Addressing the Difficulties and Opportunities to Bridge the Integration Gaps of Bio-Based Insulation Materials in the European Construction Sector: A Systematic Literature Review

Abstract

1. Introduction

1.1. Background

1.2. Rational and Objectives of the Study

2. Materials and Methods

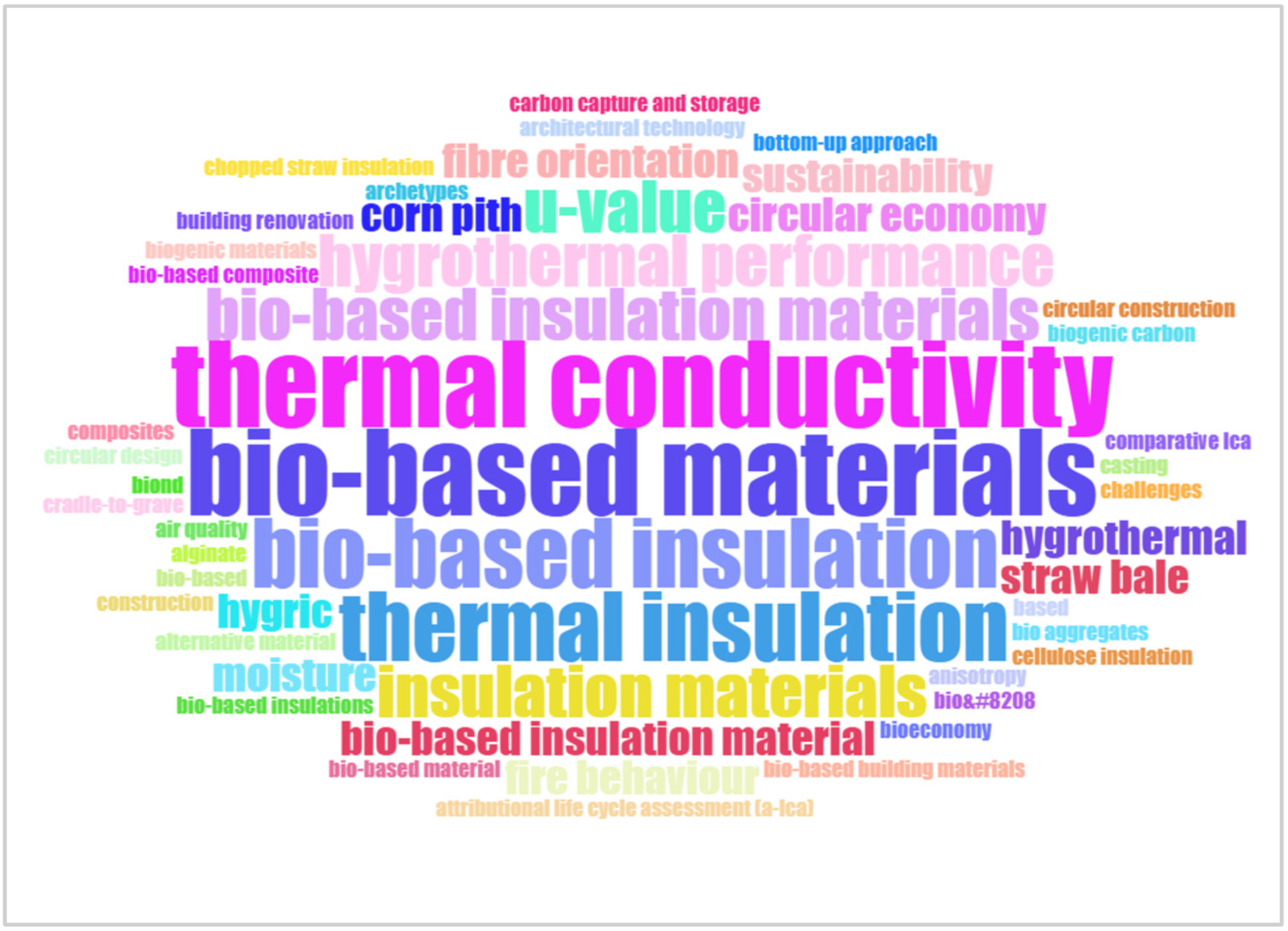

2.1. Search Strategy

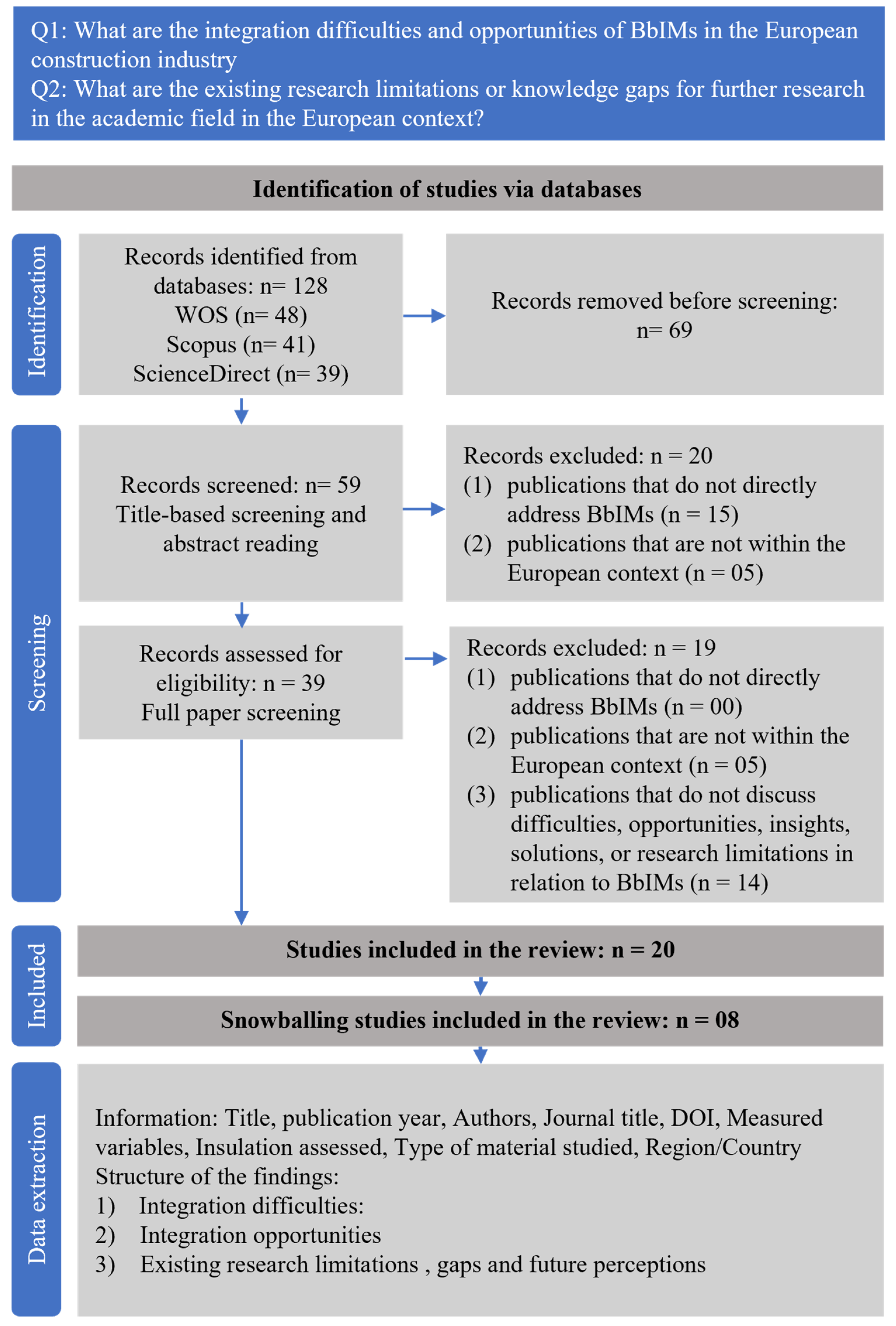

2.2. Data Collection and Selection Process

2.3. Data Items and Synthesis Methods

- (1)

- Integration difficulties: refer to the difficulties related to policy and regulations at the European and national levels that may limit the use of such materials, as well as materials performance integration difficulties, which include the performance of BbIMs, their impacts on the environment, and cost barriers.

- (2)

- Integration opportunities: indicate opportunities for policies and regulations that motivate and emphasize the use of BbIMs, as well as the benefits of using certain insulations, and solutions to improve their production and performance.

- (3)

- Existing research limitations, gaps, and future perceptions: highlight areas of scientific studies uncertainties, knowledge gaps, and suggestions relating to BbIMs. The flowchart of conducting this SLR is presented in Figure 3.

