Analysis of the Use of Energy Storage in the Form of Concrete Slabs as a Method for Sustainable Energy Management in a System with Active Thermal Insulation and Solar Collectors

Abstract

:1. Introduction

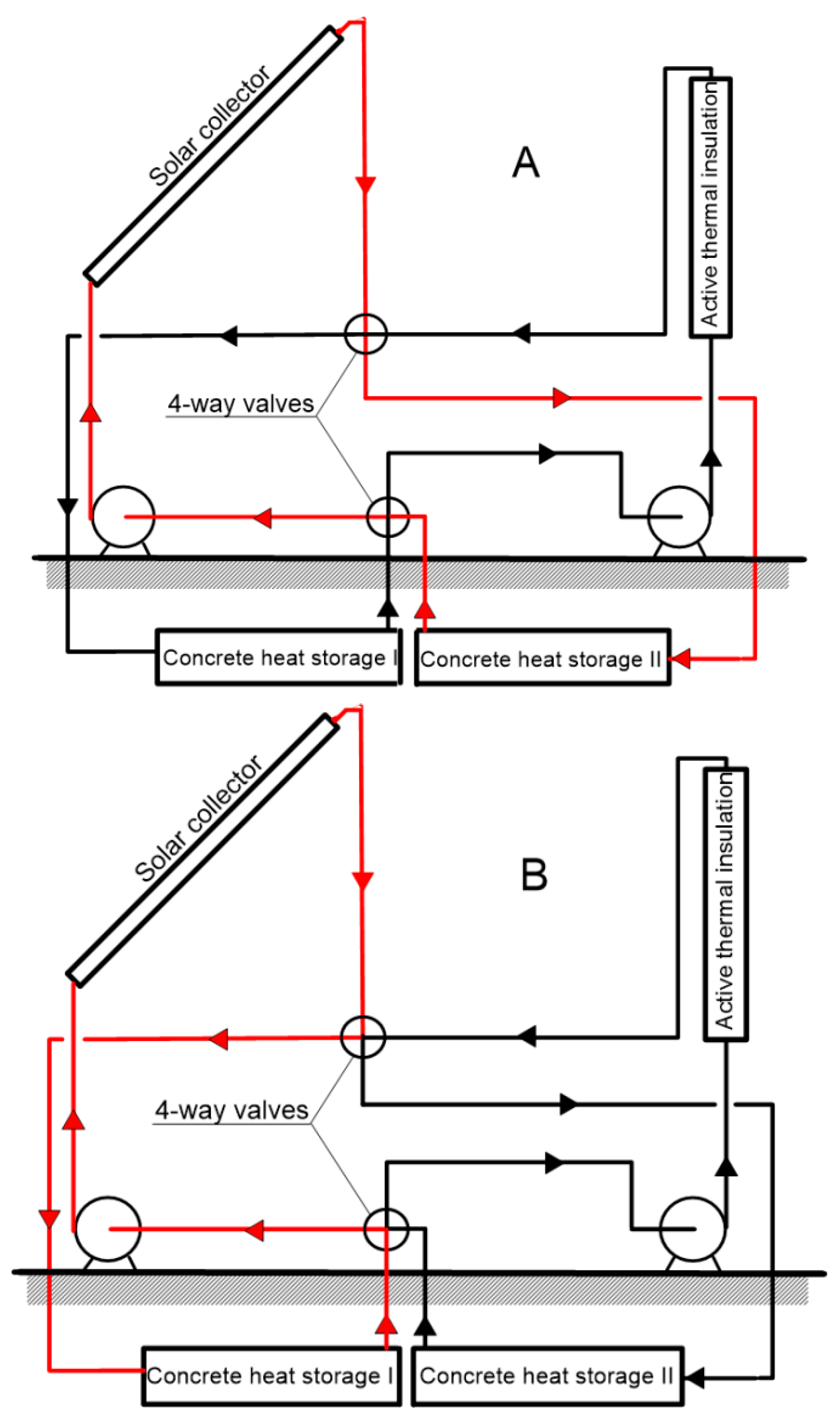

2. Description of the Mathematical Model

2.1. Assumptions

2.2. Usable Heat Produced in a Solar Collector

- (τα)—effective transmittance–absorptance product, -;

- UL—overall heat transfer coefficient between collector and environment, W/(m2K);

- Ta—ambient temperature, °C;

- Tst—the temperature at the inlet to the collector equals the temperature at the outlet from the thermal energy storage unit, °C.

