Abstract

Plastic film mulching technology occupies a prominent position in China’s agricultural production and plays an important role in improving crop yields, which can increase farmers’ income and ensure national food security. As the current residual film recycling mechanism is incomplete, the accumulation of residual film in the soil has gradually increased, and the problem of residual film pollution has posed a serious threat to agricultural production and the natural environment. Ridge mulching cultivation is one of the main planting patterns for grain and oil crops, such as peanuts, potatoes, and maize, in China. In this paper, the planting patterns, mulching conditions, characteristics, and distribution of residual film of the typical ridge mulching crops, such as peanut and potato, were analyzed. The merits and demerits of various kinds of residual film recycling machines and the application status and operation quality of peanut and potato residual film recycling machines are summarized. Problems and suggestions for the mechanized recycling of residual film were raised. This study may provide ideas for the development of residual film mechanization recycling of ridge mulching crops. The aim of this study is to propose practical solutions by analyzing the current status and existing problems of mechanized residual film recovery in order to reduce residual film pollution, protect the environment, and achieve sustainable agricultural development.

1. Introduction

In the late 1970s, plastic film mulching technology was introduced in China from Japan and has been widely promoted and applied throughout the country. It is an effective method to improve the yield and quality of crop [1]. This technology creates a micro growth environment by laying a film on the surface of the farmland to provide better growing conditions for crops. Plastic film can prevent surface water evaporation, effectively maintain soil moisture, provide sufficient water for crop growth [2,3,4], and raise soil temperatures to promote the early growth and development of crops. To some extent, it can also isolate the transmission routes of pests and diseases and reduce the degree of crop damage [5,6]. China has become the country that uses the most amount of plastic film and covers the largest area in the world. In 2022, the quantity of plastic film used in China has reached 1.342 million tons, accounting for about 75% of the global total, and the crop coverage area was about 17.33 million hectares.

The negative impact of residual plastic film on soil, crops, and the ecological environment is also increasing with the large-scale application of plastic film. The average quantity of residual film in China’s farmland is as high as 67.5 kg/hm2, and the threshold of 75 kg/hm2 has been exceeded in some areas because of a lack of awareness and means of recycling residual film and the high cost of recycling [7]. Residual plastic film can damage the soil structure of the cultivated layer in farmland [8,9], cause soil compaction, reduce the quality of agricultural machinery operations, affect seed germination and nutrient absorption, and ultimately lead to reduced crop yields [10,11,12,13,14,15,16,17,18]. The “white pollution” caused by residual plastic film has become an issue that cannot be ignored.

China has formulated relevant policies and measures for residual film pollution control. From the analysis of China’s national conditions, the plastic film made of polyethylene material will continue to be used for a certain period, so it is necessary to increase the efforts of residual film recycling. At present, there are usually two ways of residual film recycling, namely, manual picking and mechanized recycling [19]. The manual picking of residual film is inefficient and costly, while mechanized recycling can make up for the shortcomings of manual picking, which is an effective method of addressing the residual film pollution.

In recent years, China has developed various types of residual film recycling machines, which have played a significant role in reducing the quantity of residual agricultural film and protecting the ecological environment. However, its universality is poor, and it does not perform well in the field of the residual film recycling of ridge mulching crops, such as peanuts and potatoes [20]. In this paper, peanuts and potatoes were taken as examples to analyze the planting patterns, residual film characteristics, and residual film pollution of ridge crops covered with plastic film. The current research status of residual film recycling machinery suitable for ridge crops, as well as the status and operational performance of residual film recycling machinery for peanuts and potatoes, was summarized. The problems existing in the mechanized recycling of residual film in ridge crops were pointed out, and development suggestions were proposed to solve the problem of residual film pollution and achieve sustainable agricultural development.

2. Analysis of Planting Patterns of Typical Ridge and Mulching Crops

The main ridge mulching crops in China include peanuts, potatoes, maize, etc., with different planting patterns in different regions. Potato is the fourth largest staple crop after maize, wheat, and rice and has significant strategic importance in ensuring national food security. In recent years, China’s potato planting area has fluctuated up and down to 4.7 million hectares, accounting for about 25% of the world’s potato planting area, with a production of about 90 million tons, ranking first in the world. China has become the largest country in potato production and consumption [21]. Peanuts are an important oil and cash crop in China, which plays a significant role in securing the supply of edible vegetable oil. The peanut planting area in 2022 is 4.68 million hectares, which is second only to India and accounts for around 14% of the global planting area. According to statistics, the peanut mulching area accounts for about 27% of the whole peanut planting area in China, with different provinces having varying proportions. In Shandong Province, the peanut mulching planting area accounts for as much as 70% [22].

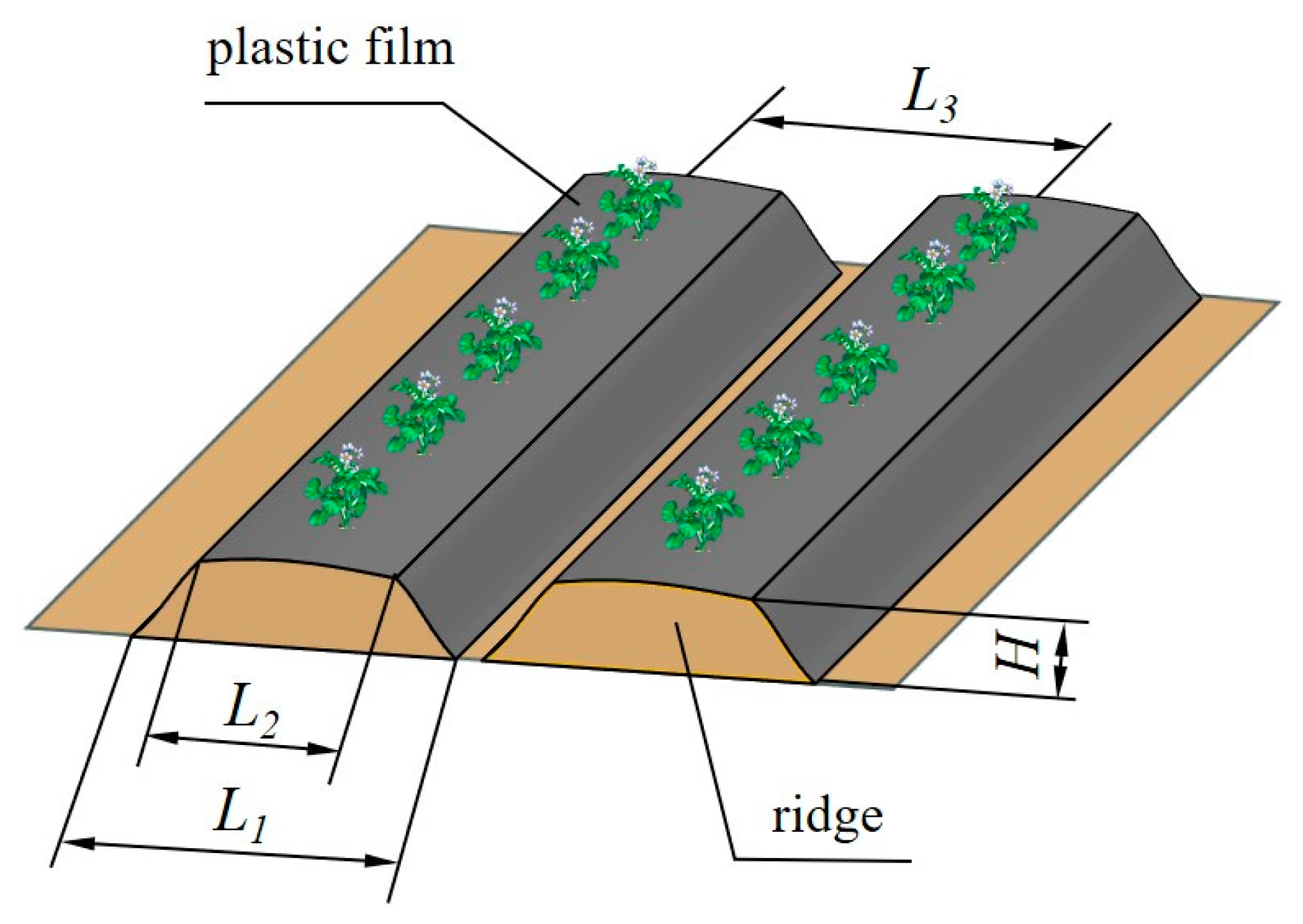

2.1. Analysis of Ridge and Mulching Planting Patterns of Potato

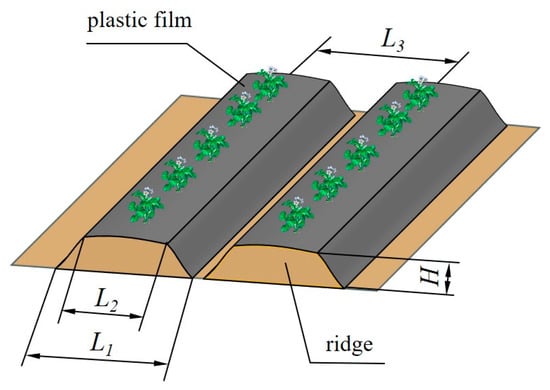

There are two modes of potato ridge planting, as follows: one row per ridge and two rows per ridge. As shown in Figure 1, there is a planting pattern of one row per ridge in the north of China. The ridges are like an irregular trapezoid. The ridge spacing L3 is about 900 mm, the top width of the ridge L2 is about 400 mm, the bottom width of the ridge L1 is about 700 mm, the height of the ridge H is about 240 mm, and the circumference of the ridge is about 900 mm [23]. For two-row planting in a large ridge, the top width of the ridge L2 is 310–400 mm, the bottom width of the ridge L1 is 610–810 mm, the height of the ridge H is 150–200 mm, the spacing of the ridge L3 is 800–900 mm, and the width of the plastic film used is 700 mm [24].

