Abstract

During energy transition, where sustainability and environmental protection are increasingly prioritized, ensuring safety in coal exploitation remains a critical issue, especially in the context of worker safety. This research focuses on predicting methane concentrations in underground mines, which is vital for both safety and operational efficiency. The article presents a methodology developed to predict methane concentrations at specific points in mine workings using artificial neural networks. The core of this methodology is a forecasting model that allows for the selection and adjustment of the neural network to the phenomenon being studied. This model, based on measurements of ventilation parameters, including methane concentrations in a given area, enables the prediction of gas concentrations at measurement points. The results indicate that with appropriate neural network selection and based on ventilation measurements, it is possible to forecast methane concentrations at acceptable levels in selected excavation points. The effectiveness of these forecasts depends on their timing and the input data to the model. The presented example of applying this methodology in a real mine working demonstrates its high efficiency. The best results were obtained for a 5 min forecast, with slightly less accuracy for longer times (10, 15, 30, and 60 min), though all results remained at an acceptable level. Therefore, it can be concluded that the developed methodology can be successfully applied in underground mining operations to forecast dangerous methane concentrations. Its implementation should improve mining efficiency by reducing instances of exceeding permissible methane concentrations and enhance occupational safety.

1. Introduction

Coal remains one of the world’s primary energy resources, playing a significant role in the production of electricity and heat [1,2,3,4]. However, in the context of sustainable development, the global energy landscape is undergoing a transformation. According to the International Energy Agency [5], global demand for coal is expected to decline gradually, with a much faster decrease in its importance in developed economies compared to developing ones. Despite this trend, coal will continue to play a crucial role in the global energy landscape during the ongoing energy transition. This shift underscores the need to maintain the highest safety standards in coal mining operations, particularly as we move towards more sustainable energy sources.

One of the key challenges associated with coal extraction is the environmental and safety hazards posed by methane. In recent years, methane, which is found in large quantities in coal deposits, has posed a significant threat to mining operations. Under certain conditions, it becomes a highly flammable and explosive gas [6,7,8,9]. These characteristics necessitate various preventive measures in underground mining to avoid dangerous situations. The primary goal of these actions is to prevent the accumulation of dangerous concentrations of this gas in mine workings. Mining regulations set strict limits on the allowable methane concentrations in individual mine areas to mitigate the risk of ignition or explosion [10]. These regulations require meticulous management of the mining process to ensure that these thresholds are not exceeded. However, the unpredictable nature of the mining environment means that exceeding permissible values is still possible during operations. Such instances can lead to interruptions in the operation of equipment and machinery, thereby reducing overall efficiency. When methane levels exceed safety limits, automatic power disconnections are triggered to restore safe conditions, causing unscheduled outages that not only disrupt work cycles but also increase energy inefficiency. Additionally, more severe consequences, such as fires or methane explosions, can have catastrophic effects, resulting in significant material losses, environmental damage, and risks to human life [11]. Even more severe consequences arise from fires or methane explosions, which can lead to catastrophic events with significant material and human losses. Numerous publications document the statistics and consequences of such incidents [12,13].

Therefore, methane poses a serious threat to the safety, continuity, and efficiency of underground mining processes. The increasing depth of mining operations and higher methane levels in mined seams further exacerbate this risk [14]. Given these facts, implementing measures to enhance methane safety during underground mining operations is fully justified. Identifying potentially hazardous conditions during exploitation is particularly crucial. One effective measure is forecasting methane concentrations in mine workings, which can support the management of ventilation systems and operational parameters. Accurate forecasts of methane concentrations can improve process efficiency and reduce the occurrence of dangerous events.

Forecasting, which involves predicting future outcomes based on known data, inherently involves uncertainty [15]. However, in the case of methane hazards, forecasting gas concentrations at specific points in mine workings can significantly enhance the safety and efficiency of mining operations.

In recent years, modern research methods and tools have increasingly been utilized for forecasting various physical and chemical phenomena. These methods include numerical fluid mechanics (CFD) studies [16,17,18,19,20,21], artificial neural networks, fuzzy set theory, and machine learning [22,23,24,25,26,27,28]. Each of these approaches requires specific input data, the development of models to simulate the phenomena, and rigorous verification and validation.

For forecasting methane concentrations in mine workings, artificial neural networks offer significant advantages. Forecasts using these networks typically rely on time-series data of relevant parameters, offering substantial potential for producing reliable results that closely align with actual measurements. A key advantage of this approach is the networks’ ability to continuously improve through ongoing learning from new data [29,30]. Moreover, neural networks can generate output values based on input data without requiring explicit knowledge of the relationships between variables. This method also eliminates the need to construct complex structural models, thereby optimizing both time and cost in its application. As a result, enhanced computational tools enable efficient and timely forecasting through artificial neural networks, contributing to their growing use in predicting various phenomena and conditions. However, in the context of predicting methane hazards in underground mining operations, the existing literature on the use of artificial neural networks is currently limited [22,23,24,25,26,27,28]. Traditionally, general statistical methods [31,32,33] and CFD techniques [16,17,18,19,20,21,22] have been the most commonly used approaches for predicting methane hazards, specifically the distribution of methane concentrations in mine workings. These studies highlight the diversity of methods and tools used to forecast methane concentrations and associated risks in mine environments, underscoring the ongoing relevance of these issues and the imperative to explore and implement new solutions. The adoption of modern forecasting techniques, particularly artificial neural networks, represents a valid and innovative approach to addressing this challenge.

The primary objective of the research presented in this paper was to forecast short-term methane concentrations at the longwall outlet during the mining process. The forecasting spanned five different time intervals: 5, 10, 15, 30, and 60 min. Based on the rationale outlined above, a methodology has been developed for predicting methane concentrations at specific points within mine workings using artificial neural networks, which has been subsequently applied in practical settings. Artificial neural networks, in conjunction with data from the automatic gasometry system of a specific mine, were utilized to generate these predictions. Thus, the developed model has a practical application in predicting methane concentrations within the study area. This process relies on real data from automatic gasometry systems, which are increasingly utilized in mines. Naturally, the accuracy and speed of these predictions largely depend on the quality and availability of the data. Meeting these requirements allows for the quick generation of forecasts of hazardous gas concentrations at an acceptable level of precision. Consequently, this should enable rapid responses to potentially dangerous situations by implementing measures to prevent the formation of hazardous methane concentrations.

The selection, training, and testing of the neural network were conducted using actual data collected from the surveyed longwall. The network identified through this process was employed to predict methane concentrations at the outlet of the studied longwall, and these predictions were subsequently compared with real measurement results. Based on the validation process, the predicted results were positively evaluated.

The scientific problem addressed in this paper is the lack of a methodology for using continuous ventilation parameter data in mines to predict emergency conditions. The developed methodology and the achieved results can effectively support methane safety management in mining operations, aiming to enhance both safety and operational efficiency in underground coal production processes. In contrast to earlier methodologies that often required complex structural models or extensive prior knowledge of inter-variable relationships, the use of artificial neural networks in this study provides a more efficient and flexible solution. This technique allows for rapid adjustments based on new data, making it highly effective in the dynamic and unpredictable environment of underground mining.

2. Literature Review

2.1. Advantages of Neural Networks

Artificial neural networks have been increasingly used for many years to study various phenomena. However, their application in the mining industry has been limited so far [26,28,34,35,36,37,38,39,40,41,42,43,44,45,46]. Analysis of ventilation processes, particularly methane hazards, suggests that these algorithms could be highly effective in forecasting methane concentrations in mine workings. This is due to the unique adaptive properties of neural networks and their ability to model complex nonlinear relationships [46]. When studying methane concentrations at specific points within mine workings, artificial neural networks appear to be a very promising solution. This is because they allow for accurate predictions at locations where methanometry sensors are installed. This, in turn, enables the collection of data recorded by these sensors, which is essential for training and validating the developed model. The availability of such data should facilitate real-time forecasting, crucial for ensuring crew safety and the effectiveness of preventive measures.

