Optimization and Analysis of the Impact of Food Hub Location on GHG Emissions in a Short Food Supply Chain

Abstract

:1. Introduction

1.1. Research Gap

1.2. Objective of the Paper

1.3. Contribution of the Paper

- Integrating strategic decisions with tactical decisions to propose a hub location–vehicle planning problem in SFSCs;

- Incorporating real-world constraints such as products demand/production unbalance;

- Providing a model for estimating individual food hub GHG emissions by a piece-wise linear function;

- Integrating hub selection with the evaluation of GHG emissions across various hub sizes and various food production levels;

- Considering Normandy, France, as an realistic case study for evaluating the proposed framework.

2. Literature Review

2.1. Short Food Supply Chains (SFSCs)

2.2. Food Hubs in SFSCs

- Direct shipping happens when freight is delivered directly from its origin to its destination;

- Indirect shipping occurs when freight, or part of the freight, is transited through one or more intermediate facilities (e.g., cross-docks, distribution centers, or hubs) before reaching its destination.

2.3. Multi-Commodities in SFSCs

- Strategic planning decisions: they include concerning the infrastructure of the network, typically the number and the location of the facilities;

- Tactical planning decisions: they include the routing of freight through the network and allocation of customers to the intermediate facilities.

2.4. Logistic Issues in SFSCs

2.5. Greenhouse Gas (GHG) Emissions in SFSCs

2.6. Two-Echelon Location Routing Problem in SFSCs from the OR Perspectives

3. The Two-Echelon Distribution System in SFSCs and Optimization Issues

3.1. Presentation of the Logistic Scheme

- Farmers serving as the origins or production points within the network,

- Food hubs acting as intermediate points for food collection, storage, and distribution within the network,

- Consumers representing all endpoints for food consumption within the network.

3.2. Optimization of Food Hub Design and Selection

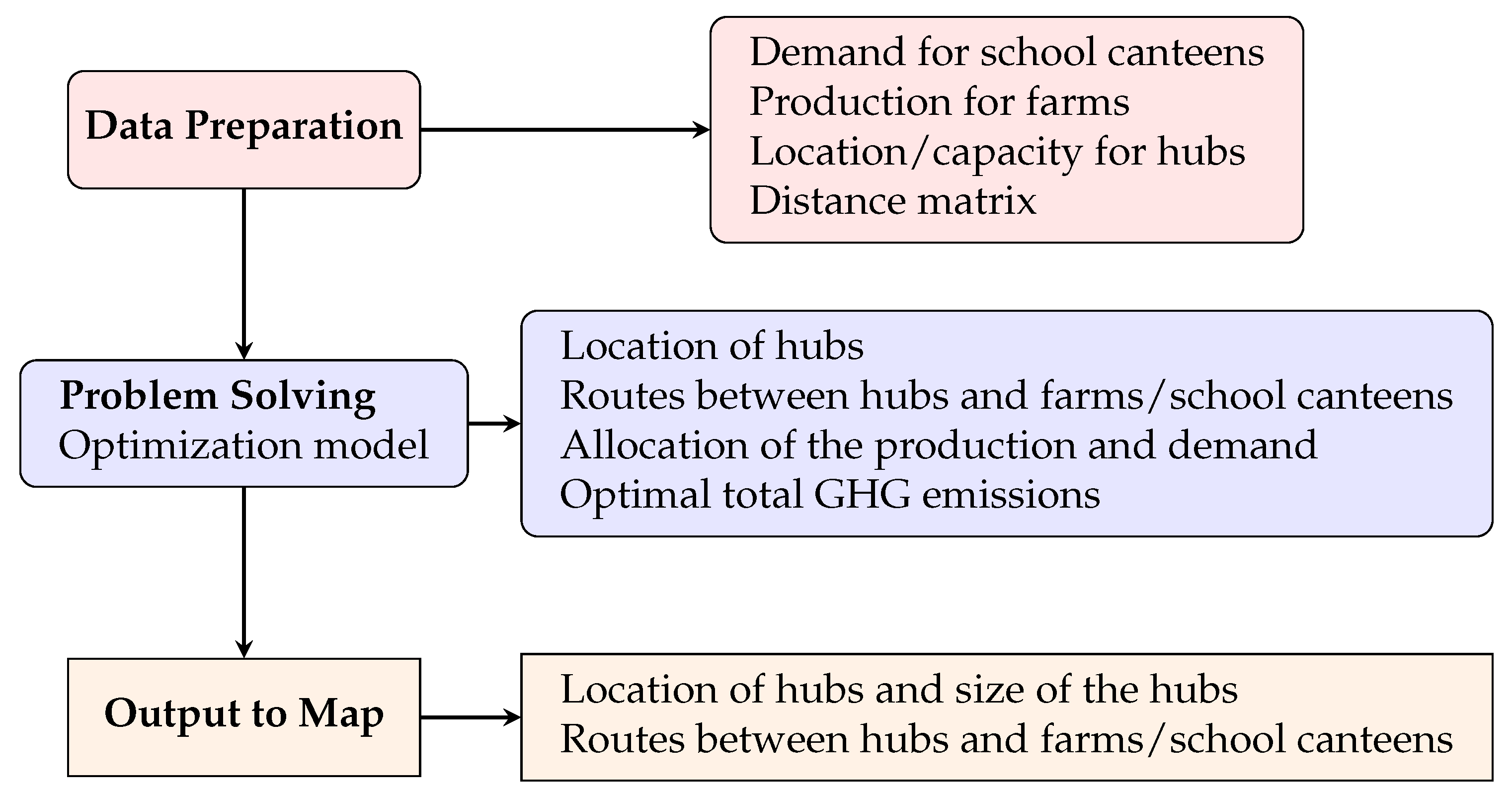

4. Methodology and Material

4.1. Framework for Assessing Total GHG Emissions

4.1.1. Estimation of the Emission by Transportation

4.1.2. Estimating the Emission by Each Hub

- Emission Sources

- Unit of Analysis

- Facility Consumption Assumptions

- Small Warehouse: Pallet capacity of 345 pallets;

- Large Warehouse: Pallet capacity exceeding 5000 pallets.

