A Comprehensive Review and Mapping Citrus Supply Chains from a Sustainability Perspective across the European Union, Middle East, and Africa

Abstract

1. Introduction

- What are the recent research topics in the studied regions?

- Which research methodology is applied in the research field?

- Which echelons of the citrus supply chain are studied?

2. Citrus Production and Exports in European Union, Middle East, and Africa

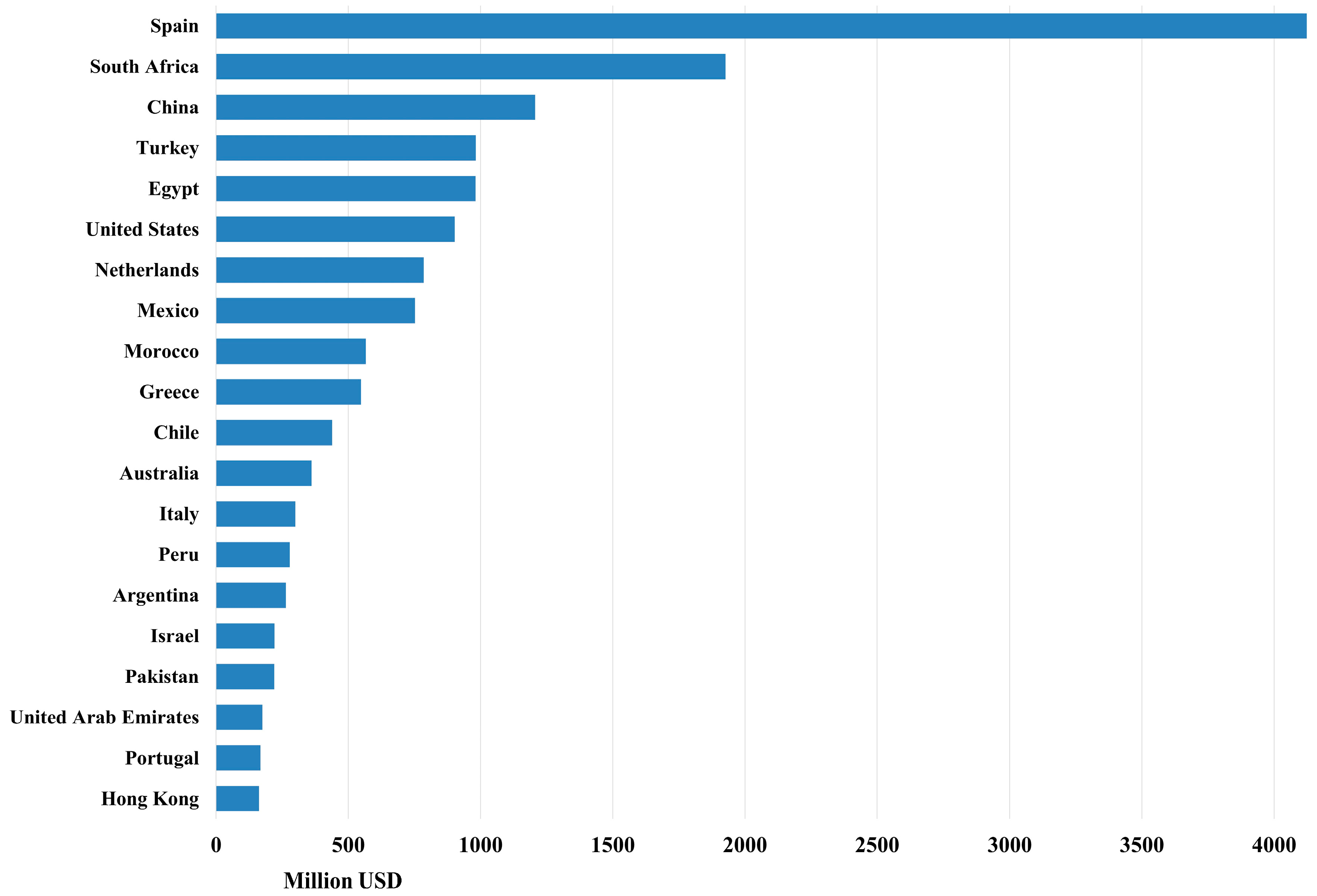

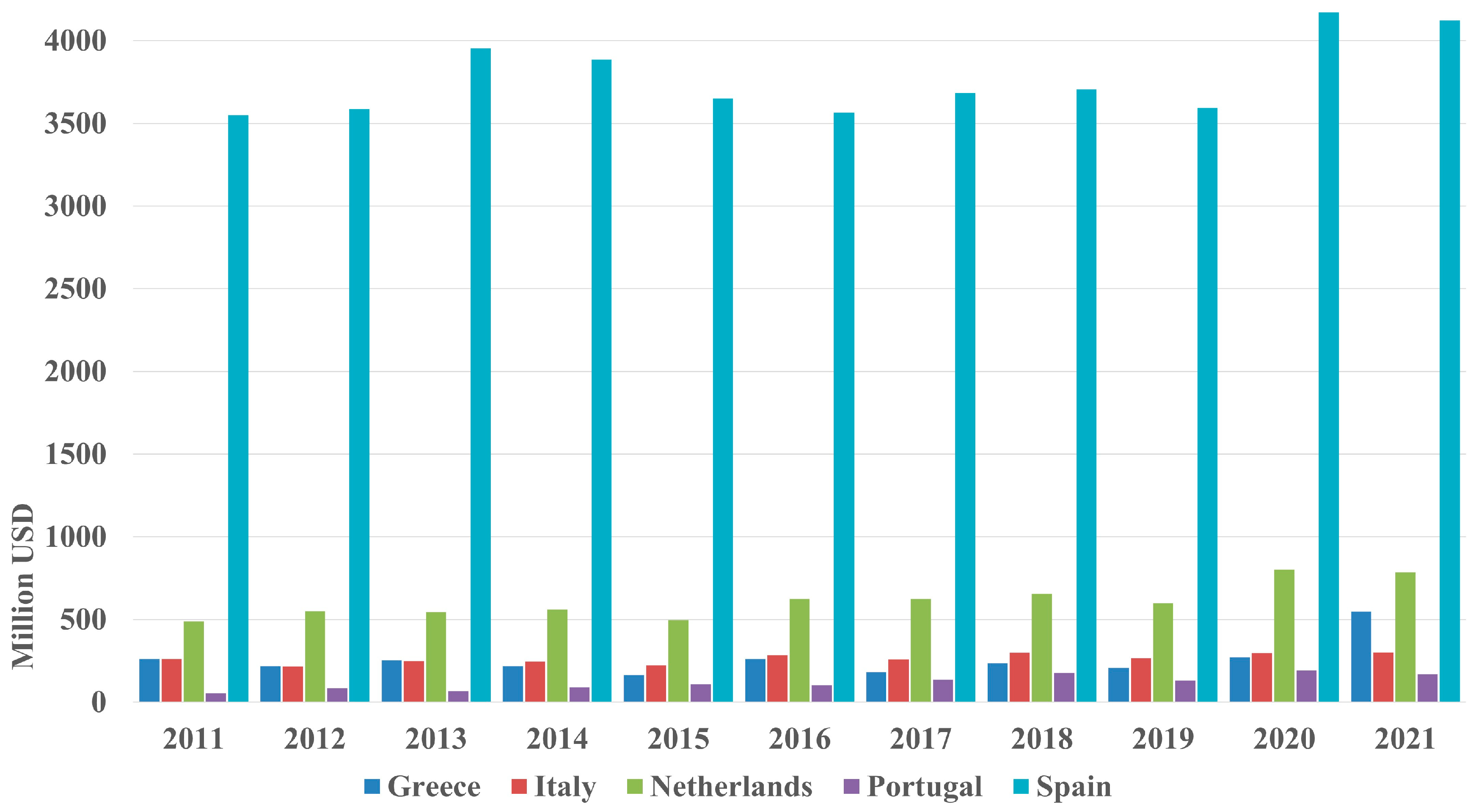

