Derived Environmental Impacts of Organic Fairtrade Cocoa (Peru) Compared to Its Conventional Equivalent (Ivory Coast) through Life-Cycle Assessment in the Basque Country

Abstract

1. Introduction

| Organic Agriculture (OA) | Convergence for Forbidden Hazardous Substances | Fairtrade (FT) |

|---|---|---|

| European Commission [24] | Fairtrade [25] | Fairtrade [26] |

| (Part I:1.9.8) Prohibition of use of mineral nitrogen fertilizers. | Prohibited Substances: Nitrobenzene Nitrogen | Minimized and safe use of agrochemicals. |

| (Points: 23, 32, 40) (Article 6. d,e,f) (Part I:1.8.4) To reduce the impact of weeds and pests, organic farmers choose resistant varieties (not genetically modified) and breeds and techniques encouraging natural pest control. | ||

| (Points: 24, 70) (Part I:1.1) Limiting the use of artificial fertilizers, herbicides, and pesticides. | Prohibited Substances: Disulfoton Endosulfan Sulfotep Famphur Thallium sulphate Azinphos-ethy Azinphos-ethy Chlormephos Coumaphos Dicrotophos Edifenphos (EDDP) Ethoprophos (Ethoprop) Fenamiphos Heptenophos Methamidophos Mevinphos Monocrotophos Phosphamidon (Fosfamidon) Phostebupirim (tebupirimfos) Propetamphos Tebupirimifos (phostebupirim) Triazophos Tris (2,3-dibromopropyl) Phosphate Zinc phosphide DNOC (dinitro-ortho-cresol) and its salts (ammonium, potassium, sodium) | |

| Monitored Substances: Carbosulfan Leptophos OMPA (octamethylpyrophosphoramide) Phosalone Pyrazophos 2,4,5-TCP (potassium 2,4,5- Trichlorophenate) | ||

| Proper and safe management of waste. | ||

| (Point: 34) (Article 6. d) Crop rotation. | Maintenance of soil fertility and water resources. | |

| (Part I: 1.9.2 & 1.9.4) Cultivation of nitrogen-fixing plants and other green manure crops to restore the fertility of the soil. | ||

| (Point: 23) (Article 5: f.iii) Prohibition of the use of GMOs. | No use of genetically modified organisms (GMOs). | |

| (Point: 23) Forbidding the use of ionizing radiation. |

2. Methods

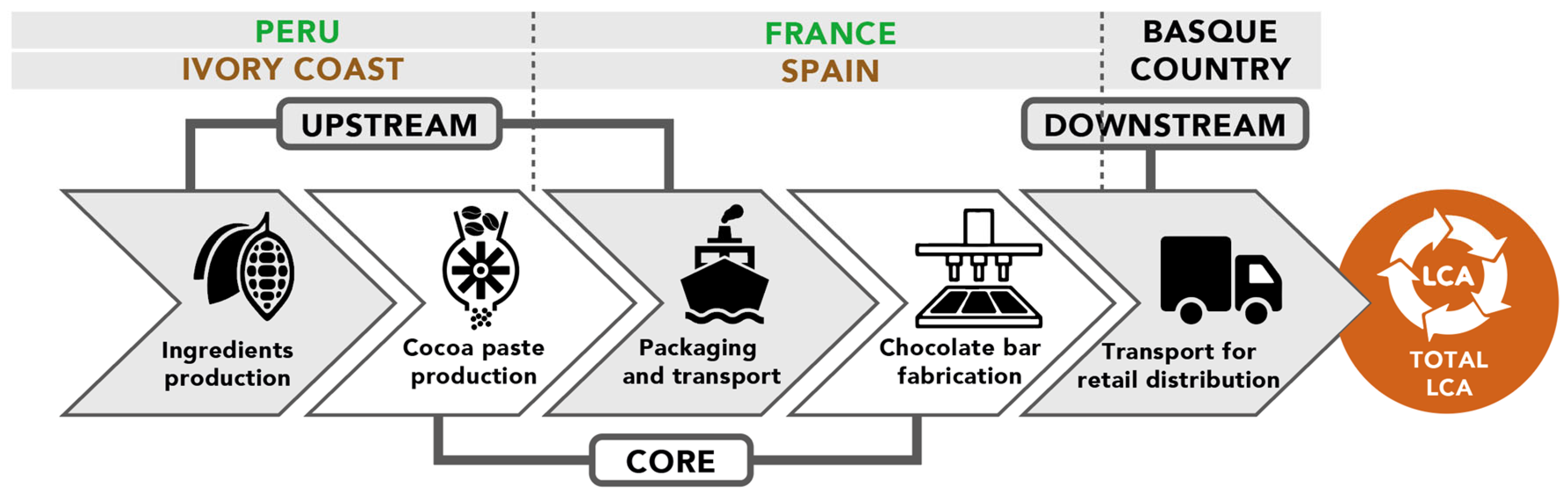

2.1. Methodology, Scope and Boundaries

2.2. Designed Scenarios

- Scenario 1—CA Chocolate (72%): this chocolate has been modelled to represent a standard supermarket chocolate bar (original bar of 150 g, adjusting to the FU of 1 kg), originating from Conventional Agriculture (CA) in Ivory Coast, this being the origin of most of the cocoa on the market as [80] shows. The other ingredients (sugar and additives) are also of CA origin. The transport has been hypothesized as progressing from the cocoa crop area of the Ivory Coast to a chocolate factory in Barcelona (Catalonia) and its subsequent distribution to the Basque Country (See Supporting Information).

