Abstract

This study explores the challenges and solutions faced by manufacturing companies in one industry when integrating green suppliers into their supply chains. The FGD transcripts were analyzed using NVivo 12 Pro for coding and thematic analysis, which helped identify key challenges and solutions. The key challenges identified included higher procurement costs, limited availability of green materials, quality assurance issues, and difficulties in verifying green practices. Strategic solutions involve establishing partnership strategies, conducting supply chain audits, and developing clear evaluation criteria. The content analysis shows that higher procurement costs can be mitigated through strategic partnerships offering better terms and pricing stability. Diversifying the supplier base and investing in supplier development programs address the limited availability of green materials. Quality assurance is maintained through stringent controls and regular audits, while verification challenges are managed with third-party certifications and robust audits to prevent greenwashing. The SWOT analysis highlights strengths such as strategic partnerships and regular audits, opportunities like developing evaluation criteria and technological advancements, and acknowledges weaknesses and threats. This comprehensive analysis provides a nuanced understanding of the practical challenges and solutions in green supply chain management, offering a strategic framework for manufacturing companies to enhance sustainability and achieve competitive advantage.

1. Introduction

Manufacturing companies are increasingly under pressure to adopt green supply chains as part of their commitment to environmental sustainability [,,]. This shift is driven by regulatory requirements [], consumer demand for eco-friendly products [], and corporate social responsibility goals []. Green supply chain management (GSCM) involves integrating environmental considerations into every aspect of supply chain management, from product design to material sourcing, manufacturing processes, delivery, and end-of-life management [,]. Despite the growing emphasis on GSCM, many companies face significant challenges in collaborating with suppliers who implement environmentally friendly practices [,].

One of the primary challenges is the higher cost associated with green materials and technologies [,]. Suppliers who adhere to green practices often incur additional expenses due to the need for sustainable materials, energy-efficient processes, and waste management systems. For instance, the authors of [] highlight that green technology requires significant upfront investment, particularly during the initial implementation phase. Moreover, the authors of [] indicate that while many companies initially avoid the development of green technologies and their applications due to its costs, market demands and regulatory pressures have compelled them to adopt such innovations appropriately. These costs are typically passed on to manufacturing companies, making it financially challenging to maintain competitive pricing []. Additionally, the availability of green materials can be limited [], particularly in regions where suppliers have not yet adopted sustainable practices. This scarcity can disrupt production schedules and affect the overall efficiency of the supply chain.

Quality concerns also pose a significant challenge in green supply chains []. Green materials and processes may require new technologies and standards, which can lead to inconsistencies in product quality. Ensuring that green products meet the same quality standards as conventional ones is crucial for maintaining customer satisfaction and brand reputation []. Furthermore, verifying that suppliers comply with green practices is a complex and resource-intensive process. It involves regular audits, certifications, and continuous monitoring, which can strain the resources of manufacturing companies, particularly smaller ones.

Despite these challenges, some companies have successfully implemented solutions to overcome the obstacles associated with green supply chains (see []). Partnership strategies, where companies work closely with their suppliers to promote sustainable practices, have proven effective [,,]. These partnerships often involve sharing knowledge, resources, and best practices to help suppliers transition to greener operations. Regular supply chain audits [,] and the development of clear evaluation criteria for suppliers’ environmental performance [] are also common strategies. These solutions not only help ensure compliance but also foster a culture of continuous improvement and sustainability throughout the supply chain.

The novelty of this research lies in its comprehensive analysis of the specific challenges and solutions encountered by manufacturing companies in working with green suppliers. While previous studies have identified general challenges and solutions in green supply chains (e.g., [,,,]), this research focuses on the practical experiences of companies and provides a detailed examination of the strategies they have employed. By using qualitative data from focus group discussions and supporting documentation, this study offers a nuanced understanding of the real-world implications of GSCM. Additionally, the use of SWOT analysis to categorize the findings provides a strategic framework that can guide companies in developing more effective green supply chain practices.

This study aims to achieve three primary objectives, each contributing to a comprehensive understanding of the interactions between manufacturing companies and their green suppliers. First, the research seeks to identify the main challenges manufacturing companies face when working with suppliers who implement environmentally friendly practices. These challenges are multifaceted, encompassing financial, logistical, and verification difficulties among suppliers, as previously discussed in prior research.

Second, the study analyzes the solutions that have been successfully implemented by these companies to overcome the identified challenges. By examining specific case studies and examples from focus group discussions, the research uncovers practical strategies that have been employed to mitigate the obstacles in green supply chains.

Third, the research compares these findings with the existing literature on challenges and solutions in green supply chains to highlight similarities and differences. This comparative analysis not only situates the current research within the broader academic discourse but also underscores the unique contributions and insights offered by this study. By integrating these objectives, the research provides a detailed and practical framework that can guide manufacturing companies in their transition to greener supply chains.

2. Literature Review

2.1. Challenges in Green Supply Chains

The implementation of green supply chains has become a growing focus for both researchers and businesses as they respond to increasing environmental and regulatory demands. However, despite the potential environmental and financial benefits, numerous challenges have been identified that can impede the widespread adoption of green supply chain practices.

One of the most significant challenges is the higher cost associated with green technologies and materials. Many studies, such as those by [,], have pointed out that adopting sustainable practices often requires substantial upfront investments. These costs include the purchase of new energy-efficient technologies, eco-friendly materials, and the development of sustainable processes. For companies, particularly small- and medium-sized enterprises (SMEs), these investments can be financially burdensome []. SMEs, in particular, face difficulties as they typically have limited access to the capital needed to make these transitions. Nonetheless, research by [,] indicates that, over time, these investments can lead to significant savings by reducing the overall supply chain costs through more efficient resource use, waste reduction, and lower energy consumption, even in regions with strict carbon regulations.

Another challenge frequently discussed is the availability of sustainable materials. The literature notes that sourcing environmentally friendly materials can be complicated by limited supply and higher costs compared to traditional options []. Researchers, including [,], emphasize that uneven access to these materials across various regions can lead to disruptions and inefficiencies within supply chains. In some cases, geographic disparities in material availability require companies to source from distant locations, driving up both transportation costs and the risk of supply chain interruptions. Moreover, fluctuating availability can result in price volatility, further complicating procurement efforts and increasing operational uncertainty for businesses committed to sustainability.

Ensuring quality standards in green supply chains presents another critical hurdle. Integrating new, eco-friendly materials and processes often involves revising or establishing new quality control standards. Studies by [,,] stress that maintaining consistent product quality while adopting green practices requires significant adjustments to manufacturing procedures, often necessitating rigorous quality assurance protocols. This can complicate the production process, particularly when traditional quality benchmarks do not align seamlessly with the characteristics of new green materials. For instance, industries transitioning to biodegradable or recycled materials may encounter challenges in ensuring these products meet established durability or performance criteria without compromising their environmental benefits.

Finally, the verification of sustainability practices throughout the supply chain is an additional area of concern. As companies expand their supply chains globally, ensuring that suppliers comply with environmental standards becomes increasingly complex and resource-intensive. Research by [,] suggests that the cost and logistical challenges of auditing and monitoring suppliers, especially across multiple regions, can be substantial. This complexity is heightened by the risk of greenwashing, where suppliers may falsely claim adherence to sustainability practices without providing verifiable evidence. Greenwashing is often employed by companies to gain legal subsidies and attract market attention []. Companies, especially those with large, diverse supplier bases, often struggle to maintain visibility and transparency across their supply networks, complicating efforts to ensure consistent compliance with green standards.