3. Results

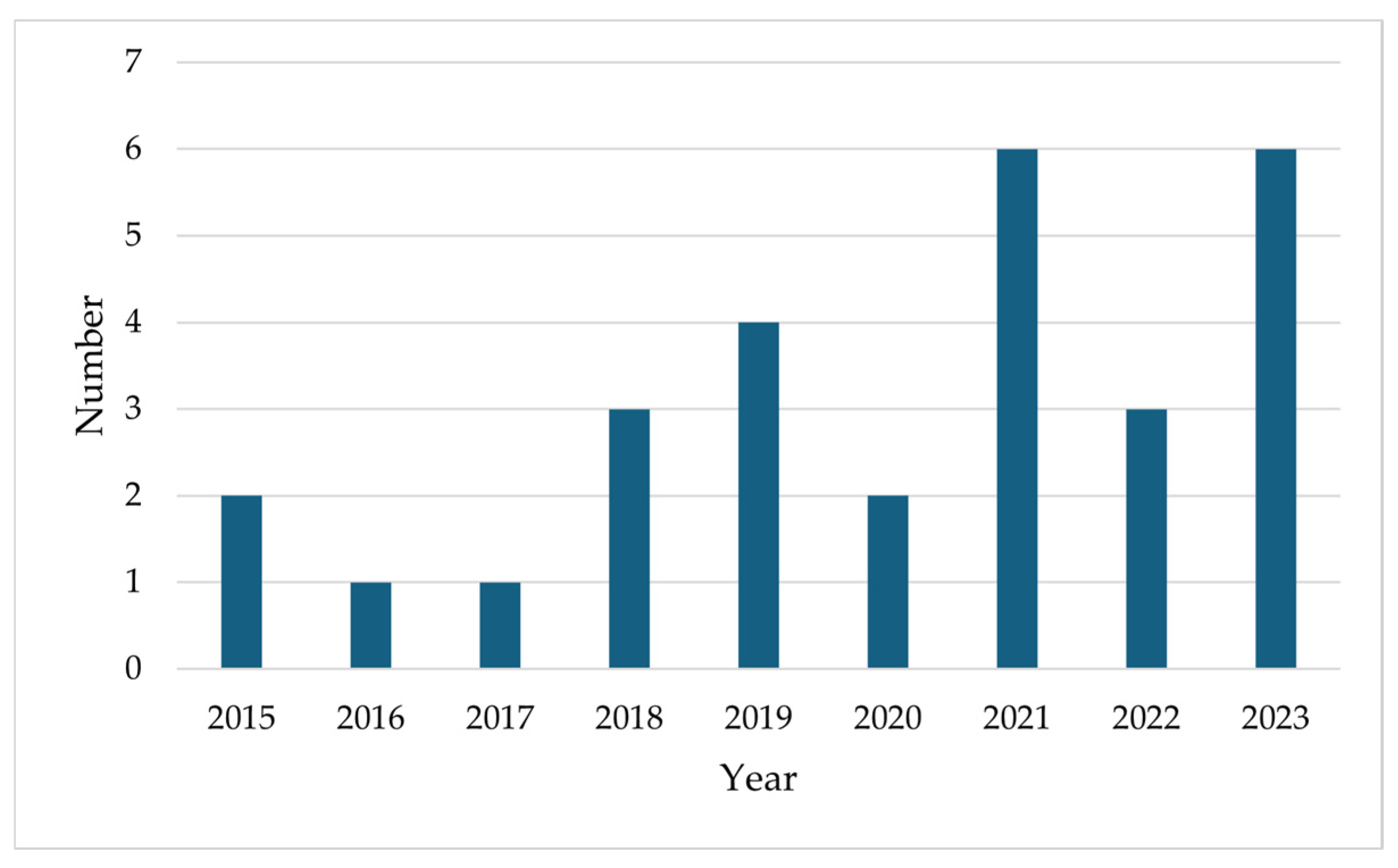

3.1. Description of the Selected Studies

3.2. Integration Difficulties of BbIMs in the European Construction Sector

3.2.1. Regulations and Policy Difficulties

3.2.2. Materials Performance Difficulties

Certain Materials Performance Difficulties

3.2.3. Cost-Related Integration Difficulties

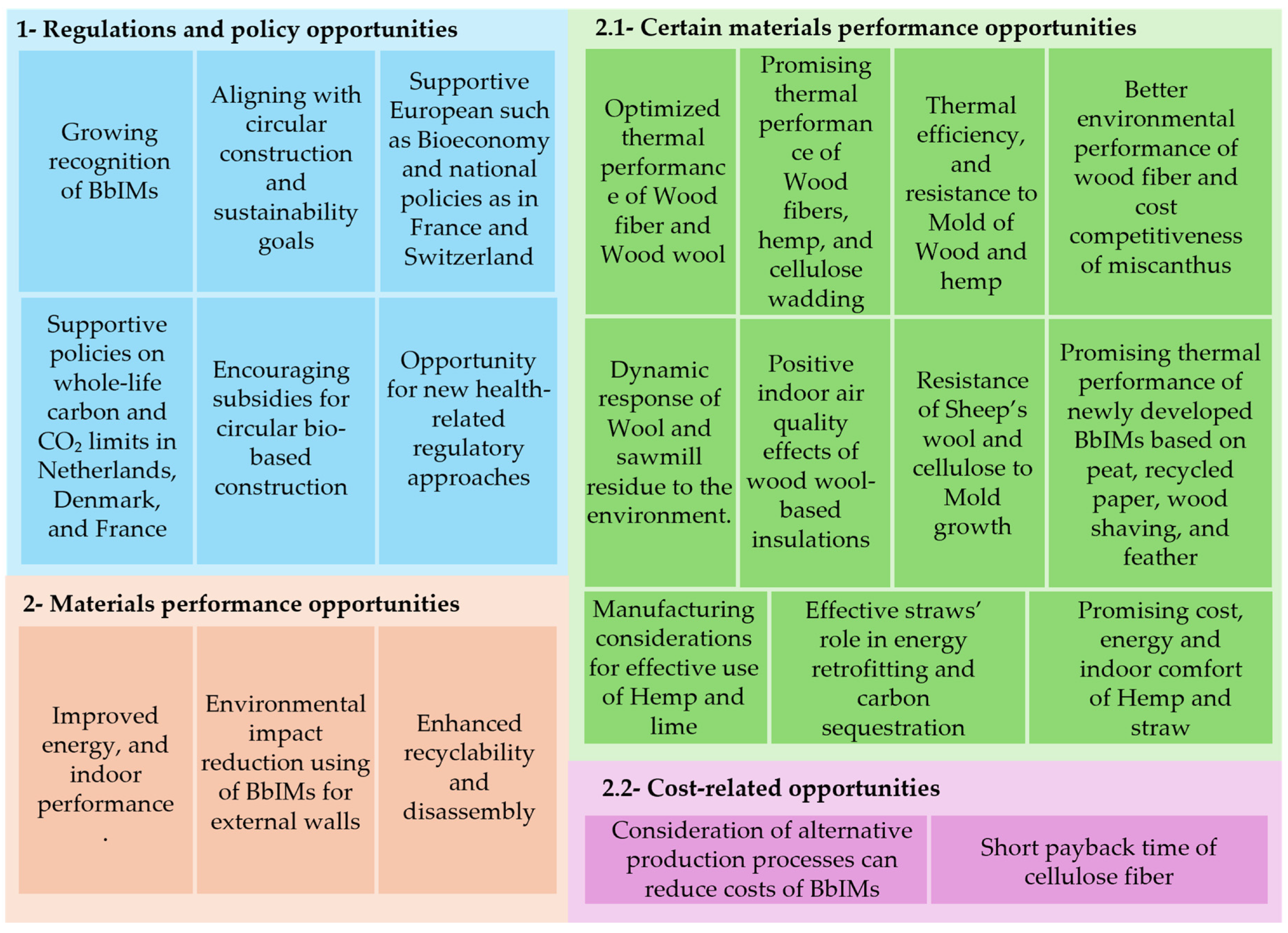

3.3. Integration Opportunities of BbIMs in the European Construction Sector

3.3.1. Regulations and Policy Opportunities

3.3.2. Material Performance Opportunities

Certain Materials Performance Opportunities

3.3.3. Cost Opportunities

4. Discussion

4.1. Regulations and Policy

4.2. Materials Performance

4.3. Cost Considerations

4.4. Existing Research Limitations, Gaps, and Future Perceptions

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ingrao, C.; Arcidiacono, C.; Bezama, A.; Ioppolo, G.; Winans, K.; Koutinas, A.; Gallego-Schmid, A. Sustainability issues of by-product and waste management systems, to produce building material commodities: A comprehensive review of findings from a virtual special issue. Resour. Conserv. Recycl. 2019, 146, 358–365. [Google Scholar] [CrossRef]

