Feasibility of Using Ferronickel Slag as a Sustainable Alternative Aggregate in Hot Mix Asphalt

Abstract

:1. Introduction

2. Materials and Methods

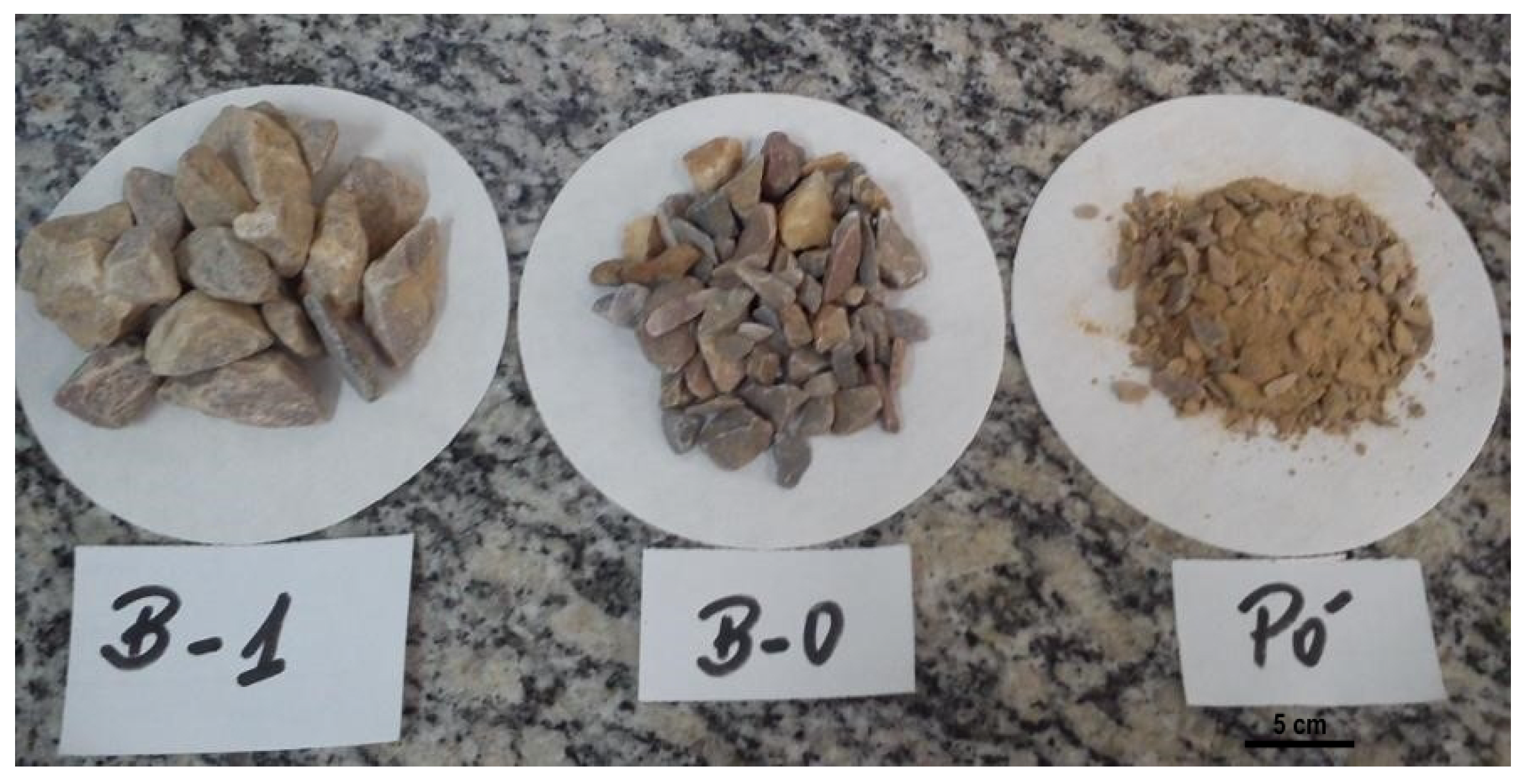

2.1. Raw Materials

2.2. Physical Characterization

2.3. Mineralogical, Chemical, and Environmental Characterization of the RFNS

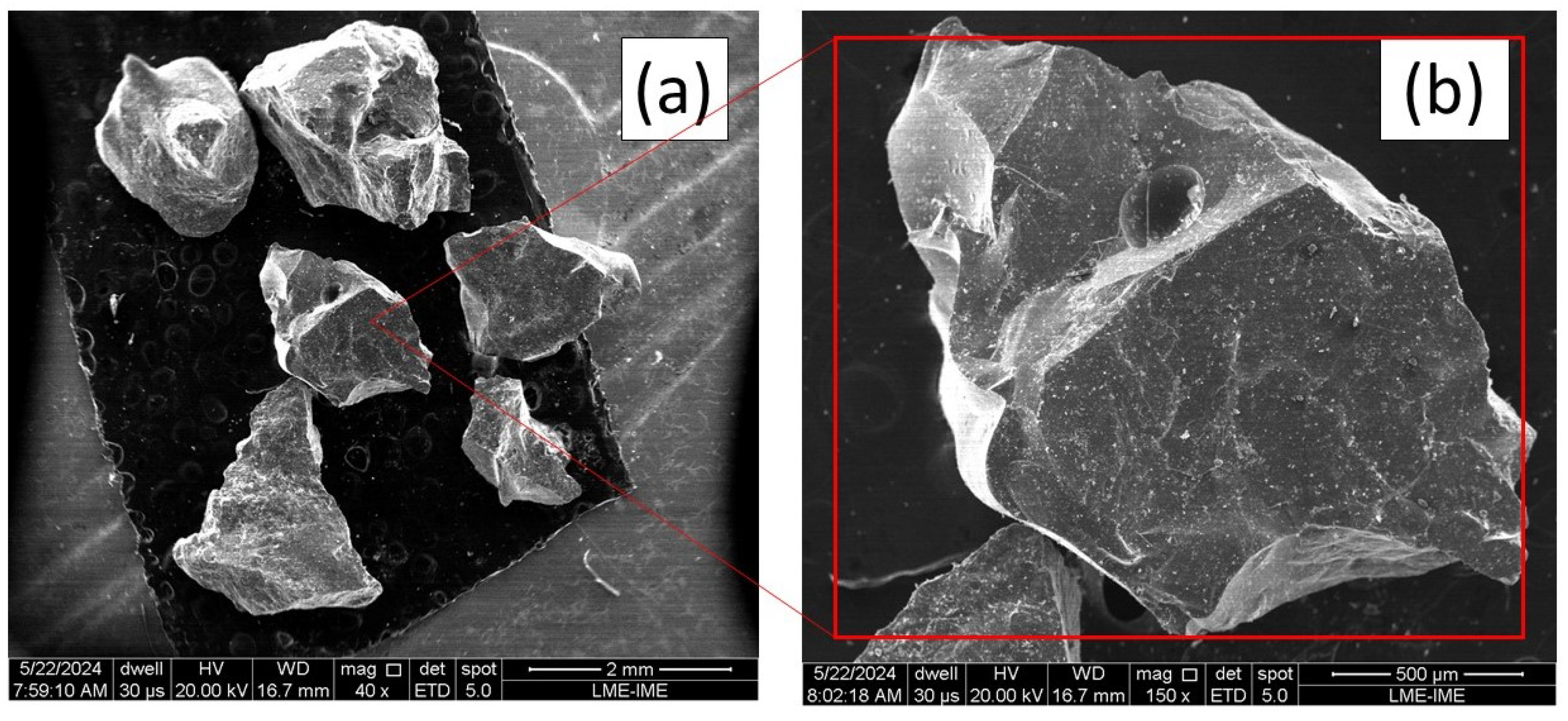

2.3.1. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDX)