2.1. European Union

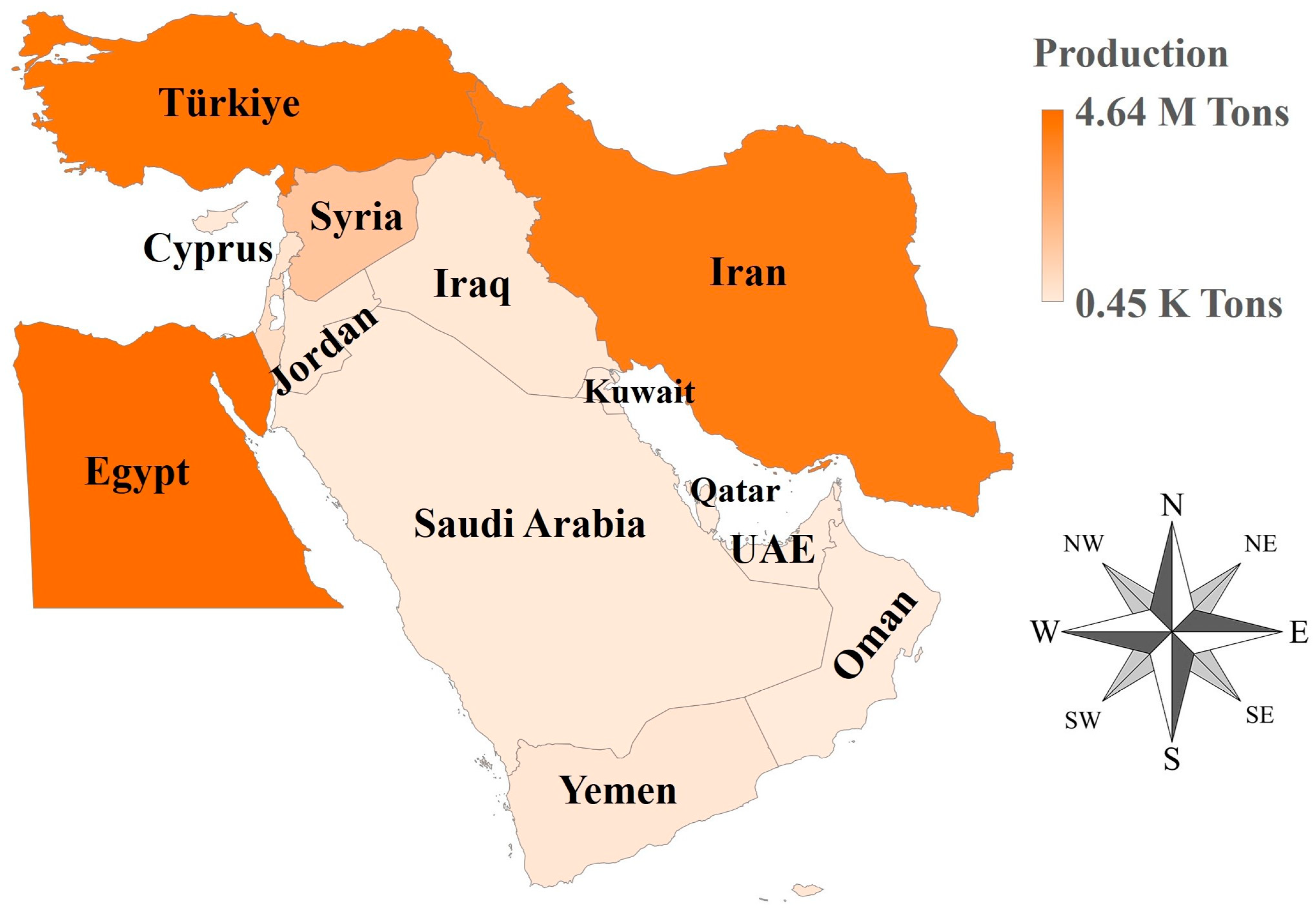

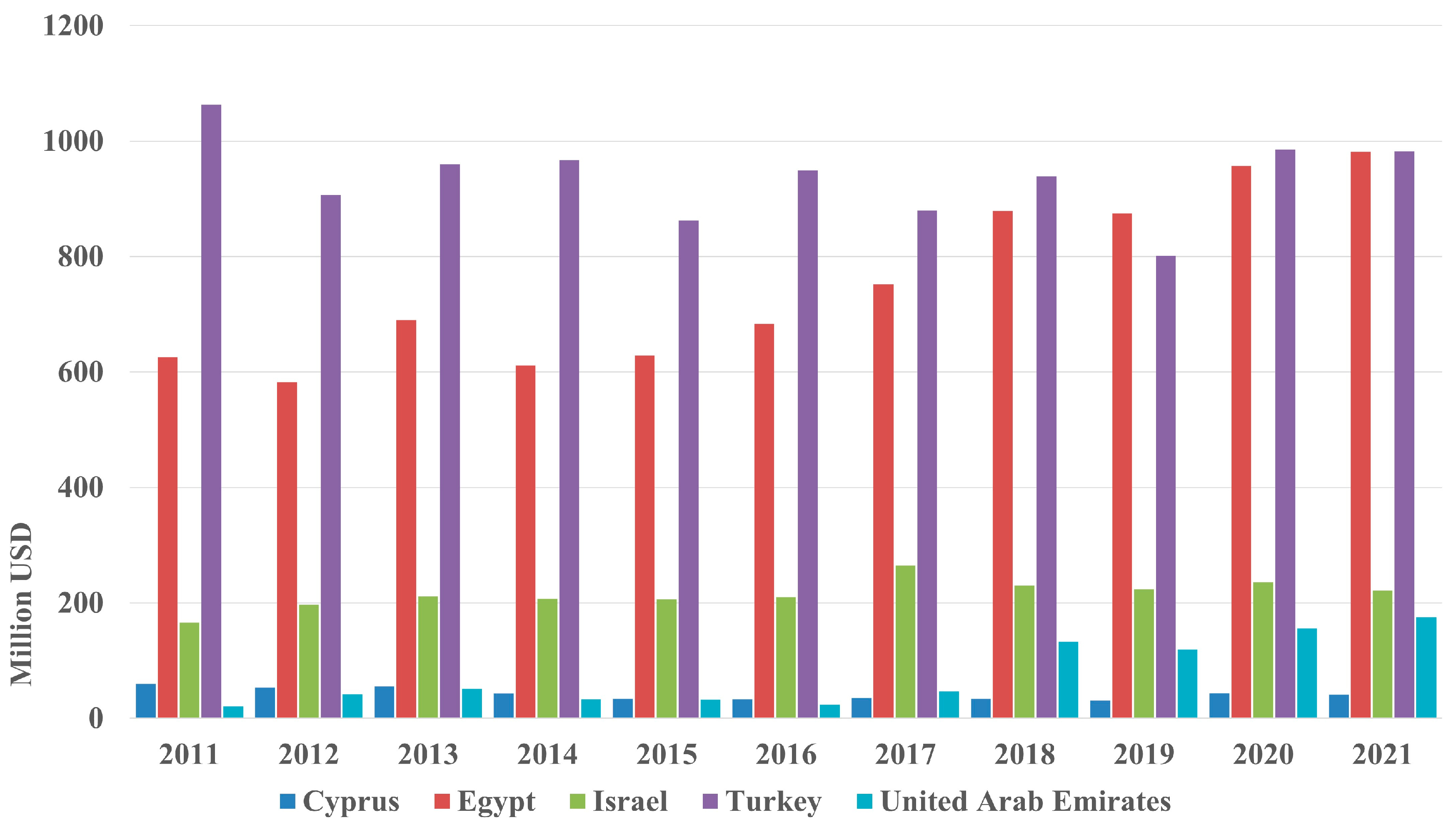

2.2. Middle East

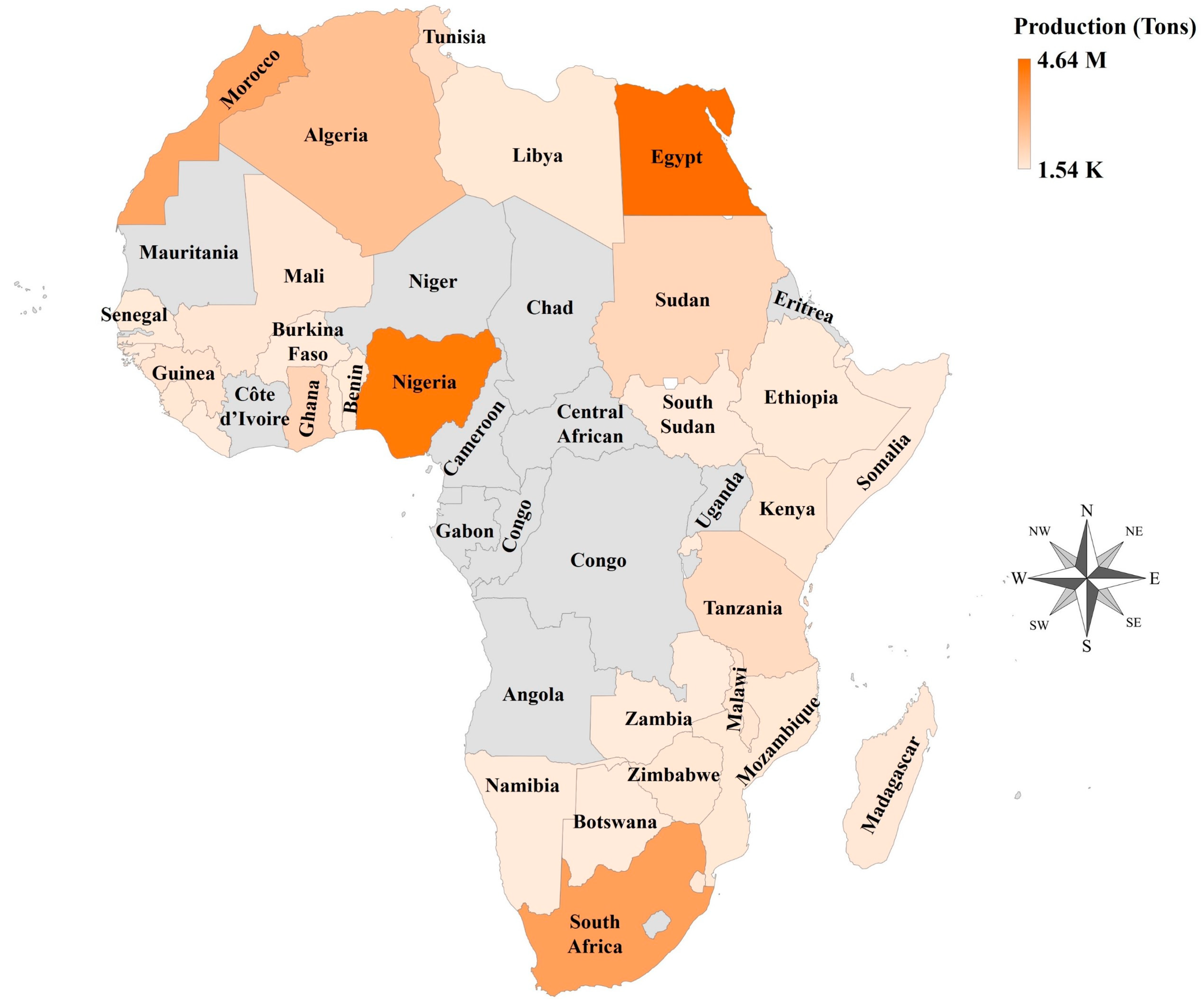

2.3. Africa

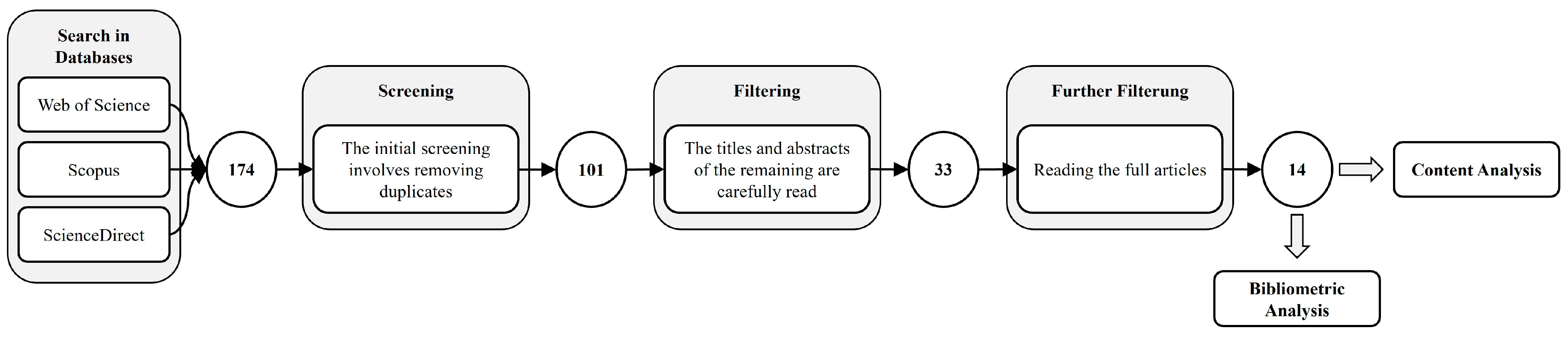

3. Methodology

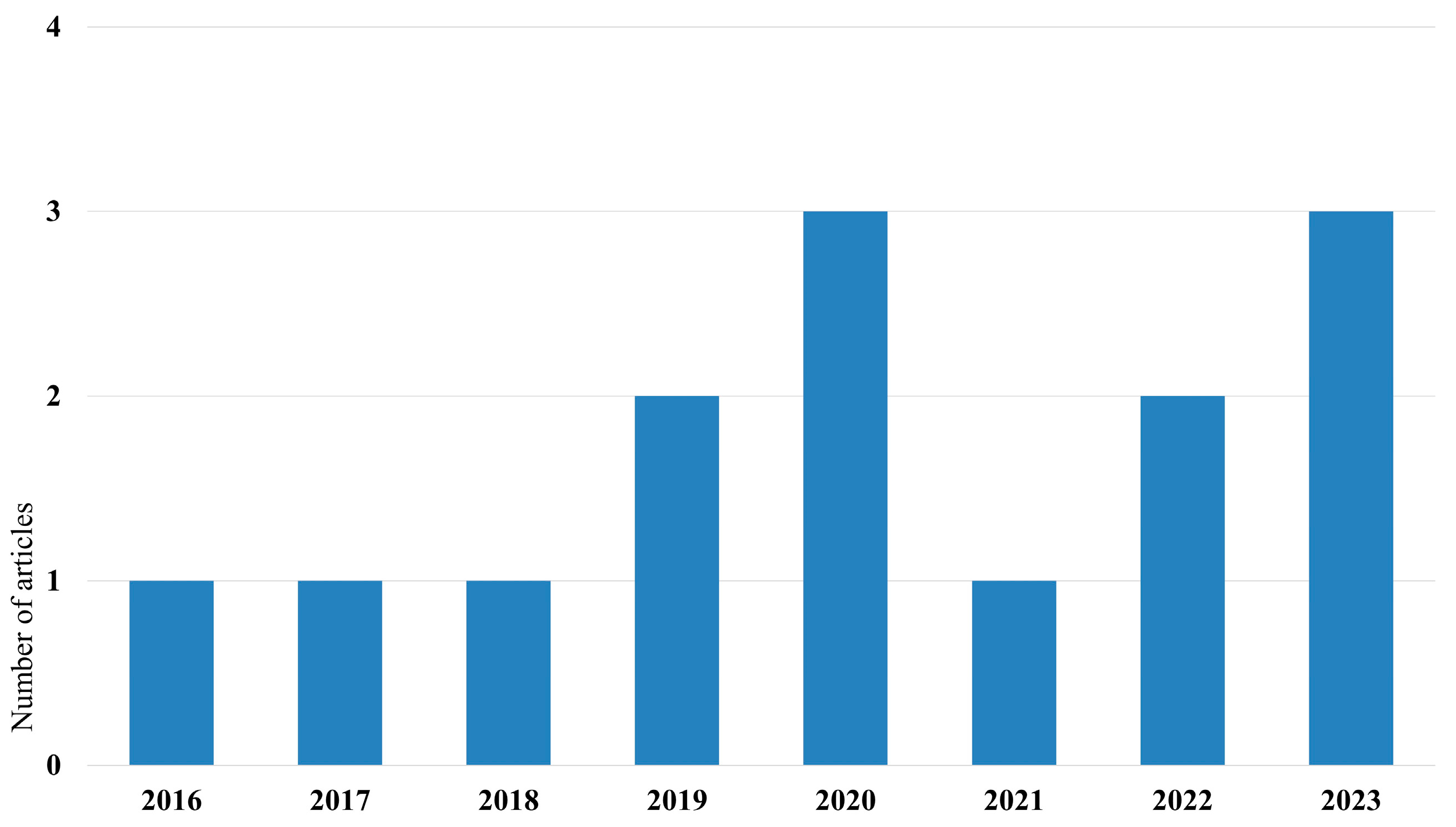