2.2. Solutions and Mitigation Strategies

To address the numerous challenges present in green supply chains, a range of effective solutions has been proposed in the literature. A key recommendation is the implementation of partnership strategies, which emphasize the importance of building stronger and more collaborative relationships between manufacturers and suppliers. By fostering deeper partnerships, companies can create synergies that facilitate the exchange of crucial resources, such as knowledge on sustainable technologies, process improvements, and best practices. Research by [,] demonstrates that such partnerships are vital for overcoming the barriers suppliers face in transitioning to green practices, as they allow for the sharing of technical expertise and financial resources that smaller suppliers might otherwise lack. Additionally, a study by [] highlights the significance of partnerships in facilitating contractual arrangements, such as revenue sharing and discounting, particularly in the context of perishable goods sourced from international manufacturers. These contractual mechanisms help reduce the financial risks for both parties, ensuring a more balanced and sustainable supply chain. Furthermore, partnerships encourage long-term commitments from suppliers, promoting sustained environmental compliance and continuous improvement. This close cooperation also makes it easier for manufacturers to monitor the environmental performance of their suppliers and provide targeted assistance where necessary.

Moreover, regular supply chain audits have proven to be essential tools for ensuring compliance with environmental regulations and standards, as well as for identifying potential areas for improvement [,,]. Comprehensive audits not only verify that suppliers adhere to the agreed-upon environmental standards but also provide valuable insights into operational inefficiencies that could hinder sustainable performance. According to [], these audits allow organizations to systematically examine their entire supply chain, ensuring transparency and accountability from each stakeholder involved. Regular audits are especially important in detecting discrepancies or lapses in sustainability practices, which can result in reputational damage or regulatory penalties if left unchecked. Furthermore, internal audits, as emphasized by [], are instrumental in promoting sustainable economic growth by increasing the transparency and accountability of business operations. Integrating advanced analytics into the audit process, as exemplified by the CARE framework, further enhances this effort by enabling companies to proactively identify potential sustainability violations. This analytical approach not only streamlines the audit process but also improves supplier sustainability performance, thus strengthening the overall resilience and sustainability of the green supply chain []. By conducting regular and rigorous audits, organizations can enhance transparency, accountability, and sustainability practices, thereby fortifying the overall green supply chain and contributing to long-term value creation [].

In addition to audits, the development of clear and effective evaluation criteria for assessing the environmental performance of suppliers is critical for the success of green supply chains. These criteria must go beyond traditional cost and quality metrics to include key environmental indicators, such as carbon footprint, energy consumption, and waste management practices. Studies by [,] emphasize that incorporating such environmental factors into supplier selection not only enhances operational efficiency but also strengthens the company’s competitiveness in an increasingly eco-conscious market. The use of advanced decision-making tools, such as Fuzzy Decision-Making Trial and Evaluation Laboratory (DEMATEL) and Fuzzy Technique for Order Performance by Similarity to Ideal Solution (TOPSIS), allows companies to assess and rank suppliers based on their environmental performance in a structured and data-driven manner. These methodologies provide decision-makers with clear insights into the strengths and weaknesses of each supplier, guiding them toward selecting those that are most aligned with their sustainability goals. Furthermore, employing trapezoidal interval type-2 fuzzy numbers (TIT2FNs) and cloud probability dominance relations (PDRs) in the evaluation process allows for more nuanced decision-making, especially when dealing with uncertainties or imprecise data related to environmental performance [].

3. Methods

This study employs a qualitative research approach to gain a comprehensive understanding of the challenges and solutions associated with working with green suppliers in the paper products and packaging industry. The methodology is designed to capture detailed insights and practical experiences from industry practitioners, ensuring a robust analysis of green supply chain practices within this specific sector.

3.1. Data Collection Techniques

3.1.1. Focus Group Discussion (FGD)

Focus group discussions (FGDs) serve as the primary data collection method for this study. FGDs are particularly effective for exploring complex topics and gaining a nuanced understanding of participants’ perspectives [,]. Data for the FGDs were collected from a series of structured discussions involving ten experts with a minimum managerial position, who are actively engaged in the paper products and packaging industry. These experts represent three different companies within the same industry, providing a diverse yet focused perspective on green supply chain practices.

The participants included supply chain managers, procurement officers, and sustainability experts, who offered insights into their experiences with green suppliers. This study focuses on experts from companies located in the largest industrial area in Southeast Asia, situated in Indonesia. The companies serve both local and large multinational clients, which influences their operational strategies. The increasing demand for green materials, particularly from foreign markets, compels these companies to develop effective strategies for integrating sustainable practices into their supply chains. In addition to initiating the use of green materials, these companies actively encourage their local customers to adopt similar sustainable products. The participants in this study include supply chain managers, procurement officers, and sustainability experts from these firms, all of whom hold at least an undergraduate degree and possess a minimum of three years of relevant work experience. Their combined expertise provides valuable insights into the challenges and solutions associated with working with green suppliers in the paper products and packaging industry.

3.1.2. Documentation

Focus group discussions (FGDs) serve as the primary data collection method for this study. FGDs are particularly effective for exploring complex topics and gaining a nuanced understanding of participants’ perspectives. The FGDs were conducted using a semi-structured format, which allowed for an in-depth exploration of topics while maintaining flexibility to probe emerging issues. The discussions were recorded, transcribed, and analyzed to identify key challenges and solutions related to green supply chain management in the paper products and packaging industry.

3.2. Data Analysis Techniques

3.2.1. Content Analysis

Content analysis is a qualitative research method used to systematically analyze textual data to identify patterns, themes, and meanings [,]. In the context of this study, content analysis is employed to explore the challenges and solutions that manufacturing companies encounter when working with green suppliers. By examining the transcripts from focus group discussions (FGDs), this method enables a deep understanding of the practical experiences and strategies employed by these companies to navigate the complexities of green supply chain management.

The content analysis technique involves coding and categorizing textual data to identify recurring themes and patterns [,]. The analysis focused on extracting the key challenges and solutions mentioned by participants, which were then organized into thematic categories. This process allowed for the identification of the common issues faced by companies in the paper products and packaging industry and the strategies they employed to address these challenges. Content analysis was conducted using NVivo 12 Pro software, which facilitated the management and organization of qualitative data.

In addition to content analysis of the FGD results, this study also employed a comparative analysis approach. The findings from the FGDs within the paper products and packaging industry were systematically compared with insights derived from 15 relevant papers (in Table 1) that examined similar issues with a green supplier in other industries. By juxtaposing the FGD results with the literature, the study provided a better understanding of the unique and common challenges faced by companies, as well as the effectiveness of various strategies employed to overcome them. This dual approach of content and comparative analysis enriched the study’s conclusions, offering a robust framework for understanding the complexities of working with green suppliers across diverse industrial contexts.

Table 1.

List of references for comparative analysis.

3.2.2. SWOT Analysis

SWOT analysis, which stands for strengths, weaknesses, opportunities, and threats, is a strategic planning tool extensively used in various fields to evaluate internal strengths and weaknesses alongside external opportunities and threats [,]. By conducting a systematic analysis of these four elements, organizations can gain a comprehensive understanding of their current position, capitalize on strengths, address weaknesses, leverage opportunities, and mitigate potential threats. SWOT analysis aids in formulating effective strategies, making informed decisions, and enhancing competitiveness in dynamic and challenging business environments []. It enables companies to identify areas for improvement, develop action plans, and drive sustainable growth while navigating changing market landscapes. Ultimately, SWOT analysis serves as a fundamental framework for organizations to adapt, innovate, and thrive in the face of evolving industry trends and global competition.

To provide a strategic framework for understanding the challenges and solutions, SWOT (strengths, weaknesses, opportunities, and threats) analysis was employed. This technique helps categorize and evaluate the internal and external factors affecting green supply chain management, as demonstrated by previous research (e.g., []). The identified challenges and solutions from the FGDs were mapped onto the SWOT matrix to assess their impact on the overall effectiveness of green supply chains. This analysis provided a structured way to evaluate the strengths and weaknesses of existing practices and identify opportunities and threats related to green supply chain management.

4. Results

4.1. Results of Content Analysis

Using NVivo 12 Pro, the content analysis process involves coding the data to identify recurring themes, conducting queries to reveal patterns, and utilizing visualizations to understand relationships within the data. This approach not only facilitates the identification of key challenges, such as higher costs and quality assurance issues, but also uncovers the solutions implemented by companies, including partnership strategies and rigorous evaluation processes. The detailed examination provided by content analysis offers valuable insights into the real-world implications of green supply chain management and contributes to the development of effective strategies for enhancing sustainability practices.