- Ac—collector surface area, m2;

- FR—collector heat removal factor, -;

- —monthly average daily irradiation on a collector plane, J/(m2days);

- Δt—the cycle duration (with a monthly cycle, the number of days or seconds in the month), s or days.

2.3. Concrete Thermal Storage

- Ust—the overall heat transfer coefficient between the surface of the concrete slab walls with an average temperature of Tst and the ground with a temperature of Tg, W/(m2K).

- Qst—the amount of heat transferred from the storage to the ATI layer in one cycle (month), J.

- Tfmin—the minimum acceptable storage temperature at the end of the cycle, °C.

- Ti—storage temperature at the beginning of a given cycle (month), °C;

- cv—volumetric heat capacity of the thermal energy storage (concrete), J/(m3K).

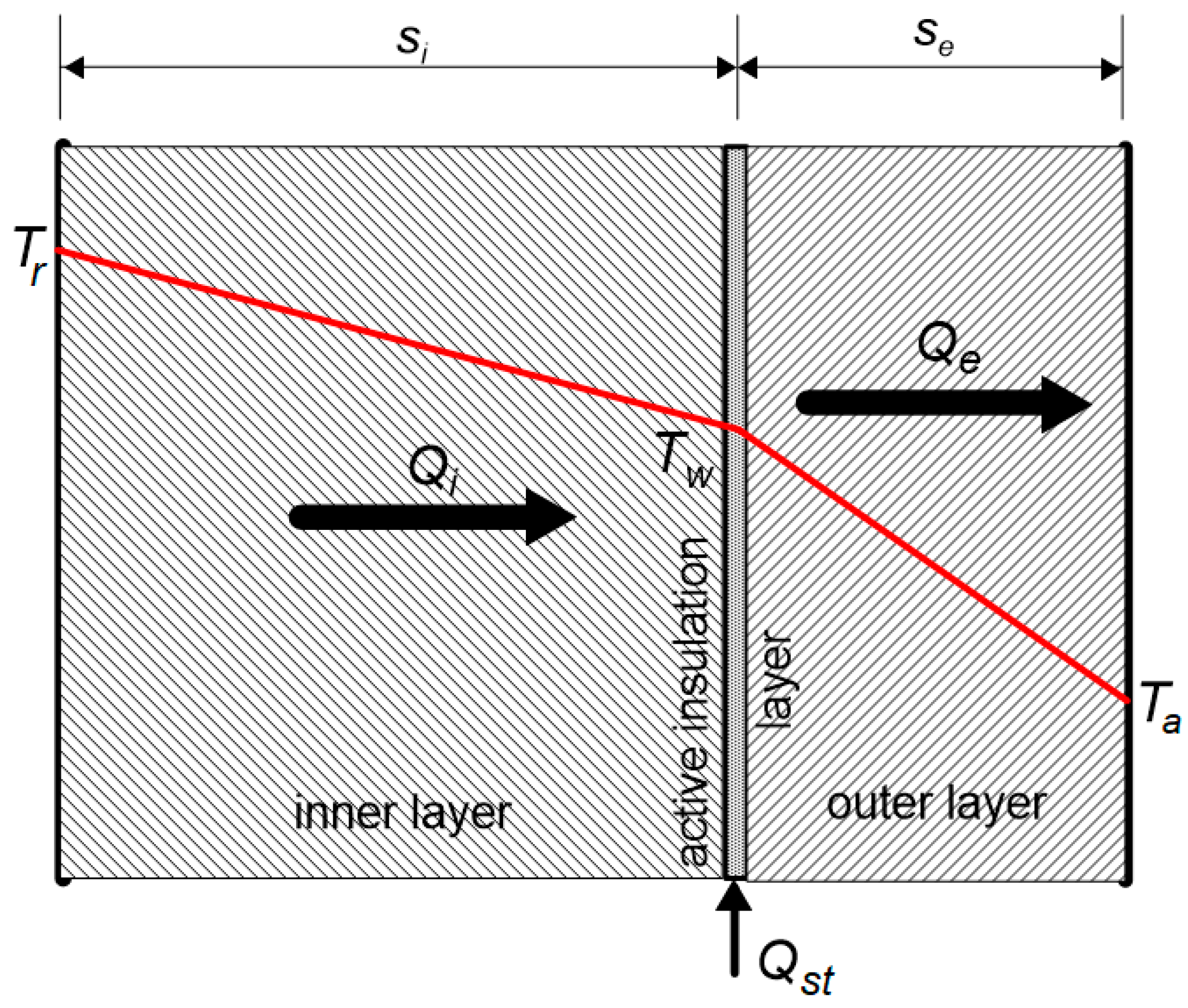

2.4. Active Thermal Insulation

- s—insulation thickness, m,

- kins—insulation conductivity, W/(mK).

