Performance Evaluation of Compost of Windrow Turner Machine Using Agriculture Waste Materials

Abstract

:1. Introduction

2. Material and Methods

2.1. Study Area

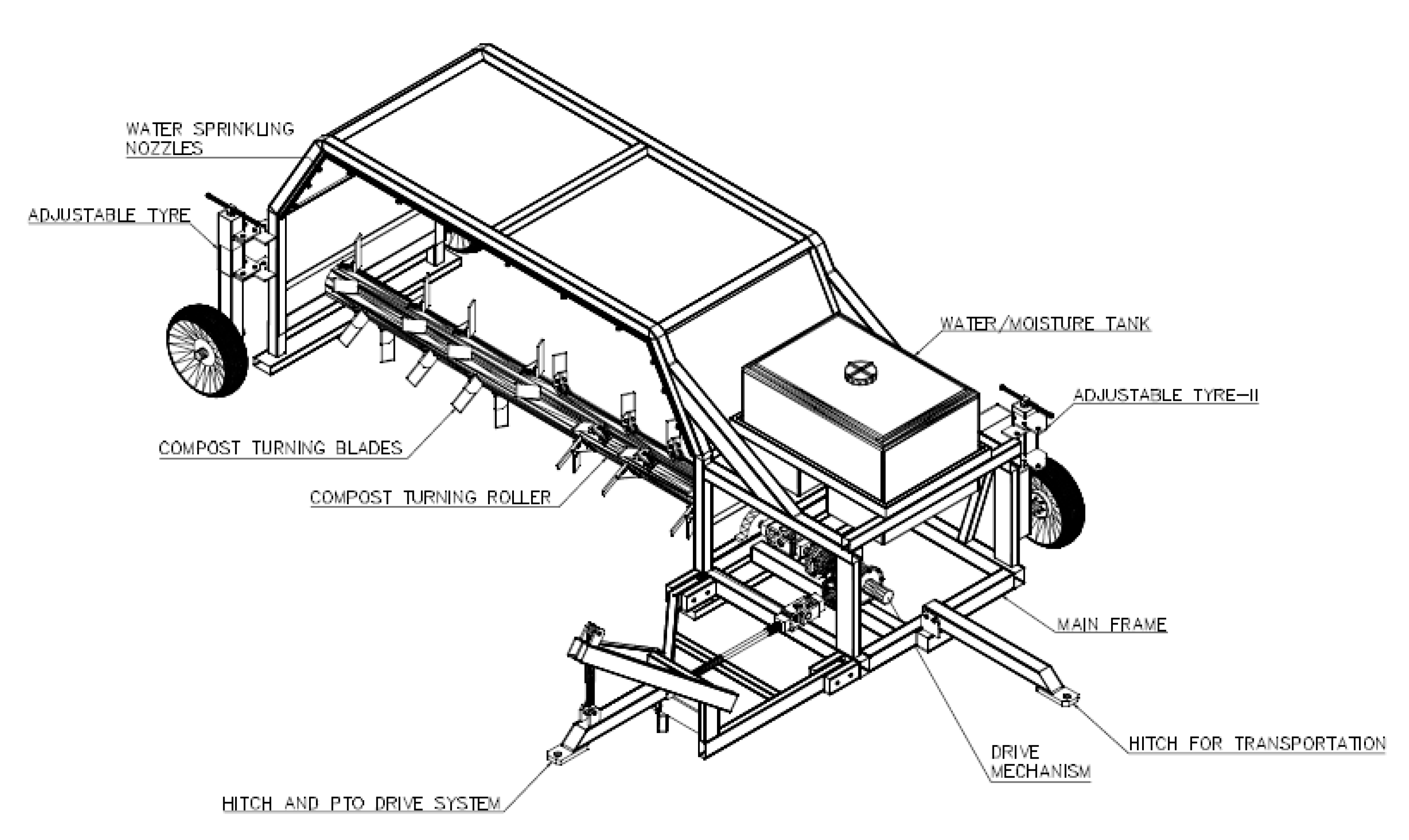

2.2. Compost Windrow Turner Machine

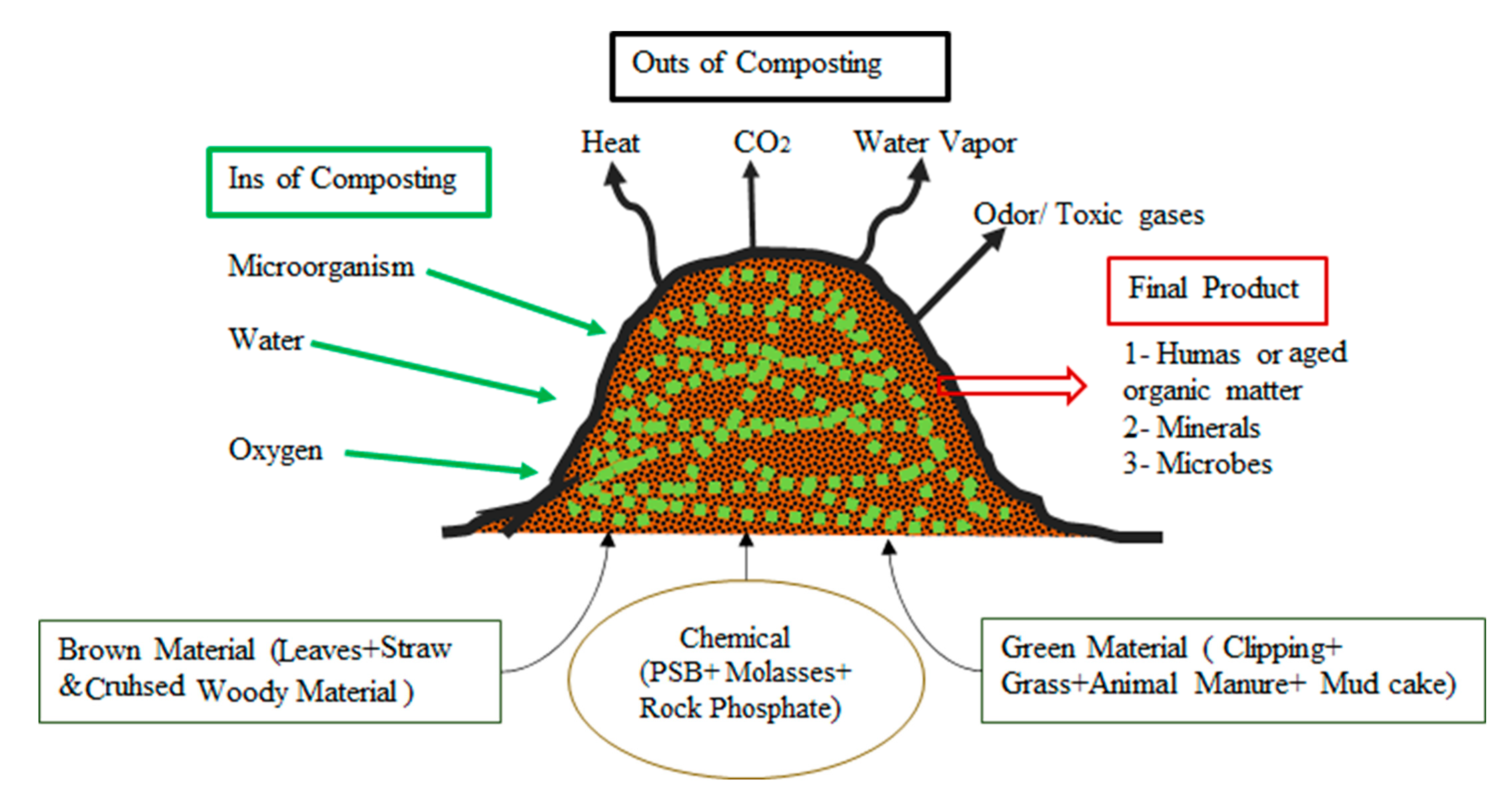

2.3. Compost Process and Data Collection