The preference for using artificial neural networks over traditional statistical methods in methane concentration forecasting arises from several factors. First, neural networks offer significant advantages compared to traditional statistical methods and some newer machine learning algorithms. Traditional statistical methods, such as linear regression, typically assume simple, linear relationships between variables [46]. However, predicting methane concentrations involves a more complex process influenced by numerous variables (e.g., airflow velocity) that are often interrelated in nonlinear and unpredictable ways. Neural networks, with their architecture and the use of hidden layers, can effectively model these complex relationships, leading to more accurate predictions that consider multiple evaluation criteria [47].

Moreover, neural networks can learn from large datasets, which is particularly important in analyzing ventilation process data that are often extensive, incomplete, and noisy. Traditional methods may struggle to handle such large and heterogeneous datasets. Neural networks, on the other hand, can effectively process these large datasets, learning and identifying important patterns and relationships that may be difficult to detect using statistical techniques [48,49].

Compared to newer machine learning algorithms, such as decision trees or support vector machines, neural networks excel in their ability to scale and work with large datasets that have complex, multidimensional structures. This allows them to better capture the dynamics and variability of methane concentrations, leading to more precise forecasts and, consequently, a higher level of safety in mines [50].

Therefore, it can be assumed that neural networks represent an important and innovative solution for building an effective tool for forecasting methane concentrations in the mining industry. These networks’ ability to model nonlinearities, process large datasets, and adapt to complex and changing conditions makes them more effective and reliable than traditional statistical methods and many newer machine learning algorithms.

2.2. Previous Papers

Neural networks, though limited in their application within the mining industry, have been explored in various studies. In the literature, there are several examples of using artificial neural networks (ANNs) to predict gas emissions, including methane, during mining operations.

One study employed both back-propagation (BP) and radial basis function (RBF) neural network models to predict methane concentrations based on actual coal mine data. The results showed that the RBF model outperformed the BP model in prediction accuracy, highlighting the potential of this approach [38]. Another study introduced a hybrid model combining the Grey GM theory with an RBF neural network. The Grey model preprocesses the input data, which is then used to train the RBF network. This hybrid method improved prediction accuracy compared to the traditional Grey model by addressing the limitations of individual models [39].

The RBF neural network variant has shown promise in predicting methane concentrations in coal mines. For instance, a study presented a new methodology using a modified long short-term memory (LSTM) algorithm to detect the formation of explosive methane–air mixtures in longwall mining. This LSTM model, trained and tested using computational fluid dynamics (CFDs), results from six longwall locations [26]. Another study proposed a neuro-fuzzy model for predicting methane hazards during underground coal mining. This approach diagnoses and predicts methane hazards based on real ventilation measurements [24]. Additionally, logistic regression and deep neural network models have been applied to fire forecasting in mines, built on real mine data [40]. Mishra et al. [28] used ANNs to develop a model predicting methane concentrations in mine pits, considering various geological and mining factors. Zhang et al. [41] introduced a model for predicting gas concentrations using a single-layer random-weighted neural network (SRWNN) with interval prediction, leveraging a genetic sorting algorithm (NSGA-II) for training. Another paper discussed a dynamic neural network model for real-time methane concentration prediction, although it noted difficulties in adapting to diverse gas concentration sequences [42].

These studies demonstrate that artificial neural networks, including various variants, are promising tools for predicting methane concentrations in coal mines. Models such as the single-layer neural network with random weights, dynamic neural networks, and hybrid approaches like Grey GM and RBF offer advanced forecasting methods that enhance accuracy and efficiency. A common strength across these methods is the use of real data for model training, underscoring their value in improving mining safety.

2.3. Research Gap

None of the studies reviewed in Section 2.2 employed Multi-Layer Perceptron (MLP) neural networks. Instead, they focused on other architectures, such as single-layer neural networks with random weights, dynamic networks, or hybrid models. While these approaches yielded positive results, introducing MLP networks could further advance methane concentration forecasting and offer an alternative to existing, relatively complex models. With data from automatic ventilation systems, MLP networks can provide rapid and accurate forecasts, adaptable to varying conditions and states in the mining environment based on data from the mine’s gas monitoring system.

3. Material and Methods

This section presents the research methodology developed and discusses the tools used and the model developed. The study longwall is also characterized and the method of obtaining the ventilation parameters that are the input data for the study is presented.

3.1. Research Methodology

The developed approach for predicting methane concentrations at the longwall exit using MLP artificial neural networks (ANNs) relies on data from the mine’s automatic gas measuring system sensors. The quality and availability of these data are crucial to the accuracy of the results. By utilizing ANNs, it is possible to model and predict methane concentrations based on the collected data, enabling early detection of dangerous situations and the implementation of appropriate preventive measures. The ANN model can learn from historical sensor data, identifying patterns and relationships that influence methane concentrations in a specific wall. A key advantage of this approach is its ability to adapt and learn from new data, which enhances the accuracy of predictions. Implementing such a system improves mine safety by allowing for rapid responses to changing atmospheric conditions, thereby reducing the risk of methane explosions.

The model does not incorporate geological parameters, as collecting and analyzing this information is often more complex, time-consuming, and costly compared to using gas sensor data. Data from gas sensors are readily available, regularly updated, and directly related to actual mine conditions, making them more suitable and relevant for rapid and effective methane concentration forecasting. Therefore, to simplify the model and enhance its operational efficiency, the focus was placed on data closely related to methane emissions.

The idea behind the developed methodology is to utilize real-time gas monitoring data to provide fast and effective methane concentration forecasts, which is crucial for ensuring safety in underground mining operations. The variability of methane emissions during mining activities, as recorded by the sensor system, is key to the efficiency of the mining process.

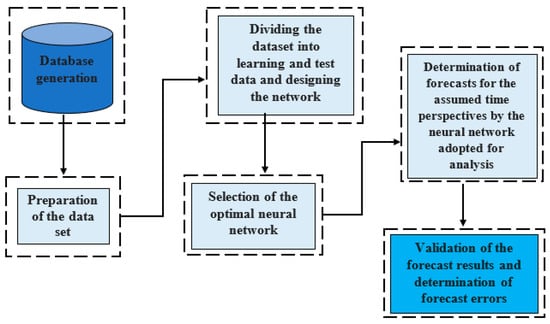

To determine the prediction of methane concentrations at the outlet of the longwall, a methodology was developed for the research procedure, which includes the following six main steps (Figure 1):

Figure 1.

Methodology of the research procedure (own study).

- (1)

- Acquisition of data from automatic gasometry system (database generation).

- (2)

- Preparation of the dataset (averaging of measurement values for one minute).

- (3)

- Dividing the dataset into learning and test data and designing the network.

- (4)

- Selection of the optimal neural network (based on the criterion of the error function during the network learning process).

- (5)

- Determination of forecasts (forecasting) for the assumed time perspectives by the neural network adopted for analysis.

- (6)

- Validation of the obtained forecast results and determination of forecast errors.

Using one-week data spanning enables the model to capture short-term trends and patterns related to methane concentrations at the wall outlet. This timeframe allows the artificial neural network model to account for temporal fluctuations and detect both regular and irregular patterns in methane concentrations. By employing this approach, the model can be updated more frequently, enhancing its adaptability and likely improving the accuracy of its predictions.

