Abstract

One of the most important values in human life is health and safety. This is reflected in the Sustainable Development Goals (SDG3, SDG8), which were presented by the United Nations in 2015. These goals emphasize the importance of ensuring healthy lives, promoting well-being for all, and fostering inclusive and sustainable economic growth through decent work and safe working conditions. Taking into account the importance of issues related to safety, including occupational safety and human health, research was carried out to examine the impact of the development of a safety culture during employees’ work on improving public health. In order to conduct the research, a survey questionnaire was developed, consisting of 20 questions relating to 10 attributes of safety culture. The research surveys were carried out among 363 employees in a production enterprise, and an interview questionnaire was administered to 3 employees of the Occupational Health and Safety Service of this enterprise. The results revealed that the enterprise’s employees rate the level of safety culture very highly. Along with the improvement of working conditions in the enterprise, the level of safety increases, the number of accidents at work decreases, and thus the protection of employee health is higher. Therefore, a high level of safety culture is correlated with a high value attached to the health and life of employees, and this, in turn, affects public health. Moreover, fostering a strong safety culture aligns with the principles of sustainable development, contributing to long-term societal well-being and aligning with global goals for responsible and ethical growth.

1. Introduction

Health is one of the most important values in human life [1,2]. Its deficiency prevents or significantly hinders the achievement of both individual and social plans and ambitions. Good health is a crucial condition for socio-economic development, adaptability, and coping with emerging challenges [3]. In recent years, there has been a significant increase in activities related to health protection and promotion on a large scale, along with a whole catalog of new challenges and threats in this area [4].

Civilization’s progress, including the advancement of knowledge, is associated with the discovery of successive laws governing the surrounding world, which includes developments in medicine, psychology, and technology that allow the extension or preservation of human life [5]. However, scientific and technological progress does not always lead to an improvement in the quality of life and health of the population. This is often linked to the deteriorating quality of air, water, and soil in many parts of the world [6,7,8].

Furthermore, civilization’s advancement has caused lifestyle changes that lead to behaviors detrimental to health, particularly with the decrease in physical activity, changes in eating habits, and the increased consumption of processed foods. Additionally, the fast-paced modern lifestyle and the need to adapt to constant changes result in an increased number of stress-inducing stimuli. Therefore, effective methods are sought to manage sustainable socio-economic development, ensuring an adequate standard of living for present and future generations while balancing economic goals with social objectives within natural limitations [9,10,11,12].

This approach represents a compromise between economic growth, societal enrichment, and health protection because, according to the World Health Declaration, one of the basic rights of every human being is the highest attainable standard of health [13].

Health is a state of complete physical, mental, and social well-being that should be nurtured and protected [14,15]. Healthy individuals contribute to the socio-economic development of the country and require fewer financial outlays for maintaining good physical, mental, spiritual, and social conditions.

It is essential to pay special attention to the conditions in which people work, as they spend a large part of their day there. The safety culture within a company plays a key role in ensuring employee health [16]. As working conditions improve, workplace safety levels increase—in other words, better working conditions lead to higher safety levels, greater health protection for employees, and improved prevention of workplace accidents and occupational diseases [17,18]. Developing a safety culture involves activities that aim to protect employees’ health and ensure their well-being. Specifically, this means creating safe and hygienic working conditions, which includes regularly conducting risk assessments, implementing appropriate safety procedures, and educating employees on health and safety rules. Employees must be aware of potential hazards in their work environment and know how to respond appropriately in crisis situations [19].

A company’s safety culture should go beyond merely meeting minimum legal requirements. It should also involve promoting a healthy lifestyle by organizing health programs, such as regular preventive examinations, workshops on healthy eating, and initiatives encouraging physical activity. Supporting employees’ mental health is equally important; this can be achieved through access to psychological services and emotional support programs.

The development of a safety culture is an ongoing process that demands continuous commitment from both employers and their employees. Only with such commitment is it possible to create a work environment where health and safety are prioritized, leading to increased work efficiency, fewer accidents and occupational illnesses, and an overall improvement in employees’ quality of life.

Given the significance of occupational safety culture in enhancing public health, research was conducted to examine the impact of safety culture development on public health improvement.

To carry out the research, a methodology was developed that included survey methods, interview methods, and statistical analysis. The surveys and interviews were conducted in a company within the food and beverage packaging industry. Interviews were conducted with employees from the occupational health and safety department.

2. Literature Review

The concept of “safety culture” is polysemantic and lacks a clear, universally accepted definition within the scientific community. As a result, there are numerous definitions and interpretations of this term in the scientific literature. To better organize the understanding of safety culture and to identify the key features that highlight its uniqueness, we conducted an analysis of safety culture from a structural perspective by examining the components of various definitions proposed by authors over the last 30 years. Table 1 presents a selection of these definitions, including the author, the content of the definition, and the semantic characteristics associated with it.

Table 1.

Review of the definition of safety culture.

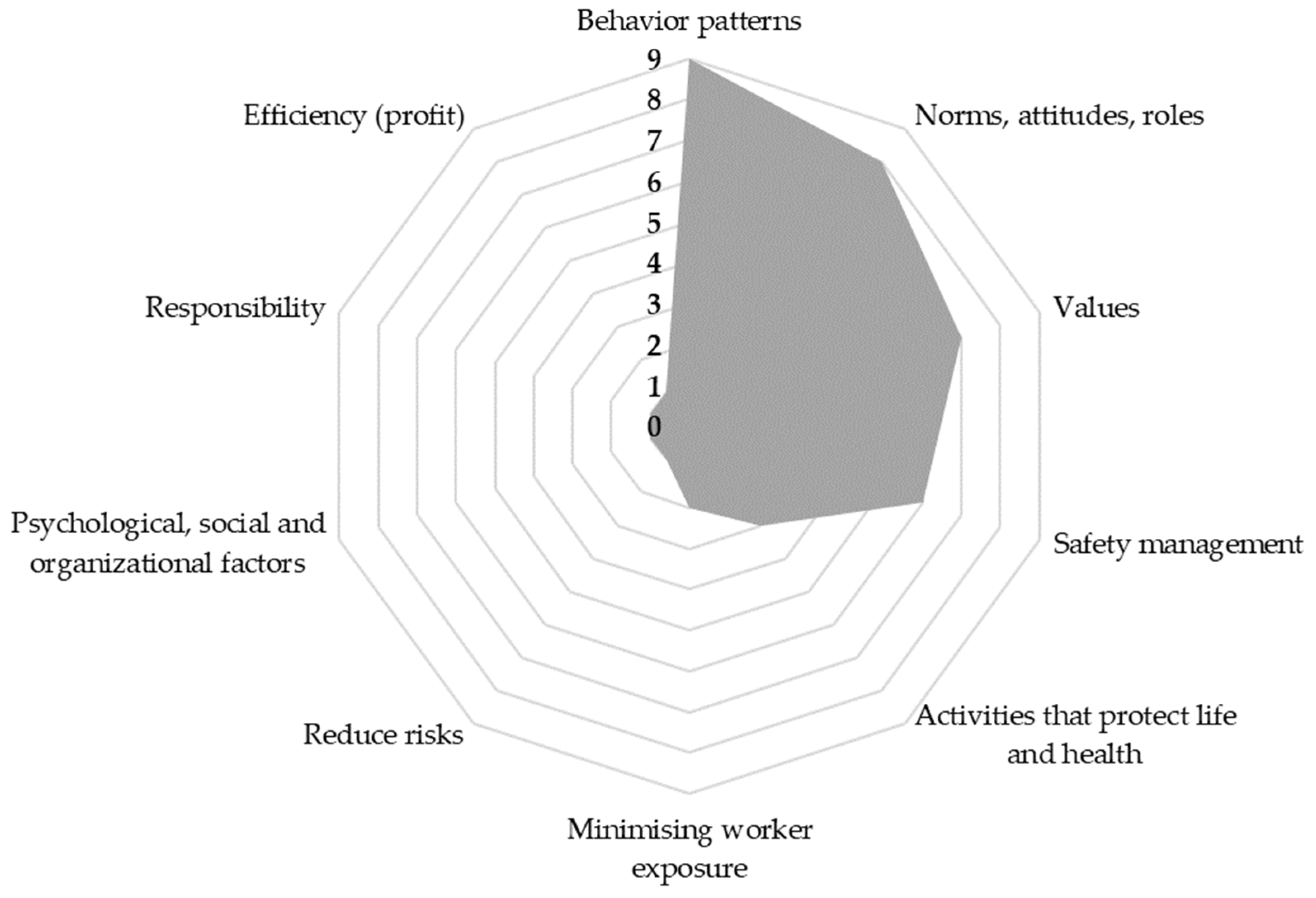

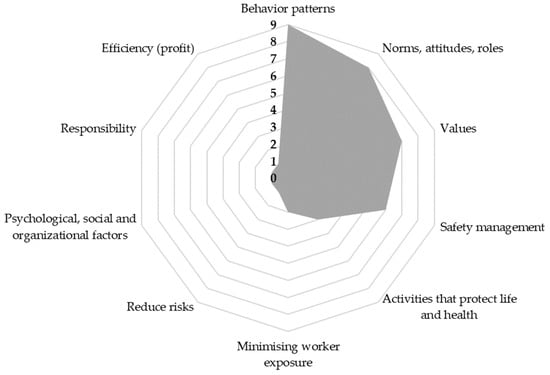

A comparative analysis of the semantic features of individual definitions, presented in the graph in Figure 1, revealed the dominant attributes of the concept of “safety culture.” These attributes primarily include patterns of behavior, norms, attitudes, roles, safety management, values, and activities that protect life and health.