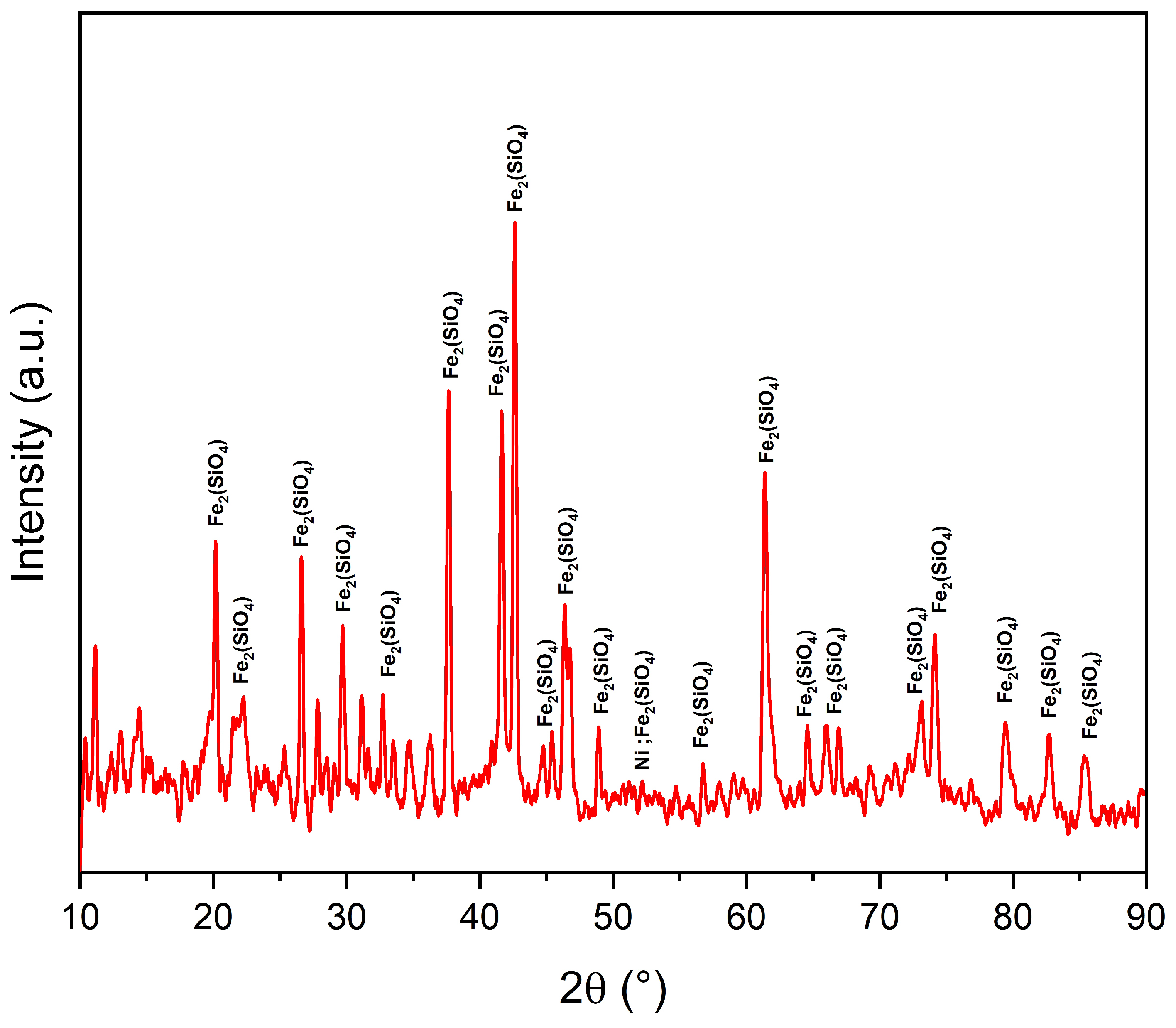

2.3.2. X-ray Diffraction (XRD)

2.3.3. Optical Microscopy (OM)

2.3.4. Environmental Analysis

2.4. Dosage

2.5. Experimental Area

3. Results and Discussion

3.1. Physical Evaluation (Ferronickel Slag and Virgin Aggregates)

3.2. Asphalt Binder

3.3. Mineralogical, Chemical, and Environmental Analysis of Ferronickel Slag

3.3.1. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDX)

3.3.2. X-ray Diffraction (XRD)

3.3.3. Optical Microscopy

3.3.4. Environmental Analysis

3.4. Dosage Design

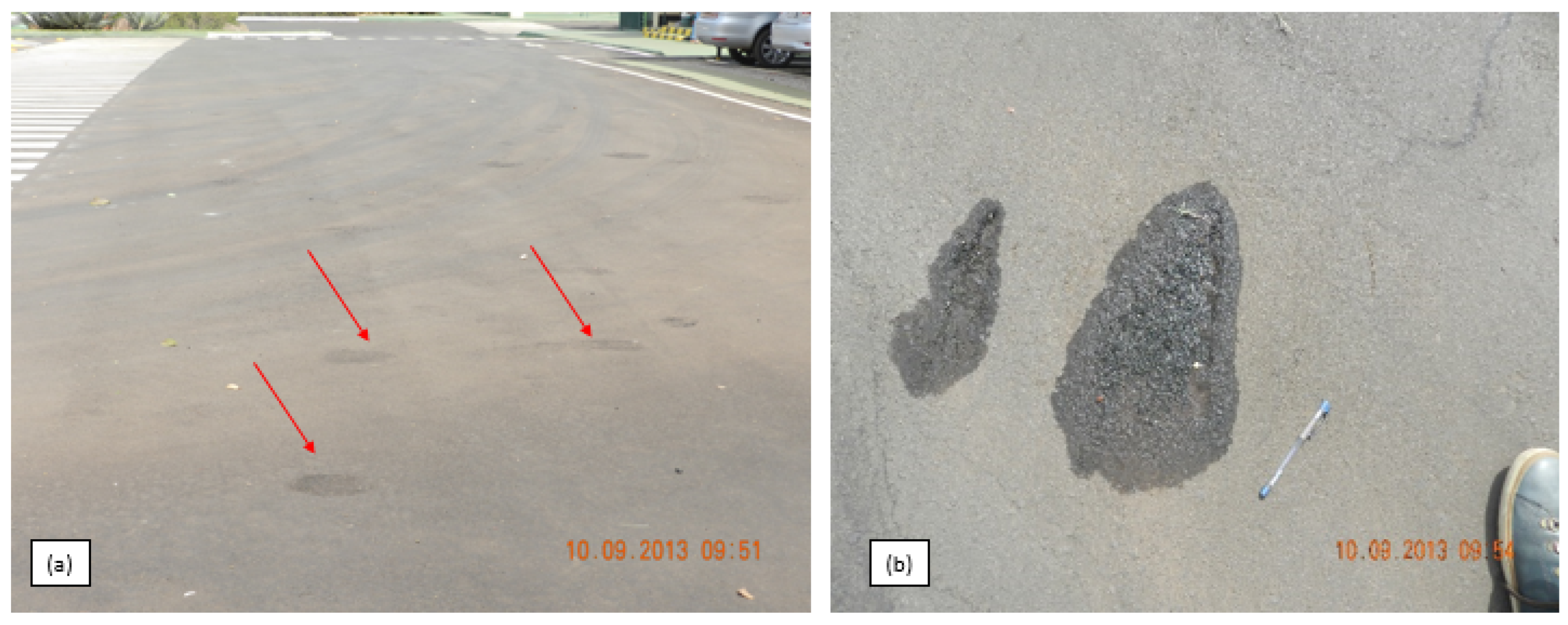

3.5. Experimental Area Analysis

4. Conclusions

- Reduction ferronickel slag (RFNS) is considered inert, as it has low concentrations of harmful elements to the environment, allowing its use in pavements without soil or water contamination;

- The chemical analysis of RFNS revealed that it is primarily composed of MgO, Fe2O3, and SiO2, which pose minimal environmental risk. The absence of significant calcium content reduces concerns about expansion issues typical of calcium-rich slags. The X-ray diffractogram indicated a predominantly crystalline structure with minerals like Laihunite and Magnetite, suggesting that FNS has high hardness. This crystalline structure and mineral content enhance the wear and abrasion resistance of asphalt mixtures, potentially improving their durability and extending their service life;

