Experimental Study on Static and Dynamic Characteristics of Sand–Clay Mixtures with Different Mass Ratios

Abstract

:1. Introduction

2. Sample Preparation and Test Method

2.1. Test Device and Test Procedure

2.2. Sample Preparation and Saturation

2.3. Test Scheme

- (1)

- Triaxial shear test

- (2)

- Vibration triaxial test

3. Shear Mechanical Properties of Mixed Soil

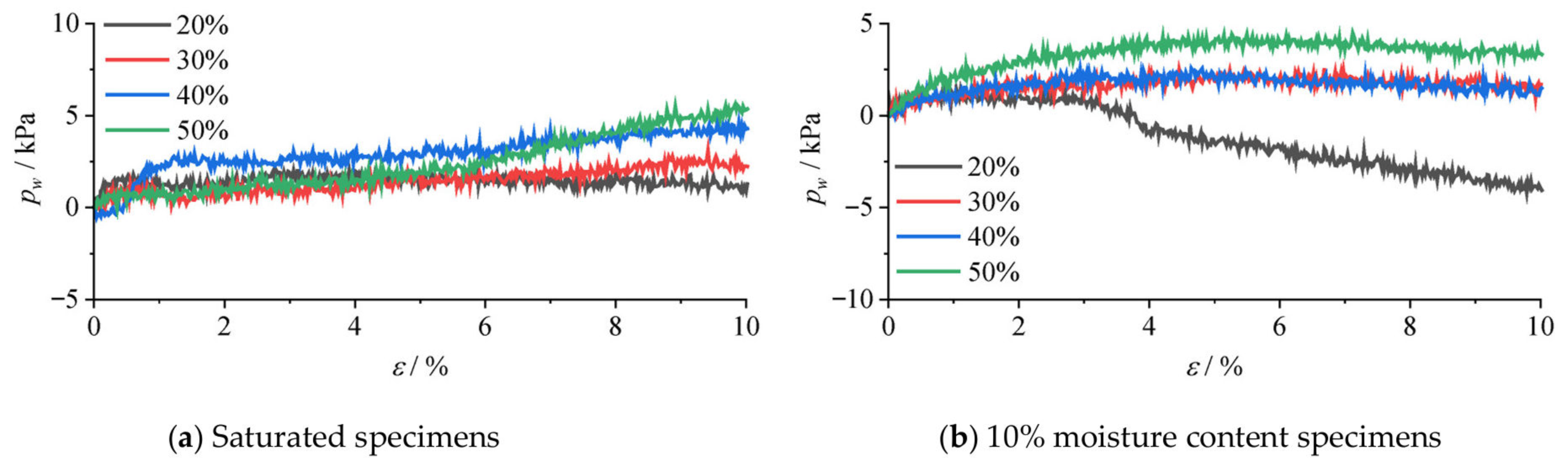

3.1. Shear Mechanical Properties of Samples with Different Clay Content

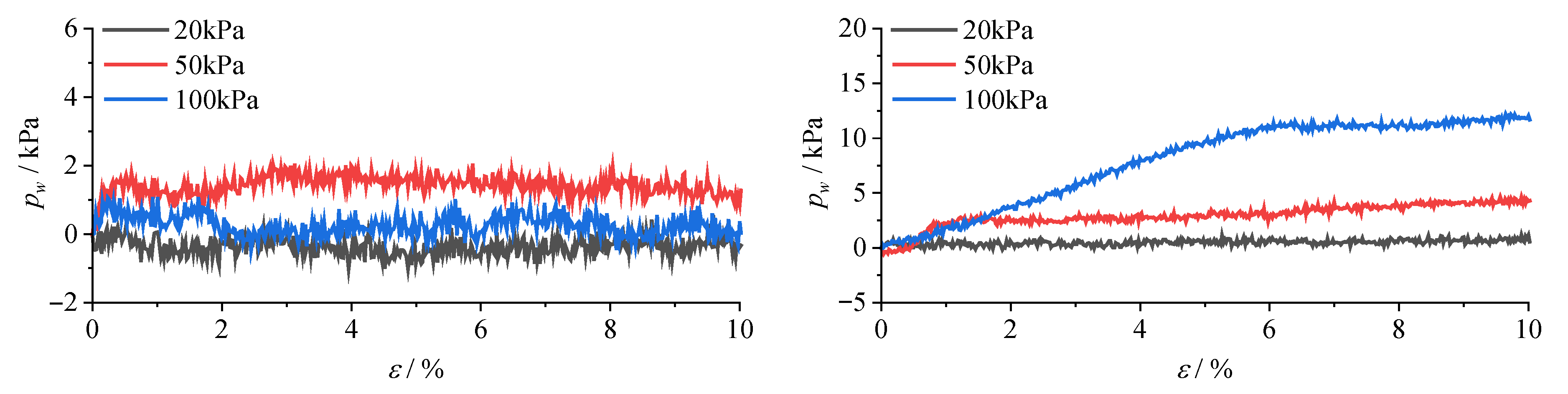

3.2. Influence of Confining Pressure on Sample Strength and Static Liquefaction Characteristics

4. The Dynamic and Liquefaction Characteristics of the Mixed Soil

