Review of Root–Stubble Characteristics and Root–Stubble Crushing and Clearing Technologies for Conservation Tillage

Abstract

:1. Introduction

2. Study on the Characteristics of Root-Stubble Their Growth Environment

2.1. Study on Morphological Characteristics

2.2. Study on Physical Properties

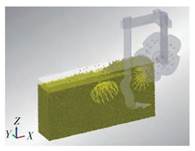

2.3. Application of Characteristic Parameters of Crop Root–Stubble and the Environment in Numerical Simulations

3. Mechanized Treatment Technology for Crop Root–Stubble

3.1. Technology of Passive Crushing and Side Throwing of Root–Stubble

3.1.1. Technology of Crushing and Clearing Root–Stubble

3.1.2. Technology of Side-Throwing Stubble

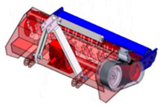

3.2. Technology of Active Crushing of Root–Stubble

3.3. Methods to Test the Performance of the Root–Stubble Crushing Device

4. Prospects

4.1. Strengthening the Analysis of the Physical Properties of the Root–Stubble Soil

4.2. Application of Wear-Resistant Parts in Soil Engaging and Crushing of Roots

4.3. Application of the Reduction of Soil Adhesion to the Cutter during Root Crushing

4.4. Tracking the Long-Term Effects of Different Methods on the Soil Physicochemical Properties in Various Regions

4.5. An Intelligent Device for Root–Stubble Crushing

4.6. Challenges and Strategies in Promoting the Application of New Root–Stubble Crushing and Clearing Technologies and Machinery

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Govardhan, G.; Ambulkar, R.; Kulkarni, S.; Vishnoi, A.; Yadav, P.; Choudhury, B.A.; Khare, M.; Ghude, S.D. Stubble-burning activities in north-western India in 2021: Contribution to air pollution in Delhi. Heliyon 2023, 9, e16939. [Google Scholar] [CrossRef] [PubMed]

- Del Valle, T.M.; Yang, X.; Jiang, P. Evaluation of straw and agricultural policy impacts on the sustainability of the straw-based bioeconomy with an agent-based model. Biomass Bioenergy 2024, 184, 107177. [Google Scholar] [CrossRef]

- Parshad, J.; Kumar, R.; Chhokar, V.; Partil, N.; Beniwal, V.; Singh, N.; Kumar, A.; Singh, N.; Rajesh, Y.O.G.I.; Kemar, M.; et al. Paddy straw management: Alternative strategies and emerging technology for sustainable ecosystem. Pedosphere, 2024; in press. [Google Scholar] [CrossRef]

- Guo, J.P. Advances in impacts of climate change on agricultural production in China. Journal of applied meteorological science. J. Appl. Meteorol. Sci. 2015, 26, 1–11. [Google Scholar]

- Röder, M.; Thornley, P.; Jamieson, C. The greenhouse gas performance and climate change mitigation potential from rice straw biogas as a pathway to the UN sustainable development goals. Biomass Bioenergy 2024, 182, 107072. [Google Scholar] [CrossRef]

- He, J.; Li, H.W.; Chen, H.T.; Lu, C.Y.; Wang, Q.J. Research progress of conservation tillage technology and machine. Trans. CSAM 2018, 49, 1–19. [Google Scholar]

- Wang, L.J.; Liu, T.H.; Feng, X.; Gao, Y.P.; Wang, B.; Zhang, S. Research progress of the restitution coefficients of collision of particles in agricultural and food fields. Trans. CSAE 2021, 37, 313–322. [Google Scholar]

- Rhofita, E.I.; Ouaret, R.; Montastruc, L.; Meyer, M. Mapping analysis of farmers’ perceptions of rice straw valorization in Indonesia. Environ. Dev. 2024, 51, 101021. [Google Scholar] [CrossRef]

- Roper, M.M.; Ward, P.R.; Keulen, A.F.; Hill, J.R. Under no-tillage and stubble retention, soil water content and crop growth are poorly related to soil water repellency. Soil Tillage Res. 2013, 126, 143–150. [Google Scholar] [CrossRef]

- Roper, M.M.; Kerr, R.; Ward, P.R.; Micin, S.F.; Krishnamurthy, P. Changes in soil properties and crop performance on stubble-burned and cultivated water-repellent soils can take many years following reversion to no-till and stubble retention. Geoderma 2021, 402, 115361. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, Q.J.; Zhong, G.Y.; Tong, Z.W.; Wang, X.H.; Xu, J. Brief review of minimum or no-till seeders in China. AgriEngineering 2021, 3, 605–621. [Google Scholar] [CrossRef]

- Zhu, D.Q.; Shi, M.H.; Yu, C.Y.; Yu, Z.Y.; Kuang, F.M.; Xiong, W.; Xue, K. Tool-straw-paddy soil coupling model of mechanical rotary-tillage process based on DEM-FEM. Comput. Electron. Agric. 2023, 215, 108410. [Google Scholar] [CrossRef]

- Matin, M.A.; Fielke, J.M.; Desbiolles, J.M.A. Torque and energy characteristics for strip-tillage cultivation when cutting furrows using three designs of rotary blade. Biosyst. Eng. 2014, 129, 329–340. [Google Scholar] [CrossRef]

- Aikins, K.A.; Barr, J.B.; Antille, D.L.; Ucgul, M.; Jensen, T.A.; Desbiolles, J.M. Analysis of effect of bentleg opener geometry on performance in cohesive soil using the discrete element method. Biosyst. Eng. 2021, 209, 106–124. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Xu, L.; Jiang, X.Z.; Wang, S.L.; Cui, Z.C. Study on the reduction of soil adhesion and tillage force of bionic cutter teeth in secondary soil crushing. Biosyst. Eng. 2021, 213, 133–147. [Google Scholar] [CrossRef]

- Kešner, A.; Chotěborský, R.; Linda, M.; Hromasová, M.; Katinas, E.; Sutanto, H. Stress distribution on a soil tillage machine frame segment with a chisel shank simulated using discrete element and finite element methods and validate by experiment. Biosyst. Eng. 2021, 209, 125–138. [Google Scholar] [CrossRef]

- Yan, D.Q.; Xue, Y.H.; Xu, Z.Y.; Sun, Y.F.; Sun, R.H.; Hu, X.F. Current utilization status, technical models and development proposals for direct crop straw returning to field in China. Chin. J. Agric. Resour. Reg. Plan. 2023, 44, 1–14. [Google Scholar]

- Qiu, Z.G.; Wang, Y.X.; Tang, Y.Q.; Luo, W.H.; Ye, Z.L. Analysis of blockage and wrapping by leaves in the cutting mechanism of a sugarcane leaf shredder. Biosyst. Eng. 2021, 211, 152–166. [Google Scholar] [CrossRef]

- Xu, C.; Li, R.; Song, W.; Wu, T.; Sun, S.; Shen, W.; Hu, S.; Han, T.; Wu, C. Integrating straw management and seeding to improve seed yield and reduce environmental impacts in soybean production. Agronomy 2021, 11, 1033. [Google Scholar] [CrossRef]

- Lin, J.; Zhao, D.F.; Hu, Y.Q.; Li, B.F. Analysis on physical and mechanical characteristics of corn residue for no-till planter. J. Agric. Mech. Res. 2012, 34, 162–166. [Google Scholar]

- Lin, J.; Lv, Z.Y.; Li, H.Z.; Wang, X.Y.; Wang, D.R. Design and experiment of passive anti-winding stubble breaking and ridge cleaning device for ridge no-tillage planter. Trans. CSAM 2023, 54, 19–27+37. [Google Scholar]

- Zhao, S.H.; Liu, H.P.; Yang, C.; Yang, L.L.; Gao, L.L.; Yang, Y.Q. Design and discrete element simulation of interactive layered subsoiler with maize straw returned to filed. Trans. CSAM 2021, 52, 75–87. [Google Scholar]

- Sharratt, B.S. Corn stubble height and residue placement in the northern US Corn Belt: Part I. Soil physical environment during winter. Soil Tillage Res. 2002, 64, 243–252. [Google Scholar] [CrossRef]

- Sharratt, B.S. Corn stubble height and residue placement in the northern US Corn Belt: II. Spring microclimate and wheat development. Soil Tillage Res. 2002, 64, 253–261. [Google Scholar] [CrossRef]

- Gu, C.J.; Xi, X.B.; Han, L.J.; Zhang, Y.F.; Zhang, B.F.; Zhang, R.H. Design and experiment research of double-axis rotaty tillage machine for sowing, ditching, and covering soil. J. Chin. Agric. Mech. 2021, 42, 17–22. [Google Scholar]

- Zeng, S.; Tang, H.; Luo, X.; Ma, G.; Wang, Z.; Zang, Y.; Zhang, M. Design and experiment of precision rice hill-drop drilling machine for dry land with synchronous fertilizing. Trans. Chin. Soc. Agric. Eng. 2012, 28, 12–19. [Google Scholar]

- Hu, J.P.; Zhao, J.; Pan, H.R.; Liu, W.; Zhao, X.S. Prediction model of double axis rotary power consumption based on discrete element method. Trans. CSAM 2020, 51, 9–16. [Google Scholar]

- Harrell, D.L.; Bond, J.A.; Blanche, S. Evaluation of main-crop stubble height on ratoon rice growth and development. Field Crops Res. 2009, 114, 396–403. [Google Scholar] [CrossRef]

- Jiang, J.L.; Gong, L.N.; Wang, D.W.; Wang, G.P. Development and experiment for driving double coulters anti-blockage device of no-till planter. Trans. CSAE 2012, 28, 17–22. [Google Scholar]