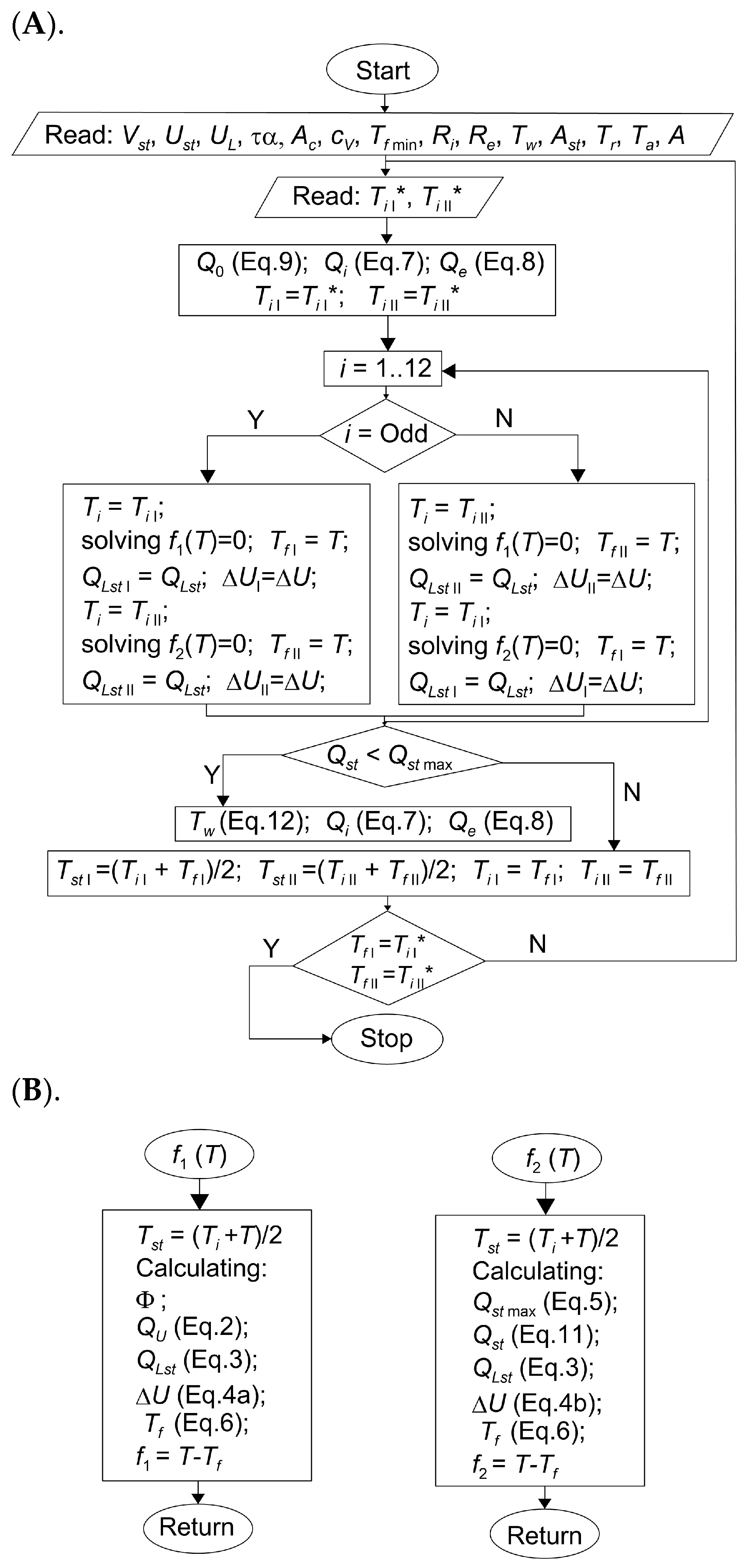

2.5. Calculation Algorithm

- x—depth, m;

- L—damping depth, m;

- Tsm—annually averaged value of the ground temperature, K;

- As—amplitude of the ground temperature, K;

- Ps—phase angle, rad;

- ω (=2π/365)—frequency, days−1 or s−1.