Figure 1.

Schematic diagram of one row per ridge in potato planting.

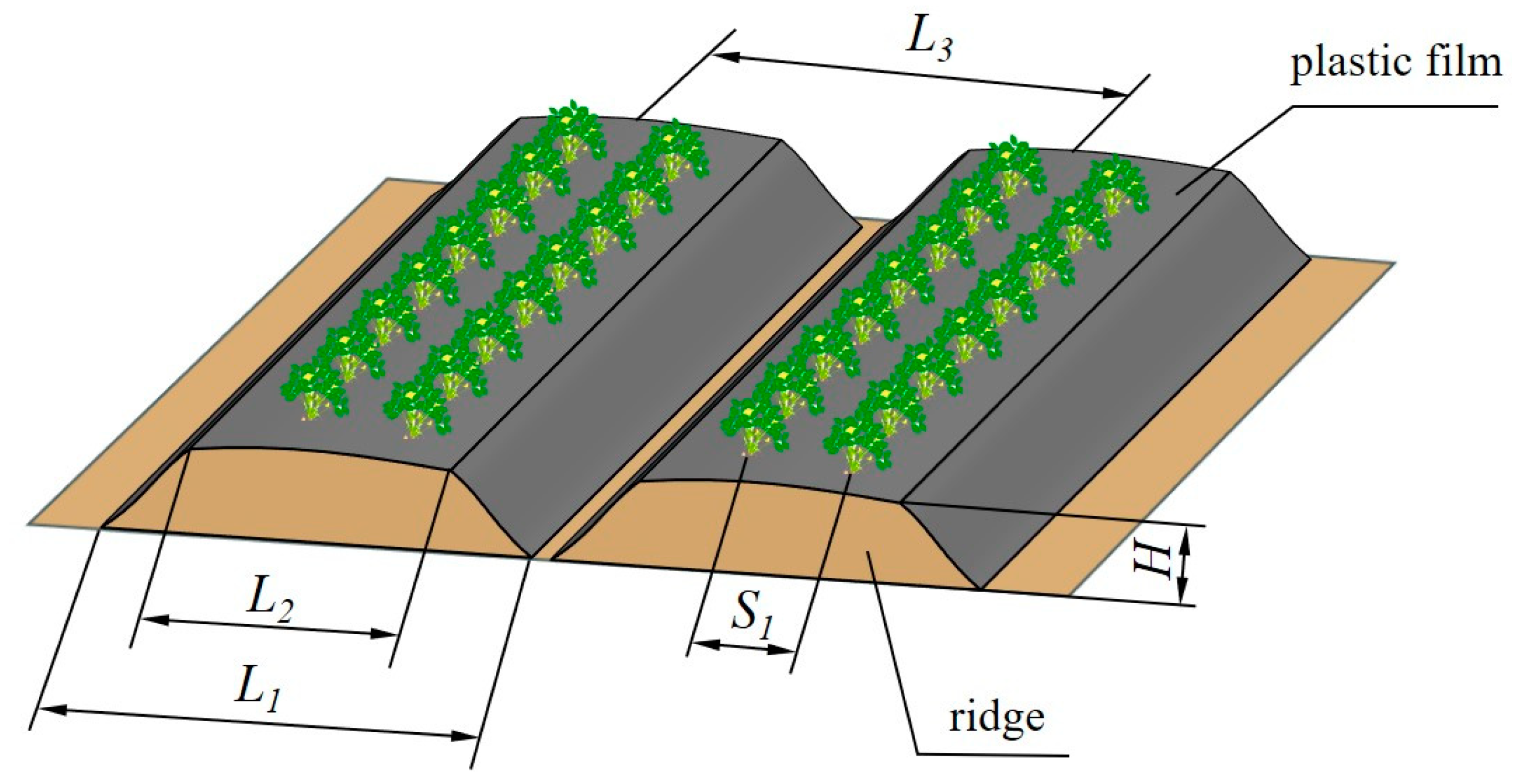

2.2. Analysis of Ridge and Mulching Planting Patterns of Peanuts

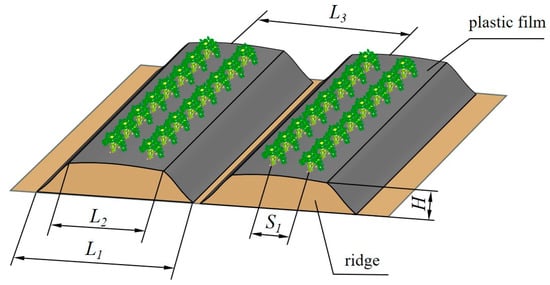

There are usually two modes of peanut ridge planting, as follows: one row per ridge and two rows per ridge. Four rows with two ridges and eight rows with four ridges are also used in farmland with larger areas. For example, as shown in Figure 2, in the two-row per ridge planting pattern in Hebei Province, the ridge spacing L3 is 850~900 mm, the top width of the ridge L2 is 550~600 mm, the bottom width of the ridge L1 is about 800~850 mm, the narrow row spacing on the ridge S1 is 250~300 mm, the height of the ridge H is 100~150 mm. As for Shandong Province, the ridge spacing L3 is 800~850 mm, the top width of the ridge L2 is 500~550 mm, the bottom width of the ridge L1 is about 750~800 mm, the narrow row spacing on the ridge S1 is 300 mm, and the height of the ridge H is 100~150 mm.

Figure 2.

Schematic diagram of two rows per ridge in peanut planting.

3. Characteristics and Distribution of Residual Film of Typical Ridge Mulching Crops

3.1. Morphological Characteristics of Residual Film

The characteristics of residual film from crops grown on flat land are relatively simple. Taking cotton as an example, since the soil is not dug during cotton harvesting, the impact on the plastic film is relatively small. The plastic film is in a long strip shape, and the land is relatively flat, which makes the film easy to be mechanically recycled [25].

Among ridge mulching crops, the residual film morphologies of peanuts and potatoes are the most complex. Because the fruit of ridge crops such as maize is on the stem, there is no need to dig during harvesting, so the plastic film is barely damaged by harvest machinery. It is all on the surface of farmland and relatively intact. However, the fruit of peanuts and potatoes is grown in the soil, and the soil is dug during harvesting, which can cause significant damage to the plastic film. The shape and distribution of the plastic film are complex, which poses higher requirements for residual film recycling.

The residual film of peanuts and potatoes is usually collected after harvesting. At this time, the residual film will undergo a certain degree of aging and be easily damaged, and the degree of damage is affected by different mechanized harvesting methods. When peanut plants are clamped and lifted, the plastic film is barely damaged and in a relatively complete long strip shape, as shown in Figure 3. However, the residual films of peanuts and potatoes are similar when they are harvested through digging using a conveying chain. They are short and small and wrapped around the stems, as shown in Figure 4.

Figure 3.

Morphology of residual film and surface after peanut harvest.

Figure 4.

Morphology of residual film and surface after potato harvest.

The farmland is uneven after harvesting because of the ridge. Part of the residual film remains in the ditch between two ridges, while another part is distributed on the surface of the ridge and mixed with the stems. There are many broken stems, and some residual film may be buried in the overturned soil. All the facts above will make it more difficult for the mechanized recycling of residual film [26].

3.2. Quantity and Distribution Characteristics of Residual Film

Researchers have fully studied and analyzed the quantity and spatial distribution of the residual film in the farmland of Shandong, Henan, Hebei, Anhui, and Gansu Provinces from the perspectives of regions, crop types, mulch years, recycling methods, film thickness, soil texture, and other aspects [11,27,28,29,30,31,32,33,34], indicating that the morphology and amount of residual film are comprehensively affected by the abovementioned factors.

Table 1 shows the quantity of residual plastic film in the major planting areas of peanuts and potatoes in the last ten years. Although the warning line of 75 kg·hm−2 has not been reached, the quantity of residual film is still steadily increasing with each year of film mulching, which needs to garner adequate attention.

Table 1.