- Karimpour, M.; Belusko, M.; Xing, K.; Bruno, F. Minimising the life cycle energy of buildings: Review and analysis. Build. Environ. 2014, 73, 106–114. [Google Scholar] [CrossRef]

- Coma, J.; Maldonado, J.M.; de Gracia, A.; Gimbernat, T.; Botargues, T.; Cabeza, L.F. Comparative analysis of energy demand and CO2 emissions on different typologies of residential buildings in Europe. Energies 2019, 12, 2436. [Google Scholar] [CrossRef]

- Jensen, P.A.; Maslesa, E.; Gohardani, N.; Björk, F.; Kanarachos, S.; Fokaides, P.A. Sustainability Evaluation of Retrofitting and Renovation of Buildings in Early Stages. In Proceedings of the 7th Nordic Conference on Construction Economics and Organisation, Trondheim, Norway, 12–14 June 2013. [Google Scholar]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Zerari, S.; Franchino, R.; Pisacane, N. The potential impacts of using bio-based building materials on human health and wellbeing. E3S Web Conf. 2023, 436, 01006. [Google Scholar] [CrossRef]

- Llatas, C.; Bizcocho, N.; Soust-Verdaguer, B.; Montes, M.V.; Quiñones, R. An LCA-based model for assessing prevention versus non-prevention of construction waste in buildings. Waste Manag. 2021, 126, 608–622. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Env. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