- Scenario 2—OA&FT Chocolate (72%): specifically, “Noir dessert corsé 72% de cacao équitable and bio” chocolate bar (original bar of 150 g, adjusting to the FU of 1 kg) from the brand Ethiquable. This chocolate has been modelled following the Organic Agriculture and Fairtrade (OA&FT) certificates for the cultivation of the ingredients (cocoa and raw cane sugar) from Peru, and its transformation processes and transport (from the cultivation and processing of cocoa paste in Peru, to the chocolate factory in France and the subsequent distribution to the Basque Country market) (See Supporting Information).

2.3. Life Cycle Assumptions and Inventory

| 1 kg Cocoa Paste Manufacturing Energy Consumption | ||

| Indicator | Unit | Amount |

| Electricity | kWh | 0.269 |

| Water | m3 | 0.008 |

| Gas (LPG) | kg | 0.063 |

| Waste (solids) | kg | 13.766 |

| 1 kg Chocolate Manufacturing Energy Consumption | ||

| Indicator | Unit | Amount |

| Electricity | kWh | 0.6497 |

| Water | m3 | 0.01397 |

| Gas (LPG) | kg | 0.528 |

| Efficiency | Production Phase | Description |

|---|---|---|

| 13.05 kg | Cocoa cultivation | Cocoa trees require special care to produce high-quality beans. Farmers must select the right varieties, keep the soil in good condition, and protect the trees from diseases and pests. |

| 3.51 kg | Fermentation and drying | After harvest, the cocoa beans are fermented and dried to develop their characteristic flavour. During this process, farmers must carefully control the temperature and humidity to prevent the growth of mould or bacteria. |

| 0.73 kg | Roasting and grinding | The cocoa beans are roasted to develop their flavour and aroma, and then ground to produce cocoa paste. |

| 0.01 kg | Pressing | The cocoa paste is pressed to extract cocoa butter. |

| 1 kg chocolate (72% cocoa) = 0.71 kg cocoa paste + 0.01 kg cocoa butter + 0.28 kg raw cane sugar (optional lecithin 0.2%) | Conched and tempered | Afterwards, the cocoa paste, cocoa butter and raw brown sugar are conched and blended to produce a silky-smooth chocolate. Then, it is tempered so that it has a suitable texture and shine. |

| 1 kg | Packaging and distribution | The chocolate is packaged in bars (150 g) and distributed to stores, supermarkets and so on. |

3. Results

3.1. Life-Cycle Impact Assessment (LCIA)

3.2. Overall Process

| UPSTREAM | CORE | DOWNSTREAM | |||||

|---|---|---|---|---|---|---|---|

| Conventional Agriculture (CA) Chocolate (72%) | Ingredient Production (IVORY COAST) | Packaging and Transport | Cocoa Paste Production (IVORY COAST) | Chocolate bar Fabrication (SPAIN) | Transport for Retail Distribution | TOTAL | ANALYSED AVERAGE |

| Global Warming Potential (GWP) kg CO2-eq | 4.41 | 0.19 | 2.38 | 0.71 | 0.22 | 7.90 | 3.88 |

| 55.82% | 2.37% | 30.08% | 8.94% | 2.79% | 100.0% | −50.91% | |

| 4.60 | 3.08 | 0.22 | 7.90 | ||||

| 58.19% | 39.02% | 2.79% | 100.0% | ||||

| Terrestrial Ecotoxicity (TE) kg 1,4-DCB | 102.83 | 1.50 | 1.09 | 0.83 | 2.39 | 108.64 | 0.009 |

| 94.66% | 1.38% | 1.00% | 0.76% | 2.20% | 100.0% | −99.99% | |

| 104.33 | 1.92 | 2.39 | 108.64 | ||||

| 96.03% | 1.77% | 2.20% | 100.0% | ||||

| Environmental Footprint (ENVF) Land Use (m2a crop-eq) | 47.05 | 0.01 | 0.03 | 0.01 | 0.00 | 47.10 | 56.12 |

| 99.88% | 0.01% | 0.07% | 0.03% | 0.01% | 100.0% | 19.15% | |

| 47.05 | 0.04 | 0.00 | 47.10 | ||||

| 99.89% | 0.10% | 0.01% | 100.0% | ||||

| Water Footprint (WF) m3 | 116.22 | 0.03 | 0.67 | 2.36 | 0.01 | 119.30 | 243.83 |

| 97.42% | 0.03% | 0.56% | 1.98% | 0.01% | 100.0% | 104.39% | |

| 116.25 | 3.03 | 0.01 | 119.30 | ||||

| 97.44% | 2.54% | 0.01% | 100.0% | ||||

| Energy Footprint (EF) MJ-eq | 155.24 | 3.69 | 9.74 | 37.82 | 2.97 | 209.46 | 89.61 |

| 74.11% | 1.76% | 4.65% | 18.06% | 1.42% | 100.0% | −57.22% | |

| 158.93 | 47.56 | 2.97 | 209.46 | ||||

| 75.88% | 22.70% | 1.42% | 100.0% | ||||

| UPSTREAM | CORE | DOWNSTREAM | ||||||

|---|---|---|---|---|---|---|---|---|

| Fairtrade Organic Agriculture (OA&TF) Chocolate (72%) | Ingredient Production (PERU) | Packaging and Transport | Cocoa Paste Production (PERU) | Chocolate Bar Fabrication (FRANCE) | Transport for Retail Distribution | TOTAL | ANALYSED AVERAGE | Reduction from CA (Scenario 1) |

| Global Warming Potential (GWP) kg CO2-eq | 1.24 | 0.37 | 1.01 | 0.56 | 0.19 | 3.37 | 2.273 | −57.32% |

| 36.85% | 10.85% | 30.00% | 16.73% | 5.58% | 100.0% | −32.61% | ||

| 1.61 | 1.58 | 0.19 | 3.37 | |||||

| 47.69% | 46.73% | 5.58% | 100.0% | |||||

| Terrestrial Ecotoxicity (TE) kg 1,4-DCB | 7.24 | 3.10 | 0.54 | 0.79 | 2.04 | 13.71 | 0.005 | −87.38% |