- The hot mix asphalt (HMA) containing RFNS meets the regulatory specifications and technological control during the execution of the experimental area and obtained an average resilient modulus value of 6323 MPa, indicating the coating’s efficiency regarding pavement mechanics parameters;

- Visual inspections conducted four years after the construction of the experimental area showed that the pavement is still in excellent condition. These findings confirm that RFNS slag is a promising alternative aggregate for asphalt mixtures, providing both durability and long-term performance for local road infrastructure projects. The successful application of RFNS highlights both its viability for local road paving near industrial sites and its potential for promoting sustainable waste management solutions. The results underscore the importance of academia–industry collaboration in advancing environmentally responsible practices, reinforcing the contribution of RFNS to enhancing local infrastructure and promoting a more sustainable future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and recycling of by-products in the steel sector: Recent achievements paving the way to circular economy and industrial symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef]

- Birat, J.P. Recycling and by-products in the steel industry. Revue de Métallurgie 2003, 100, 339–348. [Google Scholar] [CrossRef]

- Iluţiu-Varvara, D.A.; Aciu, C. Metallurgical wastes as resources for sustainability of the steel industry. Sustainability 2022, 14, 5488. [Google Scholar] [CrossRef]

- Strauch, J.C.M.; Souza, K.V.d.; Ajara, C.; Teixeira, M.d.P.; Cardoso, S.C. Grandes Mineradoras e a Comunidade em Niquelândia (GO); CETEM/MCTI: Rio de Janeiro, Brazil, 2011; pp. 135–162. [Google Scholar]

- Especial-Panorama do Mapeamento Geológico no Brasil-Anglo American 50 anos, 2023. Available online: https://www.brasilmineral.com.br/revista/429/Revista%20Brasil%20Mineral%20-%20429.pdf (accessed on 19 September 2024).

- Kurniati, E.O.; Pederson, F.; Kim, H.J. Application of steel slags, ferronickel slags, and copper mining waste as construction materials: A review. Resour. Conserv. Recycl. 2023, 198, 107175. [Google Scholar] [CrossRef]

- Long, W.J.; Peng, J.K.; Gu, Y.C.; Li, J.L.; Dong, B.; Xing, F.; Fang, Y. Recycled use of municipal solid waste incinerator fly ash and ferronickel slag for eco-friendly mortar through geopolymer technology. J. Clean. Prod. 2021, 307, 127281. [Google Scholar] [CrossRef]

- Bao, J.; Yu, Z.; Wang, L.; Zhang, P.; Wan, X.; Gao, S.; Zhao, T. Application of ferronickel slag as fine aggregate in recycled aggregate concrete and the effects on transport properties. J. Clean. Prod. 2021, 304, 127149. [Google Scholar] [CrossRef]

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Saha, A.K.; Khan, M.; Sarker, P.K. Value added utilization of by-product electric furnace ferronickel slag as construction materials: A review. Resour. Conserv. Recycl. 2018, 134, 10–24. [Google Scholar] [CrossRef]

- Qian, Y.; Xu, C.; Yang, T.; Yu, H.; Zhou, G.; Zhuang, P. Alkali-silica reaction of ferronickel slag fine aggregate in Portland cement and alkali-activated slag mortars: Pessimum effect investigation. J. Build. Eng. 2024, 89, 109349. [Google Scholar] [CrossRef]

- Tang, Z.; Peng, H.; Mei, P.; Huang, F.; Yi, S.; Feng, F. Performance Analysis of Ferronickel Slag-Ordinary Portland Cement Pervious Concrete. Materials 2024, 17, 1628. [Google Scholar] [CrossRef]

- Jiang, Y.; Duan, X.; Li, B.; Lu, S.; Liu, T.; Li, Y. Synergistic Activation of Electric Furnace Ferronickel Slag by Mechanical Grinding and Chemical Activators to Prepare Cementitious Composites. Materials 2024, 17, 1247. [Google Scholar] [CrossRef]

- Saha, A.K.; Sarker, P.K. Sustainable use of ferronickel slag fine aggregate and fly ash in structural concrete: Mechanical properties and leaching study. J. Clean. Prod. 2017, 162, 438–448. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Castel, A.; Kim, T.; Khan, M.S. Performance of fly ash concrete with ferronickel slag fine aggregate against alkali-silica reaction and chloride diffusion. Cem. Concr. Res. 2021, 139, 106265. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Khan, M.S.H.; Castel, A.; Kim, T. Durability and Microstructure Properties of Low-Carbon Concrete Incorporating Ferronickel Slag Sand and Fly Ash. J. Mater. Civ. Eng. 2021, 31, 8. [Google Scholar] [CrossRef]

- Nuruzzaman, M.; Kuri, J.C.; Sarker, P.K. Strength, permeability and microstructure of self-compacting concrete with the dual use of ferronickel slag as fine aggregate and supplementary binder. Constr. Build. Mater. 2022, 318, 125927. [Google Scholar] [CrossRef]

- Ernawan, E.; Sjah, J.; Handika, N.; Astutiningsih, S.; Vincens, E. Mechanical Properties of Concrete Containing Ferronickel Slag as Fine Aggregate Substitute Using Digital Image Correlation Analysis. Buildings 2023, 13, 1463. [Google Scholar] [CrossRef]