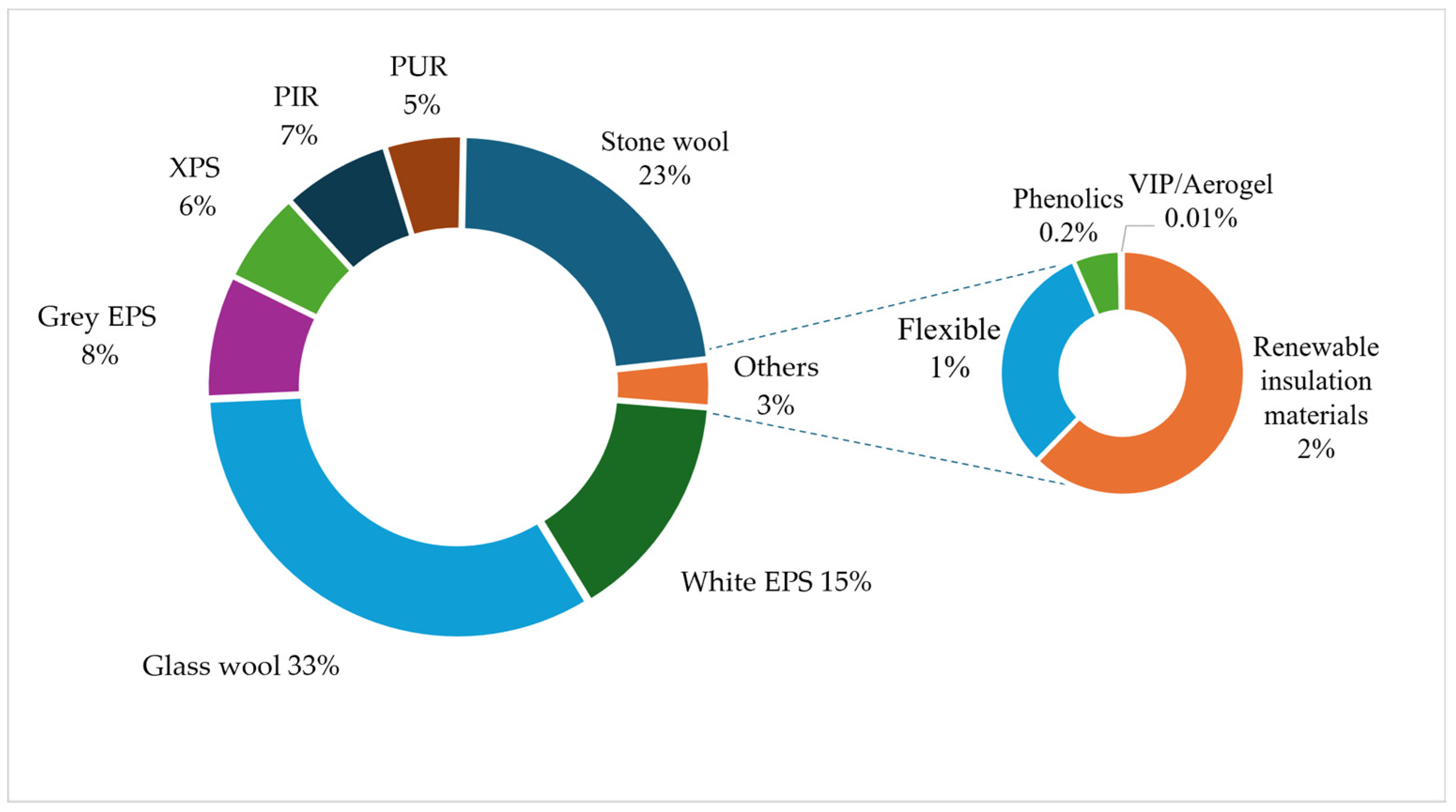

- Pavel, C.C.; Blagoeva, D.T. Competitive Landscape of the EU’s Insulation Materials Industry for Energy-Efficient Buildings; Publications Office of the European Union: Luxembourg, 2018; Volume EUR 28816. [Google Scholar]

- Siksnelyte-Butkiene, I.; Streimikienė, D.; Baleentis, T.; Skulskis, V. A Systematic Literature Review of Multi-Criteria Decision-Making Methods for Sustainable Selection of Insulation Materials in Buildings. Sustainability 2021, 13, 737. [Google Scholar] [CrossRef]

- Nawrocka, N.; Machova, M.; Jensen, R.L.; Kanafani, K.; Birgisdottir, H.; Hoxha, E. Influence of BIM’s level of detail on the environmental impact of buildings: Danish context. Build. Env. 2023, 245, 110875. [Google Scholar] [CrossRef]

- European Environmental Bureau. Milestones Achieved: EU Adopts Crucial Building Law for Energy Transition. Available online: https://eeb.org/milestones-achieved-eu-adopts-crucial-building-law-for-energy-transition/ (accessed on 13 April 2024).

- Cascione, V.; Roberts, M.; Allen, S.; Dams, B.; Maskell, D.; Shea, A.; Walker, P.; Emmitt, S. Integration of life cycle assessments (LCA) in circular bio-based wall panel design. J. Clean. Prod. 2022, 344, 130938. [Google Scholar] [CrossRef]

- UNEP. 2021 Global Status Report for Buildings and Construction: Towards a Zero-Emission. Efficient and Resilient Buildings and Construction Sector. 2021; pp. 1–105. Available online: https://www.unep.org/resources/report/2021-global-status-report-buildings-and-construction (accessed on 13 April 2024).

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Techno 2015, 4, 1–17. [Google Scholar] [CrossRef]