2.6. Economic Analysis

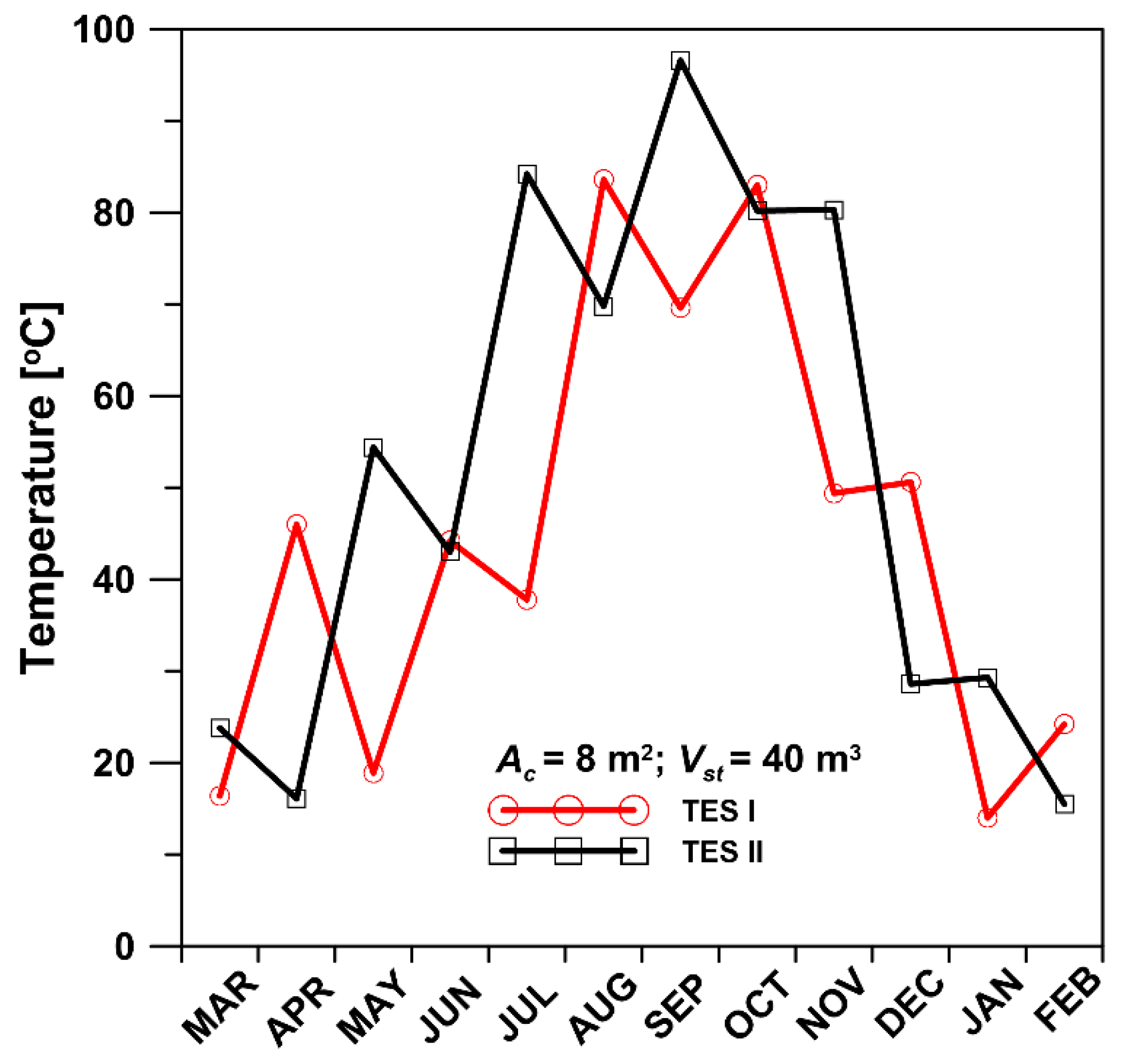

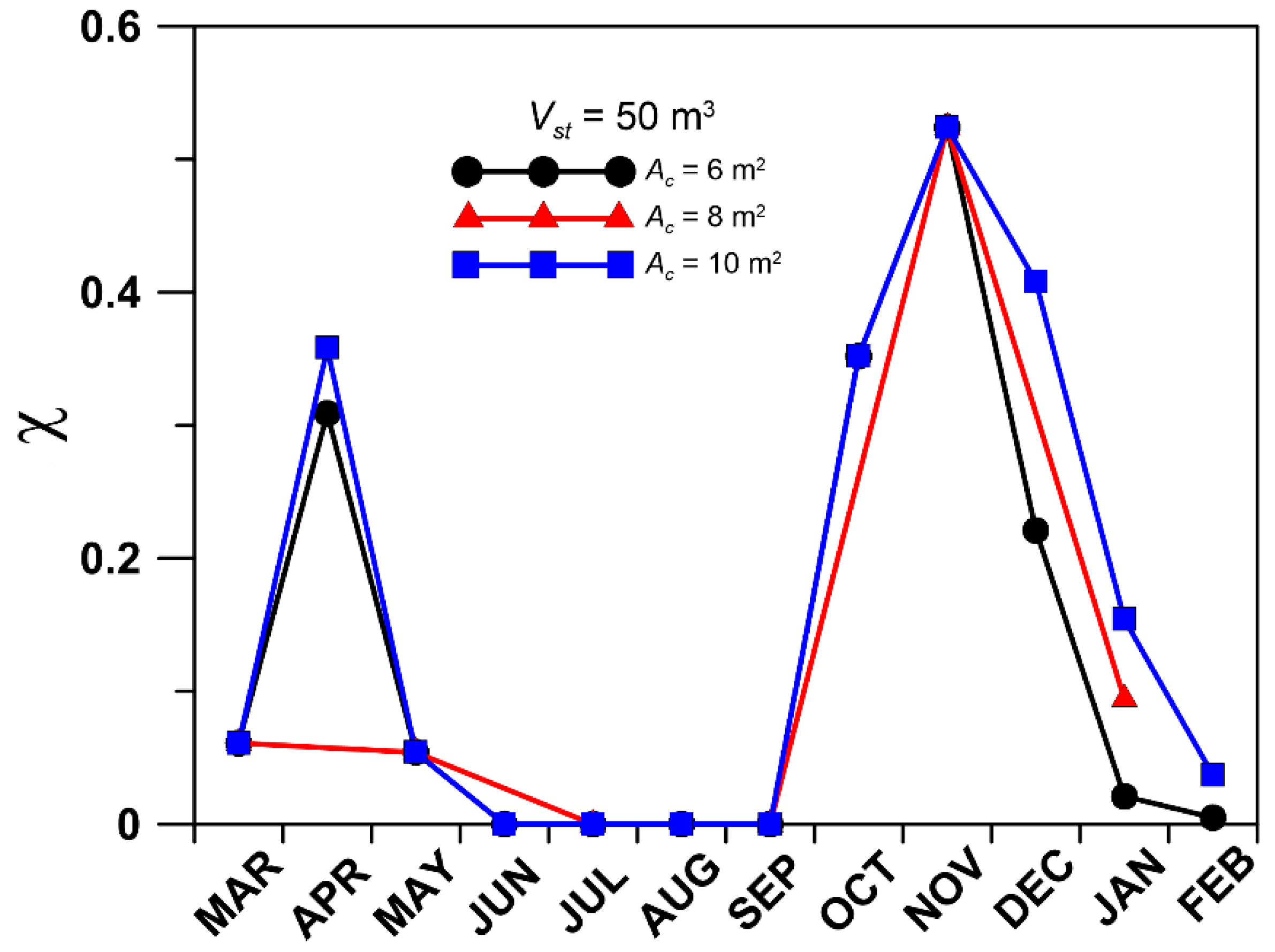

3. Results Discussion

4. Conclusions

- ∘

- Utilizing active thermal insulation (ATI) for building heating significantly reduces costs by harnessing low-cost, low-temperature heat sources delivered to exterior walls. This approach is particularly valuable in capturing energy from solar collectors.

- ∘

- Emphasis should be placed on sustainably managing and storing the energy generated by solar panels for future use in powering the ATI layer. Solar energy storage should be optimized to minimize heat loss, ensuring that it remains a negligible proportion of the energy supplied to the storage system.

