Current Status of Green Hydrogen Production Technology: A Review

Abstract

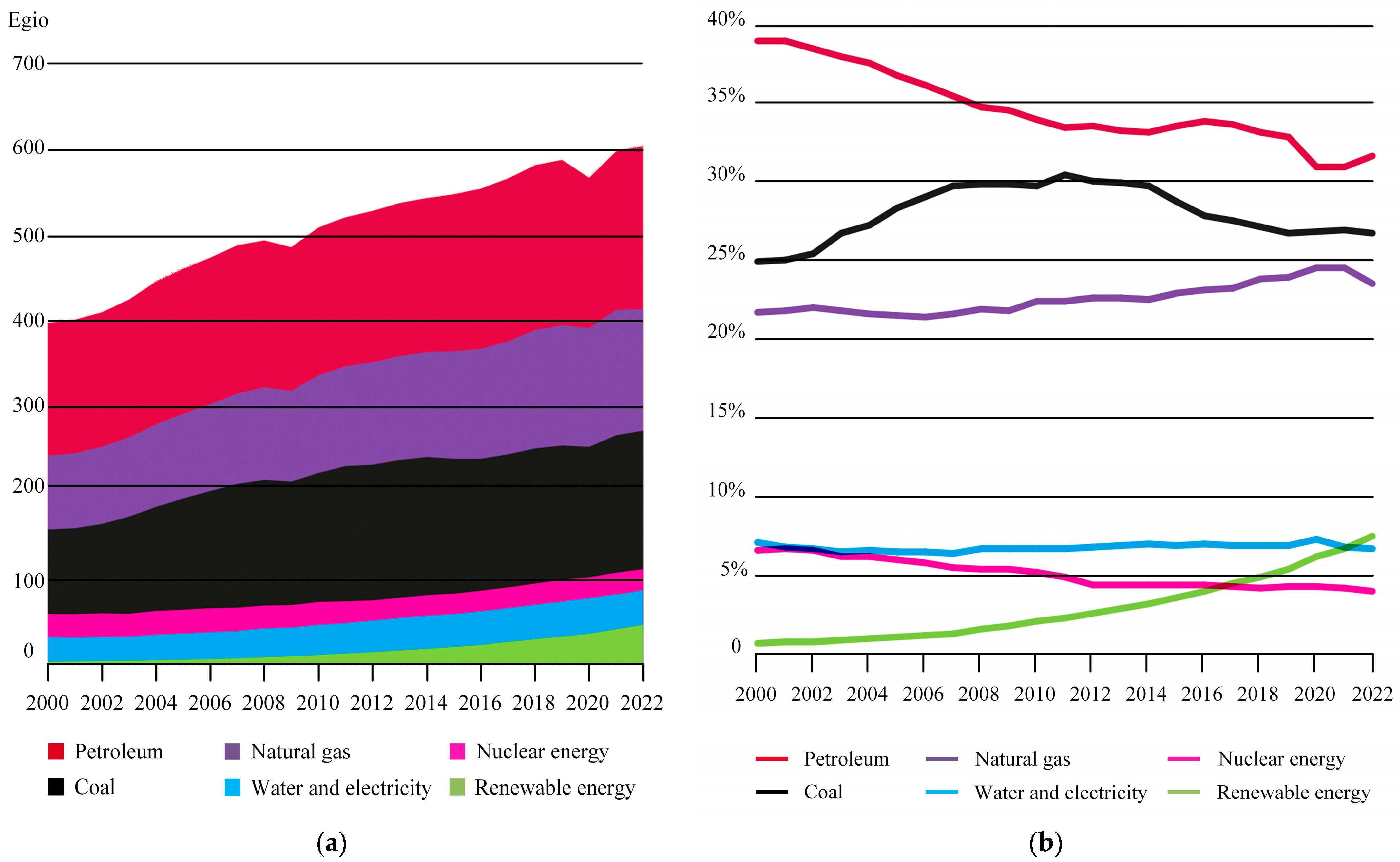

:1. Introduction