3.2. Characteristics of the Neural Network Model Used

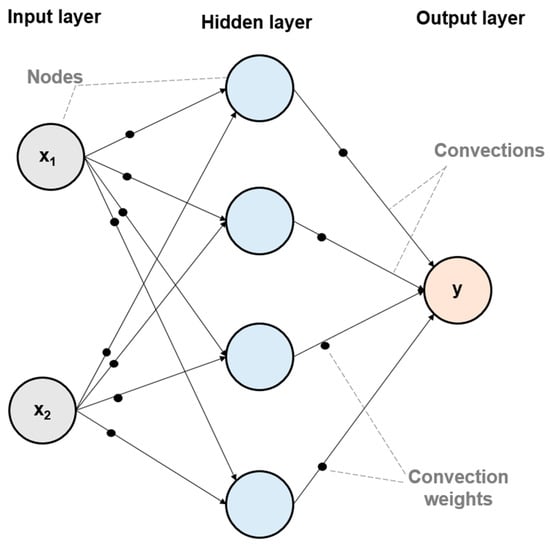

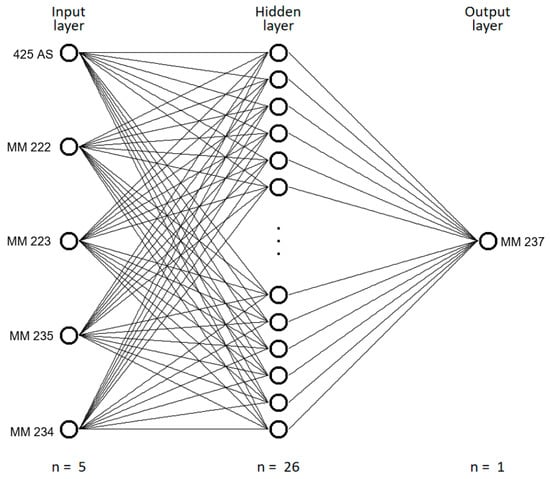

In the methodology using artificial neural networks, simulating neuronal activity with a mathematical model is an information processing system based on imitating the structure and function of the brain’s neural network [51,52]. A neural network consists of many interconnected elements, or neurons. The structure of a basic artificial neural network includes three layers of neurons: the first layer serves as the input layer, the second layer is the hidden layer (there may be several hidden layers), while the third layer is the output layer (Figure 2).

Figure 2.

Structure of a typical neural network.

The input layer receives data that are analogous to external stimuli in biological systems. In the case presented here, these are data from an automated gasometry system. The hidden layers process the input data using weights that are adjusted during training. Neurons in these layers apply activation functions to the weighted inputs and pass the result to the next layer. The last layer, the output layer, generates the final result, which in our case is the prediction.

There are many types of neural networks, which differ in structure, mode of operation, and complexity. In general, these networks can be divided into two types, namely unidirectional and recurrent networks [53]. In the present study, a unidirectional network model was used. In these networks, neurons are grouped in the three layers already mentioned, and the signal passes from the input layer through successive connections to the output layer (Figure 3). One-way networks include the multilayer perceptron (MLP), the cerebellar model articulation control (CMAC) network, and the learning vector quantization (LVQ) network [54].

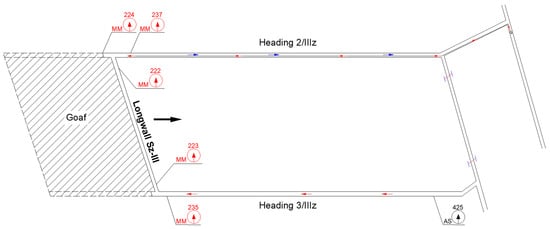

Figure 3.

Schematic of the ventilation of the longwall under study with the location of the sensors.

The most common type of unidirectional network is the multilayer perceptron (MLP) model, which incorporates a backward error propagation algorithm [55]. This means that in this model, each variable xi, from the input layer is connected to each neuron of the hidden layer through connections to the weights wij. These values are then summed, resulting in a signal yi.

The mathematical representation of the MLP neural network concept is described by Equation (1):

where f—activation function; wij—weights connecting the input i-th to the neuron; xi—input i-th to the neuron; bj—bias term for neuron jℎ; n—number of inputs.

A differential activation function inside the hidden layer processes this signal and sends the result to the output layer. The number of neurons in the hidden layer is determined by the given approximation error. The relationship between the number of neurons in the hidden layer and the accuracy of the approximation is directly proportional. The weights of a given predictive model are modified using an optimization algorithm, and this process is called network learning. Due to the use of the fastest-declining method in the backward error propagation algorithm, the algorithm requires a large number of iterations, which, of course, can affect the speed of calculation [52,53,54].

The key elements of the internal logic of the ANN model include

- Layers of the neural network;

- Connections between layers and weights;

- Activation function;

- Back-propagation;

- Cost function (prediction errors);

- Optimization of the network model (updating the weights in the neural network).

The research aimed at generating short-term methane concentration forecasts was conducted using an MLP network. The choice of a Multi-Layer Perceptron for predicting methane concentrations is based on several key factors. Firstly, MLP networks are widely recognized for their effectiveness in modeling complex, nonlinear relationships, which is crucial in the context of predicting methane concentrations in a mining environment. This relatively simple and understandable approach, even for practitioners, makes MLP easier to implement in real mining conditions compared to more complex methods. Its results and the algorithm itself are easier to interpret in comparison to more sophisticated models, such as transformers or recurrent neural networks (RNNs). Moreover, MLP networks require fewer computational resources and shorter training times than advanced models like RNNs or transformers, which is crucial for their practical application. Considering the practical aspects of the developed methodology and the need for rapid decision-making in real mining conditions, the use of MLP represents a significant advantage.

3.3. Evaluating the Effectiveness of the Model

In order to compare the results obtained from the model using artificial neural networks with the actual methane concentrations recorded by the automatic gasometry sensor located at the exit of the mining longwall, the following types of statistical errors were determined:

- (1)

- The mean absolute percentage error (MAPE):

- (2)

- The mean squared error (MSE):

- (3)

- Pearson correlation coefficient:

- (4)

- Index of Agreement

These errors are typical in assessing the quality of results obtained from models using artificial neural networks. In the case of MAPE and MSE-type error calculations, the results, and thus the entire model, are better the closer their values are to “zero”. The index of agreement (IA) measures the degree of agreement between predicted and observed values, including errors. A value close to 1 indicates a strong match between the predicted and observed values. IA is a standardized statistical metric used to assess the correspondence between actual measurements and predicted results, offering an unbiased and dimensionless evaluation.

3.4. Area of Research

Forecasting of methane hazard, characterized by the value of methane concentration at the longwall exit, using artificial neural networks, was carried out for a longwall region in one of Poland’s coal mines. The region included the longwall of the mine, along with adjacent roadheadings. A ventilation diagram of this region, along with the distribution of automatic gasometry sensors, is shown in Figure 3.

The surveyed longwall was ventilated using a “U” system from the boundaries. Fresh air was supplied to it via heading 3/IIIz in deposit 408/1, and used air was discharged via heading 2/IIIz in deposit 408/1, toward test cross heading 1/IIIz. A refreshing air stream was supplied via heading 2/IIIz to the exit region of the longwall.

The projected, at the stage of designing the operation, value of absolute methane quantity for the area of this longwall was slightly more than 13 m3 min. In turn, the projected value of the criterion methane rate was about 24 m3/min.

For the area of this longwall, with the indicated methane values, for the extraction of 2000 Mg/day, it was necessary, according to the mining project, to supply about 1318 m3/min of fresh air, and to the longwall itself, about 700 m3/min.

