Optimization of a Typical Gas Injection Pressurization Process in Underground Gas Storage

Abstract

:1. Introduction

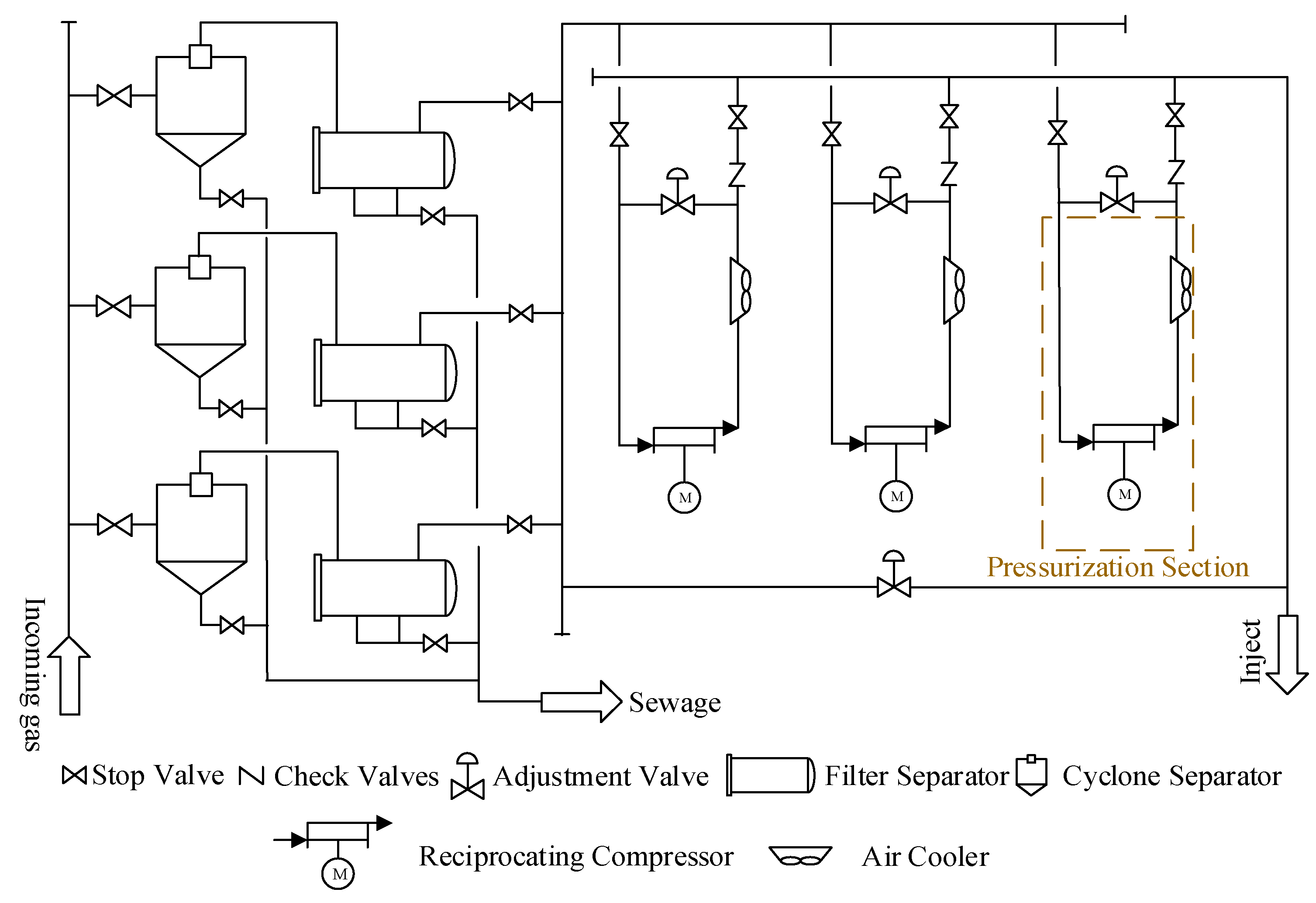

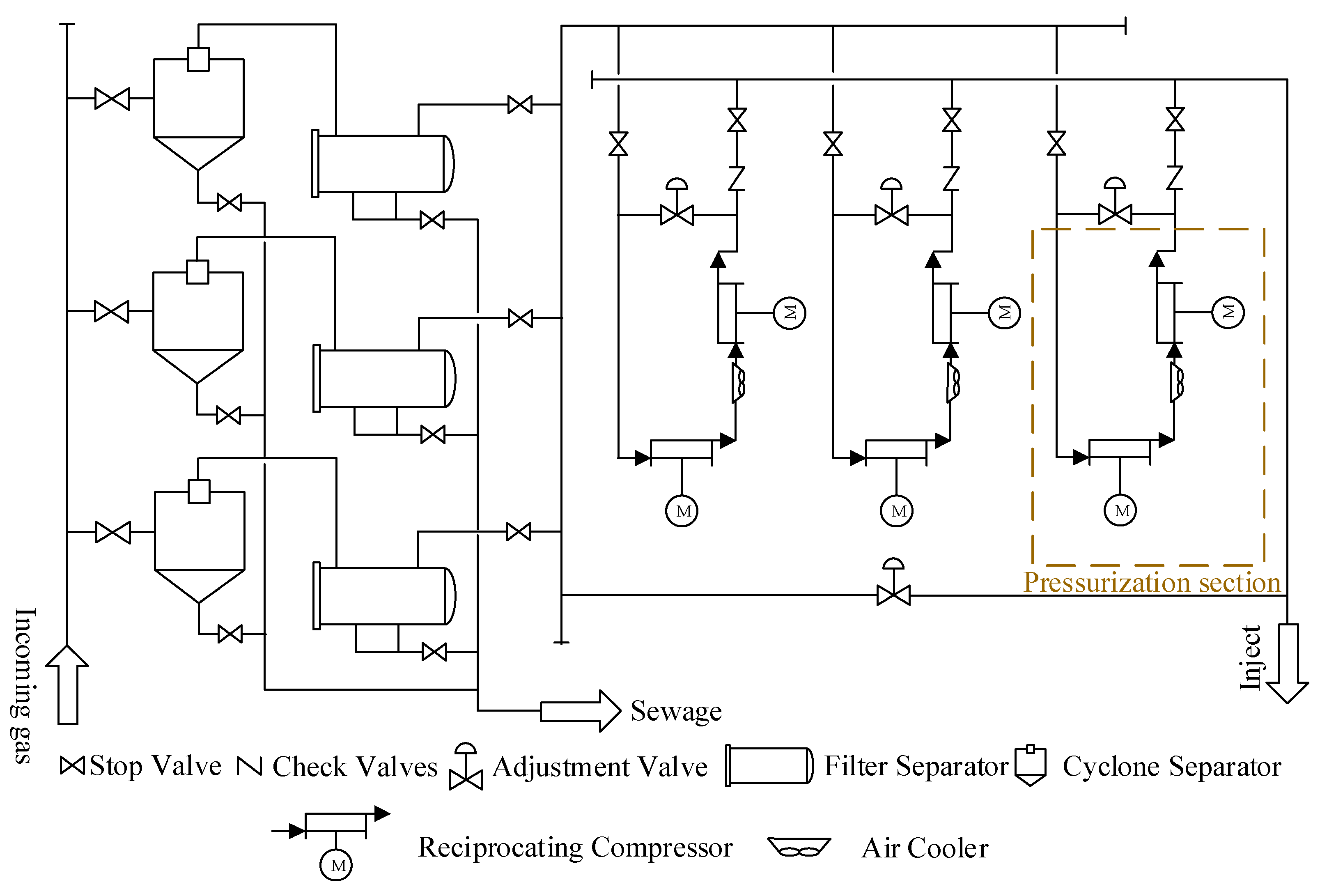

2. Overview of an Underground Gas Storage in Chinese Southwest Oil and Gas Field

3. Simulation of Multi-Stage Compression Schemes

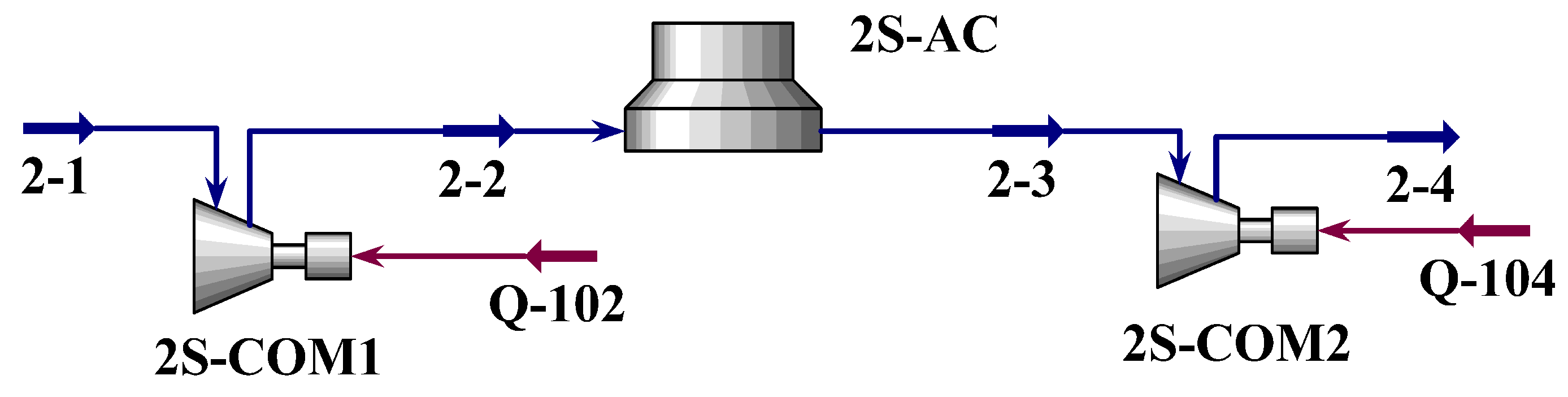

3.1. Two-Stage Compression Scheme Simulation

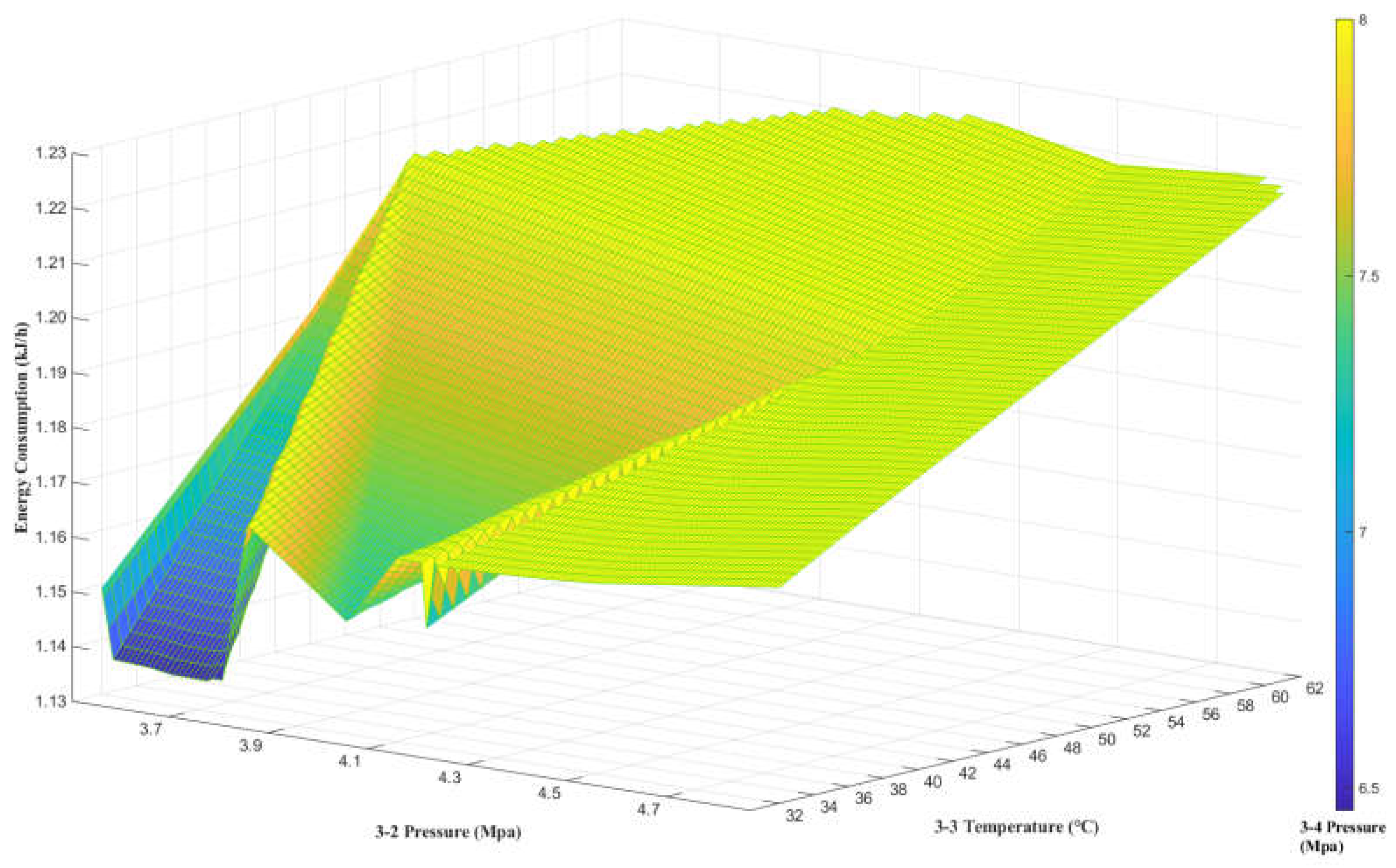

3.2. Three-Stage Compression Scheme Simulation

4. Process Optimization of Pressurization Based on Software Interaction

4.1. Optimization Model of Pressurization Process

4.2. Optimization Process Based on HYSYS and PSO

- (1)

- Establish the model using HYSYS and import the relevant parameters into the spreadsheet within HYSYS. An example is shown in Figure 8.

- (2)

- Store the HYSYS simulation file and MATLAB code file in the same folder and link HYSYS and MATLAB through ActiveX components within the MATLAB file.

- (3)

- Utilize the particle swarm optimization algorithm to control the relevant parameters of the input material stream in HYSYS through MATLAB code and activate the HYSYS solver.

- (4)

- Read the values of each cell in the spreadsheet within HYSYS using MATLAB code and assign these values to the corresponding variables in MATLAB, which represent the various energy consumption components mentioned in the objective function.

- (5)

- After receiving the simulation results from HYSYS, MATLAB evaluated the objective function and adjusted the parameter update strategy of the PSO algorithm based on this evaluation. This process guided the direction of the next iteration. Through this iterative loop, the optimal pressurization process parameters were gradually approached.

5. Results

5.1. Joint Optimization Results

- (1)

- Analysis of optimization results for two-stage compression

- (2)