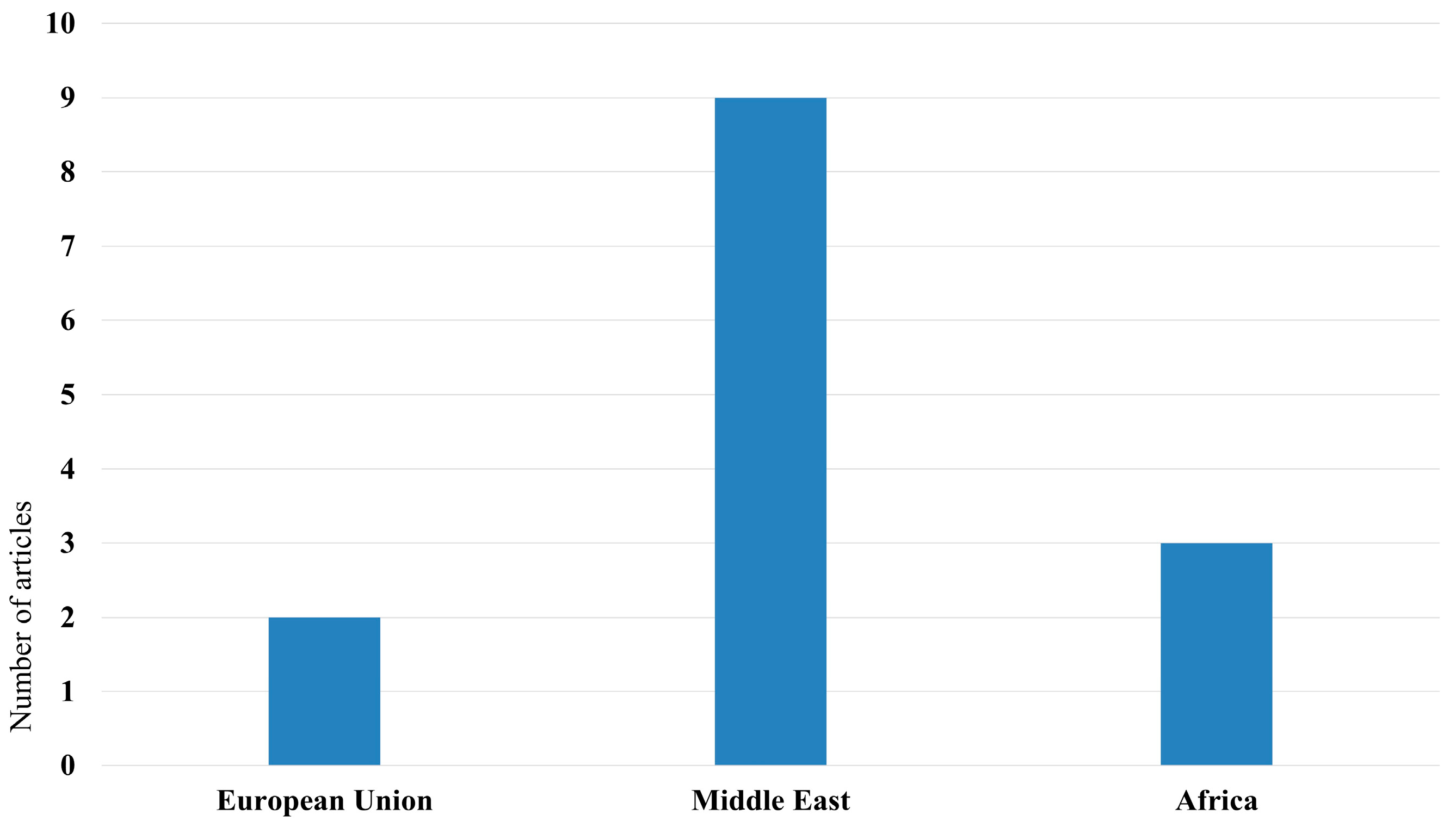

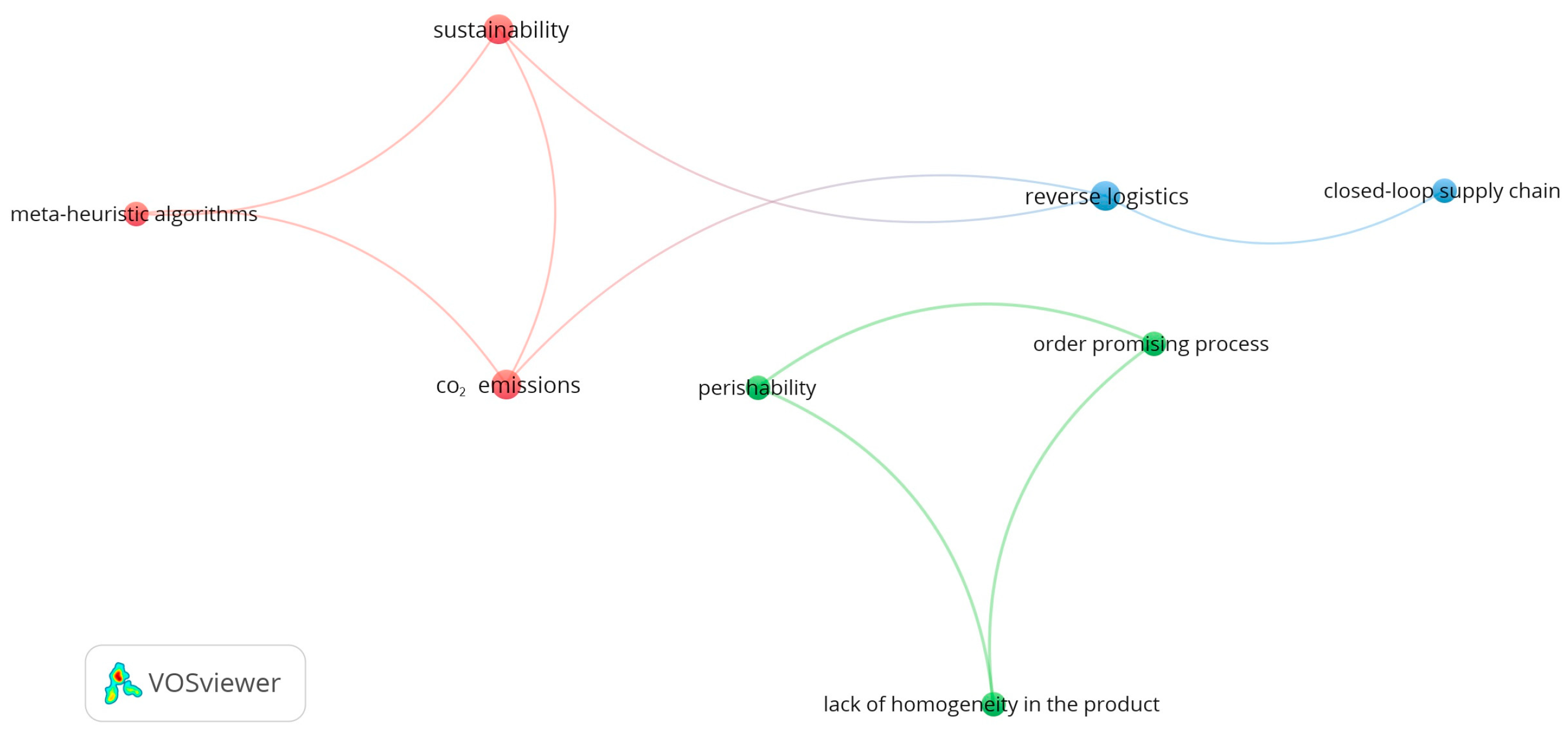

4. Bibliometric Analysis Results

5. Content Analysis Results

5.1. Research Topics

| No. | Reference | Facility Location/Allocation | Cold Chain | Ordering Process | Pre-Harvesting Best Practices | Traceability | Quality | Pricing | Resources | Time Window | CO2 Emissions | Economic | Social | Waste & Residuals | Crates | Circularity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | [20] | x | x | |||||||||||||