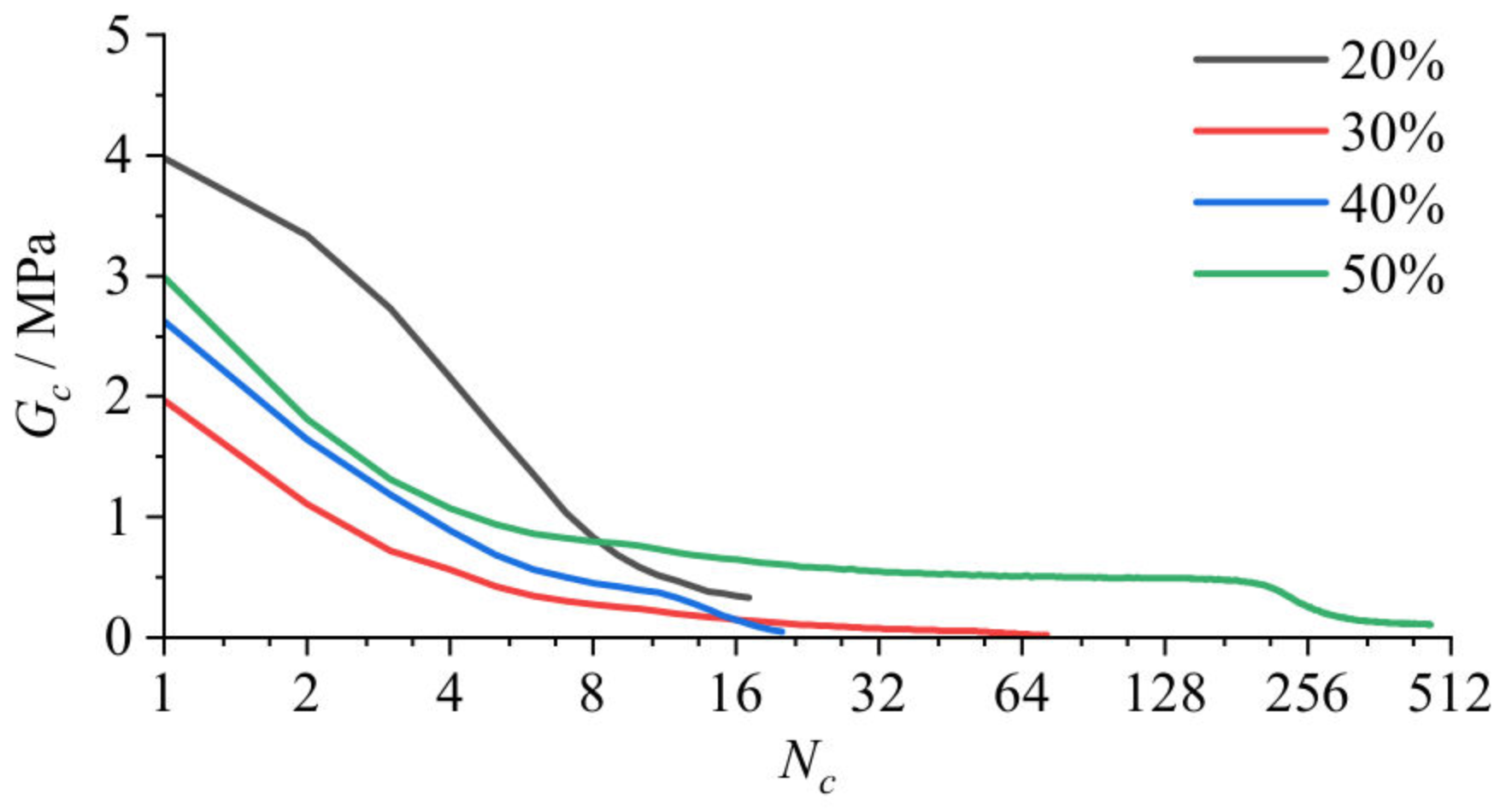

4.1. Dynamic Shear Modulus and Damping Ratio of Sand–Viscous Mixed Soil

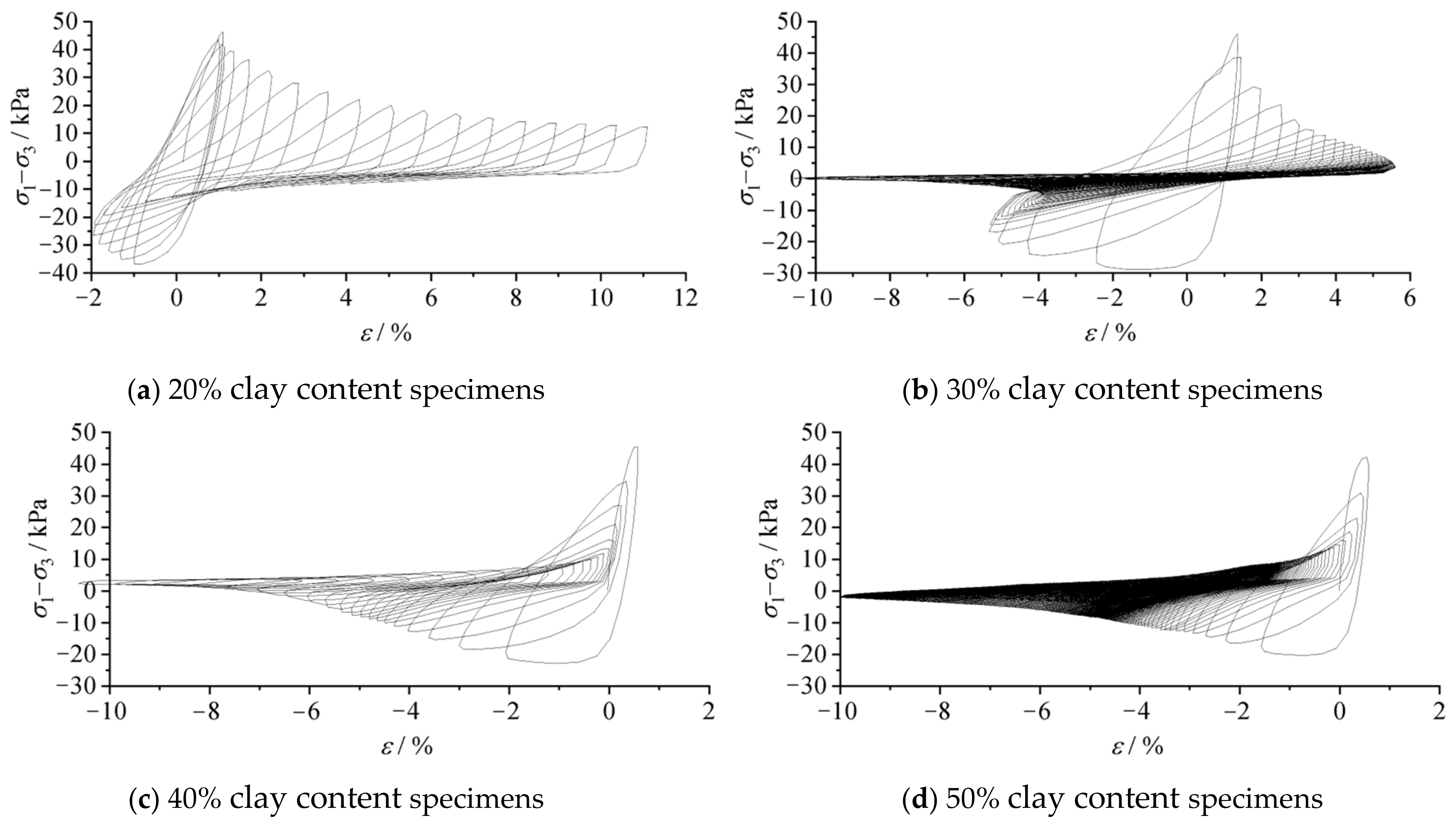

4.2. Hysteretic Curve of Liquefaction Process of Sand–Viscous Mixed Soil

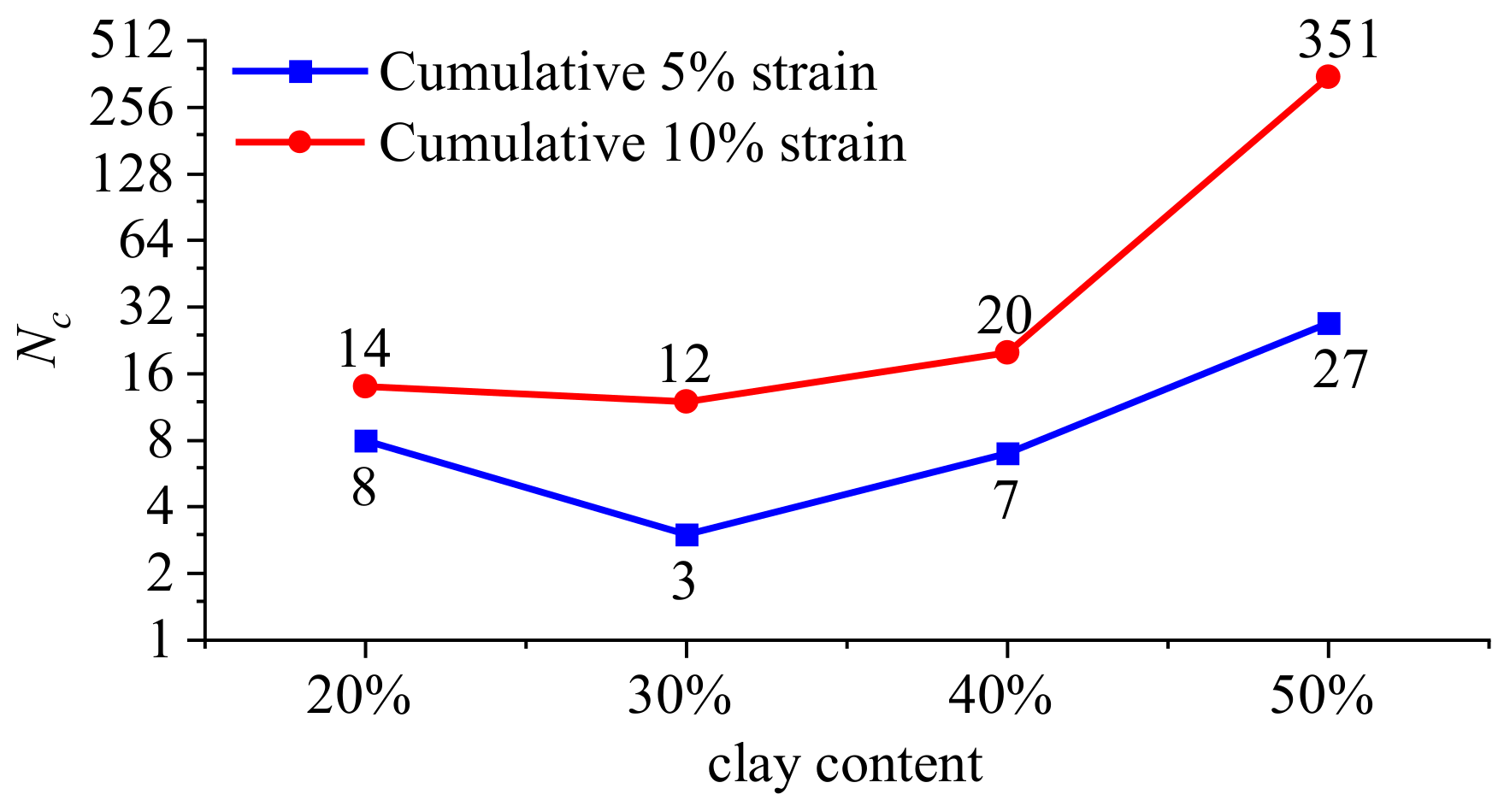

4.3. Liquefaction Resistance of Sand–Clay Mixture

5. Conclusions

- (1)

- According to the results obtained from the triaxial shear test, it is observed that the sample with a clay content of 30% exhibits the lowest values for both tangential modulus and peak strength. However, an increase in clay content within the soil leads to a reduction in liquefaction resistance under static