4.1.1. Data Coding and Theme Identification

The coding process in NVivo involved creating nodes for significant themes, which allowed for the systematic categorization of the data. The initial coding highlighted several prominent challenges and solutions:

- Challenges in Working with Green Suppliers;

- Higher Procurement CostsIn the context of the paper products and packaging industry, focus group discussions (FGDs) revealed that participants consistently face significantly higher costs associated with procuring green materials and technologies compared to conventional options. This financial burden extends beyond the price of materials; it encompasses the substantial additional expenditures required to ensure compliance with the stringent environmental standards unique to this industry. Companies often invest heavily in certifications, environmental audits, and enhanced quality assurance processes to verify that the materials they use genuinely meet established environmental criteria. Moreover, operational costs tend to escalate as firms may need to provide specialized training for employees to handle these new materials effectively and modify existing production processes accordingly. These cumulative factors create a significant financial challenge, complicating the implementation of green supply chain practices within the manufacturing sector.In an interview with an industry expert specializing in sustainable procurement, they shed light on the significant cost differences when sourcing green materials. “The price gap for green materials typically ranges between 15–25% higher than traditional materials”, the expert explained. “This is largely because suppliers of green materials employ specialized technologies in their production processes, which drives up costs”. The expert also highlighted cases where the price differential is even more pronounced. “In some instances, the cost of green materials can be extremely high, with differences ranging from 25% to as much as 75% compared to conventional materials. This premium is often linked to the complexity of the sustainable technologies and the limited availability of green resources”. These insights underline the financial challenges companies face when integrating green materials into their supply chains, particularly in industries heavily dependent on traditional materials.

- Limited Availability of Green MaterialsThe limited availability of green materials poses a significant challenge for companies within the paper products and packaging industry. Participants noted considerable difficulties in sourcing reliable suppliers who can consistently provide environmentally friendly products in the required quantities. This scarcity can lead to production delays and compromises in the supply chain, as companies struggle to maintain a steady flow of green materials essential for their manufacturing needs. The limited pool of suppliers forces companies to rely heavily on a few sources, heightening their vulnerability to supply chain disruptions. Additionally, the unpredictability of availability can lead to inconsistencies in product quality, further complicating the manufacturing process. This challenge is particularly pronounced for companies looking to scale their green initiatives, as the demand for sustainable materials frequently outstrips the available supply, creating a bottleneck that hinders the broader adoption of environmentally friendly practices in the sector.The expert addressed the limitations in sourcing green materials, emphasizing the scarcity of suppliers. “There aren’t many suppliers providing green materials at the moment”, they noted. “This is largely because the market still widely accepts non-green alternatives. As a result, suppliers aren’t under significant pressure to shift to sustainable options, and this limits the availability of green materials”. In some cases, companies face additional challenges due to geographic limitations. “Certain green materials are difficult to source locally and have to be imported”, the expert added. “This not only increases the cost but also complicates the supply chain due to import regulations and longer lead times”. These challenges highlight the current gap in the market for sustainable materials and the need for further development in local supply chains to meet growing sustainability demands.

- Quality Assurance IssuesThe quality assurance of green materials remains a critical concern for participants in the paper products and packaging industry. Many expressed doubts regarding the reliability and performance of green alternatives when compared to traditional materials. Instances were highlighted where green materials failed to meet the expected quality standards, leading to production issues such as delays, defects, and increased costs. These quality concerns are exacerbated by the distinct handling and processing techniques often required for green materials, which can complicate their integration into existing manufacturing systems. The perceived trade-off between environmental benefits and product performance adds another layer of complexity, compelling companies to balance their sustainability goals with the need to maintain high-quality outputs. This uncertainty surrounding the quality and durability of green materials acts as a substantial barrier to the wider adoption of green supply chain practices in this specific industry context.On the topic of quality and reliability issues, the expert explained the inherent challenges in working with green materials, particularly those derived from recycling processes. “The quality of green materials can sometimes fluctuate”, the expert stated. “This is largely because many green materials are recycled, so their quality heavily depends on the input material. If the input is inconsistent, the end product may reflect that variability”. Reliability in supply is another concern. “The supply of green materials is often seasonal or inconsistent because it depends on the availability of recyclable inputs and the efficiency of the recycling process. This creates uncertainty in the supply chain, making it harder to maintain a steady flow of materials”, the expert explained. They also provided a specific example of quality issues. “For instance, companies using recycled paper often experience inconsistent quality because the natural characteristics of recycled inputs vary. This can result in product defects or variations that are difficult to manage in a manufacturing process”. Supply reliability also affects delivery schedules. “Lead times often get delayed beyond the expected timeframe”, the expert noted, “which disrupts production timelines and can cause operational bottlenecks”. This unpredictability presents significant challenges in managing both the quality and reliability of green materials in a sustainable supply chain.

- Verification of Green PracticesThe verification of suppliers’ green credentials is particularly challenging for companies in the paper products and packaging industry. Participants voiced concerns regarding the complexities involved in ensuring that suppliers genuinely adhere to sustainable practices rather than merely engaging in greenwashing. The transparency and reliability of the information provided by suppliers regarding their environmental practices often lack standardization, complicating companies’ efforts to ascertain true commitments to sustainability. This issue is further amplified by the global nature of supply chains, where varying regulations and standards across countries add layers of complexity to the verification process. The risk of greenwashing undermines not only the integrity of the supply chain but also poses reputational risks for companies relying on these suppliers. Consequently, businesses must allocate additional resources toward rigorous audits, certifications, and continuous monitoring to ensure alignment with sustainability goals, rendering this a persistent and costly issue within the framework of green supply chain management.

- Solutions for Overcoming Challenges;

- Partnership StrategiesEstablishing strategic partnerships with green suppliers has emerged as a highly effective solution for companies in the paper products and packaging industry. Participants emphasized that long-term collaborations are vital for ensuring the reliability and consistency of supply while fostering mutual benefits for both parties. These partnerships extend beyond transactional relationships, involving deep cooperation, shared objectives, and joint problem-solving that are essential in a sector characterized by rapid changes in sustainability demands. By working closely with suppliers, companies can better align their sustainability objectives and expectations, leading to a more integrated and resilient supply chain. Participants noted that such collaborations often result in improved communication, trust, and a stronger commitment to shared environmental standards. Furthermore, long-term partnerships facilitate joint innovations, allowing companies and suppliers to co-develop new green technologies and explore cost-effective solutions that might not be feasible in traditional, short-term arrangements. This strategic approach not only helps secure a steady supply of green materials but also advances sustainable practices within the industry as a whole.

- Supply Chain AuditsConducting regular audits of the supply chain has been identified as a crucial solution for verifying adherence to environmental standards in the paper products and packaging industry. Participants highlighted that these audits play a vital role in maintaining accountability and ensuring that suppliers consistently meet the required sustainability criteria specific to the industry. By systematically reviewing the practices and processes of their suppliers, companies can identify potential non-compliance issues early and address them proactively. Regular audits also help verify the authenticity of the green credentials claimed by suppliers, mitigating the risks associated with superficial or misleading eco-friendly assertions. Additionally, these audits reinforce the importance of environmental standards within the supply chain, encouraging suppliers to continuously improve their practices to meet evolving expectations. Participants noted that audits can strengthen relationships with suppliers by providing constructive feedback and support, enhancing sustainability efforts across the board. This ongoing scrutiny bolsters the integrity of the green supply chain and contributes to the overall credibility and reputation of the companies involved, positioning them as leaders in sustainable practices.

