Operational and Design Factors in Air Staging and Their Effects on Fouling from Biomass Combustion

Abstract

:1. Introduction

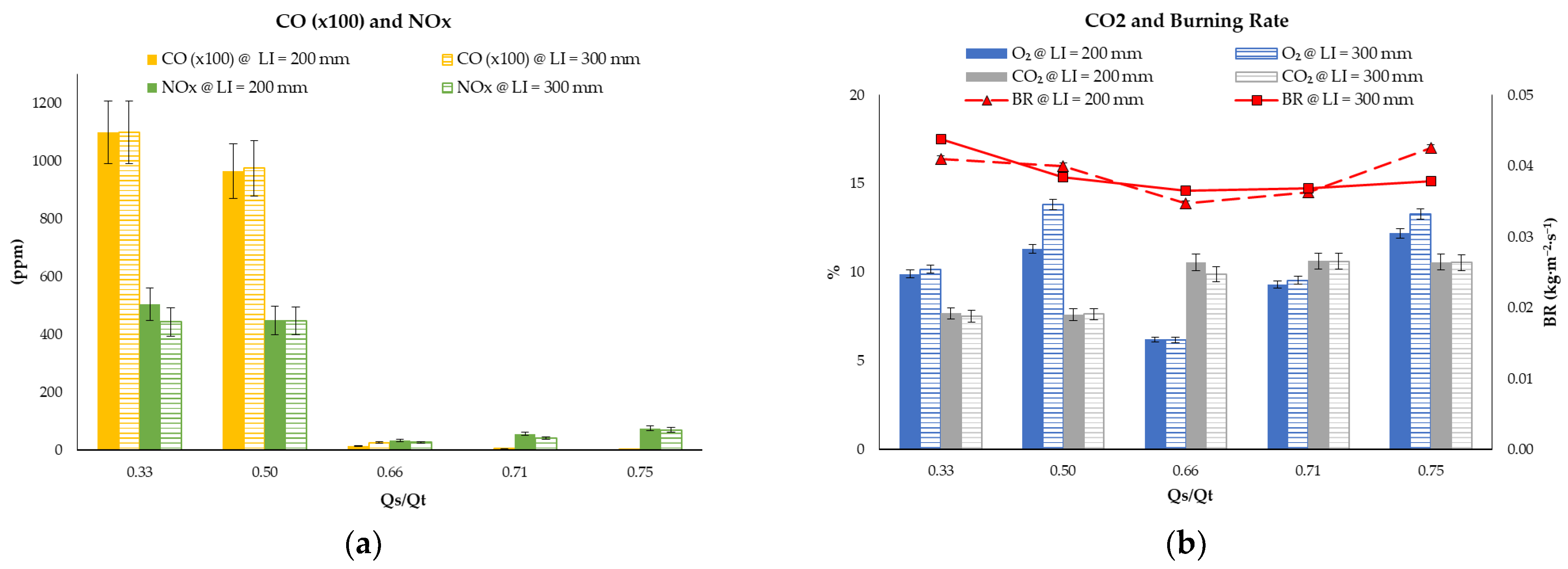

- Operational factors: the effect of secondary air flowrate on fouling.

- Design factors: the effect of secondary positioning on biomass fouling.

- Fouling deposits: the chemical composition of biomass fouling deposits, as both operational and design factors vary, is analysed.