- The weight difference between food types and packaging configurations is negligible, implying all pallets of fruit and vegetable share the same weight;

- All pallets experience the same number of dwell days in a facility, irrespective of the food type or destination market;

- The energy consumed due to cold sterilization is distributed across all pallets moving through the facility, with the impact of fruit destined for different markets considered negligible;

- The time aspect is incorporated by collecting average dwell days or obtaining the average utilization percentage of the facilities. For example, the estimated dwell days for fruit in the facility are noted as 6.72 days, according to [30].

- Energy-to-Emission Conversion

- Electricity: The emission factor (EF) for electricity is obtained from Carbon Footprint Ltd’s 2023 Integrated Report, https://www.carbonfootprint.com/international_electricity_factors.html, accessed on 30 July 2023, which, for example, reveals an EF of 0.06207 kg CO2 per kWh for France consumers. Nevertheless, it is imperative for readers to specify this value in accordance with the region under study; this figure can fluctuate significantly based on the country and region.

- Diesel: The EF for diesel fuel (World-to-Wheel of 3.24 kg CO2 per unit) is sourced from the European Standard [84].

- Hub CO2 Emission Function

4.2. The Mathematical Formulation of the Problem

4.2.1. Input Data

- Parameters

- be the Emission Function of the hub . The function is defined with the piece-wise linear objective function as in Figure 2;

- be the transportation emission between the farm and the hub ;

- be the unit transportation emission between the hub and the consumer ;

- be the demand quantity of customer for product for the period ;

- be the quantity of product produced by farm for the period ;

- , be the truck capacity of farm and of consumer ;

- be the pallet capacity defined with respect to each product .

- Assumptions

- Case 1: ;

- Case 2: .

4.2.2. Decision Variables

- be the quantity of product transported on transition (from the farm a to the hub h) for the period ;

- be the quantity of product transported on transition (from the hub h to the consumer c) for the period ;

- be the number of pallets passing through hub for the period ;

- be the number of trucks used for each farm–hub pair for the period ;

- be the number of trucks used for each hub–consumer pair for the period ;

- if the transportation link for the farm–hub pair is activated for period , 0 otherwise;

- if the transportation link for the hub–consumer pair is activated for period , 0 otherwise;

- if the hub is open, 0 otherwise.