- Development of Clear Evaluation CriteriaDeveloping and implementing clear criteria for evaluating the environmental performance of suppliers has been a widely adopted strategy among participants in the paper products and packaging industry. This structured framework enables companies to assess suppliers’ sustainability efforts effectively, making it easier to establish clear expectations from the outset. By establishing specific and measurable criteria, companies can ensure that all suppliers are held to consistent standards, minimizing ambiguity in environmental compliance. These criteria facilitate transparent communication between companies and their suppliers, helping to align their goals toward sustainable practices specific to the industry. Participants emphasized that well-defined evaluation benchmarks streamline the supplier selection process while enabling ongoing monitoring and improvement of environmental performance. This approach fosters a culture of continuous improvement in sustainability across the supply chain and acts as a deterrent against greenwashing, as suppliers must demonstrate tangible evidence of their environmental efforts, thereby reinforcing the integrity of the green supply chain.

4.1.2. Pattern Identification

- Matrix Coding Query

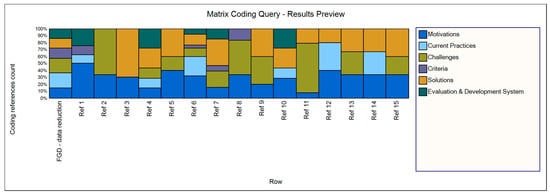

This section discusses the key themes identified across the various references, as illustrated in the matrix coding query shown in Figure 1. The analysis reveals six primary themes that are central to the discourse on green supply chain management: motivations, current practices, challenges, criteria, solutions, and evaluation and development systems. Motivations explore the drivers behind organizations adopting green supply chain practices, including regulatory pressure, market demand, and the desire to enhance corporate image. Current practices capture the strategies and methods organizations currently use, ranging from basic compliance with environmental regulations to advanced initiatives like green procurement and the use of eco-friendly materials. Challenges address the barriers to implementing green practices, such as the high cost of green materials, resistance to change, and the complexity of ensuring supplier compliance. Criteria focus on the standards used to evaluate and select green suppliers, emphasizing the need for a clear and consistent assessment of environmental performance. Solutions discuss strategies to overcome these challenges, often involving collaboration, technology adoption, and employee training. Finally, evaluation and development systems examine how organizations monitor and improve their practices over time, highlighting the need for robust systems to track progress and make continuous improvements. These themes provide a comprehensive understanding of the critical aspects of green supply chain management, offering valuable insights into the opportunities and challenges organizations face in their sustainability efforts.

Figure 1.

Matrix coding query of various themes.

Figure 1 demonstrates that not all critical themes are discussed across the 15 main references. Motivations emerge as the most universally explored theme, addressed by all the researchers. Following closely, the themes of challenges and solutions are also widely discussed, indicating a strong focus among researchers on identifying barriers to green supply chain practices and exploring potential strategies to overcome them. These themes underscore the prevalent concern among scholars about the difficulties in implementing sustainable practices and the efforts to find effective solutions.

- 2.

- Word Cloud Visualization

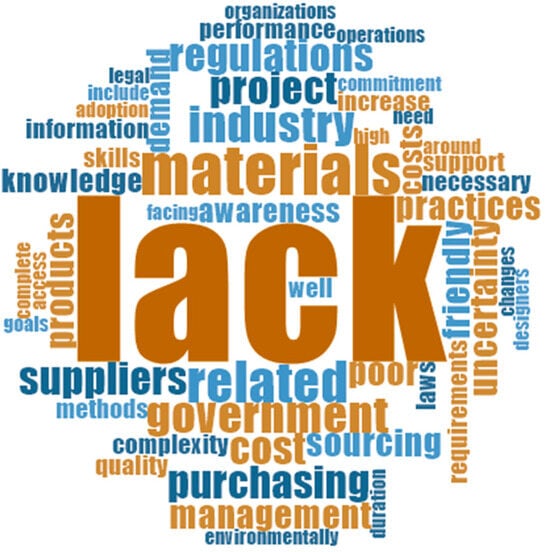

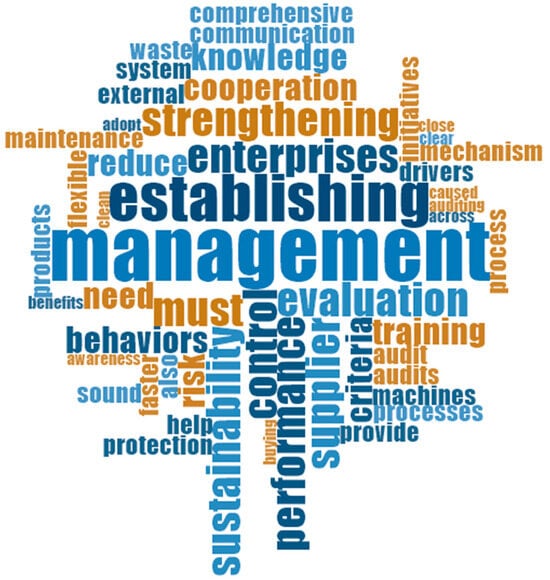

The word cloud visualization highlighted the prominence of key terms. In this study, the challenges and solutions themes take center stage as the primary focus. The results of the word cloud analysis for these two themes are illustrated in Figure 2 and Figure 3, respectively. These visual representations highlight the key terms and concepts that are most frequently discussed within each theme, offering insights into the specific obstacles faced in green supply chain management and the strategies proposed to address them.

Figure 2.

Word cloud visualization of challenges theme.

Figure 3.

Word cloud visualization of solutions theme.

The word cloud visualization using NVivo reveals that the most frequently occurring terms within the “Challenges” theme are lack, materials, government, and cost. These terms highlight the critical obstacles encountered in implementing green supply chain practices.

The prominence of the term “lack” reflects the widespread deficiencies across various aspects that constitute major barriers. According to the coded data, these deficiencies include a lack of resources, knowledge, experience, and support from top management and government bodies. For instance, the lack of knowledge and experience in green practices hinders effective implementation, as many organizations struggle to adopt and integrate sustainable methods into their supply chains.

Additionally, the term “materials” points to the challenges related to the availability and quality of green materials. The limited access to environmentally friendly materials often results in increased procurement costs and compromises on quality and reliability. This shortage is further compounded by inadequate market demand for recyclable materials, which discourages suppliers from investing in greener options.

The recurring mention of “government” underscores the role of regulatory frameworks and government support in facilitating green supply chain practices. The analysis indicates that inadequate legal enforcement and inconsistent regulations across regions create obstacles for companies attempting to standardize their green criteria and practices.

Finally, cost emerges as a significant challenge, as the transition to green practices often involves substantial financial investments. High costs associated with sourcing eco-friendly materials, upgrading infrastructure, and ensuring compliance with environmental standards can deter companies from fully committing to sustainable practices. These financial burdens, combined with the uncertainty of returns on investment, exacerbate the difficulties companies face in aligning their operations with green supply chain goals.

In summary, the most frequently mentioned terms in the word cloud encapsulate the core challenges of implementing green supply chain practices, with the lack of resources and support, material constraints, inadequate government regulations, and the high cost of transition being the predominant issues. These findings provide a comprehensive understanding of the barriers that must be addressed to achieve effective and sustainable supply chain management.

The word cloud analysis for the “Solutions” theme reveals that the most frequently occurring terms are management, establishing, control, and evaluation. These key terms encapsulate the strategies and practices that organizations are adopting to overcome challenges in implementing green supply chain management.

The prominence of “management” underscores the crucial role that effective supply chain management plays in addressing sustainability challenges. Companies are increasingly focusing on strengthening their supply chain management mechanisms to ensure flexibility, transparency, and resilience. This involves close monitoring of external environments, fostering strong communication with suppliers, and implementing risk management tools to mitigate disruptions and enhance supply chain stability.

The term “establishing” reflects the importance of building and solidifying new practices and systems within the supply chain. Organizations are establishing long-term partnerships with reliable green suppliers, developing stringent supplier evaluation criteria, and setting up sound supply chain risk control systems. These efforts are aimed at ensuring the consistent delivery of sustainable practices across the supply chain, even when faced with uncertainties and challenges.

“Control” is another critical aspect highlighted in the solutions theme, particularly in terms of process control and governance mechanisms. Companies are adopting process control measures to reduce uncertainty and improve efficiency within their supply chains. Robust governance mechanisms are also essential for managing supplier relationships, safeguarding assets, and preventing opportunistic behavior. These controls help to maintain alignment with environmental sustainability goals.