3.5. Data

The study used data recorded by the gasometry system, which consisted of a number of sensors, including for automatic recording of methane concentrations at measurement points (i.e., the locations where these sensors are mounted). Weekly data (7 days) from six sensors, including five methane sensors and one anemometer, were used for the study. These were averaged minute data from each measurement sensor. Their set, for one week of measurements, thus included 10,080 records for each sensor individually. The forecast was based on recorded and averaged (per minute) measurements from the automatic gasometry sensors. The choice of a one-minute interval is due to the fact that high-frequency (1 Hz) tests did not reveal significant differences for this dataset. The nature of the phenomenon studied suggests that analyzing methane outflow processes at a one-minute frequency is acceptable.

The data used for the study came from the following sensors included in the automatic gasometry system:

- −

- 425 anemometer (airflow velocity measurement);

- −

- Automatic methane meter 222 (measurement of methane concentration);

- −

- Automatic methane meter 223 (measurement of methane concentration);

- −

- Automatic methane meter 235 (measurement of methane concentration);

- −

- Automatic methane meter 234 (measurement of methane concentration);

- −

- Automatic methane meter 237 (measurement of methane concentration).

The values of ventilation parameters recorded by these sensors were the input data for the basic tests.

The data used for the study, originating from the mine’s automatic gas monitoring system, were appropriately prepared to generate methane concentration forecasts:

- −

- The data underwent preprocessing to remove noise, outliers (caused, for example, by sensor malfunctions or environmental disturbances), and missing values that could distort the forecasted results.

- −

- The prepared data were subjected to a normalization procedure, which involved averaging them to one-minute intervals for each measurement sensor.

- −

- Input and output data for the model were defined. The goal of the study was to forecast methane concentration levels for sensor 237 using data collected from other sensors (425, 222, 223, 234, and 235).

- −

- The model’s performance was validated using cross-validation techniques. The dataset was split into training (70%) and test sets (30%) to assess the predictive capabilities of the MLP neural network.

All calculations were performed using the Statistica software (Version 13.6), in the automated neural networks module [56].

4. Results and Discussion

The study aimed to predict methane concentrations at the exit of a longwall using data from the mine’s automatic gasometry system, following the methodology outlined in Section 2. Predictions were made for five-time intervals: 5, 10, 15, 30, and 60 min.

The primary objective of the study was to forecast methane concentrations over a time horizon ranging from 5 to 60 measurement cycles from the last recorded measurement included in the model. As mentioned earlier, the sampling interval used was one minute.

The dataset used for the study consisted of 10,080 records from one sensor over a seven-day operational period, starting from 6:00 a.m. on the first day to 5:59 a.m. on the seventh day. This dataset was divided into two subsets: a training set (70% of the data) used for network learning, and a test set (30% of the data) used to evaluate the training progress and prevent overtraining. Overtraining occurs when a network becomes overly specialized to the training data, thereby reducing its ability to generalize knowledge.

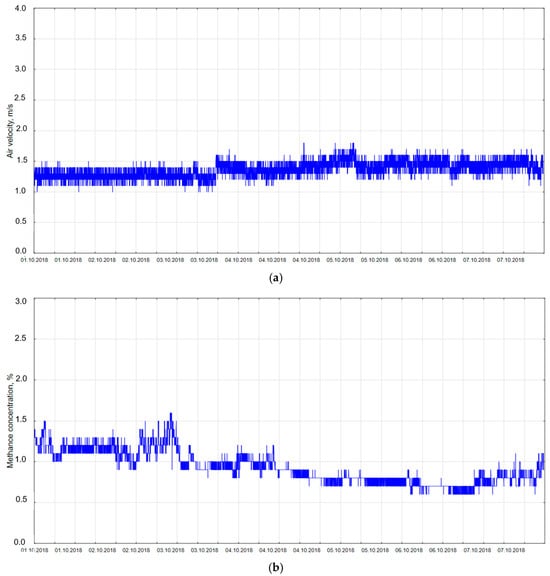

Figure 4 illustrates examples of time waveforms for airflow velocity recorded by the AS425 sensor and methane concentration values recorded by the MM237 sensor (longwall outlet).

Figure 4.

Time waveforms of airflow velocity (a) and methane concentration (b) recorded by the sensors of the gasometric system in the studied mining region.

The time series data recorded by the sensors of the mine’s automatic gasometry system formed the foundation for determining both current and predicted methane concentrations at the sensor located on the longwall outlet, situated up to 10 m from the longwall (Figure 3).

Following the developed methodology, the next stage of the research involved testing a variety of neural network models to identify the most optimal one for the main research task. Multiple Multilayer Perceptron (MLP) configurations were analyzed to assess their effectiveness in predicting methane concentrations at specified future times. Each model underwent rigorous testing to evaluate its accuracy and prediction stability.

The selection criterion for the models was based on achieving the best fit between the forecast results and both the training and test datasets. The research encompassed models with diverse structures, ranging from 3 to 30 neurons in the hidden layer, employing different activation functions such as Hyperbolic tangent, Logistic, Exponential, and Linear. This approach resulted in the development of several forecasting models, each tailored to achieve optimal performance across various forecast time horizons.

Table 1 presents the developed forecasting models for time perspectives of 5, 10, 15, 30, and 60 min. These models exhibit high quality, reflected in their strong correlation coefficients between actual and predicted data. The error function used during the learning process of these networks was based on the sum of squares.

Table 1.

Results of selection of artificial neural networks for the study depending on the prediction time.

The results from testing these MLP network models, as shown in Table 1, reveal varying levels of prediction accuracy depending on the time interval. The model identified as MLP 5-26-1, which predicts methane concentrations five minutes in advance, yielded the highest accuracy, demonstrating the strongest correlation between predicted and actual data. This suggests that for very short-term forecasts, this model is particularly effective and reliable.

In contrast, the least satisfactory results were observed with the same MLP 5-26-1 model when predicting methane concentrations one hour (60 min) in advance. This indicates that the predictive capability of the model decreases as the forecast horizon extends, which is likely due to the increasing complexity and variability of the factors influencing methane levels over longer periods.

For forecasts spanning 15 and 30 min, the MLP 5-28-1 model, which features 28 neurons in the hidden layer, provided the best results. This model employs a Hyperbolic tangent activation function in the hidden layer and an Exponential activation function in the output layer. The use of different activation functions helps to capture the nonlinear relationships between input data and methane concentrations, thereby improving the accuracy of the predictions.

The models listed in Table 1 differ not only in their forecast time horizons but also in their network configurations, including the number of neurons in the hidden layer and the types of activation functions used. These configurations significantly impact the quality of their predictions. The general trend observed is that shorter time horizons result in better prediction accuracy, suggesting that these models are more adept at handling the immediate and short-term dynamics of methane concentration changes.

In subsequent stages of the research, efforts were made to identify the most versatile neural network model from those listed in Table 1. The goal was to find a model that could consistently deliver high-quality forecasts across all the designated time horizons. This involved evaluating each model’s performance not just for a specific time interval, but across all intervals, to determine which model offered the best balance between accuracy and versatility.

The versatility of the neural network model was assessed based on its ability to provide reliable and accurate forecasts regardless of the forecast period. A model that could maintain high prediction quality across different time horizons would be considered highly valuable, as it could be used in a broader range of scenarios within the mining operation. Such a model would enhance the overall safety and efficiency of the mining process by enabling more consistent and proactive management of methane hazards.

Table 2 presents the test outcomes for various neural network models, each evaluated for its performance in predicting methane concentrations over the study’s designated time spans. The goal was to select a model demonstrating robust forecasting capability across all time horizons, characterized by low prediction errors and stable performance.