| 52.80% | 22.64% | 3.93% | 5.76% | 14.87% | 100.0% | −99.96% | ||

| 10.34 | 1.33 | 2.04 | 13.71 | |||||

| 75.44% | 9.69% | 14.87% | 100.0% | |||||

| Environmental Footprint (ENVF) Land Use (m2a crop-eq) | 55.87 | 0.01 | 0.02 | 0.01 | 0.00 | 55.92 | 28.62 | 18.72% |

| 99.91% | 0.02% | 0.04% | 0.02% | 0.01% | 100.0% | −48.82% | ||

| 55.88 | 0.03 | 0.00 | 55.92 | |||||

| 99.94% | 0.05% | 0.01% | 100.0% | |||||

| Water Footprint (WF) m3 | 112.23 | 0.05 | 0.66 | 0.14 | 0.01 | 113.09 | 135.99 | −5.20% |

| 99.24% | 0.05% | 0.58% | 0.12% | 0.01% | 100.0% | 20.25% | ||

| 112.28 | 0.80 | 0.01 | 113.09 | |||||

| 99.28% | 0.71% | 0.01% | 100.0% | |||||

| Energy Footprint (EF) MJ-eq | 114.09 | 5.32 | 6.86 | 36.19 | 2.53 | 164.99 | 35.1 | −21.23% |

| 69.15% | 3.22% | 4.16% | 21.94% | 1.54% | 100.0% | −78.73% | ||

| 119.41 | 43.05 | 2.53 | 164.99 | |||||

| 72.37% | 26.09% | 1.54% | 100.0% | |||||

3.3. Introduction of Organic and Fairtrade Chocolate in the Basque Country

4. Discussion

4.1. Global Warming Potential

4.2. Terrestrial Ecotoxicity

4.3. Environmental Footprint (Land Use)

4.4. Water Footprint

4.5. Energy Footprint

4.6. Strategic Implications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| FT | Fairtrade |

| CE | Circular Economy |

| LCA | Life-Cycle Assessment |

| LCIA | Life-Cycle Impact Assessment |

| OA | Organic Agriculture |

| CA | Conventional Agriculture |

| GWP | Global Warming Potential |

| TE | Terrestrial Ecotoxicity |

| GG | Greenhouse Gases |

| ISO | International Organization for Standardization |

| PCR | Product Category Rules |

| EPD | Environmental Product Declarations |

| CMD | Cumulative Energy Demand |

| EF | Energy Footprint |

| WF | Water Footprint |

| ENVF | Environmental Footprint |

| CED | Cumulative Energy Demand |

| FU | Functional Unit |

References

- San Salvador del Valle, M.; Akizu-Gardoki, O.; Bueno, G.; Bermejo, R. Quantifying international energy justice: The cost of electricity within footprint accounts. J. Clean. Prod. 2022, 341, 130797. [Google Scholar] [CrossRef]

- Saavedra, E. Comercio justo. Obs. Económico 2012, 62, 6–7. [Google Scholar] [CrossRef]

- CECJ. El Comercio Justo Como Herramienta de Cooperación al Desarrollo; Comercio Justo: Madrid, Spain, 2008. [Google Scholar]

- WTFO. Qué es el Comercio Justo. Coordinadora Estatal de Comercio Justo. 2021, pp. 1–10. Available online: https://comerciojusto.org/que-es-el-comercio-justo-2/ (accessed on 15 November 2023).

- Adams, M.A.; Carodenuto, S. Stakeholder perspectives on cocoa’s living income differential and sustainability trade-offs in Ghana. World Dev. 2023, 165, 106201. [Google Scholar] [CrossRef]

- Carodenuto, S.; Buluran, M. The effect of supply chain position on zero-deforestation commitments: Evidence from the cocoa in-dustry. J. Environ. Policy Plan. 2021, 23, 716–731. [Google Scholar] [CrossRef]

- Maguire-Rajpaul, V.A.; Sandbrook, C.; McDermott, C.; Hirons, M.A. Climate-smart cocoa governance risks entrenching old hegemonies in Côte d’Ivoire and Ghana: A multiple environmentality analysis. Geoforum 2022, 130, 78–91. [Google Scholar] [CrossRef]

- Roessler, P.; Pengl, Y.I.; Marty, R.; Titlow, K.S.; van de Walle, N. The cash crop revolution, colonialism and economic reorganization in Africa. World Dev. 2022, 158, 105934. [Google Scholar] [CrossRef]

- Mustapha, K. Taste of Child Labor Not So Sweet: A Critique of Regulatory Approaches to Combating Child Labor Abuses by the U.S. Chocolate Industry. Wash. Univ. Law Rev. 2009, 87, 1163. [Google Scholar]

- Sellare, J. New insights on the use of the Fairtrade social premium and its implications for child education. J. Rural Stud. 2022, 94, 418–428. [Google Scholar] [CrossRef]

- Sellare, J.; Meemken, E.-M.; Qaim, M. Fairtrade, Agrochemical Input Use, and Effects on Human Health and the Environment. Ecol. Econ. 2020, 176, 106718. [Google Scholar] [CrossRef]

- MAPA, Ministerio de Agricultura Pesca y Alimentación. Informe del Consumo de Alimentación en España; Ministerio de Agricultura Pesca y Alimentación: Madrid, Spain, 2021. [Google Scholar]

- Fernández Ferrín, P.; Galán Ladero, M.M.; Calvo Turrientes, A.; Castro González, S. El Comercio Justo en Euskadi; Comercio Justo: Madrid, Spain, 2021. [Google Scholar]

- Tran-Nam, Q.; Tiet, T. The role of peer influence and norms in organic farming adoption: Accounting for farmers’ heterogeneity. J. Environ. Manag. 2022, 320, 115909. [Google Scholar] [CrossRef]

- CROP. Agricultura Sostenible: La Aplicación Del Nuevo Concepto. In Earth Observing System; EOS Data Analytics: Mountain View, CA, USA, 2020; Available online: https://eos.com/es/blog/agricultura-sostenible/ (accessed on 15 November 2023).