Quantity of residual peanut and potato plastic film in various regions.

The residual film can be categorized into large-piece film (>2500 mm2), medium-piece film (400~2500 mm2), and small-piece film (<400 mm2) according to its size. Almost all of the film exists in the soil at a depth of 0–300 mm, and more than 90% is in the plow layer of 0~200 mm, with relatively little in the plow pan layer [31,32,33]. In the above mentioned regions in Table 1, the vertical distribution of residual films of different sizes in the farmland is also not the same, but the film shows a decreasing trend with increasing soil depth, and the deeper the soil is, the smaller the fragment of residual film is. The specific vertical distribution of residual film in the soil is shown in Table 2; the range of 0~100 mm is mainly composed of large-piece film, the range of 100~200 mm is mainly composed of medium- and small-piece film, and the range of 200~300 mm is mainly composed of small-piece film. The longer the film mulching years are, the higher the proportion of small- and medium-piece film in 200–300 mm soil layer will be, which makes residual film recycling more difficult in long-term mulching farmland.

Table 2.

Vertical distribution of residual film in the soil.

4. Application Status and Quality Analysis of Residual Film Recycling Machinery for Typical Ridge Mulching Crop

Due to the differences in thickness and strength in plastic film used between China and developed regions, such as Europe and America, there are significant differences in research directions in this field. Developed regions, such as Europe and America, mainly use thicker and stronger plastic film, which is not easily damaged by machinery during the recycling process. The residual film is almost intact and can be separated from the soil and recycled using its own pulling force. Therefore, the main recycling method abroad is rolling. The plastic film used in China has a relatively low thickness and strength and is fragile during the fruit harvest and mechanized recycling process. Therefore, China’s residual film recycling machines mainly use picking or digging methods for recycling. This research mainly focuses on key components, such as film lifting, film impurity separation, film detachment, and film collection [35,36].

The residual film recycling machines of China can be classified into different types according to the operating period and key film-collecting components. According to the operation period, it can be classified into the seedling stage, pre-sowing, post-harvest residual film recycling machine, and residual film recycling machine during fruit harvesting [37,38,39,40]. Residual film recycling after fruit harvesting will not affect crop quality and yield, which is currently the most widely used residual film recycling method [41]. According to the key components, there are telescopic rod tine types, elastic tine types, shovel stubble types, wheel tine types, drum types, tine chain types, rake-toothed types, etc. [42,43,44,45,46]. The residual film recycling machine during fruit harvesting has both fruit harvesting and residual film recycling functions and can complete fruit and residual film recycling in one operation.

4.1. Classification and Characteristics of Residual Film Recycling Machine for Typical Ridge Mulching Crop

There are two main ways to mechanically recycle residual film for ridge mulching crops. One is the post-harvest residual film recycling machine. Due to the complexity of residual film and surface conditions of farmland after harvesting, there are only rake-toothed type, shovel-chain type, toothed chain type, and shovel-sieve combined residual film recycling machines suitable for ridge mulching crops. Another one is the residual film recycling machine during fruit harvesting, which is currently mainly used for the recycling of potato residual film. The characteristics and work stages of various types of residual film recycling machines are shown in Table 3.

Table 3.

Characteristics of residual film recycling machine for ridge planting crops.

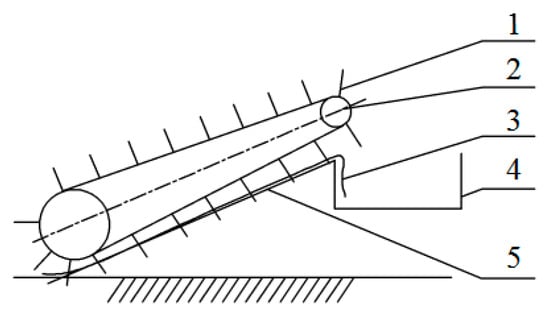

Figure 9.

Structure diagram of shovel–sieve residual film recycling machine: 1—frame; 2—conveyor chain; 3—digging shovel; 4—film roller.

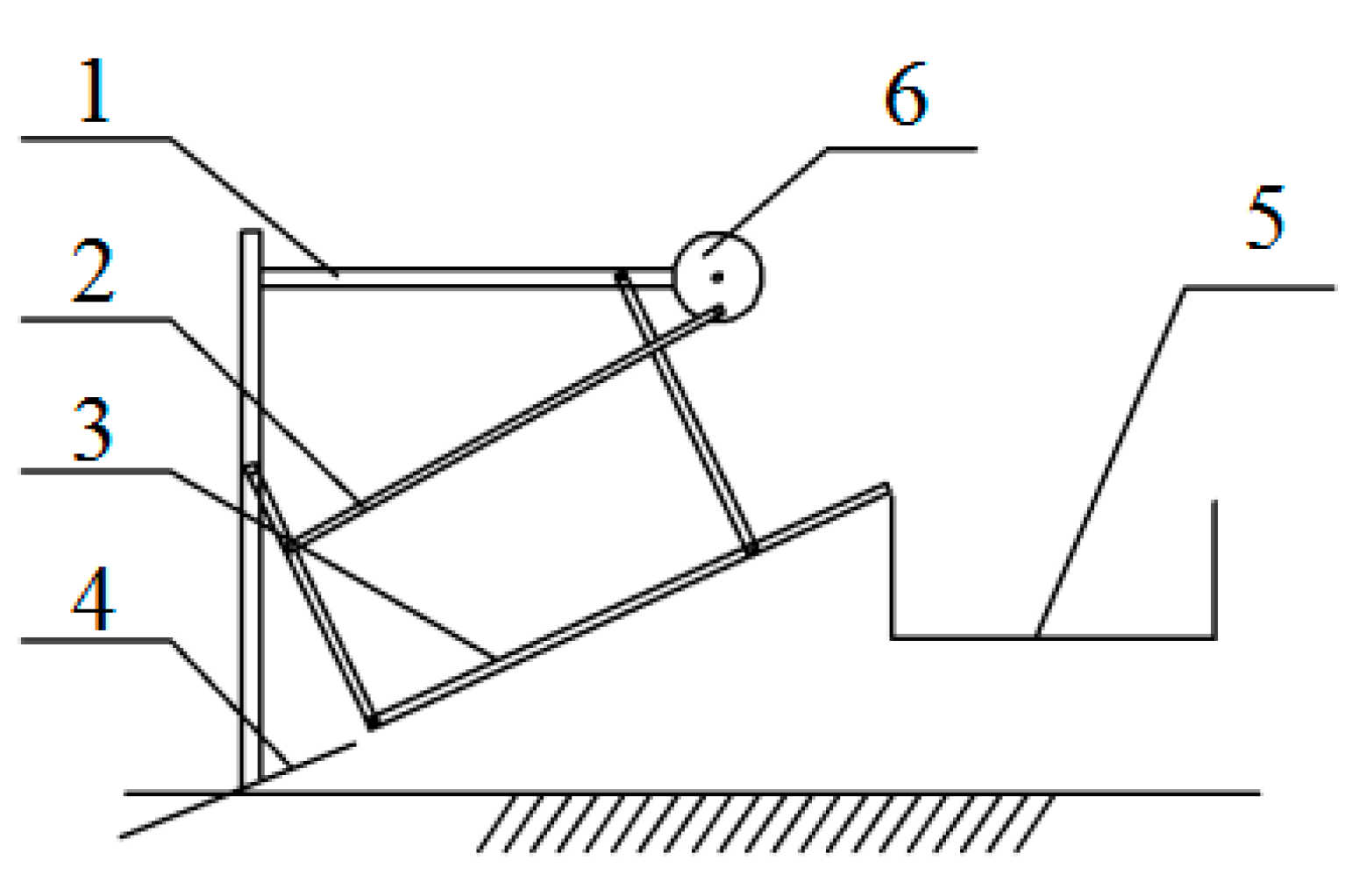

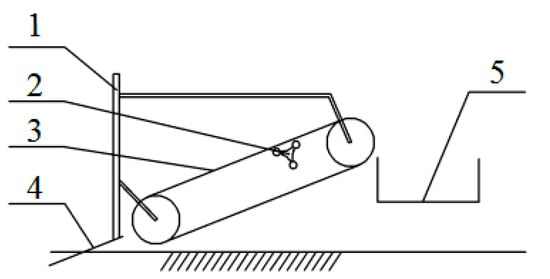

Figure 8.

Structure diagram of shovel–sieve residual film recycling machine: 1—frame; 2—connecting rod assembly; 3—sieve; 4—digging shovel; 5—film collection box; 6—eccentric wheel.

