Abstract

Mulching is one of the most recommended practices in agriculture due to its positive effects on the plant/soil system. Very few experiments have been conducted to date to investigate the effect of mulching, with both organic and inorganic materials, on tobacco. The main aim of this study was to test the synergic effect of a soil-biodegradable (according to standard EN17033) mulching film (the commercial Mater-Bi®, Novamont SpA, Novara, Italy) and drip irrigation (M-D) compared with that of bare soil and sprinkler/drip irrigation (first/second part of the growing season; BS-SD) on a tobacco crop (Nicotiana tabacum L., flue-cured Virginia) grown in the Tiber Valley (the tobacco cultivation district of Central Italy). BS-SD represents the standard practice applied by tobacco growers in the study area. The plants grown under the M-D management system grew more and developed faster than the plants grown under BS-SD conditions. Under the M-D system, yields increased in comparison with the BS-SD conditions (+29%, on average). The gross revenue obtained via the M-D-cured products also increased (+63%, on average) thanks to higher prices assigned by expert evaluators on the basis of the extrinsic quality traits (color, structure and texture, degree of ripeness, elasticity, lamina integrity, handling defects, and vein incidence). The economic value of the cured products increased with the leaf crowns; it was the lowest in the basal (B) leaves and the highest in the middle-upper (MU) leaves. The intrinsic quality traits of the cured leaves (total N and nitrate contents, alkaloids, and reducing sugars) also confirmed that the best quality was found in the M-D-cured products, as determined by expert evaluation. Interestingly, the reducing sugar (RS) contents of tobacco obtained using the M-D management system were 2.5-, 1.1-, and 0.9-fold greater than those under the BS-SD conditions (B, M, and MU products, respectively). An additional commercial value of the cured products was thus obtained with the M-D crop management system due to RS, an intrinsic quality trait considered by manufacturing industries.

1. Introduction

Mulching is one of the most recommended practices in agriculture due to its positive effects on the plant/soil system. It is considered a useful tool for crop management within so-called “sustainable development” because it may help to better address the effects of climate change, thus becoming relevant to agriculture in the near future.

Mulching may favor soil water conservation and may reduce both soil and nutrient losses (environmental benefits [1,2,3,4,5,6,7]). It can lead to an improvement in the yield and quality of crops by increasing heat accumulation in the soil and thus shortening crop growth periods, both positive factors for plant response [6,7,8,9,10,11]. It also improves weed and insect control [3,12], reducing the use of chemicals, the risk of soil and water pollution of agricultural origin, and the impact on human well-being [12]. Farmers’ incomes may also increase (economic benefits [3,13]).

Several materials are currently used to mulch, with each one having specific physical (i.e., mechanical strength, thickness, heat preservation, water and light permeability, resistance to chemical agents, etc. [3,5,6,14,15]) and chemical characteristics (i.e., the rate and extent of biodegradation in the soil [14,16,17,18]), which differently influence the crop/soil systems or production costs. There are (i) inorganic types, like rocks and gravels; (ii) petroleum-based plastics, such as high- or low-density polyethylene (HDPE or LDPE), polypropylene (PP), polyvinyl chloride (PVC), etc.; (iii) so-called bioplastics (bio-based biodegradable, bio-based non-biodegradable, and petroleum-based biodegradable [17,19]); and (iv) organic types, like crop residues, sawdust, straw, paper, animal wastes, etc. [17,20]. HDPE, LDPE, PP, and PVC are still the most used due to their low costs.

In Europe, about 80–83,000 Mg of plastic mulching films were sold in 2019 [17,21,22], only 5% of which comprised biodegradable materials [21]. Since conventional plastic mulches (petroleum-based non-biodegradable) produce great disposal problems [23], resulting in environmental hazards like (i) soil pollution from plastic residues (macro-, micro-, and nano-plastics [24]), (ii) alterations in soil microbial populations, and (iii) interference with soil structural changes and plant root development [24,25], several alternatives have been intensively explored with the aim of preserving both soil and food health. In this regard, photodegradable and biodegradable films have been investigated and frequently proposed as possible solutions [14,26,27,28,29,30,31,32]. Their main advantage is that they are not necessarily removed and discarded at the end of cropping (labor and disposal costs are then reduced) since they must be buried and left to biodegrade in the soil thanks to the action of soil microorganisms [15,24,33]. Interestingly, they show all of the same positive effects of non-biodegradable plastic mulching films [17,19,24,31,33,34], albeit with higher prices (the main disadvantage).

Bio-based biodegradable materials improve the circularity of agricultural production processes. They are manufactured starting from renewable non-fossil resources (“green” sources) and have a low carbon footprint [35]. In addition, they can rapidly break down into natural substances (“clean” removal), such as carbon dioxide, water, and nutrients [35,36]. Their use reduces the negative environmental impact that fossil-based plastics may cause [35,37].

The contamination of the environment with plastic debris is reported as the major environmental problem caused by fossil-based plastics [38]. Unfortunately, the short-term agronomic benefits obtained with petroleum-based plastics are coupled with serious long-term soil degradation problems [39]. The agronomic benefits could instead be maintained over long periods with bio-based biodegradable plastics, even though the effects on soil health as well as the degradation pattern of these materials are still of concern. Studies on these aspects often showed inconsistent results, which strictly depend on the soil type, environmental conditions, and microbial communities [40,41,42,43,44]. There is contrasting evidence on the effect on soil microorganisms [40]. Regardless of the type of material, some studies have reported that mulching has a positive effect on the microbial community [45,46], while other investigations have reported opposite results [43,47]. Brown et al. [43] found that the bio-based microplastic PHBV, a co-polymer of hydroxybutyrate and hydroxyvalerate, reduced bacterial diversity, shifting the structure of microbial communities. In addition, it modified microorganism functions through the inhibition of microbial activity because of soil contamination. Moreno and Moreno (2008) [47] also reported decreased soil microorganism activity due to excessive soil warming under biodegradable mulching films during warmer seasons. Therefore, it is clear that this aspect requires further investigation.

Mater Bi® (Novamont S.p.A., Novara, Italy) is one of the new prospective bio-based biodegradable polymers used in agriculture. It is a starch-based-material certified as completely biodegradable in soil in less than 24 months according to European standard EN 17033 [48]. Since it was designed, Mater-Bi® films of different colors have been investigated. Black Mater-Bi® film showed the same main valuable properties commonly found in conventional black plastic mulches [49,50,51,52,53] but with no disposal problems [48]. By minimizing the impact on the environment and saving time and resources in managing the end of life of mulched crops, Mater Bi® mulch film provides an agronomically and environmentally efficient alternative to traditional mulching film [48,49,50,51,52,53].

Tobacco is an annual cash crop widely cultivated globally (3.1 million ha [54]). In 2022, Europe had 65,428 ha of cultivated tobacco, of which 10,970 ha were in Italy [54]. The use of plastic mulching films is currently not a common practice in European tobacco farms, but interest in this practice has grown in recent years in Japan, where about 98% of tobacco is cultivated under plastic mulching [55]; in Brazil, where organic mulching is preferably used when sustainable practices are applied [56]; and in China [57], where an area of 31.9 × 104 haof tobacco cultivated using plastic mulching was reported in 2001 by Yang et al. [1]. At present, Japan, Brazil, and China are the world’s major producers of this important non-food crop.