- European Commission. La agricultura ecológica en pocas palabras. In Web Oficial de la Unión Europea; Agriculture and rural development: Washington, DC, USA, 2021; Available online: https://ec.europa.eu/info/food-farming-fisheries/farming/organic-farming/organics-glance_es#legislation (accessed on 15 November 2023).

- Macarthur, E. What is the Circular Economy? Ellen Macarthur Foundation: Cowes, UK, 2017; Available online: https://www.ellenmacarthurfoundation.org/circular-economy/what-is-the-circular-economy (accessed on 15 November 2023).

- Regueiro, C.; Gómez-Goiri, A.; Pedrosa, N.; Semertzidis, C.; Iturbe, E.; Mansell, J. Blockchain-based refurbishment certification system for enhancing the circular economy. Blockchain Res. Appl. 2023, 100172. [Google Scholar] [CrossRef]

- ISO_IEC 17065_2012(en); Conformity Assessment—Requirements for Bodies Certifying Products, Processes and Services. International Organization for Standardization: Geneva, Switzerland, 2012.

- SO 14020:2000; Environmental Labels and Declarations—General Principles. International Organization for Standardization: Geneva, Switzerland, 2000; p. 10.

- International guide Fair Trade labels. Guía Internacional de Selloa de Comercio Justo. 2020. Available online: https://comerciojusto.org/wp-content/uploads/2018/03/GUIA_INTERNACIONAL_DE_SELLOS_web.pdf (accessed on 15 November 2023).

- Makita, R. A Role of Fair Trade Certification for Environmental Sustainability. J. Agric. Environ. Ethics 2016, 29, 185–201. [Google Scholar] [CrossRef]

- Hamilton, E.R. 10 Principles of Fair Trade; World Fair Trade Organization: Culemborg, The Netherlands, 2017; pp. 1–21. Available online: https://www.hamiltonbook.com/catalog/c.pdf (accessed on 15 November 2023).

- European Commission. Regulation (EU) 2018/848 on organic production and labelling of organic product. Off. J. Eur. Union 2018, 2018, 1–92. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018R0848&from=EN (accessed on 15 November 2023).

- FairTrade. Hazardous Materials List; Fairtrade International: Bonn, Germany, 2022; pp. 1–19. [Google Scholar]

- FairTrade. Fairtrade Standard for Coffee; Fairtrade International: Bonn, Germany, 2021; pp. 1–25. Available online: www.fairtrade.net/standards.html (accessed on 15 November 2023).

- Wielechowski, M.; Roman, M. The essence of fair trade and its importance in the world economy. Oeconomia 2012, 11, 47–57. [Google Scholar]

- ICO. International Coffee Organization—Trade Statistics Tables. 2021. Available online: http://www.ico.org/trade_statistics.asp?section=Statistics (accessed on 15 November 2023).

- ICCO. Statistics—International Cocoa Organization. 2021. Available online: https://www.icco.org/statistics/ (accessed on 15 November 2023).

- Rainforest Alliance. Rainforest Alliance. 2023. Available online: https://www.rainforest-alliance.org/ (accessed on 15 November 2023).

- Fairtrade International. Fairtrade products: Bananas. 2023. Available online: https://info.fairtrade.net/product/bananas (accessed on 15 November 2023).

- Renier, C.; Vandromme, M.; Meyfroidt, P.; Ribeiro, V.; Kalischek, N.; Ermgassen, E.K.H.J.Z. Transparency, traceability and deforestation in the Ivorian cocoa supply chain. Environ. Res. Lett. 2023, 18, 024030. [Google Scholar] [CrossRef]

- FAO—Food and Agriculture Organization of the United Nations. Zero-deforestation cocoa sweetens World Food Day. 2023. Available online: https://www.fao.org/gcf/news-and-events/news-detail/http-www.fao.org-climate-change-news-detail-en-c-1314699/en (accessed on 15 November 2023).

- Ivanova, Y.; Tristán, M.C.; Romero, M.; Charry, A.; Lema, S.; Sánchez, J.; Vélez, A.; Castro, A.; Quintero, M. Moving towards a Deforestation-free Cacao and Chocolate Value Chain with Low Greenhouse Gas Emissions; International Center for Tropical Agriculture (CIAT): Cali, Colombia, 2020; 136p, Available online: https://cgspace.cgiar.org/bitstream/handle/10568/110541/CacaoValueChain_2020.pdf?sequence=1 (accessed on 15 November 2023).