- He, M.D.; Zhong, X.B.; Zhou, Q.Z.; Cui, N.; Wang, G.F.; Ma, W.J.; Tang, G.X. Effects of nitrogen fertilizer on root morphogenesis and physiological characteristics under drought stress at seedling stage in wheat. J. Nucl. Agric. Sci. 2019, 33, 2246–2253. [Google Scholar]

- Zhang, S.L.; Zhao, H.B.; Wang, X.Z.; Dong, J.X.; Zhao, P.F.; Yang, F.F.; Chen, X.H.; Liu, F.; Huang, Y.X. Discrete element modeling and shear properties of the maize stubble-soil complex. Comput. Electron. Agric. 2022, 204, 107519. [Google Scholar] [CrossRef]

- Zheng, K.; He, J.; Li, H.W.; Diao, P.S.; Wang, Q.J. Research on polyline soil-breaking blade subsoiler based on subsoiling soil model using discrete element method. Trans. CSAM 2016, 47, 62–72. [Google Scholar]

- Chen, G.; Wang, Q.; Li, H.; He, J.; Wang, X.; Zhang, X.; He, D. Experimental research on vertical straw cleaning and soil tillage device based on Soil-Straw composite model. Comput. Electron. Agric. 2024, 216, 108510. [Google Scholar] [CrossRef]

- Wei, J. Experimental Study on Rice Straw Stubble Burying Device in Saline-Alkali. Land. Thesis, Jilin Agricultural University, Jilin, China, 2023. [Google Scholar]

- Zhou, H.; Zhang, J.M.; Zhu, Y.H.; Zhang, C.L.; Tahir, H.M.; Xia, J.F. Design and experiment of combined tillage machine for subsoiling and rotary burying of straw incorporated into soil. Trans. CSAE 2017, 33, 17–26. [Google Scholar]

- Fang, H.M.; Zhang, Q.Y.; Ji, C.Y.; Guo, J. Soil shear properties as influenced by straw content: An evaluation of field-collected and laboratory-remolded soils. J. Integr. Agric. 2016, 15, 2848–2854. [Google Scholar] [CrossRef]

- Ding, Q.S.; Ren, J.; Adam, B.E.; Zhao, J.K.; Ge, S.Y.; Li, Y. DEM analysis of subsoiling process in wet clayey paddy soil. Trans. CSAM 2017, 48, 38–48. [Google Scholar]

- Li, L.; Chan, K.Y.; Niu, Y.; Li, G.; Oates, A.; Dexter, A.; Huang, G. Soil physical qualities in an Oxic Paleustalf under different tillage and stubble management practices and application of S theory. Soil Tillage Res. 2011, 113, 82–88. [Google Scholar] [CrossRef]

- Kemper, W.D.; Rosenau, R.C. Soil cohesion as affected by time and water content. Soil Sci. Soc. Am. J. 1984, 48, 1001–1006. [Google Scholar] [CrossRef]

- Wei, S.Y.; Zhang, Y.L.; Liu, B.H.; Fu, Y. Spatial distribution characteristics of soil physical properties of sloping cultivated land with ridges in the black soil region of northeast China. Res. Soil Water Conserv. 2024, 31, 135–144. [Google Scholar]

- Sui, P.X.; Luo, Y.; Zheng, H.B.; Li, R.P.; Wang, H.; Yuan, Y.; Zheng, J.Y.; Liu, W.R. Effects of long-term tillage practices on the stability of soil aggregates and organic carbon in black soil farmland. J. Appl. Ecol. 2023, 34, 1853–1861. [Google Scholar]

- Robertson, P.K. Interpretation of cone penetration tests—A unified approach. Can. Geotech. J. 2009, 46, 1337–1355. [Google Scholar] [CrossRef]

- Abdullah, N.H.H.; Gofar, N.; Rahman, N.A.A.; Roslan, S.M. Empirical correlation for estimation of unsaturated soil shear strength. In Proceedings of the 2013 IEEE Business Engineering and Industrial Applications Colloquium (BEIAC), Langkawi, Malaysia, 7–9 April 2013; IEEE: New York, NY, USA; pp. 690–694. [Google Scholar]

- Chukka, D.; Chakravarthi, V.K. Evaluation of properties of soil subgrade using dynamic cone penetration index–a case study. Int. J. Eng. Res. Dev. 2012, 4, 7–15. [Google Scholar]

- Bilanski, W.K.; Graham, V.A. A viscoelastic model for forage wafering. Trans. Can. Soc. Mech. Eng. 1984, 8, 70–76. [Google Scholar] [CrossRef]

- Birle, E.; Heyer, D.; Vogt, N. Influence of the initial water content and dry density on the soil–water retention curve and the shrinkage behavior of a compacted clay. Acta Geotech. 2008, 3, 191–200. [Google Scholar] [CrossRef]

- Yong, K.K.; Xian, L.J.; Li, Y.C.; Lee, L.M.; Tanaka, Y.; Zhao, J.J. Shaking table test on dynamic behaviours of tropical residual soils in Malaysia. KSCE J. Civ. Eng. 2017, 21, 1735–1746. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chern, S.G.; Hwang, H. A study on nonlinear dynamic properties of soils. In Proceedings of the 2013 World Congress on Advances in Structural Enginering and Mechanics (ASEM13), Jeju, Korea, 8–12 September 2013. [Google Scholar]

- Vardanega, P.J.; Bolton, M.D. Stiffness of clays and silts: Normalizing shear modulus and shear strain. J. Geotech. Geoenvironmental Eng. 2013, 139, 1575–1589. [Google Scholar] [CrossRef]

- Singh, A.; Dhaliwal, I.S.; Dixit, A. Performance evaluation of tractor mounted straw chopper cum spreader for paddy straw management. Indian J. Agric. Res. 2011, 45, 21–29. [Google Scholar]

- Li, W.X.; Zhang, F.B.; Luo, Z.T.; Zheng, E.L.; Pan, D.C.; Qian, J.; Yao, H.; Wang, X. Straw movement and flow field in a crushing device based on CFD-DEM coupling with flexible hollow straw model. Biosyst. Eng. 2024, 242, 140–153. [Google Scholar] [CrossRef]

- Shi, Y.Y.; Sun, X.; Wang, X.C.; Hu, Z.C.; Newman, D.; Ding, W.M. Numerical simulation and field tests of minimum-tillage planter with straw smashing and strip laying based on EDEM software. Comput. Electron. Agric. 2019, 166, 105021. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; McHugh, A.D.; Li, H.W.; Ma, S.C.; Wang, Q.J.; He, J.; Zheng, K. Global overview of research and development of crop residue management machinery. Appl. Eng. Agric. 2017, 33, 329. [Google Scholar] [CrossRef]

- Zeng, Z.Y.; Chen, Y. Simulation of straw movement by discrete element modelling of straw-sweep-soil interaction. Biosyst. Eng. 2019, 180, 25–35. [Google Scholar] [CrossRef]

- Hang, C.G.; Gao, X.J.; Yuan, M.C.; Huang, Y.X.; Zhu, R.X. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, F.; Zhao, M.Q.; Ma, Q.; Wang, W.; Fan, Q.; Yan, P. Determination of corn stalk contact parameters and calibration of discrete element method simulation. J. China Agric. Univ. 2018, 23, 120–127. [Google Scholar]

- Wang, L.J.; Zhang, Z.H.; Liu, T.H.; Wang, Y.J.; Jia, F.; Jiang, J.X. Design and experiment of device for chopping stalk of header of maize harvester. Trans. CSAM 2020, 51, 109–117. [Google Scholar]

- Tu, M.; Cao, T.; Wan, Z.H.; Mo, H.T.; Zhang, G.Z. Calibration and shear experiments of discrete element bonding parameters for water caltrop. J. Huazhong Agric. Univ. 2023, 42, 270–278. [Google Scholar]

- Wang, L.J.; Yu, Y.T.; Zhang, S.; Song, L.L.; Feng, X. Motion characteristics of maize mixture on bionic screen based on earthworm motion characteristics. Trans. CSAM 2022, 53, 158–166. [Google Scholar]

- Liao, Q.X.; Xie, H.M.; Zhang, Q.S.; Zhang, J.Q.; Ao, Q.; Wang, L. Design and experiment of driven disc plow and double-edged rotary tillage combined tiller. Trans. CSAM 2023, 54, 99–110+195. [Google Scholar]

- Liu, L.; Wang, X.L.; Zhang, X.C.; Cheng, X.P.; Wei, Z.C.; Zhou, H.; Zhao, K.L. The impact of ‘T’-shaped furrow opener of no-tillage seeder on straw and soil based on discrete element method. Comput. Electron. Agric. 2023, 213, 108278. [Google Scholar] [CrossRef]

- Parihar, D.S.; Dogra, B.; Narang, M.K.; Singh, S.K.; Khurana, R. Development and evaluation of notched concave disc seed drill for direct seeding of wheat in paddy stubble field. J. Agric. Food Res. 2022, 10, 100421. [Google Scholar] [CrossRef]

- Li, M.; Chen, D.; Zhang, S.; Tong, J. Biomimeitc design of a stubble-cutting disc using finite element analysis. J. Bionic Eng. 2013, 10, 118–127. [Google Scholar] [CrossRef]

- Zhang, S.; Jia, X.; Dong, J.; Wang, X.; Zhao, H.; Chen, X.; Zhang, Z.; Huang, Y.; Shi, J. Optimization of operating angles of disc coulters for maize residue management using discrete element method. Comput. Electron. Agric. 2024, 218, 108691. [Google Scholar] [CrossRef]

- Yang, F.; Li, W.; Li, H.; Su, Y. Finite element analysis for gap disc of no-till planter. Trans. CSAM 2010, 41, 53–80. [Google Scholar]