Lastly, the frequent mention of “evaluation” points to the growing emphasis on assessing and improving supply chain performance. Companies are implementing comprehensive evaluation systems to measure supplier performance against predefined goals, ensuring that environmental and sustainability criteria are met. Continuous evaluation and feedback loops are vital for identifying areas of improvement and driving further innovation in green supply chain practices.

In summary, the key terms management, establishing, control, and evaluation reflect the multifaceted strategies that organizations are employing to navigate the complexities of green supply chain management. By focusing on these areas, companies are better equipped to overcome challenges and achieve sustainable outcomes.

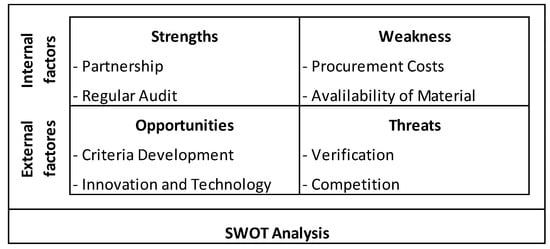

4.2. Results of SWOT Analysis

SWOT analysis is a strategic planning tool used to identify the strengths, weaknesses, opportunities, and threats associated with a particular subject. In this study, SWOT analysis is applied to assess the dynamics of working with green suppliers in the manufacturing industry. By systematically evaluating the internal and external factors that impact the collaboration with green suppliers, SWOT analysis provides a comprehensive framework to understand the strategic position of manufacturing companies and to formulate actionable strategies.

Building on the findings from the NVivo content analysis, a SWOT analysis was conducted to further understand the strategic implications of working with green suppliers. The SWOT analysis categorized the identified challenges and solutions into strengths, weaknesses, opportunities, and threats, providing a comprehensive strategic framework for green supply chain management.

4.2.1. S, W, O, T Identification

- Strengths;

- Strategic Partnerships with Green SuppliersEstablishing long-term relationships with green suppliers strengthens the supply chain by ensuring a reliable supply of quality materials. These partnerships facilitate better negotiation terms, joint problem-solving, and collaborative efforts towards achieving sustainability goals. Strong partnerships can also foster trust and innovation, leading to more effective and efficient green practices.

- Regular Supply Chain AuditsConducting regular audits ensures accountability and adherence to environmental standards, thereby maintaining the integrity of the green supply chain. These audits help in identifying areas for improvement, ensuring continuous compliance, and building trust with stakeholders. Regular audits also provide valuable feedback for suppliers, helping them improve their practices and meet the required standards consistently.

- Weaknesses;

- Higher Procurement CostsThe higher costs associated with green materials and technologies pose a significant financial burden on companies, making it challenging to compete with those using cheaper, non-green alternatives. This can impact profitability and pricing strategies, potentially limiting the adoption of green practices. Addressing these costs requires strategic financial planning and exploring cost-saving innovations.

- Limited Availability of Green MaterialsThe scarcity of reliable suppliers who can consistently provide green materials in the required quantities hampers the scalability of green supply chain initiatives. This can lead to supply chain disruptions, increased lead times, and difficulty in meeting production targets. Companies need to develop strategies to mitigate these risks, such as diversifying their supplier base and investing in supplier development programs.

- Opportunities;

- Development of Clear Evaluation CriteriaImplementing well-defined criteria for evaluating suppliers’ environmental performance can enhance transparency and set clear expectations, leading to improved supplier performance and compliance. This can also facilitate better decision-making in selecting and managing suppliers, ensuring that they meet the company’s sustainability standards. Clear criteria can drive continuous improvement and innovation among suppliers.

- Innovation and Technological AdvancementsContinuous innovation and advancements in green technologies present opportunities for companies to adopt more efficient and cost-effective sustainable practices. This can lead to reduced overall costs, improved quality, and enhanced environmental performance. Investing in R&D and staying abreast of technological trends can provide a competitive edge and help companies meet their sustainability goals more effectively.

- Threats;

- Verification of Green PracticesEnsuring that suppliers genuinely adhere to sustainable practices and are not engaging in greenwashing remains a significant threat. This requires robust verification mechanisms, such as third-party certifications, continuous monitoring, and stringent auditing processes. Without proper verification, companies risk damaging their reputation and facing regulatory penalties.

- Market CompetitionThe competitive pressure from companies using cheaper, non-green materials can undermine the efforts of those committed to green supply chains, making it difficult to maintain market share and profitability. Companies need to differentiate themselves through their commitment to sustainability and educate consumers about the benefits of green products to counter this threat.

The key results derived from the SWOT analysis are presented in Figure 4.

Figure 4.

Summary of main findings of SWOT analysis.

4.2.2. Strategic Recommendations

- SO (Strengths–Opportunities) Strategies;

- Develop and Implement Clear Evaluation CriteriaLeverage strategic partnerships to collaboratively develop and implement clear evaluation criteria for environmental performance, enhancing transparency and setting industry standards. This can improve supplier performance and ensure consistency in green practices.

- Adopt Advanced Green TechnologiesUtilize regular supply chain audits to identify opportunities for adopting innovative green technologies, thereby improving efficiency and reducing costs. This can help in achieving sustainability goals while maintaining competitiveness.

- ST (Strengths–Threats) Strategies;

- Strengthen Verification MechanismsUse strategic partnerships and regular audits to establish robust verification mechanisms, ensuring suppliers adhere to genuine green practices and mitigating the risk of greenwashing. This can build trust with stakeholders and enhance the company’s reputation.

- Sustainable DifferentiationUse strong supplier partnerships to differentiate products through sustainability, positioning the company competitively in the market and mitigating pressures from competitors.

- WO (Weaknesses–Opportunities) Strategies;

- Invest in Supplier DevelopmentAddress the limited availability of green materials and higher costs by investing in the development of green suppliers, enhancing their capacity to meet demand and potentially reducing costs over time. In [], the authors underscore the critical role of supplier development within integrated green supply chain management practices, highlighting its significance in achieving superior outcomes.

- Expand Supplier BaseDevelop a broader network of green suppliers to mitigate the risks associated with limited availability and ensure a consistent supply of quality materials. This can reduce dependency on a few suppliers and enhance supply chain resilience.

- WT Strategy (Weaknesses–Threats);

- Enhance Competitive PositioningMitigate the higher procurement costs and limited availability of green materials by adopting cost-saving green technologies and practices, while also improving competitive positioning through branding and marketing initiatives focused on sustainability.

- Risk ManagementImplement comprehensive risk management strategies that account for potential supply chain disruptions due to the limited availability of green materials, ensuring continuity and stability in operations.

5. Discussion

5.1. Addressing Key Challenges in Green Supply Chain Management

The findings from the content analysis reveal significant challenges that the paper products and packaging industry face in their efforts to incorporate green suppliers into their supply chains. These challenges—higher procurement costs, limited availability of green materials, quality assurance issues, and verification of green practices—highlight the complexity and multifaceted nature of transitioning towards sustainable supply chain practices. The systematic approach adopted in this study, using NVivo for content analysis, has enabled a detailed understanding of these issues and provided a foundation for developing strategic responses.

Higher procurement costs were consistently identified as a major challenge, with participants citing cost increases from 15% to 75% when switching to green-certified materials. This increase is largely attributed to the scarcity of sustainable materials, higher production costs due to environmental regulations, and the need for specialized certifications. This aligns with the existing literature, which frequently cites the cost barrier as a significant impediment to the adoption of green practices [,]. The additional expenses associated with green materials, compliance with environmental standards, and the need for innovative technologies impose a financial burden on companies. The data suggest that strategic partnerships can mitigate some of these costs by fostering long-term relationships that lead to better negotiation terms and more stable pricing. Such partnerships, as noted by participants, can help companies manage costs more effectively while maintaining their commitment to sustainability.