2.4. Statistical Analysis

3. Results and Discussions

3.1. Compost Yield Data

3.2. Cation Exchange Capacity (CEC) Results

3.3. Results for Electrical Conductivity and Carbon to Nitrogen Ratio

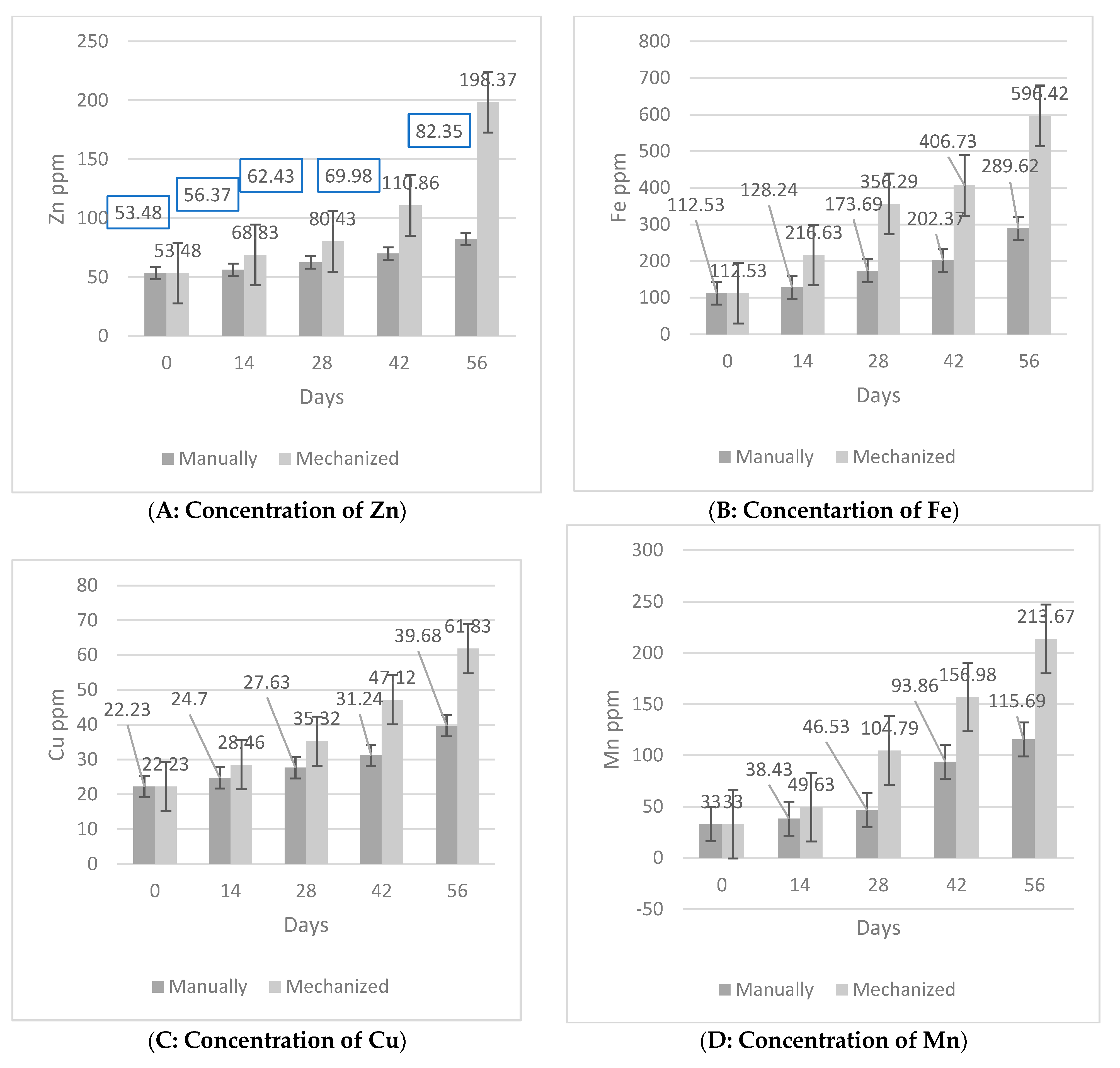

3.4. Results for Variation in Micronutrients during Composting Process

3.5. Discussion and Results of Temperature Variation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rastegari, H.; Nooripoor, M.; Sharifzadeh, M.; Petrescu, D.C. Drivers and barriers in farmers’ adoption of vermicomposting as keys for sustainable agricultural waste management. Int. J. Agric. Sustain. 2023, 21, 2230826. [Google Scholar] [CrossRef]