2. Materials and Methods

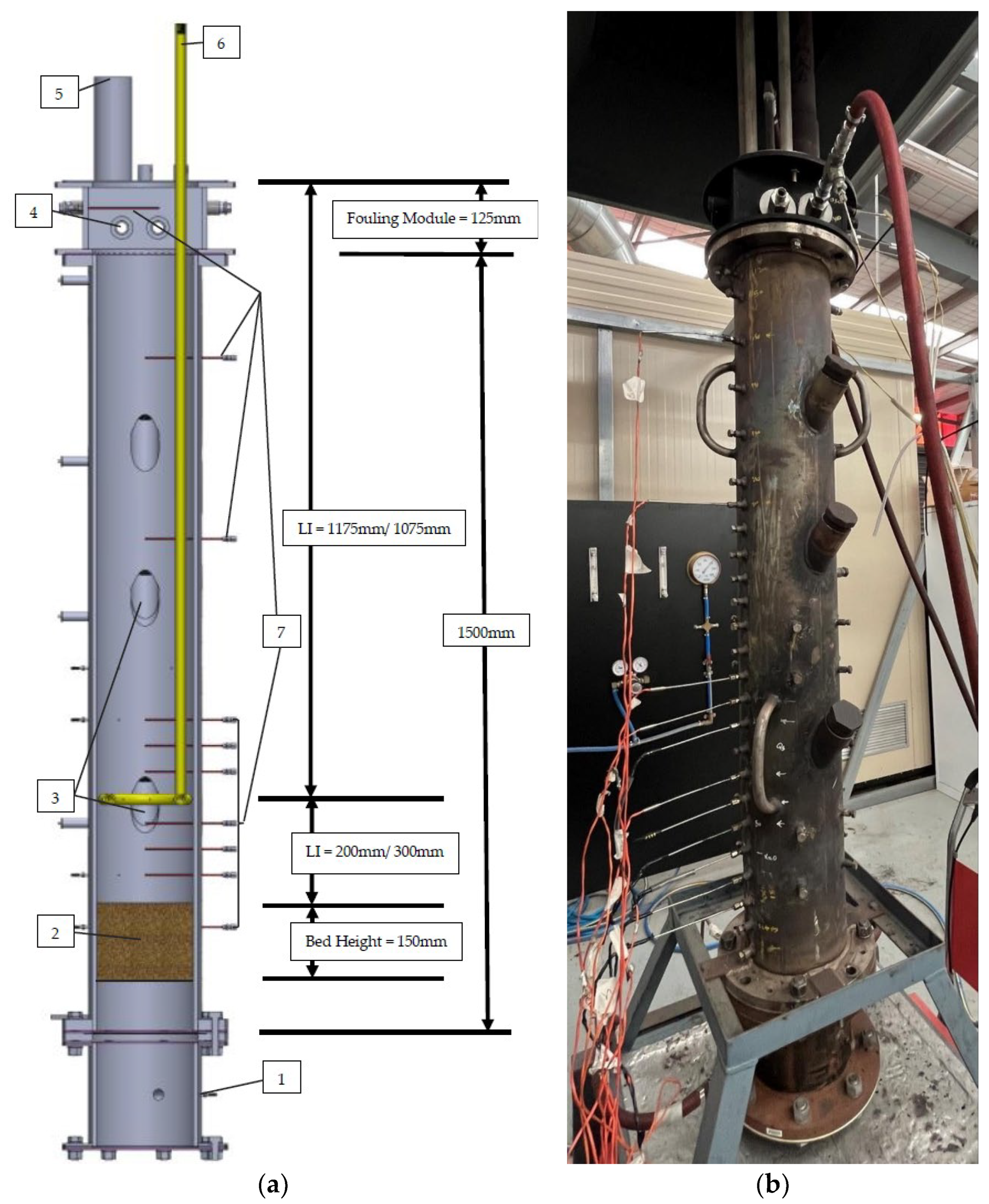

2.1. Combustor and Fuel

2.2. Fouling Module and Deposit Characterisation

2.3. Data Acquisition

2.4. Fuel and Testing/Operating Conditions

2.5. Repeatability and Uncertainty Analysis

- Fuel bed peak temperature;

- Primary freeboard steady-state temperatures;

- Secondary freeboard steady-state temperatures;

- Fouling deposition probe location steady-state temperature;

- Ash percentage content measured by TGA.