- Nguyen-Duy, N.; Talsma, T.; Nguyen, T.K.; Nguyen, Q.T.; Laderach, P. Carbon Assessment for Cocoa (Theobroma cacao L.) Cropping Systems in Lampung, Indonesia; International Center for Tropical Agriculture (CIAT): Hanoi, Vietnam, 2018; p. 32. [Google Scholar]

- Romero, M.; Pareja, P.; Tristán, M.; Sanchez, J.; Quintero, M. Análisis ex ante de Estrategias de Mitigación de GEI en el Cultivo de palma Aceitera en la Región de Ucayali, Perú; International Center for Tropical Agriculture (CIAT): Cali, Colombia, 2022; 43p. [Google Scholar]

- Boeckx, P.; Bauters, M.; Dewettinck, K. Poverty and climate change challenges for sustainable intensification of cocoa systems. Curr. Opin. Environ. Sustain. 2020, 47, 106–111. [Google Scholar] [CrossRef]

- Recanati, F.; Marveggio, D.; Dotelli, G. From beans to bar: A life cycle assessment towards sustainable chocolate supply chain. Sci. Total Environ. 2018, 613–614, 1013–1023. [Google Scholar] [CrossRef]

- Konstantas, A.; Jeswani, H.K.; Stamford, L.; Azapagic, A. Environmental impacts of chocolate production and consumption in the UK. Food Res. Int. 2018, 106, 1012–1025. [Google Scholar] [CrossRef]

- Schroth, G.; Jeusset, A.; da Silva Gomes, A.; Florence, C.T.; Coelho, N.A.P.; Faria, D.; Läderach, P. Climate friendliness of cocoa agroforests is compatible with productivity increase. Mitig. Adapt. Strateg. Glob. Change 2016, 21, 67–80. [Google Scholar] [CrossRef]

- Ortiz-Rodríguez, O.O.; Villamizar-Gallardo, R.A.; Naranjo-Merino, C.A.; García-Caceres, R.G.; Castañeda-Galvís, M.T. Carbon footprint of the colombian cocoa production. Eng. Agric. 2016, 36, 260–270. [Google Scholar] [CrossRef]

- Pérez Neira, D. Energy efficiency of cacao agroforestry under traditional and organic management. Agron. Sustain. Dev. 2016, 36, 1–10. [Google Scholar] [CrossRef]

- Neale, B. Evaluating the True Cost of Cocoa Production & the Viability of Mondelēz International’s Farm of the Future Model. 2016. Available online: https://dukespace.lib.duke.edu/items/2801e3f9-120c-494b-9d36-01348f1769bf (accessed on 15 November 2023).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. Available online: http://link.springer.com/10.1007/s11367-016-1087-8 (accessed on 15 November 2023). [CrossRef]

- FitzGerald, D.; Sonderegger, T. Document of Changes Implement Ted in the Ecoinvent Database v3.9.1. 2022. Available online: https://ecoinvent.org/wp-content/uploads/2022/12/Change-Report-v3.9.1.pdf (accessed on 15 November 2023).

- Boakye-Yiadom, K.A.; Duca, D.; Pedretti, E.F.; Ilari, A. Environmental performance of chocolate produced in ghana using life cycle assessment. Sustainability 2021, 13, 6155. [Google Scholar] [CrossRef]

- Pérez-Neira, D.; Copena, D.; Armengot, L.; Simón, X. Transportation can cancel out the ecological advantages of producing organic cacao: The carbon footprint of the globalized agrifood system of cuadorian chocolate. J. Environ. Manag. 2020, 276, 111306. [Google Scholar] [CrossRef] [PubMed]

- Armengot, L.; Beltrán, M.J.; Schneider, M.; Simón, X.; Pérez-Neira, D. Food-energy-water nexus of different cacao production systems from a LCA approach. J. Clean. Prod. 2021, 304, 126941. [Google Scholar] [CrossRef]

- Miah, J.H.; Griffiths, A.; McNeill, R.; Halvorson, S.; Schenker, U.; Espinoza-Orias, N.D.; Morse, S.; Yang, A.; Sadhukhan, J. Environmental management of confectionery products: Life cycle impacts and improvement strategies. J. Clean. Prod. 2018, 177, 732–751. [Google Scholar] [CrossRef]

- Parra-Paitan, C.; Verburg, P.H. Accounting for land use changes beyond the farm-level in sustainability assessments: The impact of cocoa production. Sci. Total Environ. 2022, 825, 154032. [Google Scholar] [CrossRef]

- Ortiz-Rodriguez, O.O.; Naranjo, C.A.; García-Caceres, R.G.; Villamizar-Gallardo, R.A. Water footprint assessment of the Colombian cocoa production. Rev. Bras. De Eng. Agric. E Ambient. 2015, 19, 823–828. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. The green, blue and grey water footprint of crops and derived crop products. Hydrol. Earth Syst. Sci. 2011, 15, 1577–1600. [Google Scholar] [CrossRef]

- van Oel, P.R.; Mekonnen, M.M.; Hoekstra, A.Y. The external water footprint of the Netherlands: Geographically-explicit quantification and impact assessment. Ecol. Econ. 2009, 69, 82–92. [Google Scholar] [CrossRef]

- Miglietta, P.P.; Fischer, C.; De Leo, F. Virtual water flows and economic water productivity of Italian fair-trade: The case of bananas, cocoa and coffee. Br. Food J. 2022, 124, 4009–4023. [Google Scholar] [CrossRef]

- Félix Olegário, K.; Pereira Andrade, E.; Coelho Sampaio, A.P.; Mato, S.J.; de Figueirêdo, M.C.B.; de Almeida Neto, J.A. Water scarcity footprint of cocoa irrigation in Bahia. Rev. Ambiente E Agua 2014, 9, 445–458. [Google Scholar] [CrossRef]

- Bulsink, F.; Hoekstra, A.Y.; Booij, M.J. Hydrology and Earth System Sciences The water footprint of Indonesian provinces related to the consumption of crop products. Hydrol. Earth Syst. Sci 2010, 14, 119–128. Available online: www.hydrol-earth-syst-sci.net/14/119/2010/ (accessed on 15 November 2023). [CrossRef]

- Dianawati, D.; Indrasti, N.S.; Ismayana, A.; Yuliasih, I.; Djatna, T. Carbon Footprint Analysis of Cocoa Product Indonesia Using Life Cycle Assessment Methods. J. Ecol. Eng. 2023, 24, 187–197. [Google Scholar] [CrossRef] [PubMed]

- Ethiquable. Entreprise Coopérative, Citoyenne et Solidaire. 2023. Available online: https://www.ethiquable.coop/ (accessed on 15 November 2023).