- Zhao, X.; Zhang, Z.L.; Tang, P.; Zhang, G.L.; Zhang, W.Z. Behavior of passive stubble-cutting disc with oblique ripples. Trans. CSAM 2011, 42, 64–67. [Google Scholar]

- Huo, J.; Sun, W.; Chen, J.; Su, P.; Deng, L. Optimal disc cutters plane layout design of the full-face rock tunnel boring machine (tbm) based on a multi-objective genetic algorithm. J. Mech. Sci. Technol. 2010, 24, 521–528. [Google Scholar] [CrossRef]

- Wang, Q.J.; Li, H.W.; He, J.; Li, W.Y.; Rabi, G.R. Design and experiment on concave disc type maize ridge-till and no-till planter. Trans. CSAE 2011, 27, 117–122. [Google Scholar]

- Che, G.; Zhang, W.; Wang, L.; Zou, L.; Liang, Y. Design and experiment of multifunctional tillage machine with driven bent blade by stubble ploughing disk. Trans. CSAM 2012, 42, 64–67. [Google Scholar]

- Zhuang, J.; Jia, H.L.; Ma, Y.H.; Li, Y.; Di, Y.K. Design and experimental of sliding-knife notched disc opener. Trans. CSAM 2013, 44, 83–88. [Google Scholar]

- Lin, J.; Li, B.; Li, B.F.; Niu, J.L.; Qiang, W. Parameter optimization and experiment on archimedes spiral type of gap cutting disc. Trans. CSAM 2014, 45, 118–124. [Google Scholar]

- Wang, J.Y.; Zhao, S.H.; Gao, L.L.; Yuan, Y.W.; Yang, Y.Q. Design and experiment of passive disc cutting blade in corn ridges. Trans. CSAM 2021, 52, 59–67. [Google Scholar]

- Jia, H.L.; Zhao, J.L.; Jiang, X.M.; Jiang, T.J.; Wang, Y.; Guo, H. Design and experiment of anti-blocking mechanism for inter-row no-tillage seeder. Trans. CSAM 2013, 29, 16–25. [Google Scholar]

- Jia, H.L.; Liu, X.; Yu, H.B.; Lu, Y.; Guo, C.J.; Qi, J.T. Simulation and experiment on stubble clearance mechanism with concave claw-type for no-tillage planter. Trans. CSAM 2018, 49, 68–77. [Google Scholar]

- Wang, Q.; Jia, H.L.; Zhu, L.T.; Li, M.W.; Zhao, J.L. Design and test of star-tooth concave disc straw cleaning and anti-blocking device for no-tillage seeder. Trans. CSAM 2019, 50, 68–77. [Google Scholar]

- Cao, X.P.; Wang, Q.J.; Li, H.W.; He, J.; Lu, C.Y. Combined row cleaners research with side cutter and stubble clean disk of corn no-till seeder. Trans. CSAM 2021, 52, 36–44. [Google Scholar]

- Liu, Z.J.; Liu, L.J.; Yang, X.J.; Zhao, Z.B.; Liu, X.Q. Design and experiment of no-till precision planter for corn. Trans. CSAE 2016, 32, 1–6. [Google Scholar]

- Zhu, H.B.; Zhang, X.; Hong, Y.; Bai, L.Z.; Zhao, H.R.; Ma, S.A. Design and experiment of bionic shifting and diffluence straw anti-blocking device. Agric. Res. Arid. Areas 2023, 41, 318–328. [Google Scholar]

- Huang, Y.X.; Gao, P.Y.; Zhang, Q.K.; Shen, H.; Zhu, R.X.; Shi, J.T. Design and experiment of grass soil separation device with combination of stubble cutting and grass guiding used for no-till planter. Trans. CSAM 2020, 51, 67–78. [Google Scholar]

- Yuan, P.P.; Li, H.W.; Jiang, G.J.; He, J.; Lu, C.Y.; Huang, S.H. Design and experiment of straw cleaning device for wide narrow maize no-tillage sowing strip in drip irrigation area. Trans. CSAM 2021, 52, 43–52. [Google Scholar]

- Zhao, H.B.; Li, H.W.; Ma, S.C.; He, J.; Wang, Q.J.; Lu, C.Y.; Zheng, Z.Q.; Zhang, C. The effect of various edge-curve types of plain-straight blades for strip tillage seeding on torque and soil disturbance using DEM. Soil Tillage Res. 2020, 202, 104674. [Google Scholar] [CrossRef]

- Zhang, X.R.; He, J.; Li, H.W.; Li, W.Y.; Li, H. Design and experiment on the driving disc of anti-blocking unit for no-tillage planter. Trans. CSAE 2009, 25, 117–121. [Google Scholar]

- Jia, H.L.; Gou, M.Z.; Guo, C.J.; Zheng, J.; Zhang, C.L.; Zhao, J.L. Design of dynamic bionic stubble cutting device and optimization test of parameters. Trans. CSAM 2018, 49, 103–114. [Google Scholar]

- Shi, Y.P.; Zhai, C.Y.; Zhu, R.X.; Yan, X.L.; Ge, S.Q.; Li, C.X.; Shi, Y. Design and operating performance of a trapezoidal combination cutterhead. Agric. Mech. Res. 2015, 37, 182–187. [Google Scholar]

- Wang, J.Y.; Zhao, S.H.; Yang, Z.J.; Gao, L.L.; Yang, Y.Q. Design and experiment of driving stubble cutter for corn strip with less tillage operation. Trans. CSAM 2021, 52, 51–61. [Google Scholar]

- Zhao, H.B.; He, J.; Zheng, Z.Q.; Zhang, Z.G.; Liu, W.Z. Strip tillage inter-row residue side-throwing device of no/minimum-till seeder for anti-blocking and seedbed-cleaning. Trans. CSAM 2018, 51, 24–34. [Google Scholar]

- Zhao, H.B.; He, J.; Li, H.W.; Liu, C.G.; Zheng, K.; Zhang, Z.Q. Design and experiment of strip rotary-cut-throw anti-blocking implement. Trans. CSAM 2018, 49, 65–75. [Google Scholar]

- Hou, S.Y.; Chen, H.T.; Zou, Z.; Shi, N.Y. Design and test of side-direction straw-cleaning blade for seedbed treatment of original stubble planter. Trans. CSAE 2019, 36, 59–69. [Google Scholar]

- Hou, S.Y.; Chen, H.T.; Zhou, Z.; Wei, Z.P.; Zhang, Y.L. Design and test of lateral stubble cleaning blade for corn stubble field. Trans. CSAE 2020, 36, 59–69. [Google Scholar]

- Gao, N.N.; Zhang, D.X.; Yang, L.; Liu, J.; Shi, S.; Cui, T. Design and experiment of drum-type anti-blocking mechanism of no-till planter for maize. Trans. CSAE 2012, 28, 31–37. [Google Scholar]

- Chen, H.T.; Hou, L.; Hou, S.Y.; Li, Y.; Min, S.Y.; Chai, Y.D. Design and optimization experiment of anti-blocking mechanism of no-tillage planter for grand ridge with raw corn stubble. Trans. CSAM 2018, 49, 59–67. [Google Scholar]

- Zhang, J.C.; Yan, X.L.; Xue, S.P.; Zhu, R.X.; Su, G.Y. Design of no-tillage maize planter with straw smashing and fertilizing. Trans. CSAM 2012, 43, 51–55. [Google Scholar]

- Yu, C.C.; Wang, Q.J.; Li, H.W.; He, J.; Lu, C.Y.; Liu, H. Design and experiment of spiral-split sowing strip Cleaning device. Trans. CSAM 2020, 51, 212–219. [Google Scholar]

- Lu, C.Y.; Li, H.W.; He, J.; Zhu, H.B.; Xu, D.J. Floated support anti-blocking device of wheat no-till seeder. Trans. CSAM 2013, 44, 52–153. [Google Scholar]

- Liu, J.X.; Wang, H.; Wang, Q.J.; Li, S.H.; Li, H.W.; He, J. Design and experiment of strip cleaning device of no and minimum-tillage corn planter. Trans. CSAM 2018, 49, 132–140. [Google Scholar]

- Li, Y.; Guo, C.F.; Yao, D.Y.; He, N.B.; Zhang, X.R. Design and experiment of banana straw crushing and returning machine with anti-wrapping device supported by flailing blade. Trans. CSAE 2021, 37, 11–19. [Google Scholar]

- Liu, X.P.; Du, J.H.; Li, Z.X.; Jiao, J.; Huang, X.H.; Niu, Z.J. Design and experiment of picking up and crushing mechanism of sugarcane leaf round baler. Chin. J. Agric. Mech. 2023, 44, 26–31. [Google Scholar] [CrossRef]

- Zhang, S.L.; Huang, Y.X.; Zhao, H.B.; Fu, Z.L.; Liu, Z.D.; Shi, J.T. Design and experiment of cutting and throwing combined anti-blocking device for wide-seedbed seeding of wheat. Trans. CSAM 2024, 55, 40–52. [Google Scholar]

- Li, Y.; Li, Z.; Cui, S.; Zhang, Q. Trade-off between soil pH, bulk density and other soil physical properties under global no-tillage agriculture. Geoderma 2020, 361, 114099. [Google Scholar] [CrossRef]

- Lal, R. Soil carbon sequestration impacts on global climate change and food security. Science 2004, 304, 1623–1627. [Google Scholar] [CrossRef]

- Bronick, C.J.; Lal, R. Soil structure and management: A review. Geoderma 2005, 124, 3–22. [Google Scholar] [CrossRef]

- Malik, A.A.; Puissant, J.; Buckeridge, K.M.; Goodall, T.; Jehmlich, N.; Chowdhury, S.; Gweon, H.S.; Peyton, J.M.; Mason, K.E.; Agtmaal, M.; et al. Land use driven change in soil pH affects microbial carbon cycling processes. Nat. Commun. 2018, 9, 3591. [Google Scholar] [CrossRef]