loading conditions. Increasing confining pressure in the triaxial shear tests resulted in higher tangential modulus and larger peak deviating stress values. For a clay content of 20%, there was no significant change in pore water pressure. However, at a clay content of 40%, higher confining pressures led to larger peak values of pore water pressure.

- (2)

- Based on the results of vibration triaxial testing, it is evident that the dynamic shear modulus of the sample decreases with increasing shear strain, while the damping ratio initially increases and then decreases. Moreover, the dynamic shear modulus decreases as clay content increases, whereas the damping ratio decreases with an increase in clay content. Among samples tested, those containing 30% clay content exhibited the most rapid increase in pore water pressure, the lowest shear modulus, and experienced fewer cyclic loading cycles until failure occurred. Enhancing soil gradation and adjusting the sand–clay ratio can effectively increase soil strength and enhance its resistance against liquefaction.

- (3)

- In this study, the sample containing 30% clay content exhibits the lowest liquefaction strength, shear modulus, and fastest rising rate of pore water pressure, as well as the highest damping ratio. It is important to note that soil strength and liquefaction resistance are influenced by various factors, necessitating further investigation into their combined effects.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.; Zhao, H.; Luo, Z.; Liu, H. Investigation of the mechanical behavior of soft clay under combined shield construction and ocean waves. Ocean. Eng. 2020, 206, 107250. [Google Scholar]

- Goodarzi, S.; Shahnazari, H. Strength enhancement of geotextile-reinforced carbonate sand. Geotext. Geomembr. 2019, 47, 128–139. [Google Scholar] [CrossRef]

- Rezvani, R. Shearing response of geotextile-reinforced calcareous soils using monotonic triaxial tests. Mar. Georesources Geotechnol. 2020, 38, 238–249. [Google Scholar] [CrossRef]