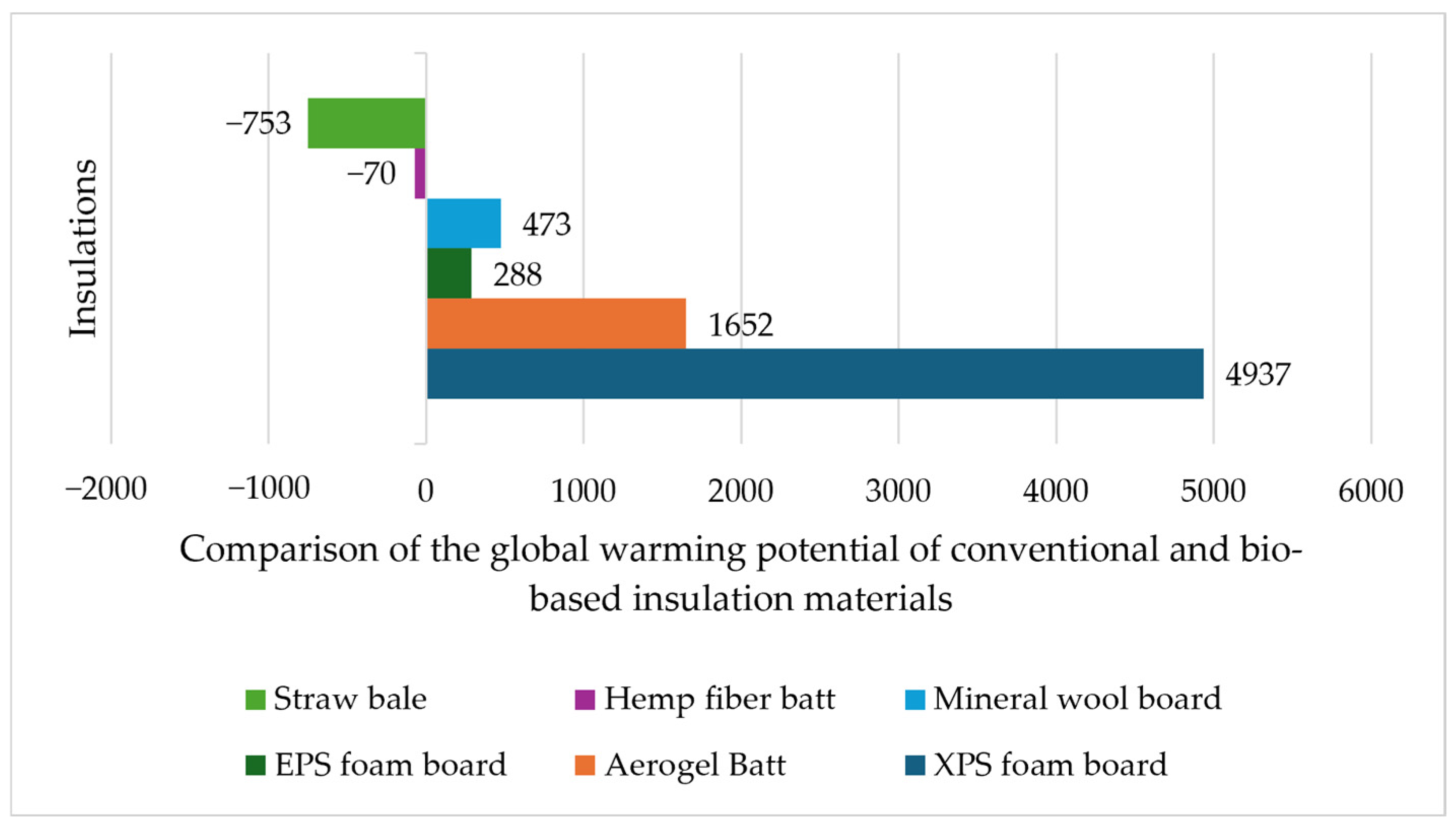

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 2016, 125, 219–226. [Google Scholar] [CrossRef]

- Lafond, C.; Blanchet, P. Technical performance overview of bio-based insulation materials compared to expanded polystyrene. Buildings 2020, 10, 81. [Google Scholar] [CrossRef]

- IAL Consultants. The European Market for Thermal Insulation Products. Available online: https://www.ialconsultants.com/media/1118/thermal-insulation-press-release-2023.pdf (accessed on 13 April 2024).

- Cosentino, L.; Fernandes, J.; Mateus, R. A Review of Natural Bio-Based Insulation Materials. Energies 2023, 16, 4676. [Google Scholar] [CrossRef]

- Le, D.L.; Salomone, R.; Nguyen, Q.T. Circular bio-based building materials: A literature review of case studies and sustainability assessment methods. Build. Env. 2023, 244, 110774. [Google Scholar] [CrossRef]

- Raja, P.; Murugan, V.; Ravichandran, S.; Behera, L.; Mensah, R.A.; Mani, S.; Kasi, A.; Balasubramanian, K.B.N.; Sas, G.; Vahabi, H.; et al. A Review of Sustainable Bio-Based Insulation Materials for Energy-Efficient Buildings. Macromol. Mater. Eng. 2023, 308, 2300086. [Google Scholar] [CrossRef]

- Cintura, E.; Nunes, L.; Esteves, B.; Faria, P. Agro-industrial wastes as building insulation materials: A review and challenges for Euro-Mediterranean countries. Ind. Crops Prod. 2021, 171, 113833. [Google Scholar] [CrossRef]

- Schritt, H.; Pleissner, D. Recycling of organic residues to produce insulation composites: A review. Clean. Waste Syst. 2022, 3, 100023. [Google Scholar] [CrossRef]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A mini-review on building insulation materials from perspective of plastic pollution: Current issues and natural fibres as a possible solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Steel, P.; Fariborzi, H.; Hendijani, R. An Application of Modern Literature Review Methodology: Finding Needles in Ever-Growing Haystacks. In Sage Research Methods: Business; Sage Publications Ltd.: London, UK, 2023. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Inf. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Kitchenham, B. Guidelines for Performing Systematic Literature Reviews in Software Engineering; Version 2.3 EBSE Technical Report; EBSE, Durham University: Durham, UK, 2007. [Google Scholar]

- Romano, A.; Grammatikos, S.; Riley, M.; Bras, A. Physicochemical characterisation of bio-based insulation to explain their hygrothermal behaviour. Constr. Build. Mater. 2020, 258, 120163. [Google Scholar] [CrossRef]