Figure 1.

The attributes of “safety culture” concept.

The comprehensive interpretation of the definitions, along with certain features described by the authors as crucial in creating a safety culture, overlap. Therefore, safety culture represents the patterns of behavior of a given community towards threats and safety, as well as the values, attitudes, and norms considered important in this context. A high level of safety culture is associated with a strong emphasis on human health and life. In a company, the level of safety culture is linked to employees’ greater concern for their own health and safety, resulting in fewer accidents and occupational diseases. Additionally, shaping the desired safety culture must be a continuous process because real cultural change is challenging and requires time [37].

3. Materials and Methods

The research was conducted in 2023 in a Polish enterprise producing disposable packaging that comes into direct contact with food products. This enterprise employed more than 800 people and was founded in 2016.

In the first stage of the research, a quantitative method was employed, using a questionnaire as a research tool. The questionnaire was developed based on two existing tools: the Agency for Healthcare Research and Quality (2011) [38] and Cox and Cheyne [39]. To achieve the research objective, these two questionnaires were merged into one, with redundant and irrelevant questions removed, similar questions combined, and some questions modified to fit the context of the enterprise where the research was conducted. The questionnaire was then presented to an independent Occupational Health and Safety (OHS) service employee for verification and validation. The enterprise was subsequently contacted, informed about the study, and asked for feedback on the questionnaire. Some questions were slightly adjusted to ensure better understanding by the respondents. The primary purpose of the survey was to provide an up-to-date assessment of the level of safety culture in the enterprise.

The first set of questions in the questionnaire concerned demographic data, including the type of work performed (administration, production worker, leader, manager, maintenance), gender (woman, man), years of experience (0–3, 4–6, 7 or more), age (18–29, 30–39, 40–49, 50–59, 60 or more), education (primary, vocational, high school, bachelor’s/master’s or above), and involvement in an accident in the last 6 years (yes, no). Respondents were then asked to express their opinion on 20 statements by selecting an answer from 5 options ranging from strongly disagree (1 point) to strongly agree (5 points). These statements represented 10 attributes of safety culture: (1) behavioral patterns; (2) norms, attitudes, and roles; (3) values; (4) safety management; (5) activities that protect life and health; (6) minimizing workers’ exposure; (7) risk reduction; (8) psychological, social, and organizational factors; (9) responsibility; (10) efficiency (profit). Each of these statements was carefully developed based on the components included in the existing questionnaires that formed the basis of our study.

During a company-wide meeting with the director, employees were informed about the study and invited to participate by completing the survey. The questionnaire was made available to all employees in paper form, and completed questionnaires were then placed in a ballot box. The meeting was attended by 683 employees, of whom 363 agreed to participate in the study. However, 56 questionnaires were rejected for formal reasons, such as being incomplete or missing responses. Therefore, 307 questionnaires were included in the survey, all of which were correctly completed by company employees.

In the second stage of the research, a qualitative method was used, employing an interview questionnaire as the research tool. Three employees from the OHS service participated in the study. The research focused on the development of safety culture in the enterprise over a six-year period (2018–2022). It is worth noting that, although the interview was conducted simultaneously with three employees, its structure and purpose differed from a traditional focus group discussion. Unlike a focus group, where the main goal is to encourage interactive exchange of views and generate new ideas based on participants’ shared experiences, our meeting was more formal. It was designed as a structured interview with a set of pre-prepared questions aiming to collect specific, structured data.

While participants were free to share their observations and thoughts, the interview was primarily focused on obtaining answers to specific questions about the development of safety culture, corrective and preventive measures, and the analysis of workplace accident causes. This approach allowed for the collection of data suitable for qualitative analysis, providing a foundation for further conclusions.

The main purpose of the interview was to obtain information on the following aspects:

- –

- The development of safety culture over six years, including actions implemented to improve safety culture.

- –

- Workplace accidents (number and types of accidents, including accident registers, causes of accidents, and corrective and preventive measures).

- –

- Identification of occupational diseases.

During the meeting, employee records related to accidents, as well as other documents related to safety, were presented in accordance with data protection principles. In particular, the following principles were observed: the principle of data minimization, which involved limiting the scope of the information presented to only what was necessary for the purposes of analysis, and the principle of confidentiality, whereby all personal data were properly anonymized to protect employees’ privacy.

The presentation of this documentation not only allowed for the necessary information on the company’s development and its safety culture to be obtained, but also qualified as a method of document analysis, which is a key aspect of the qualitative data collection methods used. This analysis provided valuable insights for better understanding the issues under study. The meeting lasted approximately two hours.

4. Results

4.1. Questionnaire Survey

As mentioned earlier, a total of 307 valid questionnaires were included in the study. Table 2 shows the demographic data of the respondents.

Table 2.

Demographic data of respondents.

The presented demographic data clearly demonstrate that the respondents represent different demographic groups in terms of job type, gender, age, professional experience, and level of education. This diversity enhances the credibility of the data gathered through the questionnaire. In the analyzed enterprise, 6% of respondents reported having experienced a workplace accident in the last six years. Table 3 presents the results for the ten components of safety culture dimensions in the analyzed manufacturing enterprise. The values in the table are presented as percentages to better illustrate the findings.

Table 3.

Assessment of safety culture components.

In the enterprise under review, the average safety culture score out of 5 was 4.59, which indicates a very high level, although there is still room for improvement. The component for psychological, social, and organizational factors received the highest score among respondents, with an average of 4.96. This suggests that both management and employees place significant importance on occupational safety training. Such training raises awareness of workplace safety and influences employees’ attitudes, which ultimately contributes to building a robust safety culture in the enterprise [40,41]. With an increased awareness of safety culture, employees are more committed to creating a safe work environment, understanding that it directly impacts the efficiency of the enterprise as well as their own health and safety [11,42].

The safety management component ranked second with an average score of 4.94, indicating that it is very well-developed within the company. This is evident in the respondents’ feedback, which highlights that management prioritizes employee safety over productivity, a crucial characteristic of a safe workplace [43].

The values component ranked third with an average score of 4.84. The knowledge and adherence to safety protocols by employees have a positive impact on the development of the safety management system [44].

The behavior patterns component (average score 4.64) and minimizing worker exposure (average score 4.61) ranked fourth and fifth, respectively. It is worth noting that the statement “At work, all employees treat each other with respect” received a very high score, indicating a strong sense of mutual respect among employees. The enterprise encourages open and effective communication between management and staff. While workstations are generally well-designed, there is room for improvement to enhance ergonomics, as working in uncomfortable positions can lead to the overloading of joints, muscles, and tendons [45]. One of the most common work-related health issues is Work-Related Musculoskeletal Disorders (WMSDs) [46]. The early symptoms of WMSDs typically include pain that subsides after work. However, years of neglect can result in permanent musculoskeletal damage, leading to chronic conditions and injuries that limit functional abilities and may contribute to disability [47].

The components for norms, attitudes, roles (average score 4.49), and activities that protect life and health (average score 4.45) were ranked sixth and seventh, respectively. Employees positively noted the strict adherence to safety regulations, the appropriate staffing levels, and additional breaks during heavy and strenuous work, which positively impact work quality and employee comfort [48].

The last three components were reducing risk (average score 4.34), responsibility (average score 4.34), and efficiency (profit) (average score 4.31). The company should focus on improving employees’ understanding of occupational risk, which refers to the likelihood of adverse events related to work, particularly the potential health impacts resulting from occupational hazards in the workplace environment [49].

4.2. Questionnaire Interview

As mentioned earlier, the enterprise was established in 2016, making it a relatively new plant with a well-developed and modern machine park. In 2017, the enterprise was still in the process of implementing new technologies and hiring employees, and safety measures were somewhat overlooked. It was only in 2018 that the development of a safety culture in the enterprise began to take shape, with the following solutions being implemented over the years:

- –

- Quality Management System according to ISO 9001:2015 [50], Environmental Management System according to ISO 14001:2015 [51], and OHS Management System according to ISO 45001:2018 [52].

- –

- Near-Miss Reporting: Encouraging employees to identify and report incidents without injuries.

- –

- The Kaizen System: Involving all employees at every management level in the continuous search for ideas to improve all areas of the organization.