- Luo, Z.; Ding, X.; Ou, Q.; Fang, H. Bearing capacity and deformation behavior of rigid strip footings on coral sand slopes. Ocean Eng. 2023, 267, 113317. [Google Scholar] [CrossRef]

- Ghassemi-Golezani, K.; Farhangi-Abriz, S. Improving plant available water holding capacity of soil by solid and chemically modified biochars. Rhizosphere 2022, 21, 100469. [Google Scholar] [CrossRef]

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Shahnazari, H.; Rezvani, R. Effective parameters for the particle breakage of calcareous sands: An experimental study. Eng. Geol. 2013, 159, 98–105. [Google Scholar] [CrossRef]

- Salem, M.; Elmamlouk, H.; Agaiby, S. Static and cyclic behavior of North coast calcareous sand in Egypt. Soil Dyn. Earthq. Eng. 2013, 55, 83–91. [Google Scholar] [CrossRef]

- Wang, X.; Weng, Y.; Wei, H.; Meng, Q.; Hu, M. Particle obstruction and crushing of dredged calcareous soil in the Nansha Islands, South China Sea. Eng. Geol. 2019, 261, 105274. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Xiao, P.; Xiang, J. Fractal crushing of carbonate sands under impact loading. Geotech. Lett. 2016, 6, 199–204. [Google Scholar] [CrossRef]

- Li, W.; Lang, L.; Wang, D.; Wu, Y.; Li, F. Investigation on the dynamic shear modulus and damping ratio of steel slag sand mixtures. Constr. Build. Mater. 2018, 162, 170–180. [Google Scholar] [CrossRef]

- Ashiango, A.A.; Patra, N.R. Behavior of expansive soil treated with steel slag, rice husk ash, and lime. J. Mater. Civ. Eng. 2016, 28, 06016008. [Google Scholar] [CrossRef]

- Min, Y.; Wu, J.; Li, B.; Zhang, J. Dynamic shear modulus and damping ratio of the one-part geopolymer stabilized soft clay. Mater. Civ. Eng. 2022, 34, 04022120. [Google Scholar] [CrossRef]

- Yin, P.; Zou, M.; Wei, H.; Yang, K.; Zhang, Y.; Li, X.; Chen, Y.; Zhang, X. Dynamic characteristics and constitutive model of ferronickel slag clay under cyclic loading. China J. Highw. Transp. 2024, 37, 155–165. [Google Scholar]

- Fedakar, H.I.; Rutherford, C.J.; Cetin, B. Effect of principal stress rotation on deformation behavior of dense sand-clay mixtures. Road Mater. Pavement Des. 2022, 23, 2035–2056. [Google Scholar] [CrossRef]

- Kim, U.; Kim, D.; Zhuang, L. Influence of fines content on the undrained cyclic shear strength of sand-clay mixtures. Soil Dyn. Earthq. Eng. 2016, 83, 124–134. [Google Scholar] [CrossRef]

- Lü, X.; Xue, D.; Zhang, B.; Zhong, Q. Experimental studies and constitutive modeling of static liquefaction instability in sand-clay mixtures. Int. J. Geomech. 2022, 22, 0002472. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, L.; Wang, L.; Hou, G.L.; Gu, C.Q. Influence of clay content on compressive strength of silt. Subgrade Eng. 2022, 220, 44–48. [Google Scholar]

- Wang, Y.; Cao, T.; Gao, Y.; Shao, J. Experimental study on liquefaction characteristics of saturated silty soil at Yellow River Delta. J. Eng. Geol. 2018, 26, 451–458. [Google Scholar]

- Xu, G.; Liu, H.; Liu, J.; Yu, Y. Role of clay content in silty soil liquefaction. Mar. Geol. Quat. Geol. 2012, 32, 31–35. [Google Scholar] [CrossRef]

- Wang, G.X.; Jiro, K.; Jiro, T. Study on excess pore water pressures of sands mixed with clays under cyclic loading. Chin. J. Geotech. Eng. 2004, 26, 541–545. [Google Scholar]

