conserv. Recycl. 2016, 111, 42–52. [Google Scholar] [CrossRef]

- Kosasih, W.; Pujawan, I.N.; Karningsih, P.D. Integrated Lean-Green Practices and Supply Chain Sustainability for Manufacturing SMEs: A Systematic Literature Review and Research Agenda. Sustainability 2023, 15, 12192. [Google Scholar] [CrossRef]

- Van Zanten, J.A.; Van Tulder, R. Multinational Enterprises and the Sustainable Development Goals: An Institutional Approach to Corporate Engagement. J. Int. Bus. Policy 2018, 1, 208–233. [Google Scholar] [CrossRef]

- Akbari, M.; Kok, S.; Hopkins, J.; Frederico, G.; Nguyen, H.; Alonso, A. The Changing Landscape of Digital Transformation in Supply Chains: Impacts of Industry 4.0 in Vietnam. Int. J. Logist. Manag. 2023, 35, 1040–1072. [Google Scholar] [CrossRef]

- Akbari, M. Revolutionizing Supply Chain and Circular Economy with Edge Computing: Systematic Review, Research Themes and Future Directions. Manag. Decis. 2023. ahead-of-print. [Google Scholar] [CrossRef]

- Stroumpoulis, A.; Kopanaki, E. Theoretical Perspectives on Sustainable Supply Chain Management and Digital Transformation: A Literature Review and a Conceptual Framework. Sustainability 2022, 14, 4862. [Google Scholar] [CrossRef]

- Kilibarda, M.; Andrejić, M.; Popović, V. Research in Logistics Service Quality: A Systematic Literature Review. Transport 2020, 35, 224–235. [Google Scholar] [CrossRef]

- Agatz, N.A.H.; Fleischmann, M.; van Nunen, J.A.E.E. E-Fulfillment and Multi-Channel Distribution—A Review. Eur. J. Oper. Res. 2008, 187, 339–356. [Google Scholar] [CrossRef]

- Chichilnisky, G. What Is Sustainable Development? Land Econ. 1997, 467–491. [Google Scholar] [CrossRef]

- Emas, R. The Concept of Sustainable Development: Definition and Defining Principles. Brief GSDR 2015, 2015, 10–13140. [Google Scholar]

- Robert, K.W.; Parris, T.M.; Leiserowitz, A.A. What Is Sustainable Development? Goals, Indicators, Values, and Practice. Environ. Sci. Policy Sustain. Dev. 2005, 47, 8–21. [Google Scholar] [CrossRef]

- Purvis, B.; Mao, Y.; Robinson, D. Three Pillars of Sustainability: In Search of Conceptual Origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Hansmann, R.; Mieg, H.A.; Frischknecht, P. Principal Sustainability Components: Empirical Analysis of Synergies between the Three Pillars of Sustainability. Int. J. Sustain. Dev. World Ecol. 2012, 19, 451–459. [Google Scholar] [CrossRef]

- Weiland, S.; Hickmann, T.; Lederer, M.; Marquardt, J.; Schwindenhammer, S. The 2030 Agenda for Sustainable Development: Transformative Change through the Sustainable Development Goals? Politics Gov. 2021, 9, 90–95. [Google Scholar] [CrossRef]

- Miles, M.P.; Munilla, L.S. The Potential Impact of Social Accountability Certification on Marketing: A Short Note. J. Bus. Ethics 2004, 50, 1–11. [Google Scholar] [CrossRef]

- Mani, V.; Gunasekaran, A.; Delgado, C. Supply Chain Social Sustainability: Standard Adoption Practices in Portuguese Manufacturing Firms. Int. J. Prod. Econ. 2018, 198, 149–164. [Google Scholar] [CrossRef]

- Bhuniya, S.; Pareek, S.; Sarkar, B. A Supply Chain Model with Service Level Constraints and Strategies under Uncertainty. Alex. Eng. J. 2021, 60, 6035–6052. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Kumar, A.; Shrivastav, S.K.; Shrivastava, A.K.; Panigrahi, R.R.; Mardani, A.; Cavallaro, F. Sustainable Supply Chain Management, Performance Measurement, and Management: A Review. Sustainability 2023, 15, 5290. [Google Scholar] [CrossRef]

- Al-Emran, M.; Griffy-Brown, C. The Role of Technology Adoption in Sustainable Development: Overview, Opportunities, Challenges, and Future Research Agendas. Technol. Soc. 2023, 73, 102240. [Google Scholar] [CrossRef]