To our knowledge, very few experiments have been conducted to date to investigate the effect of mulching, both with organic and inorganic materials, on tobacco [58,59], although the above reported positive effects of this agronomic practice should be considered remarkable for this crop, which is not usually rotated in the field (monoculture is the standard cultivation system for tobacco globally). All hazards due to monoculture (i.e., soil degradation, fertility losses, changes in soil microbial composition, etc. [60,61]) could in fact be profitably alleviated by mulching. The results found for tobacco [58,59] are consistent with those reported for other species [14,62].

The use of mulching implies the application of specific crop management systems, which may include irrigation by drips and, frequently, fertigation. In contrast, in conditions without mulching, surface irrigation methods like floods, furrows, or sprinklers are often preferred [63,64]. The main aim of the present study was to test the synergic effect of a soil bio-based biodegradable mulching film (commercial Mater-Bi®, 15 µm thick) and drip irrigation (M-D treatment) compared with that of bare soil and sprinkler/drip irrigation (the first/second part of the growing season; BS-SD treatment) on a flue-cured Virgina tobacco crop (Nicotiana tabacum L.) grown in the Tiber Valley (tobacco cultivation district of Central Italy). The BS-SD treatment represents the standard cultivation practice applied by tobacco growers in the study area.

2. Materials and Methods

2.1. Plant Materials, Experimental Treatments, Field Preparation, Crop Management, Samplings, and Measurements

The trial was conducted in 2021 at Città di Castello (43°27′26″ N, 12°14′25″ E, 288 m above sea level, Perugia, Italy) on a tobacco crop (Nicotiana tabacum L.) of the Virginia Bright type. Seedlings of cv. ITB6178 (Bergerac Seed & Breeding, La Tour, Bergerac, France) were transplanted on 28 May 2021 in plots of 50 m2 at distances of 1.15 m × 0.35 m (between and within rows, respectively). The soil characteristics are reported in Table 1.

Table 1.

Physical and chemical characteristics of soil in the experimental season.

The following two crop management systems were compared: (1) tobacco crop grown on bare soil with plants irrigated using a combination of sprinklers and drips in the first and the second parts of the growing season, respectively, which is the standard agronomic practice for tobacco growers in the area (BS-SD); (2) tobacco crop grown using bio-based biodegradable mulch and drip irrigation (M-D). For M-D, a strip (0.7 m wide) of a black, bio-based biodegradable film (Mater-Bi®, 15 µm thick; Novamont Company, Novara, Italy) was placed during the transplanting stage by using a transplanting machine (TwinDrive TC, Spapperi, Città di Castello, Perugia, Italy), which combines mulch and drip laying with transplanting capabilities to cover a 0.4 m width across the ridge. A T-Tape micro-fertigation system (Giunti S.P.A. Group, Umbertide, Perugia, Italy) was used by placing drip lines under mulch or on bare soil in each row (drippers with a 2 L h−1 flow and 0.3 m apart).

In both treatments, the plants were fully irrigated based on the crop water needs that were empirically determined as the standard management of irrigation practiced in the area. The seasonal volume under mulching was lower than that under bare soil conditions (1809 and 2812 m3 ha−1, respectively) due to a reduction in the evapotranspiration of the soil covered with the mulching film [65].

Both the BS-SD and M-D treatments received 40 kg N ha−1, 90 kg P2O5 ha−1, and 140 kg K2O ha−1 before transplanting. Moreover, BS-SD received additional N and K fertilizer doses in 2 and 1 steps, respectively, at the beginning and end of stem elongation for N (68 and 13 kg ha−1, respectively) and at the end of stem elongation for K (46 kg ha−1). For M-D, additional N fertilizer doses were applied with 4 fertigation repetitions from the beginning of stem elongation to flowering (13.6 kg ha−1 at each application). At flowering, 46 kg K ha−1 was also applied. During the first (M-D) and third (BS-SD) weeks of August, when about 60% of plants per plot had flowered, the plants were topped, and suckering was controlled by applying a contact chemical (n-decanol). On the BS-SD plots, weeds were controlled by applying Clomazone (0.5 L ha−1) after transplanting.

During cropping, one plant per plot was sampled for a growth analysis at about 2-week intervals at 19 (rosette), 33 (the beginning of stem elongation), 47 and 67 (rapid growth), and 88 (leaf ripeness) days after transplanting (DAT). The leaves (n plant−1) and stem heights (cm) were measured. The plants were weighed and dried at 60 °C to a constant weight to calculate the above-ground dry biomass (dry weight, d.w.; g plant−1).

The plants were harvested three times following the ripeness of the basal (B), middle (M), and middle-upper (MU) crowns, respectively, on 26 August, 13 September, and 1 October in M-D and on 10 and 22 September and 8 October in BS-SD. The leaves were bulk-cured by following the standard practice of this kind of tobacco [66].

The cured tobacco was graded by an expert team based on the 8 main basic characteristics of cured leaves: crown, color, structure and texture, degree of ripeness, elasticity, lamina integrity, handling defects, and vein incidence. This was a blind evaluation based on a consensus between 2 experts. According to the grades, each cured product was assigned to the following price classes: (i) Class I = EUR 1.30 per kg; (ii) Class II = EUR 2.30 per kg; (iii) Class III = EUR 2.70 per kg; (iv) Class IV = EUR 2.75 per kg; (v) Class V = EUR 3.30 per kg; (vi) Class VI = EUR 3.55 per kg. The gross returns were then calculated, first by multiplying each product quota for the corresponding price and then by summing the results for each management system.

One sample of 100 g of cured leaves per plot was collected, dried at 60 °C to a constant weight, and ground by passing it through a 1 mm screen using an IKA A11 basic mill (IKA-Werke, Staufen, Germany) to be used for the analytical determination of the total N, nitrates, alkaloids, and reducing sugars.

2.2. Analytical Determination of Cured Products

The total N (Kjeldahl) concentration (%, d.w.) was determined by semi-automated block digestion (Heating Digestor DK, Velp Scientifica, Usmate, Monza Brianza, Italy) followed by continuous flow colorimetry (Autoanalyzer III, Bran Luebbe, Elmsford, NY, USA) to measure NH4+ by means of the Berthelot Reaction [67].

For the contents of nitrates, total alkaloids, and reducing sugars, 250 mg of each ground sample was extracted with 25 mL of 5% acetic acid solution by shaking for 30 min at 150 rpm (G10 Gyratory Shaker, New Brunswick Scientific Co. Inc., Edison, NJ, USA). The extract was filtered through quantitative filter paper (Whatman No 40) and analyzed.

The nitrate content (mg kg−1 d.w.) was determined using a continuous flow analyzer (Autoanalyzer III, Bran Luebbe, Elmsford, NY, USA) during the reduction of nitrate to nitrite with hydrazinium sulfate in the presence of a copper catalyst, followed by reaction with sulfanilamide to form the diazo compound. This latter was coupled with N−1-naphthylethylenediamine dihydro-chloride to form a colored complex whose absorbance was measured at 520 nm [68].