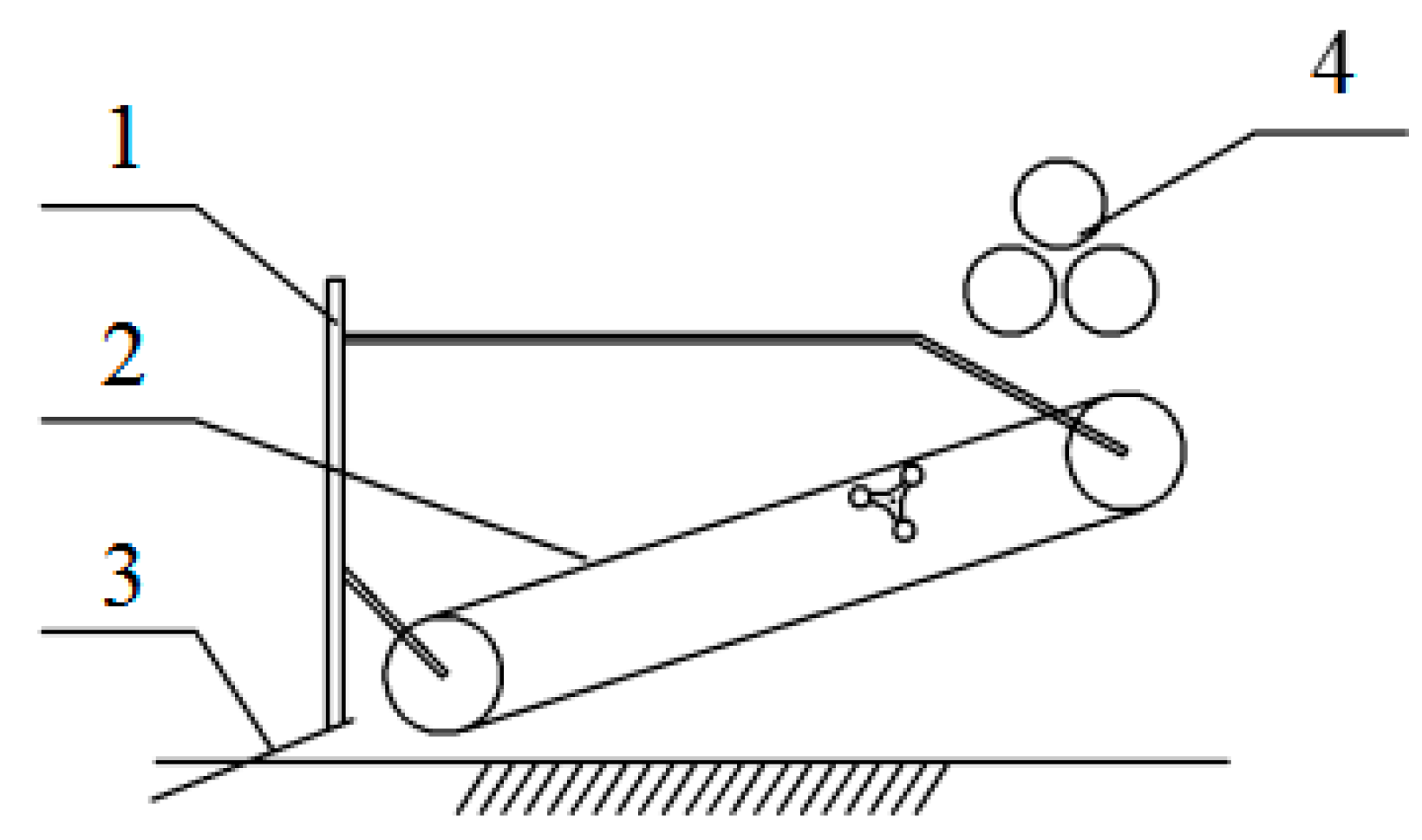

Figure 7.

Structure diagram of toothed chain residual film recycling machine: 1—film-picking teeth; 2—driving wheel; 3—residual film; 4—film collection box; 5—film support plates.