- –

- The 5S System: Implementing simple techniques and methods aimed at establishing and maintaining high-quality workstations. This system also introduces order in common areas used by all employees, focuses on reducing waste during work, and enhances safety and comfort.

- –

- Good Change Meetings: Quarterly meetings between the employer and all employees to discuss significant changes in the plant.

- –

- Daily Managerial-Level Meetings: These involve morning meetings led by the Production Manager, with representatives of employees, leaders, quality control staff, maintenance teams, warehouse staff, and the OHS Service. The meetings cover current issues, proposals for improving safety, near-miss incidents, and solutions to eliminate hazards and associated risks.

- –

- Director-Level Meetings: These are daily meetings between the Production Director and department managers (including Production, Quality, Maintenance, Logistics, and OHS Services). The same issues discussed at the managerial meetings are addressed, with decisions made on how to eliminate hazards and near-miss risks. Additionally, twice a week (on Tuesdays and Thursdays), all participants of the meeting inspect the production hall, warehouses, and external areas of the plant to assess safety conditions.

- –

- Weekly Meetings with the Production Manager: Held every Wednesday with all employees, these meetings discuss the causes and consequences of workplace accidents. Short training sessions are also conducted on new instructions, procedures, forms, and standards, and employees are informed about corrective actions taken after near-miss incidents. Basic health and safety rules are reiterated, and mistakes made during routine tasks are reviewed.

- –

- Safety Steering Committee: Monthly meetings with a group of employee representatives, during which OHS indicators are presented (e.g., number of workplace accidents and near-misses). Good practices recently implemented in various production areas are also discussed.

- –

- The Health and Safety Committee: A quarterly meeting where the committee reviews working conditions, assesses the OHS status, gives feedback on the measures taken by the employer to prevent accidents and occupational diseases, and proposes improvements to working conditions. Minutes are prepared after each meeting, and the committee’s conclusions are presented to the Production Director in writing.

- –

- Safety Leadership Audit: A weekly safety audit conducted across the entire facility by employees according to an annual schedule. The auditor uses a software tool (IAudytor 5.0) on a tablet to document non-conformities with photos and descriptions. The auditor inspects all areas of the plant, allowing them to identify non-compliances more effectively. The software automatically generates a report, which is sent to managers and OHS Services, enabling quick responses and corrective actions. At the end of each month, a summary of all reports is prepared, non-conformities are analyzed, and corrective actions are verified.

- –

- Safety Day: Organized annually in April to mark Safety Day on April 28. Training sessions are held for all employees, focusing on safety and health, and supporting the development of a safety culture.

- –

- “Five Minutes for Safety”: A safety campaign for all employees to improve occupational safety, increase awareness of risky behavior, and take actions to minimize workplace accidents. Once a week, employees answer a few safety-related questions before starting their duties. The questions change each week, and if there are doubts or knowledge gaps, managers conduct immediate training sessions after the survey.

- –

- Annual Evacuation Drill on Each Work Shift: A special exercise that helps improve emergency evacuation procedures in the event of a fire or other emergencies.

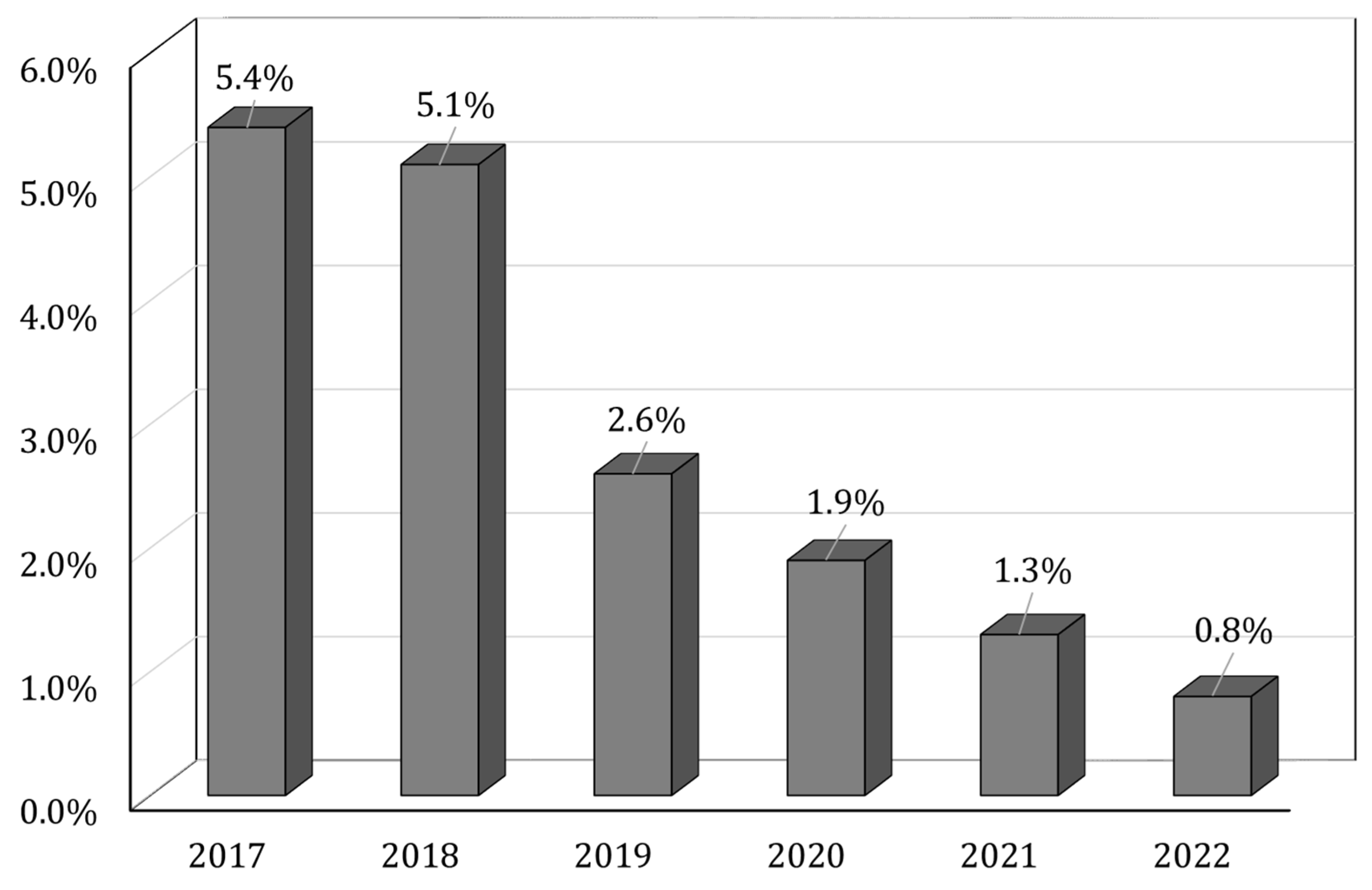

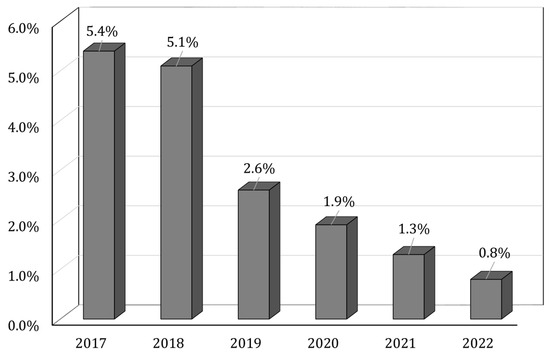

Subsequently, an analysis of the accident documentation was carried out. Figure 2 presents the research results, showing the percentage of accidents relative to the number of employees for each analyzed year. Between 2017 and 2022, 85 accidents occurred in the plant, none of which were serious, fatal, or collective. Most incidents were minor accidents that did not result in more than 14 days of work incapacity (85% of accidents). The majority of accidents (46%) did not lead to any work incapacity at all.

Figure 2.

Percentage of the number of accidents to the number of employees.

