Abstract

The convergence of industry 4.0 technologies with supply chain operations and sustainability initiatives has sparked interest in integrating supply chain quality management with these advancements, termed SCQM 4.0. A comprehensive literature review spanning 1998 to 2023, analyzing 232 papers, unveiled key trends, identified research gaps, and outlined a future research agenda for SCQM 4.0. The review culminated in the development of a comprehensive theoretical framework for SCQM 4.0 geared towards fostering sustainability within a circular economy framework, encompassing economic, social, and environmental dimensions. Notably, the study implies a rising enthusiasm for leveraging industry 4.0 tools such as the internet of things, blockchain, traceability systems, and smart packaging to enhance quality management within circular supply chain operations. Additionally, it proposes SCQM 4.0 strategies aimed at achieving holistic sustainability objectives in circular economies, underscoring implications for further scholarly inquiry in this dynamic field. To promote supply chain quality management digitalization, supply chain stakeholders should analyze research gaps and develop practical implementation plans using the SCQM 4.0 framework. Additionally, exploratory qualitative investigations among organizations and industries should be conducted to identify essential components in sustainable SCQM 4.0.

1. Introduction

The growing interest in the circular economy (CE) reflects its compelling advantages for corporate organizations. As businesses increasingly prioritize sustainability and resource efficiency, the volume of studies on the CE has nearly tripled throughout the last five years [1]. This shift in economic thinking promises to mitigate environmental degradation, enhance resilience, and drive innovation in corporate landscapes, offering significant long-term benefits [2] such as a 40% global emission reduction from key industry materials in 2050 [3] and a 20% increase in productivity [4]. Advancing a CE aids in addressing resource scarcity and environmental issues [5] while enhancing a company’s performance across economic, social, and environmental sustainability dimensions [6]. In simple words, supply chain quality management (SCQM) is about implementing quality management principles in supply chains, serving as a company’s approach to partnering with suppliers and customers to enhance quality standards [7]. SCQM has transitioned from an activity-centric approach to a strategy-centric approach, working together and combining activities throughout the supply chain to detect and resolve quality concerns, with the ultimate goal of enhancing customer satisfaction and overall performance [8]. The shift to a CE is essential for production firms to accommodate rising consumer demands for sustainability while meeting product quality and safety criteria [9]. Meanwhile, industry 4.0 (I4.0) is an emerging area with a ten-fold increase in the number of articles from 2016 to 2021 [10] and growing industrial applications encompassing a wide range of advanced technologies merging physics, digital, and biology knowledge that change industrial operations across diverse sectors, industries, and economies [11]. The integration of SCQM with I4.0 technologies (SCQM 4.0) includes transformative technologies like AI, robotics, the IoT, biotechnology, autonomous vehicles, 3D printing, nanotechnology, and big data that enhance sustainable supply chain performance [12]. In order to achieve the objective of sustainable development, it is important to possess a comprehension of SCQM 4.0. Therefore, this article strives to answer two research questions:

- What are the current trends in the field of SCQM 4.0?

- What is the comprehensive framework for SCQM 4.0 adoption?

The aim of this study is to create a comprehensive conceptual framework for SCQM 4.0 to support a sustainable CE. Initially, a comprehensive literature review was conducted to explore the research and technology advancements in SCQM 4.0 for environmental analytics and management toward achieving a sustainable CE. Subsequently, a holistic SCQM 4.0 framework was proposed in three phases, utilizing environmental analytics and management strategies within the CE context. We anticipate that this framework will provide practical guidance for the implementation of SCQM 4.0 and establish a foundation for future research.

This study makes a dual contribution to the existing literature. First, the proposed conceptual framework for SCQM 4.0 provides a theoretical reference to practitioners in SCQM 4.0 deployment to achieve the execution and management of SCQM 4.0 that ensures sustainability in terms of economics, society, and the environment, as well as provide future research directions for the experimental or applied studies in this area. Second, the conceptual framework of SCQM 4.0 is a practical tool to measure and implement SCQM 4.0 in supply chain operations. Therefore, the findings of this research suggest that it is crucial to apply the SCQM 4.0 practices at a larger scale to assess the effects of SCQM 4.0 applications on supply chain operations and sustainable performance, with a focus on the bottom-up approach to obtain more accurate results. The bottom-up causal relationship between the constructs within the conceptual framework can be perceived as a roadmap for the implementation of SCQM 4.0.

The paper’s remainder is organized as follows: Section 2 outlines the comprehensive literature review conducted to gather pertinent resources regarding the incorporation of I4.0, quality management, and supply chain management. Section 3 presents the results and discussion from the literature review. The Section 4 presents the theoretical model of SCQM 4.0. In conclusion, Section 5 discusses the limitations and proposes future research directions.

2. Research Methodology

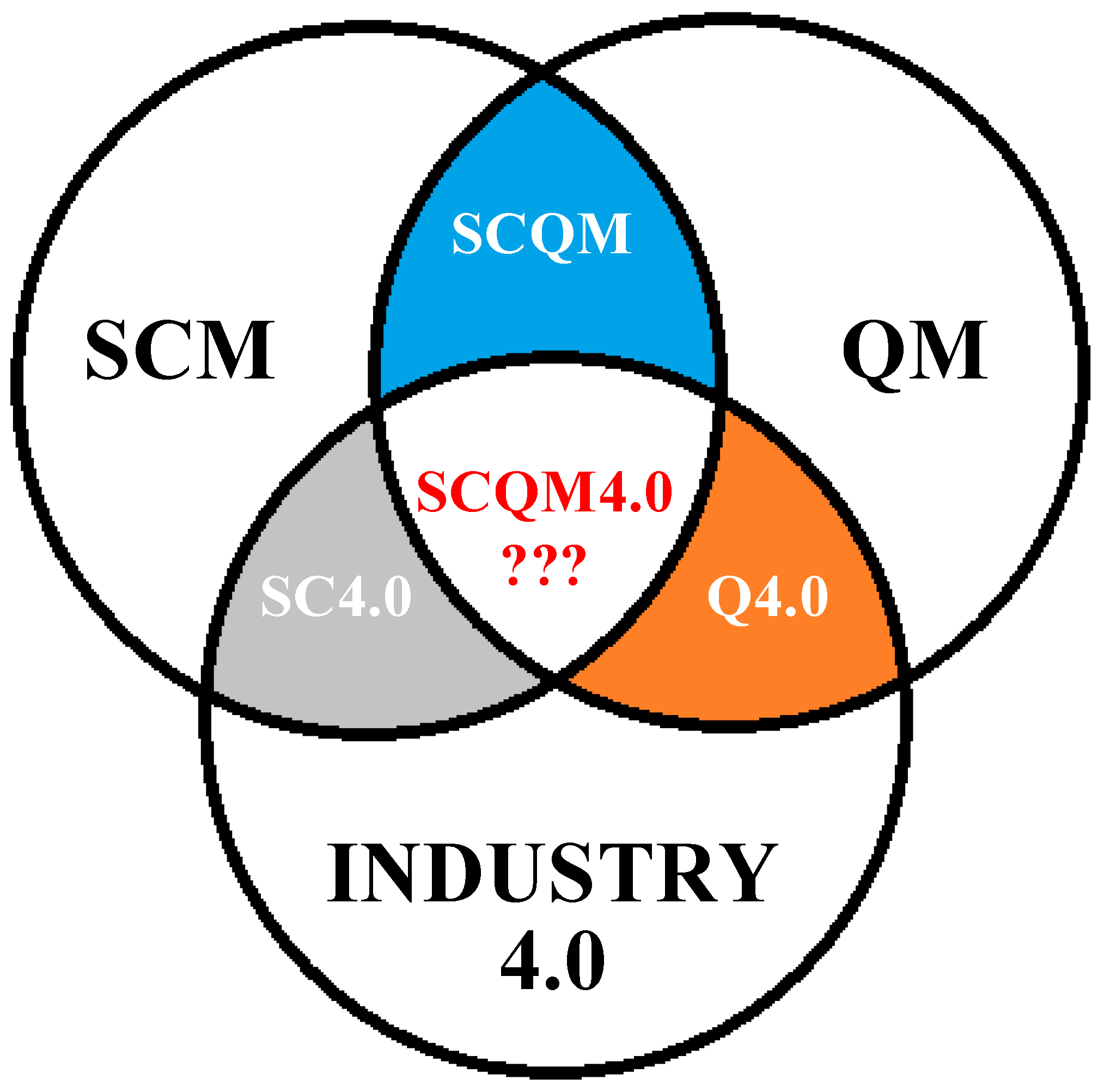

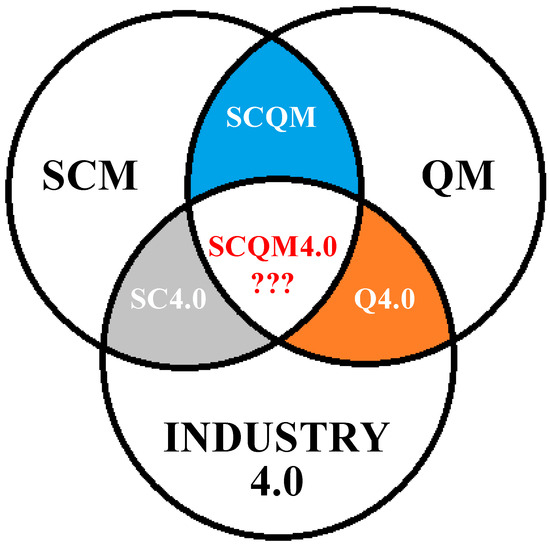

This study will tackle research goals such as constructing a conceptual framework for SCQM 4.0 with the literature review method (Table 1). Figure 1 presents the cluster integration of the I4.0 technologies and the management of quality and supply chain operations, which forms SCQM 4.0. The literature review method is an appropriate analytical method for this study to establish a solid knowledge base and facilitate theoretical exploration and analysis. As seen in Table 1, the literature review involved thorough research methods to address research issues by conducting thorough document searches, taking detailed notes, evaluating the significance, and outlining what is already known and what remains unknown in the field of research [13]. In particular, the authors first defined the research objective for the review and developed a search strategy, such as databases, keywords, and inclusion criteria. When the papers were identified and screened based on such criteria, data extraction was undertaken to collect crucial information. Afterward, the authors conducted a synthesis to determine patterns across the literature. Ultimately, the findings were analyzed in connection with the study’s aim, providing theoretical and practical implications. Discoveries are made through examinations focused on stimulating thoughts and developing future theories in these fields; the field of strategic management is being investigated [14]. Additionally, a comprehensive review is seen as an effective and verifiable approach that kickstarts theory development, recognizes principles, and reaches conclusions. Due to the potential for bias, the comprehensive review ensures a thorough, transparent, and reproducible evaluation of necessary research with great certainty [15]. The main method for a comprehensive and structured comprehensive literature review involves three steps: selection, synthesis, and results [16].

Table 1.

Comprehensive literature review protocol for SCQM 4.0.

Figure 1.

Integration of I4.0 of QM, SCQM, and SCM.