- Norandino. Cooperativa Agraria Norandino Ltda. 2023. Available online: https://coopnorandino.com.pe/nosotros/ (accessed on 15 November 2023).

- Orgenstra. Cocoa, the Black Gold of Côte d’Ivoire. 2023. Available online: https://www.orgenstra.com/en/23-actualites-cocoa-the-black-gold-of-cote-d-ivoire.html (accessed on 12 December 2023).

- Public Agency Ihobe. Ihobe—News—Greenhouse Gas Emissions in the Basque Country Were 2% Lower in the Year before the Pandemic. 2021. Available online: https://www.ihobe.eus/news/greenhouse-gas-emissions-in-the-basque-country-were-2-lower-in-the-year-before-the-pandemic (accessed on 15 November 2023).

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- de Lapuente Díaz de Otazu, R.L.; Akizu-Gardoki, O.; de Ulibarri, B.; Iturrondobeitia, M.; Minguez, R.; Lizundia, E. Ecodesign coupled with Life Cycle Assessment to reduce the environmental impacts of an industrial enzymatic cleaner. Sustain. Prod. Consum. 2022, 29, 718–729. [Google Scholar] [CrossRef]

- Coloma-Jiménez, M.; Akizu-Gardoki, O.; Lizundia, E. Beyond ecodesign, internationalized markets enhance the global warming potential in the wood furniture sector. J. Clean. Prod. 2022, 379, 134795. [Google Scholar] [CrossRef]

- Izaola, B.; Akizu-Gardoki, O.; Oregi, X. Setting baselines of the embodied, operational and whole life carbon emissions of the average Spanish residential building. Sustain. Prod. Consum. 2023, 40, 252–264. [Google Scholar] [CrossRef]

- Izaola, B.; Akizu-Gardoki, O. Biodiversity burdens in Spanish conventional and low-impact single-family homes. Sci. Total Environ. 2024, 909, 168371. [Google Scholar] [CrossRef]

- Montoya-Torres, J.; Akizu-Gardoki, O.; Alejandre, C.; Iturrondobeitia, M. Towards sustainable passenger transport: Carbon emission reduction scenarios for a medium-sized city. J. Clean. Prod. 2023, 418, 138149. [Google Scholar] [CrossRef]

- Villamor, E.; Akizu-Gardoki, O.; Heinonen, J.T.; Bueno, G. Global Multi-Regional Input-Output methodology reveals lower energy foot-print in an alternative community project. Sustain. Prod. Consum. 2022, 34, 65–77. [Google Scholar] [CrossRef]

- Environdec. Bakery Products. 2022. Available online: https://api.environdec.com/api/v1/EPDLibrary/Files/d4f8143a-4daa-4a55-5070-08dbd569605a/Data (accessed on 15 November 2023).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/03/74/37456.html (accessed on 15 November 2023).

- ISO 14044:2006; Environmental Management. Life Cycle Assessment. Requirements and Guidelines. ISO: Geneva, Switzerland, 2014.

- Aguirre, N. Análisis Comparativo de Impactos Ambientales de Productos de Comercio Justo con Respecto a Productos Convencionales; El caso de la panela La Cesta Sostenible y el café Nicaragua; Todos Tus Libros: Madrid, Spain, 2022; pp. 12–26. ISBN 9788409547418. [Google Scholar]

- OpenLCA. OpenLCA.org|OpenLCA Is a Free, Professional Life Cycle Assessment (LCA) and Footprint Software with a Broad Range of Features and Many Available Databases, Created by GreenDelta since 2006. 2023. Available online: https://www.openlca.org/ (accessed on 15 November 2023).

- Epd Buondì. Environmental Product Declaration of Buondì Cioccolato. In Accordance with ISO 14025. 2023. Available online: https://api.environdec.com/api/v1/EPDLibrary/Files/32a88b1f-abf7-4572-4f0f-08dbdfa90a02/Data (accessed on 12 September 2023).

- Muralikrishna, I.V.; Manickam, V. Air Pollution Control Technologies. In Environmental Management; Springer: Cham, Switzerland, 2017; pp. 337–397. [Google Scholar] [CrossRef]

- Dincer, I.; Bicer, Y. 2.1 Ammonia. Compr. Energy Syst. 2018, 2, 1–39. [Google Scholar] [CrossRef]

- De Baan, L.; Mutel, C.L.; Curran, M.; Hellweg, S.; Koellner, T. Land use in life cycle assessment: Global characterization factors based on regional and global potential species extinction. Environ. Sci. Technol. 2013, 47, 9281–9290. [Google Scholar] [CrossRef] [PubMed]

- Chapagain, A.K.; Hoekstra, A.Y. Water Footprints of Nations Volume 2: Appendices Value of Water; UNESCO-IHE Institute for Water Education: Delft, The Netherlands, 2004. [Google Scholar]

- ICTFootprint. What Is an Energy Footprint? 2018. Available online: https://ictfootprint.eu/en/faq-page/what-energy-footprint (accessed on 15 November 2023).

- López Cuadra, Y.M.; Cunias Rodríguez, M.Y.; Carrasco Vega, Y.L.; López Cuadra, Y.M.; Cunias Rodríguez, M.Y.; Carrasco Vega, Y.L. El cacao peruano y su impacto en la economía nacional. Rev. Univ. Y Soc. 2020, 12, 344–352. Available online: http://scielo.sld.cu/scielo.php?script=sci_arttext&pid=S2218-36202020000300344&lng=es&nrm=iso&tlng=es (accessed on 15 November 2023).