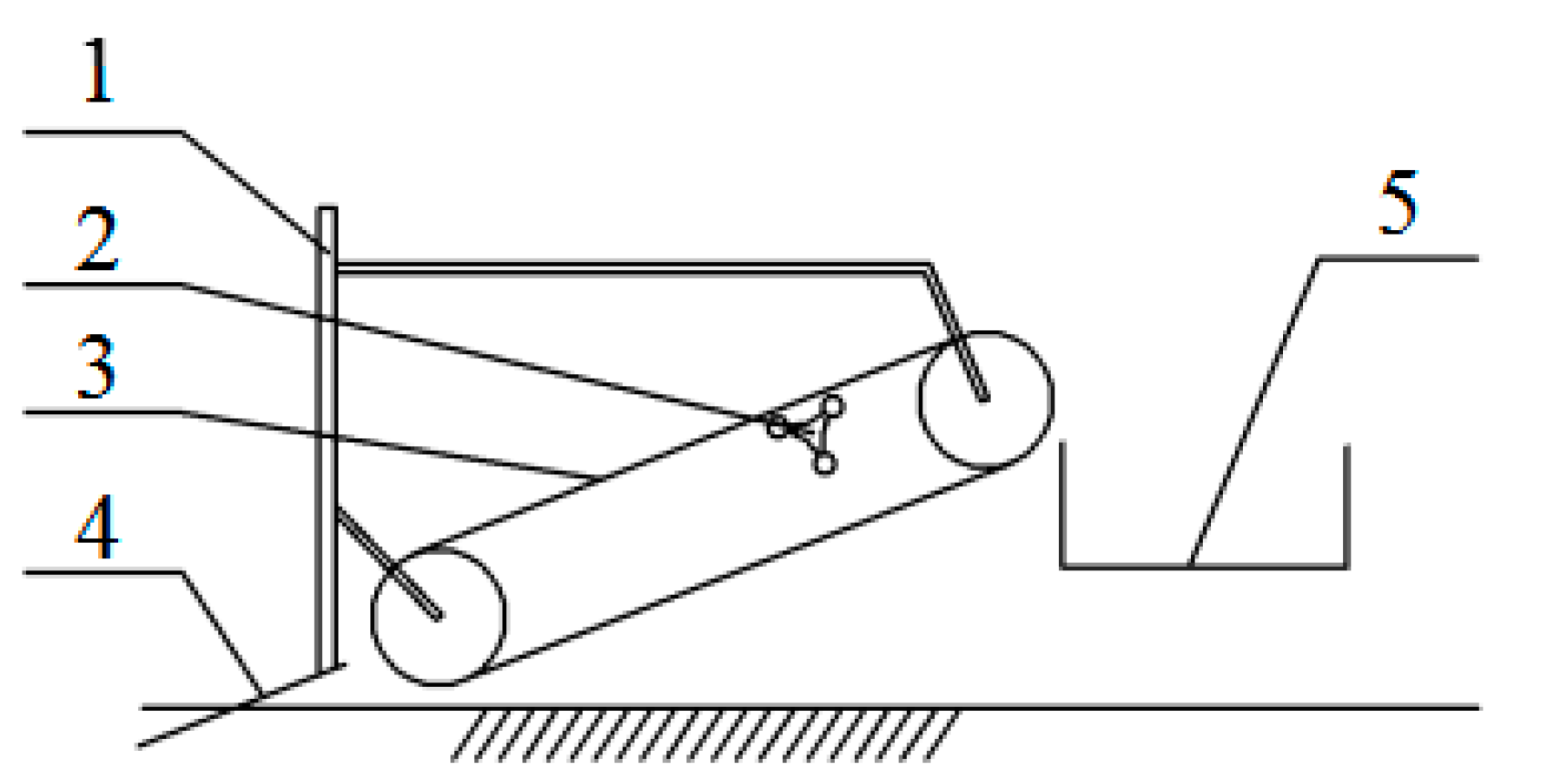

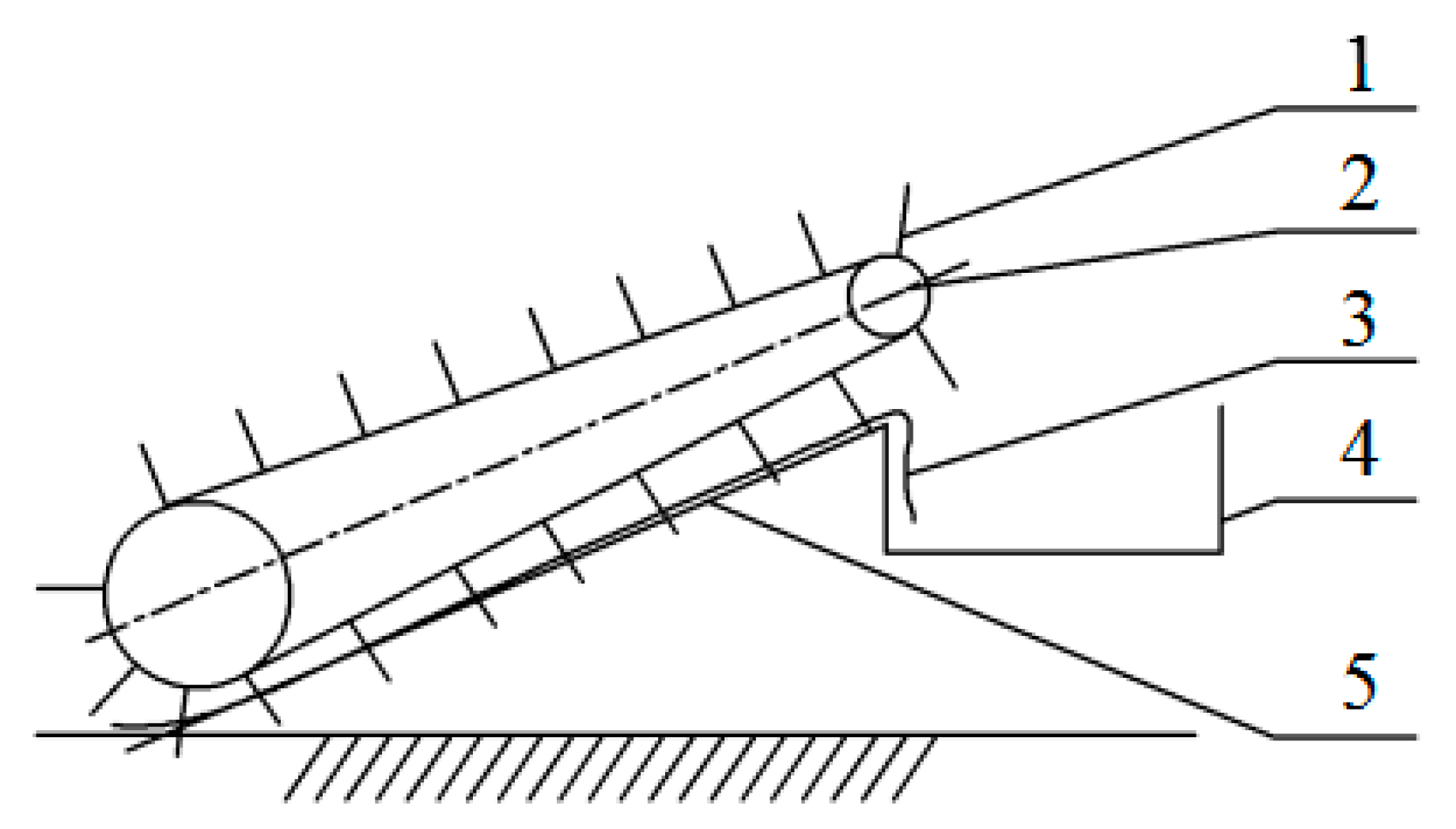

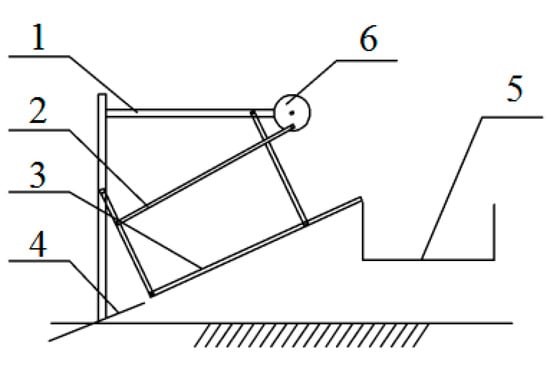

Figure 6.

Structure diagram of shovel-chain residual film recycling machine: 1—frame; 2—shake wheel; 3—convey chain; 4—digging shovel; 5—film collection box.

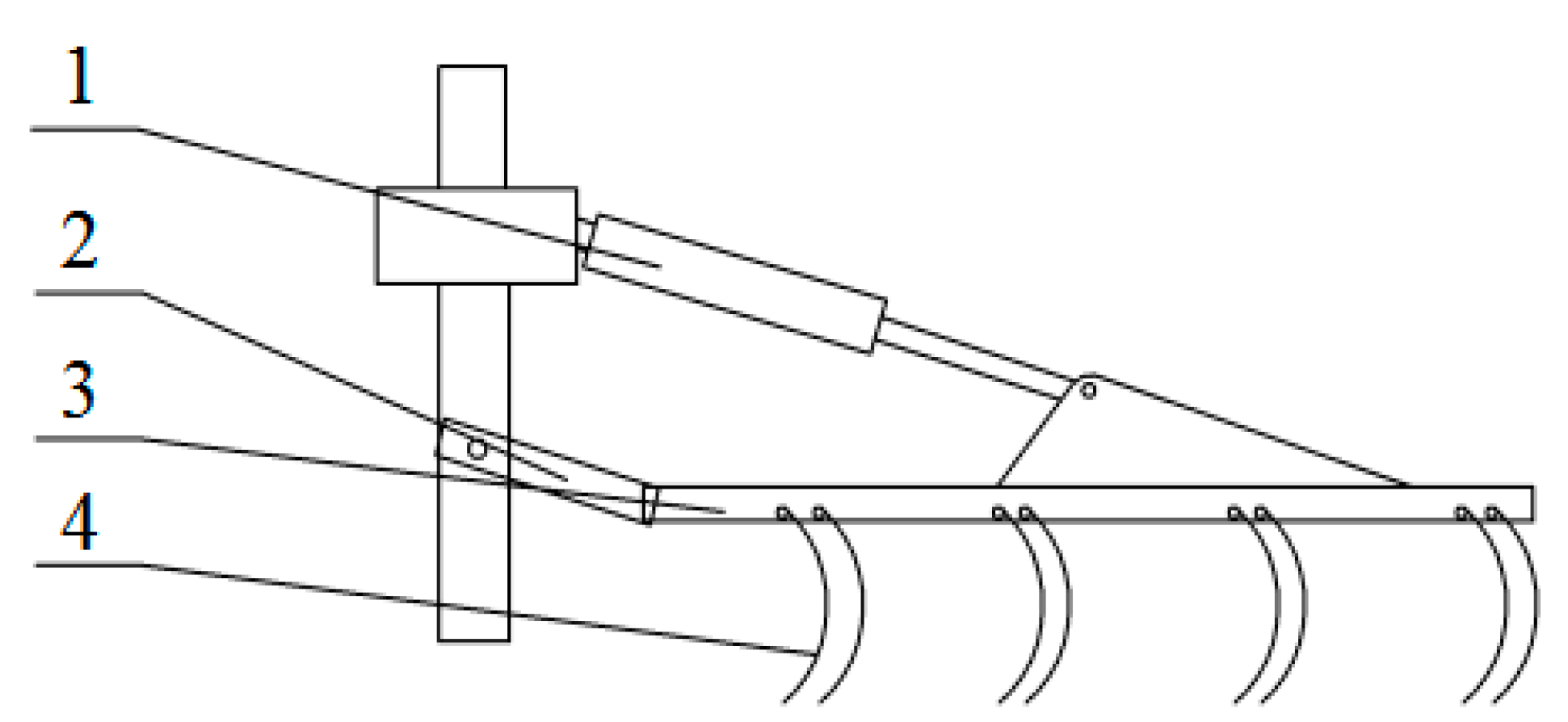

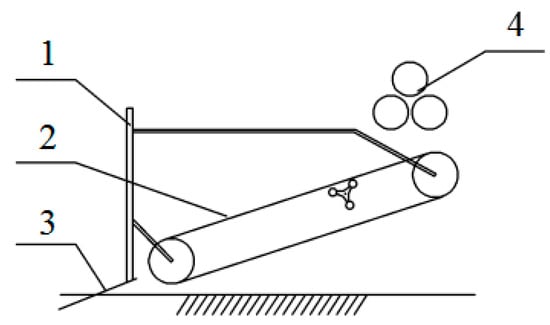

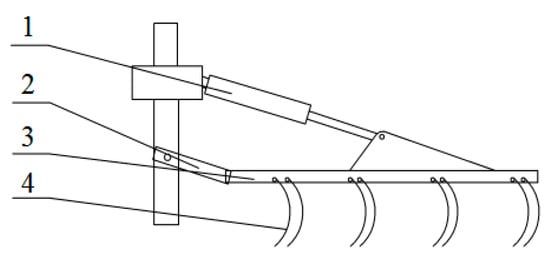

Figure 5.

Structure diagram of rake-toothed residual film recycling machine: 1—hydraulic lifting mechanism; 2—frame; 3—frame of rake tooth; 4—rake tooth.

4.2. Analysis of the Current Situation and Operational Quality of Residual Film Recycling Machine for Peanuts

There are three types of machinery commonly used for peanut residual film recycling at present: rake-tooth type, mesh chain type, and shovel screen type (see Table 4). The research institution is the Nanjing Agricultural Mechanization Research Institute of the Ministry of Agriculture and Rural Affairs of China.

Table 4.

Peanut residual film recycling machine.