3. Results and Discussion

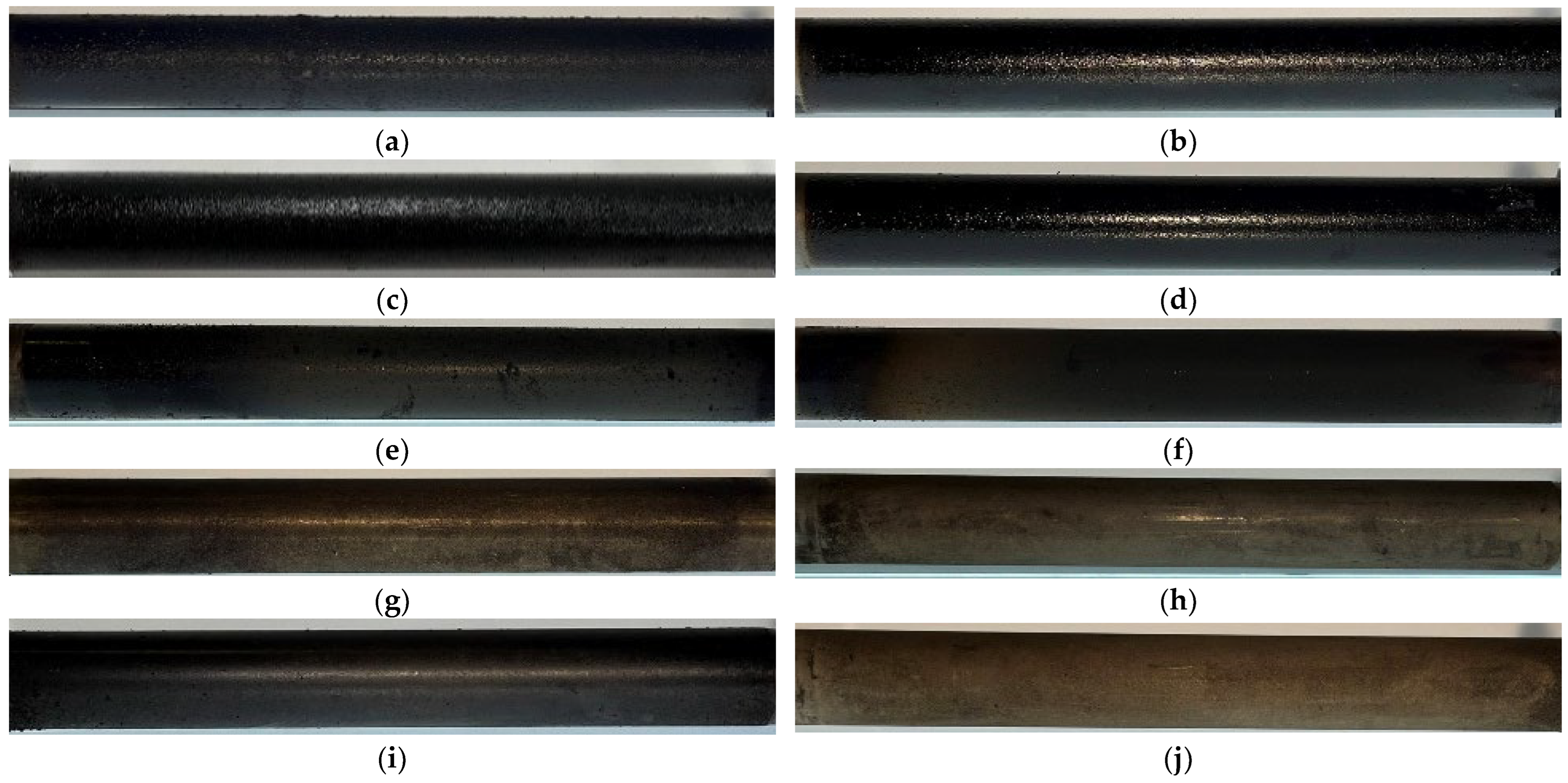

3.1. Physical Appearance and Hydrocarbon Deposits

3.2. Temperatures and Ash Deposits

3.3. Morphology Analysis and Deposits

4. Conclusions

4.1. Physical Appearance and Hydrocarbon Deposits

- At lower Qs/Qt ratios (0.33 and 0.50), the fouling deposits were thicker and stickier, indicating a higher content of unburnt hydrocarbons, which was confirmed by TGA analysis, showing gradual weight loss over an extended period during the heating process.

- Higher Qs/Qt ratios (0.66, 0.71, and 0.75) resulted in thinner fouling layers, suggesting more complete combustion and less hydrocarbon residue.

- At higher Qs/Qt ratios, particularly 0.75, the hydrocarbon content in the fouling was significantly reduced, with the weight loss curve indicating a faster and more complete combustion process.

4.2. Ash Deposits and Morphology

- The ash content, as indicated by the TGA data, was directly proportional to the Qs/Qt ratios.

- The experiments showed that conditions with a larger primary freeboard (LI = 300 mm) were correlated with higher ash content compared to a shorter primary freeboard (LI = 200 mm) at similar Qs/Qt ratios.