- Optimization results for three-stage compression

5.2. Results of Various Pressurization Schemes

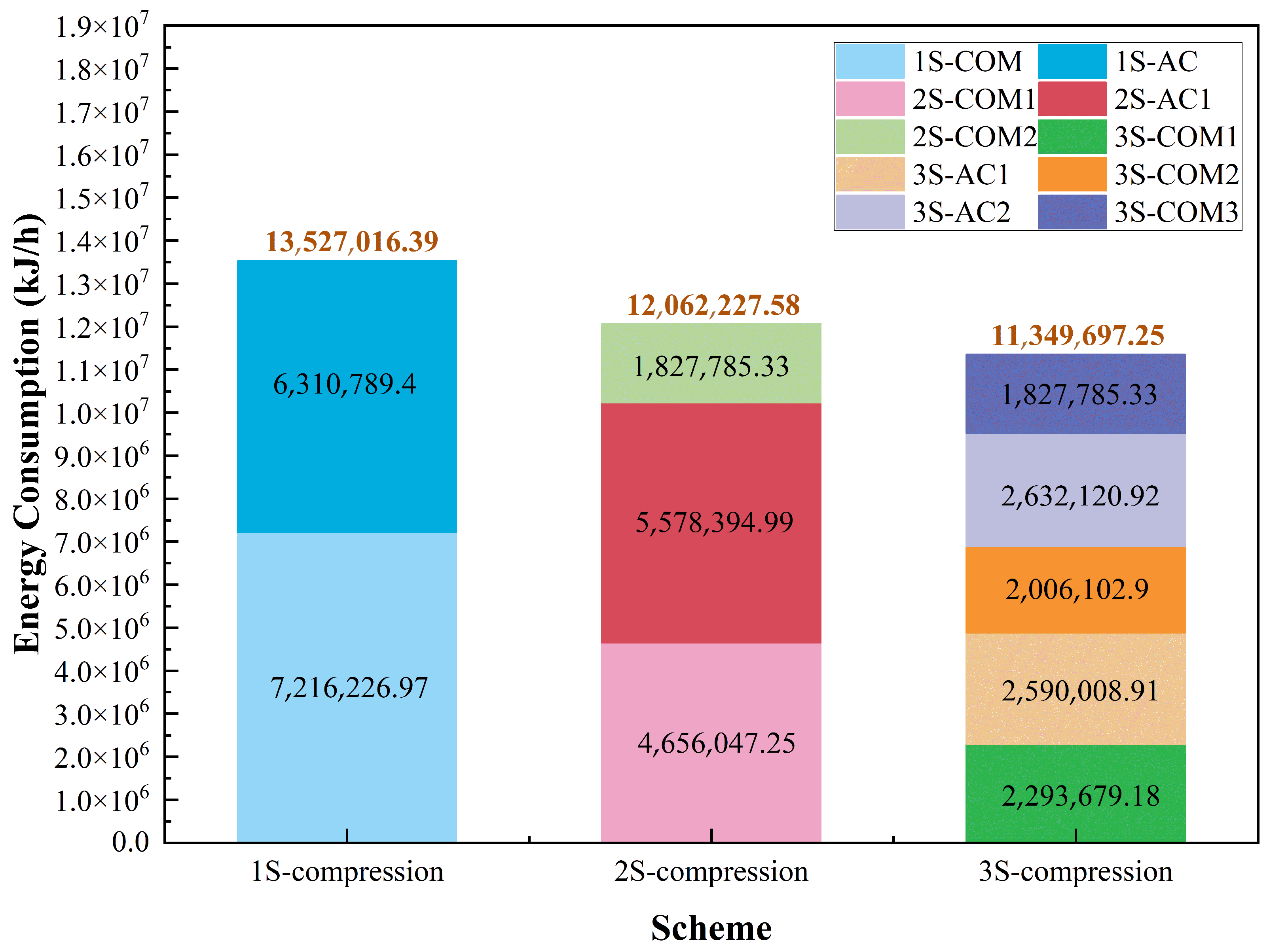

- (1)

- Results of energy consumption

- (3)

- Construction costs

- (3)

- Comprehensive costs

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, J.; Wang, J.; Liu, M.; Sun, W.; Lan, Z. Scenario Simulations of China’s Natural Gas Consumption under the Dual-Carbon Target. Energy 2022, 252, 124106. [Google Scholar] [CrossRef]

- Zhao, X.-G.; Zhu, J. Industrial Restructuring, Energy Consumption and Economic Growth: Evidence from China. J. Clean. Prod. 2022, 335, 130242. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, G.; Li, Z.; Xu, W.; Zhu, J.; He, L.; Xiong, Z.; Qiao, X. Retrieving the Displacements of the Hutubi (China) Underground Gas Storage during 2003–2020 from Multi-Track InSAR. Remote Sens. Environ. 2022, 268, 112768. [Google Scholar] [CrossRef]

- Haske, B.; Rudolph, T.; Bernsdorf, B. Sustainability in Energy Storages-How Modern Geoscience Concepts Can Improve Underground Storage Monitoring. In Proceedings of the 2nd Geoscience & Engineering in Energy Transition Conference, Online, 23–25 November 2021; European Association of Geoscientists & Engineers: Utrecht, the Netherlands, 2021; Volume 2021, pp. 1–4. [Google Scholar]

- Qiao, Y.-K.; Peng, F.-L.; Sabri, S.; Rajabifard, A. Socio-Environmental Costs of Underground Space Use for Urban Sustainability. Sustain. Cities Soc. 2019, 51, 101757. [Google Scholar] [CrossRef]

- Menéndez, J.; Ordóñez, A.; Álvarez, R.; Loredo, J. Energy from Closed Mines: Underground Energy Storage and Geothermal Applications. Renew. Sustain. Energy Rev. 2019, 108, 498–512. [Google Scholar] [CrossRef]

- Schultz, R.A.; Heinemann, N.; Horváth, B.; Wickens, J.; Miocic, J.M.; Babarinde, O.O.; Cao, W.; Capuano, P.; Dewers, T.A.; Dusseault, M.; et al. An Overview of Underground Energy-Related Product Storage and Sequestration. In Enabling Secure Subsurface Storage in Future Energy Systems; Miocic, J.M., Heinemann, N., Edlmann, K., Alcalde, J., Schultz, R.A., Eds.; Geological Society of London: Bath, UK, 2023; pp. 15–35. ISBN 978-1-78620-576-6. [Google Scholar]