- Andriole, S.J.; Cox, T.; Khin, K.M. The Innovator’s Imperative: Rapid Technology Adoption for Digital Transformation; Auerbach Publications: Boca Raton, FL, USA, 2017. [Google Scholar]

- Yin, W. Identifying the Pathways through Digital Transformation to Achieve Supply Chain Resilience: An fsQCA Approach. Environ. Sci. Pollut. Res. 2022, 30, 10867–10879. [Google Scholar] [CrossRef]

- Fitzgerald, M.; Kruschwitz, N.; Bonnet, D.; Welch, M. Embracing Digital Technology: A New Strategic Imperative. MIT Sloan Manag. Rev. 2014, 55, 1. [Google Scholar]

- de Camargo Fiorini, P.; Jabbour, C.J.C. Information Systems and Sustainable Supply Chain Management towards a More Sustainable Society: Where We Are and Where We Are Going. Int. J. Inf. Manag. 2017, 37, 241–249. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Benitez-Amado, J. How Information Technology Influences Environmental Performance: Empirical Evidence from China. Int. J. Inf. Manag. 2015, 35, 160–170. [Google Scholar] [CrossRef]

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; acatech—National Academy of Science and Engineering: Munich, Germany, 2013; Available online: https://www.din.de/resource/blob/76902/e8cac883f42bf28536e7e8165993f1fd/recommendations-for-implementing-industry-4-0-data.pdf (accessed on 6 March 2024).

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The Industrial Management of SMEs in the Era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Bigliardi, B.; Filippelli, S.; Petroni, A.; Tagliente, L. The Digitalization of Supply Chain: A Review. Procedia Comput. Sci. 2022, 200, 1806–1815. [Google Scholar] [CrossRef]

- Schallmo, D.; Williams, C.A.; Boardman, L. Digital transformation of business models—Best practice, enablers, and roadmap. Int. J. Innov. Mgt. 2017, 21, 1740014. [Google Scholar] [CrossRef]

- Shee, H.; Miah, S.J.; Fairfield, L.; Pujawan, N. The Impact of Cloud-Enabled Process Integration on Supply Chain Performance and Firm Sustainability: The Moderating Role of Top Management. Supply Chain Manag. Int. J. 2018, 23, 500–517. [Google Scholar] [CrossRef]

- Jahani, H.; Jain, R.; Ivanov, D. Data Science and Big Data Analytics: A Systematic Review of Methodologies Used in the Supply Chain and Logistics Research. Ann. Oper. Res. 2023. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S. Digital Supplier Selection Reinforcing Supply Chain Quality Management Systems to Enhance Firm’s Performance. TQM J. 2020, 35, 102–130. [Google Scholar] [CrossRef]

- Verma, A.; Tripathy, S.; Singhal, D. The Significance of Warehouse Management in Supply Chain: An ISM Approach. Decis. Mak. Appl. Manag. Eng. 2023, 6, 92–110. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Kashem, M.; Nasir, T. Smart Transportation Logistics: Achieving Supply Chain Efficiency with Green Initiatives. In Data Analytics for Supply Chain Networks; Springer International Publishing: Berlin/Heidelberg, Germany, 2023; pp. 243–258. ISBN 978-3-031-29822-6. [Google Scholar]

- Debnath, A.; Sarkar, B. Effect of Circular Economy for Waste Nullification under a Sustainable Supply Chain Management. J. Clean. Prod. 2023, 385, 135477. [Google Scholar] [CrossRef]

- Wang, M.; Wang, B.; Abareshi, A. Blockchain Technology and Its Role in Enhancing Supply Chain Integration Capability and Reducing Carbon Emission: A Conceptual Framework. Sustainability 2020, 12, 10550. [Google Scholar] [CrossRef]

- Kabadurmus, O.; Kayikci, Y.; Demir, S.; Koc, B. A Data-Driven Decision Support System with Smart Packaging in Grocery Store Supply Chains during Outbreaks. Socio-Econ. Plan. Sci. 2023, 85, 101417. [Google Scholar] [CrossRef]

- Aldhaheri, R.T.; Ahmad, S.Z. Factors Affecting Organisations’ Supply Chain Agility and Competitive Capability. Bus. Process Manag. J. 2023, 29, 505–527. [Google Scholar] [CrossRef]

- Chan, H.-L.; Shen, B.; Cai, Y. Quick Response Strategy with Cleaner Technology in a Supply Chain: Coordination and Win-Win Situation Analysis. Int. J. Prod. Res. 2018, 56, 3397–3408. [Google Scholar] [CrossRef]