- Scanning electron microscopy (SEM) revealed that higher Qs/Qt ratios promoted increased turbulence and finer particle dispersion, resulting in more dispersed fouling deposits. Lower Qs/Qt ratios, however, were associated with more cohesive particles, suggesting a distinct morphological impact on the fouling characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Hilmawan, E.; Kuswa, F.M.; Darmawan, A.; Aziz, M. A comprehensive evaluation of cofiring biomass with coal and slagging-fouling tendency in pulverized coal-fired boilers. Ain Shams Eng. J. 2023, 14, 102001. [Google Scholar] [CrossRef]

- Kongto, P.; Palamanit, A.; Ninduangdee, P.; Singh, Y.; Chanakaewsomboon, I.; Hayat, A.; Wae-hayee, M. Intensive exploration of the fuel characteristics of biomass and biochar from oil palm trunk and oil palm fronds for supporting increasing demand of solid biofuels in Thailand. Energy Rep. 2022, 8, 5640–5652. [Google Scholar] [CrossRef]

- Febrero, L.; Granada, E.; Regueiro, A.; Míguez, J.L. Influence of Combustion Parameters on Fouling Composition after Wood Pellet Burning in a Lab-Scale Low-Power Boiler. Energies 2015, 8, 9794–9816. [Google Scholar] [CrossRef]

- Jagodzińska, K.; Gądek, W.; Pronobis, M.; Kalisz, S. Investigation of ash deposition in PF boiler during combustion of torrefied biomass. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012080. [Google Scholar] [CrossRef]

- Sandberg, J. Long time investigation of the effect of fouling on the superheaters in a circulating fluidized biomass boiler. Int. J. Energy Res. 2006, 30, 1037–1053. [Google Scholar] [CrossRef]

- Chapela, S.; Porteiro, J.; Gómez, M.A.; Patiño, D.; Míguez, J.L. Comprehensive CFD modeling of the ash deposition in a biomass packed bed burner. Fuel 2018, 234, 1099–1122. [Google Scholar] [CrossRef]

- Cai, Y.; Tay, K.; Zheng, Z.; Yang, W.; Wang, H.; Zeng, G.; Li, Z.; Keng Boon, S.; Subbaiah, P. Modeling of ash formation and deposition processes in coal and biomass fired boilers: A comprehensive review. Appl. Energy 2018, 230, 1447–1544. [Google Scholar] [CrossRef]

- Koppejan, J.; van Loo, S. The Handbook of Biomass Combustion and Co-Firing; Taylor & Francis: Abingdon, UK, 2012. [Google Scholar]

- Singh, A.; Sharma, V.; Mittal, S.; Pandey, G.; Mudgal, D.; Gupta, P. An overview of problems and solutions for components subjected to fireside of boilers. Int. J. Ind. Chem. 2018, 9, 1–15. [Google Scholar] [CrossRef]

- Baxter, L. Biomass-Coal Cofiring: An Overview of Technical Issues. In Solid Biofuels for Energy: A Lower Greenhouse Gas Alternative; Grammelis, P., Ed.; Springer: London, UK, 2011; pp. 43–73. [Google Scholar]

- Sandberg, J.; Sand, U.; Bel Fdhila, R.; Sand, U. Measurements, Theories and Simulations of Particle Deposits on Super-Heater Tubes in a CFB Biomass Boiler. Int. J. Green Energy 2006, 3, 43–61. [Google Scholar] [CrossRef]

- Wang, L.; Skjevrak, G.; Hustad, J.E.; Skreiberg, Ø. Investigation of Biomass Ash Sintering Characteristics and the Effect of Additives. Energy Fuels 2014, 28, 208–218. [Google Scholar] [CrossRef]

- Patiño, D.; Crespo, B.; Porteiro, J.; Míguez, J.L. Experimental analysis of fouling rates in two small-scale domestic boilers. Appl. Therm. Eng. 2016, 100, 849–860. [Google Scholar] [CrossRef]

- Theis, M.; Skrifvars, B.-J.; Hupa, M.; Tran, H. Fouling tendency of ash resulting from burning mixtures of biofuels. Part 1: Deposition rates. Fuel 2006, 85, 1125–1130. [Google Scholar] [CrossRef]

- Regueiro, A.; Patiño, D.; Granada, E.; Porteiro, J. Experimental study on the fouling behaviour of an underfeed fixed-bed biomass combustor. Appl. Therm. Eng. 2017, 112, 523–533. [Google Scholar] [CrossRef]