Table 2.

Summary of test results of the developed neural network models for the adopted forecast horizons.

The results summarized in Table 2 highlight the comparative performance of different neural network models, all based on Multi-Layer Perceptron (MLP) structures, in predicting methane concentrations across various forecast horizons. Each model configuration was meticulously evaluated for its effectiveness, with performance metrics including correlation coefficients for both training and test datasets. Among the models tested, the MLP 5-26-1 network consistently achieved the highest correlation coefficients across nearly all forecast horizons. This indicates its superior ability to generalize from training data and maintain accuracy when applied to unseen test data. This model outperformed the others in terms of prediction accuracy, indicating its superior ability to generalize and perform well across different forecast times:

- −

- For the 5 min forecast, the MLP 5-26-1 achieved a correlation coefficient of 0.932 for training and 0.930 for testing, the highest among all models tested;

- −

- At the 10 min forecast horizon, the model maintained a strong performance with coefficients of 0.923 for training and 0.925 for testing, demonstrating its reliability in slightly longer-term predictions;

- −

- For longer horizons, such as 15, 30, and 60 min, the MLP 5-26-1 continued to outperform other models, consistently yielding the highest correlation coefficients. Although there was a slight decline in accuracy as the forecast time increased, this model remained the most accurate across all time spans.

Overall, the MLP 5-26-1 model demonstrated the most consistent and reliable performance across various prediction times, making it the most effective among those evaluated. Its robustness in short-term predictions and relatively stable accuracy in longer-term forecasts render it a valuable tool for predicting methane concentrations in mining operations. This model’s ability to perform well across different time horizons suggests its potential for broad applicability in enhancing the safety and efficiency of underground mining processes.

Figure 5 illustrates the structure and parameters of the MLP 5-26-1 neural network used for predicting methane concentrations.

Figure 5.

Structure and parameters of the MLP 5-26-1 neural network model for determining the prediction of methane concentration at the longwall outlet.

The neural network model chosen for the study (MLP 5-26-1) underwent a validation process in the subsequent stage of research (Figure 5). This involved comparing predictions generated by the model across all designated time perspectives with actual methane concentration measurements at the longwall outlet.

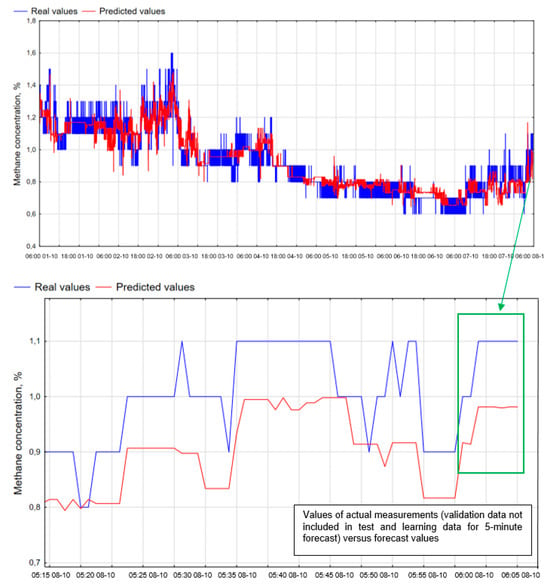

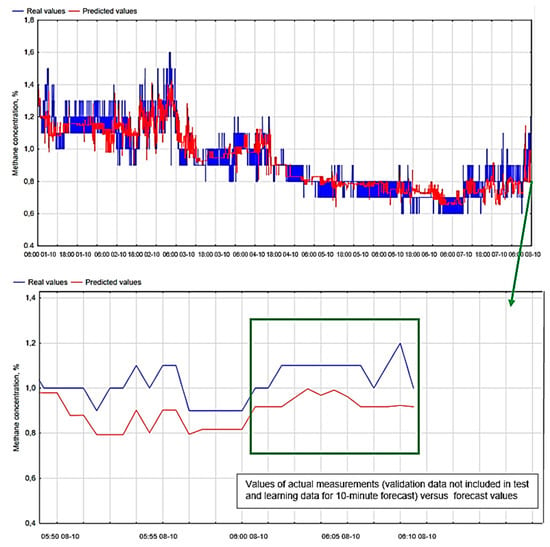

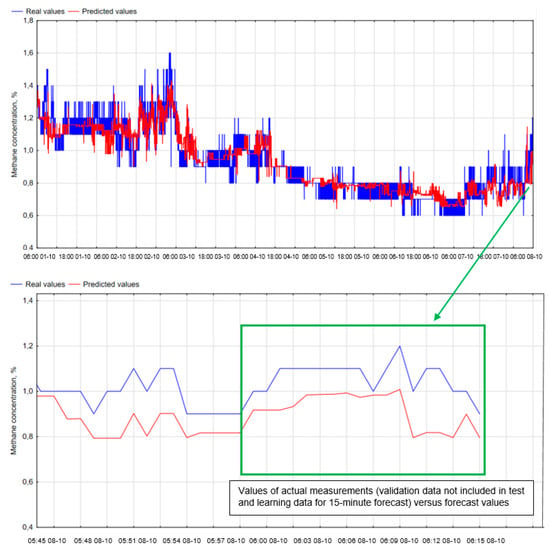

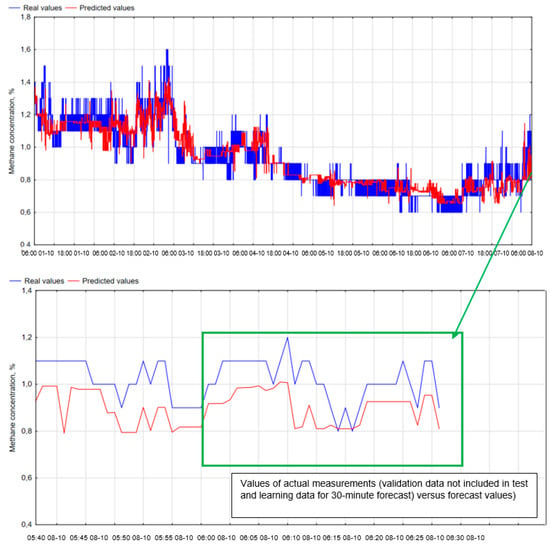

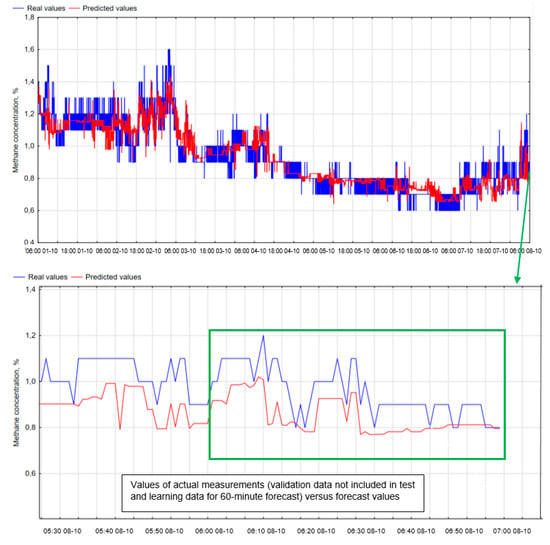

The results of this analysis are depicted in Figure 6, Figure 7, Figure 8, Figure 9 and Figure 10. In these figures, actual methane concentrations represent measured values obtained from the sensor at the longwall outlet, while predicted concentrations are those determined by the model based on analysis of both the learning and test datasets.

Figure 6.

Comparison of actual measurements with 5 min forecast results.

Figure 7.

Comparison of actual measurements with 10 min forecast results.