- ∘

- The shape of the storage system is crucial for minimizing the ratio of external surface area to volume, which helps reduce heat loss. Equally important is the specific heat capacity of the storage medium. However, simulation results suggest that the proposed solution of placing concrete slabs beneath the building has significant drawbacks. High temperatures within the concrete storage negatively impact system efficiency by increasing heat losses. During the summer, inadequate insulation can exacerbate this issue, leading to additional heat leakage into the building.

- ∘

- Future research should abandon the use of TES in the form of concrete slabs and instead explore water-based storage with a different configuration than slabs. Consideration should be given to using cylindrical storage with water as the thermal storage medium. Consequently, the results of this work provide a direction for further research on energy storage aimed at improving the energy efficiency of the active thermal insulation layer.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | envelope of building area, m2; |

| Ac | collectors surface area, m2; |

| As | amplitude of the ground temperature, K; |

| cv | volumetric heat capacity of concrete, J/(m3K); |

| FR | collector heat removal factor; |

| monthly average daily irradiation on a collector plane, J/(m2day); | |

| L | damping depth, m; |

| Q | the amount of heat, J; |

| Ps | phase angle, rad; |

| R | thermal resistance, (m2K)/W; |

| t | time, s or days; |

| T | temperature, °C; |

| Tsm | annually averaged value of the ground temperature, K; |

| UL | overall heat transfer coefficient between collector and environment, W/(m2K); |

| Ust | overall heat transfer coefficient to the ground, W/(m2K); |

| Vst | volume of TES, m3; |

| x | depth, m; |

| β | collectors slope; |

| (τα) | effective transmittance–absorptance product; |

| Φ | utilizability; |

| Φlat | latitude; |

| χ | economic factor, -; |

| ω (=2π/365) | frequency, days−1 or s−1. |

| Subscripts | |

| a | ambient; |

| e | external; |

| i | initial or external; |

| r | room; |

| g | ground; |

| L | lost; |

| st | storage; |

| w | wall. |

References

- Iffa, E.; Hun, D.; Salonvaara, M.; Shrestha, S.; Lapsa, M. Performance evaluation of a dynamic wall integrated with active insulation and thermal energy storage systems. J. Energy Storage 2023, 46, 103815. [Google Scholar] [CrossRef]

- Navarro, L.; de Gracia, A.; Colclough, S.; Browne, M.; McCormack, S.J.; Griffiths, P.; Cabeza, L.F. Thermal energy storage in building integrated thermal systems: A review. Part 1. active storage systems. Renew. Energy 2016, 88, 26–547. [Google Scholar] [CrossRef]

- Kashan, M.E.; Fung, A.S.; Eisapour, A.H. Insulated concrete form foundation wall as solar thermal energy storage for Cold-Climate building heating system. Energy Convers. Manag. X 2023, 19, 100391. [Google Scholar]

- Abanda, F.H.; Byers, L. An investigation of the impact of building orientation on energy consumption in a domestic building using emerging BIM (Building Information Modelling). Energy 2016, 97, 517–527. [Google Scholar] [CrossRef]

- Ai, W.; Wang, L.; Lin, X.; Zhang, S.; Bai, Y.; Chen, H. Mathematical and thermo-economic analysis of thermal insulation for thermal energy storage applications. Renew. Energy 2023, 213, 233–245. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Incorporation of phase change materials into building envelope for thermal comfort and energy saving: A comprehensive analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar] [CrossRef]

- Dardour, S.; Mankai, S.; Almoneef, M.M.; Mbarek, M.; Sghaier, J. Energy performance based optimization of building envelope containing PCM combined with insulation considering various configurations. Energy Rep. 2023, 10, 895–909. [Google Scholar] [CrossRef]

- Murathan, E.K.; Manioğlu, G. Evaluation of phase change materials used in building components for conservation of energy in buildings in hot dry climatic regions. Renew. Energy 2020, 162, 1919–1930. [Google Scholar] [CrossRef]

- Rai, A.C. Energy performance of phase change materials integrated into brick masonry walls for cooling load management in residential buildings. Build. Environ. 2021, 199, 107930. [Google Scholar] [CrossRef]

- Li, Z.X.; Al-Rashed, A.A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavar, A.; Afrand, M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: Effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]