- Ali, M.; Geng, Y.; Robins, D.; Cooper, D.; Roberts, W.; Vogtländer, J. Improvement of waste management practices in a fast expanding sub-megacity in Pakistan, on the basis of qualitative and quantitative indicators. Waste Manag. 2019, 85, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Hussain, J.; Shah, S.; Ali, M.; Shah, J. Determine the macro-micro nutrients and some physico-chemical properties of soil case study of Jamshoro Distric Sindh, Pakistan. JIS 2020, 6, 30–33. [Google Scholar] [CrossRef]

- Bhat, M.; Mani, I.; De, D.; Lande, S. Influence of operational parameters of windrow turner for mass production of compost. Int. J. Agric. Stat. Sci 2013, 9, 19–28. [Google Scholar]

- Alkarimiah, R.; Suja, F. Effects of Technical Factors Towards Achieving the Thermophilic Temperature Stage in Composting Process and the Benefits of Closed Rector System Compared to Conventional Method—A Mini Review. Appl. Ecol. Environ. Res. 2019, 17, 9979–9996. [Google Scholar] [CrossRef]

- Ventorino, V.; Pascale, A.; Fagnano, M.; Adamo, P.; Faraco, V.; Rocco, C.; Fiorentino, N.; Pepe, O. Soil tillage and compost amendment promote bioremediation and biofertility of polluted area. J. Clean. Prod. 2019, 239, 118087. [Google Scholar] [CrossRef]

- Hashim, S.; Waqas, M.; Rudra, R.P.; Khan, A.A.; Mirani, A.A.; Sultan, T.; Ehsan, F.; Abid, M.; Saifullah, M. On-Farm Composting of Agricultural Waste Materials for Sustainable Agriculture in Pakistan. Scientifica 2022, 2022, 5831832. [Google Scholar] [CrossRef]

- Mehdi, S.; Sarfraz, M.; Qureshi, M.; Ilyas, M.; Zaka, M.; Qazi, M.; Rafa, H. Site-Specific Phosphorus Management with Inorganic Fertilizer and Municipal Solid Waste Compost application in Salt Affected Soil. Pak. J. Agric. Sci. 2018, 55, 103–110. [Google Scholar]

- Ali, A.; Khalid, A.; Butt, M.; Mehmood, R.; Mahmood, S.A.; Sami, J.; Qureshi, J.; Shafique, K.; Khan, A.; Waheed, R. Towards a remote sensing and GIS-based technique to study population and urban growth: A case study of Multan. Adv. Remote Sens. 2018, 7, 245–258. [Google Scholar] [CrossRef]

- Trupiano, D.; Cocozza, C.; Baronti, S.; Amendola, C.; Vaccari, F.P.; Lustrato, G.; Di Lonardo, S.; Fantasma, F.; Tognetti, R.; Scippa, G.S. The effects of biochar and its combination with compost on lettuce (Lactuca sativa L.) growth, soil properties, and soil microbial activity and abundance. Int. J. Agron. 2017, 2017, 3158207. [Google Scholar] [CrossRef]

- Ren, X.; Zeng, G.; Tang, L.; Wang, J.; Wan, J.; Wang, J.; Deng, Y.; Liu, Y.; Peng, B. The potential impact on the biodegradation of organic pollutants from composting technology for soil remediation. Waste Manag. 2018, 72, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Uyizeye, O.C.; Thiet, R.K.; Knorr, M.A. Effects of community-accessible biochar and compost on diesel-contaminated soil. Bioremediat. J. 2019, 23, 107–117. [Google Scholar] [CrossRef]

- Pose-Juan, E.; Igual, J.M.; Sánchez-Martín, M.J.; Rodríguez-Cruz, M.S. Influence of Herbicide Triasulfuron on Soil Microbial Community in an Unamended Soil and a Soil Amended with Organic Residues. Front. Microbiol. 2017, 8, 378. [Google Scholar] [CrossRef] [PubMed]