Figure 8.

Comparison of actual measurements with 15 min forecast results.

Figure 9.

Comparison of actual measurements with 30 min forecast results.

Figure 10.

Comparison of actual measurements with 60 min forecast results.

Figure 6 illustrates the comparison of forecast results (obtained using neural networks) and actual measurements for a 5 min time horizon (corresponding to five measurement records). Figure 7, Figure 8, Figure 9 and Figure 10 sequentially display similar comparisons for forecast times of 10 min, 15 min, 30 min, and 60 min, respectively. Figure 6, Figure 7, Figure 8, Figure 9 and Figure 10 collectively demonstrate how well the MLP 5-26-1 model performs across varying forecast intervals.

The results obtained were evaluated based on the equations for determining forecast error values discussed in Section 2.2. The obtained results of this analysis for all five determined forecasts are summarized in Table 3.

Table 3.

Summary of the evaluation of the convergence of the results of the determined forecasts with the results of the actual measurements.

The study’s results indicate that the 5 min forecast achieved the highest accuracy and the lowest error rate compared to longer forecast periods. Conversely, the largest errors were observed in the 60 min forecast. However, across all forecast variants analyzed, the Mean Absolute Percentage Error (MAPE) remained below 18%. This suggests that while forecast errors increase with longer time horizons, they remain within an acceptable range, signifying good overall quality of the developed forecasting model. The relatively stable MAPE values across different forecast periods indicate that the average percentage error of forecasts relative to actual measurements does not significantly change as the forecast duration extends.

The correlation coefficient R, which measures the fit between forecasts and actual data, decreases from 0.931 for 5 min forecasts to 0.902 for 60 min forecasts. This decline reflects the expected trend where the fit between forecasted and actual data diminishes as the forecast period lengthens. Similarly, the Index of Agreement, which evaluates the match between forecasts and actual measurements, drops from 0.970 for 5 min forecasts to 0.961 for 60 min forecasts. This gradual decrease suggests that while forecasts remain accurate, their consistency with actual values slightly deteriorates over longer periods. Overall, the results confirm that forecast accuracy tends to decline as the forecast period increases.

The presence of a strong relationship between predicted and actual data is underscored by correlation coefficients exceeding 0.9 across all tested forecast periods. Specifically, the highest correlation coefficient was observed for the 5 min forecast variant (0.934 for the training data and 0.930 for the test data), while the lowest values were recorded for the 60 min forecast (0.901 and 0.903, respectively). These results imply that although the model’s accuracy diminishes as the forecast horizon extends, it remains robust and reliable across all analyzed periods, demonstrating the model’s potential for practical application in monitoring and forecasting methane concentrations in mining operations.

Thus, the developed methodology and model, utilizing the MLP 5-26-1 neural network architecture, exhibit a strong capability for predicting methane concentrations at the longwall outlet within the specified forecast horizons. The model’s effectiveness, as demonstrated by the consistently high correlation coefficients across various forecast times, highlights its potential as a practical tool in mine safety management. This approach provides a reliable means for short-term methane prediction, significantly contributing to proactive monitoring and risk mitigation in mining operations.

The consistent performance of the MLP 5-26-1 network across different forecast horizons underscores its robustness and adaptability under various operational conditions. Despite the observed decrease in accuracy for longer forecast periods, the model maintains a high level of precision, making it suitable for real-time applications where timely and reliable data are crucial. The successful application of this neural network-based methodology represents a significant advancement in methane hazard prediction, contributing to safer and more efficient mining operations. This approach not only enhances current practices but also sets a strong foundation for future research and development in the critical area of mine safety.

5. Conclusions

The topic discussed in this article addresses critical issues pertaining to mining operations, specifically focusing on safety and efficiency, which are fundamental to the viability of underground mining activities.

The development of a new method for forecasting methane concentrations using an MLP network in mine workings advances this field and opens up opportunities for implementing modern solutions across the sector. The utilization of artificial neural networks for short-term forecasting (up to 60 min) of methane concentrations in underground workings represents an effective approach, as validated by the results obtained in this study.

The developed methodology and its forecast results provide actionable insights:

- −

- It is possible to use an MLP network for short-term methane concentration forecasting based solely on data from the mine’s automatic gas monitoring system (without incorporating geological or mining parameters);

- −

- The 5 min forecast demonstrated the highest accuracy and the lowest error rates compared to longer forecasting periods such as 10, 15, 30, and 60 min;

- −

- As the forecasting horizon increases, the prediction error also rises, with the largest errors observed in the 60 min methane concentration forecasts;

- −

- Across all forecast variants, the Mean Absolute Percentage Error remains below 18%, indicating acceptable forecasting quality.

- −

- The correlation coefficients for the ANN models exceed 0.9 for different short-term forecast periods, with the 5 min forecast achieving the highest values (0.934 for learning data and 0.930 for test data) and the hourly forecast yielding slightly lower but still strong correlations (0.901 and 0.903, respectively).

These results underscore the effectiveness of ANN models in short-term methane concentration prediction, which can significantly enhance safety and operational efficiency in coal mines. The objectivity of the study’s results and the numerous advantages of artificial neural networks as an effective method for time series forecasting indicate that the developed methodology and model hold promise for widespread application in mining and beyond. It is noteworthy that this methodology exhibits great flexibility, capable of adaptation to various methanometry systems with differing sensor configurations. This adaptability ensures swift and effective support for managing safety systems throughout underground mining operations, ultimately enhancing both efficiency and safety standards.

Therefore, the developed methodology utilizing artificial neural networks demonstrates research and practical potential. The use of the Multi-Layer Perceptron neural network model represents a promising alternative that warrants further research. The MLP has significant potential for practical applications, particularly in predicting methane concentrations in mines, where the users may not be specialists in artificial neural networks. Its structure allows for more intuitive and accessible research tools, which could facilitate its adoption in the mining industry.

The simplicity and versatility of the MLP methodology could be advantageous for practical implementation.

6. Directions for Future Research

Future work could focus on enhancing the model’s performance further by incorporating additional features, such as real-time data streams or more detailed environmental variables (e.g., geological and mining parameters), which may improve predictive accuracy. Additionally, exploring more advanced neural network architectures or hybrid models could offer additional improvements. Continuous validation and adaptation of the model with new data will ensure its relevance and effectiveness in evolving mining conditions. The developed model does not currently incorporate geological parameters, such as rock structure, porosity, or fault lines. In future research, it would be worthwhile to explore the inclusion of geological factors to assess whether they could improve the accuracy and robustness of methane concentration forecasts.

In future studies, it is advisable to explore various types of neural networks, such as recurrent neural networks (RNNs) or convolutional neural networks (CNNs), as well as other machine learning models. Their use would enable comparisons of forecast quality and help select the most optimal approach. This study, focusing on the research objective, did not conduct such comparisons, but in the future, a comparative analysis would be entirely justified. Beyond the scientific aspects of these new solutions, practical considerations are also very important and should be acceptable to mining practitioners.

Additionally, it is worth considering the application of XAI (explainable artificial intelligence) techniques to increase the transparency and interpretability of methane concentration forecasts. This approach would provide a better understanding of the factors influencing prediction results. The acceptance of the developed models and their outcomes is also crucial, as these results significantly impact safety decisions in mining operations. In mining practice, the acceptance of the obtained results and applied methods is of key importance.