4.2.3. Problem Formulation

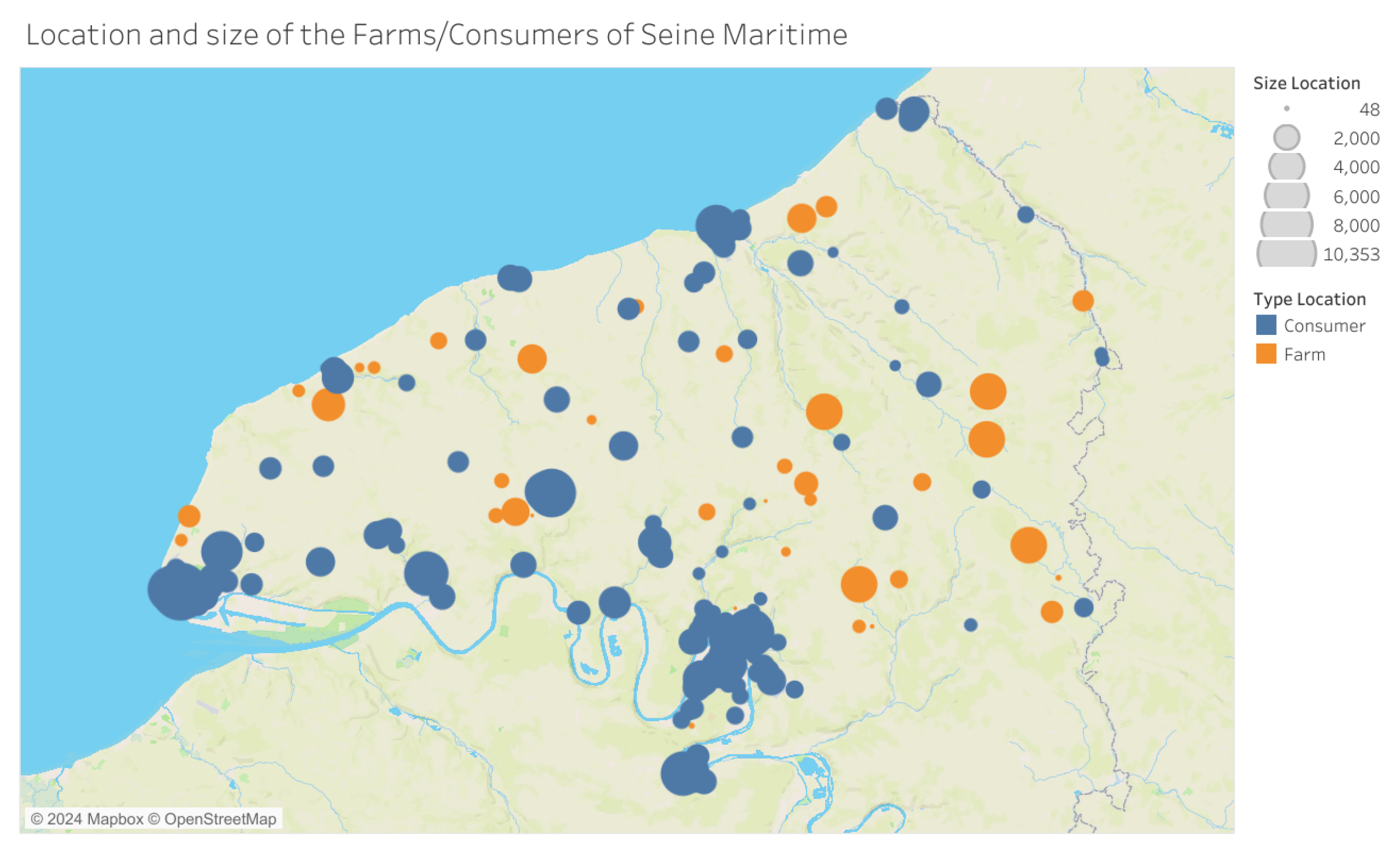

5. Case Study and Results

5.1. Data Collection

5.1.1. Demand for School Canteens

5.1.2. Production for Farms

5.1.3. Candidates Hub Locations

5.1.4. Distance Matrix for the Location Pairs

5.1.5. Truck Types

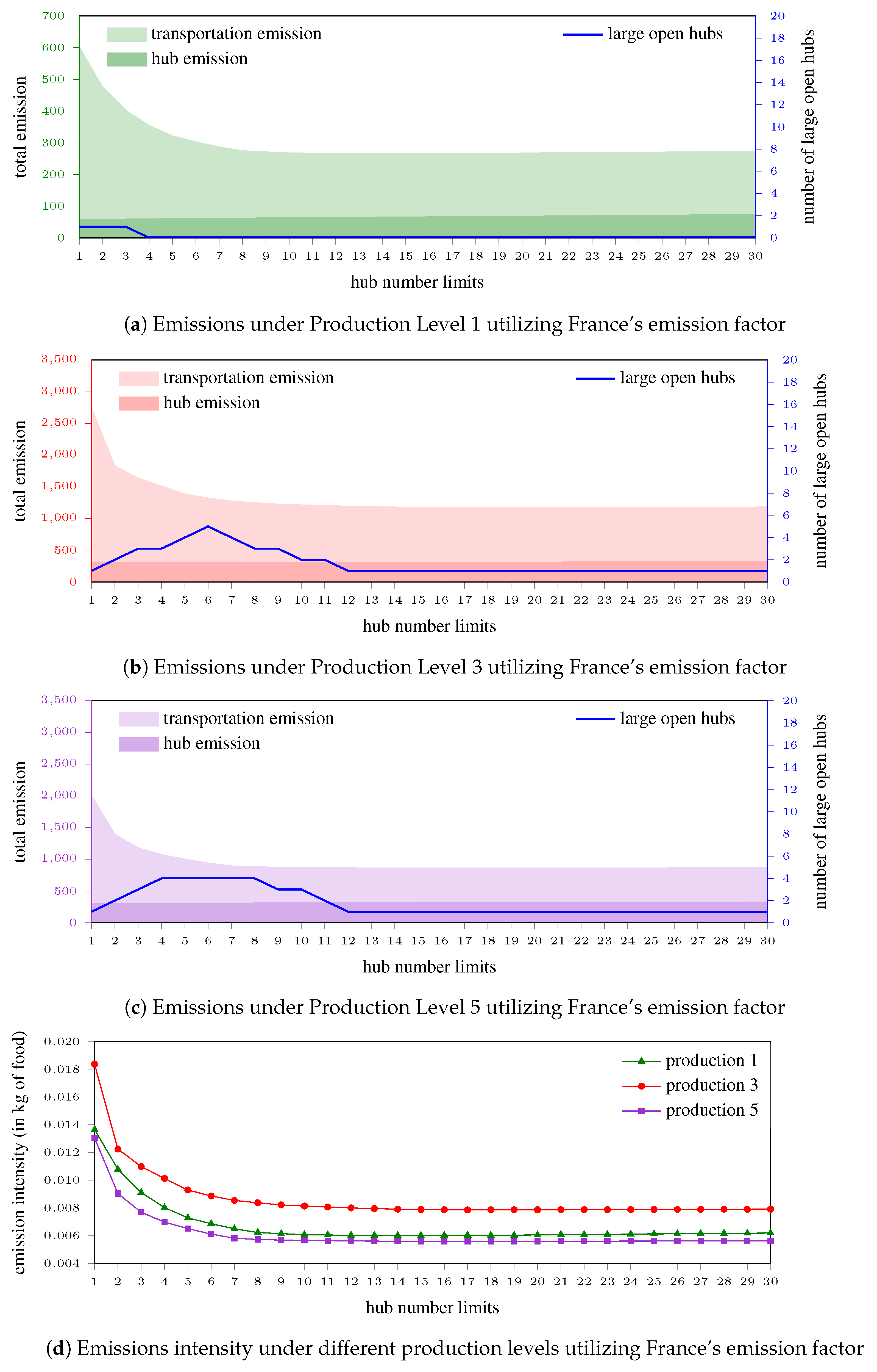

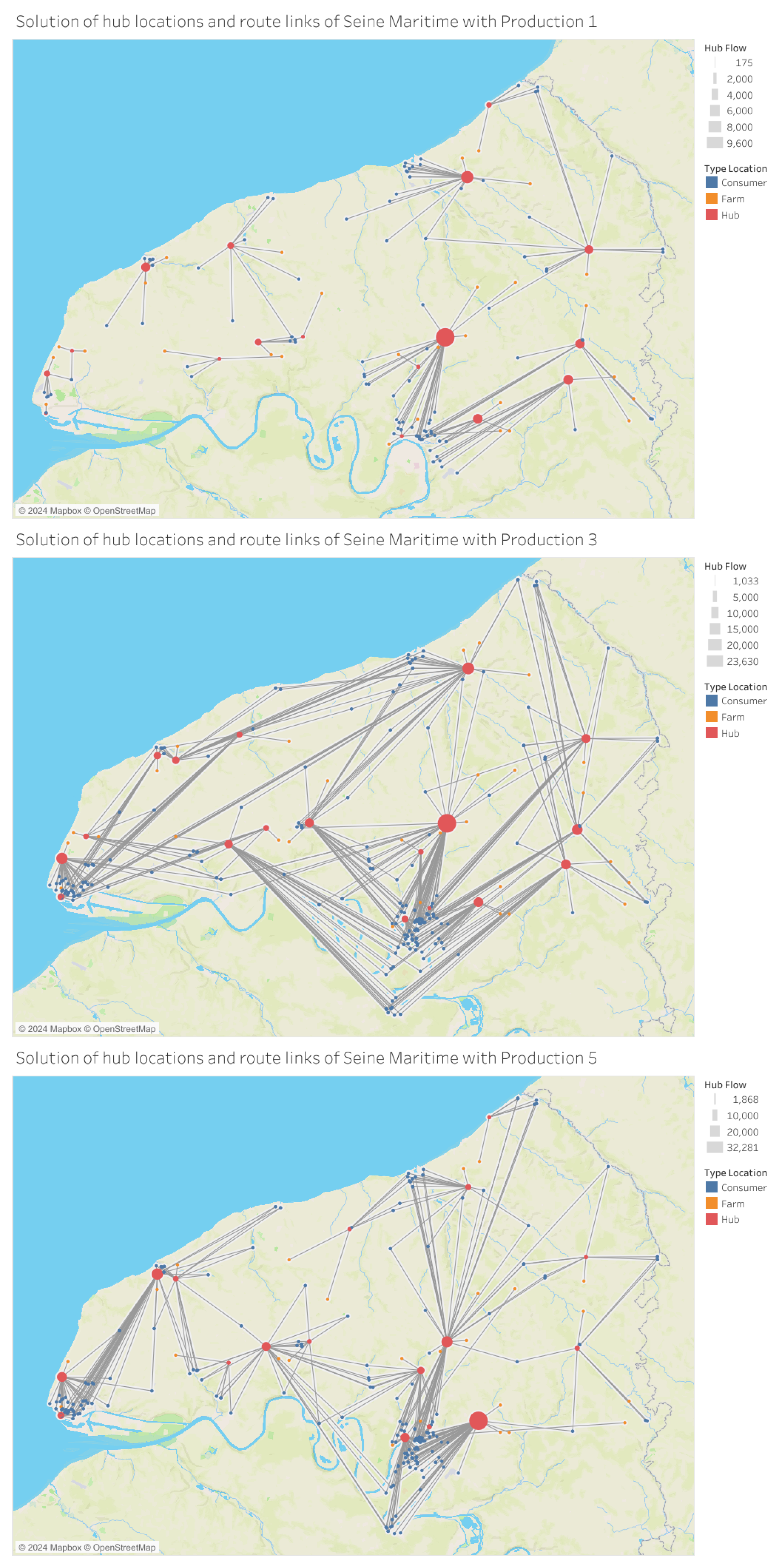

5.2. Results and Analysis

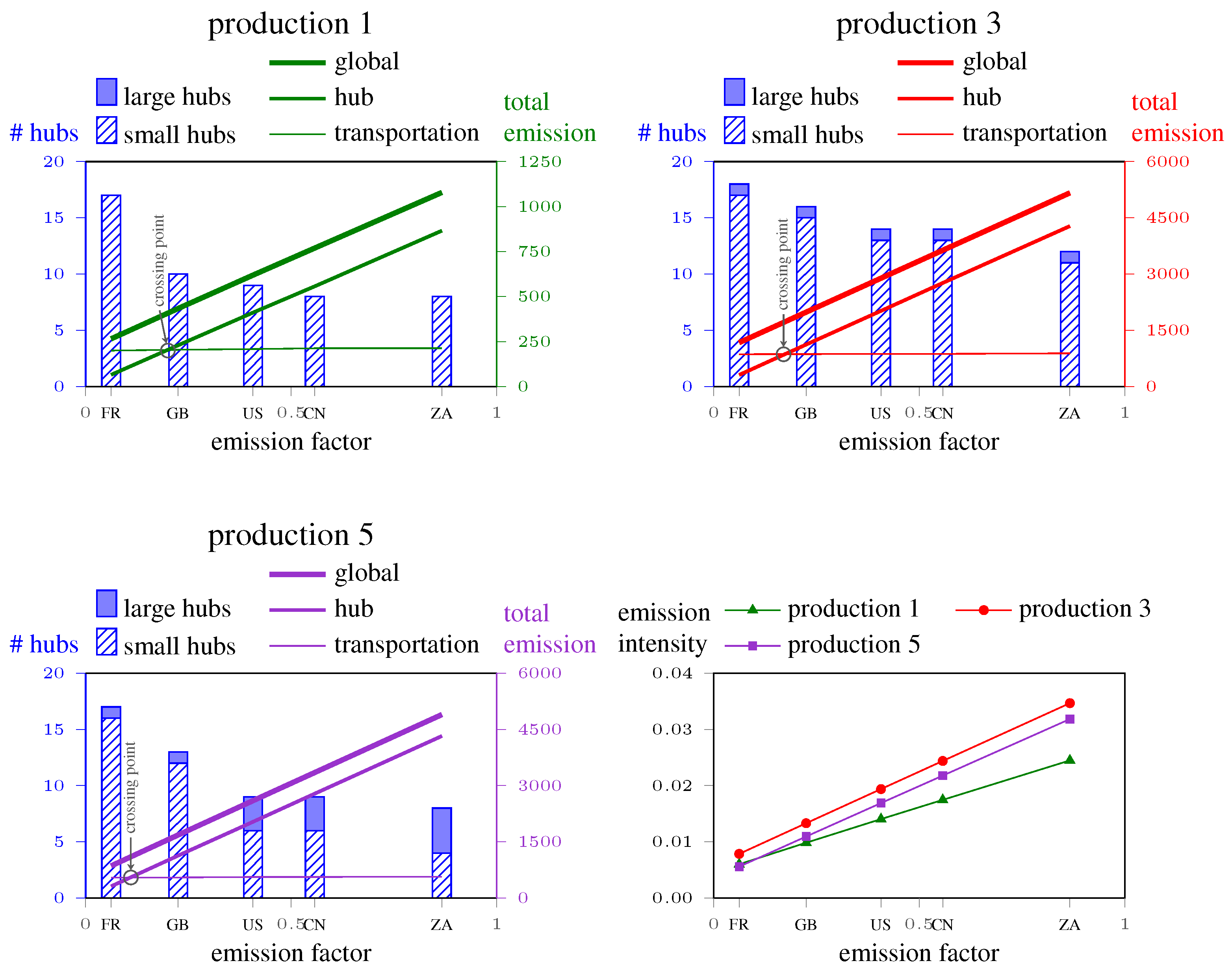

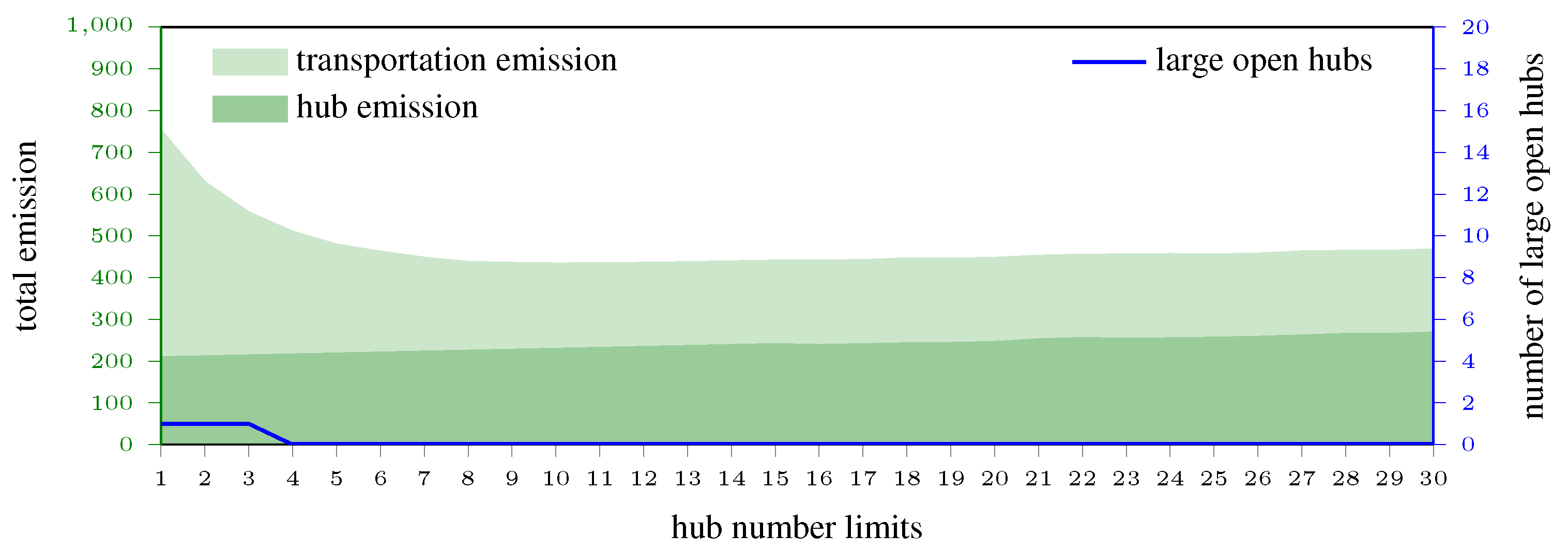

- We maintain two types of hubs: large warehouses (pallet capacity number exceeding 5000) operating throughout the entire year with a relatively consistent electricity consumption rate, and small warehouses (pallet capacity number of 345) operating flexibly on a weekly basis.

- We assess the electricity consumption in the hubs and subsequently convert the energy consumption into emissions, acknowledging the variation in emission factors from region to region.

- The emission factor (EF) for electricity is sourced from Carbon Footprint Ltd’s 2023 Integrated Report, https://www.carbonfootprint.com/international_electricity_factors.html, accessed on 30 July 2023, with five representative countries’ EFs (Table 2) selected for the experiment and comparison. The EF for diesel fuel (World-to-Wheel of 3.24 kg CO2 per unit) is sourced from the European Standard [84].

- The average dwell time for fresh food at the food hub in SFSC is fixed at 2 days.

- The total time period is fixed with 12 weeks (i.e., one season).

5.2.1. Evaluating Emissions with Hub Number Constraints

5.2.2. Evaluating Emissions with Different Emission Factors