The limited availability of green materials was another prominent challenge identified. This scarcity can lead to supply chain disruptions and difficulty in meeting production targets. The literature supports these findings, noting that the limited supply of environmentally friendly materials can hinder the scalability of green supply chains. To address this, companies must diversify their supplier base and invest in supplier development programs to increase the availability and reliability of green materials. This approach not only enhances supply chain resilience but also encourages the growth of the green materials market.

Ensuring the quality of green materials emerged as a critical concern. Participants expressed doubts about the reliability and performance of green alternatives, which can lead to production delays and additional costs. This issue is corroborated by prior research, which highlights the challenges of maintaining quality standards in green supply chains. Regular supply chain audits and the development of clear evaluation criteria were identified as effective strategies to address these quality assurance issues. By maintaining stringent quality controls and clear standards, companies can ensure that green materials meet their performance requirements and contribute to overall supply chain efficiency.

The verification of green practices remains a significant challenge due to the risk of greenwashing, where suppliers falsely claim to adhere to sustainable practices. This challenge is well documented in the literature, which emphasizes the need for robust verification mechanisms. The study’s findings suggest that regular audits and third-party certifications are critical in ensuring the authenticity of suppliers’ green credentials. Implementing these verification measures can help build trust with stakeholders and maintain the integrity of the green supply chain.

5.2. Strategic Responses: Leveraging Strengths and Opportunities

The SWOT analysis provided a comprehensive strategic framework for addressing the identified challenges and leveraging opportunities in the paper products and packaging industry. The integration of strengths, such as strategic partnerships with suppliers of sustainable materials and regular audits to ensure compliance, alongside opportunities like the development of clear evaluation criteria and technological advancements, can drive significant improvements in the green supply chain management specific to this sector. Given the industry’s reliance on both raw materials and consumer demand for sustainable packaging solutions, aligning these strengths and opportunities is essential for maintaining competitiveness.

Developing clear evaluation criteria for suppliers’ environmental performance is essential for creating an effective green supplier evaluation and development system in the paper products and packaging industry. Transparent and consistent standards not only align with sustainability goals but also promote adherence to best practices in environmental management within this industry, which often faces challenges related to procurement costs and material availability. By employing a data-driven approach, such as advanced analytical methods and comprehensive sustainability criteria, companies can ensure objective and accurate assessments. This approach fosters enhanced supplier performance, encourages continuous improvement and innovation, and supports targeted development programs that are particularly relevant in a sector focused on reducing environmental impacts. Additionally, it helps manage risks associated with environmental compliance and facilitates benchmarking against industry standards, leading to a more resilient and sustainable supply chain.

Technological advancements offer substantial opportunities for reducing costs and improving the efficiency of green supply chains in the paper products and packaging industry. The utilization of the technology is also driven by competitive pressure, compelling companies to implement it promptly []. Investing in innovative green technologies can help companies overcome the financial barriers associated with green procurement, which is especially pertinent in a sector where sustainable practices are becoming increasingly critical to meet market demands. The study’s findings support the notion that continuous innovation is crucial for achieving sustainability goals while maintaining competitive advantage in a rapidly evolving industry landscape.

5.3. Mitigating Threats: Strengthening Verification and Competitive Positioning

The risk of greenwashing is particularly pertinent in the paper products and packaging industry, where consumers are increasingly discerning about the sustainability claims made by companies. This necessitates robust verification mechanisms. The study underscores the importance of regular audits and third-party certifications in ensuring the authenticity of suppliers’ green practices. These verification measures not only mitigate the risk of reputational damage but also enhance the credibility and reliability of the green supply chain, which is critical for maintaining consumer trust in a market that is shifting toward environmentally responsible products.

Furthermore, the competitive pressure from companies using non-green materials highlights the need for effective differentiation strategies within this sector. By leveraging strategic partnerships with certified green suppliers and implementing robust verification mechanisms, companies can develop unique selling propositions grounded in their commitment to sustainability. This differentiation is crucial in the paper products and packaging industry, where market share is increasingly driven by consumer preferences for environmentally friendly solutions. As supported by the literature on green marketing, companies that effectively communicate their sustainable practices and certifications can drive consumer preference for green products, positioning themselves as leaders in the transition toward sustainable manufacturing.

6. Conclusions

The content analysis, along with the subsequent SWOT analysis, provides valuable insights into the challenges and strategic responses for managing green supply chains, particularly within the paper products and packaging industry. By addressing issues such as higher procurement costs, limited availability of green materials, quality assurance concerns, and verification of green practices through targeted strategies, manufacturing companies can enhance their sustainability efforts. The integration of strategic partnerships, regular audits, clear evaluation criteria, and technological innovations can significantly improve the efficiency and effectiveness of green supply chains, ultimately contributing to broader environmental and economic goals. However, these solutions are not without limitations. For instance, regular audits, although essential for ensuring compliance, can be financially burdensome for small enterprises that may struggle to afford the associated costs. Additionally, partnerships may not always yield significant benefits if there is a misalignment in sustainability goals or insufficient trust between the companies and their suppliers. Addressing these downsides provides a more balanced perspective, suggesting that solutions need to be tailored to the size and capacity of the enterprise.

While this study focuses on the paper products and packaging industry, which may limit the generalizability of the findings to other sectors with different supply chain dynamics, the insights provided are still valuable. They align with existing research that highlights similar challenges and strategies across various industries, suggesting that the results reflect broader trends in green supply chain management.

To enhance the applicability of these findings for industry practitioners, several actionable recommendations can be made:

- Establish Long-Term Strategic Partnerships:

Manufacturing companies should prioritize forming long-term partnerships with suppliers who are committed to sustainability. These partnerships can be mutually beneficial, as they encourage collaboration on innovative solutions and shared resources. By investing time in building relationships based on trust and shared environmental goals, companies can create a more resilient supply chain. This collaboration can lead to joint research and development efforts, enabling both parties to explore new green technologies and improve material sourcing. Additionally, fostering open communication channels will help align sustainability objectives and facilitate problem-solving.

- 2.

- Implement Third-Party Certification Processes:

To mitigate the risk of greenwashing and ensure the authenticity of green claims, companies should adopt third-party certification processes for their suppliers. This involves partnering with reputable organizations that specialize in environmental audits and certifications. By doing so, companies can establish credibility in their sustainability claims and enhance consumer trust in their products. Regular audits and certifications will not only provide assurance regarding the supplier’s environmental practices but also motivate suppliers to maintain high standards and continuously improve their sustainability efforts.

- 3.

- Develop Clear and Measurable Evaluation Criteria:

It is crucial for companies to establish clear and measurable criteria for evaluating their suppliers’ environmental performance. By creating specific benchmarks and key performance indicators (KPIs), companies can objectively assess and compare suppliers on their sustainability efforts. This structured approach not only simplifies the supplier selection process but also ensures that all suppliers are held accountable to the same environmental standards. Furthermore, transparent evaluation criteria encourage suppliers to innovate and improve their practices, fostering a culture of continuous improvement in sustainability throughout the supply chain.

Future research should address the limitations of this study by exploring green supply chain practices across multiple industries to enhance generalizability. Comparative studies across sectors, longitudinal analyses to track changes over time, and quantitative validation of qualitative findings would provide a more comprehensive understanding of the challenges and solutions in green supply chains. Additionally, future research should include quantitative studies to further explore the causality between the identified challenges and implemented solutions. Investigating emerging innovations and technologies could also offer new insights into effectively addressing the challenges identified in this study. These directions for future research will enhance the depth and clarity of the analysis, while acknowledging the complexity and evolving nature of green supply chain implementation.

Author Contributions

Validation, S.Y.O.; Writing—original draft, J.K.R.; Supervision, P.K.N. All authors have read and agreed to the published version of the manuscript.