- Wiprächtiger, M.; Haupt, M.; Heeren, N.; Waser, E.; Hellweg, S. A framework for sustainable and circular system design: Development and application on thermal insulation materials. Resour. Conserv. Recycl. 2020, 154, 104631. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Navarro, A.; Giraldo, M.P.; Lesar, B. Improvement of fire reaction and mould growth resistance of a new bio-based thermal insulation material. Constr. Build. Mater. 2017, 139, 531–539. [Google Scholar] [CrossRef]

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Investigation of material characteristics and hygrothermal performances of different bio-based insulation composites. Constr. Build. Mater. 2022, 346, 128440. [Google Scholar] [CrossRef]

- Fedorik, F.; Zach, J.; Lehto, M.; Kymäläinen, H.R.; Kuisma, R.; Jallinoja, M.; Illikainen, K.; Alitalo, S. Hygrothermal properties of advanced bio-based insulation materials. Energy Build. 2021, 253, 111528. [Google Scholar] [CrossRef]

- Braish, T.; Tinel, L.; Depelchin, L.; Gaudion, V.; Andres, Y.; Caudron, C.; Antczak, E.; Brachelet, F.; Locoge, N. Evaluation of the seasonal variation of VOC surface emissions and indoor air concentrations in a public building with bio-based insulation. Build. Env. 2023, 238, 110312. [Google Scholar] [CrossRef]

- Fischer, H.; Korjenic, A. Hygrothermal Performance of Bio-Based Exterior Wall Constructions and Their Resilience under Air Leakage and Moisture Load. Buildings 2023, 13, 2650. [Google Scholar] [CrossRef]

- Dams, B.; Maskell, D.; Shea, A.; Allen, S.; Cascione, V.; Walker, P. Upscaling bio-based construction: Challenges and opportunities. Build. Res. Inf. 2023, 51, 764–782. [Google Scholar] [CrossRef]

- Richter, M.; Horn, W.; Juritsch, E.; Klinge, A.; Radeljic, L.; Jann, O. Natural Building Materials for Interior Fitting and Refurbishment-What about Indoor Emissions? Materials 2021, 14, 234. [Google Scholar] [CrossRef]

- Latif, E.; Lawrence, R.M.H.; Shea, A.D.; Walker, P. An experimental investigation into the comparative hygrothermal performance of wall panels incorporating wood fibre, mineral wool and hemp-lime. Energy Build. 2018, 165, 76–91. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Giraldo, M.P.; Haurie, L.; Correal, E. Bio-based insulation materials and their hygrothermal performance in a building envelope system (ETICS). Energy Build. 2018, 174, 147–155. [Google Scholar] [CrossRef]

- Romano, A.; Bras, A.; Grammatikos, S.; Shaw, A.; Riley, M. Dynamic behaviour of bio-based and recycled materials for indoor environmental comfort. Constr. Build. Mater. 2019, 211, 730–743. [Google Scholar] [CrossRef]

- Nguyen, S.T.; Tran-Le, A.D.; Vu, M.N.; To, Q.D.; Douzane, O.; Langlet, T. Modeling thermal conductivity of hemp insulation material: A multi-scale homogenization approach. Build. Env. 2016, 107, 127–134. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative life cycle assessment of bio-based insulation materials: Environmental and economic performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Platt, S.L.; Walker, P.; Maskell, D.; Shea, A.; Bacoup, F.; Mahieu, A.; Zmamou, H.; Gattin, R. Sustainable bio & waste resources for thermal insulation of buildings. Constr. Build. Mater. 2023, 366, 130030. [Google Scholar] [CrossRef]

- Platt, S.L.; Maskell, D.; Shea, A.; Walker, P. Impact of fibre orientation on the hygrothermal properties of straw bale insulation. Constr. Build. Mater. 2022, 349, 128752. [Google Scholar] [CrossRef]

- Petcu, C.; Hegyi, A.; Stoian, V.; Dragomir, C.S.; Ciobanu, A.A.; Lăzărescu, A.V.; Florean, C. Research on Thermal Insulation Performance and Impact on Indoor Air Quality of Cellulose-Based Thermal Insulation Materials. Materials 2023, 16, 5458. [Google Scholar] [CrossRef]

- Latif, E.; Ciupala, M.A.; Tucker, S.; Wijeyesekera, D.C.; Newport, D.J. Hygrothermal performance of wood-hemp insulation in timber frame wall panels with and without a vapour barrier. Build. Env. 2015, 92, 122–134. [Google Scholar] [CrossRef]

- Directorate-General for Research and Innovation (European Commission). European Bioeconomy Policy—Stocktaking and Future Developments—Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; Publications Office of the European Union: Luxembourg, 2022; Available online: https://data.europa.eu/doi/10.2777/997651 (accessed on 13 April 2024).