5.2.3. Evaluating Emission with Different Short Distances Defined

6. Discussion

6.1. Practical Interpretation of the Results

6.2. Limitations and Flexibility of the Framework

6.3. Further Improvement of the Framework

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cuda, R.; Guastaroba, G.; Speranza, M.G. A survey on two-echelon routing problems. Comput. Oper. Res. 2015, 55, 185–199. [Google Scholar] [CrossRef]

- Paciarotti, C.; Torregiani, F. The logistics of the short food supply chain: A literature review. Sustain. Prod. Consum. 2021, 26, 428–442. [Google Scholar] [CrossRef]

- Dunne, J.B.; Chambers, K.J.; Giombolini, K.J.; Schlegel, S.A. What does ‘local’ mean in the grocery store? Multiplicity in food retailers’ perspectives on sourcing and marketing local foods. Renew. Agric. Food Syst. 2011, 26, 46–59. [Google Scholar] [CrossRef]

- Qaim, M. Globalisation of agrifood systems and sustainable nutrition. Proc. Nutr. Soc. 2017, 76, 12–21. [Google Scholar] [CrossRef] [PubMed]

- Pulker, C.E.; Trapp, G.S.; Scott, J.A.; Pollard, C.M. Global supermarkets’ corporate social responsibility commitments to public health: A content analysis. Glob. Health 2018, 14, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Duram, L.A.; Cawley, M. Irish chefs and restaurants in the geography of “local” food value chains. Open Geogr. J. 2012, 5, 16–25. [Google Scholar] [CrossRef]

- King, R.P.; Hand, M.S.; Gómez, M.I. Growing Local: Case Studies on Local Food Supply Chains; Univeristy of Nebraska Press: Lincoln, NE, USA, 2014. [Google Scholar] [CrossRef]