The total alkaloid content, denoted as nicotine (% d.w.), was determined using a continuous flow analyzer (Autoanalyzer II Technicon, SEAL Analytical GmbH, Norderstedt, Germany). This method is based on the reaction of alkaloids with sulfanilic acid and cyanogen chloride (from potassium thiocyanate and sodium hypochlorite). The absorbance of the color complex generated by this reaction was measured at 460 nm [69].

The content of reducing sugars (RS, % d.w.) was determined through the reduction of yellow hexacyanoferrate III to colorless hexacyanoferrate II. The decrease in absorbance was measured at 420 nm [70].

2.3. Weather Conditions

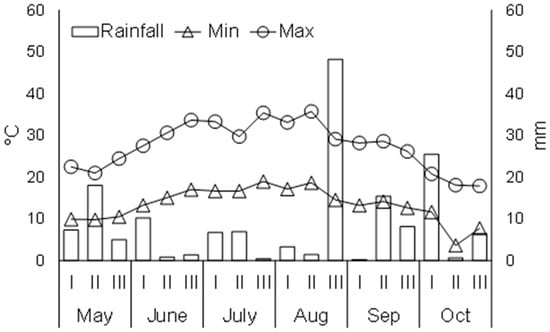

During the growing season (the end of May to mid-October), the maximum air temperatures were above 30 °C for 18 days in June, 27 days in July, 22 days in August, and 2 days in September. Rainfall amounted to 166 mm over the entire growing period. There were two rainfall events comprising 22 and 16 mm at the end of August (Figure 1).

Figure 1.

Air temperatures (minimum and maximum) and rainfall on a ten-day basis during the growing season; I, II, and III indicate the first, second, and third ten-day periods in each month.

2.4. Experimental Design and Statistical Analyses

The treatments were arranged in a completely randomized design with three replications. All the results were tested for normality and the homogeneity of variance before being subjected to an analysis of variance (ANOVA) using STATISTICA Software Version 7.1 for Windows [71] (StatSoft, Inc.: Tulsa, OK, USA). The means were separated using Tukey’s HSD Test at p < 0.05. A one-way ANOVA (BS-SD vs. M-D) was used for the number of leaves per plant, stem height, leaf and stem d.w., yield of total cured leaves, and gross returns. A two-way ANOVA (crop management systems × leaf crowns) was used to analyze the results of the total N, nitrate, alkaloid, and RS contents of the cured products.

3. Results

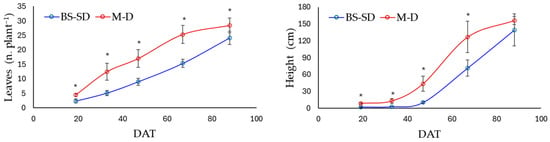

The M-D management system had a positive and significant effect on both the number of leaves per plant and the stem height over the entire growing season with differences that were already evident 19 days after transplanting (DAT; Figure 2).

Figure 2.

Leaves (n plant−1) and stem heights (cm) of the tobacco plants grown under two crop management systems. Data are shown as means ± standard deviations of three replications. BS-SD, bare soil–sprinkler/drip irrigation; M-D, mulching–drip irrigation; DAT, days after transplanting. *, significant at p < 0.05.

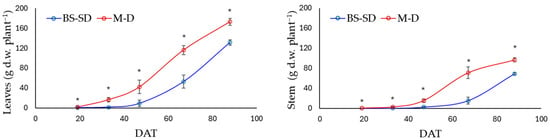

The M-D treatment also significantly increased both the leaf and stem dry matter from 19 DAT to 88 DAT (Figure 3).

Figure 3.

Leaf and stem biomasses (g d.w. plant−1) accumulated by tobacco plants grown under two crop management systems. Data are shown as the means ± standard deviations of three replications. BS-SD, bare soil–sprinkler/drip irrigation; M-D, mulching–drip irrigation; d.w., dry weight; DAT, days after transplanting. *, significant at p < 0.05.

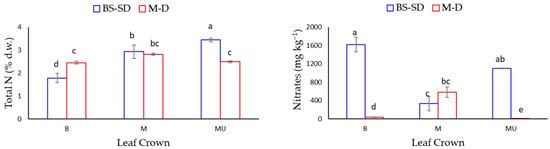

The results of the total N and nitrate contents of the cured leaves belonging to the basal (B), middle (M), and middle-upper (MU) leaf crowns are reported in Figure 4. The M-D system significantly increased the total N content of B leaves, while it decreased that of MU leaves (Figure 4). However, no difference between the M-D and the BS-SD management systems emerged in the leaves belonging to the M crown (Figure 4).

Figure 4.

Total nitrogen (total N, % d.w.) and nitrate contents (mg kg−1 d.w.) of the cured leaves belonging to the basal (B), middle (M), and middle-upper (MU) crowns in tobacco plants grown under two crop management systems. Data are shown as the means ± standard deviations of three replications. BS-SD, bare soil–sprinkler/drip irrigation; M-D, mulching–drip irrigation; d.w., dry weight. Different letters indicate significant differences at p < 0.05.

The M-D system significantly reduced the nitrate content in the cured leaves belonging to both the B and MU crowns, which specifically approached zero (Figure 4). For the M leaves, the M-D system did not result in a significantly different nitrate content with respect to the BS-SD system (Figure 4).

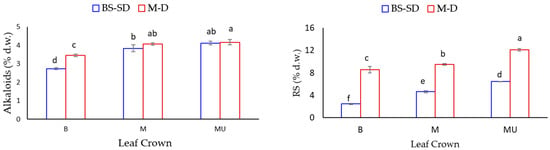

The M-D system significantly increased the alkaloid content in B leaves (Figure 5). By contrast, no difference due to different crop management systems emerged in the leaves belonging to both the M and MU crowns (Figure 5). Reducing sugars changed markedly with the two crop management systems, with significantly higher values under the M-D conditions than the BS-SD conditions and with a significant increasing behavior from the B to MU crowns under both the M-D and BS-SD conditions (Figure 5).

Figure 5.

Total alkaloid content presented as nicotine (% d.w.) and the reducing sugar content (RS, % d.w.) of cured leaves belonging to the basal (B), middle (M), and middle-upper (MU) crowns in tobacco plants grown under two crop management systems. Data are shown as the means ± standard deviations of three replications. BS-SD, bare soil–sprinkler/drip irrigation; M-D, mulching–drip irrigation; d.w., dry weight. Different letters indicate significant differences at p < 0.05.

The plants grown under the M-D system had a greater yield than those grown under the BS-SD conditions (Table 2). The same result was also recorded for cured leaves belonging to the B crown, while the opposite was found for cured leaves of the M crown (Table 2). No significant difference between the M-D and BS-SD conditions was recorded for the yield of leaves belonging to the MU crown (Table 2). The cured products obtained under the M-D system also resulted in a greater gross return than those under the BS-SD system (Table 2).

Table 2.