- Zhao, S.H.; Wang, J.Y.; Yang, C.; Chen, J.Q.; Yang, Y.Q. Design and experiment of stubble chopper under conservation tillage. Trans. CSAM 2019, 50, 57–68. [Google Scholar]

- Zhu, H.B.; Qian, C.; Bai, L.Z.; Zhao, H.R.; Ma, S.A.; Zhang, X.; Li, H. Design and experiments of active anti-blocking device with forward-reverse rotation. Trans. CSAE 2022, 38, 1–11. [Google Scholar]

- Hou, S.Y. Research on Key Technology and Equipment of Lateral and Multi-Stage Stubble Treatment Based on In-Situ Ridge-Tillage and No-Tillage Seeder. Ph.D. Thesis, Northeast Agricultural University, Harbin, China, 2020. [Google Scholar]

- Yao, W.Y.; Zhao, D.B.; Xu, G.F.; Chen, M.Z.; Miao, H.Q.; Diao, P.S. Design and experiment of anti-blocking device for strip to row active corn no-tillage seeding. Trans. CSAM 2020, 51, 55–62+71. [Google Scholar]

- Yao, W.Y.; Zhao, D.B.; Miao, H.Q.; Cui, P.D.; Wei, M.J.; Diao, P.S. Design and experiment of oblique anti-blocking device for no-tillage planter with shallow plowing stubble clearing. Trans. CSAM 2022, 53, 42–52. [Google Scholar]

- Wu, T.; Ma, X.; Qi, L.; Cheng, X.S.; Cheng, G.R. Roots-soil separating device of corn stubble. Trans. CSAM 2014, 45, 133–139. [Google Scholar]

- Xia, Y.D.; Klinger, J.; Bhattacharjee, T.; Thompson, V. The elastoplastic flexural behaviour of corn stalks. Biosyst. Eng. 2022, 216, 218–228. [Google Scholar] [CrossRef]

- Xing, R.J.; Ling, G.; Li, H.T.; Wang, Q.J.; Zheng, W.Q. Research progress and prospect of ditching disc of no-tillage seeder in China. Res. Agric. Mech. 2023, 45, 1–9. [Google Scholar]

- Sun, H.; Ling, G.; Li, H.W.; Gao, X.L.; Yao, G.C. Influence of scanning interval on microstructure and abrasive wear resistance of 45 Steel by laser melting. Trans. CSAE 2011, 27, 156–160. [Google Scholar]

- Li, C.S.; Tang, Y.L.; McHugh, A.D.; Wu, X.L.; Liu, M.; Li, M.; Xiong, T.; Ling, D.; Tang, Q.; Liao, M.; et al. Development and performance evaluation of a wet-resistant strip-till seeder for sowing wheat following rice. Biosyst. Eng. 2022, 220, 146–158. [Google Scholar] [CrossRef]

- Li, J.W.; Li, X.Y.; Hu, B.; Gu, T.L.; Wang, Z.J.; Wang, H.L. Analysis of the resistance reduction mechanism of potato bionic digging shovels in clay and heavy soil conditions. Comput. Electron. Agric. 2023, 214, 108315. [Google Scholar] [CrossRef]

- Li, B.; Chen, Y.; Chen, J. Modeling of soil-claw interaction using the discrete element method (DEM). Soil Tillage Res. 2016, 158, 177–185. [Google Scholar] [CrossRef]

- Tong, J.; Sun, J.Y.; Chen, D.H.; Zhang, S.J. Geometrical features and wettability of dung beetles and potential biomimetic engineering applications in tillage implements. Soil Tillage Res. 2015, 80, 1–12. [Google Scholar] [CrossRef]

- Sun, J.F.; Chen, H.M.; Wang, Z.M.; Ou, Z.W.; Yang, Z.; Duan, J.L. Study on plowing performance of EDEM low-resistance animal bionic device based on red soil. Soil Tillage Res. 2020, 196, 104336. [Google Scholar] [CrossRef]

- Wu, X.Q. Study on Resistance Reduction Characteristic of the Ripple-Lubrication Surface of Earthworm and Coupling. Bionic. Thesis, Jilin University, Jilin, China, 2019. [Google Scholar]

- Li, H.; Ju, W.L.; Song, Y.M.; Cao, Y.Y.; Yang, W.; Li, M.Z. Soil organic matter content prediction based on two-branch convolutional neural network combining image and spectral features. Comput. Electron. Agric. 2024, 217, 108561. [Google Scholar] [CrossRef]

- Zhang, D.J.; Lu, Z.Y.; Zhang, X.Q.; Jing, Z.J.; Yao, Z.J.; Cheng, Y.C.; Wang, Y.F.; Zhang, J.Z.; Bai, H.; Wei, F. Effects of different tillage methods on maize yield and soil physical and chemical characters of maize field. Chin. Agric. Sci. Bull. 2014, 30, 209–213. [Google Scholar]

- Pan, Y.; Li, S.Y.; Gao, J.; Shen, X.Y.; Liu, L.J. Research progress on effects of straw and its returning methods on soil properties in paddy fields under different rotation pattern. Crops 2024, 1–8. [Google Scholar]

- Gao, Y. Research progress of stubble control deep pine land preparation combined operation machine. Use Maint. Agric. Mach. 2023, 8, 99–102. [Google Scholar]

- Silva, R.D.; Cielniak, G.; Gao, J.F. Vision based crop row navigation under varying field conditions in arable fields. Comput. Electron. Agric. 2024, 217, 108581. [Google Scholar] [CrossRef]

- Wang, J.C.; Zheng, H.; Yu, Y.; He, Y.; Liu, Y.F. Robust multiple obstacle tracking method based on depth aware OCSORT for agricultural robots. Comput. Electron. Agric. 2024, 217, 108580. [Google Scholar] [CrossRef]

- Shang, X.L.; Cao, J.B.; Wang, Y.; Yang, B.N.; Li, D.Y.; Wang, H. Current situation and prospect of conservation tillage technology. J. Chin. Agric. Mech. 2021, 42, 191–201. [Google Scholar]

- Guo, F.; Jin, J.J.; Zhang, C.Y.; He, R.; Qiu, X. A review of farmers’ conservation tillage technology adoption behavior and influencing factors. Prog. Geogr. 2022, 41, 2165–2177. [Google Scholar] [CrossRef]

- Wei, G.J.; Jian, S.C.; Fang, H.M.; Peng, Q.J.; Niu, M.M. Current situation and prospect of conservation tillage technology in dry-farming areas of North China. J. Chin. Agric. Mech. 2019, 40, 195–200. [Google Scholar]

| Corn [20,21,22,23,24] | Cutting Height | Diameter | Depth of Root Upper Segment | Main Root | Vice Root | ||

| Diameter | Number | Diameter | Number | ||||

| 30–124 mm | 19–31 mm | 50–80 mm | 4–6 mm | 11–17 | 3–5 mm | 11–14 | |

| Rice [25,26,27,28] | Cutting Height | Diameter | Depth of Root Upper Segment | Root Length | Root Density | ||

| 136–223 mm | 36–84 mm | 63–144 mm | 300–500 mm | 100,000–150,000 mm2 | |||

| Wheat [29,30] | Cutting Height | Diameter | Depth of Root Upper Segment | Total Root Length | Root Surface Area | Total Root Volume | |

| 150–200 mm | 2.69–3.85 mm | 30–50 mm | 2446.8–4269.6 mm | 23,590–35,900 mm2 | 220–290 mm3 | ||

| Object | Mechanical Characteristic Parameter | Test Instrument | Research Content and Results |

|---|---|---|---|

| Loess | Shear strength | ZJ strain-controlled direct shear apparatus | Shear stress: 8.25 kPa (0–60 mm, moisture content: 17.59%), 2.47 kPa (60–120 mm, moisture content: 22.98%) and 9.01 kPa (120–180 mm, moisture content: 20.96%) [31]. |

| Loam 65 Mn | Static friction coefficient and dynamic friction coefficient | MXD-01 friction coefficient measuring instrument | The rolling friction factors for 65 Mn soil particles in different layers are as follows: loam tillage layer (moisture content: 7.54%): 0.107, loam plough bottom (moisture content: 11.45%): 0.130, loam core layer (moisture content: 14.6%): 0.078. The static friction factors are as follows: loam tillage layer: 0.313, loam plough bottom: 0.639, loam core layer: 0.427 [32]. |

| Sandy soil 65 Mn stubble | The friction factors are as follows (moisture content: 14.6%): 65 Mn and stubble: static 0.42, dynamic 0.394; stubble with itself: static 0.383, dynamic 0.263; sandy soils and stubble: static 0.378, dynamic 0.308; sandy soils and 65 Mn: static: 0.340, dynamic 0.299 [33]. | ||

| Corn stubble steel grade 45 | Sliding friction angle | Sliding friction test bench (self-made) | The sliding friction angles are as follows: Corn stalk—45 steel: 23° to 31°; Corn stubble—45 steel: 15.2° to 15.8°; Corn roots—45 steel: 30° to 38° [22]. |

| Rice | Shearing force | FUDOH texture analyzer | The cutting limit forces of the upper and lower sections of rice are 206.5 N and 156.8 N, respectively (moisture content: 27.85%) [34]. |

| Rice | Sliding cutting force | TMS-PRO texture instrument | At a sliding cut angle of 45°, the sliding shear forces per unit diameter are 4.32 N/mm for the upper section and 3.16 N/mm for the lower section of paddy (moisture content: 27.85%) [35]. |