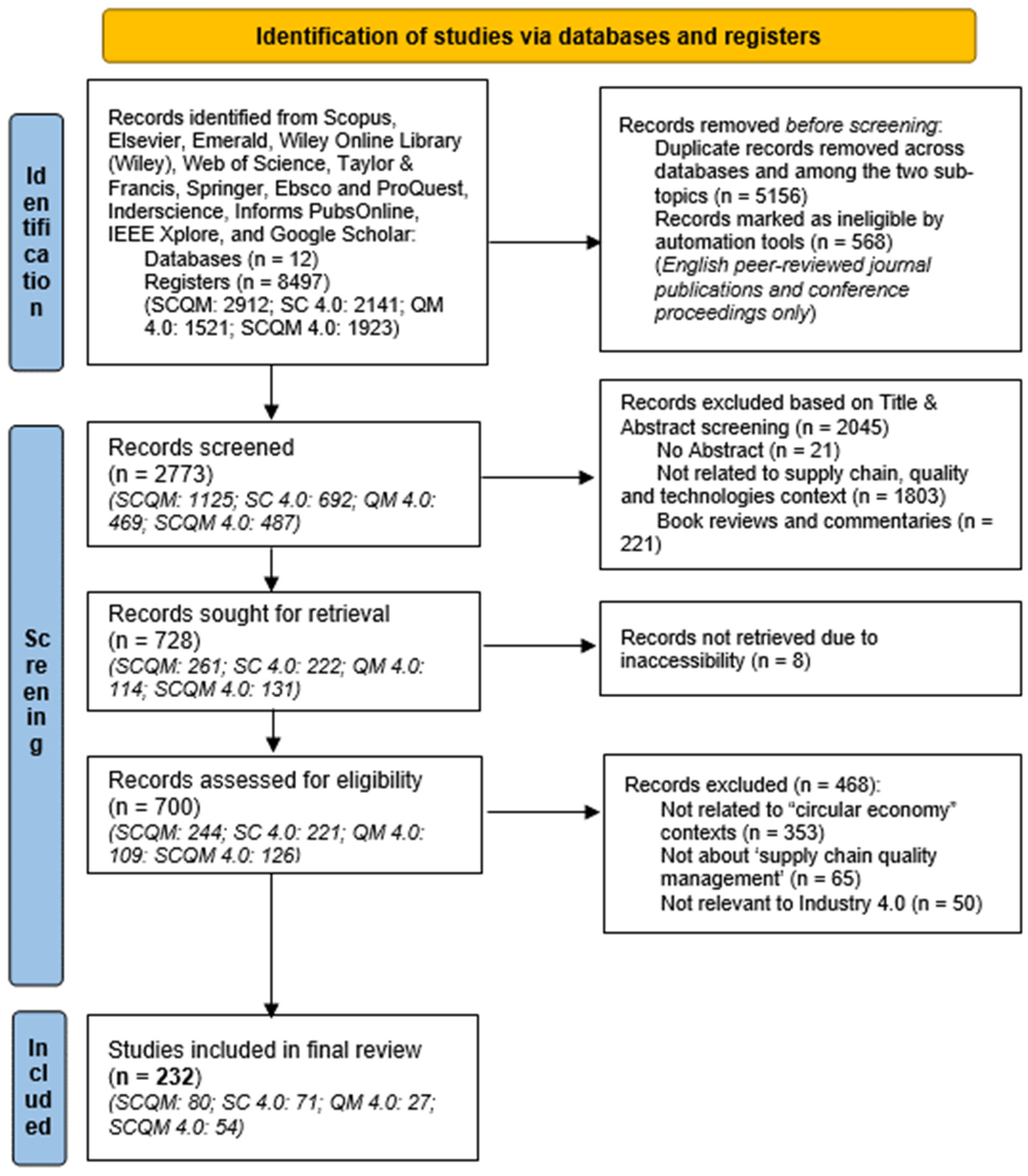

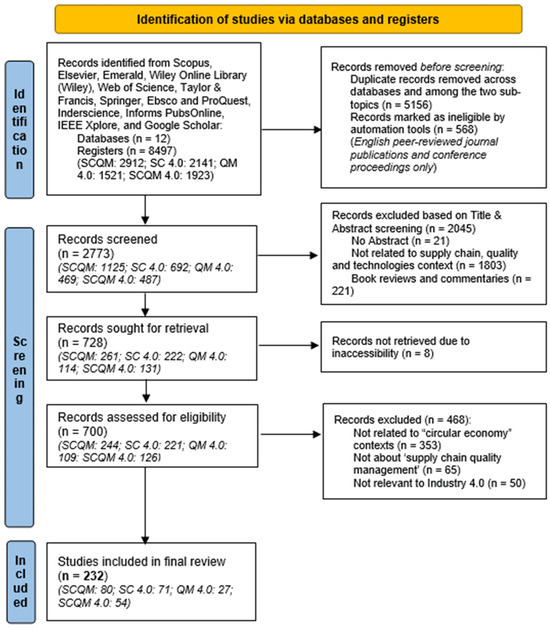

The comprehensive literature review protocol involved several key stages aimed at identifying and selecting relevant studies for inclusion in the final review (Figure 2). Firstly, the identification phase encompassed searching multiple databases and registers. Twelve databases, including Scopus, Elsevier, Emerald, Wiley Online Library, Web of Science, Taylor and Francis, Springer, Ebsco, ProQuest, Inderscience, Informs PubsOnline, and IEEE Xplore, along with Google Scholar, were queried. Additionally, registers such as SCQM, SC 4.0, QM 4.0, and SCQM 4.0 were explored, resulting in a total of 8497 records. In particular, SCQM4.0, an integration of industry 4.0 (I4.0) technologies, supply chain operations, and quality management for sustainability, involves leveraging digitalization and advanced technologies to enhance efficiency, transparency, and quality throughout the supply chain. Through the exploration of the literature on various keywords such as “Supply Chain and Quality and Digitization”, “Internet of Things and Supply Chain and Quality”, and others, organizations can integrate digital tools and platforms for end-to-end visibility, implement IoT sensors to monitor product conditions and ensure compliance with quality standards, align strategies with the objectives of the fourth industrial revolution to focus on innovation and resilience, establish smart factories equipped with IoT-enabled machines to monitor production processes, utilize big data analytics to extract actionable insights for data-driven decision-making, integrate cyber-physical systems to create a seamless connection between the physical and digital worlds, and deploy blockchain technology to establish transparent and immutable records of product provenance and quality.

Figure 2.

Identification of studies via databases and registers.

Before screening, duplicate records were removed across databases and sub-topics, resulting in the elimination of 5156 records. Moreover, records marked as ineligible by automation tools were removed, amounting to 568 records. The inclusion criteria stipulated English peer-reviewed journal publications and conference proceedings only.

During the screening phase, the remaining records (n = 2773) underwent title and abstract screening, resulting in the exclusion of 2045 records. Among these, 21 records lacked abstracts, while 1803 were deemed irrelevant to the contexts of the supply chain, quality, and technologies. Additionally, book reviews and commentaries accounted for the exclusion of 221 records.

Following screening, 728 records were sought for retrieval, with 8 records not retrieved due to inaccessibility. Of the retrieved records, 700 were assessed for eligibility. Records were excluded if they were not related to circular economy contexts (n = 353), supply chain quality management (n = 65), or industry 4.0 (n = 50).

Ultimately, 232 studies met the inclusion criteria and were included in the final review. These studies spanned various sub-topics, with 80 focusing on SCQM, 71 on SC 4.0, 27 on QM 4.0, and 54 on SCQM 4.0. This comprehensive literature review protocol ensured the thorough identification and selection of relevant studies for the final review, facilitating a comprehensive analysis of the research landscape on the intersection of circular economy, supply chain quality management, and industry 4.0.

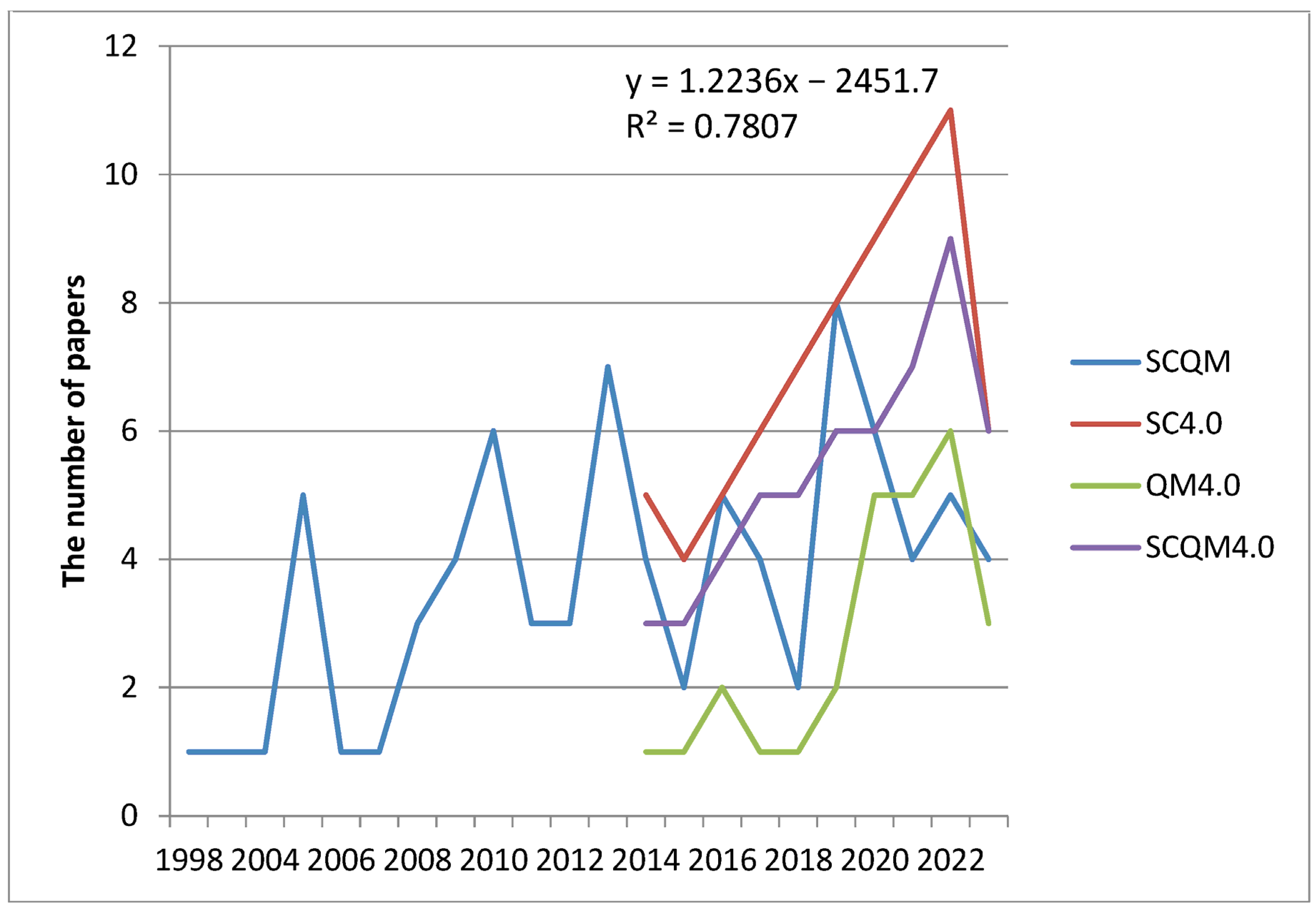

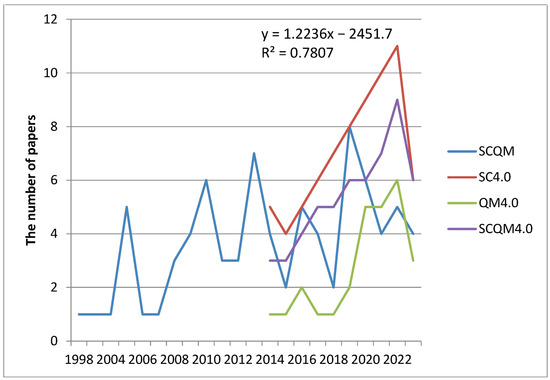

In total, 232 articles related to SCQM 4.0 were selected and classified as relevant in the literature review based on the article identification, screening, and inclusion process, as illustrated in Figure 2. Moreover, the software program Bib Excel 2017 processes and analyzes large sets of social longitudinal research data due to its adaptability and ability to integrate with various tools, including Microsoft Excel 2402, Pajek 5.18, and Gephi 0.10.0 [17]. Bib Excel provides support in preparing data for in-depth network study. According to the analysis of 54 out of 232 articles (represented in Figure 3), despite a relatively smaller number of studies compared to those on SCQM, SC4.0, and Q4.0, SCQM 4.0 holds significant potential for research and is of great interest to a wide range of academicians. The term “SCQM 4.0” can be understood to represent a combination of technological advancements and industry trends, including the internet of things (IoT), I4.0, supply chain management, and quality management. These concepts are keywords utilized to identify SCQM 4.0.

Figure 3.

SCQM4.0 publications between 1998 and 2023.

3. Analysis of the Literature Review Results

According to Figure 3, the concepts of supply chain quality management (SCQM), supply chain 4.0 (SC 4.0), quality management 4.0 (QM 4.0), and supply chain quality management 4.0 (SCQM 4.0) have evolved over time, reflecting the changing landscape of supply chain and quality management practices. SCQM emerged as a significant concept in 1998 and has since garnered increasing attention, particularly in recent years, with a notable rise in publications from 2014 onwards. SCQM focuses on the integration of quality management principles within supply chain processes to enhance overall performance and customer satisfaction. Similarly, SC 4.0 and QM 4.0 have gained prominence in the literature, reflecting the integration of industry 4.0 technologies and principles into supply chain and quality management practices. The intersection of these concepts is evident in SCQM 4.0, which represents the integration of quality management and industry 4.0 technologies within supply chain operations. The increasing publication trends for SC 4.0, QM 4.0, and SCQM 4.0 highlight the growing emphasis on leveraging advanced technologies and digitalization to optimize supply chain processes and quality management practices in the contemporary business environment.