Yield of cured leaves (Mg ha−1) from basal (BY), middle (MY), and middle-upper (MUY) crowns from total plants (TY) and gross returns obtained by tobacco crops grown under two crop management systems (CMS). BS-SD, bare soil–sprinkler/drip irrigation; M-D, mulching–drip irrigation. *, significant at p < 0.05; NS, not significant. Different letters indicate significant differences at p < 0.05.

About 54, 10, and 36% of the cured products obtained under the M-D conditions were assigned, respectively, to price classes III, V, and VI (Table 3), while for BS-SD, about 9 and 49% of the cured products were assigned, respectively, to price classes I and II, and 42% were assigned to class price IV (Table 3). In both crop management systems, the economic value of the cured leaves increased when passing from the basal to middle-upper crowns (Table 3).

Table 3.

Yield percentages (%) of basal (BY), middle (MY), and middle-upper (MUY) cured leaves assigned by expert evaluators to each price class (EUR per kg) in tobacco crops grown under two crop management systems. BS-SD, bare soil–sprinkler/drip irrigation; M-D, mulching–drip irrigation.

4. Discussion

It is now well established that mulching, regardless of the different types, can play an important role in agriculture since it enhances the nutrient content of the soil, reduces soil erosion, and suppresses weed development, thus reducing soil contamination by herbicides. Moreover, since soil water evaporation decreases under mulching, it conserves soil moisture, reducing soil temperature fluctuations. The bio-based biodegradable mulching film Mater-Bi® is produced using renewable resources made from plant material such as starches from different crops (e.g., corn, other cereals, and potatoes) and vegetable oils.

When the mulching materials are dark colored, like the black commercial bio-based biodegradable Mater-Bi® film tested in the present study, the soil temperature may increase. Studies conducted on different crops (melon and eggplant) but in warmer areas (38°01′03″ N, 12°30′54″ E, Trapani, Italy; 38°6′56″ N, 13°21′40″ E, Palermo, Italy [72,73]) than the present experiment reported average increases of about 2–3 °C in the soil temperature under the same type of mulching film. Smaller soil temperature increments (about 1 °C) were recorded under commercial Mater-Bi® film in an experiment on tomato conducted at Acerra (N 40°57′56″ N, 14°25′50″ E, Naples, Italy [52]). Such increments (from 1 to 3 °C) are capable of positively affecting soil microbial activity, favoring organic matter decomposition and N mineralization in the soil [40], but only when the soil temperature is not excessively warm.

When the values stayed below the threshold temperature for each plant species, a high soil temperature was frequently reported to improve root development and increase the water and nutrient uptake by the plants, thus positively influencing both shoot and root growth and development [11,52,56]. Onwuka and Mang [74] reported that the soil temperature directly affected nutrient uptake by changing the soil’s water viscosity and root nutrient transport. It influenced root growth by increasing the metabolic activity of root cells and favoring the development of lateral roots.

In the present experiment, plants grown under the M-D management system grew more and developed faster than the plants grown under the BS-SD conditions. As a result, there was early maturity under mulching [6,11,13,75], precisely because the mulched soil warmed more rapidly than the bare soil. When the leaf emergence rate (LER) and the stem elongation rate (SER) were calculated over the period of active tobacco growth (67 days), according to the coefficients of the linear regression between the number of leaves vs. time (LER, leaves per day) and stem height vs. time (SER, cm per day) [76], it was found that both the LER and the SER of the M-D plants were greater than those of the BS-SD plants (0.42 vs. 0.27 leaves per day, respectively; 2.52 vs. 1.44 cm per day, respectively). A greater response in the dry matter accumulation under the M-D treatment compared to the BS-SD treatment was also found with increments that, although always present, were the highest at 33 DAT (10.4- and 8.1-fold for leaves and stems, respectively) and the lowest at the end of active growth (at 67 DAT; 0.3- and 1.6-fold for leaves and stems, respectively) [6,75]. The results of the present experiment are consistent with those reported for other species typically grown in warm seasons, like some vegetables, fruit crops, etc. [6,13,77]. Martin-Closas et al. [77] found that Mater-Bi® film increased the plant height, root and shoot biomass, and yield (i.e., number of marketable fruits per plant) of tomato crops compared with bare soil. Similarly, Di Mola et al. [52] reported increases in the yield and total soluble solids in tomatoes grown under Mater-Bi® film but observed decreases in fruit firmness, which is one of the most important aspects defining the quality of commercial tomato fruits. Di Miceli et al. [78] also found increases in the marketable yield of eggplant crops grown under Mater-Bi® film compared with bare soil but without changes in firmness.

The increases in the root zone temperature, previously reported as an effect of mulching [11,52,59,79], could be responsible for early leaf ripeness. Consequently, earlier commercial harvests of tobacco under the M-D conditions with respect to the BS-SD conditions were planned, which also positively affected the yield of cured leaves [6,13,75]. Overall, according to the results previously reported for other species [3,13,52,77,78], there were increases in the cured leaf yield under the M-D system compared to the BS-SD conditions (+29%, on average over leaf crowns). Interestingly, as expected, the gross revenue obtained by the M-D-cured products also increased (+63%, on average over leaf crowns [13]) not only because of the increasing number of cured leaves, but also due to greater prices assigned by expert evaluators based on the extrinsic quality characteristics (color, structure and texture, degree of ripeness, elasticity, lamina integrity, handling defects, and vein incidence). As expected, the economic value of the cured products increased with the leaf crowns, and it was lowest for the basal leaves and highest for the middle-upper leaves [80,81].

The intrinsic quality traits also confirmed that the M-D-cured products had the best quality according to expert evaluation. Overall, the total N content of the cured leaves obtained under the M-D system was lower than that of the cured products obtained under the BS-SD conditions, presumably because of the dilution effect for the greater biomass accumulated by the plant [82,83]. It ranged between 1.8 and 3.4% under the BS-SD conditions and between 2.5 and 2.8% under the M-D conditions. The total N content in the range of 1.3–2.3% is reported to be optimal for flue-cured tobacco [84], although even larger ranges (i.e., 2.30 and 5.25%) have been reported as normal for this kind of tobacco [80]. The lower the N content is, the flatter and less pleasant the quality of the smoke becomes, while at greater N contents, the smoke is more pungent and irritating [81,85,86]. For nitrates, lower values were found in the M-D-cured products in comparison with those that underwent the BS-SD treatment, suggesting that N was more efficiently used under the M-D conditions [87,88]. In the second part of the growing season, the leaf nitrates of the M-D leaves were more profitably converted into amino acids and other compounds, readily utilized during leaf ripening [87,88] through mobilization towards roots that are the location of nicotine synthesis [81,85,86,89]. Less nitrate accumulated in the ripened leaves before they underwent the curing period. This is a positive result since during the curing period and post-cured storage of products, nitrates turn into nitrosamines, i.e., tobacco-specific nitrosamines (TSNAs), which are potentially carcinogenic and highly dangerous to human health [86].