- Dao, V.; Langella, I.; Carbo, J. From Green to Sustainability: Information Technology and an Integrated Sustainability Framework. J. Strateg. Inf. Syst. 2011, 20, 63–79. [Google Scholar] [CrossRef]

- Dyer, J.H.; Singh, H. The Relational View: Cooperative Strategy and Sources of Interorganizational Competitive Advantage. Acad. Manag. Rev. 1998, 23, 660–679. [Google Scholar] [CrossRef]

- Hart, S.L.; Dowell, G. Invited Editorial: A Natural-Resource-Based View of the Firm: Fifteen Years After. J. Manag. 2011, 37, 1464–1479. [Google Scholar] [CrossRef]

- Mahmood, A.; Bashir, J. How Does Corporate Social Responsibility Transform Brand Reputation into Brand Equity? Economic and Noneconomic Perspectives of CSR. Int. J. Eng. Bus. Manag. 2020, 12, 1847979020927547. [Google Scholar] [CrossRef]

- Alshurideh, M.; Kurdi, B.; Alzoubi, H.; Obeidat, B.; Hamadneh, S.; Ahmad, A. The Influence of Supply Chain Partners’ Integrations on Organizational Performance: The Moderating Role of Trust. Uncertain Supply Chain Manag. 2022, 10, 1191–1202. [Google Scholar] [CrossRef]

- Qrunfleh, S.; Tarafdar, M. Supply Chain Information Systems Strategy: Impacts on Supply Chain Performance and Firm Performance. Int. J. Prod. Econ. 2014, 147, 340–350. [Google Scholar] [CrossRef]

- Saragih, J.; Tarigan, A.; Silalahi, E.F.; Wardati, J.; Pratama, I. Supply Chain Operational Capability and Supply Chain Operational Performance: Does the Supply Chain Management and Supply Chain Integration Matters? Int. J. Supply Chain Manag. 2020, 9, 1222–1229. [Google Scholar] [CrossRef]

- Bhatti, S.H.; Hussain, W.M.H.W.; Khan, J.; Sultan, S.; Ferraris, A. Exploring Data-Driven Innovation: What’s Missing in the Relationship between Big Data Analytics Capabilities and Supply Chain Innovation? Ann. Oper. Res. 2024, 333, 799–824. [Google Scholar] [CrossRef]

- El Khatib, M.; Al Falasi, A. Effects of Artificial Intelligence on Decision Making in Project Management. Am. J. Ind. Bus. Manag. 2021, 11, 251–260. [Google Scholar] [CrossRef]

- Madakam, S.; Holmukhe, R.M.; Jaiswal, D.K. The Future Digital Work Force: Robotic Process Automation (RPA). JISTEM-J. Inf. Syst. Technol. Manag. 2019, 16, e201916001. [Google Scholar] [CrossRef]

- Al-Htaybat, K.; von Alberti-Alhtaybat, L. Big Data and Corporate Reporting: Impacts and Paradoxes. Account. Audit. Account. J. 2017, 30, 850–873. [Google Scholar] [CrossRef]

- Mahapatra, S.K.; Narasimhan, R.; Barbieri, P. Strategic Interdependence, Governance Effectiveness and Supplier Performance: A Dyadic Case Study Investigation and Theory Development. J. Oper. Manag. 2010, 28, 537–552. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Sagnak, M.; Kumar Mangla, S.; Kazancoglu, Y. Circular Economy and the Policy: A Framework for Improving the Corporate Environmental Management in Supply Chains. Bus. Strategy Environ. 2021, 30, 590–608. [Google Scholar] [CrossRef]

- Hart, S.L. A Natural-Resource-Based View of the Firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and Circular Economy: Operational Excellence for Sustainable Reverse Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Biswas, D.; Jalali, H.; Ansaripoor, A.H.; De Giovanni, P. Traceability vs. Sustainability in Supply Chains: The Implications of Blockchain. Eur. J. Oper. Res. 2023, 305, 128–147. [Google Scholar] [CrossRef]

- Campbell, D.J. Legitimacy Theory or Managerial Reality Construction? Corporate Social Disclosure in Marks and Spencer Plc Corporate Reports, 1969–1997. Account. Forum 2000, 24, 80–100. [Google Scholar] [CrossRef]

- Deegan, C.M. Legitimacy Theory: Despite Its Enduring Popularity and Contribution, Time Is Right for a Necessary Makeover. Account. Audit. Account. J. 2019, 32, 2307–2329. [Google Scholar] [CrossRef]