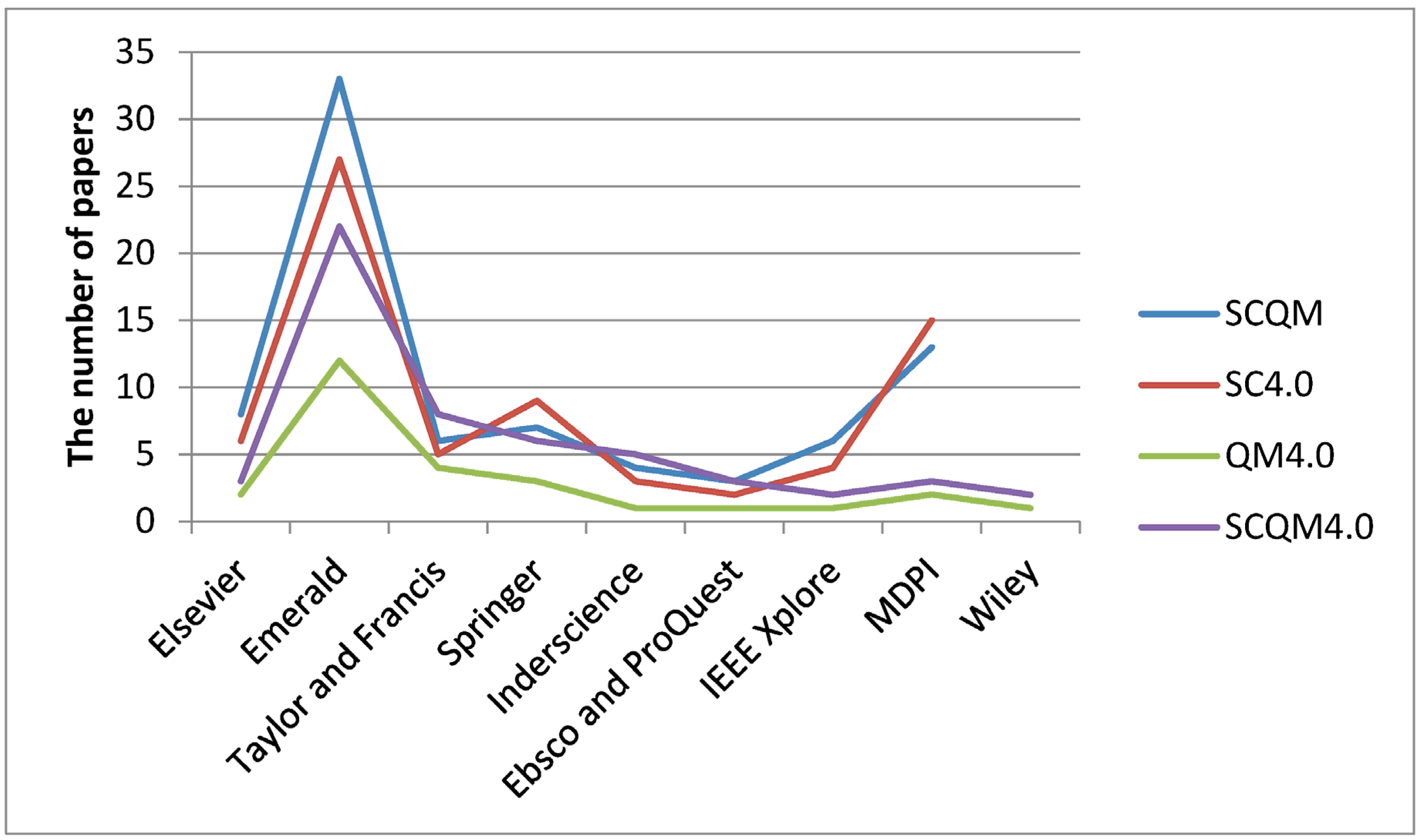

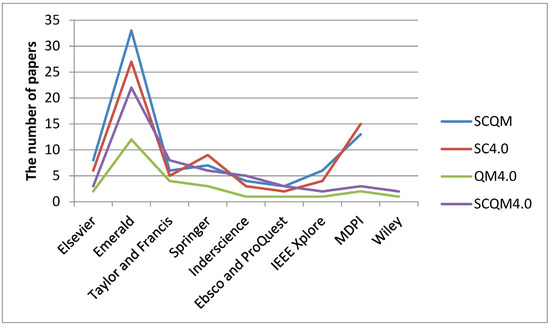

Furthermore, Figure 4 depicts the quantity of SCQM papers in each database from the antecedent literature. Although the search encompassed various databases, the articles predominantly focused on a few databases, including Emerald, Elsevier, and Taylor and Francis. Emerald published the most articles on SCQM, followed by MDPI, Springer, and Taylor and Francis, where the majority of the articles were on SCQM and SC4.0, while the articles on SCQM4.0 were shown to increase across the databases.

Figure 4.

Distribution of previous studies on different scopes of SCQM per database.

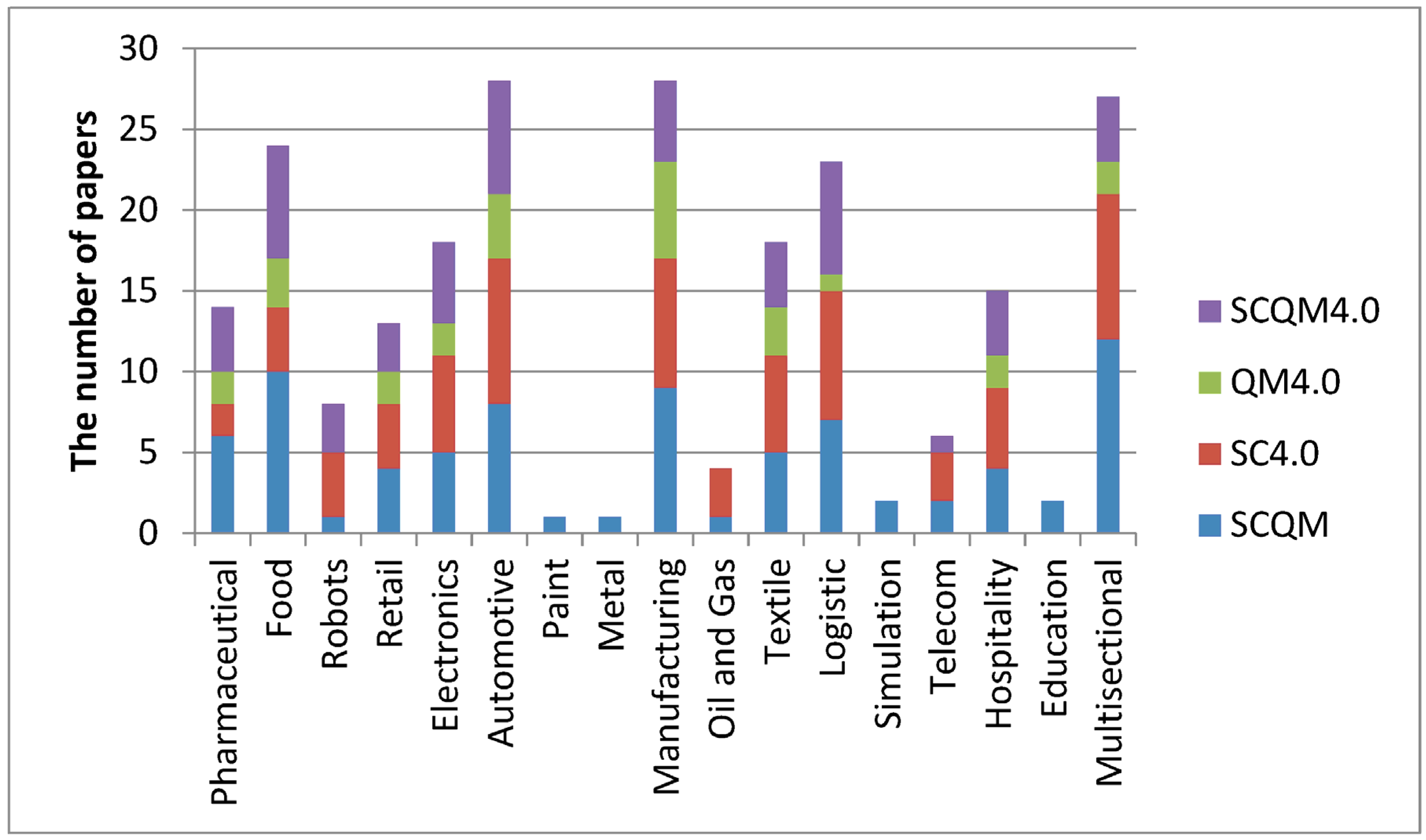

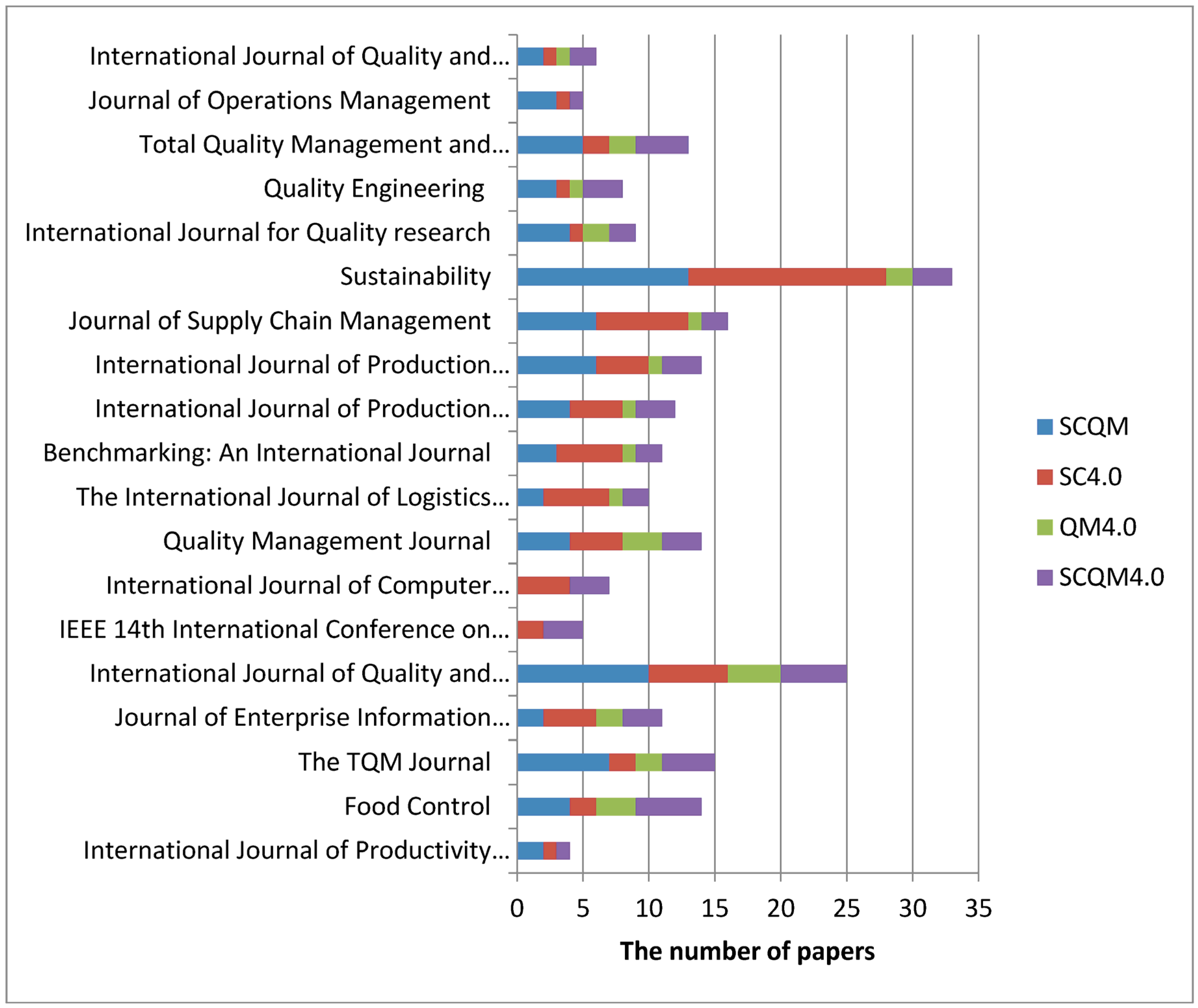

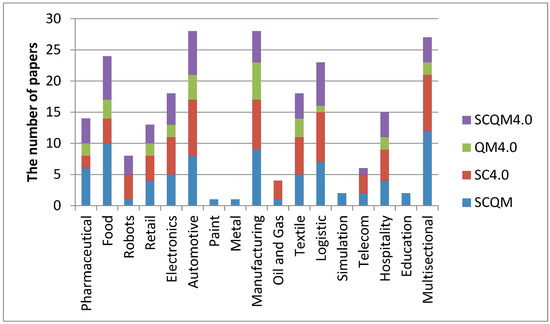

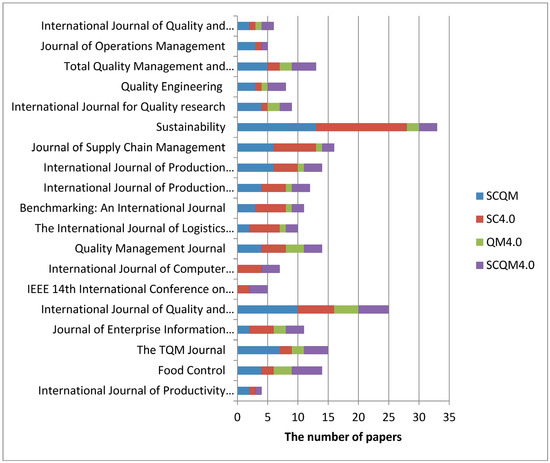

According to previous research, a range of industries have been studied in relation to SCQM (illustrated in Figure 5). The current discovery highlights a small number of empirical studies that require further examination by the academic community to validate and confirm the accuracy of conceptual models, as suggested by Frederico, et al. [18], Sony, et al. [19], Sampaio, et al. [20], and Fernandes, et al. [21]. According to Figure 5, the majority of empirical research studied was derived from automotive and manufacturing (16%), followed by multisectional (15%) sectors. Interestingly, the distribution of research across the manufacturing and service industries was relatively even, with service industries accounting for 41% to 59% of the surveyed industries, suggesting that academics place a significant emphasis on research related to service sectors. The studies on QM4.0 were comparatively less across different industries. Additionally, Figure 6 displays the number of articles about SCQM in various journals. Several academic journals, such as “The TQM Journal” and the “International Journal of Quality and Reliability Management”, have presented a wide range of articles on SCQM 4.0. These publications have showcased thorough research on SCQM 4.0, as seen in “Industrial Management and Data Systems” and “Food Control”. Furthermore, Figure 6 shows that studies on SCQM and SC4.0, followed by SCQM4.0, appeared the most in the majority of the journals.