- Cho, W.J.; Kim, M.J.; Lee, D.S.V. Characterization of Portland Cement Incorporated with FNS. Mater. Sci. Eng. 2020, 7047549. [Google Scholar] [CrossRef]

- Navaratnam, S.; Tushar, Q.; Jahan, I.; Zhang, G. Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment. Sustainability 2023, 15, 1873. [Google Scholar] [CrossRef]

- Delgado, B.G.; Viana da Fonseca, A.; Fortunato, E. Stress–Strain Analysis of Heavy Haul Rail Track with Steel Slag Ballast by Laboratory Tests and Numerical Simulations. In Advances in Transportation Geotechnics IV; Springer: Cham, Switzerland, 2022; pp. 195–207. [Google Scholar] [CrossRef]

- Jing, G.; Aela, P.; Zhou, Q.; Jia, W. Steel Slag Aggregate Characteristics Evaluation as Railway Ballast. In Advances in Transportation Geotechnics IV; Springer, C., Ed.; Springer: Cham, Switzerland, 2022; pp. 449–460. [Google Scholar] [CrossRef]

- Delgado, B.G.; da Fonseca, A.V.; Fortunato, E.; Paixão, A.; Alves, R. Geomechanical assessment of an inert steel slag aggregate as an alternative ballast material for heavy haul rail tracks. Constr. Build. Mater. 2021, 279, 122438. [Google Scholar] [CrossRef]

- Gomes, B.; Guimarães, A.C.R.; do Nascimento, F.A.C.; Tanabe, J. Ballast with siderurgic aggregates: Variation analysis of the shape parameters of particles submitted to triaxial tests through 3D scanner. Soils Rocks 2023, 46, 3. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Ávila Costa, K.; de Miranda Reis, M.; Santana, C.S.A.; Castro, C.D. Study of controlled leaching process of steel slag in soxhlet extractor aiming employment in pavements. Transp. Geotech. 2021, 27, 100485. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Q.; Deng, Y.; Yu, X.; Feng, Q.; Yan, C. Residual Steel Slag-Modified Expansive Soil and Its Application in Highway Subbase Layer. Soils Found. 2019, 59, 955–965. [Google Scholar] [CrossRef]

- Lopes, E.C.; da Silva, T.O.; Pitanga, H.N.; Pedroti, L.G.; Franco de Carvalho, J.M.; Nalon, G.H.; de Lima, G.E.S.; de Araújo, E.N.D. Stabilization of Clayey and Sandy Soils with Slag Fines from Cupola Furnace for Road Construction. Road Mater. Pavement Des. 2023, 24, 247–266. [Google Scholar] [CrossRef]

- Lopes, E.C.; da Silva, T.O.; Pitanga, H.N.; Pedroti, L.G.; de Carvalho, J.M.F.; Nalon, G.H.; de Paula Rodrigues, K.H. Chemical, Mineralogical, Microstructural, and Engineering Properties of Tropical Soils Stabilized with the Combined and Individual Use of Different Types of Steel Slag. Road Mater. Pavement Des. 2023, 25, 1507–1527. [Google Scholar] [CrossRef]

- Alves, R.; Rios, S.; Fortunato, E.; Viana da Fonseca, A.; Guimarães Delgado, B. Mechanical Behaviour of Steel Slag–Rubber Mixtures: Laboratory Assessment. Sustainability 2023, 15, 1563. [Google Scholar] [CrossRef]

- Rodrigues, K.H.d.P.; da Silva, T.O.; Pitanga, H.N.; de Almeida, M.S.d.S.; Pedroti, L.G.; Rodrigues, M.H.R.; Lopes, E.C. Effect of Carbonation of Soil-Slag Mixtures on the Resilient Behaviour and Structural Response of an Asphalt Pavement. Road Mater. Pavement Des. 2024, 25, 2101–2120. [Google Scholar] [CrossRef]

- Shamsi Susahab, J.; Ardakani, A.; Hassanlourad, M. Strength Improvement of Clay Subgrade Soil Stabilised with Recycled Concrete Aggregate and Granulated Blast Furnace Slag. Road Mater. Pavement Des. 2024, 1–16. [Google Scholar] [CrossRef]

- Asi, I.M.; Qasrawi, H.Y.; Shalabi, F.I. Use of steel slag aggregate in asphalt concrete mixes. Can. J. Civ. Eng. 2007, 34, 902–911. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Ruge-Cárdenas, J.C.; Farias, M.M.D. Hot Asphalt Behavior Containing Blast Furnace Slag as Aggregate: Evaluation by Mass and Volume Replacement. J. Mater. Civ. Eng. 2019, 31, 04018364. [Google Scholar] [CrossRef]

- Masoudi, S.; Abtahi, S.M.; Goli, A. Evaluation of electric arc furnace steel slag coarse aggregate in warm mix asphalt subjected to long-term aging. Constr. Build. Mater. 2017, 135, 260–266. [Google Scholar] [CrossRef]

- Georgiou, P.; Loizos, A. Environmental assessment of warm mix asphalt incorporating steel slag and high reclaimed asphalt for wearing courses: A case study. Road Mater. Pavement Des. 2021, 22, S662–S671. [Google Scholar] [CrossRef]