- Ramos-Ramos, T.P.; Guevara-Llerena, D.J.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. Producción Más Limpia Y Ecoeficiencia En El Procesado Del Cacao: Un Caso De Estudio En Ecuador. Investig. Desarro. 2020, 20, 135–146. [Google Scholar] [CrossRef]

- Lacasa. 0. Información General 0.1; Lacasa Inc.: Goshen, IN, USA, 2021; pp. 1–38. [Google Scholar]

- Rofner, N.F.; Salinas, S.J.; de Lara, T.F.G.M. Comportamiento Del Cadmio Y Otros Indicadores En Suelo Y Almendra De Cacao (Theobroma cacao L.), Bajo Aplicación De Compost Y Npk. Folia Amaz. 2018, 27, 193–202. [Google Scholar] [CrossRef]

- Yadav, A.N. (Ed.) Soil Microbiomes for Sustainable Agriculture: Functional Annotation, Sustainable Development and Biodiversity; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Molina-Cedeño, C.S.; Pillco-Herrera, B.M.; Salazar-Muñoz, E.F.; Coronel-Espinoza, B.D.; Sarduy-Pereira, L.B.; Diéguez-Santana, K. Producción más limpia como estrategia ambiental preventiva en el proceso de elaboración de pasta de cacao. Un caso en la Amazonia Ecuatoriana. Ind. Data 2020, 23, 59–72. [Google Scholar] [CrossRef]

- Stuart, D.A. How is chocolate “Put Together”? The Confectionery Foundation: Washington, DC, USA, 2014. [Google Scholar]

- Wang, B.; Jin, C.; Shao, S.; Yue, Y.; Zhang, Y.; Wang, S.; Chang, R.; Zhang, H.; Zhao, J.; Li, X. Electron-deficient Cu site catalyzed acetylene hydrochlorination. Green Energy Environ. 2023, 8, 1128–1140. [Google Scholar] [CrossRef]

- Seufert, V.; Ramankutty, N.; Foley, J.A. Comparing the yields of organic and conventional agriculture. Nature 2012, 485, 229–232. [Google Scholar] [CrossRef]

- Muller, A.; Schader, C.; El-Hage Scialabba, N.; Brüggemann, J.; Isensee, A.; Erb, K.H.; Smith, P.; Klocke, P.; Leiber, F.; Stolze, M.; et al. Strategies for feeding the world more sustainably with organic agriculture. Nat. Commun. 2017, 8, 1290. [Google Scholar] [CrossRef]

- Póo, J.M.R. Indicadores de la Agenda 2030 para el Desarrollo Sostenible; Instituto Nacional de Estadística: Madrid, Spain, 2021. [Google Scholar]

- Tapia, C. Aprovechamiento de Residuos Agroindustriales, Cascarilla de Cacao (Theobroma cacao L.) Variedad Arriba y ccn51 Para la Elaboración de una Infusión; Universidad Técnica de Ambato: Ambato, Ecuador, 2015; pp. 3–143. [Google Scholar]

- Sarbu, I.; Csutak, O. The microbiology of cocoa fermentation. Sci. Beverages 2019, 8, 423–446. [Google Scholar] [CrossRef]

| GWP Impacts for 1 kg of Cocoa in Different Stages | ||||||

|---|---|---|---|---|---|---|

| Source | Region | Organic/ Conventional | Format | GWP kg CO2-eq | Dif. GWP (%) | TE kg 1,4 DCB-eq |

| Ivanova et al. [34] | Peru | Conventional | Dry beans | 0.17 | +82% | |

| Organic | 0.93 | |||||

| Nguyen-Duy et al. [35] | Indonesia | Conventional | Dry beans | 4.79 | ||

| Romero et al. [36] | Peru | Conventional | Dry beans | 0.19 | +78% | |

| Organic | 0.87 | |||||

| Boeckx et al. [37] | World | Conventional | Dry beans | 1.7–3.9 | ||

| Chocolate (40%) | 0.7–1.6 | |||||

| Recanati et al. [38] | World | Organic | Italian dark chocolate | 2.62 | ||

| Konstantas et al. [39] | UK | Conventional | Chocolates in bag | 4.15 | 0.03 | |

| Moulded chocolate | 3.39 | 0.03 | ||||

| Chocolate countlines | 2.91 | 0.02 | ||||

| Schroth et al. [40] | Brazil | Conventional | Dry beans | 0.25 | ||

| Ortiz-Rodríguez et al. [41] | Colombia | Conventional | Dry beans | 0.8 | ||

| Pérez Neira, [42] | Ecuador | Conventional | Pure chocolate (100%) | 2.49 | ||

| Neale [43] | World | Conventional | Chocolate LCA | 0.36 | 0.00638 | |

| Ecoinvent v39.1 [44,45] | World | Conventional | Dry beans | 1.184 | 0.01524 | |

| Boakye-Yiadom et al. [46] | Ghana | Conventional | Extra-dark chocolate | 1.61 | 0.00035 | |

| Flavoured milk chocolate | 4.21 | 0.00027 | ||||

| Pérez-Neira et al. [47] | Ecuador | Conventional | Dark chocolate (100%) | 4.66 | −56% | 0.0215 |

| Organic | 2.04 | 0.0045 | ||||

| Armengot et al. [48] | World | Conventional | Dry beans | 3.740 | −58% | 0.0314 |