In the present experiment, the alkaloid content of both crop management systems (BS-SD and M-D) showed the same response overall that was already reported for total N, confirming the strict, albeit indirect, correlation between these two intrinsic quality traits [81,85,86,90]. In both treatments, the alkaloid content was greater than that reported as optimal for flue-cured Virginia tobacco by Banožić et al. [91] but consistent with that found by Vann et al. [84] and Tso [80], confirming that it can vary with cultivar and cultural practices (i.e., planting densities, time of topping, suckering control, etc.). However, several other complicated physiological mechanisms participate in alkaloid synthesis (for example, the plant’s responses to shoot apex and axillary bud removal) [89]. High alkaloids, such as nicotine, are generally reported to be responsible for a strong taste [81,85,86].

There was an interesting increase in RS due to mulching: values ranged between 8 and 12% d.w., i.e., within acceptable limits [80,81,85]. Surprisingly, the RS contents in the tobacco obtained under the M-D management system were 2.5-, 1.1-, and 0.9-fold (B, M, and MU products, respectively) greater than those obtained under the BS-SD treatment. This result is of interest, since the preference of tobacco users often appears positively and closely related to the RS content [91]. When sugars are too low, manufacturers add authorized additives to increase their levels to improve smokers’ acceptability of the tobacco [91]. Therefore, an additional commercial value for the cured products was obtained with the M-D crop management system due to this intrinsic quality trait appreciable by manufacturing industries [91].

5. Conclusions

In conclusion, this work showed for the first time that the crop management system characterized by mulching with the soil biodegradable film Mater-Bi® and drip irrigation was able to achieve good responses in field-grown tobacco, allowing for more rapid growth, early leaf ripeness, and increases in the yield and quality of the cured product (both the extrinsic and intrinsic quality traits were positively influenced). Very promising economic results were also achieved, since the gross return of the same management system was almost doubled in comparison to that obtained with the standard practice currently applied by tobacco growers in the study area (bare soil and sprinkler/drip irrigation).

Although bio-based biodegradable materials can be more expensive, eliminating disposal costs, increasing the efficiency of resource use, and proper waste management can lead to additional economic benefits, also supporting a sustainable circular economy.

According to our results, tobacco growers should be encouraged to use the M-D system considering that it provides economic and environmental benefits. Moreover, a cost–benefit analysis should allow them to make better informed decisions.

Further work is needed to improve our knowledge about the long-term effects of bio-based biodegradable plastics on soil quality and on the food chain and human health because not all aspects are completely clear at present. The impacts of the end-of-life strategy for biological and biodegradable plastic should still be tested to identify the best circular economy route.

Author Contributions

Conceptualization, E.C., A.C. and M.F.; methodology, E.C. and A.C.; validation, E.C., A.C. and F.R.; formal analysis, L.d.P., F.R., M.S. and S.B.; investigation, E.C., T.E., M.S. and S.B.; resources, A.C. and M.F.; data curation, M.I.S., L.d.P., F.R. and T.E.; field assessments, A.C., F.R., E.C. and L.d.P.; writing—original draft preparation, M.I.S.; writing—review and editing, M.I.S. and L.d.P.; visualization, M.I.S., L.d.P., E.C. and F.R.; supervision, E.C. and A.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Bio-Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation program under grant agreement no. 745012 in the framework of the WP4 of the GRACE project; call identifier: H2020-BBI-JTI-2016.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data generated or analyzed during this study are included in this published article. They are available upon request from the corresponding author.

Conflicts of Interest

Authors A.C. and M.F. are employed by the company Novamont SpA (the manufacturer of Mater Bi® film used in this study). The remaining authors declare that this research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Yang, N.; Sun, Z.K.; Feng, L.S.; Zheng, M.Z.; Chi, D.C.; Meng, W.Z.; Hou, Z.Y.; Bai, W.; Li, K.L. Plastic film mulching for water-efficient agricultural applications and degradable films materials development research. Mater. Manuf. Process. 2015, 30, 143–154. [Google Scholar] [CrossRef]

- Pi, X.; Zhang, T.; Sun, B.; Cui, Q.; Guo, Y.; Gao, M.; Feng, H.; Hopkins, D.W. Effects of mulching for water conservation on soil carbon, nitrogen and biological properties. Front. Agric. Sci. Eng. 2017, 4, 146–154. [Google Scholar] [CrossRef]

- Iqbal, R.; Raza, M.A.S.; Valipour, M.; Saleem, M.F.; Zaheer, M.S.; Ahmad, S.; Toleikiene, M.; Haider, I.; Aslam, M.U.; Nazar, M.A. Potential agricultural and environmental benefits of mulches—A review. Bull. Natl. Res. Cent. 2020, 44, 44–75. [Google Scholar] [CrossRef]

- Prem, M.; Ranjan, P.; Seth, N.; Patle, G.T. Mulching Techniques to Conserve the Soil Water and Advance the Crop Production—A Review. Curr. World Environ. 2020, 15, 10–30. [Google Scholar] [CrossRef]

- El-Beltagi, H.S.; Basit, A.; Mohamed, H.I.; Ali, I.; Ullah, S.; Kamel, E.A.R.; Shalaby, T.A.; Ramadan, K.M.A.; Alkhateeb, A.A.; Ghazzawy, H.S. Mulching as a Sustainable Water and Soil Saving Practice in Agriculture: A Review. Agronomy 2022, 12, 1881. [Google Scholar] [CrossRef]

- Nithisha, A.; Bokado, K.; Charitha, K.S. Mulches: Their impact on the crop production. Pharma Innov. J. 2022, 11, 3597–3603. [Google Scholar]

- Fan, D.; Jia, G.; Wang, Y.; Yu, X. The effectiveness of mulching practices on water erosion control: A global meta-analysis. Geoderma 2023, 438, 116643. [Google Scholar] [CrossRef]

- Subrahmaniyan, K.; Veeramani, P.; Harisudan, C. Heat accumulation and soil properties as affected by transparent plastic mulch in Blackgram (Vigna mungo) doubled cropped with Groundnut (Arachis hypogaea) in sequence under rainfed conditions in Tamil Nadu, India. Field Crops Res. 2018, 219, 43–54. [Google Scholar] [CrossRef]

- Zhang, H.; Miles, C.; Ghimire, S.; Benedict, C.; Zasada, I.; DeVetter, L. Polyethylene and biodegradable plastic mulches improve growth, yield, and weed management in floricane red raspberry. Sci. Hort. 2019, 250, 371–379. [Google Scholar] [CrossRef]

- Tang, M.; Gao, X.; Wu, P.; Li, H.; Zhang, C. Effects of Living Mulch and Branches Mulching on Soil Moisture, Temperature and Growth of Rain-Fed Jujube Trees. Plants 2022, 11, 2654. [Google Scholar] [CrossRef] [PubMed]

- Sifola, M.I.; Di Mola, I.; Cozzolino, E.; Ottaiano, L.; Nocerino, S.; Riccardi, R.; Spigno, P.; Mori, M. Yield and Quality Traits of Tomato ‘San Marzano’ Type as Affected by Photo-Selective Low-Density Polyethylene Mulching. Agronomy 2024, 14, 315. [Google Scholar] [CrossRef]

- Nwosisi, S.; Nandwani, D.; Hui, D. Mulch Treatment Effect on Weed Biomass and Yields of Organic Sweet potato Cultivars. Agronomy 2019, 9, 190. [Google Scholar] [CrossRef]