- Aldieri, L.; Brahmi, M.; Chen, X.; Vinci, C.P. Knowledge spillovers and technical efficiency for cleaner production: An economic analysis from agriculture innovation. J. Clean. Prod. 2021, 320, 128830. [Google Scholar] [CrossRef]

- Feldmann, C.; Hamm, U. Consumers’ perceptions and preferences for local food: A review. Food Qual. Prefer. 2015, 40, 152–164. [Google Scholar] [CrossRef]

- Bloemhof, J.M.; van der Vorst, J.G.; Bastl, M.; Allaoui, H. Sustainability assessment of food chain logistics. Int. J. Logist. Res. Appl. 2015, 18, 101–117. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Xu, L. Manufacturers’ emission-reduction investments in competing supply chains with Prisoner’s Dilemma: The economic and environmental impacts of Retailer (s) capital Constraint (s). Transp. Res. Part E Logist. Transp. Rev. 2024, 187, 103602. [Google Scholar] [CrossRef]

- Schönhart, M.; Penker, M.; Schmid, E. Sustainable local food production and consumption: Challenges for implementation and research. Outlook Agric. 2009, 38, 175–182. [Google Scholar] [CrossRef]

- Hand, M.S.; Martinez, S. Just what does local mean. Choices 2010, 25, 13–18. [Google Scholar] [CrossRef]

- Chang, T.F.M.; Iseppi, L. EU agro-food chain and vertical integration potentiality: A strategy for diversification? Transit. Stud. Rev. 2012, 19, 107–130. [Google Scholar] [CrossRef]

- Brown, J.R.; Guiffrida, A.L. Carbon emissions comparison of last mile delivery versus customer pickup. Int. J. Logist. Res. Appl. 2014, 17, 503–521. [Google Scholar] [CrossRef]

- Peano, C.; Migliorini, P.; Sottile, F. A methodology for the sustainability assessment of agri-food systems: An application to the Slow Food Presidia project. Ecol. Soc. 2014, 19, 24. [Google Scholar] [CrossRef]