| 2 | [23] | x | x | x | x | x | ||||||||||

| 3 | [27] | x | x | x | x | |||||||||||

| 4 | [24] | x | x | x | x | x | ||||||||||

| 5 | [29] | x | x | x | x | x | ||||||||||

| 6 | [21] | x | ||||||||||||||

| 7 | [30] | x | x | x | x | x | ||||||||||

| 8 | [32] | x | x | |||||||||||||

| 9 | [33] | x | x | x | ||||||||||||

| 10 | [28] | x | x | x | x | x | ||||||||||

| 11 | [25] | x | x | x | x | |||||||||||

| 12 | [26] | x | x | x | x | |||||||||||

| 13 | [31] | x | x | x | x | x | x | |||||||||

| 14 | [22] | x | x |

5.2. Research Methodology

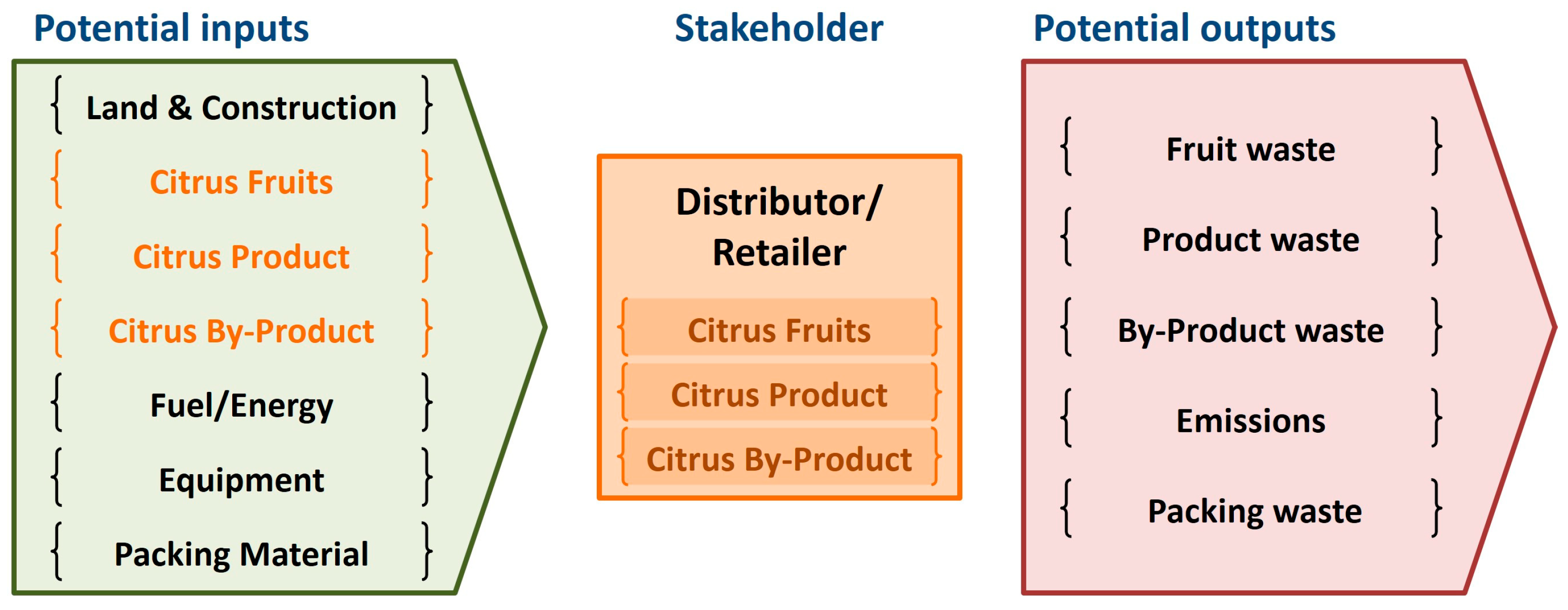

5.3. Supply Chain Echelons

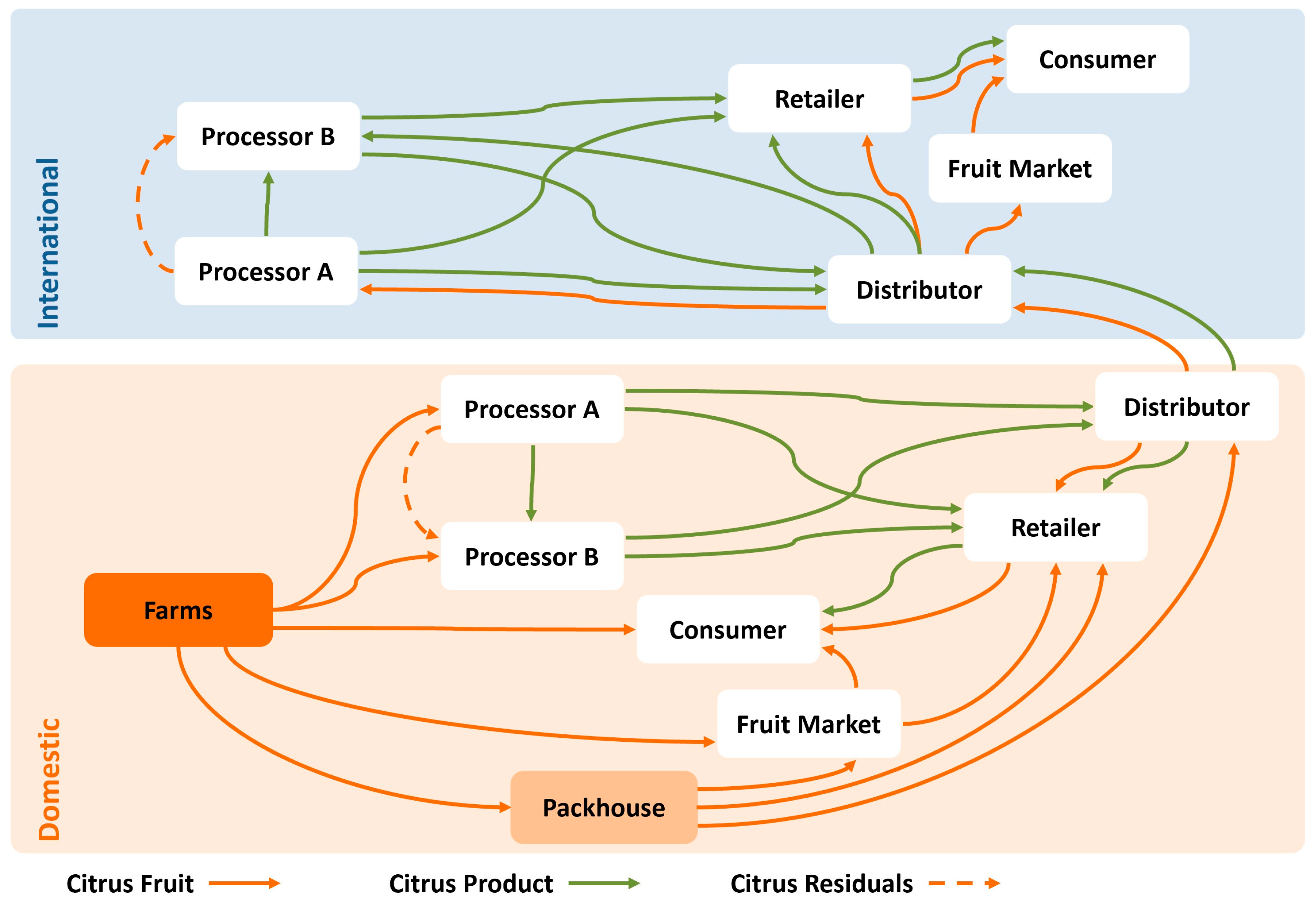

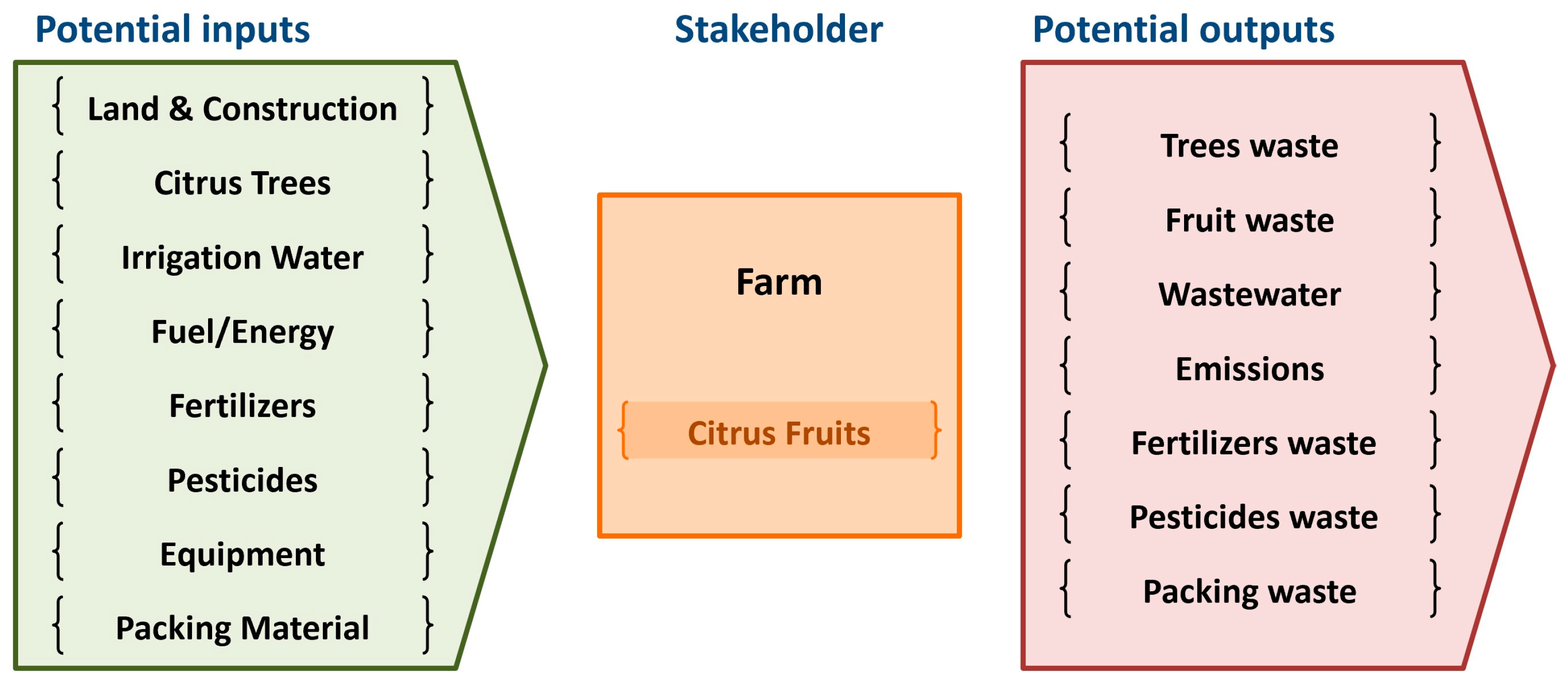

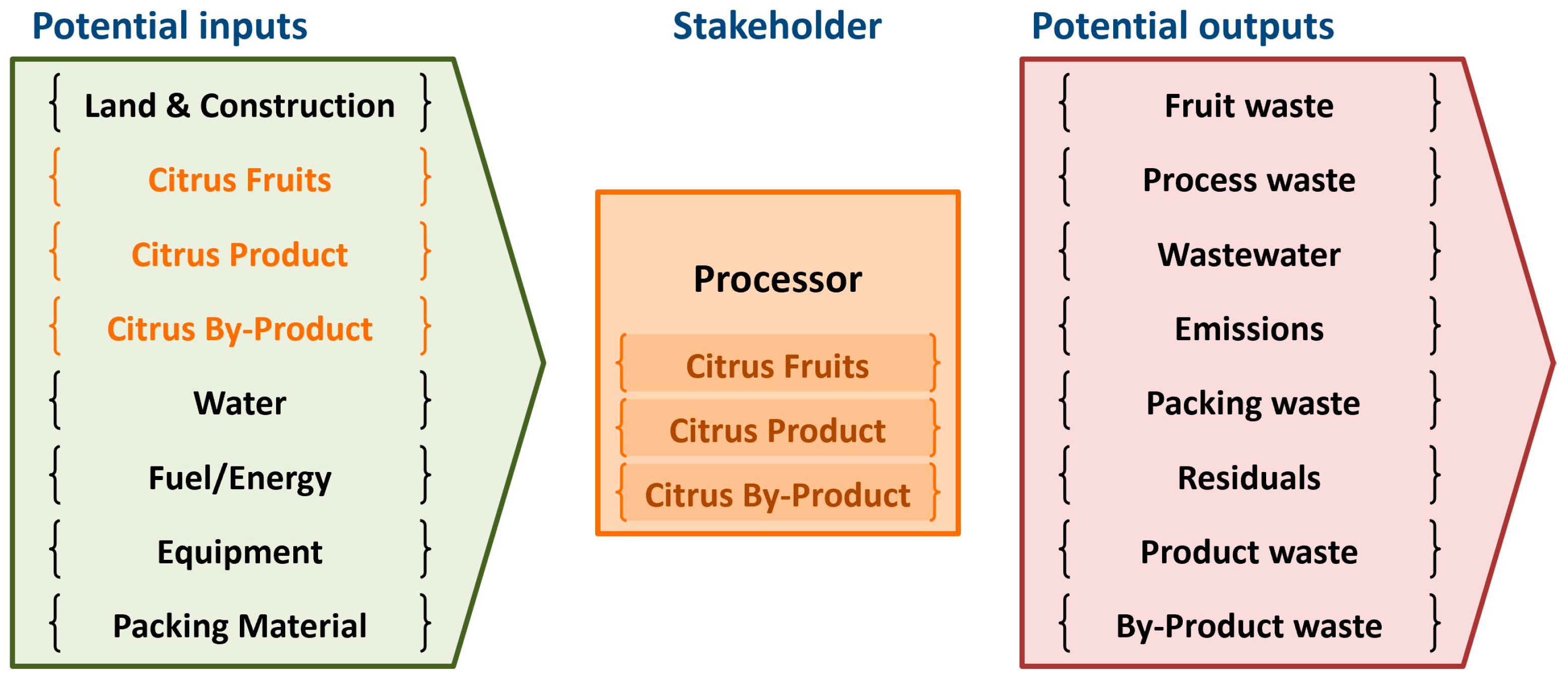

6. Citrus Supply Chain Structure

7. Conclusions and Future Work

7.1. Conclusions

7.2. Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. The State of Food and Agriculture 2021: Making Agrifood Systems More Resilient to Shocks and Stresses; FAO: Rome, Italy, 2021. [Google Scholar] [CrossRef]

- Bryceson, K.P.; Ross, A. Agrifood Chains as Complex Systems and the Role of Informality in Their Sustainability in Small Scale Societies. Sustainability 2020, 12, 6535. [Google Scholar] [CrossRef]

- Zhong, R.; Xu, X.; Wang, L. Food supply chain management: Systems, implementations, and future research. Ind. Manag. Data Syst. 2017, 117, 2085–2114. [Google Scholar] [CrossRef]

- Sharma, P.; Vishvakarma, R.; Gautam, K.; Vimal, A.; Kumar Gaur, V.; Farooqui, A.; Varjani, S.; Younis, K. Valorization of citrus peel waste for the sustainable production of value-added products. Bioresour. Technol. 2022, 351, 127064. [Google Scholar] [CrossRef]

- Knoema. Citrus Fruit Production by Country, 2022—knoema.com. Available online: https://knoema.com/atlas/topics/Agriculture/Crops-Production-Quantity-tonnes/Citrus-fruit-production (accessed on 9 October 2023).

- AtlasBig. World Total Citrus Production by Country. Available online: https://www.atlasbig.com/en-us/countries-total-citrus-production (accessed on 9 October 2023).