- Sharma, V.; Rai, A.C. Performance assessment of residential building envelopes enhanced with phase change materials. Energy Build. 2020, 208, 109664. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, Y.; Xie, K.; Medina, M.A. A parametric study on the thermal response of a building wall with a phase change material (PCM) layer for passive space cooling. J. Energy Storage 2022, 47, 103548. [Google Scholar] [CrossRef]

- Kishore, R.A.; Bianchi, M.V.; Booten, C.; Vidal, J.; Jackson, R. Parametric and sensitivity analysis of a PCM-integrated wall for optimal thermal load modulation in lightweight buildings. Appl. Therm. Eng. 2021, 187, 116568. [Google Scholar] [CrossRef]

- Kishore, R.A.; Bianchi, M.V.; Booten, C.; Vidal, J.; Jackson, R. Enhancing building energy performance by effectively using phase change material and dynamic insulation in walls. Appl. Energy 2021, 283, 116306. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Building envelope-combined phase change material and thermal insulation for energy-effective buildings during harsh summer: Simulation-based analysis. Energy Sustain. Dev. 2023, 72, 326–339. [Google Scholar] [CrossRef]

- Kalbasi, R.; Afrand, M. Which one is more effective to add to building envelope: Phase change material, thermal insulation, or their combination to meet zero-carbon-ready buildings? J. Clean. Prod. 2022, 367, 133032. [Google Scholar] [CrossRef]

- Abden, M.J.; Tao, Z.; Alim, M.A.; Pan, Z.; George, L.; Wuhrer, R. Combined use of phase change material and thermal insulation to improve energy efficiency of residential buildings. J. Energy Storage 2022, 56, 105880. [Google Scholar] [CrossRef]

- Arumugam, P.; Ramalingam, V.; Vellaichamy, P. Effective PCM, insulation, natural and/or night ventilation techniques to enhance the thermal performance of buildings located in various climates—A review. Energy Build. 2022, 258, 111840. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Haryoko, L.A.; Taufiqurrahman, I.; Chen, L.; Jiang, L.; Sasmito, A.P. Optimization of an innovative hybrid thermal energy storage with phase change material (PCM) wall insulator utilizing taguchi method. J. Energy Storage 2022, 49, 104067. [Google Scholar] [CrossRef]

- Solgi, E.; Hamedani, Z.; Fernando, R.; Kari, B.M. A parametric study of phase change material characteristics when coupled with thermal insulation for different Australian climatic zones. Build. Environ. 2019, 163, 106317. [Google Scholar] [CrossRef]

- Arumugam, P.; Ramalingam, V.; Vellaichamy, P. Optimal positioning of phase change material and insulation through numerical investigations to reduce cooling loads in office buildings. J. Energy Storage 2022, 52, 104946. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, Y. Evaluation and optimisation of hybrid sensible-latent heat thermal energy storage unit with natural stones to enhance heat transfer. Renew. Energy 2023, 215, 118921. [Google Scholar] [CrossRef]

- Braun, J.E.; Klein, S.A.; Mitchell, J.W. Seasonal storage of energy in solar heating. Sol. Energy 1981, 26, 403–411. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; p. 928. [Google Scholar]

- Li, J.; Li, X.; Wang, Y.; Tu, J. Long-term performance of a solar water heating system with a novel variable-volume tank. Renew. Energy 2021, 164, 230–241. [Google Scholar] [CrossRef]

- El-Sebaey, M.S.; Mousavi, S.M.T.; Sathyamurthy, R.; Panchal, H.; Essa, F.A. A detailed review of various design and operating parameters affecting the thermal performance augmentation of flat-plate solar collectors. Int. J. Ambient. Energy 2024, 45, 2351100. [Google Scholar] [CrossRef]

- El-Sebaey, M.S.; Ellman, A.; El-Din, S.S.; Essa, F.A. Thermal Performance Evaluation for Two Designs of Flat-Plate Solar Air Heater: An Experimental and CFD Investigations. Processes 2023, 11, 1227. [Google Scholar] [CrossRef]

- El-Sebaey, M.S. Proposing novel approach for indirect solar dryer integrated with active-fan and passive-chimney: An experimental and analytical investigation. Energy 2024, 304, 132215. [Google Scholar] [CrossRef]

- Sathyamurthy, R.; Ali, H.M.; Said, Z.; Kabeel, A.E.; El-Sebaey, M.S.; Gopalsamy, S.; Nagaraj, M.; Almasoud, N.; Alomar, T.S. Enhancing solar still thermal performance: The role of surface coating and thermal energy storage in repurposed soda cans. J. Energy Storage 2024, 77, 109807. [Google Scholar] [CrossRef]

- Isomax-Terrasol. Available online: https://isomax-terrasol.eu/ (accessed on 28 August 2024).