| Organic | 1.560 | 0.0075 | ||||

| Miah et al. [49] | World | Conventional | Dark chocolate | 6.76 | −68% | |

| Organic | 2.16 | |||||

| AVERAGE (Dry beans) | Conventional | 1.741 | −36% | 0.023 | ||

| Organic | 1.12 | 0.008 | ||||

| AVERAGE (Dark chocolate) | Conventional | 3.88 | −59% | 0.009 | ||

| Organic | 2.273 | 0.005 (−44%) | ||||

| TYPICAL DEVIATION (Dry beans) | Conventional | 1.801 (103.4%) | 0.011 | |||

| Organic | 0.382 (34.1%) | - | ||||

| TYPICAL DEVIATION (Dark chocolate) | Conventional | 2.308 (59.5%) | - | |||

| Organic | 0.306 (13.5%) | - | ||||

| Cocoa in Different Stages (1 kg) | |||||

|---|---|---|---|---|---|

| Source | Region | Organic/ Conventional | Format | ENVF Land Use m2a Crop-eq | Dif. (%) |

| Parra-Paitan & Verburg [50] | Ghana | Conventional | Dry beans needed for 1 kg of chocolate | 49.14 | +21% |

| Organic | 59.67 | ||||

| Miah et al. [49] | World | Organic | Dark chocolate | 4.09 | |

| Pérez-Neira et al. [47] | Ecuador | Conventional | Dark chocolate | 63.10 | −65% |

| Organic | 22.10 | ||||

| AVERAGE (1 kg chocolate) | Conventional | 56.12 | −49% | ||

| Organic | 28.62 | ||||

| TYPICAL DEVIATION (1 kg chocolate) | Conventional | 9.87 (17.59%) | |||

| Organic | 28.36 (99.09%) | ||||

| Cocoa in Different Stages (1 kg) | |||||

|---|---|---|---|---|---|

| Source | Region | Organic/ Conventional | Format | WF m3 | Dif. (%) |

| Félix Olegário et al. [55] | Brazil | Conventional | Dry beans needed for 1 kg of chocolate | 1135.09 | |

| Armengot et al. [48] | World | Conventional | Dry beans needed for 1 kg of chocolate | 271.46 | +17% |

| Organic | 328.78 | ||||

| Miglietta et al. [54] | Italy | Organic | Dry beans needed for 1 kg of chocolate | 78.18 | |

| Bulsink et al. [56] | Indonesia | Conventional | Dry beans needed for 1 kg of chocolate | 28.24 | |

| Van Oel et al. [53] | Netherlands | Conventional | Dry beans needed for 1 kg of chocolate | 10.45 | |

| Mekonnen & Hoekstra, 2011 [52] | World | Conventional | Chocolate | 17.19 | |

| Ortiz-Rodríguez et al. [51] | World | Conventional | Chocolate | 0.6 | |

| Miah et al. [49] | World | Organic | Dark chocolate | 1.02 | |

| AVERAGE (1 kg chocolate) | Conventional | 243.83 | −44% | ||

| Organic | 135.99 | ||||

| TYPICAL DEVIATION (1 kg chocolate) | Conventional | 448.68 (184%) | |||

| Organic | 171.38 (126%) | ||||

| Cocoa in Different Stages (1 kg) | |||||

|---|---|---|---|---|---|

| Source | Region | Organic/ Conventional | Format | EF MJ-eq | Dif. (%) |

| Recanati et al. [38] | World | Conventional | Dark chocolate | 33.71 | |

| Pérez-Neira et al. [47] | Ecuador | Conventional | Dark chocolate | 11.20 | +22% |

| Organic | 14.40 | ||||

| Boakye-Yiadom et al., [46] | Ghana | Conventional | Extra-dark chocolate | 144 | |

| Armengot et al. [48] | World | Conventional | Dry beans needed for 1 kg of chocolate | 169.53 | −67% |

| Organic | 55.80 | ||||

| Dianawati et al. [57] | Indonesia | Conventional | Dark chocolate | 323.67 | |

| AVERAGE (1 kg chocolate) | Conventional | 89.61 | −61% | ||

| Organic | 35.1 | ||||

| TYPICAL DEVIATION (1 kg chocolate) | Conventional | 78.78 (87.9%) | |||

| Organic | 29.27 (83.4%) | ||||

| Chocolate Consumption in the Basque Country | |||

|---|---|---|---|

| 4.73 kg·Person−1·Year−1 | |||

| GWP kg CO2-eq | TE kg 1,4-DCB | ||

| CA Chocolate (72% cocoa) | 37.90 | 513.87 | |

| OA&FT Chocolate 72% (72% cocoa) | 15.95 | 64.85 | |

| Avoided emissions | 21.95 | 449.02 | |

| Reductions | −57.32% | −87.38% | |

| Total impacts in the Basque Country | 8.4 × 103 | ||

| Relative decrease from national emissions per capita and year | −0.26% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López del Amo, B.; Akizu-Gardoki, O. Derived Environmental Impacts of Organic Fairtrade Cocoa (Peru) Compared to Its Conventional Equivalent (Ivory Coast) through Life-Cycle Assessment in the Basque Country. Sustainability 2024, 16, 493. https://doi.org/10.3390/su16020493

López del Amo B, Akizu-Gardoki O. Derived Environmental Impacts of Organic Fairtrade Cocoa (Peru) Compared to Its Conventional Equivalent (Ivory Coast) through Life-Cycle Assessment in the Basque Country. Sustainability. 2024; 16(2):493. https://doi.org/10.3390/su16020493

Chicago/Turabian StyleLópez del Amo, Blanca, and Ortzi Akizu-Gardoki. 2024. "Derived Environmental Impacts of Organic Fairtrade Cocoa (Peru) Compared to Its Conventional Equivalent (Ivory Coast) through Life-Cycle Assessment in the Basque Country" Sustainability 16, no. 2: 493. https://doi.org/10.3390/su16020493

APA StyleLópez del Amo, B., & Akizu-Gardoki, O. (2024). Derived Environmental Impacts of Organic Fairtrade Cocoa (Peru) Compared to Its Conventional Equivalent (Ivory Coast) through Life-Cycle Assessment in the Basque Country. Sustainability, 16(2), 493. https://doi.org/10.3390/su16020493