| Rice and loam mixture, wheat and loam mixture | At the soil moisture content of 10.2%, the shear strength of both rice and wheat mixed with loam is 7.92 MPa. At 20.5% moisture content, the shear strength is 19.85 MPa for rice and 13.45 MPa for wheat. At 29.6% moisture content, the shear strength increases to 21.56 MPa for rice and 15.27 MPa for wheat [36]. | ||

| Corn | Shearing stress | Universal material tester | At a shear speed of 240 mm/min, the ultimate shear value of the corn system is 83.59 N [37]. |

| Region | Type [38] | Soil Cohesion (kPa) [39,40,41] | Angle of Internal Friction (°) [42,43] | Dry Density (g/cm3) [44] | Wet Density (g/cm3) [45] | Poisson’s Ratio for Soil [46] | Shear Modulus (MPa) [47,48,49] |

|---|---|---|---|---|---|---|---|

| Asian | Clay soils | 20~100 kPa | 15°~25° | 1.2–1.4 g/cm3 | 1.5–1.7 g/cm3 | 0.30~0.45 | 1~20 MPa |

| Sandy soils | 0~10 kPa | 30°~45° | 1.5–1.7 g/cm3 | 1.8–2.0 g/cm3 | 0.25~0.35 | 10~100 MPa | |

| Loam soils | 10~40 kPa | 25°~35° | 1.3–1.5 g/cm3 | 1.6–1.8 g/cm3 | 0.30~0.40 | 5~50 MPa | |

| Silty soils | 15~30 kPa | 25°~35° | 1.4–1.6 g/cm3 | 1.7–1.9 g/cm3 | 0.30~0.40 | 5~50 MPa | |

| Phaeozem | 20~30 kPa | 15°~25° | 1.1–1.3 g/cm3 | 1.4–1.7 g/cm3 | 0.30~0.40 | 10~25 MPa | |

| European | Peat soils | 1~10 kPa | 5°~20° | 0.1–0.8 g/cm3 | 0.2–0.9 g/cm3 | 0.10~0.30 | 1~10 MPa |

| Sandy soils | 5~20 kPa | 30°~40° | 1.5–1.7 g/cm3 | 1.6–1.8 g/cm3 | 0.2~0.35 | 10~50 MPa | |

| Loam soils | 10~30 kPa | 20°~35° | 1.2–1.6 g/cm3 | 1.3–1.7 g/cm3 | 0.25~0.35 | 20~80 MPa | |

| Silty soils | 5~25 kPa | 25°~35° | 1.5–1.7 g/cm3 | 1.6–1.8 g/cm3 | 0.25~0.35 | 15~50 MPa | |

| Clay soil | 20~100 kPa | 20°~35° | 1.1–1.4 g/cm3 | 1.2–1.5 g/cm3 | 0.4~0.45 | 10~30 MPa | |

| Phaeozem | 20~40 kPa | 25°~35° | 1.2–1.4 g/cm3 | 1.5–1.7 g/cm3 | 0.30~0.35 | 10~50 MPa | |

| Americas | Sandy soil | 10~50 kPa | 30°~40° | 1.5–1.7 g/cm3 | 1.6–1.8 g/cm3 | 0.25~0.35 | 5~50 MPa |

| Loam | 30~100 kPa | 25°~35° | 1.2–1.4 g/cm3 | 1.3–1.5 g/cm3 | 0.25~0.40 | 10~100 MPa | |

| Clay soil | 50~200 kPa | 20°~30° | 1.1–1.3 g/cm3 | 1.2–1.4 g/cm3 | 0.35~0.45 | 30~300 MPa | |

| Peat soil | 5~30 kPa | 10°~20° | 0.1–0.2 g/cm3 | 0.2–0.3 g/cm3 | 0.05~0.15 | 0.1~1 MPa | |

| Rocky soil | 50~300 kPa | 30°~60° | 2.0–2.5 g/cm3 | 1.8–2.3 g/cm3 | 0.15~0.35 | 50~200 MPa | |

| Phaeozem | 15~30 kPa | 25°~35° | 1.1–1.4 g/cm3 | 1.4–1.7 g/cm3 | 0.20~0.30 | 50~200 MPa | |

| Oceania | Sandy soil | 100~200 kPa | 30°~40° | 1.5–1.8 g/cm3 | 1.6–2.0 g/cm3 | 0.25~0.35 | 5~50 MPa |

| Loam | 20~300 kPa | 25°~35° | 1.2–1.5 g/cm3 | 1.3–1.6 g/cm3 | 0.25~0.40 | 10~100 MPa | |

| Clay soil | 200~1000 kPa | 15°~30° | 1.0–1.4 g/cm3 | 1.1–1.6 g/cm3 | 0.35~0.45 | 30~300 MPa | |

| Peat soil | 10~100 kPa | 5°~15° | 0.1–0.3 g/cm3 | 0.2–0.5 g/cm3 | 0.05~0.15 | 0.1~1 MPa | |

| Africa | Sandy soil | 50~150 kPa | 30°~40° | 1.5–1.8 g/cm3 | 1.6–2.0 g/cm3 | 0.25~0.35 | 5~40 MPa |

| Loam | 100~250 kPa | 25°~35° | 1.2–1.5 g/cm3 | 1.3–1.6 g/cm3 | 0.25~0.40 | 10~80 MPa | |

| Clay soil | 500~1000 kPa | 15°~30° | 1.0–1.4 g/cm3 | 1.1–1.6 g/cm3 | 0.30~0.45 | 20~200 MPa | |

| Peat soil | 5~100 kPa | 5°~15° | 0.1–0.3 g/cm3 | 0.2–0.5 g/cm3 | 0.05~0.20 | 0.1~1 MPa |

| Particle Contact Model | Model Characteristic | Application Range | Model Characteristic Parameters | Getparms Method | Applications |

|---|---|---|---|---|---|

| Hertz Mindlin | Normal and tangential forces of particles include damping components, related to the coefficient of restitution between particles. | Root–stubble (regarded as a rigid body) mixed with buried soil is simulated. | Crash restitution coefficient, static friction coefficient, dynamic friction coefficient (all conventional). | Velocity of the object before and after collision is measured using a flat plate, high-speed camera and wire rope suspension, among other methods; calculations are conducted. Static and dynamic friction coefficients are measured via the inclined plane method [56]. | This model was employed to analyze the effects of the parameters of the rotary cutter-burying finger combination machine on the root–stubble rotary-burying quality. The structure of the device was optimized. A field experiment was carried out to verify the accuracy of the model used to simulate root–stubble incorporation. Compared with the traditional rotary tiller, the combined machine enhanced the depth of root–stubble incorporation and reduced the proportion of the root–stubble in the 0–5 cm soil layer by 12.47% after operation [57]. |

| Hertz Mindlin with Bonding | Bonding bonds are employed to connect particles. These bonds resist tangential and normal movement and break when stress exceeds a threshold. | The crushing effects of stubble, roots and soil are simulated. | Normal stiffness coefficient, tangential stiffness coefficient, critical normal stress, critical tangential stress. | A shear test of the measured object by a texture analyzer is performed to obtain the normal and tangential shear forces, normal stiffness per unit area and tangential stiffness per unit area. Four key parameters are derived using a relational formula [58]. | This model was employed to simulate the effect of spring-rake teeth on the movement of the stubble along the ridge, and the optimal structural combination of spring-rake teeth was determined. A new machine with spring-rake teeth was processed, and a field experiment was conducted to measure the rate of root–stubble clearing of the machine. The discrepancy between the rate of root–stubble clearing in the simulation and that in the field experiment was only 1.1%, verifying the accuracy of the simulation results. Compared with the traditional horizontal stubble cleaner, the new machine showed a 3.7% increase in the rate of clearing root–stubble. |

| Hertz Mindlin with JKR | The contact model accounts for cohesion between particles, considering the influence of van der Waals forces in the contact zone. | The adhesion effects between soil particles, the soil root system and soil–soil components are simulated. | Surface energy. | The surface energy of the object is tested using three types of liquids and a camera with the droplet method, followed by calculations to obtain the results [59]. | The model was employed to analyze the interactions among different soil layers in heavy clay. The performance of the driven disc plow and double-edged rotary tillage combined machine was investigated on stubble returning. The combined machine was processed, and a field experiment was conducted. Under heavy clay conditions, the rate of returning stubble of the combined machine reached 97.7%, with an error of just 2.01% between the simulation and the actual results, which verified the accuracy of the simulation results. Compared with the traditional rotary cultivator, the stubble returning rate of the new machine increased by 24.23% [60]. |

| Type | Structure | Application Environment | Characteristics |

|---|---|---|---|

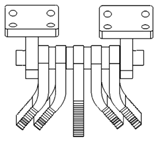

| Angle-notched disc |  | Zones of high root–stubble intensity and coverage | The edge of the disc has some gaps, resulting in a small contact area with the soil and strong trafficability. The gap structure has a gathering effect on the root–stubble, which is beneficial in cutting off the stem. However, the cutting resistance is significant, and the power consumption is high [65]. |

| Corrugated disc |  | Arid and semi-arid zones | The surface of the disc is corrugated, relying on the corrugated grooves to disturb the soil. It has a strong ability to loosen the soil, and the disturbance to the soil is considerable. The number of corrugated grooves can be reasonably selected according to the working object’s condition. The root–stubble are mainly cut by sliding, which provides a certain ability to cut stubble [66]. |

| Planar disc |  | Zones of low root–stubble intensity and coverage | The disc is a complete circle, which causes low soil disturbance during operation, low working resistance and good cutting performance for root–stubble. However, the effectiveness of cutting stubble is not optimal when the root straw coverage is extensive [67]. |