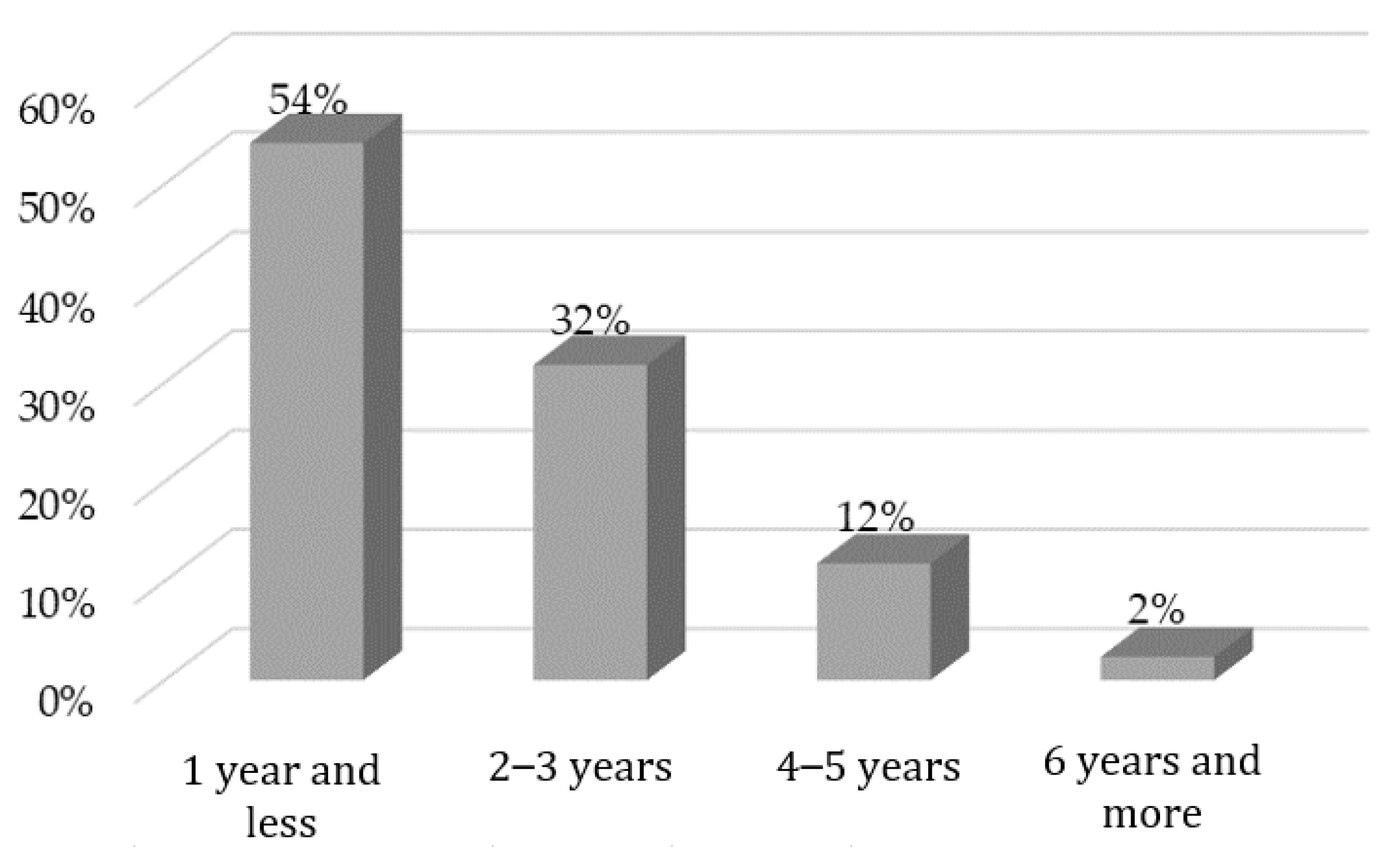

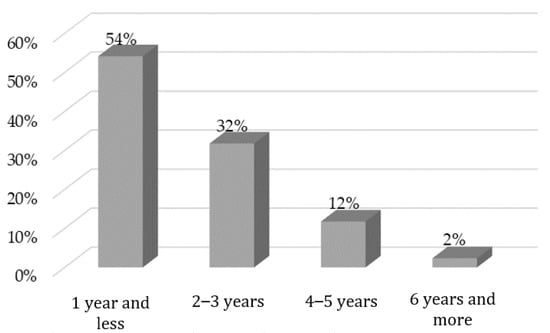

The analysis showed that employees with shorter work experience were more likely to suffer workplace accidents compared to those with longer experience. This was mainly due to a lack of appropriate knowledge, experience, and the tendency to engage in risky and irresponsible actions (Figure 3). The majority of workplace accident victims had at most one year of experience at the site where the accident occurred, and over 80% of victims had no more than three years of work experience. This suggests that the factors contributing to these incidents include a very short period of experience in the workplace, limited practice in performing professional activities, and incomplete knowledge of the work environment. The lowest percentage of injured individuals were those with the longest work experience, which is equal to six years or more.

Figure 3.

Accident victims at work by length of service between 2017 and 2022.

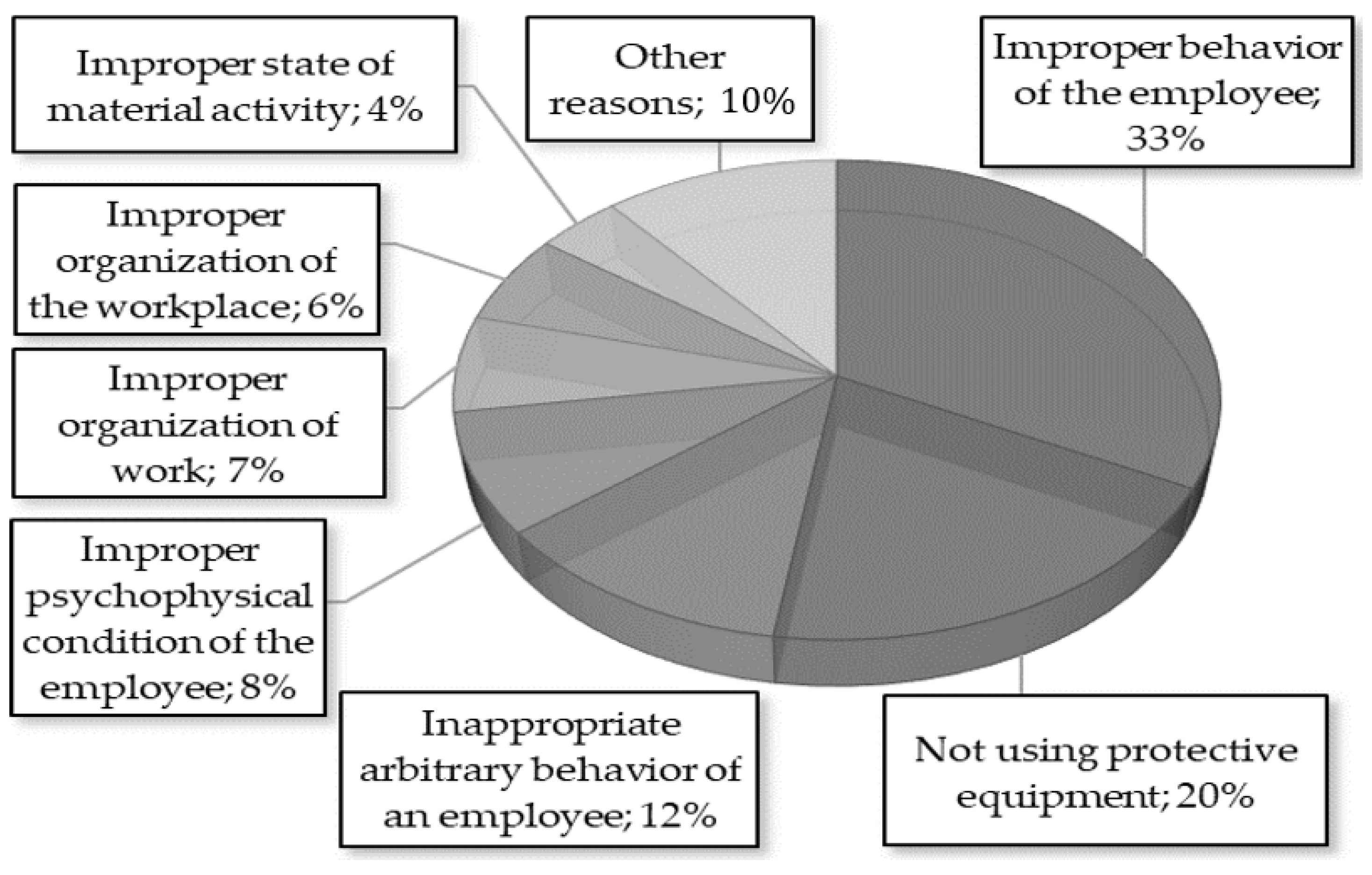

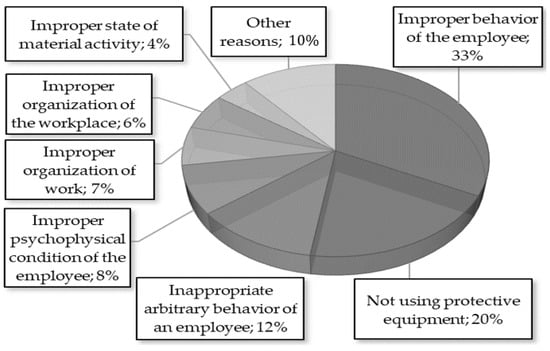

The analysis of existing data revealed that, unfortunately, the majority of workplace accidents were still caused by employees themselves. The most common causes of injury were improper behavior (33%) and failure to use protective equipment (20%). This issue was often linked to undisciplined behavior and employees rushing to complete their tasks. Another significant cause of workplace accidents was inappropriate, arbitrary behavior (12%). This is associated with a careless approach to equipment handling and delays in adhering to safety regulations. Employees frequently underestimated the importance of health and safety guidelines (law regulations).