- Meggers, F.; Baldini, L.; Leibundgut, H. An innovative use of renewable ground heat for insulation low energy building system. Energies 2012, 5, 3149–3166. [Google Scholar] [CrossRef]

- Shen, C.; Li, X. Energy saving potential of pipe-embedded building envelope utilizing low-temperature hot water in the heating season. Energy Build. 2017, 138, 318–331. [Google Scholar] [CrossRef]

- Krzaczek, M.; Kowalczuk, Z. Thermal Barrier as a technique of indirect heating and cooling for residential buildings. Energy Build. 2011, 4, 823–837. [Google Scholar] [CrossRef]

- Krecke, E.; Ulbrich, R.; Radlak, G. Connection of Solar and Near-Surface Geothermal Energy in Isomax Technology. In Proceedings of the CESB 07 Prague International Conference, Prague, Czech Republic, 24–25 September 2007; pp. 622–628. [Google Scholar]

- Kisilewicz, T.; Fedorczak-Cisak, M.; Sadowska, B.; Ickiewicz, I.; Barkanyi, T.; Bomberg, M.; Gobcewicz, E. On the results of long-term winter testing of active thermal insulation. Energy Build. 2023, 296, 113412. [Google Scholar] [CrossRef]

- Kalus, D.; Janik, P.; Koudelkova, D.; Muckova, V.; Sokol, M. Contribution to research on ground heat storages as part of building energy systems using RES. Energy Build. 2022, 267, 112125C. [Google Scholar] [CrossRef]

- Król, B.; Kupiec, K. Optimal location of the active thermal insulation layer in the building envelope. Thermo 2023, 3, 176–199. [Google Scholar] [CrossRef]

- Photovoltaic Geographical Information System (PVGIS). Available online: https://joint-research-centre.ec.europa.eu/photovoltaic-geographical-information-system-pvgis_en (accessed on 28 August 2024).

- Larwa, B.; Kupiec, K. Heat transfer in the ground with a horizontal heat exchanger installed–Long-term thermal effect. Appl. Therm. Eng. 2020, 164, 114539. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Clarendon Press: Oxford, UK, 1959. [Google Scholar]

| Symbol | Value | |

|---|---|---|

| Solar collectors | Φlat | 50° |

| β | 40° | |

| FR | 0.95 | |

| UL | 2.78 W/(m2K) | |

| (τα) | 0.75 | |

| Ac | 6 ÷ 10 m2 | |

| Concrete thermal energy storage | Vst | 30 ÷ 50 m3 |

| cV | 2.4∙106 J/(m3K) | |

| Ust | 0.08 W/(m2K) | |

| Active thermal insulation | Re | 2.5 m2K/W |

| Ri | 2.5 m2K/W | |

| A | 250 m2 | |

| Tg | 2.4 ÷ 17.1 °C | |

| Ta | −7.6 ÷ 20.0 °C | |

| Tr | 20 °C | |

| Tw | 16.5 °C | |

| (2.8 ÷ 19)∙109 J/(m2day) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Król, B. Analysis of the Use of Energy Storage in the Form of Concrete Slabs as a Method for Sustainable Energy Management in a System with Active Thermal Insulation and Solar Collectors. Sustainability 2024, 16, 7645. https://doi.org/10.3390/su16177645

Król B. Analysis of the Use of Energy Storage in the Form of Concrete Slabs as a Method for Sustainable Energy Management in a System with Active Thermal Insulation and Solar Collectors. Sustainability. 2024; 16(17):7645. https://doi.org/10.3390/su16177645

Chicago/Turabian StyleKról, Barbara. 2024. "Analysis of the Use of Energy Storage in the Form of Concrete Slabs as a Method for Sustainable Energy Management in a System with Active Thermal Insulation and Solar Collectors" Sustainability 16, no. 17: 7645. https://doi.org/10.3390/su16177645

APA StyleKról, B. (2024). Analysis of the Use of Energy Storage in the Form of Concrete Slabs as a Method for Sustainable Energy Management in a System with Active Thermal Insulation and Solar Collectors. Sustainability, 16(17), 7645. https://doi.org/10.3390/su16177645