- FAS/USDA. Citrus: World Markets and Trade: U.S. Production and Exports Forecast Down Despite Global Gains; FAS/USDA: Washington, DC, USA, 2021; Available online: https://downloads.usda.library.cornell.edu/usda-esmis/files/w66343603/b8516k98g/2514ph35q/citrus.pdf (accessed on 9 October 2023).

- FAS/USDA. Citrus: World Markets and Trade: Chile Mandarin Production and Exports Estimated to Rebound; FAS/USDA: Washington, DC, USA, 2023. Available online: https://apps.fas.usda.gov/psdonline/circulars/citrus.pdf (accessed on 9 October 2023).

- EC. The Citrus Market in the EU: Trade on Processed Citrus Fruit. Available online: https://agriculture.ec.europa.eu/system/files/2022-11/citrus-trade-processed-products_en.pdf (accessed on 9 October 2023).

- Barbosa, M.W. Uncovering research streams on agri-food supply chain management: A bibliometric study. Glob. Food Secur. 2021, 28, 100517. [Google Scholar] [CrossRef]

- Esposito, B.; Sessa, M.R.; Sica, D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector. A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Zhong, J.; Cheng, H.; Chen, X.; Jia, F. A systematic analysis of quality management in agri-food supply chains: A hierarchy of capabilities perspective. SCM 2023, 28, 619–637. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Coluccia, B. Sustainable agrifood supply chains: Bibliometric, network and content analyses. Sci. Total Environ. 2022, 824, 153704. [Google Scholar] [CrossRef]

- OEC. Citrus. Available online: https://oec.world/en/profile/hs/citrus (accessed on 9 October 2023).

- EC. Directorate-General for Agriculture and Rural Development. In Citrus Fruit Statistics; European Commission: Brussels, Belgium, 2023; Available online: https://agriculture.ec.europa.eu/data-and-analysis/markets/overviews/market-observatories/fruit-and-vegetables/citrus-fruit-statistics_en (accessed on 16 March 2023).

- EC, Eurostat. Agricultural Production—Crops; European Commission: Brussels, Belgium, 2023; Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agricultural_production_-_crops#Fruit (accessed on 24 February 2024).