Figure 4 presents the main causes of workplace accidents in the analyzed enterprise over the six-year period.

Figure 4.

Causes of accidents at work.

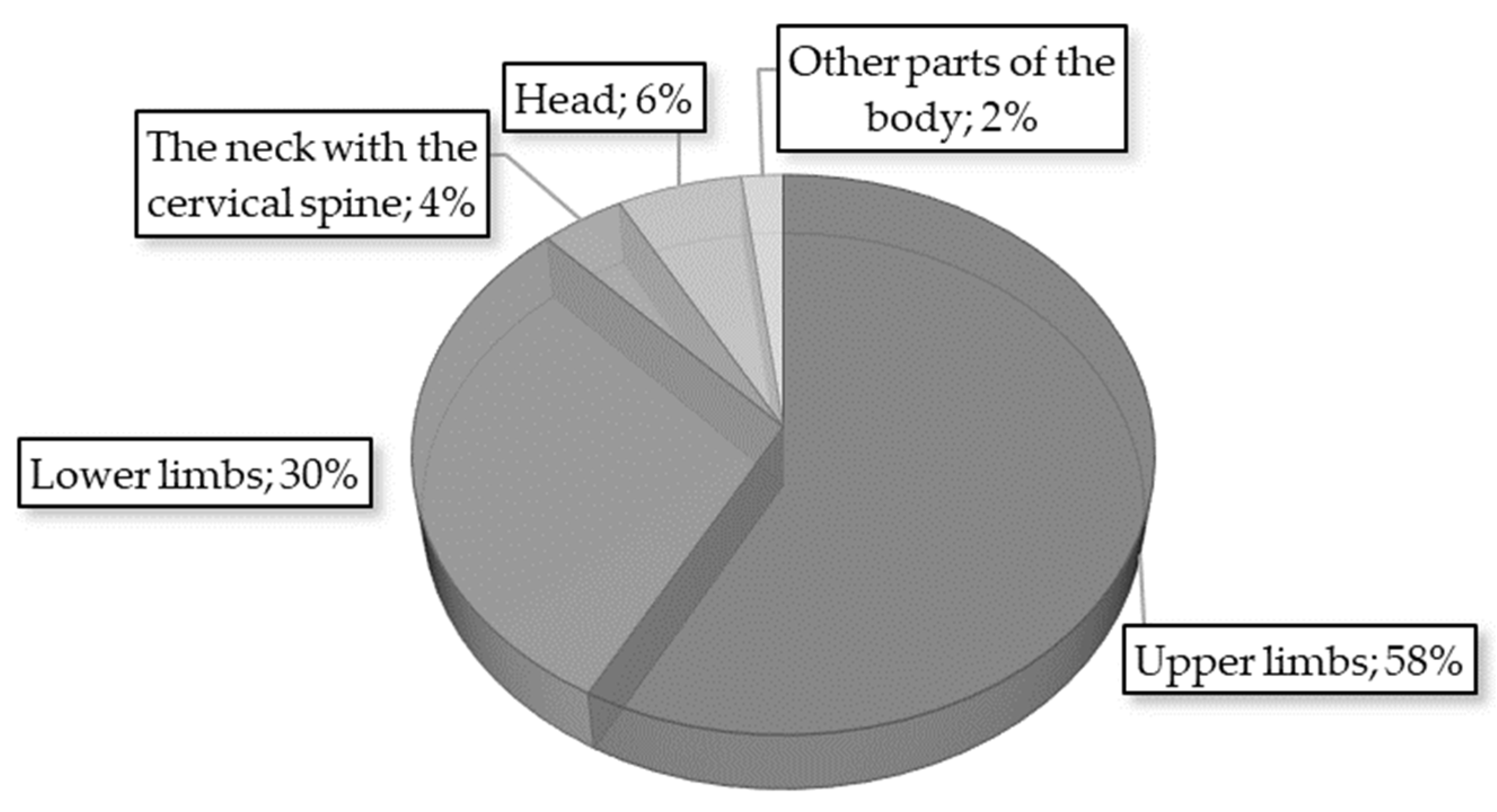

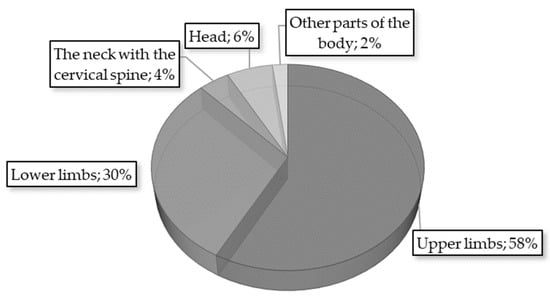

Statistics show that all workplace accidents in the analyzed enterprise resulted in only minor wounds and injuries (Figure 5). Approximately 90% of injured workers sustained limb injuries, with 58% involving upper limbs and 30% involving lower limbs.

Figure 5.

Location of the injury.

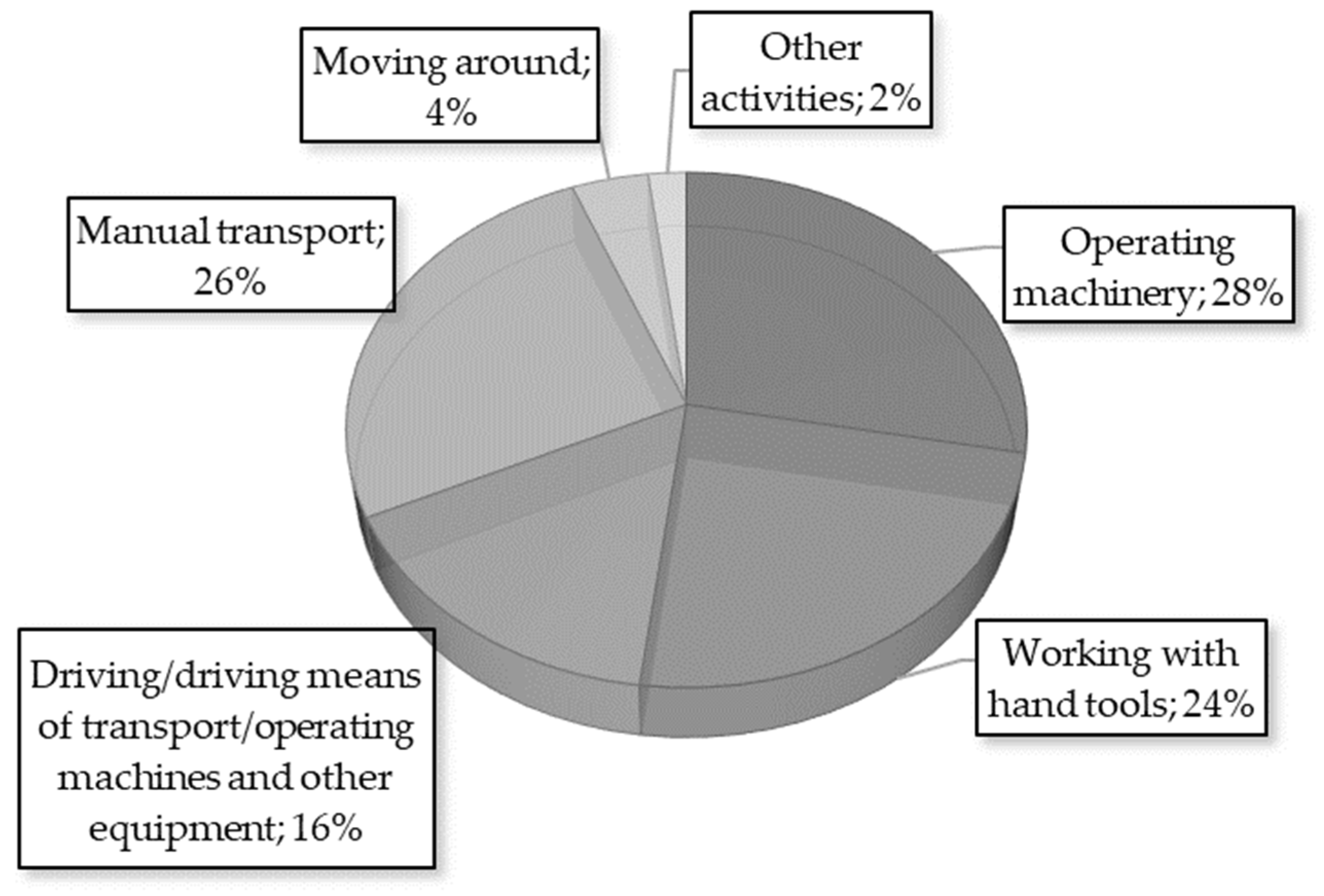

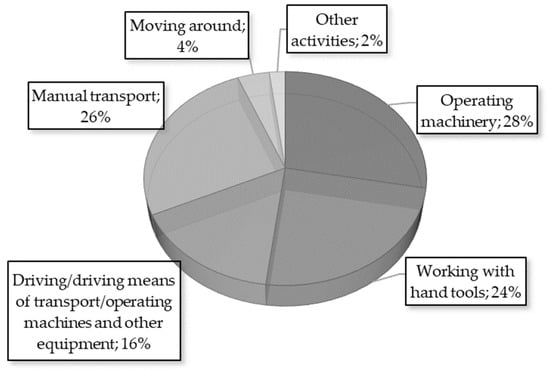

A detailed analysis revealed that the most common activity being performed by the victim at the time of the accident was operating machinery (28%). It is worth noting that the production halls are densely populated with a large variety of machinery and equipment. The second most common activity was working with hand tools (24%). Figure 6 shows the activities performed by the victims at the time of the accidents.