Table 5 shows the actual operating parameters of the three types of machines mentioned above. According to the industry standard, “Retrieving machines for residual film-Operation quality” (NY/T 1227-2019) [53], the experimental results of the three types of peanut residual film recycling machines mentioned above are analyzed, as shown in Table 5. The netting rates of the three machines is are all above 90%, among which the mesh chain type residual film recycling machine has the highest rate, reaching 93.15%, which is much higher than the industry standard requirement. However, only the shovel -screen type residual film recycling machine has been tested for the film wrapping rate, and the test results do not meet the industry standard. The other two machines have not been tested for the film wrapping rate, so research on anti-film wrapping technology must be enhanced to reduce the film wrapping rate and improve the reliability of the machine.

Table 5.

Performance parameters of peanut residual film recycling machine.

4.3. Analysis of the Current Situation and Operational Quality of Residual Film Recycling Machine for Potatoes

There are three main methods for potato residual film recycling, as follows: the first one is manual residual film recovery after or during potato harvesting. Manual recovery during potato harvesting means that the operator sits on the potato digger to pick up and collect the residual film on the conveying chain. This method can remove the residual film in a timely manner, prevent film wrapping effectively, and avoid secondary recovery, but it is not safe for the operator, and the working conditions are poor. The second one is that the residual film is mechanized and recovered after the potato harvest. Since the morphological characteristics of residual film and debris on the field after potato harvest usually resemble the remains of the peanut harvest, the peanut residual film recycling machine can be used for recovery of potato residual film, but there are still some adaptability problems. The third is the integrated operation of potato digging and residual film recovery. Based on the potato digger, the mechanical recovery of the residual film is realized by adding a film impurity separation device, film rolling device, fan, film collecting device, etc. [54]. Potato digging and residual film recycling are carried out at the same time, without a secondary operation, which can greatly enhance operation efficiency and reduce labor costs. At present, this kind of machinery is still being researched. The problems of the machinery have been solved to some extent. There is still room for improvement in stem film separation, film impurity separation, and film wrapping [55,56]. The structure and technical characteristics of these types of combined machinery are shown in Table 6.

Table 6.

Potato harvesting and residual film collecting combined operation machine.

According to the industrial standard “Technical specification for quality evaluation for potato harvesters” (NY/T 648-2015) [63], the operation quality of the abovementioned six machines was analyzed. As shown in Table 7, both the residual film collection rate and the loss rate of each machine attained and exceeded the requirements set in the current industrial standards. The canvas belt combined operation machine for potato digging and plastic film collecting had the best effect, with a residual film collection rate of 92.1%. The damaged potato rate was implemented according to the standard of version 2002. Therefore, at that time, it met the requirements of the standard. Subsequently, it was necessary to optimize the material and structure to reduce the damaged potato rate to meet the technical indicators of the current standard.

Table 7.

Performance parameters of potato harvesting and residual film collecting combined operation machine.

5. Problems and Suggestions for the Mechanized Recovery of Plastic Film Residue from Ridge Planting and Film Mulching

5.1. Problems

- The plastic film is thin, easily broken, and hard to recycle.

The current thickness of the used plastic film is mostly around 0.008 mm to save costs and has a relatively low strength. It is already aged and damaged after months. After being harvested by machinery, the plastic film becomes more fragmented, which poses difficulties for mechanized recycling.

- Insufficient integration of agricultural machinery and agronomy and low adaptability of residual film recycling machine

As discussed in Section 2, the varieties of ridge crops are diverse, and the planting patterns are complex. The width of the ridge is different in different planting methods, and the width of the mulching film is also different. In addition, the degree of damage to the ridge and plastic film is determined by the method of fruit harvesting. The condition of residual film recycling operation is more complex. The residual film recycling machine cannot adapt to different soil conditions and planting patterns. Different types of residual film recycling machinery are suitable for different operation periods, while different crops have different stages of residual film recycling, some in the seedling stage, some after harvesting, and some before sowing. All these factors lead to low universality and scalability.

- The performance and reliability of the recycling machine needs to be improved.

At present, the most widely used is the rake-toothed recycling machine, which has a simple structure and low cost, but its performance is general. However, other types of residual film recycling machines, such as pneumatic and roller types, are only in the research stage and have not been widely applied due to their complex structure, low operational efficiency, high operating cost, and low recovery rate.

The ability to recycle small pieces of residual film and deep residual film is poor. The film impurity separation ability needs to be improved, and the film wrapping rate is high. For small pieces of residual film, the rake-toothed residual film collector is unable to hold them, the tooth chain residual film collector has difficulty picking them up, and the vibrating screen residual film collector leaks them during screen vibration. For the deep residual film, the operation depth of most residual film collectors is less than 100 mm, and they cannot reach the required recovery depth. Furthermore, the deep residual film is firmly attached to the soil and root system, rendering its detachment from impurities exceedingly challenging. Consequently, this leads to a low residual film net collected rate and a high impurity rate. Due to the complex structure of some film collecting parts, it is easy to cause wear in the process of movement, so the failure rate is high. In addition, a high film entanglement rate will also lead to the operation of the machine becoming stuck, which will cause faults and affect the operation efficiency of film recycling.

- Lack of resource utilization mode of residual film, resulting in secondary pollution

Due to the difficulties in recycling the residual film, the high cost of reprocessing and utilization, and the lack of policy support and implementation, there is a lack of economic and effective resource utilization path, mode, and equipment for the recycled residual film, which results in disorderly stacking of recycled residual film and the prominent problem of secondary pollution.

5.2. Recommendations

- Accelerate the popularization and application of high-standard plastic film or fully biodegradable film.

Research and develop high-strength film with a higher performance–price ratio, reduce the film manufacturing costs, and make it more suitable for the mechanized recovery of residual film without affecting the yield and quality of crops. Vigorously promote the use of high-standard or fully biodegradable film. Establish special funds to provide financial subsidies to users. Implement a market access system for agricultural plastic film. Prohibit the production and sale of substandard plastic film to solve the problem of film pollution at the source.

- Strengthen the integration of agricultural machinery and agronomy.

The complex and diverse planting patterns of ridge crops greatly limit the application and development of residual film recycling machinery. It is necessary to standardize agronomic standards and unify crop farming norms, planting patterns, and harvesting methods to fully integrate agricultural machinery and agronomy to enhance the adaptability of machines. Exploring new ways to recover residual film, such as in potato crops, we can consider recycling the residual film after removing the stems and harvesting the potatoes. This will maximize the integrity of the film, make it easy to recycle, and improve the residual film net collection rate.

- Strengthen the research and development, promotion, and application of residual film recycling machines.

Strengthen the study of the principle and mechanism of residual film collection and develop a combined film collection device. Research the ground contour-following technology and develop the adaptive film collection device to improve the residual film collecting ability. Strengthen research on the mechanism of deep residual film collecting to improve the collecting capacity for deep residual film. Strengthen the research on the technology of stem–film separation, film–soil separation, and film impurity separation to increase the residual film net collected rate and reduce the impurity rate. Strengthen the research on anti-wrapping technology to reduce the film wrapping rate of the machine. Select wear-resistant materials or metal coatings to improve the wear resistance of the parts and extend the service life.

- Establish the resource utilization system of residual film.

Integrate film-covered planting with mechanized recovery and resource utilization, systematically plan from technical, equipment, policy, and mechanism perspectives to establish a system for the resource utilization of residual film. Develop laws and regulations for the recovery and utilization of agricultural residual film that are suitable for China’s national conditions. Accelerate the development of technologies and equipment for the resource utilization of residual film, conduct research on common technologies for residual film resource utilization, overcome key challenges, such as film contamination removal and recycling, develop supporting equipment for residual film recycling, and enhance the capacity for residual film resource utilization.

6. Conclusions

In this paper, peanuts and potatoes, two main ridge film mulching crops, were used as the research objects. The morphology of residual film was affected by planting patterns and harvesting methods. The residual film is fragile, and the recycling operation conditions are much more complex than those of crops planted on flat land.

At present, there are two types of machinery available for residual film recycling. One is the post-harvest residual film recycling machine; another is the residual film recycling machine during harvesting. The former can be used for peanuts and potatoes, while the latter is used for potatoes, but it is currently in the research stage and has not been widely used. The residual film recycling machinery has low compatibility with planting patterns, and its adaptability is poor. The operating performance, such as the net picking and film wrapping rates, needs to be improved, and the reliability is low. In addition, due to the lack of effective treatment methods for the recovered residual film, secondary pollution is serious.

Efforts should be made in four aspects, namely, plastic film, the integration of agricultural machinery and agronomy, residual film recycling machines, and the system of resource utilization of residual film, to promote the development of residual film recycling, reduce residual film pollution, and achieve sustainable agricultural development.