- Clay, D.E.; Alverson, R.; Johnson, J.M.; Karlen, D.L.; Clay, S.; Wang, M.Q.; Bruggeman, S.; Westhoff, S. Crop Residue Management Challenges: A Special Issue Overview. Agron. J. 2019, 111, 1–3. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Dróżdż, D.; Malińska, K.; Kacprzak, M.; Mrowiec, M.; Szczypiór, A.; Postawa, P.; Stachowiak, T. Potential of fish pond sediments composts as organic fertilizers. Waste Biomass Valorization 2020, 11, 5151–5163. [Google Scholar] [CrossRef]

- Qasim, W.; Lee, M.H.; Moon, B.E.; Okyere, F.G.; Khan, F.; Nafees, M.; Kim, H.T. Composting of chicken manure with a mixture of sawdust and wood shavings under forced aeration in a closed reactor system. Int. J. Recycl. Org. Waste Agric. 2018, 7, 261–267. [Google Scholar] [CrossRef]

- Cook, K.L.; Ritchey, E.L.; Loughrin, J.H.; Haley, M.; Sistani, K.R.; Bolster, C.H. Effect of turning frequency and season on composting materials from swine high-rise facilities. Waste Manag. 2015, 39, 86–95. [Google Scholar] [CrossRef]

- He, X.; Han, L.; Fu, B.; Du, S.; Liu, Y.; Huang, G. Effect and microbial reaction mechanism of rice straw biochar on pore methane production during mainstream large-scale aerobic composting in China. J. Clean. Prod. 2019, 215, 1223–1232. [Google Scholar] [CrossRef]

- Biruntha, M.; Karmegam, N.; Archana, J.; Karunai Selvi, B.; John Paul, J.A.; Balamuralikrishnan, B.; Chang, S.W.; Ravindran, B. Vermiconversion of biowastes with low-to-high C/N ratio into value added vermicompost. Bioresour. Technol. 2020, 297, 122398. [Google Scholar] [CrossRef]

- Waqas, M.; Hashim, S.; Humphries, U.W.; Ahmad, S.; Noor, R.; Shoaib, M.; Naseem, A.; Hlaing, P.T.; Lin, H.A. Composting Processes for Agricultural Waste Management: A Comprehensive Review. Processes 2023, 11, 731. [Google Scholar] [CrossRef]

- Patil, P.M.; Mahamuni, P.P.; Shadija, P.G.; Bohara, R.A. Conversion of organic biomedical waste into value added product using green approach. Environ. Sci. Pollut. Res. 2019, 26, 6696–6705. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, L.; Sha, G.; Liu, C.; Wang, Z.; Wang, L. Aerobic composting as an effective cow manure management strategy for reducing the dissemination of antibiotic resistance genes: An integrated meta-omics study. J. Hazard. Mater. 2020, 386, 121895. [Google Scholar] [CrossRef]

- Kebibeche, H.; Khelil, O.; Kacem, M.; Harche, M.K. Addition of wood sawdust during the co-composting of sewage sludge and wheat straw influences seeds germination. Ecotoxicol. Environ. Saf. 2019, 168, 423–430. [Google Scholar] [CrossRef]

- Aguilar-Paredes, A.; Valdés, G.; Araneda, N.; Valdebenito, E.; Hansen, F.; Nuti, M. Microbial community in the composting process and its positive impact on the soil biota in sustainable agriculture. Agronomy 2023, 13, 542. [Google Scholar] [CrossRef]

- Huynh, T.L.; Le, T.K.O.; Wong, Y.J.; Phan, C.T.; Trinh, T.L. Towards sustainable composting of source-separated biodegradable municipal solid waste—Insights from Long An Province, Vietnam. Sustainability 2023, 15, 13243. [Google Scholar] [CrossRef]