- Benis, K.; Ferrão, P. Potential mitigation of the environmental impacts of food systems through urban and peri-urban agriculture (UPA)—A life cycle assessment approach. J. Clean. Prod. 2017, 140, 784–795. [Google Scholar] [CrossRef]

- Bayir, B.; Charles, A.; Sekhari, A.; Ouzrout, Y. Issues and challenges in short food supply chains: A systematic literature review. Sustainability 2022, 14, 3029. [Google Scholar] [CrossRef]

- Raftowicz, M.; Solarz, K.; Dradrach, A. Short Food Supply Chains as a Practical Implication of Sustainable Development Ideas. Sustainability 2024, 16, 2910. [Google Scholar] [CrossRef]

- Torquati, B.; Taglioni, C.; Cavicchi, A. Evaluating the CO2 emission of the milk supply chain in Italy: An exploratory study. Sustainability 2015, 7, 7245–7260. [Google Scholar] [CrossRef]

- Striebig, B.; Smitts, E.; Morton, S. Impact of transportation on carbon dioxide emissions from locally vs. non-locally sourced food. Emerg. Sci. J. 2019, 3, 222–234. [Google Scholar] [CrossRef]

- BÜYÜKSAATÇI, S.; ESNAF, Ş. Carbon emission based optimisation approach for the facility location problem. Tojsat 2014, 4, 9–20. [Google Scholar]

- Musavi, M.; Bozorgi-Amiri, A. A multi-objective sustainable hub location-scheduling problem for perishable food supply chain. Comput. Ind. Eng. 2017, 113, 766–778. [Google Scholar] [CrossRef]

- Cui, Y.; Diarrassouba, I.; Joncour, C.; Michel, S. Outil d’aide à la décision pour le placement de hub dans un circuit alimentaire de proximité. Cah. Logistique 2022, 3, 15–27. [Google Scholar]

- Bourlakis, M.A.; Bourlakis, C.A. Deliberate and emergent logistics strategies in food retailing: A case study of the Greek multiple food retail sector. Supply Chain. Manag. Int. J. 2001, 6, 189–200. [Google Scholar] [CrossRef]

- Oglethorpe, D.; Heron, G. Testing the theory of constraints in UK local food supply chains. Int. J. Oper. Prod. Manag. 2013, 33, 1346–1367. [Google Scholar] [CrossRef]

- Berti, G.; Mulligan, C. Competitiveness of small farms and innovative food supply chains: The role of food hubs in creating sustainable regional and local food systems. Sustainability 2016, 8, 616. [Google Scholar] [CrossRef]

- Lutz, J.; Smetschka, B.; Grima, N. Farmer cooperation as a means for creating local food systems—potentials and challenges. Sustainability 2017, 9, 925. [Google Scholar] [CrossRef]

- Sarabia, N.; Peris, J. Emergence and Development of Transformative Capacities for the Sustainability of the Agri-Food System: The Process in Valdivia, Chile. Sustainability 2024, 16, 4849. [Google Scholar] [CrossRef]

- du Plessis, M.J.; van Eeden, J.; Goedhals-Gerber, L.L. The carbon footprint of fruit storage: A case study of the energy and emission intensity of cold stores. Sustainability 2022, 14, 7530. [Google Scholar] [CrossRef]

- Blanquart, C.; Gonçalves, A.; Vandenbossche, L.; Kebir, L.; Petit, C.; Traversac, J.B. The logistic leverages of short food supply chains performance in terms of sustainability. In Proceedings of the 12th World Conference on Transport Research 2010, Lisbon, Portugal, 11–15 July 2010; p. 10. [Google Scholar]

- Gu, W.; Archetti, C.; Cattaruzza, D.; Ogier, M.; Semet, F.; Speranza, M.G. A sequential approach for a multi-commodity two-echelon distribution problem. Comput. Ind. Eng. 2021, 163, 107793. [Google Scholar] [CrossRef]

- Brown, C.; Miller, S. The impacts of local markets: A review of research on farmers markets and community supported agriculture (CSA). Am. J. Agric. Econ. 2008, 90, 1296–1302. [Google Scholar] [CrossRef]

- Vasquez, A.; Sherwood, N.E.; Larson, N.; Story, M. Community-supported agriculture as a dietary and health improvement strategy: A narrative review. J. Acad. Nutr. Diet. 2017, 117, 83–94. [Google Scholar] [CrossRef] [PubMed]

- Ilbery, B.; Maye, D. Retailing local food in the Scottish–English borders: A supply chain perspective. Geoforum 2006, 37, 352–367. [Google Scholar] [CrossRef]

- Kebir, L.; Torre, A. Geographical proximity and new short supply food chains. In Creative Industries and Innovation in Europe; Routledge: Milton Park, UK, 2012; pp. 212–229. [Google Scholar] [CrossRef]

- Zepeda, L.; Leviten-Reid, C. Consumers’ views on local food. J. Food Distrib. Res. 2004, 35, 1–6. [Google Scholar] [CrossRef]

- Engelseth, P.; Hogset, H. Adapting supply chain management for local foods logistics. In Proceedings of the Food System Dynamics, Innsbruck-Igls, Austria, 15–19 February 2016; pp. 143–160. [Google Scholar] [CrossRef]

- Chambers, S.; Lobb, A.; Butler, L.; Harvey, K.; Traill, W.B. Local, national and imported foods: A qualitative study. Appetite 2007, 49, 208–213. [Google Scholar] [CrossRef]

- Durham, C.A.; King, R.P.; Roheim, C.A. Consumer definitions of “Locally Grown” for fresh fruits and vegetables. J. Food Distrib. Res. 2009, 40, 56–62. [Google Scholar] [CrossRef]

- Pretty, J.N.; Ball, A.S.; Lang, T.; Morison, J.I. Farm costs and food miles: An assessment of the full cost of the UK weekly food basket. Food Policy 2005, 30, 1–19. [Google Scholar] [CrossRef]

- Nilsson, H. Local food systems from a sustainability perspective: Experiences from Sweden. Int. J. Sustain. Soc. 2009, 1, 347–363. [Google Scholar] [CrossRef]

- Kremer, P.; DeLiberty, T.L. Local food practices and growing potential: Mapping the case of Philadelphia. Appl. Geogr. 2011, 31, 1252–1261. [Google Scholar] [CrossRef]

- Engelseth, P. Developing exchange in short local foods supply chains. Int. J. Food Syst. Dyn. 2016, 7, 229–242. [Google Scholar] [CrossRef]

- Galli, F.; Brunori, G. (Eds.) Short Food Supply Chains as Drivers of Sustainable Development. Evidence Document; Document developed in the framework of the FP7 project FOODLINKS (GA No. 265287); Laboratorio di studi rurali Sismondi: Pisa, Italy, 2013; ISBN 978-88-90896-01-9. [Google Scholar]

- European-Union. Regulation (EU) No. 1305/2013 of the European Parliament and of the Council of 17 December 2013 on support for rural development by the European Agricultural Fund for Rural Development (EAFRD) and repealing Council Regulation (EC) No 1698/2005. Off. J. Eur. Union 2013, L 347, 487.