Figure 5.

Distribution of researched sectors in the previous articles on different scopes of SCQM.

Figure 6.

Number of previous studies on different scopes of SCQM published in different journals.

According to the graph, there was an anticipated increase in research activity from 2020 onwards, with notable publications like “The TQM Journal”, “Industrial Management and Data Systems”, “Food Control”, “International Journal of Quality and Reliability Management”, “International Journal of Production Economics”, and “Sustainability” concentrating on the topic (Figure 6).

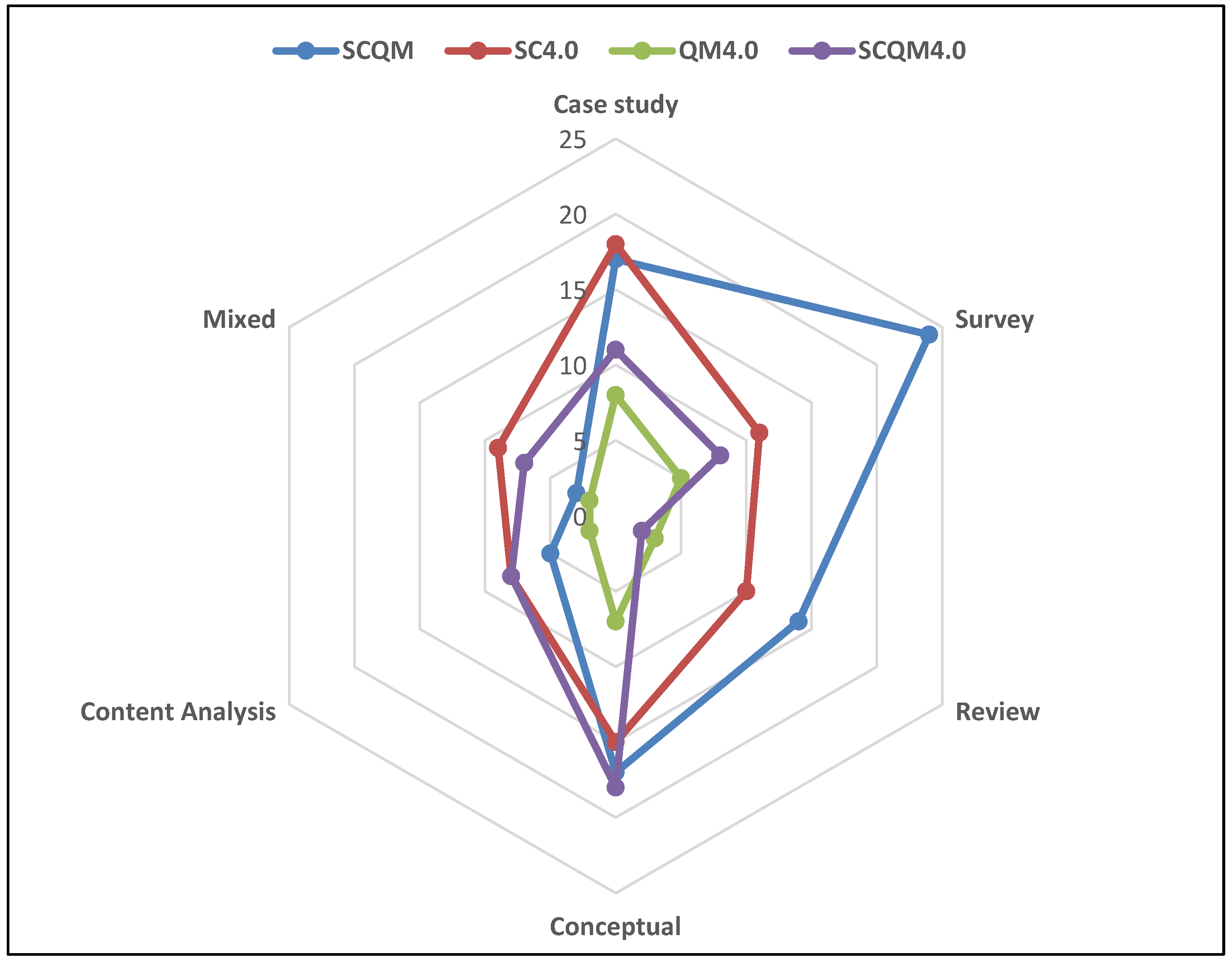

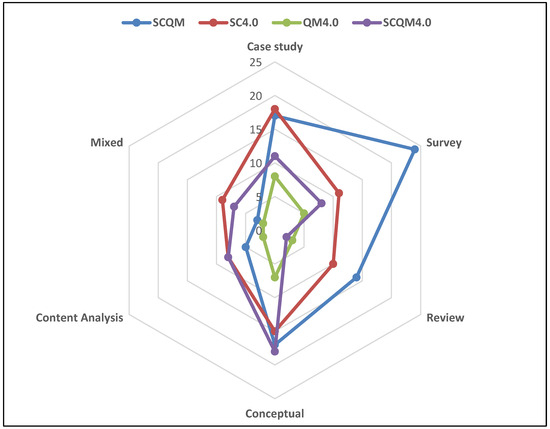

According to Figure 7, the majority of research methodologies used in the antecedent literature on SCQM were empirical studies, comprising 53% of the publications. These studies include surveys (29%) and case studies (24%). The majority of these methodologies aimed to provide insights into how supply chain management, quality management, and digital transformation are implemented in multiple industries by collecting data through questionnaires, surveys, and case studies of firms in different industries. Remarkably, 19% of the publications put forward novel frameworks for techniques, tools, and practice integration. Literature reviews contributed 7% of the total quantity of articles, facilitating theory contribution and novel directions for future studies. The frequencies of empirical study techniques, including case studies and surveys, were comparable, with 19% and 23.5%, respectively. A mere 4% of articles employed qualitative and quantitative methodologies. As shown in Figure 7, we found that content analyses and mixed methods were less applied in the studies on SCQM, and the review method was also less applied in the studies on SCQM4.0 Meanwhile, case studies, surveys, and conceptual methods were most applied in the studies on QM4.0. Carranza [22] proposed the following two strategies to enhance the precision and reliability of study results: (1) knowledge-based/directional and (2) data-based/quantitative.

Figure 7.

Number of research methodologies utilized in previous articles on different scopes of SCQM.

Thematic Synthesis and Analysis

The research on traceability technology trends has identified several applications within supply chain management. Bhatt, et al. [23] and Olsen and Borit [24] examined traceability technologies’ broader applications. Specifically, scholars have investigated the application of RFIDs in traceability [25], RFIDs with PDA and barcodes [26], “gapless” RFID-based traceability [27], RFID technology’s applications in logistics [28], and anti-counterfeit operations [29]. The role of the IoT and EPC global standards in enhancing traceability was explored by Furdik, et al. [30], emphasizing interoperability and data exchange. Óskarsdóttir and Oddsson [31] specifically investigated traceability challenges in cold supply chains, emphasizing temperature control. Through traceability, while Wang, et al. [32] and Xiao, et al. [33] focused on ensuring product quality, ensuring security and safety was addressed by Liu, et al. [34]. Moreover, other perspectives of traceability technologies were researched: traceability’s value to customers [35], implementation requirements, consistency, data security and big data expertise [36], and technology challenges in handling the heterogeneous nature of the supply chain [37].

According to recent research on SCQM 4.0, there is a growing trend towards utilizing blockchain technology to mitigate risks and enhance supply chain quality management, e.g., [38]. Blockchain, a groundbreaking and transformative technology, is revolutionizing the agricultural industry (e-agriculture). The integration of blockchain technology has shown significant potential in various business applications, particularly in supply chain management [39]. The incorporation of blockchain technology can enhance data collaboration and trust among various stakeholders due to its inherent qualities, including transparency, resistance to censorship, distributed ledger technology (DLT), and smart contract functionality [40], and can create top-notch data infrastructure [41]. Blockchains were used in an intelligent SCQM framework [42], supply chain traceability systems integrating blockchain and IoT technology [43], and a supply chain traceability system utilizing HACCPs (hazard analysis and critical control points), blockchains, and the IoT [44]. Additionally, the adoption of blockchains was studied to evaluate the practical implications and effectiveness of blockchain solutions in supply chain operations. While Kamath [45] analyzed the implementation of a prototype project utilizing blockchain technology and a trial deployment, Galvez, et al. [46] and Tripoli and Schmidhuber [40] discussed challenges associated with implementing blockchains and smart contracts in supply chain management. The use of blockchain technology will be applied in supply chain operations management, which is a viable and promising area of implementation [47].

Recently, more research has been dedicated to integrating blockchain technology with other advanced technologies [48]. The IoT represents a groundbreaking technology that is transforming various industries, including QM. Moreover, the IoT enables seamless communication between people and objects, as well as the automated coordination of “things” while they are stored or transported between different entities [49]. For example, Puligundla, et al. [50] contributed to the exploration of carbon dioxide sensors, focusing on different types and their applications in smart packaging systems. To monitor the history of temperature variations over time, while Brizio and Prentice [51] and Gao, et al. [52] investigated the use of photochromic time-temperature indicators (TTIs), Zavala, et al. [53] and Lorite, et al. [54] delved into the development of smart time-temperature indicators. Moreover, Tsang, et al. [55] explored the utilization of IoT technology for item monitoring within smart packaging systems, emphasizing enhanced tracking and traceability functionalities. Regarding sustainability initiatives, Fang, et al. [56] and Poyatos-Racionero, et al. [57] contributed to research on intelligent packaging solutions designed to minimize waste through innovative design and material selection strategies. The IoT is experiencing rapid growth and is the focus of increasing attention in both academic and industrial circles, offering enhanced visibility, agility, and adaptability in solving multiple quality problems within the supply chain [49].

The current literature also provides a comprehensive overview of supply chain IoT implementation and frameworks, detailing various contributions from researchers in the field. In terms of implementation, several studies have explored the use of the IoT for monitoring processes to ensure quality [58] and safety [59] within supply. Specific areas of focus include monitoring cold supply chains using the IoT [60], cargo monitoring systems leveraging the IoT for product quality assurance [61], and monitoring cold supply chains using the IoT and cloud computing [62]. Additionally, Liu, et al. [63] and Luo, et al. [64] contributed to the development of intelligent IoT-based tracking systems for cold chains and traceability in duck products, respectively. Apart from the IoT, RFID and sensor-based systems have been developed for the real-time inventory tracking of critical temperatures [54] and for the tracking of refrigerated distribution chains [65]. Regarding frameworks, Pang, et al. [66] suggested a framework prioritizing value in IoT technologies, while Verdouw, et al. [67] developed an architecture for logistics information systems based on the IoT. In supply chains, specific fields have been studied, such as planning with the IoT [68], virtualization [69], and hierarchical data architecture for sustainability [70]. With the use of the IoT, scholars have developed an assessment technique for producing [71] and monitoring cold supply chains [60].

Despite advancements in security technology, fundamental flaws continue to pose significant risks to privacy and security [72]. The current security and privacy measures are not adequate for the IoT due to its decentralized network structure and the limited resources of mobile devices [73]. Challenges in the widespread adoption of the IoT include the significant cost of investing in IoT technology [74], the extensive data produced by the IoT requiring strong software and hardware, and a secure environment to efficiently handle and analyze it. However, the lack of standardization in IoT systems [72] creates barriers for companies to adopt IoT technology. Due to the extensive variety of products, a situation-by-situation implementation strategy is frequently adopted as a result of the absence of standardization, which can lead to inefficiencies and inconsistencies (Badia-Melis et al. 2018) [75], and the lack of adequate government oversight and subpar internet infrastructure are significant contributors to the complexity of the situation [76].

4. A Conceptual Framework for Sustainable SCQM 4.0

The research seeks to develop a definition of SCQM 4.0 that can serve as a guiding framework for its construction in the following section:

“Supply chain quality management 4.0 is a holistic and transformative approach to supply chain and quality management where companies are applying breakthrough I4.0 technologies to their operations in the industry network of companies for higher quality products and services, streamlining processes and supply chain relationships to achieve high levels of customer satisfaction and benefit significant strategy for all stakeholders in the supply chain.”