Figure 6.

Activities performed by the victim at the time of the accident.

In discussions with the OHS Service employees of the analyzed enterprise during the preparation of this research, the importance of qualified employees and their competencies to the entire production cycle was frequently highlighted. No occupational diseases were identified in the analyzed enterprise.

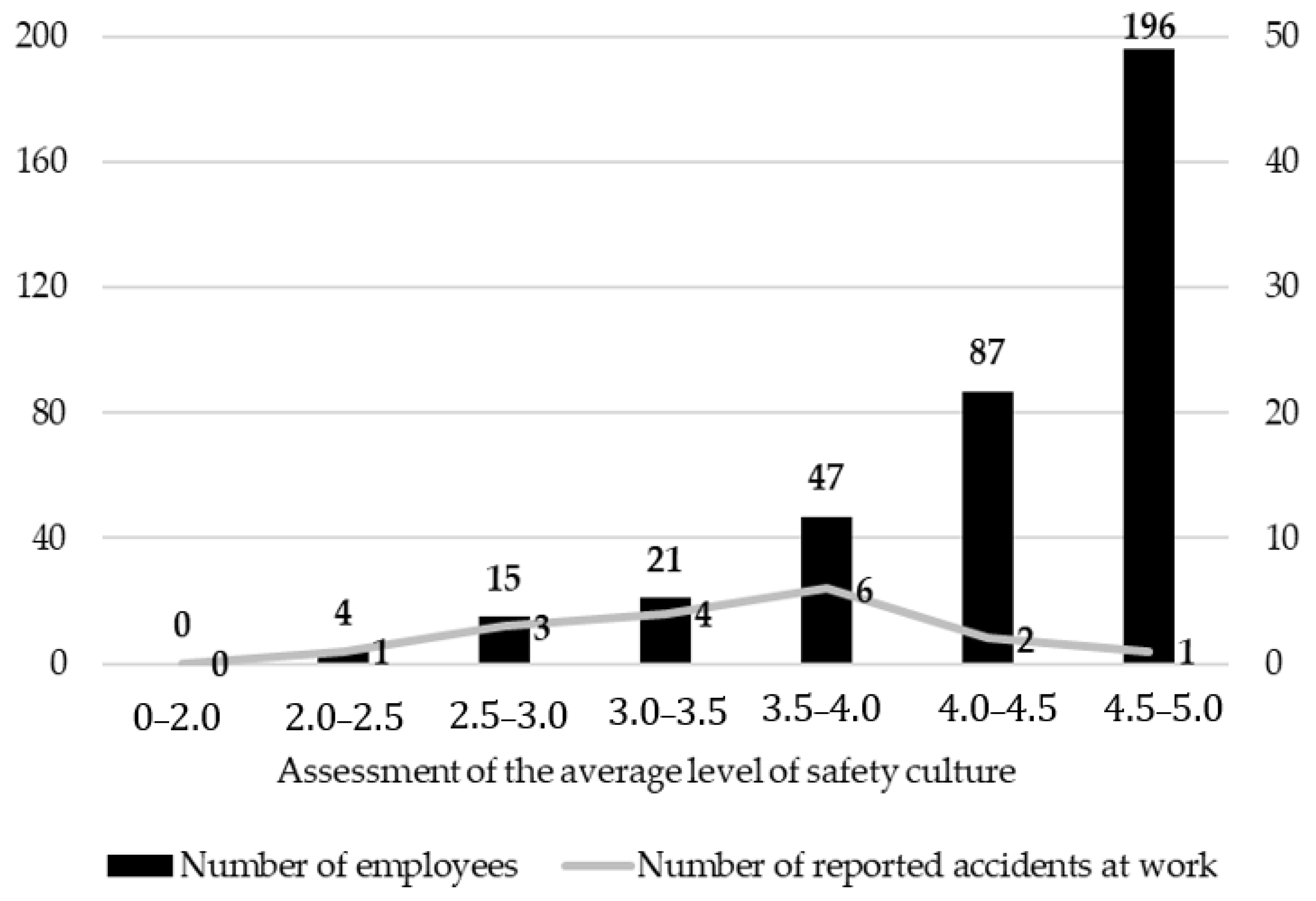

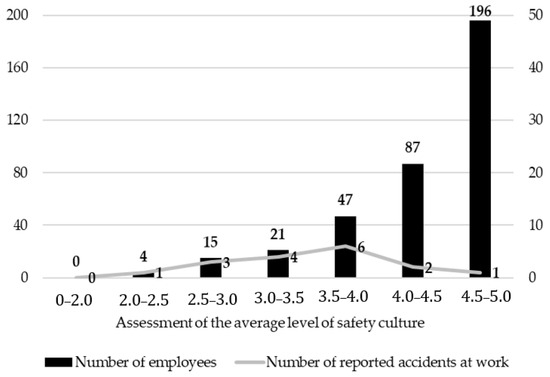

The research conducted in the enterprise indicated that employees who rated the safety culture very highly experienced fewer workplace accidents compared to those who rated it lower. Figure 7 shows the results of this analysis.

Figure 7.

The number of accidents at work and the assessment of the level of safety culture.

When considering the components of safety culture, psychological, social, and organizational factors received the highest ratings from respondents. This suggests that management should prioritize the development of safety training within the enterprise. Additionally, management should implement strategies to reduce high workloads and the associated adverse health effects. Such measures are essential to improving the overall level of safety culture in the organization.

Moreover, workers who are men reported more workplace accidents than workers who are women. These differences may stem from the varying types of tasks typically performed by each gender. Men are more likely to engage in riskier jobs than women, which might contribute to their higher involvement in accidents, including those caused by improper behavior (33%).

The research also showed that older workers with longer work experience reported fewer accidents in the past six years compared to younger workers. This highlights the importance of providing more training to younger employees to help them become familiar with plant safety rules and develop safe work habits [53,54]. The results also indicated a significant relationship between the number of workplace accidents over the last six years and the level of safety culture. The higher the safety culture level, the lower the number of accidents in the enterprise. This insight should be leveraged to strengthen safety culture across manufacturing companies in various industries and to raise safety awareness among employees.

Furthermore, research conducted through interview questionnaires confirmed that ongoing employee training plays a crucial role in shaping the level of safety culture (Table 4). In 2018, the analyzed enterprise began implementing solutions to improve safety culture, focusing largely on safety education and open, transparent communication between employees. Employee involvement also emerged as a key factor, as maintaining safety standards should be considered as important as achieving economic outcomes. The enterprise employs a participatory management style to engage employees in cultivating a safety-oriented atmosphere. Additionally, motivating and reinforcing safe behaviors by rewarding employees for actions that enhance safety was identified as an important aspect.

Table 4.

Number of accidents at work and their causes.

After the first safety culture improvements were implemented in 2019, a noticeable decrease in workplace accidents occurred despite a significant increase in the number of employees. The most common causes of accidents in the enterprise include improper employee behavior and failure to use protective equipment. However, a decline in these factors has been observed since 2019. In the analyzed enterprise, the impact of safety culture development and the effectiveness of the implemented solutions on the number and causes of workplace accidents are clearly visible.

Shaping a high level of safety culture is crucial as it directly affects employees’ health. It impacts not only their physical health (the proper functioning of the body) but also their social health (the ability to maintain appropriate relationships and perform social roles) and spiritual health (related to faith and religious practices). The need to improve safety culture also stems from the fact that health is a social resource, as it underpins economic development. A healthy society is capable of producing and multiplying material goods, fostering growth, and achieving a satisfactory standard of living. In this context, health is a means of achieving a higher quality of life, reflected in effective and productive functioning into old age, high professional productivity, and life satisfaction. Consequently, the level of safety culture in enterprises directly impacts public health.

5. Discussion

When comparing our research results with other studies conducted in similar fields, we note several key similarities and differences.