- Liu, Y.; Ba, X.; Wang, N.; Cheng, T.; Wen, Y. The Current Status and Optimization Recommendations of Surface Engineering Technologies for Gas Storage Facilities in China. Pet. New Energy 2021, 33, 19–26. [Google Scholar]

- Tarkowski, R. Underground Hydrogen Storage: Characteristics and Prospects. Renew. Sustain. Energy Rev. 2019, 105, 86–94. [Google Scholar] [CrossRef]

- Al-Shafi, M.; Massarweh, O.; Abushaikha, A.S.; Bicer, Y. A Review on Underground Gas Storage Systems: Natural Gas, Hydrogen and Carbon Sequestration. Energy Rep. 2023, 9, 6251–6266. [Google Scholar] [CrossRef]

- Iwaszczuk, N.; Zapukhliak, I.; Iwaszczuk, A.; Dzoba, O.; Romashko, O. Underground Gas Storage Facilities in Ukraine: Current State and Future Prospects. Energies 2022, 15, 6604. [Google Scholar] [CrossRef]

- Vo Thanh, H.; Safaei-Farouji, M.; Wei, N.; Band, S.S.; Mosavi, A. Knowledge-Based Rigorous Machine Learning Techniques to Predict the Deliverability of Underground Natural Gas Storage Sites for Contributing to Sustainable Development Goals. Energy Rep. 2022, 8, 7643–7656. [Google Scholar] [CrossRef]

- Liu, H.; Yang, C.; Liu, J.; Hou, Z.; Xie, Y.; Shi, X. An Overview of Underground Energy Storage in Porous Media and Development in China. Gas Sci. Eng. 2023, 117, 205079. [Google Scholar] [CrossRef]

- Tong, G.; Guiqiang, L.; Jinxiu, W.; Ping, W.; Dandan, S.; Shan, G.; Pai, L.; Qiang, W. Research on Energy Saving and Consumption Reduction Technology of Underground Gas Storage Compressor. J. Phys. Conf. Ser. 2019, 1187, 032059. [Google Scholar] [CrossRef]

- Chen, Q.; Zuo, L.; Wu, C.; Li, Y.; Hua, K.; Mehrtash, M.; Cao, Y. Optimization of Compressor Standby Schemes for Gas Transmission Pipeline Systems Based on Gas Delivery Reliability. Reliab. Eng. Syst. Saf. 2022, 221, 108351. [Google Scholar] [CrossRef]

- Li, Z.; Li, C.; Jia, W.; Chen, Y.; Zhang, C.; Xiao, H.; Pu, Z. Co-Optimization Method for Injection Strategy of Underground Natural Gas Storage Integrating Aboveground and Underground Parts. Gas Sci. Eng. 2024, 128, 205376. [Google Scholar] [CrossRef]

- Jokar, S.M.; Parvasi, P. Compressed, Liquefied, and Adsorbed Natural Gas Processes Simulation and Modeling. In Advances Natural Gas: Formation, Processing, and Applications. Volume 8: Natural Gas Process Modelling and Simulation; Elsevier: Amsterdam, The Netherlands, 2024; pp. 529–553. [Google Scholar]

- Hasan, M.H.; Hassan, Q.A.; Amit, S.K.; Amin, R. ASPEN-HYSYS Simulation of Natural Gas Processing Plant & Analysis of Different Operating Parameters. In Proceedings of the International Conference on Materials, Electronics & Information Engineering, ICMEIE-2015, Rajshahi, Bangladesh, 27–28 February 2015. [Google Scholar] [CrossRef]

- Ansari, N.; Ayatollahi, S.; Riazi, M. Underground Natural Gas Storage in a Low Quality Gas Reservoir-Produced Gas Quality Control by Rate Optimization. In Proceedings of the 79th EAGE Conference and Exhibition 2017, Paris, France, 12 June 2017. [Google Scholar]

- Szablowski, L.; Krawczyk, P.; Badyda, K.; Karellas, S.; Kakaras, E.; Bujalski, W. Energy and Exergy Analysis of Adiabatic Compressed Air Energy Storage System. Energy 2017, 138, 12–18. [Google Scholar] [CrossRef]

- Krawczyk, P.; Szabłowski, Ł.; Karellas, S.; Kakaras, E.; Badyda, K. Comparative Thermodynamic Analysis of Compressed Air and Liquid Air Energy Storage Systems. Energy 2018, 142, 46–54. [Google Scholar] [CrossRef]