| Name | Structure | Application Environment | Content | Comparison |

|---|---|---|---|---|

| Concave disc for cleaning of root–stubble on the ridge |  | Row crop area in the Northern Temperate Zone | A concave disc for the cleaning of root–stubble on the ridge was designed. The device is composed of double concave discs inclined symmetrically. Through the flipping effect of the concave disc, the root–stubble could be cut off and pushed into the furrows on both sides by using the device. The rate of disturbed soil of the unit was 22%, and the rate of covered straw and root–stubble after operation was only 12.7%, which was 75.9% lower than that before operation [68]. | The ground temperature of the seed strip at 5 cm was increased by 0.6–2.4 °C compared to a no-till planter for corn rows not equipped with concave discs. |

| Self-driven arc tooth disc stubble-crushing device |  | Northern Temperate Zone | Based on the multi-tooth structure, a passive arc-shaped tooth disc stubble-crushing device was designed. Using its ground wheel effect, combined with the power of the soil-crushing device during operation, the stubble cutting, rotary tillage and ridging processes were completed in one step. The rates of root–stubble and soil crushing of the unit are 93.5% and 92.4%, respectively [69]. | Compared with traditional tillage equipment and imported combines, the soil breaking rate is increased by 2.4–6.9%, the stubble breaking rate is increased by 6.3–12.9% and the fuel consumption is reduced by 26.3–40.4%. |

| Combined curve stubble-crushing disc cutter |  | Phaeozem region of the Northern Temperate Zone | The combined curve disc cutter was designed by combining the sliding blade edge with the arc blade curve. Experiments proved that the combined curve disc cutter had a good stubble-cutting ability and improved the no-till planter’s passing ability through black soil corn stubble. The root–stubble could be crushed completely when the rate of the covered straw was 62.77% [70]. | —— |

| Archimedes spiral notch disc stubble cutter |  | Corn row crop area in the Northern Temperate Zone | By utilizing the Archimedes spiral, the structure of the notch disc stubble cutter was optimized, the stubble resistance of the disc cutter was reduced and the quality of the disc cutter’s stubble trenching was improved. The power consumption and the rate of root–stubble crushing of the cutter are 0.86 kW and 95.7%, respectively [71]. | —— |

| Passive disc stubble-crushing cutter with automatic cutting edge angle |  | No-tillage corn rows under straw crushing and returning to the field | A passive disc stubble-crushing cutter with an automatic cutting edge angle was designed. The cutting edge angle could be adjusted according to the characteristics of the stubble and soil at different depths, reducing tillage resistance and increasing the stubble-crushing ratio. The rate of root–stubble crushing of the cutter is 96.8% [72]. | Reduces tillage resistance by 13.3% and 20.6%, reduces fuel consumption by 19.3% and 35.3% and improves stubble breakage by 16.1% and 4.6% relative to disc and gap disc cutters. |

| Anti-blocking device of no-tillage planter |  | Zones with inter-row intercropping patterns and alternating wide and narrow row recreation patterns | A combined blade suitable for inter-row interaction and wide–narrow row modes was designed. It reduced the operating power consumption and improved the straw-cutting rate. The rate of root–stubble cutting and the power consumption of a single cutter are 90.9% and 8.15 W, respectively [73]. | —— |

| Concave arc-shaped lateral blade notched single-disc circular blade |  | No-tillage corn row field | A concave arc-shaped lateral blade notch single-disc circular blade was designed, which has a disruptive effect on the soil below the ground surface, can cause the secondary cutting of stubble and enhances the stubble-cutting efficiency. When the level of straw covering is large, the cutter at the forward speed of 6 km/h can achieve root–stubble crushing and side-throwing under the condition of less disturbed soil [61]. | Compared with circular blades, the average forward displacement of stubble under the action of lateral blades is 568 mm, 639 mm and 502 mm, respectively, increasing by 1.15 times, 1.12 times and 1.21 times. This enhances the working duration of the blades on the stubble. |

| Name | Structure | Application Environment | Content | Comparison |

|---|---|---|---|---|

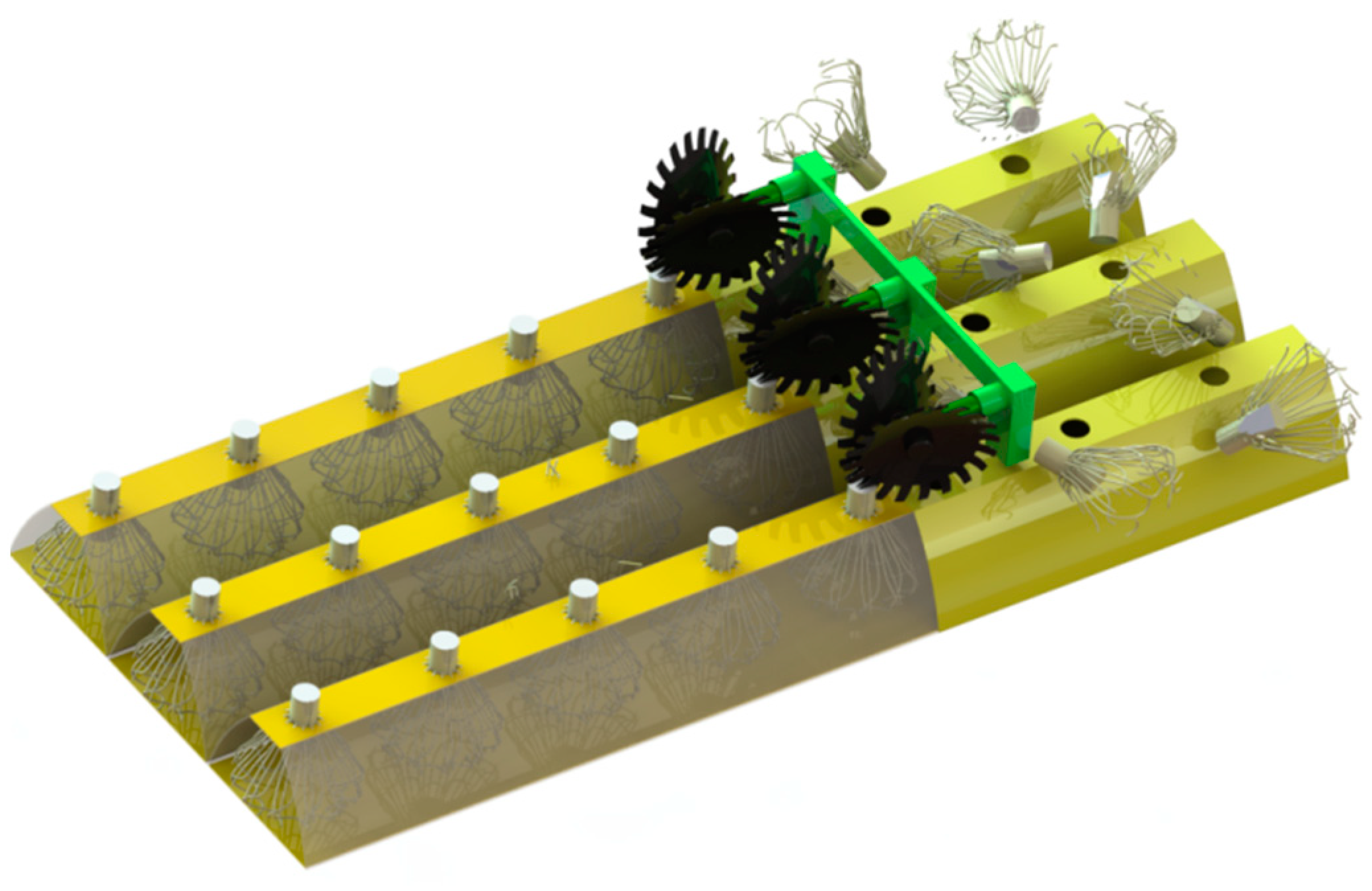

| Archimedes spiral serrated notched disc stubble-crushing cutter-star ridge-cleaning wheel-combined stubble-cleaning device |  | Row crop area in the Northern Temperate Zone | By integrating the Archimedes spiral serrated notched disc stubble-crushing cutter with the star-shaped ridge-clearing wheel, the anti-winding stubble-crushing ridge-clearing device was designed, enhancing the passability of the corn ridge no-tillage planter. The rates of root–stubble clearing and crushing of the unit are 93.49% and 92.21%, respectively [21]. | —— |

| Concave claw-type stubble-cleaning tooth plate |  | Thick corn stalk zone | A concave claw-type straw stubble-cleaning disc was designed. The wheel grab was used to grasp the stubble on the side and cast it behind, improving the stubble-cleaning rate of the device. The improved rate of root–stubble clearing of the unit is 83.61% [74]. | Compared with the traditional plane stubble-cleaning wheel, the average lateral throwing speed of the root straw of the concave stubble-cleaning wheel was increased by 31.02%. |

| Star-tooth concave disc straw-cleaning anti-blocking device |  | Row crop area in the Northern Temperate Zone | A star-tooth concave disc straw-cleaning anti-blocking device was engineered. The stubble and straw could be side-thrown to both sides of the machine along the tangential direction of the star-tooth concave surface. The device operated stably and enhanced the straw cleaning rate. The rate of clearing root–stubble and the operating resistance of the unit are 92.2% and 142.6 N, respectively [75]. | Compared with the flat claw wheel straw-cleaning and anti-blocking device, the straw-cleaning rate of the seedling belt was increased by 27.5%, and the working resistance was reduced by 23.1%. |

| Side cutter and stubble tooth plate combined stubble-cleaning device |  | Zones with high straw cover | A combined stubble-cleaning device composed of a side cutter and stubble tooth plate was designed. The straw on one side of the seed belt was cut by the notched stubble-cutting disc, and the straw on the seed belt was removed by the stubble tooth plate, thus improving the stubble-cleaning rate of the seed belt. The rate of root–stubble clearing of the unit is 91.4% [76]. | —— |