- Diamond, A.; Barham, J. Money and mission: Moving food with value and values. J. Agric. Food Syst. Commun. Dev. 2011, 1, 101–117. [Google Scholar] [CrossRef]

- Martikainen, A.; Niemi, P.; Pekkanen, P. Developing a service offering for a logistical service provider—Case of local food supply chain. Int. J. Prod. Econ. 2014, 157, 318–326. [Google Scholar] [CrossRef]

- Horst, M.; Ringstrom, E.; Tyman, S.; Ward, M.; Werner, V.; Born, B. Toward a more expansive understanding of food hubs. J. Agric. Food Syst. Commun. Dev. 2011, 2, 209–225. [Google Scholar] [CrossRef]

- Matson, J.; Thayer, J. The role of food hubs in food supply chains. J. Agric. Food Syst. Commun. Dev. 2013, 3, 43–47. [Google Scholar] [CrossRef]

- Manikas, I.; Malindretos, G.; Moschuris, S. A community-based Agro-Food Hub model for sustainable farming. Sustainability 2019, 11, 1017. [Google Scholar] [CrossRef]

- Guastaroba, G.; Speranza, M.G.; Vigo, D. Intermediate facilities in freight transportation planning: A survey. Transp. Sci. 2016, 50, 763–789. [Google Scholar] [CrossRef]

- Dellaert, N.; Van Woensel, T.; Crainic, T.G.; Saridarq, F.D. A multi-commodity two-Echelon capacitated vehicle routing problem with time windows: Model formulations and solution approach. Comput. Oper. Res. 2021, 127, 105154. [Google Scholar] [CrossRef]

- Bosona, T.G.; Gebresenbet, G. Cluster building and logistics network integration of local food supply chain. Biosyst. Eng. 2011, 108, 293–302. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G.; Nordmark, I.; Ljungberg, D.; Jüriado, R. Integrated logistics network for the supply chain of locally produced food, Part I: Location and route optimization analyses. J. Serv. Sci. Manag. 2011, 4, 174. [Google Scholar] [CrossRef]

- Nordmark, I.; Ljungberg, D.; Gebresenbet, G.; Bosona, T.; Jüriado, R. Integrated logistics network for the supply chain of locally produced food, part II: Assessment of E-trade, economic benefit and environmental impact. J. Serv. Sci. Manag. 2012, 5, 22448. [Google Scholar] [CrossRef]

- Tong, D.; Ren, F.; Mack, J. Locating farmers’ markets with an incorporation of spatio-temporal variation. Socio-Econ. Plan. Sci. 2012, 46, 149–156. [Google Scholar] [CrossRef]

- Bosona, T.; Nordmark, I.; Gebresenbet, G.; Ljungberg, D. GIS-based analysis of integrated food distribution network in local food supply chain. Int. J. Bus. Manag. 2013, 8, 13. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G.; Nordmark, I.; Ljungberg, D. Box-scheme based delivery system of locally produced organic food: Evaluation of logistics performance. J. Serv. Sci. Manag. 2011, 4, 357. [Google Scholar] [CrossRef]

- Saetta, S.A.; Caldarelli, V.; Tiacci, L.; Lerche, N.; Geldermann, J. A logistic network to harmonise the development of local food system with safety and sustainability. Int. J. Integr. Supply Manag. 2015, 9, 307–328. [Google Scholar] [CrossRef]

- Duram, L.; Oberholtzer, L. A geographic approach to place and natural resource use in local food systems. Renew. Agric. Food Syst. 2010, 25, 99–108. [Google Scholar] [CrossRef]

- Nsamzinshuti, A.; Janjevic, M.; Rigo, N.; Ndiaye, A.B. Logistics collaboration solutions to improve short food supply chain solution performance. In Proceedings of the 3rd World Conference on Supply Chain Management, Colombo, Sri Lanka, 17–19 May 2017; Volume 2, pp. 57–69. [Google Scholar]

- Kukovič, D.; Topolšek, D.; Rosi, B.; Jereb, B. A comparative literature analysis of definitions for logistics: Between general definition and definitions of subcategories. In Proceedings of the 14th International Scientific Conference Business Logistics in Modern Management, Osijek, Croatia, 16 October 2014. [Google Scholar]

- Ringsberg, H. Perspectives on food traceability: A systematic literature review. Supply Chain. Manag. Int. J. 2014, 19, 558–576. [Google Scholar] [CrossRef]

- Markley, M.J.; Davis, L. Exploring future competitive advantage through sustainable supply chains. Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 763–774. [Google Scholar] [CrossRef]

- Kneafsey, M.; Venn, L.; Schmutz, U.; Balázs, B.; Trenchard, L.; Eyden-Wood, T.; Bos, E.; Sutton, G.; Blackett, M. Short food supply chains and local food systems in the EU. A state of play of their socio-economic characteristics. JRC Sci. Policy Rep. 2013, 123, 129. [Google Scholar] [CrossRef]

- Bask, A.; Rajahonka, M. The role of environmental sustainability in the freight transport mode choice: A systematic literature review with focus on the EU. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 560–602. [Google Scholar] [CrossRef]

- Sini, M.P. Long and short supply chain coexistence in the agricultural food market on different scales: Oligopolies, local economies and the degree of liberalisation of the global market. Eur. Sci. J. 2014, 10, 26.363–26.401. [Google Scholar]

- Rapisarda, P. Analysis of a direct selling network for agrifood products. Ital. J. Food Sci. 2015, 27, 109–117. [Google Scholar] [CrossRef]

- Wallgren, C. Local or global food markets: A comparison of energy use for transport. Local Environ. 2006, 11, 233–251. [Google Scholar] [CrossRef]

- Edwards-Jones, G.; i Canals, L.M.; Hounsome, N.; Truninger, M.; Koerber, G.; Hounsome, B.; Cross, P.; York, E.H.; Hospido, A.; Plassmann, K.; et al. Testing the assertion that ‘local food is best’: The challenges of an evidence-based approach. Trends Food Sci. Technol. 2008, 19, 265–274. [Google Scholar] [CrossRef]

- Glettner, C. Energy Use in the Transport of Food: Comparing Local and Conventional Food Systems in Berkeley, CA. 2008. Available online: https://nature.berkeley.edu/classes/es196/projects/2008final/Glettner_2008.pdf (accessed on 5 July 2024).