For instance, studies by Fernández-Muñiz et al. [55], Martínez-Córcoles et al. [56], and Thompson et al. [57] in the industrial sector also indicated a strong relationship between a well-developed safety culture and a reduced number of workplace accidents. The authors emphasized that management commitment and appropriate training are key factors in building an effective safety culture. Therefore, it can be concluded that our findings align with international observations, confirming the universality of effective safety management principles.

Similarly, research conducted by Okonkwo and Wium [58] in South Africa within the construction sector showed that factors such as safety leadership and employee health programs significantly reduce accident risks and improve employee health. Their study also highlighted the need for continuous education and raising employee awareness about workplace safety. These findings support our conclusions regarding the importance of safety management components and values in assessing safety culture.

However, research by Griffin and Curcuruto [59] suggests that while a developed safety culture is important, its effectiveness may be limited by external factors such as economic pressures or insufficient resources to implement proper safety procedures. This indicates that a company’s economic and operational context plays a crucial role in determining the effectiveness of safety culture implementation.

Another interesting study by Wu et al. [60] in Taiwan’s electronics manufacturing sector found that regular safety audits and accident reporting systems are key elements in reducing workplace accidents. Their results highlight the importance of transparency and accountability in maintaining a high level of safety culture.

Furthermore, research by Klajkó et al. [61] suggests that psychological support for employees and health programs contribute to higher job satisfaction and improved employee health. These findings are consistent with our research, which emphasizes the significance of psychological support and health-promoting programs in building a strong safety culture. Regular training, access to psychological consultations, and initiatives promoting healthy living, such as workshops on nutrition and physical activity, can significantly enhance employees’ well-being and efficiency, leading to fewer accidents and occupational diseases.

Similarly, studies by Vinodkumar and Bhasi [62] in construction companies showed that safety leadership and employee health programs are key in reducing accident risks and improving health. Their research also underlined the need for continuous education and raising employee awareness about workplace safety. These findings align with our conclusions regarding the importance of safety management components and values in assessing safety culture.

However, research by Michael et al. [63] in American factories indicates that although a developed safety culture is important, its effectiveness can be limited by external factors such as economic pressures or a lack of resources for implementing proper safety procedures. This suggests that a company’s economic and operational context may play a key role in the success of safety culture initiatives.

Drawing these conclusions together, it can be said that effective safety management requires a holistic approach, considering both internal aspects such as culture and education, and external factors like economic support and resources. Our research findings are consistent with international observations, confirming the universality of effective safety management principles across various industrial contexts.

6. Conclusions

Employee health and safety are key factors that directly impact socio-economic development and overall quality of life. In the context of manufacturing enterprises, cultivating a strong safety culture not only enhances work efficiency but also improves public health by reducing the number of occupational accidents and diseases.

Taking into account the importance of this topic, research was conducted to examine the impact of the development of safety culture on public health in manufacturing enterprises.

The research findings are as follows:

- The company’s employees rate the level of safety culture highly, reflected in an average score of 4.59 out of 5.

- The highest scores were given to components such as “psychological, social, and organizational factors” (4.96), “safety management” (4.94), and “values” (4.84), highlighting the importance of training and management involvement.

- A high level of safety culture correlates with fewer workplace accidents and improved overall employee health.

- Increased awareness of occupational safety and employee engagement in safety activities contribute to a safer working environment.

Enterprises should invest in ongoing occupational safety training and develop health and psychological support programs for employees. Management should actively promote safety culture to help reduce workplace accidents and diseases, improving public health. Regular safety audits and transparency in accident reporting are key to maintaining a high level of safety culture.

The research was conducted in a single manufacturing company, which may limit the generalizability of the results to other industrial sectors. Additionally, questionnaires and interviews may not fully capture all aspects of safety culture, and responses may be subjective.

Future research should cover various industrial sectors and countries to compare results and identify universal factors influencing safety culture. It would also be beneficial to analyze the impact of specific health and psychological programs on employee safety and health. Long-term studies on the effects of safety culture development on public health and enterprise efficiency could provide valuable insights for further policy and practice development in this field.

Developing a safety culture in manufacturing enterprises is not only about regulatory compliance but, more importantly, an investment in employee health and well-being, which has a direct impact on public health and socio-economic development.

Author Contributions

Conceptualization, P.K.; methodology, P.K. software, P.K.; formal analysis, P.K.; investigation, P.K.; resources, P.K. and M.T.; data curation, P.K.; writing—original draft preparation, P.K. and M.T.; writing—review and editing, P.K. and M.T.; visualization, P.K.; supervision, P.K.; project administration, P.K. and M.T. funding acquisition, M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Silesian University of Technology (Faculty of Organization and Management), supported this work as a part of Statutory Research 13/030/BK_24/0083 (BK-266/ROZ3/2024).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data available on request from the authors.

Acknowledgments

Thank you for supporting the enterprise that enabled us to perform the research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Asvall, J.E. Health for all in the 21st century a policy framework for the WHO European region. Int. J. Occup. Med. Environ. Health 2000, 13, 5–13. [Google Scholar] [PubMed]

- Koller, T.; Morgan, A.; Guerreiro, A.; Currie, C.; Ziglio, E. Addressing the socioeconomic determinants of adolescent health: Experiences from the WHO/HBSC Forum 2007. Int. J. Public Health 2009, 2, 278–284. [Google Scholar] [CrossRef] [PubMed]

- Kraft, P.; Kraft, B. Explaining socioeconomic disparities in health behaviours: A review of biopsychological pathways involving stress and inflammation. Neurosci. Biobehav. Rev. 2021, 127, 689–708. [Google Scholar] [CrossRef] [PubMed]

- Caron, R.M.; Noel, K.; Reed, R.N.; Sibel, J.; Smith, H.J. Health Promotion, Health Protection, and Disease Prevention: Challenges and Opportunities in a Dynamic Landscape. AJPM Focus 2023, 3, 100167. [Google Scholar] [CrossRef] [PubMed]

- Tutak, M.; Brodny, J. Business Digital Maturity in Europe and Its Implication for Open Innovation. J. Open Innov. Technol. Mark. Complex. 2022, 8, 27. [Google Scholar] [CrossRef]

- Kelly, F.J.; Fussell, J.C. Air pollution and public health: Emerging hazards and improved understanding of risk. Environ. Geochem. Health 2015, 37, 631–649. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. Analysis of the diversity in emissions of selected gaseous and particulate pollutants in the European Union countries. J. Environ. Manag. 2019, 231, 582–5951. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. The analysis of similarities between the European Union countries in terms of the level and structure of the emissions of selected gases and air pollutants into the atmosphere. J. Clean. Prod. 2021, 279, 123641. [Google Scholar] [CrossRef]

- Jie, H.; Khan, I.; Alharthi, M.; Zafar, M.W.; Saeed, A. Sustainable energy policy, socio-economic development, and ecological footprint: The economic significance of natural resources, population growth, and industrial development. Util. Policy 2023, 81, 101490. [Google Scholar] [CrossRef]

- Irfan, M.; Chen, Z.; Adebayo, T.S.; Al-Faryan, M.A.S. Socio-economic and technological drivers of sustainability and resources management: Demonstrating the role of information and communications technology and financial development using advanced wavelet coherence approach. Resour. Policy 2022, 79, 103038. [Google Scholar] [CrossRef]

- Ferreira, F.A.F.; Ferreira, J.J.M. Methodologies for improving technology decision making for sustainable socio-economic development. Technol. Soc. 2023, 72, 102172. [Google Scholar] [CrossRef]

- Mura, M.; Longo, M.; Zani, S.; Toschi, T. Exploring socio-economic externalities of development scenarios. An analysis of EU regions from 2008 to 2016. J. Environ. Manag. 2023, 332, 117327. [Google Scholar] [CrossRef]

- World Health Organization (WHO); World Health Declaration. HEALTH 21. Health for All in the 21st Century. Basic Tenets of Health Policy for All in the WHO European Region; World Health Organization: Copenhagen, Denmark, 1998. [Google Scholar]

- World Health Organization. Constitution of the World Health Organization—Basic Documents, 49th ed.; World Health Organization: Geneva, Sweden, 2020. [Google Scholar]

- Tutak, M.; Brodny, J. Evaluating differences in the level of working conditions between the European Union member states using topsis and k-means methods. Decis. Mak. Appl. Manag. Eng. 2022, 5, 1–29. [Google Scholar] [CrossRef]

- Bautista-Bernal, I.; Quintana-García, C.; Marchante-Lara, M. Safety culture, safety performance and financial performance. A longitudinal study. Saf. Sci. 2024, 172, 106409. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. The level of implementing sustainable development goal “Industry, innovation and infrastructure” of Agenda 2030 in the European Union countries: Application of MCDM methods. Oeconomia Copernic. 2023, 14, 47–102. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J.; Dobrowolska, M. Assessment of Work Conditions in a Production Enterprise—A Case Study. Sustainability 2020, 12, 5390. [Google Scholar] [CrossRef]