Author Contributions

Conceptualization, M.T.; methodology, M.T.; software, M.T., T.K., R.P. and J.B.; formal analysis, M.T. and J.B.; investigation, M.T.; resources, M.T., T.K., R.P., J.B. and W.W.G.; data curation, M.T.; writing—original draft preparation, M.T.; writing—review and editing, M.T., T.K., R.P., J.B. and W.W.G.; visualization, M.T.; supervision, M.T.; project administration, M.T., T.K., R.P., J.B. and W.W.G.; funding acquisition, M.T., T.K., R.P. and J.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by VEGA 1/0241/22 Mobile robotic systems for support during crisis situations. The preparation of this paper was also supported by the European Union’s Horizon Europe research and innovation programme under the Marie Skłodowska-Curie grant agreement No. 101086487, project SME 5.0.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| ANN | Artificial neural network |

| BP | Back-propagation |

| CFD | Computational fluid dynamics |

| CNN | Convolutional neural network |

| CMAC | Cerebellar model articulation control |

| IA | Index of Agreement |

| LSTM | Long short-term memory |

| LVQ | Learning vector quantization |

| MAPE | Mean Absolute Percentage Error |

| MLP | Multi-Layer Perceptron |

| MSE | The mean squared error |

| NSGA | Genetic sorting algorithm |

| R | Pearson correlation coefficient |

| RBF | Radial basis function |

| RNN | Recurrent neural networks |

| SRWNN | Single-layer random-weighted neural network |

References

- Brodny, J. Analysis of operation of new construction of the frictional joint with the resistance wedge. Arch. Min. Sci. 2012, 57, 733–746. [Google Scholar]

- Brodny, J. Determining the working characteristic of a friction joint in a yielding support. Arch. Min. Sci. 2010, 55, 209–227. [Google Scholar]

- Wang, Y. What drives sustainable development? Evaluating the role of oil and coal resources for selected resource rich economies. Resour. Policy 2023, 80, 103078. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Adapting the Powered Roof Support to Diverse Mining and Geological Conditions. Energies 2020, 13, 405. [Google Scholar] [CrossRef]

- International Energy Agency. Coal 2023. Analysis and Forecast to 2026. Available online: https://iea.blob.core.windows.net/assets/a72a7ffa-c5f2-4ed8-a2bf-eb035931d95c/Coal_2023.pdf (accessed on 3 July 2024).

- Obracaj, D.; Korzec, M.; Deszcz, P. Study on Methane Distribution in the Face Zone of the Fully Mechanized Roadway with Overlap Auxiliary Ventilation System. Energies 2021, 14, 6379. [Google Scholar] [CrossRef]

- Swolkień, J.; Szlązak, N. The Impact of the Coexistence of Methane Hazard and Rock-Bursts on the Safety of Works in Underground Hard Coal Mines. Energies 2021, 14, 128. [Google Scholar] [CrossRef]

- Szlązak, N.; Obracaj, D.; Swolkień, J. Enhancing Safety in the Polish High-Methane Coal Mines: An Overview. Min. Metall. Explor. 2020, 37, 567–579. [Google Scholar] [CrossRef]

- Regulation of the Minister of Energy on Detailed Requirements for Operating Underground Mining Plants. 23 November 2016 Journal of Laws 2017, Item 1118, Warsaw. Available online: https://dziennikustaw.gov.pl/DU/rok/2017/pozycja/1118 (accessed on 3 July 2024).

- Gajdzik, B.; Sujova, E.; Małysa, T.; Biały, W. The accident rate in Polish mining. Current status and forecast. Acta Montan. Slovaca 2022, 27, 620–634. [Google Scholar]

- Brodny, J.; Tutak, M.; Michalak, M. A Data Warehouse as an Indispensable Tool to Determine the Effectiveness of the Use of the Longwall Shearer. In Beyond Databases, Architectures and Structures. Towards Efficient Solutions for Data Analysis and Knowledge Representation, Proceedings of the 13th International Conference, BDAS 2017, Ustroń, Poland, 30 May–2 June 2017; Kozielski, S., Mrozek, D., Kasprowski, P., Małysiak-Mrozek, B., Kostrzewa, D., Eds.; Communications in Computer and Information Science; Springer: Cham, Switzerland, 2017; Volume 716. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, D.; Shao, Z.; Xu, C.; Zhu, X.; Qi, X.; Liu, F. A statistical analysis of coal mine fires and explosions in China. Process Saf. Environ. Prot. 2019, 121, 357–366. [Google Scholar] [CrossRef]

- Ray, S.K.; Khan, A.M.; Mohalik, N.K.; Mishra, D.; Mandal, S.; Pandey, J.K. Review of preventive and constructive measures for coal mine explosions: An Indian perspective. Int. J. Min. Sci. Technol. 2022, 32, 471–485. [Google Scholar] [CrossRef]

- Kędzior, S.; Dreger, M. Geological and Mining Factors Controlling the Current Methane Conditions in the Rydułtowy Coal Mine (Upper Silesian Coal Basin, Poland). Energies 2022, 15, 6364. [Google Scholar] [CrossRef]

- Liu, X.; Wang, W. Deep Time Series Forecasting Models: A Comprehensive Survey. Mathematics 2024, 12, 1504. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M.; John, A. Analysis of influence of types of rocks forming the goaf with caving on the physical parameters of air stream flowing through these gob and adjacent headings. Mechanika 2017, 24, 43–49. [Google Scholar] [CrossRef]

- Janoszek, T.; Krawczyk, J. Methodology development and initial results of CFD simulations of methane distribution in the working of a longwall ventilated in a short “Y” manner. Arch. Min. Sci. 2022, 67, 3–24. [Google Scholar]

- Rao, S.; Mishra, D.P.; Mishra, A. Methane migration and explosive fringe localisation in retreating longwall panel under varied ventilation scenarios: A numerical simulation approach. Environ. Sci. Pollut. Res. 2023, 30, 66705–66729. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, H.; Qin, Y.; Guo, M.; He, S.; Wang, K.; Shi, Y.; Xiang, Z. Numerical simulation and investigation of methane gas distribution and extraction in goaf with U-type ventilation of working face. Environ. Sci. Pollut. Res. 2023, 30, 59510–59527. [Google Scholar] [CrossRef]

- Wang, Y.; Si, G.; Belle, B.; Webb, D.; Zhao, L.; Oh, J. Impact of goaf gas drainage from surface vertical boreholes on goaf explosive gas zones. Int. J. Coal Geol. 2024, 284, 104461. [Google Scholar] [CrossRef]

- Trybała, P.; Rigon, S.; Remondino, F.; Banasiewicz, A.; Wróblewski, A.; Macek, A.; Kujawa, P.; Romańczukiewicz, K.; Redondo, C.; Espada, F. Optimizing Mining Ventilation Using 3D Technologies. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2024, 48, 427–434. [Google Scholar] [CrossRef]

- Mardani, A.; Liao, H.; Nilashi, M.; Alrasheedi, M.; Cavallaro, F. A multi-stage method to predict carbon dioxide emissions using dimensionality reduction, clustering, and machine learning techniques. J. Clean. Prod. 2020, 275, 122942. [Google Scholar] [CrossRef]

- Acheampong, A.O.; Boateng, E.B. Modelling carbon emission intensity: Application of artificial neural network. J. Clean. Prod. 2019, 225, 833–856. [Google Scholar] [CrossRef]

- Brodny, J.; Felka, D.; Tutak, M. The use of the neuro-fuzzy model to predict the methane hazard during the underground coal mining production process. J. Clean. Prod. 2022, 368, 133258. [Google Scholar] [CrossRef]

- Mathatho, S.; Owolawi, P.A.; Tu, C. Prediction of Methane Levels in Underground Coal Mines using Artificial Neural Networks. In Proceedings of the 2019 International Conference on Advances in Big Data, Computing and Data Communication Systems (icABCD), Winterton, South Africa, 5–6 August 2019; pp. 1–4. [Google Scholar]