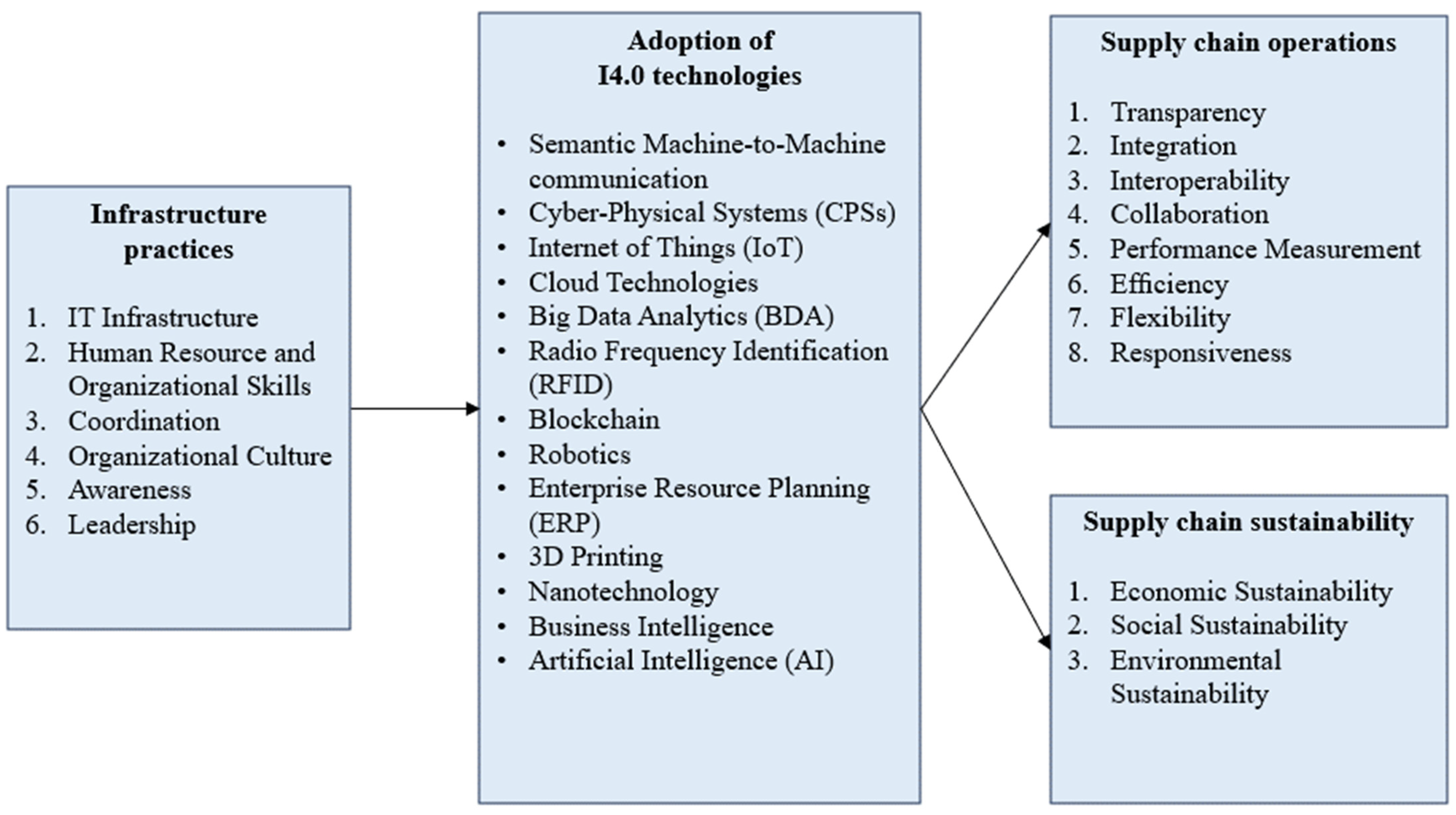

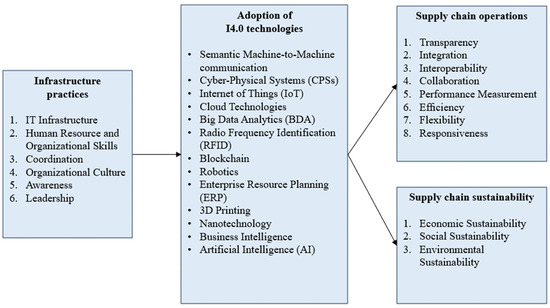

This study aims to propose a SCQM 4.0 conceptual framework and integrate the components of I4.0 technologies, supply chain operations, and quality management to achieve sustainability in a CE. The focus is on simultaneously achieving economic, social, and environmental sustainability through this integrated approach. The components were generated using the literature review method. SCQM incorporates two key elements of sustainable supply chain operations and quality management practices into its conceptual framework. The text describes two interrelated components of a company’s operations: (1) infrastructure practices and (2) sustainable performance, which encompasses three sustainability components: economic profitability, social engagement, and environmental respect. Figure 8 provides a comprehensive conceptual framework for the study, including infrastructure practices, the adoption of I4.0 technologies, supply chain operations, and supply chain sustainability, which is further elaborated upon in the following sections.

Figure 8.

The SCQM 4.0 conceptual framework of this study.

4.1. Infrastructure Practices in SCQM 4.0

Table 2 displays the significant infrastructure practices present in SCQM 4.0, the first component in the conceptual framework, which includes technology systems, personnel and workplace management, collaboration, company principles, understanding, and management. To illustrate this, the personnel and workplace management suggest that the business structure, human resources strategy, workplace environment, and capability improvement are significant factors in the implementation of SCQM 4.0 [77]. Furthermore, the company principles play a key role by highlighting the collection of norms, beliefs, and values that are mutually held by employees within a company when embracing innovative I4.0 technologies, along with the backing of senior management for these disruptive technologies to enhance supply chain quality [78].

Table 2.

Infrastructure practices in SCQM 4.0.

4.2. Adoption of I4.0 Technologies in SCQM 4.0

The SCQM 4.0 disruptive technologies in Table 3 involve the integration of 13 cutting-edge innovations to enhance product quality within the supply chain. Such devices necessitate a robust technological system for their development, initial implementation, and ongoing maintenance to ensure their optimal functioning. The continuous research and advancements in I4.0 and its devices are a major influence on social and economic advancements in different fields. In recent years, various initiatives have been implemented, building upon advancements in technology. Advancements in the digital, biotechnological, and physical domains have been progressing quickly and significantly improving. The core technologies of I4.0 have been integral to these developments. Therefore, these technologies have significant impacts on new product development, quality improvement, and operations management, which will improve supply chain quality management [92,93].

Table 3.

Adoption of I4.0 technology in SCQM 4.0.

4.3. Supply Chain Operations in SCQM 4.0

Table 4 summarizes the supply chain operations in SCQM 4.0 that are defined and discussed in the current literature. In order to effectively implement technologies, employees must strategically participate in continuous training provided by organizations. The necessary skills for SCQM 4.0 encompass technical elements as well as transferable skills like adaptability, critical thinking, creativity, teamwork, and knowledge sharing [141]. In addition to a transformational leadership approach, it is essential to also focus on incorporating elements of learning and innovation. The current forms of transformational leadership consist of idealized influence, inspirational motivation, intellectual stimulation, and individualized consideration [142]. The difficulty arises in connecting diverse systems, platforms, and standards due to the absence of standardization in IoT systems. Fast detection sensors that can withstand challenging conditions are necessary [143]. Anyway, the resistance to change of stakeholders during technology implementation in organizations and business processes hinders the technological adoption and resulting challenges for SCQM 4.0 implementation. Hence, the commitment from senior leadership to facilitate these changes is pivotal. Furthermore, the effectiveness of SCQM 4.0 hinges on the integration of technologies into corporate tactics. Top management backing and a leadership style focused on knowledge are required. A lack of standardization leads to a fragmented approach to implementation because of the wide variety of products in use [75]. In summary, further obstacles come about because of insufficient government supervision and ineffectual internet infrastructure [76]. While the enhancement of regulatory frameworks and standards can be achieved via collaboration between the private and public sectors, the vital aspect of infrastructure development, particularly internet access, necessitates investment [144]. Initiatives aimed at enhancing capacity and advocacy endeavors directed at policymakers have the potential to empower parties and enhance awareness, thereby supporting the successful adoption of SCQM 4.0 and enhancing the performance of supply chains [145].

Table 4.

Supply chain operations in SCQM 4.0.

4.4. Economic, Social, and Environmental Sustainability in SCQM 4.0

The concept of the circular economy (CE) had a surge in prominence throughout the 1960s. According to Preston [159], industrial ecology (IE), which serves as the foundation of the CE, initially originated in the 1970s. The CE refers to a theoretical framework of economic circulation that aims to minimize resource use within closed-loop production and consumption systems. According to a number of studies [160], it is widely acknowledged that the theoretical and empirical underpinnings of the CE are mostly rooted in IE theory. The term CE, similar to IE, denotes an analogy that draws a comparison between industrial and natural systems. The objective of this approach is to enhance the efficiency of matter and energy movement with the aim of minimizing the depletion of natural resources and environmental emissions, which entails transitioning towards a state of closed-loop supply chain [161]. Berlin, et al. [162] investigated the interconnectedness of open- and closed-loop supply chains in a CE, thereby advocating for the adoption of closed-loop systems to achieve resource sustainability. Regarding the most important factor in sustainability, carbon emissions, Li, et al. [163] and Abbasi and Erdebilli [164] proposed a necessity-based optimization approach and explored the resilience of green closed-loop supply chains under the uncertainty of carbon policies, respectively. Scholars have also discussed critical factors in closed-loop supply chains, such as the strategic dimensions of pricing and advertising decisions in direct sales [165] and hybrid meta-heuristic algorithms tailored for dual-channel networks [166]. Moreover, the CE is mostly focused on the examination of the movement of matter, energy, and information within both natural and industrial systems. Interactions between industrial and natural systems are examined by IE at several levels, including the corporate, firm, regional, and higher levels. To achieve success in a CE, it is necessary to exert efforts at three levels [167]. At the micro level, the product-focused strategy is linked to cleaner manufacturing, life-cycle management, environmentally friendly design, and several stakeholders, including the suppliers, producers, customers, and designers [168]. The eco-industrial and eco-agricultural park or system strategy at the meso level encompasses the industrial symbiosis (IS) concept as a waste-trading network that is structured around clustered companies engaged in the exchange of by-products and the sharing of standardized services or infrastructures [159]. However, this approach can additionally include alternative forms of inter-organizational environmental management [169]. The service or functional economy, at the macro level (local, regional, or national level), focuses on the use of services as by-products [170] and is connected to various kinds of dematerialization and rematerialization [171]. The IS concept is expanded to include urban symbiosis, which is predicated on the synergistic prospects that emerge from geographical closeness facilitated by the exchange of physical resources for the benefit of both the environment and the economy [172].

Multiple scholars have established different CE frameworks, some of which are incorporated in the research following the number of approaches, such as 3R (i.e., reduce, reuse, and recycle) [173], 4R, 5R, 6R, 10R, or the ReSOLVE framework [174]. According to [175], the spectrum of circular economy strategies encompasses several frameworks, from the 3R framework (which includes reduce, reuse, and recycle) to the 6R framework (which includes repair, reduce, reuse, recycle, redesign, and remanufacture). The body of scholarly work pertaining to the CE has seen significant expansion over the last decade, mostly attributed to its capacity to provide viable alternatives for sustainable production, with a particular focus on small- and medium-sized enterprises [176].

Drivers for Circular Economy Adoption

Comprehending the factors that influence the CE is crucial as it has a significant role in driving development in developing nations [177]. Stakeholders engage in the CE for a variety of reasons, including resource scarcity, environmental degradation, favorable business opportunities, regulatory compliance, consumer pressure, customer collaboration, and enhanced firm performance [161]. The primary motivations for the adoption of CE initiatives are categorized into two types: internal and external [177].

According to Tan, et al. [178], the possibility of higher revenue is what drives organizations’ internal pressure to adopt the CE. The researchers identified five primary internal drivers, namely, advantages to the economy and environment, increased resilience and supply security, new and improved customer relationships, and corporate values, approaches, and ambitions. Moreover, it was emphasized that the attainment of the advantages of a CE necessitates the presence of two key external forces: market force and coercive pressure. Several factors have been identified by numerous researchers as the driving forces behind the CE, including lowering expenses in manufacturing [179], a diversified and customized offering, increased brand safety and commitment [178], a rise in revenue from recovering waste products, and increasing rivalry from low-cost nations [180].

Additionally, there is a growing trend in society towards environmentally friendly consumption, accompanied by an increase in consumers’ environmental knowledge and their preference for sustainable products [181]. Furthermore, sustainability-minded entrepreneurs strive to combat the excessive use of natural resources, including degradation issues [182], and advocate for innovation as a crucial catalyst for achieving sustainability [183]. As a result, the CE approach offers a robust strategic framework that facilitates the shift towards environmentally sustainable production and consumption [184].