- Mikołajczak, A.; Krawczyk, P.; Kurkus-Gruszecka, M.; Badyda, K. Analysis of the Liquid Natural Gas Energy Storage Basing on the Mathematical Model. Energy Procedia 2019, 159, 231–236. [Google Scholar] [CrossRef]

- Alnili, F.N.H. Natural Gas Processing for Removal of Sour Gases and Their Storage for Production of LNG and Its Gasification. Ph.D. Thesis, Curtin University, Bentley, Australia, 2020. [Google Scholar]

- Zhou, J.; Qin, C.; Peng, J.; Fang, S.; Hu, C.; Liang, G. Multiobjective Operation Optimization of Depleted Gas Storage Based on a Reference Vector–Guided Evolutionary Algorithm. J. Energy Eng. 2024, 150, 04023055. [Google Scholar] [CrossRef]

- Zhou, J.; Fu, T.; Wu, K.; Zhao, Y.; Feng, L. Optimization Design of Multi-Gathering Mode for the Surface System in Coalbed Methane Field. Petroleum 2023, 9, 237–247. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, C.; Zuo, L.; Mehrtash, M.; Wang, Y.; Bu, Y.; Sadiq, R.; Cao, Y. Multi-Objective Transient Peak Shaving Optimization of a Gas Pipeline System under Demand Uncertainty. Comput. Chem. Eng. 2021, 147, 107260. [Google Scholar] [CrossRef]

- Hao, Y.; He, Q.; Fu, H.; Du, D.; Liu, W. Thermal Parameter Optimization Design of an Energy Storage System with CO2 as Working Fluid. Energy 2021, 230, 120688. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, Y.; Fu, T.; Zhou, X.; Liang, G. Dimension Optimization for Underground Natural Gas Storage Pipeline Network Coupling Injection and Production Conditions. Energy 2022, 256, 124651. [Google Scholar] [CrossRef]

- Pan, J.; Li, Y.; Cao, Q.; Han, B.; Wang, J.; Li, R. Simulation and optimization of natural gas liquefaction process based on two-stage throttling refrigeration cycle. Nat. Gas Ind. 2024, 44, 111–121. [Google Scholar]

- Qiao, W.; Fu, Z.; Du, M.; Nan, W.; Liu, E. Seasonal Peak Load Prediction of Underground Gas Storage Using a Novel Two-Stage Model Combining Improved Complete Ensemble Empirical Mode Decomposition and Long Short-Term Memory with a Sparrow Search Algorithm. Energy 2023, 274, 127376. [Google Scholar] [CrossRef]

- Vo Thanh, H.; Zamanyad, A.; Safaei-Farouji, M.; Ashraf, U.; Hemeng, Z. Application of Hybrid Artificial Intelligent Models to Predict Deliverability of Underground Natural Gas Storage Sites. Renew. Energy 2022, 200, 169–184. [Google Scholar] [CrossRef]

- Ali, A. Data-Driven Based Machine Learning Models for Predicting the Deliverability of Underground Natural Gas Storage in Salt Caverns. Energy 2021, 229, 120648. [Google Scholar] [CrossRef]

- Jelušič, P.; Kravanja, S.; Žlender, B. Optimal Cost and Design of an Underground Gas Storage by ANFIS. J. Nat. Gas Sci. Eng. 2019, 61, 142–157. [Google Scholar] [CrossRef]

- Wang, J.; An, G.; Shan, B.; Wang, W.; Jia, J.; Wang, T.; Zheng, X. Parameter Optimization of Solution Mining under Nitrogen for the Construction of a Gas Storage Salt Cavern. J. Nat. Gas Sci. Eng. 2021, 91, 103954. [Google Scholar] [CrossRef]

- Curin, N.; Kettler, M.; Kleisinger-Yu, X.; Komaric, V.; Krabichler, T.; Teichmann, J.; Wutte, H. A Deep Learning Model for Gas Storage Optimization. Decis. Econ. Financ. 2021, 44, 1021–1037. [Google Scholar] [CrossRef]

- Zhou, J.; Peng, J.; Liang, G.; Sun, J. Optimization of Injection-Withdrawal Schedules for Underground Gas Storage in a Multi-Block Depleted Gas Reservoir Considering Operation Stability. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–16. [Google Scholar] [CrossRef]

- Joseph, M.; Fu, P.; Sherman, C.; Wu, H.; Huang, J.; Fu, W. An Investigation of Candidate Mechanisms for Hydraulic Fracture Swarming through High-Fidelity Numerical Modeling. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2022; p. D021S004R003. [Google Scholar]