- Cooper, M.D. The Safety Culture Construct: Theory and Practice. In Safety Cultures, Safety Models. SpringerBriefs in Applied Sciences and Technology; Gilbert, C., Journé, B., Laroche, H., Bieder, C., Eds.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Uttal, B. The corporate culture vultures. Fortune Mag. 1983, 108, 66–72. [Google Scholar]

- Schein, E.H. Organizational Culture and Leadership, 3rd ed.; Jossey-Bass: San Francisco, CA, USA, 1985. [Google Scholar]

- Turner, B.A.; Pidgeon, N.F.; Blockley, D.I.; Toft, B. Safety culture: Its importance in future risk management. In Proceedings of the Position Paper for Second World Bank Workshop on Safety Control and Risk Management, Karlstad, Sweden, 6–9 November 1989. [Google Scholar]

- IAEA. Safety Culture; International Atomic Energy Agency: Vienna, Austria, 1991. [Google Scholar]

- Pidgeon, N.F. Safety culture and risk management in organizations. J. Cross-Cult. Psychol. 1991, 22, 129–140. [Google Scholar] [CrossRef]

- Cox, S.; Cox, T. The structure of employee attitudes to safety: A European Example. Work Stress 1991, 5, 93–106. [Google Scholar] [CrossRef]

- CBI. Developing a Safety Culture; Confederation of British Industry: London, UK, 1991. [Google Scholar]

- Health and Safety Commission. ACSNI Human Factors Study Group: Third report—Organizing for Safety; Health and Safety Commission: Beverly Hills, CA, USA, 1993. [Google Scholar]

- Ostrom, L.; Wilhelmsen, C.; Kaplan, B. Assessing safety culture. Nucl. Saf. 1993, 34, 163–172. [Google Scholar]

- Geller, E.S. Ten principles for achieving a Total Safety Culture. Prof. Saf. 1994, 39, 18–24. [Google Scholar]

- Berends, J.J. On the Measurement of Safety Culture (Unpublished Graduation Report); Eindhoven University of Technology: Eindhoven, The Netherlands, 1996. [Google Scholar]

- Lee, T.R. Perceptions, attitudes and behaviour: The vital elements of a safety culture. Health Saf. Oct. 1996, 10, 1–15. [Google Scholar]

- Studenski, R. Kultura bezpieczeństwa pracy w przedsiębiorstwie. Bezpieczeństwo Pracy. Nauka I Prakt. 2000, 9, 1–4. [Google Scholar]

- International Maritime Organization. MSC 77/17—Role of the Human Element; IMO: London, UK, 2003. [Google Scholar]

- Mearns, K.; Whitaker, S.M.; Flin, R. Safety Climate, safety management practice and safety performance in offshore environments. Saf. Sci. 2003, 41, 641–680. [Google Scholar] [CrossRef]

- Von Thaden, T.L.; Gibbons, A.M. The Safety Culture Indicators Scale Measurement System (SCISMS); National Technical Information Service Final Report: Washington, DC, USA, 2008. [Google Scholar]

- Butler, J. Developing and safety culture: Business for safety. IEEE Power Energy 2016, 14, 34–37. [Google Scholar] [CrossRef]

- Yorio, P.L.; Edwards, J.; Hoeneveld, D. Safety culture across cultures. Saf. Sci. 2019, 120, 402–410. [Google Scholar] [CrossRef]

- Medical Office Survey on Patient Safety Culture. Available online: http://www.ahrq.gov/professionals/quality-patient-safety/patientsafetyculture/index.html (accessed on 17 June 2023).

- Cox, S.J.; Cheyne, A.J.T. Assessing safety culture in offshore environments. Saf. Sci. 2000, 34, 111–129. [Google Scholar] [CrossRef]

- Bruch, Q.J.; Butler, S.K.; Tonks, I.A.; Miller, A.J.M. Resources for Improving Safety Culture, Training, and Awareness in the Academic Laboratory. Compr. Coord. Chem. III 2021, 1, 1125–1143. [Google Scholar]

- Bartnicka, J.; Kabiesz, P.; Palka, D.; Gajewska, P.; Islam, E.I.; Szymanek, D. Evaluation of the effectiveness of employers and H&S Services in relation to the COVID-19 system in polish manufacturing companies. Int. J. Environ. Res. Public Health 2021, 18, 9302. [Google Scholar] [CrossRef]

- Andreassi, J.K.; Lawter, L.; Brockerhoff, M.; Rutigliano, P.J. Cultural impact of human resource practices on job satisfaction: A global study across 48 countries. Cross Cult. Manag. Int. J. 2014, 21, 55–77. [Google Scholar] [CrossRef]

- Hashemian, S.M.; Triantis, K. Production pressure and its relationship to safety: A systematic review and future directions. Saf. Sci. 2023, 159, 106045. [Google Scholar] [CrossRef]

- Guldenmund, F.W. The nature of safety culture: A review of theory and research. Saf. Sci. 2020, 34, 215–257. [Google Scholar] [CrossRef]

- Grobelny, J.; Michalski, R. Preventing Work-Related Musculoskeletal Disorders in Manufacturing by Digital Human Modeling. Int. J. Environ. Res. Public Health 2020, 17, 8676. [Google Scholar] [CrossRef] [PubMed]

- Bartnicka, J.; Kowalski, G.; Ziętkiewicz, A. Identification of musculoskeletal hazards for laparoscopic surgeons. Prog. Med. 2015, 28, 515–523. [Google Scholar] [CrossRef]

- Kiełbasa, P.; Juliuszewski, T.; Pawłowicz, J.; Dróżdż, T.; Zagórda, M.; Sęk, S. Ergonomiczna analiza wybranych stanowisk pracy kierowców samochodów ciężarowych. Autobusy Technol. Eksploat. Syst. Transp. 2016, 12, 1030–1037. [Google Scholar]

- Pilat, D. Competition. Productivity and Efficiency; OECD Economic Studies: Paris, France, 1996; pp. 108–109. [Google Scholar]

- Yang, K.; Liquan, T.; Bai, J. Assessment of Flight Crew Errors Based on THERP. Procedia Eng. 2014, 80, 49–58. [Google Scholar] [CrossRef]

- ISO 9001:2015; Quality Management Systems—Requirements. DNV, GL: Oslo, Norway, 2015.

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. Available online: https://www.iso.org/standard/60857.html (accessed on 17 June 2023).

- ISO 45001:2018; Occupational Health and Safety Management Systems—Requirements with Guidance for Use. BSI Standards Limited: London, UK, 2018.

- Kabiesz, P.; Bartnicka, J. Modern training methods in the field of occupational safety. In Proceedings of the 12th International Conference of Education, Research and Innovation (ICERI 2019), Seville, Spain, 11–13 November 2019. [Google Scholar]

- Bartnicka, J.; Kabiesz, P.; Kaźmierczak, J. Standardization of human activities as the component of a workflow efficiency model—A research experiment from a meat producing plant. Prod. Eng. Arch. 2020, 26, 73–77. [Google Scholar] [CrossRef]

- Fernandez-Muniz, B.; Montes-Peon, J.M.; Vazquez-Ordas, C.J. Relation between occupational safety management and firm performance. Saf. Sci. 2009, 47, 980–991. [Google Scholar] [CrossRef]

- Martinez-Córcoles, M.; Gracia, F.J.; Tomás, I.; Peiró, J.M.; Schöbel, M. Empowering team leadership and safety performance in nuclear power plants: A multilevel approach. Saf. Sci. 2013, 51, 293–301. [Google Scholar] [CrossRef]

- Thompson, J.; Davis, R.; Lee, K. The Impact of Safety Culture on Accident Rates in Industrial Settings: A Comprehensive Review. J. Occup. Saf. 2021, 58, 256–273. [Google Scholar] [CrossRef]

- Okonkwo, P.; Wium, J.A. Investigating the Effectiveness of Health and Safety Management Systems within Construction Organizations. Int. J. Occup. Saf. Ergon. 2022, 29, 785–795. [Google Scholar] [CrossRef] [PubMed]

- Griffin, M.A.; Curcuruto, M. Safety Climate in Organizations. Annu. Rev. Organ. Psychol. Organ. Behav. 2016, 3, 191–212. [Google Scholar] [CrossRef]

- Wu, T.C.; Liu, C.W.; Lu, M.C. Safety climate in university and college laboratories: Impact of organizational and individual factors. J. Saf. Res. 2016, 38, 91–102. [Google Scholar] [CrossRef] [PubMed]

- Klajkó, D.; Restás, P.; Szabó, Z.P.; Czibor, A. The Effect of Organizational Culture on Employee Well-Being: Work-Related Stress, Employee Identification, Turnover Intention. J. Int. Coop. Dev. 2019, 2, 19–35. [Google Scholar]

- Vinodkumar, M.N.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef]

- Michael, J.H.; Evans, D.D.; Jansen, K.J.; Haight, J.M. Management commitment to safety as organizational support: Relationships with non-safety outcomes in wood manufacturing employees. J. Saf. Res. 2005, 36, 171–179. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).