- Mariola, M.J. The local industrial complex? Questioning the link between local foods and energy use. Agric. Hum. Values 2008, 25, 193–196. [Google Scholar] [CrossRef]

- Cleveland, D.A.; Radka, C.N.; Müller, N.M.; Watson, T.D.; Rekstein, N.J.; Van M. Wright, H.; Hollingshead, S.E. Effect of localizing fruit and vegetable consumption on greenhouse gas emissions and nutrition, Santa Barbara County. Environ. Sci. Technol. 2011, 45, 4555–4562. [Google Scholar] [CrossRef] [PubMed]

- Pirog, R.S.; Van Pelt, T.; Enshayan, K.; Cook, E. Food, Fuel, and Freeways: An IOWA Perspective on How Far Food Travels, Fuel Usage, and Greenhouse Gas Emissions; Leopold Center for Sustainable Agriculture, Iowa State University: Ames, IA, USA, 2001. [Google Scholar]

- Jones, A. An environmental assessment of food supply chains: A case study on dessert apples. Environ. Manag. 2002, 30, 560–576. [Google Scholar] [CrossRef]

- Auld, G.W.; Thilmany, D.; Jones, K. Factors affecting small Colorado producers’ local food sales. J. Hunger. Environ. Nutr. 2009, 4, 129–146. [Google Scholar] [CrossRef]

- Dong, Y.; Miller, S.A.; Keoleian, G.A. Estimating the greenhouse gas emissions of cold chain infrastructure in China from 2021 to 2060. Sustain. Prod. Consum. 2022, 31, 546–556. [Google Scholar] [CrossRef]

- Bauskar, M.E. Special Models for a Multi-Item, Multi-Location, Multi-Echelon, Multi-Period Inventory System with Centralized Replenishments and Restricted Transshipments; The University of Alabama: Tuscaloosa, AL, USA, 1997. [Google Scholar]

- Hinojosa, Y.; Puerto, J.; Fernández, F.R. A multiperiod two-echelon multicommodity capacitated plant location problem. Eur. J. Oper. Res. 2000, 123, 271–291. [Google Scholar] [CrossRef]

- Sadjady, H.; Davoudpour, H. Two-echelon, multi-commodity supply chain network design with mode selection, lead-times and inventory costs. Comput. Oper. Res. 2012, 39, 1345–1354. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R.; Franco, J.L.; Isaza, S.N.; Jiménez, H.F.; Herazo-Padilla, N. A literature review on the vehicle routing problem with multiple depots. Comput. Ind. Eng. 2015, 79, 115–129. [Google Scholar] [CrossRef]

- Dobers, K.; Perotti, S.; Fossa, A. Emission Intensity Factors for Logistics Buildings; Fraunhofer IML: Dortmund, Germany, 2022. [Google Scholar] [CrossRef]

- BSI BS EN 16258:2012; Methodology for Calculation and Declaration of Energy Consumption and GHG Emissions of Transport Services (Freight and Passengers). BSI: London, UK, 2012.

- Tassou, S.; Ge, Y.; Hadawey, A.; Marriott, D. Energy consumption and conservation in food retailing. Appl. Therm. Eng. 2011, 31, 147–156. [Google Scholar] [CrossRef]

- Foster, A.; Brown, T.; Evans, J.; Maidment, G. Relationship between specific energy consumption and size of supermarket stores. Refrig. Sci. Technol. 2019, 2019, 4973–4980. [Google Scholar] [CrossRef]

- Franco, A.; Cillari, G. Energy Sustainability of Food Stores and Supermarkets through the Installation of PV Integrated Plants. Energies 2021, 14, 5678. [Google Scholar] [CrossRef]

| Truck Type | Capacity (kg) | Diesel Consumption (L/100 km) |

|---|---|---|

| Kangoo | 600 | 5.33 |

| Fourgon | 1500 | 8.2 |

| Country | Country Code | Emission Factor (kg CO2/kWh) |

|---|---|---|

| France | FR | 0.06207 |

| United Kingdom | GB | 0.22499 |

| United States | US | 0.40706 |

| China | CN | 0.55720 |

| South Africa | ZA | 0.86650 |

| Production Level | Demand Satisfaction Percentage (%) |

|---|---|

| 1 | 30 |

| 2 | 50 |

| 3 | 100 |

| 4 | 160 |

| 5 | 300 |

| 6 | 1500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Diarrassouba, I.; Joncour, C.; Michel Loyal, S. Optimization and Analysis of the Impact of Food Hub Location on GHG Emissions in a Short Food Supply Chain. Sustainability 2024, 16, 7781. https://doi.org/10.3390/su16177781

Cui Y, Diarrassouba I, Joncour C, Michel Loyal S. Optimization and Analysis of the Impact of Food Hub Location on GHG Emissions in a Short Food Supply Chain. Sustainability. 2024; 16(17):7781. https://doi.org/10.3390/su16177781

Chicago/Turabian StyleCui, Yaheng, Ibrahima Diarrassouba, Cédric Joncour, and Sophie Michel Loyal. 2024. "Optimization and Analysis of the Impact of Food Hub Location on GHG Emissions in a Short Food Supply Chain" Sustainability 16, no. 17: 7781. https://doi.org/10.3390/su16177781

APA StyleCui, Y., Diarrassouba, I., Joncour, C., & Michel Loyal, S. (2024). Optimization and Analysis of the Impact of Food Hub Location on GHG Emissions in a Short Food Supply Chain. Sustainability, 16(17), 7781. https://doi.org/10.3390/su16177781