- Awed, A.M.; Tarbay, E.W.; El-Badawy, S.M.; Azam, A.M. Performance Characteristics of Asphalt Mixtures with Industrial Waste/Subproduct Materials as Mineral Fillers under Static and Cyclic Loading. Road Mater. Pavement Des. 2022, 23, 335–357. [Google Scholar] [CrossRef]

- Goli, A. The study of the feasibility of using recycled steel slag aggregate in hot mix asphalt. Case Stud. Constr. Mater. 2022, 16, e00861. [Google Scholar] [CrossRef]

- Raschia, S.; Tattolo, S.; Rilievi, A. Evaluation of high percentage of alternative aggregates for the production of hot mix asphalt surface layers. Road Mater. Pavement Des. 2023, 25, 56–71. [Google Scholar] [CrossRef]

- Zhong, T.; Zheng, Y.; Chen, Z.; Yao, L.; Zhang, W.; Zhu, Y.; Fu, L. Utilization of steel slag as coarse aggregate and filler in stone mastic asphalt (SMA) mixture: Engineering performance, environmental impact and economic benefits analysis. J. Clean. Prod. 2024, 450, 141891. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhu, H.; Xu, P. The Interfacial Adhesion Performance and Mechanism of a Modified Asphalt–Steel Slag Aggregate. Materials 2020, 13, 1180. [Google Scholar] [CrossRef]

- Hasita, S.; Rachan, R.; Suddeepong, A.; Horpibulsuk, S.; Arulrajah, A.; Mohammadinia, A.; Nazir, R. Performance Improvement of Asphalt Concretes Using Steel Slag as a Replacement Material. J. Mater. Civ. Eng. 2020, 32, 8. [Google Scholar] [CrossRef]

- Huang, D.; Chen, S.H.; Mon, H.H. California Bearing Ratio (CBR), Ferrous-Nickel Slag, Soil Improvement, Unconfined Compressive Strength (UCS). Adv. Mater. Res. 2013, 723, 694–702. [Google Scholar] [CrossRef]

- Gökalp, İ.; Uz, V.E.; Saltan, M.; Tutumluer, E. Technical and environmental evaluation of metallurgical slags as aggregate for sustainable pavement layer applications. Transp. Geotech. 2018, 14, 61–69. [Google Scholar] [CrossRef]

- He, W.; Liu, J.F.; Yin, P.B.; Chen, Y.H.; Yang, W.B.; Chen, Y.L.; Wu, Y.C. Properties and field tests of industrial ferro-nickel slag for roads. Chin. J. Geotech. Eng. 2019, 41, 1809–1816. [Google Scholar] [CrossRef]

- Mrema, A.; Yeon-Tae, K.; Jae-Jun, L.; Su-Hyung, L. Utilization of Ferronickel Slags as Aggregate in Hot Mix Asphalt: Laboratory Evaluation. J. Korean Road Soc. (Int. J. Highw. Eng.) 2023, 25, 133–141. [Google Scholar] [CrossRef]

- Yin, P.; Wang, J.; He, W.; Wang, S.; Li, X.; Jia, Z. Machine learning-based study on the mechanical properties and embankment settlement prediction model of nickel–iron slag modified soil. Constr. Build. Mater. 2024, 431, 136468. [Google Scholar] [CrossRef]

- Wang, G.; Thompson, R. Slag Use in Highway Construction—The Philosophy and Technology of its Utilization. Int. J. Pavement Res. Technol. 2011, 4, 97–103. [Google Scholar]

- Wang, G.; Thompson, R.G.; Wang, Y. Hot Mix Asphalt Containing Nickel Slag Aggregate: Laboratory Evaluation for Use in Highway Construction. Transp. Res. Rec. 2011, 2208, 1–8. [Google Scholar] [CrossRef]

- Cosme, J.; Fernandes, G.; Pinto Fernandes, D. Utilization of ferronickel slag in hot mix asphalt. Civ. Eng. REM Int. Eng. J. 2021, 74, 19–26. [Google Scholar] [CrossRef]

- DNER—Departamento Nacional de Rodagem. Agregados—Análise Granulométrica; ME 083; DNER: Rio de Janeiro, Brazil, 1998. [Google Scholar]

- DNER—Departamento Nacional de Rodagem. Agregado Miúdo—Determinação da Densidade Real; ME 084; DNER: Rio de Janeiro, Brazil, 1995. [Google Scholar]

- DNER—Departamento Nacional de Estradas de Rodagem. Agregados: Determinação da Absorção e da Massa Específica de Agregado graúDo; Norma DNER ME 195; DNER: Rio de Janeiro, Brazil, 1997. [Google Scholar]

- DNER—Departamento Nacional de Rodagem. Agregado—Adesividade a Ligante Betuminoso; ME 079; DNER: Rio de Janeiro, Brazil, 1994. [Google Scholar]

- DNER—Departamento Nacional de Rodagem. Agregados—Determinação da Perda ao Choque no Aparelho Treton; ME 399; DNER: Rio de Janeiro, Brazil, 1999. [Google Scholar]

- DNER—Departamento Nacional de Rodagem. Agregados—Determinação da Abrasão Los Angeles; ME 035; DNER: Rio de Janeiro, Brazil, 1998. [Google Scholar]

- Departamento Nacional de Infraestrutura e Transporte (DNIT). Material Asfáltico—Determinação da Penetração; DNIT-ME 155/2010; DNIT: Rio de Janeiro, Brazil, 2010. [Google Scholar]