Funding

The article processing charge (APC) was funded by the Research Management Centre (RMC) of Multimedia University, with the approval number MMU/RMC/PC/2024/167710 (Approved on 11 October 2024).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sarin, I.; Srivastava, A. Investigating barriers in green supply chain management. J. Multidiscip. Res. 2024, 4, 41–46. [Google Scholar] [CrossRef]

- Solomon, N.O.; Simpa, P.; Adenekan, O.A.; Obasi, S.C. Sustainable Nanomaterials’ Role in Green Supply Chains and Environmental Sustainability. Eng. Sci. Technol. J. 2024, 5, 1678–1694. [Google Scholar] [CrossRef]

- Le, T.T. The Association of Corporate Social Responsibility and Sustainable Consumption and Production Patterns: The Mediating Role of Green Supply Chain Management. J. Clean. Prod. 2023, 414, 137435. [Google Scholar] [CrossRef]

- Lee, T.; Phuong Nha Le, T.; Genovese, A.; Koh, L.S.C. Using FAHP to Determine the Criteria for Partner’s Selection within a Green Supply Chain: The Case of Hand Tool Industry in Taiwan. J. Manuf. Technol. Manag. 2011, 23, 25–55. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green Supply Chain Management Practices: Impact on Performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Cheng, Y.; Pan, J.; Gong, Y. Who Will Undertake Corporate Social Responsibility in Supply Chain Encroachment? Manufacturer or Retailer. Manag. Decis. Econ. 2024, 45, 1511–1527. [Google Scholar] [CrossRef]

- Sarkis, J.; Dou, Y. Green Supply Chain Management: A Concise Introduction; Routledge: New York, NY, USA, 2017; ISBN 978-1-315-23300-0. [Google Scholar]

- Handfield, R.; Sroufe, R.; Walton, S. Integrating Environmental Management and Supply Chain Strategies. Bus. Strategy Environ. 2005, 14, 1–19. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Tai, P.-Y.; Chu, C.-Y. Developing a Smart Green Supplier Risk Assessment System Integrating Natural Language Processing and Life Cycle Assessment Based on AHP Framework: An Empirical Study. Resour. Conserv. Recycl. 2024, 207, 107671. [Google Scholar] [CrossRef]

- Tronnebati, I.; Jawab, F.; Frichi, Y.; Arif, J. Green Supplier Selection Using Fuzzy AHP, Fuzzy TOSIS, and Fuzzy WASPAS: A Case Study of the Moroccan Automotive Industry. Sustainability 2024, 16, 4580. [Google Scholar] [CrossRef]

- Basyouni, Y.A.; Mahmoud, H. Affordable Green Materials for Developed Cool Roof Applications: A Review. Renew. Sustain. Energy Rev. 2024, 202, 114722. [Google Scholar] [CrossRef]

- Ma, X.; Liu, T. Supplier Selection Analysis under the Green Supply Chain. In Proceedings of the 2011 IEEE International Conference on Automation and Logistics (ICAL), Chongqing, China, 15–16 August 2011; pp. 205–209. [Google Scholar]

- Majumdar, A.; Sinha, S. Modeling the Barriers of Green Supply Chain Management in Small and Medium Enterprises. Manag. Environ. Qual. Int. J. 2018, 29, 1110–1122. [Google Scholar] [CrossRef]

- Choi, G.; Cho, S.H. Effect of Market versus Nonmarket Environmental Policy Stringency on Knowledge Sourcing Behavior for Green Technology: Evidence from OECD Countries. Rev. Int. Bus. Strategy 2022, 32, 72–93. [Google Scholar] [CrossRef]

- Zou, Y.; He, D.; Sun, R. Research on the Mechanism of Collaborative Innovation in Green Technology among Supply Chain Enterprises Based on Cost Sharing and Market Competition. Sustainability 2024, 16, 6295. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green Supply Chain Management in China: Pressures, Practices and Performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Bejtović, M.; Andjelković, A.; Radosavljević, M. Green quality and supply chain management as a factor of sustainable competitiveness. Facta Univ. Ser. Econ. Organ. 2022, 19, 297–308. [Google Scholar] [CrossRef]

- Sharma, H. Emerging Challenges to Greening of Supply Chains: An Empirical Study. Benchmarking Int. J. 2021, 29, 2099–2121. [Google Scholar] [CrossRef]

- Khamis, A.A.; Munishi, E.J.; Issa, I.M. The Challenges Faced by Manufacturing Companies in Implementation of Green Supply Chain: Evidence from the Bakhresa Food Products Limited in Dar Es Salaam—Tanzania. Int. J. Soc. Sci. Res. Rev. 2022, 5, 69–81. [Google Scholar] [CrossRef]

- Khanal, G.; Shrestha, R.; Devkota, N.; Sakhakarmy, M.; Mahato, S.; Paudel, U.R.; Acharya, Y.; Khanal, C.K. An Investigation of Green Supply Chain Management Practices on Organizational Performance Using Multivariate Statistical Analysis. Supply Chain Anal. 2023, 3, 100034. [Google Scholar] [CrossRef]

- Klassen, R.D.; Vachon, S. Collaboration and Evaluation in the Supply Chain: The Impact on Plant-Level Environmental Investment. Prod. Oper. Manag. 2003, 12, 336–352. [Google Scholar] [CrossRef]

- Anvarjonov, N.B.U.; Um, K.-H.; Zhong, D.; Shine, E.-K. Achieving Sustainability in Manufacturing: The Nexus of Green Supplier Selection, Green Performance and Outcome and Process Controls. J. Manuf. Technol. Manag. 2024, 35, 480–501. [Google Scholar] [CrossRef]

- Fraser, I.J.; Schwarzkopf, J.; Müller, M. Exploring Supplier Sustainability Audit Standards: Potential for and Barriers to Standardization. Sustainability 2020, 12, 8223. [Google Scholar] [CrossRef]

- Huang, X.; Chen, P.-K.; Zhang, G. The Sustainable Cycle between Lean Production and Auditing Practices and Its Efficiency in Improving Supplier Relationships and Green Supply Chains. J. Bus. Econ. Manag. 2023, 24, 422–448. [Google Scholar] [CrossRef]

- Konys, A. Green Supplier Selection Criteria: From a Literature Review to a Comprehensive Knowledge Base. Sustainability 2019, 11, 4208. [Google Scholar] [CrossRef]

- Ograh, T.; Ayarkwa, J.; Asibey, D.O. Challenges to Integration of Green into Supplier Selections: Review of the State-of-the-Art Literature. Int. J. Procure. Manag. (IJPM) 2022, 15, 789. [Google Scholar] [CrossRef]

- Banihashemi, S.A.; Khalilzadeh, M.; Antucheviciene, J.; Edalatpanah, S.A. Identifying and Prioritizing the Challenges and Obstacles of the Green Supply Chain Management in the Construction Industry Using the Fuzzy BWM Method. Buildings 2023, 13, 38. [Google Scholar] [CrossRef]

- Khan, M.T.; Idrees, M.D.; Rauf, M.; Sami, A.; Ansari, A.; Jamil, A. Green Supply Chain Management Practices’ Impact on Operational Performance with the Mediation of Technological Innovation. Sustainability 2022, 14, 3362. [Google Scholar] [CrossRef]

- Wamalwa, L.S.; Nang’ole Meyer, P. Green Supplier Development and Sustainable Supply Chain Management. Bus. Strategy Dev. 2024, 7, e357. [Google Scholar] [CrossRef]

- Ghosh, A.; Sarmah, S.P.; Kanauzia, R.K. The Effect of Investment in Green Technology in a Two Echelon Supply Chain under Strict Carbon-Cap Policy. Benchmarking Int. J. 2020, 27, 1875–1891. [Google Scholar] [CrossRef]

- Eslamipoor, R.; Sepehriyar, A. Promoting Green Supply Chain under Carbon Tax, Carbon Cap and Carbon Trading Policies. Bus. Strategy Environ. 2024, 33, 4901–4912. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A Framework of Sustainable Supply Chain Management: Moving toward New Theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Hemmati, M.; Pasandideh, S.H.R. A Bi-Objective Supplier Location, Supplier Selection and Order Allocation Problem with Green Constraints: Scenario-Based Approach. J. Ambient Intell. Hum. Comput. 2021, 12, 8205–8228. [Google Scholar] [CrossRef]