- Demirkan, D.C.; Duzgun, H.S.; Juganda, A.; Brune, J.; Bogin, G. Real-Time Methane Prediction in Underground Longwall Coal Mining Using AI. Energies 2022, 15, 6486. [Google Scholar] [CrossRef]

- Miao, D.; Ji, J.; Chen, X.; Lv, Y.; Liu, L.; Sui, X. Coal and Gas Outburst Risk Prediction and Management Based on WOA-ELM. Appl. Sci. 2022, 12, 10967. [Google Scholar] [CrossRef]

- Mishra, D.P.; Panigrahi, D.C.; Kumar, P.; Kumar, A.; Kumar, P. Assessment of relative impacts of various geo-mining factors on methane dispersion for safety in gassy underground coal mines: An artificial neural networks approach. Neural Comput. Applic. 2021, 33, 181–190. [Google Scholar] [CrossRef]

- Dong, D. Mine gas emission prediction based on Gaussian process model. Procedia Eng. 2012, 45, 334–338. [Google Scholar] [CrossRef]

- Jing, G.X.; Xu, S.M.; Heng, X.W.; Li, C.Q. Research on the prediction of gas emission quantity in coal mine based on grey system and linear regression for one element. Procedia Eng. 2011, 26, 1585–1590. [Google Scholar]

- Diaz, J.; Agioutantis, Z.; Hristopulos, D.T.; Schafrik, S.; Luxbacher, K. Time Series Modeling of Methane Gas in Underground Mines. Min. Metall. Explor. 2022, 39, 1961–1982. [Google Scholar] [CrossRef]

- Diaz, J.; Agioutantis, Z.; Hristopulos, D.T.; Luxbacher, K.; Schafrik, S. Forecasting of methane gas in underground coal mines: Univariate versus multivariate time series modeling. Stoch. Environ. Res. Risk Assess. 2023, 37, 2099–2115. [Google Scholar] [CrossRef]

- Meng, X.; Chang, H.; Wang, X. Methane Concentration Prediction Method Based on Deep Learning and Classical Time Series Analysis. Energies 2022, 15, 2262. [Google Scholar] [CrossRef]

- Miller-Tait, L.; Pakalnis, R. Practical neural network applications in the mining industry. In Proceedings of the Second International Conference on Intelligent Processing and Manufacturing of Materials. IPMM’99 (Cat. No.99EX296), Honolulu, HI, USA, 10–15 July 1999; pp. 983–987. [Google Scholar]

- Al-Bakri, A.Y.; Sazid, M. Application of Artificial Neural Network (ANN) for Prediction and Optimization of Blast-Induced Impacts. Mining 2021, 1, 315–334. [Google Scholar] [CrossRef]

- Azhari, F.; Sennersten, C.C.; Lindley, C.A.; Sellers, E. Deep learning implementations in mining applications: A compact critical review. Artif. Intell. Rev. 2023, 56, 14367–14402. [Google Scholar] [CrossRef]

- Tadeusiewcz, R. Neural networks in mining sciences—General overview and some representative examples. Arch. Min. Sci. 2015, 60, 971–984. [Google Scholar]

- Yuan, D.; Yue, X.; Wang, C.; Zhang, J. Gas Emission Prediction Based on Coal Mine Operating Data. Appl. Mech. Mater. 2014, 484–485, 604–607. [Google Scholar] [CrossRef]

- Yang, Y.; Du, Q.; Wang, C.; Bai, Y. Research on the Method of Methane Emission Prediction Using Improved Grey Radial Basis Function Neural Network Model. Energies 2020, 13, 6112. [Google Scholar] [CrossRef]

- Choi, M.-Y.; Jun, S. Fire Risk Assessment Models Using Statistical Machine Learning and Optimized Risk Indexing. Appl. Sci. 2020, 10, 4199. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, H.; Lu, Z.; Zhan, L.; Hung, P. Distributed gas concentration prediction with intelligent edge devices in coal mine. Eng. Appl. Artif. Intell. 2020, 92, 103643. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiao, J.; Yu, W. Real-time prediction method of gas concentration based on dy-namic neural network. Control Eng. 2016, 23, 478–483. [Google Scholar]

- Wang, C.; Xu, J.; Li, Y.; Wang, T.; Wang, Q. Optimization of BP Neural Network Model for Rockburst Prediction under Multiple Influence Factors. Appl. Sci. 2023, 13, 2741. [Google Scholar] [CrossRef]

- Małkowski, P.; Juszyński, D. Roof fall hazard assessment with the use of artificial neural network. Int. J. Rock Mech. Min. Sci. 2021, 143, 104701. [Google Scholar] [CrossRef]

- Ghaboussi, J.; Sidarta, N.E. New nested adaptive neural networks (NANN) for constitutive modeling. Comput. Geotech. 1998, 22, 29–52. [Google Scholar] [CrossRef]

- Joseph, B.; Wang, F.; Shieh, D.S. Exploratory data analysis: A comparison of statistical methods with artificial neural networks. Comput. Chem. Eng. 1992, 16, 413–423. [Google Scholar] [CrossRef]

- Sorri, M.; Arezoo, B.; Dastres, R. Artificial neural networks in supply chain management, a review. J. Econ. Technol. 2023, 1, 179–196. [Google Scholar] [CrossRef]

- Aldoseri, A.; Al-Khalifa, K.N.; Hamouda, A.M. Re-Thinking Data Strategy and Integration for Artificial Intelligence: Concepts, Opportunities, and Challenges. Appl. Sci. 2023, 13, 7082. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Alam, M.S.B.; Hassan, M.; Rozbu, M.; Ishitak, T.; Rafa, N.; Mofijur, M.; Ali, A.; Gandomi, A. Deep learning modelling techniques: Current progress, applications, advantages, and challenges. Artif. Intell. Rev. 2023, 56, 13521–13617. [Google Scholar] [CrossRef]

- Manakitsa, N.; Maraslidis, G.S.; Moysis, L.; Fragulis, G.F. A Review of Machine Learning and Deep Learning for Object Detection, Semantic Segmentation, and Human Action Recognition in Machine and Robotic Vision. Technologies 2024, 12, 15. [Google Scholar] [CrossRef]

- Shanmuganathan, S. Artificial Neural Network Modelling: An Introduction. In Artificial Neural Network Modelling; Shanmuganathan, S., Samarasinghe, S., Eds.; Studies in Computational Intelligence; Springer: Cham, Switzerland, 2016; Volume 628. [Google Scholar]

- Montesinos López, O.A.; Montesinos López, A.; Crossa, J. Fundamentals of Artificial Neural Networks and Deep Learning. In Multivariate Statistical Machine Learning Methods for Genomic Prediction; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Borowski, M.; Życzkowski, P.; Cheng, J.; Łuczak, R.; Zwolińska, K. The Combustion of Methane from Hard Coal Seams in Gas Engines as a Technology Leading to Reducing Greenhouse Gas Emissions—Electricity Prediction Using ANN. Energies 2020, 13, 4429. [Google Scholar] [CrossRef]

- Hornik, K.; Stinchcombe, M.; White, H. Multilayer feedforward networks are universal approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar] [CrossRef]

- Wall, C.; Zhang, L.; Yu, Y.; Kumar, A.; Gao, R. A Deep Ensemble Neural Network with Attention Mechanisms for Lung Abnormality Classification Using Audio Inputs. Sensors 2022, 22, 5566. [Google Scholar] [CrossRef]

- TIBCO Software Inc. Statistica (Data Analysis Software System); Version 13.6; TIBCO Software Inc.: Palo Alto, CA, USA, 2020. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).