- Departamento Nacional de Infraestrutura e Transporte (DNIT). Materiais Asfálticos—Determinação do Ponto de Amolecimento—Método do Anel e Bola; DNIT-ME 131/2010; DNIT: Rio de Janeiro, Brazil, 2010. [Google Scholar]

- de Normas Técnicas, A.A.B. Adhesives—Determination of the Viscosity—Method Brookfield Viscometer, NBR9277; ABNT: Rio de Janeiro, Brazil, 2020. [Google Scholar]

- de Normas Técnicas, A.A.B. Petroleum Products—Determination of the Flash and Fire Points by Cleveland Open Cup, NBR11341; ABNT: Rio de Janeiro, Brazil, 2014. [Google Scholar]

- Departamento Nacional de Estradas de Rodagem. Materiais Betuminosos—Determinação da Ductilidade, DNER-ME 163/98; DNER: Rio de Janeiro, Brazil, 1998. [Google Scholar]

- ASTM D 2872; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2012.

- ABNT—Associação Brasileira de Normas Técnicas. Resíduos Sólidos—Classificação, NBR 10004; ABNT: Rio de Janeiro, Brazil, 2004. [Google Scholar]

- DNER—Departamento Nacional de Estradas de Rodagem. Misturas Betuminosas a Quente, Norma DNER 043/1995; DNER: Rio de Janeiro, Brazil, 1995. [Google Scholar]

- DNIT—Departamento Nacional de Infraestrutura de Transportes. Pavimentos Flexíveis—Concreto AsfáLtico—Especificação de Serviço, Norma DNIT 031/2006-ES; DNIT: Rio de Janeiro, Brazil, 2006. [Google Scholar]

- DNIT—Departamento Nacional de Infraestrutura de Transportes. Pavimentação AsfáLtica—Misturas AsfáLticas—Determinação do Módulo de Resiliência—Método de Ensaio, Norma DNIT 135/2018-ME; DNIT: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Balbo, J.T. Pavimentação AsfáLtica: Materiais, Projeto e Restauração; Oficina de Textos: São Paulo, Brazil, 2007. [Google Scholar]

- Silva, R.G.O. Estudo Laboratorial do Desempenho Mecânico de Misturas Asfálticas com Resíduos Industriais de Minério de Ferro. Master’s Thesis, Universidade Federal de Ouro Preto, Ouro Preto, Brazil, 2010. [Google Scholar]

- de Infraestrutura de Transportes, D.N. Pavimentos Flexíveis—Cimentos Asfálticos de Petróleo—Especificação de Material; DNIT-EM 095; DNIT: Rio de Janeiro, Brazil, 2006. [Google Scholar]

- Branco, P.M. Dicionário de Mineralogia e Gemologia; Oficina de Textos: São Paulo, Brazil, 2008. [Google Scholar]

- Kitamura, M.; Shen, B.; Banno, S.; Morimoto, N. Fine textures of laihunite, a nonstoichiometric distorted olivine-type mineral. Am. Mineral. 1984, 69, 154–160. [Google Scholar]

- Faialita. Available online: http://www.mindat.org/min-1458.html (accessed on 22 July 2024).

- Wenk, H.R.; Bulakh, A. Minerals: Their Constitution and Origin; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- Deer, W.A.; Howie, R.A.; Zussman, J. An Introduction to the Rock-Forming Minerals, 3rd ed.; Mineralogical Society: London, UK, 2013. [Google Scholar]

- National Department of Roads and Highways. Bituminous Mixtures—Bitumen Percentage; DNER ME 53; National Department of Roads and Highways: Rio de Janeiro, Brazil, 1994. [Google Scholar]

- Bernucci, L.B.; da Motta, L.M.G.; Ceratti, J.A.P.; Soares, J.B. Pavimentação Asfáltica: Formação Básica para Engenheiros, 4th ed.; Petrobras: Rio de Janeiro, Brazil, 2010. [Google Scholar]

| Sieve # | Coarse Gravel 1 | Coarse Gravel 0 | Stone Dust | Cement | RFNS |

|---|---|---|---|---|---|

| 1 and ½” | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| 1” | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| ¾” | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| ½” | 42.5 | 98.9 | 100.0 | 100.0 | 100.0 |

| 3/8” | 4.8 | 82.8 | 100.0 | 100.0 | 100.0 |

| No. 4 | 0.2 | 13.1 | 95.5 | 100.0 | 97.7 |

| No. 10 | 0.2 | 4.5 | 61.9 | 100.0 | 63.8 |

| No. 40 | 0.2 | 2.7 | 33.3 | 100.0 | 4.0 |

| No. 80 | 0.2 | 2.4 | 27.7 | 100.0 | 0.8 |

| No. 200 | 0.2 | 1.5 | 15.3 | 92.0 | 0.4 |

| Material | True Density (g/cm³) | Apparent Density (g/cm³) | Absorption (%) | Adhesiveness | Treton Impact (%) | Los Angeles Abrasion (%) |