| Organic Waste Use | Animal Manure | Rice Residue | Sewage Sludge |

|---|---|---|---|

| Total Nitrogen % | 2.21 | 0.87 | 2.43 |

| Total Organic Carbon% | 38.76 | 42.34 | 41.58 |

| C/N Ratio | 17.53 | 48.66 | 17.11 |

| Total Phosphorus % | 6.4 | 0.58 | 0.89 |

| Total Potassium % | 0.97 | 0.35 | 0.68 |

| Bulk Density kg/m3 | 1043.6 | 68.21 | 398.25 |

| Moisture Content % | 78.12 | 4.67 | 3.91 |

| Time Period | Cation Exchange Capacity (meq/100 g) | |

|---|---|---|

| Pile 1 (Mechanized Turning) * | Pile 2 (Manual Turning) | |

| 0 | 21.23 ± 1.01 | 21.23 ± 1.01 |

| 2 | 38.56 ± 1.13 | 23.17 ± 0.54 |

| 4 | 49.63 ± 0.52 | 28.86 ± 1.20 |

| 6 | 57.37 ± 0.96 | 31.16 ± 0.75 |

| 8 | 68.87 ± 0.85 | 33.28 ± 0.82 |

| Time Period | Electrical Conductivity (ds/m) | |

|---|---|---|

| Pile 1 (Mechanized Turning) * | Pile 2 (Manual Turning) | |

| 0 | 1.98 ± 0.15 | 1.98 ± 0.15 |

| 2 | 3.86 ± 0.25 | 2.46 ± 0.11 |

| 4 | 5.78 ± 0.33 | 4.86 ± 0.30 |

| 6 | 8.88 ± 0.30 | 5.12 ± 0.13 |

| 8 | 11.34 ± 0.47 | 7.86 ± 0.36 |

| Time Period | Pile 1 (Mechanized Turning) | Pile 2 (Manual Turning) | ||||

|---|---|---|---|---|---|---|

| %C | %N | C/N Ratio | %C | %N | C/N Ratio | |

| 0 | 43.53 ± 0.83 | 1.38 ± 0.12 | 31.56 ± 7.18 | 43.53 ± 0.52 | 1.38 ± 0.12 | 31.56 ± 4.49 |

| 2 | 39.34 ± 81 | 1.56 ± 0.14 | 25.23 ± 5.98 | 43.14 ± 0.32 | 1.52 ± 0.17 | 28.34 ± 1.84 |

| 4 | 38.48 ± 69 | 1.71 ± 0.12 | 22.45 ± 5.56 | 42.99 ± 0.51 | 1.66 ± 0.21 | 25.89 ± 2.46 |

| 6 | 36.96 ± 0.45 | 2.09 ± 0.50 | 17.67 ± 0.91 | 41.36 ± 0.60 | 1.92 ± 0.17 | 21.54 ± 3.46 |

| 8 | 34.34 ± 0.93 | 2.27 ± 0.48 | 15.12 ± 1.94 | 40.32 ± 0.70 | 2.14 ± 0.25 | 18.87 ± 2.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashim, S.; Bashir, R.; Khan, A.A.; Mirani, A.A.; Shoaib, M.; Razzaq, A.; Ehsan, F.; Munir, F. Performance Evaluation of Compost of Windrow Turner Machine Using Agriculture Waste Materials. Sustainability 2024, 16, 7779. https://doi.org/10.3390/su16177779

Hashim S, Bashir R, Khan AA, Mirani AA, Shoaib M, Razzaq A, Ehsan F, Munir F. Performance Evaluation of Compost of Windrow Turner Machine Using Agriculture Waste Materials. Sustainability. 2024; 16(17):7779. https://doi.org/10.3390/su16177779

Chicago/Turabian StyleHashim, Sarfraz, Rehan Bashir, Alamgir Akhtar Khan, Asif Ali Mirani, Muhammad Shoaib, Abdul Razzaq, Farrukh Ehsan, and Faseeha Munir. 2024. "Performance Evaluation of Compost of Windrow Turner Machine Using Agriculture Waste Materials" Sustainability 16, no. 17: 7779. https://doi.org/10.3390/su16177779

APA StyleHashim, S., Bashir, R., Khan, A. A., Mirani, A. A., Shoaib, M., Razzaq, A., Ehsan, F., & Munir, F. (2024). Performance Evaluation of Compost of Windrow Turner Machine Using Agriculture Waste Materials. Sustainability, 16(17), 7779. https://doi.org/10.3390/su16177779