- Alsaedi, B.S.; Alamri, O.A.; Jayaswal, M.K.; Mittal, M. A Sustainable Green Supply Chain Model with Carbon Emissions for Defective Items under Learning in a Fuzzy Environment. Mathematics 2023, 11, 301. [Google Scholar] [CrossRef]

- Myovella, G.; Karacuka, M.; Haucap, J. Digitalization and Economic Growth: A Comparative Analysis of Sub-Saharan Africa and OECD Economies. Telecommun. Policy 2020, 44, 101856. [Google Scholar] [CrossRef]

- Sezhiyan, D.M.; Page, T.; Iskanius, P. The Impact of Supply Effort Management, Logistics Capability, and Supply Chain Management Strategies on Firm Performance. Int. J. Electron. Transp. 2011, 1, 26–44. [Google Scholar] [CrossRef]

- Degraeve, Z.; Labro, E.; Roodhooft, F. An Evaluation of Vendor Selection Models from a Total Cost of Ownership Perspective. Eur. J. Oper. Res. 2000, 125, 34–58. [Google Scholar] [CrossRef]

- Gupta, H.; Kusi-Sarpong, S.; Rezaei, J. Barriers and Overcoming Strategies to Supply Chain Sustainability Innovation. Resour. Conserv. Recycl. 2020, 161, 104819. [Google Scholar] [CrossRef]

- Rigó, L.; Fabianová, J.; Lokšík, M.; Mikušová, N. Utilising Digital Twins to Bolster the Sustainability of Logistics Processes in Industry 4.0. Sustainability 2024, 16, 2575. [Google Scholar] [CrossRef]

- Walsham, G.; Han, C.K. Information Systems Strategy Formation and Implementation: The Case of a Central Government Agency. Account. Manag. Inf. Technol. 1993, 3, 191–209. [Google Scholar] [CrossRef]

- Kopanaki, E. Examining Organisational Flexibility in an Interorganisational Context: A Case Study of a Grocery Retail Supply Chain; London School of Economics and Political Science: London, UK, 2008. [Google Scholar]

- Eisenhardt, K.M. Building Theories from Case-Study Research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Cavaye, A.L.M. Case Study Research: A Multi-faceted Research Approach for IS. Inf. Syst. J. 1996, 6, 227–242. [Google Scholar] [CrossRef]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 8th ed.; Pearson Education: New York, NY, USA, 2019. [Google Scholar]

- Jick, T.D. Mixing Qualitative and Quantitative Methods: Triangulation in Action. Adm. Sci. Q. 1979, 24, 602–611. [Google Scholar] [CrossRef]

- Shih, F. Triangulation in Nursing Research: Issues of Conceptual Clarity and Purpose. J. Adv. Nurs. 1998, 28, 631–641. [Google Scholar] [CrossRef]

- Magaldi, D.; Berler, M. Semi-Structured Interviews. In Encyclopedia of Personality and Individual Differences; Zeigler-Hill, V., Shackelford, T.K., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 4825–4830. ISBN 978-3-319-24610-9. [Google Scholar]

- Cohen, L.; Manion, L.; Morrison, K. Research Methods in Education; Routledge: London, UK, 2002. [Google Scholar]

- Daymon, C.; Holloway, I. Qualitative Research Methods in Public Relations and Marketing Communications; Routledge: London, UK, 2010. [Google Scholar]

- Oakley, A. Gender, Methodology and People’s Ways of Knowing: Some Problems with Feminism and the Paradigm Debate in Social Science. Sociology 1998, 32, 707–731. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M. Qualitative Data Analysis: An Expanded Sourcebook; Sage: Los Angeles, CA, USA, 1994. [Google Scholar]

- Braun, V.; Clarke, V. Using Thematic Analysis in Psychology. Qual. Res. Psychol. 2006, 3, 77–101. [Google Scholar] [CrossRef]

- Campbell, D.T. III. “Degrees of Freedom” and the Case Study. Comp. Political Stud. 1975, 8, 178–193. [Google Scholar] [CrossRef]

- Baxter, P.; Jack, S. Qualitative Case Study Methodology: Study Design and Implementation for Novice Researchers. Qual. Rep. 2008, 13, 544–559. [Google Scholar] [CrossRef]

- Khadka, K.; Maharjan, S. Customer Satisfaction and Customer Loyalty: Case Trivsel Städtjänster (Trivsel Siivouspalvelut). Centria University of Applied Sciences: Kokkola, Finland, 2017. Available online: https://www.theseus.fi/bitstream/handle/10024/139650/khadka_kabu%20%20and%20%20maharjan_%20soniya.pdf (accessed on 6 March 2024).