- Li, S.; Sun, X.S.; Yao, M.L. Study of liquefaction evaluation used in indoor test of silt, silty sand mixed clay. Rock Soil Mech. 2006, 27, 360–364. [Google Scholar]

- Cheng, C. Research on Liquefaction Evaluation Criteria for Silty Soil in Yellow River Delta; Ocean University of China: Qingdao, China, 2007. [Google Scholar]

- Song, Y.; Sun, Y.; Song, B.; Dong, L.; Du, X. Comparative study on the liquefaction properties of seabed silt under wave loading in the Huanghe River Delta. Haiyang Xuebao 2021, 43, 129–138. [Google Scholar]

- Liu, Y. Fundamentals of Soil Dynamics; Tsinghua University Press: Beijing, China, 2019. [Google Scholar]

- Liu, X.Z.; Chen, G.X. Experimental study on influence of clay particle content on liquefaction of Nanjing fine sand. Earthq. Eng. Eng. Vib. 2003, 23, 150–155. [Google Scholar]

| Case Number | Clay Content | Moisture Content | Confining Pressure |

|---|---|---|---|

| T1 | 20% | saturated | 50 kPa |

| T2 | 30% | saturated | 50 kPa |

| T3 | 40% | saturated | 50 kPa |

| T4 | 50% | saturated | 50 kPa |

| T5 | 20% | 10% | 50 kPa |

| T6 | 30% | 10% | 50 kPa |

| T7 | 40% | 10% | 50 kPa |

| T8 | 50% | 10% | 50 kPa |

| T9 | 20% | saturated | 20 kPa |

| T10 | 20% | saturated | 100 kPa |

| T11 | 40% | saturated | 20 kPa |

| T12 | 40% | saturated | 100 kPa |

| Case Number | Clay Content | Confining Pressure | Cyclic Stress Ratio |

|---|---|---|---|

| V13 | 10% | 50 kPa | Step loading |

| V14 | 20% | 50 kPa | |

| V15 | 30% | 50 kPa | |

| V16 | 40% | 50 kPa | |

| V17 | 10% | 50 kPa | 1 |

| V18 | 20% | 50 kPa | 1 |

| V19 | 30% | 50 kPa | 1 |

| V20 | 40% | 50 kPa | 1 |

| Clay Content | 20% | 30% | 40% | 50% |

|---|---|---|---|---|

| Pore pressure at 10% strain | 30.69 kPa | 34.90 kPa | 36.14 kPa | 44.21 kPa |

| Clay Content | Liquefaction Strength | Modulus | Damping | Pore Pressure | |

|---|---|---|---|---|---|

| Results of this paper | 20~50% | 30% minimum | 30% minimum | 30% maximum | 30% fastest |

| Reference [18] | 0~30% | 6% minimum | consistent | / | / |

| Reference [19] | 50~80% | increases with the increase in particle size | / | / | decreases with the increase in powder particles |

| Reference [20] | 3~21% | 9% minimum | / | / | decreases with the increase in powder particles |

| Reference [21] | 0~78% | / | / | / | decreases with the increase in powder particles |

| Reference [26] | 5~15% | 10% minimum | / | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Yang, J. Experimental Study on Static and Dynamic Characteristics of Sand–Clay Mixtures with Different Mass Ratios. Sustainability 2024, 16, 7343. https://doi.org/10.3390/su16177343

Cheng Y, Yang J. Experimental Study on Static and Dynamic Characteristics of Sand–Clay Mixtures with Different Mass Ratios. Sustainability. 2024; 16(17):7343. https://doi.org/10.3390/su16177343

Chicago/Turabian StyleCheng, Ye, and Jinghu Yang. 2024. "Experimental Study on Static and Dynamic Characteristics of Sand–Clay Mixtures with Different Mass Ratios" Sustainability 16, no. 17: 7343. https://doi.org/10.3390/su16177343