- Ray, M.; Biswasi, S. Impact of Mulching on Crop Production: A Review. Trends Biosci. 2016, 9, 757–767. [Google Scholar]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Botta, L.; Mistretta, M.C.; Di Fiore, A.; Titone, V. Recycling of a Biodegradable Polymer Blend. Polymers 2020, 12, 2297. [Google Scholar] [CrossRef] [PubMed]

- Francioni, M.; Kishimoto-Mo, A.W.; Tsuboi, S.; Hoshino, Y.T. Evaluation of the mulch films biodegradation in soil: A methodological review. Ital. J. Agron. 2022, 17, 1936. [Google Scholar] [CrossRef]

- Abbate, C.; Scavo, A.; Pesce, G.R.; Fontanazza, S.; Restuccia, A.; Mauromicale, G. Soil Bioplastic Mulches for Agroecosystem Sustainability: A Comprehensive Review. Agriculture 2023, 13, 197. [Google Scholar] [CrossRef]

- de Sadeleer, I.; Woodhouse, A. Environmental impact of biodegradable and non-biodegradable agricultural mulch film: A case study for Nordic conditions. Int. J. Life Cycle Assess. 2024, 29, 275–290. [Google Scholar] [CrossRef]

- Mansoor, Z.; Tchuenbou-Magaia, F.; Kowalczuk, M.; Adamus, G.; Manning, G.; Parati, M.; Radecka, I.; Khan, H. Polymers Use as Mulch Films in Agriculture—A Review of History, Problems and Current Trends. Polymers 2022, 14, 5062. [Google Scholar] [CrossRef]

- Kader, M.A.; Senge, M.; Mojid, M.A.; Ito, K. Recent advances in mulching materials and methods for modifying soil environment. Soil Tillage Res. 2017, 168, 155–166. [Google Scholar] [CrossRef]

- European Bioplastics e.V. Position of European Bioplastics & EuropaBio Concerning Fertilizer Regulation: Biodegradable Mulch Film. 2016. Available online: https://www.europarl.europa.eu/cmsdata/108936/Kristy%20Barbara%20Lange%20EUBP.pdf (accessed on 28 June 2024).

- Agriculture Plastic Environment Europe, 92300 Levallois Perret–France. Available online: https://apeeurope.eu/statistics/ (accessed on 29 February 2024).

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic flexible films waste management—A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef] [PubMed]

- Salama, K.; Geyer, M. Plastic Mulch Films in Agriculture: Their Use, Environmental Problems, Recycling and Alternatives. Environments 2023, 10, 179. [Google Scholar] [CrossRef]

- Khalid, N.; Aqeel, M.; Noman, A.; Rizvi, Z.F. Impact of plastic mulching as a major source of microplastics in agroecosystems. J. Hazard. Mater. 2023, 445, 130455. [Google Scholar] [CrossRef] [PubMed]

- Sintim, H.Y.; Flury, M. Is Biodegradable Plastic Mulch the Solution to Agriculture’s Plastic Problem? Environ. Sci. Technol. 2017, 51, 1068–1069. [Google Scholar] [CrossRef] [PubMed]

- Touchaleaume, F.; Martin-Closas, L.; Angellier-Coussy, H.; Chevillard, A.; Cesar, G.; Gontard, N.; Gastaldi, E. Performance and environmental impact of biodegradable polymers as agricultural mulching films. Chemosphere 2016, 144, 433–439. [Google Scholar] [CrossRef]

- Madrid, B.; Wortman, S.; Hayes, D.G.; DeBruyn, J.M.; Miles, C.; Flury, M.; Marsh, T.L.; Galinato, S.P.; Englund, K.; Agehara, S.; et al. End-of-Life Management Options for Agricultural Mulch Films in the United States—A Review. Front. Sustain. Food Syst. 2022, 6, 921496. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; Abdul, G.A. Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr. Res. Green Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Somanathan, H.; Sathasivam, R.; Sivaram, S.; Kumaresan, S.M.; Muthuraman, M.S.; Sang, U.P. An update on polyethylene and biodegradable plastic mulch films and their impact on the environment. Chemosphere 2022, 307, 135839. [Google Scholar] [CrossRef]

- Merino, D.; Mansilla, Y.; Casalongué, C.A.; Alvarez, V.A. Performance of Bio-Based Polymeric Agricultural Mulch Films. In Polymers for Agri-Food Applications; Tomy, J., Gutiérrez, Eds.; Springer: Cham, Switzerland, 2019; Chapter 12; pp. 215–240. [Google Scholar] [CrossRef]

- Campanale, C.; Galafassi, S.; Di Pippo, F.; Pojar, I.; Massarelli, C.; Uricchio, V.F. A critical review of biodegradable plastic mulch films in agriculture: Definitions, scientific background and potential impacts. Trends Anal. Chem. 2024, 170, 117391. [Google Scholar] [CrossRef]

- Menossi, M.; Cisneros, M.; Alvarez, V.A.; Casalongué, C.A. Current and emerging biodegradable mulch films based on polysaccharide bio-composites. A review. Agron. Sustain. Dev. 2021, 41, 53. [Google Scholar] [CrossRef]

- Liu, E.; Zhang, L.; Dongand, W.; Yan, C. Biodegradable plastic mulch films in agriculture: Feasibility and challenges. Environ. Res. Lett. 2021, 16, 011004. [Google Scholar] [CrossRef]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef]

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.S.; Abdelkarim, E.A.; Elsamahy, T.; Al-Tohamy, R.; Li, F.; Kornaros, M.; Zuorro, A.; Zhu, D.; Sun, J. Bioplastic production in terms of life cycle assessment: A state-of-the-art review. Environ. Sci. Ecotechnol. 2023, 15, 100254. [Google Scholar] [CrossRef] [PubMed]

- Liwarska-Bizukojc, E. Effect of (bio)plastics on soil environment: A review. Sci. Total Environ. 2021, 795, 148889. [Google Scholar] [CrossRef]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Tröger, J.; Muñoz, K.; Oliver Frör, O.; Schaumann, G.E. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef]

- Bandopadhyay, S.; Martin-Closas, L.; Pelacho, A.M.; DeBruyn, J.M. Biodegradable Plastic Mulch Films: Impacts on Soil Microbial Communities and Ecosystem Functions. Front. Microbiol. 2018, 9, 819. [Google Scholar] [CrossRef] [PubMed]

- Hayes, D.G.; Anunciado, M.B.; DeBruyn, J.M.; Bandopadhyay, S.; Schaeffer, S.; English, M.; Ghimire, S.; Miles, C.; Flury, M.; Sintim, H.Y. Biodegradable Plastic Mulch Films for Sustainable Specialty Crop Production. In Polymers for Agri-Food Applications; Gutiérrez, T.J., Ed.; Springer: Cham, Switzerland, 2019; Chapter 11; pp. 183–213. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Bandopadhyay, S.; English, M.E.; Bary, A.I.; DeBruyn, J.M.; Schaeffer, S.M.; Miles, C.A.; Reganold, J.P.; Flury, M. Impacts of biodegradable plastic mulches on soil health. Agric. Ecosyst. Environ. 2019, 273, 36–49. [Google Scholar] [CrossRef]