- OEC. Citrus in South Africa|The Observatory of Economic Complexity. Available online: https://oec.world/en/profile/bilateral-product/citrus/reporter/zaf?redirect=true (accessed on 7 April 2024).

- OEC. Citrus in Tunisia|The Observatory of Economic Complexity. Available online: https://oec.world/en/profile/bilateral-product/citrus/reporter/tun (accessed on 7 April 2024).

- Darley-Waddilove, J.I. Allocating Commodity Volumes in the Citrus Export Cold Chain: A Case for the Port of Durban. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2021. [Google Scholar]

- Defraeye, T.; Nicolai, B.; Kirkman, W.; Moore, S.; Niekerk, S.V.; Verboven, P.; Cronjé, P.; Defraeye, T.; Nicolai, B.; Kirkman, W.; et al. Integral performance evaluation of the fresh-produce cold chain: A case study for ambient loading of citrus in refrigerated containers. Postharvest Biol. Technol. 2016, 112, 1–13. [Google Scholar] [CrossRef]

- Goedhals-Gerber, L.L.; Khumalo, G. Identifying temperature breaks in the export cold chain of navel oranges: A Western Cape case. Food Control 2020, 110, 107013. [Google Scholar] [CrossRef]

- Khumalo, G.; Goedhals-Gerber, L.L.; Cronje, P.; Berry, T.; Khumalo, G.; Goedhals-Gerber, L.L.; Cronje, P.; Berry, T. Product visibility in the South African citrus cold chain: Examining the efficacy of temperature loggers. Heliyon 2023, 9, e12732. [Google Scholar] [CrossRef] [PubMed]

- Grillo, H.; Alemany, M.; Ortiz, A.; Fuertes-Miquel, V.S. Mathematical modelling of the order-promising process for fruit supply chains considering the perishability and subtypes of products. Appl. Math. Model. 2017, 49, 255–278. [Google Scholar] [CrossRef]

- Grillo, H.; Alemany, M.; Ortiz, A.; de Baets, B. Possibilistic compositions and state functions: Application to the order promising process for perishables. Int. J. Prod. Res. 2019, 57, 7006–7031. [Google Scholar] [CrossRef]

- Alzubi, E.; Noche, B.; Alzubi, E.; Noche, B. A Multi-Objective Model to Find the Sustainable Location for Citrus Hub. Sustainability 2022, 14, 14463. [Google Scholar] [CrossRef]

- Alzubi, E.; Shbikat, N.; Noche, B. A system dynamics model to improving sustainable performance of the citrus farmers in Jordan Valley. Clean. Prod. Lett. 2023, 4, 100034. [Google Scholar] [CrossRef]

- Cheraghalipour, A.; Paydar, M.M.; Hajiaghaei-Keshteli, M. A bi-objective optimization for citrus closed-loop supply chain using Pareto-based algorithms. Appl. Soft Comput. 2018, 69, 33–59. [Google Scholar] [CrossRef]

- Goodarzian, F.; Kumar, V.; Ghasemi, P. Investigating a citrus fruit supply chain network considering CO2 emissions using meta-heuristic algorithms. Ann. Oper Res. 2024, 332, 1301. [Google Scholar] [CrossRef]

- Roghanian, E.; Cheraghalipour, A. Addressing a set of meta-heuristics to solve a multi-objective model for closed-loop citrus supply chain considering CO2 emissions. J. Clean. Prod. 2019, 239, 118081. [Google Scholar] [CrossRef]

- Liao, Y.; Kaviyani-Charati, M.; Hajiaghaei-Keshteli, M.; Diabat, A. Designing a closed-loop supply chain network for citrus fruits crates considering environmental and economic issues. J. Manuf. Syst. 2020, 55, 199–220. [Google Scholar] [CrossRef]

- Goodarzian, F.; Ghasemi, P.; Santibanez Gonzalez, E.; Tirkolaee, E.B. A sustainable-circular citrus closed-loop supply chain configuration: Pareto-based algorithms. J. Environ. Manag. 2023, 328, 116892. [Google Scholar] [CrossRef] [PubMed]

- Sahebjamnia, N.; Goodarzian, F.; Hajiaghaei-Keshteli, M. Optimization of Multi-period Three-echelon Citrus Supply Chain Problem. J. Optim. Ind. Eng. 2020, 13, 39–53. [Google Scholar] [CrossRef]

- Goodarzian, F.; Fakhrzad, M.B. A New Multi-Objective Mathematical Model for A Citrus Supply Chain Network Design: Metaheuristic Algorithms. J. Optim. Ind. Eng. 2021, 14, 127–144. [Google Scholar] [CrossRef]

| No. | Reference | Case Study | Modelling | Modelling Approach |

|---|---|---|---|---|

| 1 | [20] | x | ||

| 2 | [23] | x | MILP | |

| 3 | [27] | x | Multi-objective (MILP) | |

| 4 | [24] | x | MILP | |

| 5 | [29] | x | Multi-objective (MILP) | |

| 6 | [21] | x | ||

| 7 | [30] | x | MILP | |

| 8 | [32] | x | Multi-objective (INLP) | |

| 9 | [33] | x | MINLP | |

| 10 | [28] | x | Multi-objective (MINLP) | |

| 11 | [25] | x | ILP | |

| 12 | [26] | x | System Dynamics | |

| 13 | [31] | x | Multi-objective (MILP) | |

| 14 | [22] | x |

| No. | Reference | Farm | Packhouse | Distributor | Transport | Retailer/Market | Consumer | Manufacturer | Collection Center | Composting/ Recycling Center | Compost Market |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | [20] | x | |||||||||

| 2 | [23] | x | x | ||||||||

| 3 | [27] | x | x | x | x | x | |||||

| 4 | [24] | x | x | ||||||||

| 5 | [29] | x | x | x | x | x | x | ||||

| 6 | [21] | x | x | x | |||||||

| 7 | [30] | x | x | x | x | x | x | ||||

| 8 | [32] | x | x | x | x | ||||||

| 9 | [33] | x | x | x | x | x | |||||

| 10 | [28] | x | x | x | |||||||

| 11 | [25] | x | x | x | x | ||||||

| 12 | [26] | x | x | ||||||||

| 13 | [31] | x | x | x | x | x | |||||

| 14 | [22] | x |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beshara, S.; Kassem, A.; Fors, H.; Harraz, N. A Comprehensive Review and Mapping Citrus Supply Chains from a Sustainability Perspective across the European Union, Middle East, and Africa. Sustainability 2024, 16, 8582. https://doi.org/10.3390/su16198582

Beshara S, Kassem A, Fors H, Harraz N. A Comprehensive Review and Mapping Citrus Supply Chains from a Sustainability Perspective across the European Union, Middle East, and Africa. Sustainability. 2024; 16(19):8582. https://doi.org/10.3390/su16198582

Chicago/Turabian StyleBeshara, Sherin, Ahmed Kassem, Hadi Fors, and Nermine Harraz. 2024. "A Comprehensive Review and Mapping Citrus Supply Chains from a Sustainability Perspective across the European Union, Middle East, and Africa" Sustainability 16, no. 19: 8582. https://doi.org/10.3390/su16198582

APA StyleBeshara, S., Kassem, A., Fors, H., & Harraz, N. (2024). A Comprehensive Review and Mapping Citrus Supply Chains from a Sustainability Perspective across the European Union, Middle East, and Africa. Sustainability, 16(19), 8582. https://doi.org/10.3390/su16198582