The three main factors of sustainable supply chain management in the CE are economic, social, and environmental sustainability [185]. Sustainable SCQM 4.0 enables supply chain operations to generate profits and value for their stakeholders, improve the well-being of the employees and the communities in which the business operates, and reduce the adverse environmental impacts in supply chain operations [5]. Thus, the progression towards the achievement of the three sustainability pillars becomes achievable in the adoption of SCQM 4.0 with the empowerment of I4.0 technologies [186].

Economic sustainability attained in a CE through SCQM 4.0, such as production efficiency and business model innovation, can expand a firm’s production capacity and enable higher profitability and market expansion [187]. The indicators of economic sustainability in the CE consist of (1) product and process enhancement and (2) market development opportunities. Firstly, by incorporating sustainable product design principles, firms can develop products that appeal to environmentally conscious consumers in a CE [138]. Such products that are environmentally friendly support product brand reputation, increased customer loyalty, and higher sales volumes [188]. Moreover, sustainable production process improvements in a CE, such as energy-efficient manufacturing and waste reduction, increased productivity, and optimized resource utilization, can result in substantial production cost reduction [189]. For instance, energy-efficient buildings can reduce energy consumption and lower utility bills [190], while waste reduction and recycling initiatives can minimize waste disposal costs [191]. In addition, products that emphasize eco-friendly, socially responsible, or ethically sourced factors socially motivate the consumer’s willingness to pay premium prices that align with their perceived values [188]. By embedding sustainability into business operations, firms can achieve long-term cost savings and improve their economic performance. Secondly, sustainable performance can facilitate market expansion by unlocking new customer segments and business opportunities. As sustainability gains prominence in consumer preferences, businesses that prioritize sustainability can tap into niche markets and attract new customers [192]. Additionally, sustainability-oriented partnerships and collaborations can open doors to untapped markets, fostering growth and diversification [193]. By aligning their strategies with sustainability, companies position themselves favorably to expand their market share and seize emerging opportunities.

Social sustainability in the CE underscores the importance of social responsibility in sustainable practices and demonstrates how they can contribute to societal progress, which is related to individual knowledge, skill enhancement, and ethical business practices [194]. Social sustainability indicators focus on individual well-being, which directly influences the livelihood of individuals within organizations and communities [195]. In knowledge and skill enhancement, sustainable performance encourages organizations to provide skill enhancement, career progression, and sustainable business practices that create an organizational culture that nurtures employees’ talents, fostering job satisfaction and overall well-being [196]. More importantly, sustainable practices often involve investments in workforce training for employee education and skill development. By providing training and educational opportunities, companies contribute to the personal growth and professional advancement of their employees [2]. This not only enhances individual well-being but also cultivates a knowledgeable and skilled workforce that can drive innovation and productivity. Furthermore, ethical business practices in the CE often leverage employee awareness and initiatives on environmentally friendly operational protocols [197] through the firm’s endeavors in renewable energy, environmental conservation, and socially responsible activities, which promote social inclusion that improves livelihoods [2]. In addition, these practices emphasize the production of safe products and processes that prioritize consumer health and safety [6]. By adhering to rigorous quality standards, ethical sourcing, and responsible manufacturing practices, businesses build trust and contribute to the overall well-being of consumers [198]. Environmental respect and responsible resource management in a CE are fundamental aspects of sustainable performance that underscore the importance of integrating environmental considerations into a firm’s sustainable performance strategies [199]. In SCQM 4.0, environmental sustainability involves managing inputs, handling waste, and preserving resources. By examining these three components carefully, we aim to highlight how companies can positively impact the environment and underscore the importance of integrating environmental considerations into sustainable business strategies. The first crucial aspect of environmentally conscious and sustainable performance is the efficient management of input resources. This entails responsibly utilizing and preserving resources in all aspects of a company’s activities, aiming to reduce waste and optimize resource efficiency [200]. Input management emphasizes environmentally friendly operational practices from three perspectives: (1) companies prioritize the efficient use of energy, water, and raw materials to reduce consumption, streamline production processes, and minimize waste [201] and (2) sustainable sourcing entails implementing practices that prioritize environmental responsibility when selecting suppliers. This involves partnering with suppliers who adhere to environmentally friendly standards and practices [197]. To mitigate the adverse ecological effects of the production process, this approach prioritizes the procurement of inputs and materials in a way that minimizes harmful practices, such as deforestation or habitat destruction. [195]. Lastly, (3) businesses may conduct a comprehensive analysis of the environmental effects of their products or services from start to finish, including raw material extraction, production, use, and disposal through a process known as life-cycle assessment [202]. Through this process, companies can pinpoint areas where they can make adjustments to reduce their environmental impact and make data-driven decisions to minimize their overall ecological footprint [203]. Furthermore, efficient waste management is crucial for eco-friendly and long-lasting activities, as it minimizes contamination, preserves materials, and follows CE guidelines [189]. Waste handling emphasizes environmentally friendly operational practices in three perspectives, i.e., waste reduction, recycling and reuse, and hazardous waste management. Sustainable companies use strategies like process optimization, product redesign, and material substitution to minimize waste generation and decrease waste management costs, aiming to decrease their environmental impact and enhance sustainability [2]. Encouraging recycling and reusing practices can effectively decrease landfill waste and preserve resources. Businesses are essential in promoting a sustainable economy by implementing recycling programs and finding innovative ways to reuse materials [200]. In order to ensure environmentally responsible and sustainable performance, firms should properly manage and dispose of hazardous materials to prevent pollution and safeguard ecosystems and human health [204]. It is crucial to adhere to regulatory guidelines, establish proper storage and disposal methods, and encourage environmentally conscious waste management practices in the handling of hazardous waste [197]. Thirdly, the protection and conservation of natural resources and ecosystems are fundamental components of environmentally responsible and sustainable practices [205]. There are three perspectives: biodiversity conservation, environmental stewardship, and sustainable performance. Businesses that prioritize sustainability focus on safeguarding and revitalizing biodiversity by limiting habitat destruction, collaborating with conservation initiatives, and adopting environmentally responsible land management techniques [206]. Preserving biodiversity is crucial for the resilience of ecosystems and the long-term health of the planet [199]. Furthermore, environmental stewardship involves implementing measures to reduce emissions, minimize water and air pollution, and adopt sustainable land use practices [207]. To achieve sustainable performance, businesses must actively participate in global initiatives aimed at reducing the impact of climate change [194], such as lowering emissions, switching to renewable energy sources, and adopting carbon offset measures [190].

5. Conclusion and Future Research Directions

5.1. Findings

The research introduces a SCQM 4.0 conceptual framework incorporating I4.0 technologies, supply chain operations, and quality management to support economic, social, and environmental sustainability in a CE. The research emphasizes the significance of setting up technology systems, personnel and workplace management, collaboration, company principles, understanding, and management to effectively implement disruptive technologies. Failure to build this foundation may result in the ineffective execution of technologies for sustainable supply chain operations. Furthermore, utilizing 4.0 technologies enhances product and service quality management, addresses supply chain trust issues, and improves resource allocation efficiency and production process optimization. SCQM 4.0 strengthens manufacturing operations with I4.0 disruptive technologies that maximize outputs and create high-quality products and services whilst utilizing minimum resources [208].

From the literature, our findings about the significance of integrating I4.0 with supply chain management to attain economic, social, and environmental sustainability are supported by numerous studies. Chen and Paulraj [209] and Pagell and Wu [210] made significant contributions to the advancement of theoretical concepts and metrics in supply chain management, emphasizing the need for a holistic framework that includes aspects of technologies and businesses. More studies have highlighted the emergence of I4.0 through a framework for sustainable supply chain management 4.0 [211] and conceptual and maturity frameworks for SCQM 4.0 [130]. Sarkis, et al. [212] also placed a significant emphasis on the organizational aspects of sustainable supply chain management, which is aligned with our research’s emphasis on human resources and cooperation. Moreover, the role of digital supply chain twins in disruption management is discussed by Ivanov and Dolgui [213], corroborating our research outcomes about the importance of technological systems and resource allocation. Overall, our study extends the understanding of SCQM 4.0, underlining its potential to contribute to the CE.

5.2. Limitations and Future Research Directions

Despite its valuable contributions, this study has shortcomings.

- Firstly, it broadly focuses on research objectives instead of a specific industry, potentially limiting its applicability to other industries. It is important to note that the study did not examine SCQM 4.0 toward the CE across sectors. Different industries have unique characteristics, challenges, and opportunities that could impact the effectiveness of sustainable SCQM 4.0 practices on supply chain quality. Furthermore, SCQM 4.0 is an emerging concept that might impede a more thorough comprehension of its impact on the CE in different industries.

- Secondly, the study overlooks the influence of regulations and institutional factors on the implementation and outcomes of SCQM 4.0 practices. Variations in regulatory and institutional environments between countries and regions may affect firms’ ability to adopt SCQM 4.0 practices and attain sustainable performance. Moreover, under uncertain conditions, regulatory frameworks are constantly changing to address emerging issues, including climate change and social responsibility; companies are confronted with more confusion over their obligations to comply with regulations and adhere to standards, which in turn affects their business operations.

Furthermore, this study also sheds light on the avenues for future research on sustainable SCQM 4.0.

- This research advocates for the further exploration of the relationships between quality management, supply chain management, and I4.0 technologies to enhance sustainable supply chain performance, focusing on economic, social, and environmental sustainability.

- Additionally, future research should delve into the synergistic integration of human creativity and AI within the framework of industry 5.0. This expanded scope will facilitate a holistic comprehension of the evolving industrial landscape, marked by the collaborative interplay between humans and machines, and its impact on sustainable supply chain performance across economic, social, and environmental spheres.

- Through the proposed SCQM 4.0 conceptual framework, supply chain operators and relevant stakeholders should perform research gap assessments and actionable deployment strategies to accelerate the digitalization of supply chain quality management.

- In addition, exploratory qualitative studies should be carried out in different organizations and industry sectors to explore any potential key constructs that enhance the identification of sustainable SCQM 4.0.

5.3. Discussion

From the findings about SCQM 4.0 conceptual frameworks and their essential elements for effective implementation, this research provides benefits for stakeholders and researchers in several sectors. Supply chain operators can attain sustainability, improve performance quality, and optimize resource allocation for their business by integrating I4.0 technology and sustainable initiatives into their supply chain activities. Furthermore, researchers can use the proposed future study areas to investigate the correlation between quality management, supply chain management, and I4.0 technologies in order to improve supply chain performance and sustainability. By working together and implementing strategic plans, firms can expedite the process of digitizing supply chain quality management, leading to enhanced efficiency, productivity, and sustainability results.

Author Contributions

Formal analysis, methodology, investigation, and writing—original draft preparation: A.D.T.B., M.A. and H.T.Q.; investigation and writing: H.L.T.C. and L.N.C.; resources, methodology, validation, and formal analysis: A.D.T.B. and M.A.; conceptualization, methodology, computational frameworks, data curation and supervision: A.D.T.B., M.A. and H.T.Q.; validation, writing—review and editing: H.L.T.C. and L.N.C.; supervision and funding acquisition: A.D.T.B. and M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the RMIT University Vietnam under grant number Tier I-23-3.

Data Availability Statement

The data are available upon request from the corresponding author due to participant privacy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Fraser, M.; Conde, Á.; Haigh, L. Circularity Gap Report 2024. 2024. Available online: https://www.circularity-gap.world/2024 (accessed on 5 March 2024).