- Ozkan, M.; Cek, K.; Eyupoglu, S.Z. Sustainable Development and Customer Satisfaction and Loyalty in North Cyprus: The Mediating Effect of Customer Identification. Sustainability 2022, 14, 5196. [Google Scholar] [CrossRef]

- Abdi, Y.; Li, X.; Càmara-Turull, X. Impact of Sustainability on Firm Value and Financial Performance in the Air Transport Industry. Sustainability 2020, 12, 9957. [Google Scholar] [CrossRef]

- Bafas, S.A.; Alexandropoulou, A.P.; Fousteris, A.E.; Didaskalou, E.A.; Georgakellos, D.A. Sustainable Development and Business Strategies: An Exploratory Study of Greek Businesses. Businesses 2023, 3, 441–459. [Google Scholar] [CrossRef]

- Ersoy, P.; Börühan, G.; Kumar Mangla, S.; Hormazabal, J.H.; Kazancoglu, Y.; Lafcı, Ç. Impact of Information Technology and Knowledge Sharing on Circular Food Supply Chains for Green Business Growth. Bus. Strategy Environ. 2022, 31, 1875–1904. [Google Scholar] [CrossRef]

- Kalyar, M.N.; Shafique, I.; Saleem, S.; Humayun, S. Role of Leadership for Blockchain-Driven Supply Chain Management. In Blockchain Driven Supply Chain Management; Mubarik, M.S., Shahbaz, M., Eds.; Management for Professionals; Springer Nature: Singapore, 2023; pp. 87–100. ISBN 978-981-9906-98-7. [Google Scholar]

- Shee, H. Internet of Things: Applications and Challenges for Supply Chain Management. In The Palgrave Handbook of Supply Chain Management; Sarkis, J., Ed.; Springer International Publishing: Cham, Switzerland, 2024; pp. 1197–1215. ISBN 978-3-031-19883-0. [Google Scholar]

- Schoenherr, T. Supply Chain Management Professionals’ Proficiency in Big Data Analytics: Antecedents and Impact on Performance. Transp. Res. Part E Logist. Transp. Rev. 2023, 169, 102972. [Google Scholar] [CrossRef]

- Thottoli, M.M.; Ahmed, E.R. Information Technology and E-Accounting: Some Determinants among SMEs. J. Money Bus. 2022, 2, 1–15. [Google Scholar] [CrossRef]

| Company Main Activities Size Region | 3PL Warehousing, Distribution, Consulting Small and Medium Attica, Greece | Retailer Warehousing, Distribution, Sales Large Attica, Greece | Producer Producing Construction Materials Large Evia, Greece |

|---|---|---|---|

| Criterion 1: Industry Representation | It illustrates the logistical backbone of supply chains, crucial for understanding the operational changes enabled by digital technologies. | Interfacing directly with consumers, it offers insights into consumer behaviour and the implementation of sustainability practices in a retail setting. | Being a resource-intensive manufacturing sector entity, it was selected for its significant environmental impacts and potential for sustainability improvements through technology. |

| Criterion 2: Leadership in Innovation and Sustainability | It has been notable for its rapid adoption of innovative logistics technologies and sustainable growth practices since its recent inception. | It has implemented several initiatives emphasizing sustainability across its extensive network, effectively integrating digital platforms to enhance consumer engagement and sustainable consumption. | It is at the forefront of digitalizing production processes, which has substantially improved its resource efficiency and waste management. |

| Criterion 3: Commitment to Sustainability and Digital Transformation | Its use of technology has not only streamlined operations but also significantly reduced its environmental footprint. | Its initiatives, such as recycling programs and energy-efficient operations, are supported by digital tools that track and enhance their effectiveness. | It has invested in advanced digital systems to monitor and optimize resource use, reflecting a strong commitment to environmental sustainability. |

| Criterion 4: Geographical and Economic Context | All companies operate within Greece, providing a consistent economic and regulatory context that influences their approaches to sustainability and digitalization. This context is particularly relevant given the European Union’s strict regulations on both digital innovation and sustainability practices. | ||

| Participant Position | Company | Gender | Age Group | Highest Academic Qualification | Expertise | Experience (Years) | Interview Date | Interview Duration (min) | Interview Mode |