- Brown, R.W.; Chadwick, D.R.; Zang, H.; Graf, M.; Liu, X.; Wang, K.; Jones, D.L. Bioplastic (PHBV) addition to soil alters microbial community structure and negatively affects plant-microbial metabolic functioning in maize. J. Hazard. Mater. 2023, 441, 129959. [Google Scholar] [CrossRef]

- Guliyev, V.; Tanunchai, B.; Udovenko, M.; Menyailo, O.; Glaser, B.; Purahong, W.; Buscot, F.; Blagodatskaya, E. Degradation of Bio-Based and Biodegradable Plastic and Its Contribution to Soil Organic Carbon Stock. Polymers 2023, 15, 660. [Google Scholar] [CrossRef]

- Zhang, F.; Li, M.; Qi, J.H.; Li, F.M.; Sun, G.J. Plastic film mulching increases soil respiration in ridge-furrow maize management. Arid Soil Res. Rehab. 2015, 29, 432–453. [Google Scholar] [CrossRef]

- Mu, L.; Liang, Y.; Zhang, C.; Wang, K.; Shi, G. Soil respiration of hot pepper (Capsicum annuum L.) under different mulching practices in a greenhouse, including controlling factors in China. Acta Agric. Scand. Sec. B–Soil Plant Sci. 2014, 64, 85–95. [Google Scholar] [CrossRef]

- Moreno, M.M.; Moreno, A. Effect of different biodegradable and polyethylene mulches on soil properties and production in a tomato crop. Sci. Hortic. 2008, 116, 256–263. [Google Scholar] [CrossRef]

- EN17033; Plastics-Biodegradable Mulch Films for Use in Agriculture and Horticulture-Requirements and Test Methods. European Committee for Standardization (CEN): Bruxelles, Belgium, 2018. Available online: https://standards.globalspec.com/std/10275332/en-17033 (accessed on 28 June 2024).

- Moreno, M.M.; Moreno, A.; Mancebo, I. Comparison of different mulch materials in a tomato (Solanum lycopersicum L.) crop. Span. J. Agric. Res. 2009, 7, 454–464. [Google Scholar] [CrossRef]

- Morra, L.; Bilotto, M.; Cerrato, D.; Coppola, R.; Leone, V.; Mignoli, E.; Pasquariello, M.S.; Petriccione, M.; Cozzolino, E. The Mater-Bi® biodegradable film for strawberry (Fragaria x ananassa Duch.) mulching: Effects on fruit yield and quality. Ital. J. Agron. 2016, 11, 731. [Google Scholar] [CrossRef]

- Di Mola, I.; Ventorino, V.; Cozzolino, E.; Ottaiano, L.; Romano, I.; Duri, L.G.; Pepe, O.; Mori, M. Biodegradable mulching vs traditional polyethylene film for sustainable solarization: Chemical properties and microbial community response to soil management. Appl. Soil Ecol. 2021, 163, 103921. [Google Scholar] [CrossRef]

- Di Mola, I.; Cozzolino, E.; Ottaiano, L.; Riccardi, R.; Spigno, P.; Petriccione, M.; Fiorentino, N.; Fagnano, M.; Mori, M. Biodegradable Mulching Film vs.Traditional Polyethylene: Effects on Yield and Quality of San Marzano Tomato Fruits. Plants 2023, 12, 3203. [Google Scholar] [CrossRef]

- Merino, M.; Zych, A.; Athanassiou, A. Biodegradable and Biobased Mulch Films: Highly Stretchable PLA Composites with Different Industrial Vegetable Waste. ACS Appl. Mater. Interfaces 2022, 14, 46920–46931. [Google Scholar] [CrossRef]

- FAOSTAT 2022. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 13 March 2024).

- Chida, H. Mulching for Tobacco Cultivation in Japan. CORESTA Meeting, Agronomy/Phytopathology, 2015, Izmir, Türkiye, AP 13. Available online: https://www.coresta.org/abstracts/mulching-tobacco-cultivation-japan-28082.html (accessed on 28 June 2024).

- SindiTabaco. The environment in focus. In SindiTabaco News Santa Cruz do Sul, RS, Brazil 2023, January–April, pp. 1–6. Available online: https://www.sinditabaco.com.br/sinditabaconews-janeiro-a-abril-2023/sindifolderppp46eng/ (accessed on 28 June 2024).

- Jensen, M.H.; Malter, A.J. Protected Agriculture: A Global Review; Technical Paper Number 253; World Bank Publications: Washington, DC, USA, 1995; p. 1818. ISSN 0253-7494. [Google Scholar]

- Lin, Y.; Wei, K.; Gao, W.; Chen, Y.; Lin, Y.; Chen, W.; Li, H.; Pan, W. Effects of plastic mulching film-induced leaf burning on seedling growth in tobacco cultivation: Different findings beyond conservation view. J. Integr. Agric. 2018, 17, 1327–1337. [Google Scholar] [CrossRef]

- Machanoff, C.A.; Vann, M.C.; Woodley, A.L.; Suchoff, D. Evaluation of the use of polyethylene mulches in the production of organic flue-cured tobacco. Agron. J. 2022, 114, 2501–2517. [Google Scholar] [CrossRef]

- Tayyab, M.; Yang, Z.; Zhang, C.; Islam, W.; Lin, W.; Zhang, H. Sugarcane monoculture drives microbial community composition, activity and abundance of agricultural-related microorganisms. Environ. Sci. Pollut. Res. 2021, 28, 48080–48096. [Google Scholar] [CrossRef] [PubMed]

- Elouattassi, Y.; Ferioun, M.; El Ghachtouli, N.; Derraz, K.; Rachidi, F. Agroecological concepts and alternatives to the problems of contemporary agriculture: Monoculture and chemical fertilization in the context of climate change. J. Agric. Environ. Int. Dev. 2023, 117, 41–98. [Google Scholar] [CrossRef]

- Ibarra-Jiménez, L.; Zermeño-González, A.; Munguía-López, J.; Quezada-Martin, M.R.; De La Rosa-Ibarra, M. Photosynthesis, soil temperature and yield of cucumber as affected by coloured plastic mulch. Acta Agric. Scand. Sect. B 2008, 58, 372–378. [Google Scholar] [CrossRef]

- Sharaf-Eldin, M.A.; Etman, A.A.; Attalla, M.E. Comparative Study between Drip Irrigation with Soil Mulch and Surface Irrigation on Sweet Potato Grown under North River Nile Delta Conditions. In Proceedings of the 1st International Conference on Applied Agricultural Sciences and Prospective Technology, Luxor, Egypt, 23–26 February 2017. [Google Scholar]

- Zhao, Z.; Shi, F.; Guan, F. Effects of plastic mulching on soil CO2 efflux in a cotton field in northwestern China. Sci. Rep. 2022, 12, 4969. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop evapotranspiration: Guidelines for computing crop water requirements. In FAO Irrigation and Drainage Paper No. 56; FAO: Rome, Italy, 1998; p. 300. [Google Scholar]

- Masaf, O.I.; Tabacco Italia–OIT. Disciplinare di Produzione Tabacco Virginia Bright-Maggio 2019. Available online: https://www.ontitalia.com/wp-content/uploads/2015/08/Disciplinare_di_Produzione_Tabacco_Virginia_Bright.pdf (accessed on 30 January 2024).