- Lin, M.; Yan, G.; Liu, T.; Wu, X.; Yu, P. Simulation and Optimization of Surface Gas Injection Systems for Underground Gas Storage. ACS Omega 2023, 8, 32099–32107. [Google Scholar] [CrossRef]

- Qi, D. Feasibility and Parameter Optimization Study on the Reconstruction of Gas Storage. Master’s Thesis, China University of Petroleum, Beijing, China, 2023. [Google Scholar]

| Component | Concentrations (mol%) |

|---|---|

| Methane | 93.7959236 |

| Ethane | 3.2997936 |

| Propane | 0.8784905 |

| i-Butane | 0.1659304 |

| n-Butane | 0.2431911 |

| i-Pentane | 0.10178 |

| n-Pentane | 0.0805633 |

| n-Hexane | 0.0620488 |

| n-Heptane | 0.0360283 |

| Carbon dioxide | 0.8410611 |

| Nitrogen | 0.4951892 |

| Total | 100 |

| Parameter | Value |

|---|---|

| 1-1 pressure | 2MPa |

| 1-1 temperature | 30 °C |

| 1-1 mole flow rate | 1158 kmol/h |

| 1-1 components and concentrations | Same as the injected natural gas in Table 1 |

| 1S-COM adiabatic efficiency | 75% |

| 1-2 pressure | 11 MPa |

| 1-2 temperature | 199.3 °C |

| 1-3 temperature | 80 °C |

| Parameter | Value |

|---|---|

| 2-1 pressure | 2 MPa |

| 2-1 temperature | 30 °C |

| 2-1 mole flow rate | 1158 kmol/h |

| 2-1 components and concentrations | Same as the injected natural gas in Table 1 |

| 2S-COM1 adiabatic efficiency | 80% |

| 2-2 pressure | 6.45 MPa |

| 2-2 temperature | 143.3 °C |

| 2-3 temperature | 32 °C |

| 2S-COM2 adiabatic efficiency | 80% |

| 2-4 pressure | 11 MPa |

| 2-4 temperature | 80 °C |

| Parameter | Value |

|---|---|

| 3-1 pressure | 2 MPa |

| 3-1 temperature | 30 °C |

| 3-1 mole flow rate | 1158 kmol/h |

| 3-1 components and concentrations | Same as the injected natural gas in Table 1 |

| 3S-COM1 adiabatic efficiency | 80% |

| 3-2 pressure | 3.68 MPa |

| 3-2 temperature | 84.25 °C |

| 3-3 temperature | 32 °C |

| 3S-COM2 adiabatic efficiency | 80% |

| 3-4 pressure | 6.455 MPa |

| 3-4 temperature | 82.63 °C |

| 3-5 temperature | 32 °C |

| 3S-COM3 adiabatic efficiency | 75% |

| 3-6 pressure | 11 MPa |

| 3-6 temperature | 80 °C |

| Equipment | Equipment Costs | Accessory Cost | Installation and Transportation Costs | Total Costs |

|---|---|---|---|---|

| Compressor | USD 136,841.22 | USD 13,684.14 | USD 20,526.20 | USD 171,051.56 |

| Air Cooler | USD 50,889.87 | USD 6932.84 | USD 11,108.43 | USD 68,931.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Yu, Z.; Li, Y.; Wang, Z.; Si, M. Optimization of a Typical Gas Injection Pressurization Process in Underground Gas Storage. Sustainability 2024, 16, 8902. https://doi.org/10.3390/su16208902

Chen S, Yu Z, Li Y, Wang Z, Si M. Optimization of a Typical Gas Injection Pressurization Process in Underground Gas Storage. Sustainability. 2024; 16(20):8902. https://doi.org/10.3390/su16208902

Chicago/Turabian StyleChen, Shuangqing, Ze Yu, Yuchun Li, Zhihua Wang, and Minglin Si. 2024. "Optimization of a Typical Gas Injection Pressurization Process in Underground Gas Storage" Sustainability 16, no. 20: 8902. https://doi.org/10.3390/su16208902

APA StyleChen, S., Yu, Z., Li, Y., Wang, Z., & Si, M. (2024). Optimization of a Typical Gas Injection Pressurization Process in Underground Gas Storage. Sustainability, 16(20), 8902. https://doi.org/10.3390/su16208902