- Junejo, A.; Al-Abdeli, Y.M.; Porteiro, J. Role of Air Staging in a Batch-Type Fixed Bed Biomass Combustor under Constant Primary Air. J. Therm. Sci. 2023, 33, 284–299. [Google Scholar] [CrossRef]

- Junejo, A.; Chapela, S.; Porteiro, J.; Al-Abdeli, Y.M. Secondary air induced flow structures and mixing in a fixed bed combustor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2023, 237, 1479–1492. [Google Scholar] [CrossRef]

- Junejo, A.; Al-Abdeli, Y.M.; Ikhlaq, M. Progress Variables to Resolve the Steady State Period in a Batch-Type Fixed Bed Combustor. Combust. Sci. Technol. 2022, 196, 1–23. [Google Scholar] [CrossRef]

- Junejo, A.; Al-Abdeli, Y.M.; Porteiro, J. Freeboard Effects on Instabilities in a Fixed Bed Biomass. In Proceedings of the Australian Combustion Symposium, Queensland, Australia, 21–24 November 2021; pp. 176–180. [Google Scholar]

- Junejo, A. Freeboard Effects in a Fixed Bed Biomass Combustor. Ph.D. Thesis, Edith Cowan University, Perth, Australia, 2022. [Google Scholar]

- Riaz, S.; Al-Abdeli, Y.M.; Oluwoye, I.; Altarawneh, M. Torrefaction of Densified Woody Biomass: The Effect of Pellet Size on Thermochemical and Thermophysical Characteristics. BioEnergy Res. 2022, 15, 544–558. [Google Scholar] [CrossRef]

- ASTM E871-82(2019); Standard Test Method for Moisture Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E872-82(2019); Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D1102-84(2021); Standard Test Method for Ash in Wood. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E873-82(2019); Standard Test Method for Bulk Density of Densified Particulate Biomass Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D5865(2007); A Standard Test Method for Gross Calorific Value of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2007.

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 260–266. [Google Scholar]

- Rashidian, B.; Al-Abdeli, Y.M.; Yeoh, G.H.; Patiño, D.; Guzzomi, F. Methodologies for Processing Fixed Bed Combustor Data. Combust. Sci. Technol. 2017, 189, 79–102. [Google Scholar] [CrossRef]

- Junejo, A.; Al-Abdeli, Y.M.; Porteiro, J. Role of Primary Freeboard on Staged Combustion of Hardwood Pellets in a Fixed Bed Combustor. BioEnergy Res. 2023, 16, 1579–1591. [Google Scholar] [CrossRef]

- Elsebaie, A.; Zhu, M.; Al-Abdeli, Y.M. Experimental uncertainty and time-resolved process variability of biomass combustion during fouling tests. In Proceedings of the Australian Combustion Symposium, Darwin, Australia, 26 November 2023; pp. 54–57. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Rashidian, B.; Al-Abdeli, Y.M.; Patiño, D.; Guzzomi, F.G.; Yeoh, G.H. Effect of freeboard deflectors in the fixed bed combustion of biomass. Appl. Therm. Eng. 2016, 103, 543–552. [Google Scholar] [CrossRef]

- Mami, M.A.; Mätzing, H.; Gehrmann, H.-J.; Stapf, D.; Bolduan, R.; Lajili, M. Investigation of the Olive Mill Solid Wastes Pellets Combustion in a Counter-Current Fixed Bed Reactor. Energies 2018, 11, 1965. [Google Scholar] [CrossRef]

- Lundgren, J.; Hermansson, R.; Dahl, J. Experimental studies of a biomass boiler suitable for small district heating systems. Biomass Bioenergy 2004, 26, 443–453. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. Flue and Exhaust Gas Analysis, ASME Power Test Code 19.10; ASME: New York, NY, USA, 1981. [Google Scholar]

- Junejo, A.; Chapela, S.; Porteiro, J.; Al-Abdeli, Y.M. Secondary air induced flow structures and their interplay with the temperature field in fixed bed combustors. Proc. Inst. Mech. Eng. Part A J. Power Energy 2024, 09576509241275778. [Google Scholar] [CrossRef]