- Lahane, S.; Kant, R.; Shankar, R.; Patil, S.K. Circular supply chain implementation performance measurement framework: A comparative case analysis. Prod. Plan. Control. 2023, 1–20. [Google Scholar] [CrossRef]

- Macarthur, E.; Heading, H. How the circular economy tackles climate change. Ellen MacArthur Found 2019, 1, 1–71. [Google Scholar]

- Sartal, A.; Ozcelik, N.; Rodriguez, M. Bringing the circular economy closer to small and medium enterprises: Improving water circularity without damaging plant productivity. J. Clean. Prod. 2020, 256, 120363. [Google Scholar] [CrossRef]

- Eisenreich, A.; Füller, J.; Stuchtey, M.; Gimenez-Jimenez, D. Toward a circular value chain: Impact of the circular economy on a company’s value chain processes. J. Clean. Prod. 2022, 378, 134375. [Google Scholar] [CrossRef]

- Calzolari, T.; Genovese, A.; Brint, A. Circular Economy indicators for supply chains: A systematic literature review. Environ. Sustain. Indic. 2021, 13, 100160. [Google Scholar] [CrossRef]

- Chau, K.-Y.; Tang, Y.M.; Liu, X.; Ip, Y.-K.; Tao, Y. Investigation of critical success factors for improving supply chain quality management in manufacturing. Enterp. Inf. Syst. 2021, 15, 1418–1437. [Google Scholar] [CrossRef]

- Nguyen, K.; Akbari, M.; Quang, H.T.; McDonald, S.; Hoang, T.-H.; Yap, T.L.; George, M. Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review. Sustainability 2023, 15, 16720. [Google Scholar] [CrossRef]

- Akbari, M. Data-driven review of additive manufacturing on supply chains: Regionalization, key research themes and future directions. Comput. Ind. Eng. 2023, 184, 109600. [Google Scholar] [CrossRef]

- Elnadi, M.; Abdallah, Y.O. Industry 4.0: Critical investigations and synthesis of key findings. Manag. Rev. Q. 2023, 1–34. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar]

- Nagarajan, S.M.; Deverajan, G.G.; Chatterjee, P.; Alnumay, W.; Muthukumaran, V. Integration of IoT based routing process for food supply chain management in sustainable smart cities. Sustain. Cities Soc. 2022, 76, 103448. [Google Scholar] [CrossRef]

- Briner, R.B.; Denyer, D. Systematic review and evidence synthesis as a practice and scholarship tool. In Handbook of Evidence-Based Management: Companies, Classrooms and Research; Oxford University Press: Oxford, UK, 2012; pp. 112–129. [Google Scholar]

- Friedman, K. Theory construction in design research: Criteria: Approaches, and methods. Des. Stud. 2003, 24, 507–522. [Google Scholar] [CrossRef]

- Hiebl, M.R. Sample selection in systematic literature reviews of management research. Organ. Res. Methods 2023, 26, 229–261. [Google Scholar] [CrossRef]

- Ha, N.T.; Akbari, M.; Au, B. Last mile delivery in logistics and supply chain management: A bibliometric analysis and future directions. Benchmarking Int. J. 2023, 30, 1137–1170. [Google Scholar] [CrossRef]

- Moral-Muñoz, J.A.; Herrera-Viedma, E.; Santisteban-Espejo, A.; Cobo, M.J. Software tools for conducting bibliometric analysis in science: An up-to-date review. Prof. Inf. 2020, 29, e290103. [Google Scholar] [CrossRef]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, maturity and research agenda. Supply Chain. Manag. Int. J. 2020, 25, 262–282. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J.A. Essential ingredients for the implementation of Quality 4.0: A narrative review of literature and future directions for research. TQM J. 2020, 32, 779–793. [Google Scholar] [CrossRef]

- Sampaio, P.; Carvalho, M.S.; Fernandes, A.C. Quality and supply chain management: Integration challenges and impacts. Int. J. Qual. Reliab. Manag. 2016, 33. [Google Scholar] [CrossRef]

- Fernandes, A.C.; Sampaio, P.; Sameiro, M.; Truong, H.Q. Supply chain management and quality management integration: A conceptual model proposal. Int. J. Qual. Reliab. Manag. 2017, 34, 53–67. [Google Scholar] [CrossRef]

- Carranza, E.J.M. Geochemical Anomaly and Mineral Prospectivity Mapping in GIS; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Bhatt, T.; Cusack, C.; Dent, B.; Gooch, M.; Jones, D.; Newsome, R.; Stitzinger, J.; Sylvia, G.; Zhang, J. Project to develop an interoperable seafood traceability technology architecture: Issues brief. Compr. Rev. Food Sci. Food Saf. 2016, 15, 392–429. [Google Scholar] [CrossRef]

- Olsen, P.; Borit, M. The components of a food traceability system. Trends Food Sci. Technol. 2018, 77, 143–149. [Google Scholar] [CrossRef]

- Barge, P.; Gay, P.; Merlino, V.; Tortia, C. Item-level Radio-Frequency IDentification for the traceability of food products: Application on a dairy product. J. Food Eng. 2014, 125, 119–130. [Google Scholar] [CrossRef]

- Feng, J.; Fu, Z.; Wang, Z.; Xu, M.; Zhang, X. Development and evaluation on a RFID-based traceability system for cattle/beef quality safety in China. Food Control 2013, 31, 314–325. [Google Scholar] [CrossRef]

- Mainetti, L.; Patrono, L.; Stefanizzi, M.L.; Vergallo, R. An innovative and low-cost gapless traceability system of fresh vegetable products using RF technologies and EPCglobal standard. Comput. Electron. Agric. 2013, 98, 146–157. [Google Scholar] [CrossRef]

- Bai, H.; Zhou, G.; Hu, Y.; Sun, A.; Xu, X.; Liu, X.; Lu, C. Traceability technologies for farm animals and their products in China. Food Control 2017, 79, 35–43. [Google Scholar] [CrossRef]

- Alfian, G.; Syafrudin, M.; Rhee, J. Real-time monitoring system using smartphone-based sensors and nosql database for perishable supply chain. Sustainability 2017, 9, 2073. [Google Scholar] [CrossRef]

- Furdik, K.; Pramudianto, F.; Ahlsén, M.; Rosengren, P.; Kool, P.; Zhenyu, S.; Brizzi, P.; Paralic, M.; Schneider, A. Food Traceability Chain Supported by the Ebbits IoT Middleware, Dynamics in Logistics: Proceedings of the 4th International Conference LDIC, February 10 to 14, 2014 Bremen, Germany, 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 343–353. [Google Scholar]

- Óskarsdóttir, K.; Oddsson, G.V. Towards a decision support framework for technologies used in cold supply chain traceability. J. Food Eng. 2019, 240, 153–159. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H.; Zhou, Z. An improved traceability system for food quality assurance and evaluation based on fuzzy classification and neural network. Food Control 2017, 79, 363–370. [Google Scholar] [CrossRef]

- Xiao, X.; He, Q.; Li, Z.; Antoce, A.O.; Zhang, X. Improving traceability and transparency of table grapes cold chain logistics by integrating WSN and correlation analysis. Food Control 2017, 73, 1556–1563. [Google Scholar] [CrossRef]

- Liu, X.; Barenji, A.V.; Li, Z.; Montreuil, B.; Huang, G.Q. Blockchain-based smart tracking and tracing platform for drug supply chain. Comput. Ind. Eng. 2021, 161, 107669. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, Y.; Xu, Y. Amount of information and the willingness of consumers to pay for food traceability in China. Food Control 2017, 77, 163–170. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, C.; Chen, C.; Huang, G.Q. Big data analytics for physical internet-based intelligent manufacturing shop floors. Int. J. Prod. Res. 2017, 55, 2610–2621. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.I.R. Refrigerated fruit storage monitoring combining two different wireless sensing technologies: RFID and WSN. Sensors 2015, 15, 4781–4795. [Google Scholar] [CrossRef]

- Treiblmaier, H.; Garaus, M. Using blockchain to signal quality in the food supply chain: The impact on consumer purchase intentions and the moderating effect of brand familiarity. Int. J. Inf. Manag. 2023, 68, 102514. [Google Scholar] [CrossRef]

- Cole, R.; Stevenson, M.; Aitken, J. Blockchain technology: Implications for operations and supply chain management. Supply Chain. Manag. Int. J. 2019, 24, 469–483. [Google Scholar] [CrossRef]

- Tripoli, M.; Schmidhuber, J. Emerging Opportunities for the Application of Blockchain in the Agri-food Industry; FAO: Rome, Italy; ICTSD: Geneva, Switzerland, 2018. [Google Scholar]

- Vadgama, N.; Tasca, P. An Analysis of Blockchain Adoption in Supply Chains Between 2010 and 2020. Front. Blockchain 2021, 4, 610476. [Google Scholar] [CrossRef]

- Chen, S.; Shi, R.; Ren, Z.; Yan, J.; Shi, Y.; Zhang, J. In A blockchain-based supply chain quality management framework. In Proceedings of the 2017 IEEE 14th International Conference on E-Business Engineering (ICEBE), Shanghai, China, 4–6 November 2017; pp. 172–176. [Google Scholar]

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. In Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. In Proceedings of the 2018 IoT Vertical and Topical Summit on Agriculture-Tuscany (IOT Tuscany), Tuscany, Italy, 8–9 May 2018; pp. 1–4. [Google Scholar]

- Tian, F. In A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Kamath, R. Food traceability on blockchain: Walmart’s pork and mango pilots with IBM. J. Br. Blockchain Assoc. 2018, 1. [Google Scholar] [CrossRef] [PubMed]

- Galvez, J.F.; Mejuto, J.C.; Simal-Gandara, J. Future challenges on the use of blockchain for food traceability analysis. TrAC Trends Anal. Chem. 2018, 107, 222–232. [Google Scholar] [CrossRef]

- Niu, B.; Shen, Z.; Xie, F. The value of blockchain and agricultural supply chain parties’ participation confronting random bacteria pollution. J. Clean. Prod. 2021, 319, 128579. [Google Scholar] [CrossRef]

- Hassoun, A.; Kamiloglu, S.; Garcia-Garcia, G.; Parra-López, C.; Trollman, H.; Jagtap, S.; Aadil, R.M.; Esatbeyoglu, T. Implementation of relevant fourth industrial revolution innovations across the supply chain of fruits and vegetables: A short update on Traceability 4.0. Food Chem. 2023, 409, 135303. [Google Scholar] [CrossRef]

- Zheng, T.; Ardolino, M.; Bacchetti, A.; Perona, M. The applications of Industry 4.0 technologies in manufacturing context: A systematic literature review. Int. J. Prod. Res. 2021, 59, 1922–1954. [Google Scholar] [CrossRef]

- Puligundla, P.; Jung, J.; Ko, S. Carbon dioxide sensors for intelligent food packaging applications. Food Control 2012, 25, 328–333. [Google Scholar] [CrossRef]

- Brizio, A.P.D.R.; Prentice, C. Use of smart photochromic indicator for dynamic monitoring of the shelf life of chilled chicken based products. Meat Sci. 2014, 96, 1219–1226. [Google Scholar] [CrossRef]

- Gao, T.; Tian, Y.; Zhu, Z.; Sun, D.-W. Modelling, responses and applications of time-temperature indicators (TTIs) in monitoring fresh food quality. Trends Food Sci. Technol. 2020, 99, 311–322. [Google Scholar] [CrossRef]

- Zavala, J.; Greenan, R.; Krantz, Q.T.; DeMarini, D.M.; Higuchi, M.; Gilmour, M.I.; White, P.A. Regulating temperature and relative humidity in air–liquid interface in vitro systems eliminates cytotoxicity resulting from control air exposures. Toxicol. Res. 2017, 6, 448–459. [Google Scholar] [CrossRef]

- Lorite, G.S.; Selkälä, T.; Sipola, T.; Palenzuela, J.; Jubete, E.; Viñuales, A.; Cabañero, G.; Grande, H.J.; Tuominen, J.; Uusitalo, S. Novel, smart and RFID assisted critical temperature indicator for supply chain monitoring. J. Food Eng. 2017, 193, 20–28. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Choy, K.; Wu, C.-H.; Ho, G.; Lam, H.; Tang, V. An intelligent model for assuring food quality in managing a multi-temperature food distribution centre. Food Control 2018, 90, 81–97. [Google Scholar] [CrossRef]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and intelligent packaging in meat industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Poyatos-Racionero, E.; Ros-Lis, J.V.; Vivancos, J.-L.; Martinez-Manez, R. Recent advances on intelligent packaging as tools to reduce food waste. J. Clean. Prod. 2018, 172, 3398–3409. [Google Scholar] [CrossRef]

- Liu, C.; Yang, C.; Zhang, X.; Chen, J. External integrity verification for outsourced big data in cloud and IoT: A big picture. Future Gener. Comput. Syst. 2015, 49, 58–67. [Google Scholar] [CrossRef]

- Balamurugan, S.; Divyabharathi, N.; Jayashruthi, K.; Bowiya, M.; Shermy, R.; Shanker, R. Internet of agriculture: Applying IoT to improve food and farming technology. Int. Res. J. Eng. Technol. (IRJET) 2016, 3, 713–719. [Google Scholar]

- Tsang, Y.P.; Choy, K.L.; Wu, C.-H.; Ho, G.T.; Lam, C.H.; Koo, P. An Internet of Things (IoT)-based risk monitoring system for managing cold supply chain risks. Ind. Manag. Data Syst. 2018, 118, 1432–1462. [Google Scholar] [CrossRef]

- Tsang, Y.; Choy, K.; Wu, C.-H.; Ho, G.; Lam, H.; Koo, P. An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment. Int. J. Eng. Bus. Manag. 2017, 9, 1847979017749063. [Google Scholar] [CrossRef]

- Lu, S.; Wang, X. In Toward an intelligent solution for perishable food cold chain management. In Proceedings of the 2016 7th IEEE International Conference on Software Engineering and Service Science (ICSESS), Beijing, China, 26–28 August 2016; pp. 852–856. [Google Scholar]

- Liu, L.; Liu, P.; Wen, F.; Zhang, C.; Zhao, R.; Yan, M.; Yu, X. Information collection system of duck products based on IoT. EURASIP J. Wirel. Commun. Netw. 2018, 2018, 124. [Google Scholar] [CrossRef]