|---|---|---|---|---|---|---|---|---|---|

| CEO | 3PL | Male | 40–45 | PhD | Supply Chain Management | 10–15 | 12/09/2022 | 45 | Face-to-face |

| Warehouse Manager | 3PL | Male | 40–45 | Bachelor’s degree | Logistics | 10–15 | 12/09/2022 | 45 | Face-to-face |

| Warehouse Manager | Retailer | Male | 40–45 | Bachelor’s degree | Warehouse Management | 10–15 | 09/05/2023 | 120 | Face-to-face |

| IT Senior Manager | Retailer | Male | 55–60 | Master’s degree | Information Technology | 20–25 | 07/07/2023 | 60 | Face-to-face |

| IT Junior Manager | Retailer | Female | 35–40 | Master’s degree | Information Technology | 5–10 | 07/07/2023 | 60 | Face-to-face |

| Procurement Manager | Producer | Male | 45–50 | Master’s degree | Logistics | 15–20 | 02/10/2023 | 30 | Face-to-face |

| IT Senior Manager | Producer | Male | 40–45 | Bachelor’s degree | Information Technology | 10–15 | 03/10/2023 | 45 | Video call |

| Head of Sustainable Development Department | Producer | Male | 50–55 | Master’s degree | Sustainability | 20–25 | 10/10/2023 | 45 | Video call |

| 3PL | Retailer | Producer | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Themes | Codes | Interviews | Interview Confirmation Method | Interviews | Interview Confirmation Method | Interviews | Interviews Confirmation Method | |||

| Two Key Officers | Review of Documents and Records | On-Site Observation | Three Key Officers | Review of Documents and Records | On-Site Observation | Three Key Officers | Review of Documents and Records | On-Site Observation | ||

| Sustainable Policies | Environmental Pillar |  |  |  |  |  |  |  | ||

| Social Pillar |  |  |  |  |  |  | ||||

| Economic Pillar |  |  |  |  |  |  | ||||

| Organizational Context | IT & Digital Transformation |  |  |  |  |  |  | |||

| SCM Resources/Processes |  |  |  |  |  |  | ||||

| Capabilities | Capabilities |  |  |  | ||||||

| Sustainable Impact | Environmental |  |  |  |  |  | ||||

| Social |  |  |  |  |  | |||||

| Economic Results |  |  |  | |||||||

| Excellence | Sustainable Development |  |  |  |  | |||||

| Digital Transformation |  |  |  |  | ||||||

| Business Performance |  |  |  | |||||||

| Sustainable Strategies | Sustainable Strategies |  |  |  | ||||||

| Themes | Codes | Company | ||

|---|---|---|---|---|

| 3PL | Retailer | Producer | ||

| Sustainable Policies | Environmental Pillar |

|

|

|

| Social Pillar |

|

|

| |

| Economic Pillar |

|

|

| |

| Organizational Context | IT and Digital Transformation |

|

|

|

| SCM Resources/ Processes |

|

|

| |

| Capabilities | Capabilities |

|

|

|

| Sustainable Impact | Environmental |

|

|

|

| Social |

|

|

| |

| Economic Results |

|

|

| |

| Excellence | Sustainable Development |  | ||

| Digital Transformation |  | |||

| Business Performance |  |  |  | |

| Sustainable Strategies | Sustainable Strategies |

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stroumpoulis, A.; Kopanaki, E.; Chountalas, P.T. Enhancing Sustainable Supply Chain Management through Digital Transformation: A Comparative Case Study Analysis. Sustainability 2024, 16, 6778. https://doi.org/10.3390/su16166778

Stroumpoulis A, Kopanaki E, Chountalas PT. Enhancing Sustainable Supply Chain Management through Digital Transformation: A Comparative Case Study Analysis. Sustainability. 2024; 16(16):6778. https://doi.org/10.3390/su16166778

Chicago/Turabian StyleStroumpoulis, Asterios, Evangelia Kopanaki, and Panos T. Chountalas. 2024. "Enhancing Sustainable Supply Chain Management through Digital Transformation: A Comparative Case Study Analysis" Sustainability 16, no. 16: 6778. https://doi.org/10.3390/su16166778

APA StyleStroumpoulis, A., Kopanaki, E., & Chountalas, P. T. (2024). Enhancing Sustainable Supply Chain Management through Digital Transformation: A Comparative Case Study Analysis. Sustainability, 16(16), 6778. https://doi.org/10.3390/su16166778