- Yao, X.; Xu, K.; Yan, F.; Liang, y. The Influence of Ashing Temperature on Ash Fouling and Slagging Characteristics during Combustion of Biomass Fuels. BioResources 2017, 12, 1593–1610. [Google Scholar] [CrossRef]

| Ref. | Combustor Type | Fuel Form | Fouling Type | FR * (g·m−2·h−1) | Temp. Range |

|---|---|---|---|---|---|

| [13] | Top-feed, 24 kW | Wood pellets, 6 mm diameter | Deposited matter | 7–12 | - |

| [14] | Lab-scale, top-feed reactor | Peat (air-dried milled < 1 mm) | Fly ash deposition | 20 | 1000 |

| Bark (air-dried milled < 1 mm) | 80 | ||||

| Straw (air-dried milled < 1 mm) | 160 | ||||

| [15] | Lab-scale under-feed fixed-bed, 12 kW | Wood pellets, 6 mm diameter, 20 mm length | Attached and deposited matter | 7–28 | 550–600 |

| [5] | CFB ** boiler, 157 MW | Biomass: peat: recycling wood 55%: 38%: 7% | Fly ash and alkaline compounds, condensation and sintering | 4 | 785–820 |

| 86%: 7%: 7% | 14.5 | ||||

| 78%: 7%: 15% | 12 |

| Proximate Analysis (wt %) | |

|---|---|

| Moisture | 6.62 |

| Volatile matter * | 78.41 |

| Fixed carbon * | 14.11 |

| Ash | 0.86 |

| Ultimate Analysis (wt %) | |

| Carbon | 45.80 |

| Oxygen | 48.80 |

| Hydrogen | 5.40 |

| Nitrogen | 0 |

| Step | Program Condition | Process Detail | Purge Gas | Flowrate |

|---|---|---|---|---|

| 1 | From ambient to 105 °C | Heating rate 10 °C·min−1 | Nitrogen | 20 mL·min−1 |

| 2 | Hold at 105 °C (15 min) | Isothermal | Nitrogen | 20 mL·min−1 |

| 3 | From 105 °C to 500 °C | Heating rate 10 °C·min−1 | Nitrogen | 20 mL·min−1 |

| 4 | Hold at 500 °C (240 min) | Isothermal | Nitrogen | 20 mL·min−1 |

| 5 | Hold at 500 °C (180 min) | Isothermal | Air | 20 mL·min−1 |

| # | Qs (L·min−1) [kg·m−2·s−1] | Qt (L·min−1) [kg·m−2·s−1] | Qs/Qt | Qp (L·min−1) [kg·m−2·s−1] | LI (mm) |

|---|---|---|---|---|---|

| 1 | (70) [0.044] | (210) [0.134] | 0.33 | (140) [0.089] | 200 |

| 2 | (140) [0.089] | (280) [0.178] | 0.50 | ||

| 4 | (280) [0.178] | (420) [0.267] | 0.66 | ||

| 5 | (350) [0.223] | (490) [0.312] | 0.71 | ||

| 6 | (420) [0.267] | (560) [0.356] | 0.75 | ||

| 7 | (70) [0.044] | (210) [0.134] | 0.33 | (140) [0.089] | 300 |

| 8 | (140) [0.089] | (280) [0.178] | 0.50 | ||

| 10 | (280) [0.178] | (420) [0.267] | 0.66 | ||

| 11 | (350) [0.223] | (490) [0.312] | 0.71 | ||

| 12 | (420) [0.267] | (560) [0.356] | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsebaie, A.; Zhu, M.; Al-Abdeli, Y.M. Operational and Design Factors in Air Staging and Their Effects on Fouling from Biomass Combustion. Sustainability 2024, 16, 8584. https://doi.org/10.3390/su16198584

Elsebaie A, Zhu M, Al-Abdeli YM. Operational and Design Factors in Air Staging and Their Effects on Fouling from Biomass Combustion. Sustainability. 2024; 16(19):8584. https://doi.org/10.3390/su16198584

Chicago/Turabian StyleElsebaie, Akram, Mingming Zhu, and Yasir M. Al-Abdeli. 2024. "Operational and Design Factors in Air Staging and Their Effects on Fouling from Biomass Combustion" Sustainability 16, no. 19: 8584. https://doi.org/10.3390/su16198584

APA StyleElsebaie, A., Zhu, M., & Al-Abdeli, Y. M. (2024). Operational and Design Factors in Air Staging and Their Effects on Fouling from Biomass Combustion. Sustainability, 16(19), 8584. https://doi.org/10.3390/su16198584