Author Contributions

Conceptualization, Z.H. and F.G.; methodology, F.W. and G.R.; investigation, W.L.; data curation, H.X.; writing—original draft preparation, L.P., H.S. and M.G.; writing—review and editing, L.P., H.Y. and W.L.; project administration, F.W.; funding acquisition, Z.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the “Open bidding for selecting the best candidates” project of Xinjiang Uygur Autonomous Region: the research and demonstration application of film impurity separation equipment.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bian, S.Z.; Liu, X.J.; AN, Z.Y.; Wen, H.D.; Xie, Y.F.; Cao, Y.Z. Pollution status of film mulching in Chinese protected vegetable areas. Environ. Sci. Technol. 2015, 38, 76–81. [Google Scholar]

- Zhang, X.S.; Fang, X.Y.; Yu, T.Y.; Li, R.; Wu, F.K.; Jiang, F.; Wang, X.J. Application effect evaluation of PE mulch with different thickness on spring peanut. J. Agric. 2024, 14, 58–62. [Google Scholar]

- Tang, Y.Q.; Zhang, Y.L.; Wang, F.X.; Dou, Y.Q.; Li, D.; Feng, S.Y. Effects of different degradable film and ordinary plastic film on soil hydrothermal conditions and peanut growth. J. Irrig. Drain. 2024, 43, 17–27. [Google Scholar]

- Huang, T.T.; Wu, Q.X.; Yuan, Y.Y.; Zhang, X.T.; Sun, R.Q.; Hao, R.; Yang, X.H.; Li, C.F.; Qin, X.H.; Song, F.Q.; et al. Effects of plastic film mulching on yield, water use efficiency, and nitrogen use efficiency of different crops in China: A meta-analysis. Field Crops Res. 2024, 312, 109407. [Google Scholar] [CrossRef]

- Wang, P.; Chen, X.G.; Wen, H.J. Research and experiment on the removal mechanism of light impurities of the residual mulch film recovery machine. Agriculture 2022, 12, 775. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Yan, C.R.; Hou, J.Y.; Xu, Y.Y.; Hong, Z.J.; Ma, Z.G.; Cui, J.X. Plastic mulch film application and management: Experience from developed countries. J. Agro-Environ. Sci. 2024, 43, 1288–1293. [Google Scholar]

- Thidar, M.; Gong, D.Z.; Mei, X.R.; Gao, L.L.; Li, H.R.; Hao, W.P.; Gu, F.X. Mulching improved soil water, root distribution and yield of maize in the Loess Plateau of Northwest China. Agric. Water Manag. 2020, 241, 106340. [Google Scholar] [CrossRef]

- Li, X.Y.; Shi, H.B.; Lü, Y.; Wang, Z.C.; Lin, Y.X.; Li, X. Effects of different residual plastic film quantities in soil on drip infiltration and its uncertainty analysis. Trans. Chin. Soc. Agric. Eng. 2013, 29, 84–90. [Google Scholar]

- Li, Y.Q.; Zhao, C.X.; Yan, C.R.; Mao, L.L.; Liu, Q.; Li, Z.; He, W.Q. Effects of agricultural plastic film residues on transportation and distribution of water and nitrate in soil. Chemosphere 2020, 242, 125131. [Google Scholar]

- Hao, X.; Zhang, J.; Zang, X.W.; Yi, M.L.; Wang, M.; Dong, W.Z.; Zhang, X.Y.; Tang, F.S. Analysis of the mulching film utilization and its residue pollution in peanut fields of Henan Province. Soils Crops 2019, 8, 43–49. [Google Scholar]

- Dong, H.G.; Liu, T.; Li, Y.G.; Liu, H.F.; Wang, D. Effects of plastic film residue on cotton yield and soil physical and chemical properties in Xinjiang. Trans. Chin. Soc. Agric. Eng. 2013, 29, 91–99. [Google Scholar]

- Li, Y.Q.; He, W.Q.; Yan, C.R.; Mao, L.L.; Liu, S. Effect of residual film on soil infiltration under drip irrigation. Trans. Chin. Soc. Agric. Eng. 2015, 31, 145–149. [Google Scholar]

- Ma, H.; Mei, X.R.; Yan, C.R.; He, W.Q.; Li, K. The residue of mulching plastic film of cotton field in North China. J. Agro-Environ. Sci. 2008, 27, 570–573. [Google Scholar]

- Zhang, J.F.; Liang, J.; Luo, S.Y.; Yao, Z.M.; Tian, C.J.; Sun, Y. Current situation and countermeasures of residual plastic film pollution in farmland. Soils Crops 2022, 11, 385–397. [Google Scholar]

- Li, Z.R.; Ma, J.J.; Sun, X.H.; Guo, X.H.; Zheng, L.J.; Chen, J.P. Plastic pollution in soil and crops: Effects of film residuals on soil water content and tomato physiology. Agronomy 2022, 12, 1222. [Google Scholar] [CrossRef]

- Zang, H.D.; Zhou, J.; Marshall, M.R.; Chadwick, D.R.; Wen, Y.; Jones, D.L. Microplastics in the agroecosystem: Are they an emerging threat to the plant-soil system? Soil Biol. Biochem. 2020, 148, 107926. [Google Scholar] [CrossRef]

- Zhai, Z.Q.; Chen, X.G.; Zhang, R.Y.; Qiu, F.S.; Meng, Q.J.; Yang, J.K.; Wang, H.Y. Evaluation of residual plastic film pollution in pre-sowing cotton field using UAV imaging and semantic segmentation. Front. Plant Sci. 2022, 13, 991191. [Google Scholar] [CrossRef]

- Dong, J.H.; Wang, J.; Bi, X.S.; Zheng, Y.J.; Wang, G.H.; Wang, J.K.; Chen, Y.; Jia, J. Analysis and test of clamp conveying type residual film recycling and film impurity separation mechanism. Processes 2022, 10, 1816. [Google Scholar] [CrossRef]

- Liu, X.L.; Zhao, W.Y.; Zhang, H.; Wang, G.P.; Sun, W.; Dai, F.; Li, H.; Xin, S.L. Design and experiment of an upper-side-discharge straw-returning and bundle self-unloading integrated corn residual film recycling machine. Int. J. Agric. Biol. Eng. 2023, 16, 61–70. [Google Scholar] [CrossRef]

- Zhuo, H.M.; Fu, S.Z.; Liu, H.; Song, H.; Ren, L.J. Analyses and suggestions on current situation of potato industry standards in China. J. Anhui Agric. Sci. 2019, 47, 248–250+270. [Google Scholar]

- Xu, Y.; Jiang, L.H.; Shi, J.; Tan, D.S.; Li, Z.E. Analysis on film residual status of typical mulching crops in Shandong Province. Shandong Agric. Sci. 2018, 50, 91–95. [Google Scholar]

- Wei, Z.C.; Han, M.; Su, G.L.; Zhang, H.; Li, X.Q.; Jin, C.Q. Design and experiment of a bagging and unloading potato combine harvester. Trans. Chin. Soc. Agric. Mach. 2023, 54, 92–104. [Google Scholar]

- Lyu, J.Q.; Zhang, X.Z.; Xiao, X.X.; Li, J.C.; Yang, D.Q.; Sun, Q. Design and experiment of key components of large monopoly double row potato mulching device. J. Northeast. Agric. Univ. 2023, 54, 88–96. [Google Scholar]

- Jiang, D.L.; Yan, L.M.; Chen, X.G.; Mo, Y.S.; Yang, J.C. Design and experiment of nail tooth picking up device for strip type residual film recycling and baling machine. Int. J. Agric. Biol. Eng. 2023, 16, 85–96. [Google Scholar] [CrossRef]

- You, Z.Y.; Gu, F.W.; Wu, F.; Hu, Z.C.; Zhang, Y.L.; Tu, L.B. Research on ridged peanut residue plastic film recycling technology. J. Agric. Mech. Res. 2016, 38, 207–211. [Google Scholar]

- Wang, X.X.; Song, N.N.; Xue, Y.H.; Wang, J.C.; Liang, L.N.; Li, M.J.; Liu, S.L.; Liu, D.S. Occurrence characteristics of residual film in cultivated soil of peanut planting area in Shandong Province, China. J. Agro-Environ. Sci. 2021, 40, 1729–1737. [Google Scholar]

- Zhang, D.; Hu, W.L.; Liu, H.B.; Du, L.F.; Xu, Y.; Cheng, Z.H.; Sun, S.Y.; Wang, H.Y. Characteristics of residual mulching film and residual coefficient of typical crops in North China. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–5. [Google Scholar]

- Sun, C.; Shan, N.N.; Yang, Z.Y.; Wu, Z.Q.; Wang, Y.F. Analysis of impact factors of plastic film residue on farmland in Xinjiang. J. Environ. Eng. Technol. 2024, 5, 1627–1634. [Google Scholar]

- Li, L.L.; Dai, L.Y.; Gao, W.C.; Zhang, S.Y.; Liu, T.Z. The occurrence characteristics and influencing factors of residual mulching film of typical farmland with plastic film in Guizhou province. Ecol. Environ. Sci. 2022, 31, 2189–2197. [Google Scholar]

- Shen, Y.; Liang, C.L.; Liu, Y.; Tian, M.; Qian, X.Q. Present situation of agricultural film use in China and pollution prevention measures. Mod. Agric. Sci. Technol. 2023, 12, 147–151+159. [Google Scholar]