| Involute tooth-shaped stubble-separating grass disc |  | Zones with large quantities of straw and different cropping patterns | An involute tooth-shaped stubble-separating grass disc suitable for finger-type corn no-tillage precision seeders was designed, thereby improving the cleaning effect of stubble in the seedbed and nursery bed. The unit is suitable for use with finger-clip seeders and could achieve no-till seeding of corn at a forward speed of 9 km/h [77]. | —— |

| Bionic shifting and diffluence straw and anti-blocking device |  | Arid areas covered with a large amount of wheat straw | Based on the bionic prototype of the white star flower scarab line, a bionic shifting and diffluence straw and anti-blocking device was designed. The straw was lifted and thrown out to the side and rear by the bionic grass wheel, and then the straw was shunted to both sides by the bionic grass distribution baffle. The soil disturbance and the actual straw removal rate were 20.00% and 90.58%, respectively [78]. | —— |

| Grass soil separation device with combination of stubble cutting and grass guiding |  | Zones covered with wheat straw stubble | The combination device of the concave notched disc cutter and the opener with a grass-guiding plate was used to cut, throw and guide the straw, root–stubble and weeds, which enhanced the passing ability. The rate of clearing root–stubble and straw was 90.16%, and the rate of disturbed soil was 20.85% [79]. | —— |

| Device for cleaning of straw in sowing strip |  | No-tillage sowing strip in drip irrigation area | A device for wide–narrow maize no-tillage sowing strips in drip irrigation areas was designed, which could move the straw residues in the narrow row to the adjacent wide row, effectively avoiding the occurrence of winding blockages. The rate of stubble and straw clearing was 87.61% [80]. | —— |

| Name | Structure | Application Environment | Content | Comparison |

|---|---|---|---|---|

| Driving disc-ditcher anti-blocking unit body |  | Regions with corn stubble cover twice a year | A driving disc-ditcher anti-blocking unit body was designed. This increased the cutting rate of wheat stubble and reduced the soil disturbance. The rates of root–stubble cutting and soil disturbance of the unit are 92.1% and 8.4%, respectively [82]. | Compared to the strip crushing no-tillage wheat seeder, the driven disc-type no-tillage wheat seeder increased the rate of stubble cutting by 11.2% and reduced the soil disturbance by 58.8%. |

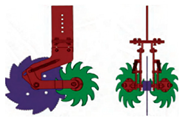

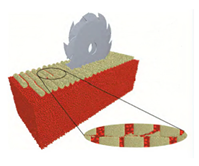

| Dynamic imitation locust mouth part stubble-crushing cutter |  | Regions with stout corn stalks | Bionic prototypes based on the structure and movement of locust mouth parts were used to design a dynamic bionic stubble-crushing cutter. It demonstrated an improved cutting rate in root straw compared to the driving gap disc stubble-crushing cutter. The rate of root–stubble cutting and torque of the unit are 92.9% and 54.1 N·m, respectively [83]. | Compared to passive notch disc stubble cutters, the active notch disc stubble cutter can increase the stubble cutting rate by 22.6% to 27.4%. Compared to driven notch disc stubble cutters, it can increase the stubble cutting rate by 8.6% to 13.5% while reducing the torque output by 19.5%. |

| Double cutter power-cutting stubble-crushing device |  | Regions with two growing seasons for wheat and corn per year | By combining active and passive disc cutters, a root–stubble crushing device for passive soil crushing and active stubble crushing was developed. It enhanced the passability of the no-tillage planter when dealing with large wheat root straw coverage. The root–stubble crushing and cutting rates of the unit are 98.7% and 96.2%, respectively [29]. | —— |

| Stubble-crushing device with trapezoidal combined cutter head |  | Regions with higher soil moisture content | A trapezoidal tooth-shaped cutter head was designed, with double cutter heads arranged at a specific angle and axially parallel in the circumferential direction. The combined cutter head improved the machine’s anti-blocking performance against stubble. The unit is suitable for crushing root–stubble in conditions where the amount of covered straw is less than 1.2 kg/m2 [84]. | —— |

| Driven stubble-crushing cutter for stripless tillage |  | The maize intercropping area in the North Temperate Zone | The strip-driven stubble-crushing cutter was designed based on the principle of sliding drag reduction. The blade curve was determined to reduce both the stubble-crushing resistance and the amount of soil moved. The tillage resistance of the driven stubble-crushing cutter is 1042.81 N. Compared to the driven disc blade assembly, the tillage resistance decreased by 19.78% [85]. | Compared to the driven disc blade assembly, the tillage resistance decreased by 19.78% and the amount of soil thrown up decreased by 13.95%. |

| Strip-type inter-row side-throwing straw anti-blocking device |  | Regions with two growing seasons for wheat and corn per year | A strip-type inter-row side-throwing straw anti-blocking device was designed to throw straw to the inter-rows on both sides of the seedbed and nursery bed using a side-tipping cutter, thereby improving the straw-cleaning performance of the seeding belt. The rate of clearing root–stubble and the torque of the unit are 82.7% and 298.2 N·m, respectively [86]. | Compared to traditional rotary tillers and flat rotary cutters, the lateral cutting blade bed cleaning rate was increased by 22.7% and 26.1%, respectively. The operating torque was decreased by 21.3% and 3.3%, respectively. |

| Strip-type rotary cutting and post-throwing anti-blocking device |  | Regions with two growing seasons for wheat and corn per year | A strip-type rotary cutting and throwing anti-blocking device was designed. By integrating the opener with the rotary cutting cutter, the soil disturbance and machine power consumption were reduced, enhancing the no-tillage planter’s passability in heavily straw-covered stubble. The rate of soil disturbance and power consumption of the unit are 25.0% and 12.08 kW, respectively [87]. | Compared to traditional rotary tillers, the designed rotary cutting blade reduced the power consumption by 13.83%, decreased the soil disturbance by 37.5% and improved the groove depth stability coefficient by 8.2%. |

| Lateral stubble cutter for original stubble field |  | Regions with a large amount of straw coverage | Lateral sliding cutting blade teeth were designed to cut, transport and throw corn stubble via rotary blade with teeth aligned vertically to the forward direction. This improved the stubble clearance rate and effectively cleaned the original stubble bed. Under the conditions of 1.28 kg/m2 straw coverage and a 273 mm average height of the stubble, the power consumption of the unit was 4.9 kW without root–stubble entanglement and the blocking of the cutters during the operation [88,89]. | After optimization, the two types of structured blade teeth exhibit a reduction in the vibration intensity of 46.5% and 41.8% compared to the existing blade tooth combinations, with the power consumption decreasing by 29.7% and 35.9%, respectively. |

| Driving drum-type active anti-blocking mechanism |  | Regions with two growing seasons for wheat and corn per year | A driving drum-type active anti-blocking mechanism was designed from the perspective of the ground wheel’s power drive drum rotation. Based on fluid mechanics principles, the stubble-cleaning effect was improved. The rate of soil disturbance of the unit is 9.6% when root–stubble crushing is performed [90]. | Compared to the strip rotary tillage maize no-tillage planter, its soil disturbance is reduced by nearly 54%. |

| Anti-blocking device straw-cleaning unit structure |  | Regions with a large amount of straw coverage | An active stubble-crushing device for a no-tillage planter was designed for large ridge corn stubble fields to address the issue of frequent blockages during no-tillage seeding in fields covered with root straw, particularly in northern cold regions. The rate of clearing root–stubble, the power consumption and the rate of soil disturbance of the unit are 93.94%, 4.36 kW and 31.9% [91]. | —— |

| Vertical shaft rotary straw-crushing device |  | Regions with large straw coverage and two harvests per year | A vertical shaft stubble-crushing straw-crushing device was proposed to crush surface straw and weeds and evenly distribute them on the surface, thus improving the machine’s passing ability. The qualified rate of the length of the root–stubble after crushing is more than 90% [92]. | —— |

| Spiral split seed belt cleaning device |  | Regions with a large amount of straw coverage | A spiral split seed belt cleaning device was designed by combining a notched disc with a helically arranged stubble cutter. It cuts the root straw and transports it to the sides of the seed belt. The rate of clearing root–stubble of the unit is 92.55% [93]. | —— |

| Anti-blocking device of rotary cutting with slide plate pressing straw |  | The region in the Northern Temperate Zone with crops having two harvests per year | A new type of anti-blocking device was developed for rotary cutting with a slide plate pressing straw. The support cutting of root straw by the skate and cutter was used to enhance the cutting rate of root straw [94]. | Compared with the belt rotary tiller, the rate of soil disturbance and the fuel consumption are reduced by 25% and 7.04%, respectively. |

| Seed belt stubble-cleaning device |  | The region in the Northern Temperate Zone with crops having one harvest per year | A combined seed belt stubble-cleaning device consisting of a cleaning belt cutter and a stubble cutter was designed to improve the cleanliness of the seed belt and reduce soil disturbance. The rates of root–stubble clearing and soil disturbance of the unit are 86.59% and 8.83%, respectively [95]. | Compared to traditional strip stubble elimination devices, the cleanliness of the planting strip after operation is increased by 26.89%, while the soil disturbance is decreased by 17.95% compared to the average. |

| Fixed flail anti-winding returning straw-crushing machine |  | Tropical and subtropical regions | A fixed flail anti-winding returning straw-crushing machine was designed. The cooperative action of the flail cutter and fixed cutter supported and crushed the stubble, solving the winding problem of the crushing cutter roller. The rate of banana root–stubble crushing of the unit is 95.1% [96]. | Compared to the existing horizontal banana straw shredder for field incorporation, the qualified rate of straw shredding is increased by 1.7%. |

| Leaf round baler picking crushing cutter |  | Tropical and subtropical regions | A symmetrical vertical oblique cutting pick-up crushing mechanism was designed. By adjusting the number of blade limit washers, the limit position of each crushing cutter on the connecting pin shaft was regulated, as well as the number of crushing cutters, to enhance the crushing effect on the stubble. The qualified rate of cane root–stubble crushing of the unit is 85.43% [97]. | —— |

| Cutting and throwing combined anti-blocking device for wide-seedbed seeding of wheat |  | Corn root–stubble covering the ground | A combined cutting and throwing device was designed for the clearing of crop residues and prevention of blockages. It utilizes vertically arranged inclined notch discs in conjunction with a spinning throwing mechanism to effectively clear crop stubble and straw. The rates of root–stubble cutting and soil disturbance of the unit are 96.2% and 6.9%, respectively [98]. | The cleanliness of the seedbed is 90.1%, the stubble-crushing rate is 96.2%, the width of soil disturbance is 127 mm and the soil disturbance volume is 6.9%. |