- Panagiotopoulou, V.C.; Papacharalampopoulos, A.; Stavropoulos, P. Developing a Manufacturing Process Level Framework for Green Strategies KPIs Handling. In Manufacturing Driving Circular Economy; Kohl, H., Seliger, G., Dietrich, F., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1008–1015. [Google Scholar]

- Yang, C.-M.; Wei, W.; Chen, C.; Deng, W. A Novel Approach to Ensure the Quality of 7075 Aluminum Alloy for Green Manufacturing. J. Phys. Conf. Ser. 2021, 1939, 012081. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do Green Supply Chains Lead to Competitiveness and Economic Performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Anonymous. Environmental strategies impacted by institutional incompleteness: How perceived business and social forces direct companies to greener or greenwashed routes. Strateg. Dir. 2022, 38, 1–3. [Google Scholar] [CrossRef]

- Chen, P.-K. Efficiency of Lean Practices and Blockchain Combinations for Green Supplier Integration Improvements in Sustainable Development. Sustain. Dev. 2023, 31, 555–571. [Google Scholar] [CrossRef]

- Wang, H.; Huang, M.; Wang, H. Fourth-Party Logistics Environmental Compliance Management: Investment and Logistics Audit. Sustainability 2022, 14, 10106. [Google Scholar] [CrossRef]

- Dawande, M.; Qi, A. Auditing, Inspections, and Testing for Social Responsibility in Supply Networks. In Responsible Business Operations: Challenges and Opportunities; Swaminathan, J.M., Deshpande, V., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 243–259. ISBN 978-3-030-51957-5. [Google Scholar]

- Mefford, R. Sustainable CSR in Global Supply Chains. J. Manag. Sustain. 2019, 9, p82. [Google Scholar] [CrossRef]

- Ferreira, A.B.S.; Sebastiani, R.T.; Nascimento, L.D.; Oliveira, K.J.d.; Carballo, F.P.; Zarpellon, C.S.d.S.; Vitaliano, F.C.B.; Silva, A.P.S.e.; Nascimento, G.G.d.; Almeida-Bezerra, J.W. Environmental Audit as A Tool for Management and Sustainability: A Qualitative Study. Rev. Gest. Soc. Ambient. 2024, 18, e05896. [Google Scholar] [CrossRef]

- Qizi, Z.S.S. Replace internal audit in ensuring sustainable economy. Eur. Int. J. Multidiscip. Res. Manag. Stud. (EIJMRMS) 2024, 4, 23–26. [Google Scholar] [CrossRef]

- Tan, T.; Akyüz, M.H.; Urlu, B.; Ruiz, S. Stop Auditing and Start to CARE: Paradigm Shift in Assessing and Improving Supplier Sustainability. Informs J. Appl. Anal. 2024, 54, 241–263. [Google Scholar] [CrossRef]

- Ahamed, N.; Dey, G.; Ahmed, T.; Rahman, R.; Taqi, H.M.M.; Ahmed, S. Embracing Sustainability in Green Supplier Evaluation: A Novel Integrated Multi-Criteria Decision-Making Framework. Contemp. Math. 2024, 5, 1891–1917. [Google Scholar] [CrossRef]

- Zhu, Q.; Liu, A.; Li, Z.; Yang, Y.; Miao, J. Sustainable Supplier Selection and Evaluation for the Effective Supply Chain Management System. Systems 2022, 10, 166. [Google Scholar] [CrossRef]

- Scheelbeek, P.F.D.; Hamza, Y.A.; Schellenberg, J.; Hill, Z. Improving the Use of Focus Group Discussions in Low Income Settings. BMC Med. Res. Methodol. 2020, 20, 287. [Google Scholar] [CrossRef] [PubMed]

- Khatun, F.; Saadat, S.Y. Focus Group Discussion (FGD). In Youth Employment in Bangladesh: Creating Opportunities—Reaping Dividends; Khatun, F., Saadat, S.Y., Eds.; Springer: Singapore, 2020; pp. 77–88. ISBN 9789811517501. [Google Scholar]

- Rucks-Ahidiana, Z. Content Analysis. In Doing Good Qualitative Research; Cyr, J., Goodman, S.W., Eds.; Oxford University Press: Oxford, UK, 2024; ISBN 978-0-19-763313-7. [Google Scholar]

- Tunison, S. Content Analysis. In Varieties of Qualitative Research Methods: Selected Contextual Perspectives; Okoko, J.M., Tunison, S., Walker, K.D., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 85–90. ISBN 978-3-031-04394-9. [Google Scholar]

- Bass, L.; Semetko, H.A. Content Analysis. In Research Methods in the Social Sciences: An A-Z of Key Concepts; Oxford University Press: Oxford, UK, 2021; ISBN 978-0-19-885029-8. [Google Scholar]

- Iqbal, M.; Waqas, M.; Ahmad, N.; Hussain, K.; Hussain, J. Green Supply Chain Management as a Pathway to Sustainable Operations in the Post-COVID-19 Era: Investigating Challenges in the Chinese Scenario. Bus. Process Manag. J. (BPMJ) 2024, 30, 1065–1087. [Google Scholar] [CrossRef]

- Yao, Q.; Liang, Y.; Feng, M.; Wang, H. Are Consumers Willing to Co-Create Value When Focal Firms’ Suppliers Are Proactive in Green Innovation? A Chain Liability and Green Halo Effect. Int. J. Phys. Distrib. Logist. Manag. 2023, 53, 1240–1260. [Google Scholar] [CrossRef]

- Walton, S.V.; Handfield, R.B.; Melnyk, S.A. The Green Supply Chain: Integrating Suppliers into Environmental Management Processes. Int. J. Purch. Mater. Manag. 1998, 34, 2–11. [Google Scholar] [CrossRef]

- Ahmed, A. Factors Influencing the Adoption of Green Supply Chain Management: A Comprehensive Empirical Study on Pressures and Practices. J. Logist. Inform. Serv. Sci. (JLISS) 2023, 10, 20–34. [Google Scholar] [CrossRef]

- Fallahpour, A.; Yazdani, M.; Mohammed, A.; Wong, K.Y. Green Sourcing in the Era of Industry 4.0: Towards Green and Digitalized Competitive Advantages. Ind. Manag. Data Syst. 2021, 121, 1997–2025. [Google Scholar] [CrossRef]

- Ograh, T.; Ayarkwa, J.; Osei-Asibey, D.; Acheampong, A.; Amoah, P. Drivers of Integration of Green into Supplier Selections: A Systematic Literature Review. Int. Trade Politics Dev. (ITPD) 2021, 5, 136–155. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Y.; Gu, Q.; Xie, H. The Antecedents and Consequences of Green Purchasing: An Empirical Investigation. Benchmarking Int. J. 2021, 29, 1–21. [Google Scholar] [CrossRef]

- Li, F. Challenges and Opportunities for Sustainable Supply Chain Management. Front. Bus. Econ. Manag. 2024, 15, 160–163. [Google Scholar] [CrossRef]

- Ivanenko, V.; Klimova, I.; Morozov, V. Swot analysis: Navigating sustainability amid uncertainty. Econ. Manag. Innov. 2024, 1. [Google Scholar] [CrossRef]

- Sharath Kumar, C.R.; Praveena, K.B. SWOT Analysis. Int. J. Adv. Res. (IJAR) 2023, 11, 744–748. [Google Scholar] [CrossRef] [PubMed]

- King, T.; Freyn, S.; Morrison, J. SWOT Analysis Problems and Solutions: Practitioners’ Feedback into the Ongoing Academic Debate. J. Intell. Stud. Bus. 2023, 13, 30–42. [Google Scholar] [CrossRef]

- Bai, C.; Satir, A. Barriers for Green Supplier Development Programs in Manufacturing Industry. Resour. Conserv. Recycl. 2020, 158, 104756. [Google Scholar] [CrossRef]

- Chen, C.; Panichakarn, B. Cultivating a Greener Future: Unveiling the Mechanism for Embracing Green Innovation in the Supply Chain. Tuijin Jishu/J. Propuls. Technol. 2024, 45, 963–973. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).