- Luo, H.; Zhu, M.; Ye, S.; Hou, H.; Chen, Y.; Bulysheva, L. An intelligent tracking system based on internet of things for the cold chain. Internet Res. 2016, 26, 435–445. [Google Scholar] [CrossRef]

- Ruiz-Garcia, L.; Lunadei, L. Monitoring cold chain logistics by means of RFID. Sustain. Radio Freq. Identif. Solut. 2010, 2, 37–50. [Google Scholar]

- Pang, Z.; Chen, Q.; Han, W.; Zheng, L. Value-centric design of the internet-of-things solution for food supply chain: Value creation, sensor portfolio and information fusion. Inf. Syst. Front. 2015, 17, 289–319. [Google Scholar] [CrossRef]

- Verdouw, C.; Robbemond, R.M.; Verwaart, T.; Wolfert, J.; Beulens, A.J. A reference architecture for IoT-based logistic information systems in agri-food supply chains. Enterp. Inf. Syst. 2018, 12, 755–779. [Google Scholar] [CrossRef]

- Accorsi, R.; Bortolini, M.; Baruffaldi, G.; Pilati, F.; Ferrari, E. Internet-of-things paradigm in food supply chains control and management. Procedia Manuf. 2017, 11, 889–895. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Wolfert, J.; Beulens, A.; Rialland, A. Virtualization of food supply chains with the internet of things. J. Food Eng. 2016, 176, 128–136. [Google Scholar] [CrossRef]

- Accorsi, R.; Cholette, S.; Manzini, R.; Tufano, A. A hierarchical data architecture for sustainable food supply chain management and planning. J. Clean. Prod. 2018, 203, 1039–1054. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, X.D. Research on the Construction of Green Evaluation Model Based on IOT of Agricultural Products. Appl. Mech. Mater. 2014, 687–691, 4631–4637. [Google Scholar] [CrossRef]

- Sengupta, J.; Ruj, S.; Bit, S.D. A comprehensive survey on attacks, security issues and blockchain solutions for IoT and IIoT. J. Netw. Comput. Appl. 2020, 149, 102481. [Google Scholar] [CrossRef]

- Lu, Y. The blockchain: State-of-the-art and research challenges. J. Ind. Inf. Integr. 2019, 15, 80–90. [Google Scholar] [CrossRef]

- Arfi, W.B.; Nasr, I.B.; Khvatova, T.; Ben Zaied, Y. Understanding acceptance of eHealthcare by IoT natives and IoT immigrants: An integrated model of UTAUT, perceived risk, and financial cost. Technol. Forecast. Soc. Chang. 2021, 163, 120437. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.R. New trends in cold chain monitoring applications—A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Mostaghel, R.; Oghazi, P.; Parida, V.; Sohrabpour, V. Digitalization driven retail business model innovation: Evaluation of past and avenues for future research trends. J. Bus. Res. 2022, 146, 134–145. [Google Scholar] [CrossRef]

- Ahmadi, H.B.; Lo, H.-W.; Gupta, H.; Kusi-Sarpong, S.; Liou, J.J. An integrated model for selecting suppliers on the basis of sustainability innovation. J. Clean. Prod. 2020, 277, 123261. [Google Scholar] [CrossRef]

- Sriram, R.; Vinodh, S. Analysis of readiness factors for Industry 4.0 implementation in SMEs using COPRAS. Int. J. Qual. Reliab. Manag. 2021, 38, 1178–1192. [Google Scholar] [CrossRef]

- Han, H.; Trimi, S. Towards a data science platform for improving SME collaboration through Industry 4.0 technologies. Technol. Forecast. Soc. Chang. 2022, 174, 121242. [Google Scholar] [CrossRef]

- Krstić, M.; Agnusdei, G.P.; Miglietta, P.P.; Tadić, S.; Roso, V. Applicability of industry 4.0 technologies in the reverse logistics: A circular economy approach based on comprehensive distance based ranking (COBRA) method. Sustainability 2022, 14, 5632. [Google Scholar] [CrossRef]

- Ortega-Gras, J.-J.; Bueno-Delgado, M.-V.; Cañavate-Cruzado, G.; Garrido-Lova, J. Twin transition through the implementation of industry 4.0 technologies: Desk-research analysis and practical use cases in Europe. Sustainability 2021, 13, 13601. [Google Scholar] [CrossRef]

- Hina, M.; Chauhan, C.; Kaur, P.; Kraus, S.; Dhir, A. Drivers and barriers of circular economy business models: Where we are now, and where we are heading. J. Clean. Prod. 2022, 333, 130049. [Google Scholar] [CrossRef]

- Alhawari, O.; Awan, U.; Bhutta, M.K.S.; Ülkü, M.A. Insights from circular economy literature: A review of extant definitions and unravelling paths to future research. Sustainability 2021, 13, 859. [Google Scholar] [CrossRef]

- Veile, J.W.; Schmidt, M.-C.; Müller, J.M.; Voigt, K.-I. The transformation of supply chain collaboration and design through Industry 4.0. Int. J. Logist. Res. Appl. 2022, 1–29. [Google Scholar] [CrossRef]

- Gebhardt, M.; Kopyto, M.; Birkel, H.; Hartmann, E. Industry 4.0 technologies as enablers of collaboration in circular supply chains: A systematic literature review. Int. J. Prod. Res. 2022, 60, 6967–6995. [Google Scholar] [CrossRef]

- Dos Santos, L.M.A.L.; da Costa, M.B.; Kothe, J.V.; Benitez, G.B.; Schaefer, J.L.; Baierle, I.C.; Nara, E.O.B. Industry 4.0 collaborative networks for industrial performance. J. Manuf. Technol. Manag. 2021, 32, 245–265. [Google Scholar] [CrossRef]

- Dillinger, F.; Bernhard, O.; Kagerer, M.; Reinhart, G. Industry 4.0 implementation sequence for manufacturing companies. Prod. Eng. 2022, 16, 705–718. [Google Scholar] [CrossRef]

- Nuttah, M.M.; Roma, P.; Nigro, G.L.; Perrone, G. Understanding blockchain applications in Industry 4.0: From information technology to manufacturing and operations management. J. Ind. Inf. Integr. 2023, 33, 100456. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Ivanov, D.; Tang, C.S.; Dolgui, A.; Battini, D.; Das, A. Researchers’ perspectives on Industry 4.0: Multi-disciplinary analysis and opportunities for operations management. Int. J. Prod. Res. 2021, 59, 2055–2078. [Google Scholar] [CrossRef]

- Tambare, P.; Meshram, C.; Lee, C.-C.; Ramteke, R.J.; Imoize, A.L. Performance measurement system and quality management in data-driven Industry 4.0: A review. Sensors 2021, 22, 224. [Google Scholar] [CrossRef] [PubMed]

- Bienhaus, F.; Haddud, A. Procurement 4.0: Factors influencing the digitisation of procurement and supply chains. Bus. Process Manag. J. 2018, 24, 965–984. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of Industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Rad, F.F.; Oghazi, P.; Palmié, M.; Chirumalla, K.; Pashkevich, N.; Patel, P.C.; Sattari, S. Industry 4.0 and supply chain performance: A systematic literature review of the benefits, challenges, and critical success factors of 11 core technologies. Ind. Mark. Manag. 2022, 105, 268–293. [Google Scholar] [CrossRef]

- Zhou, R.; Awasthi, A.; Stal-Le Cardinal, J. The main trends for multi-tier supply chain in Industry 4.0 based on Natural Language Processing. Comput. Ind. 2021, 125, 103369. [Google Scholar] [CrossRef]

- Wagire, A.A.; Rathore, A.; Jain, R. Analysis and synthesis of Industry 4.0 research landscape: Using latent semantic analysis approach. J. Manuf. Technol. Manag. 2020, 31, 31–51. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Suleiman, Z.; Shaikholla, S.; Dikhanbayeva, D.; Shehab, E.; Turkyilmaz, A. Industry 4.0: Clustering of concepts and characteristics. Cogent Eng. 2022, 9, 2034264. [Google Scholar] [CrossRef]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular supply chains in the era of Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- Lim, A.-F.; Ooi, K.-B.; Tan, G.W.-H.; Cham, T.-H.; Alryalat, M.A.; Dwivedi, Y.K. Adapt or die: A competitive digital supply chain quality management strategy. J. Enterp. Inf. Manag. 2022; ahead of print. [Google Scholar]

- Shet, S.V.; Pereira, V. Proposed managerial competencies for Industry 4.0–Implications for social sustainability. Technol. Forecast. Soc. Chang. 2021, 173, 121080. [Google Scholar] [CrossRef]

- Sima, V.; Gheorghe, I.G.; Subić, J.; Nancu, D. Influences of the industry 4.0 revolution on the human capital development and consumer behavior: A systematic review. Sustainability 2020, 12, 4035. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Rab, S. Impact of additive manufacturing in different areas of Industry 4.0. Int. J. Logist. Syst. Manag. 2020, 37, 239–251. [Google Scholar] [CrossRef]

- Aquilani, B.; Piccarozzi, M.; Abbate, T.; Codini, A. The role of open innovation and value co-creation in the challenging transition from industry 4.0 to society 5.0: Toward a theoretical framework. Sustainability 2020, 12, 8943. [Google Scholar] [CrossRef]

- Winkler, H.; Scavarda, L.F. Industry 4.0: Lessons Learned from the German Industry; Operations Management for Social Good: 2018 POMS International Conference in Rio, 2020; Springer: Berlin/Heidelberg, Germany, 2020; pp. 539–549. [Google Scholar]

- Ardito, L.; Scuotto, V.; Del Giudice, M.; Petruzzelli, A.M. A bibliometric analysis of research on Big Data analytics for business and management. Manag. Decis. 2019, 57, 1993–2009. [Google Scholar] [CrossRef]

- Dadhaneeya, H.; Nema, P.K.; Arora, V.K. Internet of Things in food processing and its potential in Industry 4.0 era: A review. Trends Food Sci. Technol. 2023, 139, 104109. [Google Scholar] [CrossRef]

- Malik, P.K.; Sharma, R.; Singh, R.; Gehlot, A.; Satapathy, S.C.; Alnumay, W.S.; Pelusi, D.; Ghosh, U.; Nayak, J. Industrial Internet of Things and its applications in industry 4.0: State of the art. Comput. Commun. 2021, 166, 125–139. [Google Scholar] [CrossRef]

- Munirathinam, S. Industry 4.0: Industrial internet of things (IIOT). In Advances in Computers; Elsevier: Amsterdam, The Netherlands, 2020; Volume 117, pp. 129–164. [Google Scholar]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ferreira-Lima, M.; Ayala, N.F.; Frank, A.G. Industry 4.0 technology provision: The moderating role of supply chain partners to support technology providers. Supply Chain. Manag. Int. J. 2022, 27, 89–112. [Google Scholar] [CrossRef]

- Ghadge, A.; Er Kara, M.; Moradlou, H.; Goswami, M. The impact of Industry 4.0 implementation on supply chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Koh, L.; Orzes, G.; Jia, F.J. The fourth industrial revolution (Industry 4.0): Technologies disruption on operations and supply chain management. Int. J. Oper. Prod. Manag. 2019, 39, 817–828. [Google Scholar] [CrossRef]

- Dalmarco, G.; Barros, A.C. Adoption of Industry 4.0 technologies in supply chains. In Innovation and Supply Chain Management: Relationship, Collaboration and Strategies; Springer: Berlin/Heidelberg, Germany, 2018; pp. 303–319. [Google Scholar]

- Kumar, A.; Singh, R.K.; Modgil, S. Influence of data-driven supply chain quality management on organizational performance: Evidences from retail industry. TQM J. 2023, 35, 24–50. [Google Scholar] [CrossRef]

- Patil, A.; Dwivedi, A.; Moktadir, M.A. Big data-Industry 4.0 readiness factors for sustainable supply chain management: Towards circularity. Comput. Ind. Eng. 2023, 178, 109109. [Google Scholar] [CrossRef]

- Van Nguyen, T.; Pham, H.T.; Ha, H.M.; Tran, T.T.T. An integrated model of supply chain quality management, Industry 3.5 and innovation to improve manufacturers’ performance—A case study of Vietnam. Int. J. Logist. Res. Appl. 2022, 27, 261–283. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Singh, S.P.; Spanaki, K.; Gunasekaran, A.; Dubey, R. Towards the Next Generation of Manufacturing: Implications of Big Data and Digitalization in the Context of Industry 4.0; Taylor & Francis: Abingdon, UK, 2022; Volume 33, pp. 101–104. [Google Scholar]

- Narwane, V.S.; Raut, R.D.; Yadav, V.S.; Cheikhrouhou, N.; Narkhede, B.E.; Priyadarshinee, P. The role of big data for Supply Chain 4.0 in manufacturing organisations of developing countries. J. Enterp. Inf. Manag. 2021, 34, 1452–1480. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Zimon, D.; Urbaniak, M.; Madzík, P.; Prokopiuk, I. Supply Chain Quality Management (Scqm) Literature Review and Model Proposal in the Era of Industry 4.0. Int. J. Qual. Res. 2022, 16, 1283–1296. [Google Scholar] [CrossRef]