- Gulotta, T.M.; Cellura, M.; Guarino, F.; Longo, S. A bottom-up harmonized energy-environmental models for Europe (BOHEEME): A case study on the thermal insulation of the EU-28 building stock. Energy Build. 2021, 231, 110584. [Google Scholar] [CrossRef]

- Sinka, M.; Bajare, D.; Gendelis, S.; Jakovics, A. In-situ measurements of hemp-lime insulation materials for energy efficiency improvement. Energy Procedia 2018, 147, 242–248. [Google Scholar] [CrossRef]

- Pittau, F.; Lumia, G.; Heeren, N.; Iannaccone, G.; Habert, G. Retrofit as a carbon sink: The carbon storage potentials of the EU housing stock. J. Clean. Prod. 2019, 214, 365–376. [Google Scholar] [CrossRef]

- Official Journal of the French Republic, Law no 2018-1021 of November 23, 2018 on the Development of Housing, Development and Digital Technology (1). 2018. Available online: https://www.legifrance.gouv.fr/loda/id/JORFTEXT000037639478 (accessed on 13 April 2024).

- Blumberga, A.; Freimanis, R.; Muizniece, I.; Spalvins, K.; Blumberga, D. Trilemma of historic buildings: Smart district heating systems, bioeconomy and energy efficiency. Energy 2019, 186, 115741. [Google Scholar] [CrossRef]

- Brás, A.; Antunes, A.; Laborel-Préneron, A.; Ralegaonkar, R.; Shaw, A.; Riley, M.; Faria, P. Optimisation of bio-based building materials using image analysis method. Constr. Build. Mater. 2019, 223, 544–553. [Google Scholar] [CrossRef]

- Hoxha, D.; Ismail, B.; Rotaru, A.; Izabel, D.; Renaux, T. Assessment of the Usability of Some Bio-Based Insulation Materials in Double-Skin Steel Envelopes. Sustainability 2022, 14, 10797. [Google Scholar] [CrossRef]

- Rosso, F.; Peduzzi, A.; Diana, L.; Cascone, S.; Cecere, C. A Sustainable Approach towards the Retrofit of the Public Housing Building Stock: Energy-Architectural Experimental and Numerical Analysis. Sustainability 2021, 13, 2881. [Google Scholar] [CrossRef]

- Alaux, N.; Vašatko, H.; Maierhofer, D.; Saade, M.R.M.; Stavric, M.; Passer, A. Environmental potential of fungal insulation: A prospective life cycle assessment of mycelium-based composites. Int. J. Life Cycle Assess 2023, 29, 255–272. [Google Scholar] [CrossRef]

- Yang, Y.; Haurie, L.; Wang, D.-Y. Bio-based materials for fire-retardant application in construction products: A review. J. Therm. Anal. Calorim. 2022, 147, 6563–6582. [Google Scholar] [CrossRef]

- Palumbo, M.; Formosa, J.; Lacasta, A.M. Thermal degradation and fire behaviour of thermal insulation materials based on food crop by-products. Constr. Build Mater. 2015, 79, 34–39. [Google Scholar] [CrossRef]

- Torres-Rivas, A.; Pozo, C.; Palumbo, M.; Ewertowska, A.; Jiménez, L.; Boer, D. Systematic combination of insulation biomaterials to enhance energy and environmental efficiency in buildings. Constr. Build. Mater. 2021, 267, 120973. [Google Scholar] [CrossRef]

| Key Thematic Gap | Insulation | Ref. |

|---|---|---|

| Fire reaction |

| [58] |

| [31] | |

| Analysis techniques |

| [53] |

| Circularity |

| [30] |

| Hygrothermal performance |

| [46] |

| [41] | |

| [39] | |

| [49] | |

| [38] | |

| [40] | |

| [52] | |

| [33] | |

| [54] | |

| [44] | |

| [35] | |

| [43] | |

| Energy—environmental performance |

| [48] |

| [59] | |

| Environmental performance |

| [42] |

| [55] | |

| [56] | |

| Indoor air quality |

| [37] |

| [34] | |

| Industry stakeholders’ insights |

| [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zerari, S.; Franchino, R.; Pisacane, N.; Llatas, C.; Soust-Verdaguer, B. Addressing the Difficulties and Opportunities to Bridge the Integration Gaps of Bio-Based Insulation Materials in the European Construction Sector: A Systematic Literature Review. Sustainability 2024, 16, 8711. https://doi.org/10.3390/su16198711

Zerari S, Franchino R, Pisacane N, Llatas C, Soust-Verdaguer B. Addressing the Difficulties and Opportunities to Bridge the Integration Gaps of Bio-Based Insulation Materials in the European Construction Sector: A Systematic Literature Review. Sustainability. 2024; 16(19):8711. https://doi.org/10.3390/su16198711

Chicago/Turabian StyleZerari, Salima, Rossella Franchino, Nicola Pisacane, Carmen Llatas, and Bernardette Soust-Verdaguer. 2024. "Addressing the Difficulties and Opportunities to Bridge the Integration Gaps of Bio-Based Insulation Materials in the European Construction Sector: A Systematic Literature Review" Sustainability 16, no. 19: 8711. https://doi.org/10.3390/su16198711

APA StyleZerari, S., Franchino, R., Pisacane, N., Llatas, C., & Soust-Verdaguer, B. (2024). Addressing the Difficulties and Opportunities to Bridge the Integration Gaps of Bio-Based Insulation Materials in the European Construction Sector: A Systematic Literature Review. Sustainability, 16(19), 8711. https://doi.org/10.3390/su16198711