- Zhao, J.J.; Tang, J.R.; Li, C.X.; He, H.Q.; Huang, H. Distribution and influencing factors of plastic film residues in topsoil of farmland in Gansu Province. Chin. J. Eco-Agric. 2024, 32, 456–467. [Google Scholar]

- Bai, X.; Zhou, H.P.; Xie, W.Y. Investigation on utilization status of agricultural film and residual membrane pollution in typical areas of Shanxi province. Chin. Agric. Sci. Bull. 2017, 33, 99–104. [Google Scholar]

- Liang, R.; Zhu, Z.J.; Peng, C.; Bian, Z.J.; Yang, X.M.; Wang, H.; Wang, X.X. Mulch film to plastic debris: A survey of agricultural soils of Hebei Province, North China. Sci. Total Environ. 2024, 918, 170509. [Google Scholar] [CrossRef]

- Zhan, Y.; Chen, X.G.; Wen, H.J.; Zheng, X.; Niu, Q.; Kang, J.M. Research status and prospect of control technology for residual plastic film pollution in farmland. Trans. Chin. Soc. Agric. Mach. 2017, 48, 1–14. [Google Scholar]

- Shi, Z.L.; Zhang, X.J.; Yan, J.S.; Jiang, Y.W.; Yao, J.T. Experiment and analysis of film-soil separation motion characteristics of a chain drive residual film recovery mechanism for the tillage layer. Appl. Sci. 2022, 12, 5884. [Google Scholar] [CrossRef]

- Wen, H.J.; Chen, X.G.; Chen, H.; Gou, H.X. Application status and development of farmland mulch recycling machinery. J. Agro-Environ. Sci. 2024, 43, 1271–1277. [Google Scholar]

- Li, D.; Zhao, W.Y.; Xin, S.L.; Liu, X.L.; Qu, H.; Xu, Y. Current situation and prospect of recycling technology of farmland residual film. J. Chin. Agric. Mech. 2020, 41, 204–209. [Google Scholar]

- Zhou, X.X.; Hu, Z.C.; Yan, W.; You, Z.Y.; Wu, N. Research status of domestic residual film recovery machine to take off the film device. J. Agric. Mech. Res. 2016, 38, 263–268. [Google Scholar]

- Xue, S.K.; Chen, X.G.; Li, J.B.; Wang, X.F.; Zhang, Z.Y. Design of and Experiment on a Film Removal Device of an Arc-Toothed Residual Film Recovery Machine before Sowing. Appl. Sci. 2021, 11, 8551. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Hu, Z.C.; Wu, F.; Gu, F.W.; Xu, H.B.; You, Z.Y.; Shi, L.L. Research key points and practice on residual film recycling equipment in China. Xinjiang Agric. Mech. 2016, 5, 8–11. [Google Scholar]

- Xu, H.B.; Xu, H.B.; Wu, F.; Gu, F.W. Study on the collecting component of plastic film residue collector. J. Agric. Mech. Res. 2016, 38, 242–249. [Google Scholar]

- Shi, Z.L.; Zhang, X.J.; Liu, X.P.; Guo, L.; Zhang, C.S.; Liu, L. Design and test of roll-type tillage layer residual film recovery machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 128–137. [Google Scholar]

- Peng, Q.J.; Li, K.K.; Wang, X.Y.; Zhang, G.H.; Kang, J.M. Design and test of stripping and impurity removal device for spring-tooth residual plastic film collector. Agriculture 2023, 13, 42. [Google Scholar] [CrossRef]

- Wang, X.Z.; Hong, T.Y.; Fang, W.Q.; Chen, X.Y. Optimized design for vibration reduction in a residual film recovery machine frame based on modal analysis. Agriculture 2024, 14, 543. [Google Scholar] [CrossRef]

- Shi, Z.L.; Zhang, X.J.; Liu, X.P.; Kang, M.C.; Yao, J.T.; Guo, L. Analysis and test of the tillage layer roll-type residual film recovery mechanism. Appl. Sci. 2023, 13, 7598. [Google Scholar] [CrossRef]

- Wang, J.K.; Fu, W.; Wang, W.B.; Li, B. Design of SMS-1500 type straw chopping and plastic film residue collecting machine. Trans. CSAE 2011, 27, 168–172. [Google Scholar]

- Ke, Z.R.; Yang, S.M.; Zhang, F.; Ma, Y.L. Design and experiment of a toothed chain residual membrane recycling machine. J. Gansu Agric. Univ. 2024, 59, 313–322. [Google Scholar]

- Su, Z.P.; Li, J.P.; Zhang, Z.Y.; Ren, S.X.; Shi, Y.M.; Wang, X.F. Analysis of the mechanical properties and wear characteristics of nail teeth based on sowing layer residual film recovery machine. Eng. Fail. Anal. 2023, 143, 106869. [Google Scholar] [CrossRef]

- Shi, L.L.; Hu, Z.C.; Gu, F.W.; Wu, F.; Wu, P.L. Design and parameter optimization on teeth residue plastic film collector of ridged peanut. Trans. Chin. Soc. Agric. Eng. 2017, 33, 8–15. [Google Scholar]

- You, Z.Y.; Hu, Z.C.; Wu, H.C.; Zhang, Y.P.; Yan, J.C.; Yan, W.; Zhou, X.X. Design and experiment of 1MCDS-100A typed shovel-sieve residual film recovery machine. Trans. Chin. Soc. Agric. Eng. 2017, 33, 10–18. [Google Scholar]

- Gu, M.; Hu, Z.C.; You, Z.Y.; Xu, H.B.; Ji, G.S.; Wu, N. Optimization design and comparison test of transport and separation mechanism of network chain residual Plastic film collector. J. Agric. Mech. Res. 2020, 42, 58–64. [Google Scholar]

- NY/T 1227-2019; Retrieving Machines for Residual Film-Operation Quality. Ministry of Agriculture and Rural Affairs of the People’s Republic of China: Beijing, China, 2018.

- Xin, R.F.; Li, H.L.; Zhao, W.Y.; Liu, X.L.; Sun, W.; Zhang, H.; Li, H.; Wang, Z.Y.; Wei, L. Research status and development trend of potato mechanized residual film recycling. For. Mach. Woodwork. Equip. 2023, 51, 16–22. [Google Scholar]

- Fang, W.Q.; Wang, X.Z.; Han, D.L.; Zang, N.; Chen, C.G.; Ohiemi, I.E. Parameter optimization and disturbance analysis of the film picking device of the chain-type plough layer residual film recovery machine based on DEM-MBD coupling. Comput. Electron. Agric. 2024, 222, 109041. [Google Scholar] [CrossRef]

- Zhang, M.J.; Jian, J.M.; Wang, F.L.; Li, W.; San, Y.L.; Guo, W.S.; Hou, S.L.; Xue, D.Q. Design and experimental study on belt-tooth type collector for potato film residues. Earth Environ. Sci. 2019, 252, 042092. [Google Scholar] [CrossRef]

- Dai, F.; Zhao, W.Y.; Sun, W.; Wu, W.Z.; Song, X.F.; Li, Y. Design and experiment of combined operation machine for potato harvesting and plastic film pneumatic auxiliary collecting. Trans. Chin. Soc. Agric. Mach. 2017, 48, 64–72. [Google Scholar]

- Li, Y.; Zhao, W.Y.; Dai, F.; Shi, L.R.; Guo, X.H. Development and experiment of combined operation machine for potato harvesting and plastic film collecting. J. Hunan Agric. Univ. (Nat. Sci.) 2016, 42, 102–107. [Google Scholar]

- Dai, F.; Guo, X.H.; Zhao, W.Y.; Xin, S.L.; Liu, X.L.; Wu, W.Z. Design and experiment of canvas belt combined operation machine for potato digging and plastic film collecting. Trans. Chin. Soc. Agric. Mach. 2018, 49, 104–113. [Google Scholar]

- Ma, Y.L.; Yang, S.M.; Li, M.Q.; Wang, Q.; Ke, Z.R. Design of integrated machine for potato harvesting and residual film collecting in complex terrain. J. Hebei Univ. (Nat. Sci. Ed.) 2022, 42, 569–579. [Google Scholar]

- Sun, W.; Wang, C.F.; Zhao, W.Y.; Zhang, H.; Liu, X.L.; Wu, J.L. Design and experiment of potato digger with waste film recollection for complete film mulching, soil covering and ridge sowing pattern. Trans. Chin. Soc. Agric. Mach. 2018, 49, 105–114. [Google Scholar]

- Ju, Y.; Sun, W.; Zhao, Z.; Wang, H.; Liu, X.; Zhang, H.; Li, H.; Simionescu, P.A. Development and testing of a self-Propelled machine for combined potato harvesting and residual plastic film retrieval. Machines 2023, 11, 432. [Google Scholar] [CrossRef]

- NY/T 648-2015; Technical Specification for Quality Evaluation for Potato Harvesters. Ministry of Agriculture and Rural Affairs of the People’s Republic of China: Beijing, China, 2015.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).