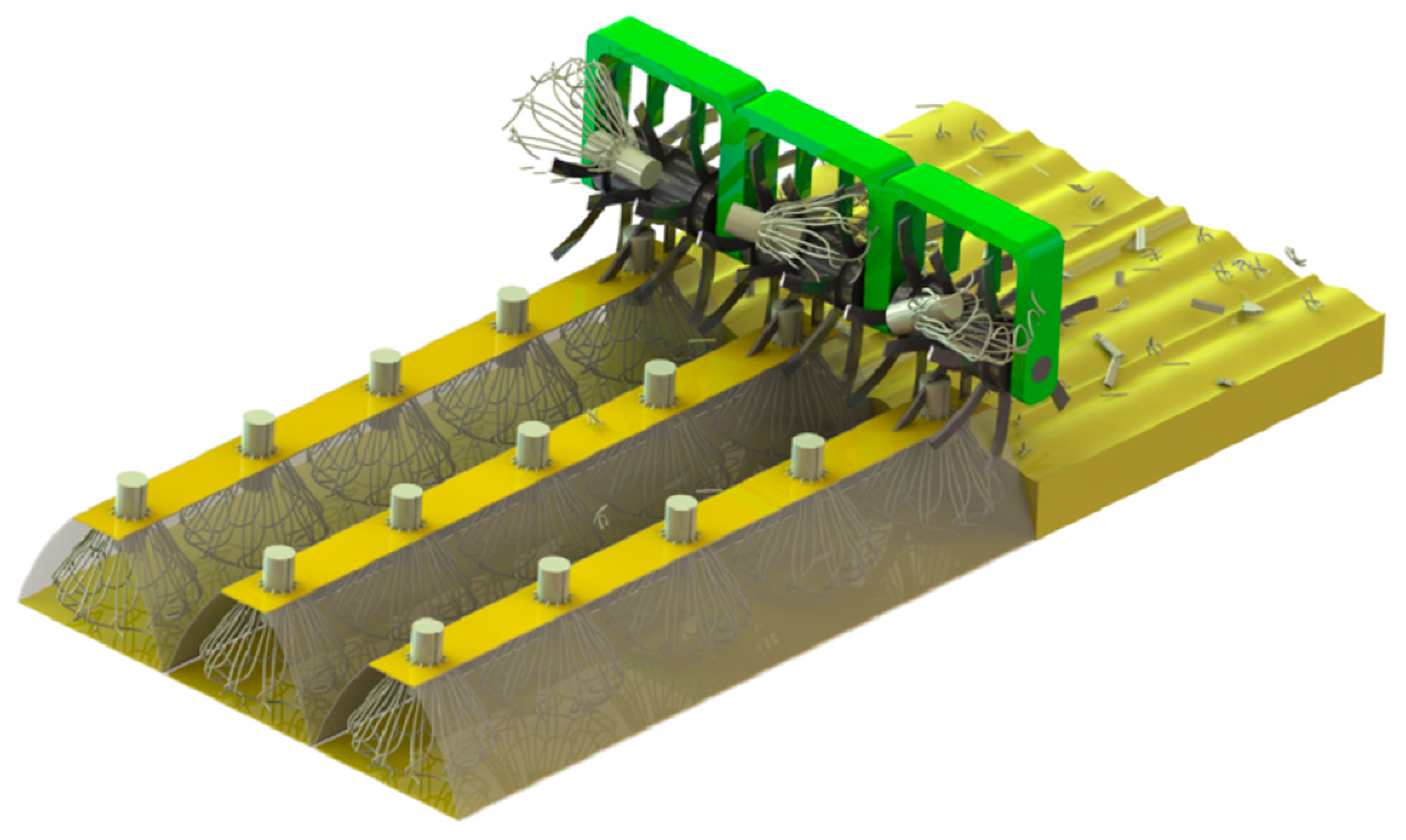

| Seed belt vertical crushing root–stubble device |  | Corn root–stubble covering the ground | Vertically rotating straight cutters were used to plow the soil and snapping fingers were used to clean the root–stubble around the tilled strip. The rates of root–stubble clearing and soil crushing of the unit are 97.7% and 96.4%, respectively [33]. | —— |

| Test System | Test Method | Type of Test | Test Content |

|---|---|---|---|

| Discrete element numerical simulation | Single-factor test, comparative validation | DEM was employed to simulate the effect of a deep loosening shovel and disc combination unit on root–stubble crushing. A reasonable assembly between a deep loosening shovel and disc was obtained through a single-factor experiment in the simulation. The rate of root–stubble crushing of the combined machine increased by 19.38% compared with the disc cutter and by 8.86% compared with the notched cutter, demonstrating the possibility of optimizing the cutter structure using discrete element simulation [103]. |

| Discrete element numerical simulation | Multi-factor test | DEM was employed to simulate the effect of the disc on clearing stubble. When the rotary radius of the disc, the radius of curvature and the length of the toothed disc were 163 mm, 350 mm and 52 mm, respectively, the rate of clearing stubble of the disc was 91%, which was obtained through a multi-factor test in the simulation. A physical experiment was conducted, and the rate of clearing stubble of the new machine was 91.4%. The accuracy of the simulation test was verified [76]. |

| Discrete element numerical simulation | Single-factor test, multi-factor test | DEM was employed to determine the form and number of the cutters with forward reverse rotation through a one-factor test. The parameters of the cutter were optimized through a multi-factor test in the simulation. A physical experiment demonstrated that the rate of root–stubble crushing of the machine composed of the cutter and planter was 95.72%, which proved the feasibility of optimizing the structure of the cutter through the multi-factor test in the simulation [104]. |

| High-speed photography test, discrete element numerical simulation, field experiment | Multi-factor test, high-speed photography test | DEM was employed to analyze the motion of the stubble after being thrown by the cutter. A multi-factor test was conducted to optimize the structure of the cutter. The optimized cutter was processed, and a high-speed camera test was conducted, demonstrating the consistency of the trajectory of cutting and throwing stubble between the simulation and physical experiments. A physical experiment demonstrated that the rate of root–stubble clearing and the power consumption of the machine were 93.2% and 2.1 kW, respectively, meeting the agronomic requirements [105]. |

| Test in soil bin, discrete element numerical simulation | Multi-factor test | DEM was employed to investigate the effect of the structure of an active cutter on the motion of the stubble after being thrown. The optimized structure of the active cutter was obtained through a multi-factor test in the simulation. A physical experiment demonstrated that the rate of root–stubble clearing of the machine was 91.85%, the stability of the furrow depth was 86.67% and the rate of soil disturbance was 26.47%. The performance of the strip no-tillage planter proved the feasibility of optimizing the structural parameters of the cutter by DEM [106]. |

| Test in soil bin, discrete element numerical simulation | Multi-factor test, comparative validation | DEM was employed to conduct a multi-factor test, and the structure of the cutter was optimized. a physical experiment was conducted, and it was shown that the rate of root–stubble clearing, the rate of soil disturbance and the power consumption of the new machine were 92.5%, 29.6% and 1.51 kW, respectively. Compared to the performance of the original machine (where the inclination angle of the cutters was 0°), it was found that the rate of root–stubble clearing of the new machine was improved by 14.7% [107]. |

| High-speed photography test | Comparison validation | Stubble movement was monitored using a high-speed camera. The working speed was the comparative factor, with the tillage resistance, fuel consumption and stubble ratio as the test indices. The performance of the passive disc cutter and the traditional disc cutter at different working speeds was compared and analyzed [72]. |

| Test in soil bin | Multi-factor test | The bionic disc cutter’s parameters were optimized through a multi-factor test, using the stubble cutting rate and cutting torque as indices. The wear resistance of the bionic disc was also assessed using a confocal laser scanning test [83]. |

| Field experiment | Multi-factor test | A multi-factor test was used to find the optimal combination of working parameters for the stubble-crushing anti-blocking device, with the stubble cutting rate and tool power consumption as indices [73]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Yao, J.; Gao, Y.; Zeng, L.; Wang, L.; Wang, B.; Yang, Z. Review of Root–Stubble Characteristics and Root–Stubble Crushing and Clearing Technologies for Conservation Tillage. Sustainability 2024, 16, 8508. https://doi.org/10.3390/su16198508

Feng X, Yao J, Gao Y, Zeng L, Wang L, Wang B, Yang Z. Review of Root–Stubble Characteristics and Root–Stubble Crushing and Clearing Technologies for Conservation Tillage. Sustainability. 2024; 16(19):8508. https://doi.org/10.3390/su16198508

Chicago/Turabian StyleFeng, Xin, Jiayue Yao, Yunpeng Gao, Longchi Zeng, Lijun Wang, Bo Wang, and Zhilei Yang. 2024. "Review of Root–Stubble Characteristics and Root–Stubble Crushing and Clearing Technologies for Conservation Tillage" Sustainability 16, no. 19: 8508. https://doi.org/10.3390/su16198508