- Technicon Industrial Systems. Ammonia in Water and Wastewater. Industrial Method No. 90-70W-B; Technicon Industrial Systems: Tarrytown, NY, USA, 1978. [Google Scholar]

- Coresta Recommended Method N° 36-Tobacco-Determination of Nitrate in Tobacco and Smokeless Tobacco Products by Reduction to Nitrite and Continuous Flow Analysis. Jan. 2015. Available online: https://www.coresta.org/sites/default/files/technical_documents/main/CRM_36-updateJan15.pdf (accessed on 13 December 2023).

- Lidzey, R.G.; Savage, G.P. An automated procedure for the determination of total alkaloids in cigarette smoke using on-line cyanogen chloride generation from low hazard starting materials. Beitr. Tabakforsch. Int. 1986, 13, 151–155. [Google Scholar] [CrossRef]

- Coresta Recommended Method N° 37-Tobacco-Determination of Reducing Substances in Tobacco by Continuous Flow Analysis (CRM Developed into ISO 15153) Aug. 2010-2nd ed. Available online: https://www.coresta.org/sites/default/files/technical_documents/main/CRM_37-update%28Aug10%29.pdf (accessed on 13 December 2023).

- STATISTICA; Software Version 7.1 for Windows; StatSoft, Inc.: Tulsa, OK, USA, 2000.

- Iapichino, G.; Mustazza, G.; Sabatino, L.; D’Anna, F. Polyethylene and Biodegradable Starch-Based Mulching Films Positively Affect Winter Melon Production in Sicily. Acta Hortic. 2014, 1015, 225–231. [Google Scholar] [CrossRef]

- Sabatino, L.; Iapichino, G.; Vetrano, F.; Moncada, A.; Miceli, A.; De Pasquale, C.; D’Anna, F.; Giurgiulescu, L. Effects of polyethylene and biodegradable starch-based mulching films on eggplant production in a Mediterranean area. Carpathian J. Food Sci. Technol. 2018, 10, 81–89. [Google Scholar]

- Onwuka, B.; Mang, B. Effects of soil temperature on some soil properties and plant growth. Adv. Plants Agric. Res. 2018, 8, 34–37. [Google Scholar] [CrossRef]

- Tarara, J.M. Microclimate Modification with Plastic Mulch. HortScience 2000, 35, 169–180. [Google Scholar] [CrossRef]

- Sifola, M.I.; Cuocolo, B.; Postiglione, L. Dry matter accumulation, leaf development and stem elongation in tobacco plants grown under different regimes of N fertilization and irrigation. Agrochimica 2003, 47, 40–53. [Google Scholar]

- Martín-Closas, L.; Bach, M.A.; Pelacho, A.M. Biodegradable Mulching in an Organic Tomato Production System. Acta Hortic. 2008, 767, 267–274. [Google Scholar] [CrossRef]

- Di Miceli, G.; Iacuzzi, N.; Leto, C.; Cozzolino, E.; Di Mola, I.; Ottaiano, L.; Mori, M.; Bella, S.L. Assessment of Yield and Quality of Eggplant (Solanum melongena L.) Fruits Improved by Biodegradable Mulching Film in Two Different Regions of Southern Italy. Agronomy 2024, 14, 867. [Google Scholar] [CrossRef]

- Snyder, K.; Grant, A.; Murray, C.; Wolff, B. The Effects of Plastic Mulch Systems on Soil Temperature and Moisture in Central Ontario. HortTechnology 2015, 25, 162–170. [Google Scholar] [CrossRef]

- Tso, T.C. Seed to Smoke. In Tobacco: Production Chemistry and Technology; Davies, D.L., Nielsen, M.T., Eds.; Blackwell Science Ltd.: Oxford, UK, 1999; Volume 1, pp. 1–31. ISBN 0-632-04791-7. [Google Scholar]

- Akehurst, B.C. Tobacco. In Tropical Agriculture Ser, 2nd ed.; Longman Inc.: London, UK, 1981; Volume 736. [Google Scholar] [CrossRef]

- Lemaire, G.; Jeuffroy, M.H.; Gastal, F. Diagnosis tool for plant and crop N status in vegetative stage: Theory and practices for crop N management. Eur. J. Agron. 2008, 28, 614–624. [Google Scholar] [CrossRef]

- Sifola, M.I.; Raimondi, G.; Maggio, A. Improving the sustainability of tobacco cultivation by optimizing nitrogen fertilization. Aust. J. Crop Sci. AJCS 2017, 11, 1399–1405. [Google Scholar] [CrossRef]

- Vann, M.C.; Fisher, L.R.; Jordan, D.L.; Hardy, D.H.; Smith, W.D.; Stewart, A.M. The effect of potassium rate on the yield and quality of flue-cured tobacco (Nicotiana tabacum L.). Tob. Sci. 2012, 49, 14–20. [Google Scholar] [CrossRef]

- Mendell, S.; Bourlas, E.C.; DeBardeleben, M.Z. Factors Influencing Tobacco Leaf Quality. Beitr. Tabakforsch. Int. 1984, 12, 153–167. [Google Scholar] [CrossRef][Green Version]

- Davies, D.L.; Nielsen, M.T. Tobacco: Production Chemistry and Technology; Blackwell Science Ltd.: Oxford, UK, 1999; p. 840. ISBN 0-632-04791-7. [Google Scholar]

- Sifola, M.; Postiglione, L. The effect of nitrogen fertilization on nitrogen use efficiency of irrigated and non-irrigated tobacco (Nicotiana tabacum L.). Plant Soil 2003, 252, 313–323. [Google Scholar] [CrossRef]

- Sifola, M.I.; Di Mola, I.; Cozzolino, E.; Ottaiano, L.; Piccirillo, G.; del Piano, L.; Mori, M. Yield Response, Quality Traits, and Nitrogen-Use Efficiency of a Burley Tobacco Crop Grown in Mediterranean Areas (Southern Italy) as Affected by Intensive N Management. Agronomy 2021, 11, 1837. [Google Scholar] [CrossRef]

- Wang, S.S.; Shi, Q.M.; Li, W.Q.; Niu, J.F.; Li, C.J.; Zhang, F.S. Nicotine Concentration in Leaves of Flue-cured Tobacco Plants as Affected by Removal of the Shoot Apex and Lateral Buds. J. Integr. Plant. Biol. 2008, 50, 958–964. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ren, K.; He, X.; Chen, Y.; Hu, B.; Hu, X.; Li, J.; Jin, Y.; Zhao, Z.; Zou, C. The response of flue–cured tobacco cultivar K326 to nitrogen fertilizer rate in China. J. Agric. Sci. 2020, 158, 371–382. [Google Scholar] [CrossRef]

- Banožić, M.; Jokić, S.; Ačkar, Đ.; Blažić, M.; Šubarić, D. Carbohydrates-Key Players in Tobacco Aroma Formation and Quality Determination. Molecules 2020, 25, 1734. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).