|---|---|---|---|---|---|---|

| Coarse Aggregate 1 | 2.82 | 2.79 | 1.7 | Satisfactory | 30.61 | 25.6 |

| Coarse Aggregate 0 | 2.88 | 2.75 | - | Satisfactory | ||

| Dust | 2.85 | - | - | - | - | |

| Cement | 3.10 | - | - | - | ||

| Slag | 3.3 | 2.99 | 0.1 | Satisfactory * |

| Test–CAP 50/70 | Units | Limits | Results |

|---|---|---|---|

| Penetration (100 g, 5 s, 25 °C, 0.1 mm) | 0.1 mm | 50 to 70 | 50 |

| Softening Point, min. | °C | 52 | 58.6 |

| Brookfield Viscosity at 135 °C, SP 21, 20 rpm, min. | - | 274 | 375 |

| Brookfield Viscosity at 150 °C, SP 21, min. | cP | 112 | 183 |

| Brookfield Viscosity at 177 °C, SP 21 | - | 57 to 285 | 68 |

| Flash Point, min. | °C | 235 | 348 |

| Ductility at 25 °C, min. | cm | 60 | >100 |

| Effect of Heat and Air (RTFOT) at 163 °C, 85 min | |||

| Increase in Softening Point, max. | °C | 8 | 65.5 |

| Retained Penetration, min. | % | 55 | 55 |

| Ductility at 25 °C, min. | cm | 20 | >100 |

| Relative Density | - | - | 1.04 |

| Raw Sample | Leaching | Solubilization | |

|---|---|---|---|

| Parameters | Contents (% and ppm) | Levels (mg/L) | Levels (mg/L) |

| Silicon | 43.60% | 2.80 | 8.10 |

| Magnesium | 0.36% | 4.60 | 4.58 |

| Aluminum | 3.90% | <0.05 | <0.05 |

| Iron | 14.90% | 0.95 | 0.19 |

| Total Hardness as CaCO3 | 1.49% | 26.41 | 26.41 |

| Mg Hardness | 1.49% | 18.92 | 18.86 |

| Chromium | 1.30% | <0.05 | <0.05 |

| Nickel | 0.14% | <0.02 | <0.02 |

| Titanium | 0.15% | <0.01 | <0.01 |

| Manganese | 0.34% | <0.11 | <0.05 |

| Niobium | <5.00 ppm | <0.10 | <0.10 |

| Copper | 106.00 ppm | <0.02 | <0.02 |

| Vanadium | 184.00 ppm | <0.01 | <0.01 |

| Zirconium | 27.00 ppm | <0.01 | <0.01 |

| Cobalt | 66.00 ppm | <0.10 | <0.10 |

| RFNS | Major Constituents Concentration: >5% | Silicon, Magnesium, Iron |

| Minor Constituents Concentration: <5% and >0.1% | Aluminum, Chromium, Calcium | |

| Traces: Concentration: <0.1% | Nickel, Titanium, Manganese, Niobium, Copper, Vanadium, Zirconium, Cobalt |

| Item | Values | Limits |

|---|---|---|

| Binder Content | 4.3% | - |

| Bulk Density | 2.52 | - |

| Air Voids (%) | 3.5 | 3–5 |

| Voids in Mineral Aggregate—VMA (%) | 15.5 | - |

| Void-Filled with Bitumen—VFB (%) | 77.0 | 75–82 |

| Maximum Theoretical Density | 2.51 | - |

| Minimum Stability (kgf) 75 blows | 850 | 500 |

| Indirect Tensile Strength (MPa) | 0.75 | 0.65 |

| Force (Unit) | Displacement (Unit) | ||

|---|---|---|---|

| Sample 1 | 313.25 | 0.003808 | 7099 |

| 313.83 | 0.003678 | 7364 | |

| 312.55 | 0.003758 | 7178 | |

| Average | 7214 | ||

| Sample 2 | 218.45 | 0.00292 | 6457 |

| 219.52 | 0.003075 | 6160 | |

| 220.5 | 0.003194 | 5959 | |

| Average | 6192 | ||

| Sample 3 | 250.91 | 0.003813 | 5679 |

| 251.5 | 0.003889 | 5581 | |

| 250.06 | 0.003972 | 5433 | |

| Average | 5564 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coelho, L.M.; Guimarães, A.C.R.; Alves Moreira, C.R.C.L.; dos Santos, G.P.P.; Monteiro, S.N.; da Silveira, P.H.P.M. Feasibility of Using Ferronickel Slag as a Sustainable Alternative Aggregate in Hot Mix Asphalt. Sustainability 2024, 16, 8642. https://doi.org/10.3390/su16198642

Coelho LM, Guimarães ACR, Alves Moreira CRCL, dos Santos GPP, Monteiro SN, da Silveira PHPM. Feasibility of Using Ferronickel Slag as a Sustainable Alternative Aggregate in Hot Mix Asphalt. Sustainability. 2024; 16(19):8642. https://doi.org/10.3390/su16198642

Chicago/Turabian StyleCoelho, Lisley Madeira, Antônio Carlos Rodrigues Guimarães, Claudio Rafael Cicuto Landim Alves Moreira, Graziella Pereira Pires dos Santos, Sergio Neves Monteiro, and Pedro Henrique Poubel Mendonça da Silveira. 2024. "Feasibility of Using Ferronickel Slag as a Sustainable Alternative Aggregate in Hot Mix Asphalt" Sustainability 16, no. 19: 8642. https://doi.org/10.3390/su16198642

APA StyleCoelho, L. M., Guimarães, A. C. R., Alves Moreira, C. R. C. L., dos Santos, G. P. P., Monteiro, S. N., & da Silveira, P. H. P. M. (2024). Feasibility of Using Ferronickel Slag as a Sustainable Alternative Aggregate in Hot Mix Asphalt. Sustainability, 16(19), 8642. https://doi.org/10.3390/su16198642