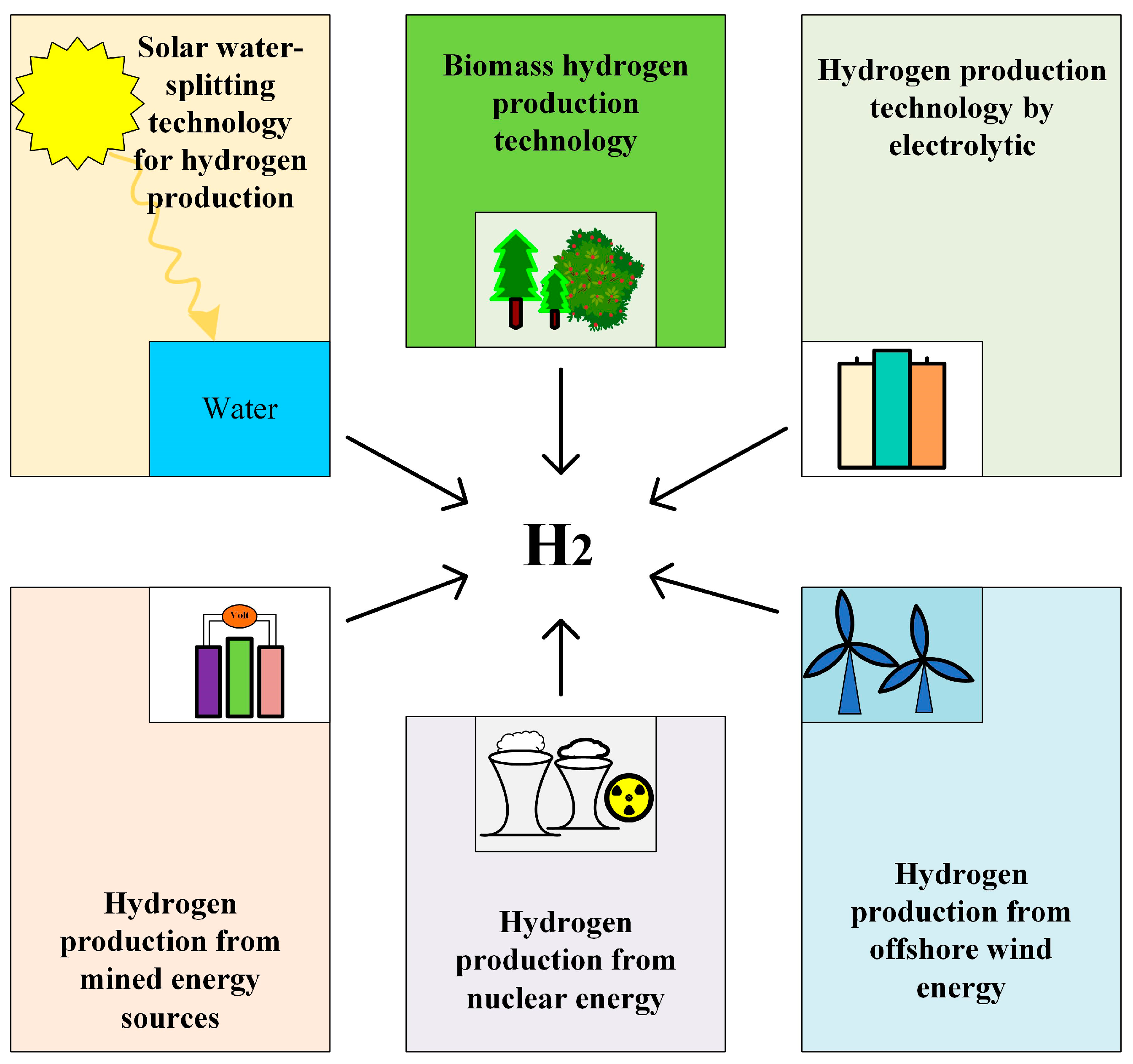

2. Research Progress of Hydrogen Production Technology

3. Solar Water Splitting Technology for Hydrogen Production

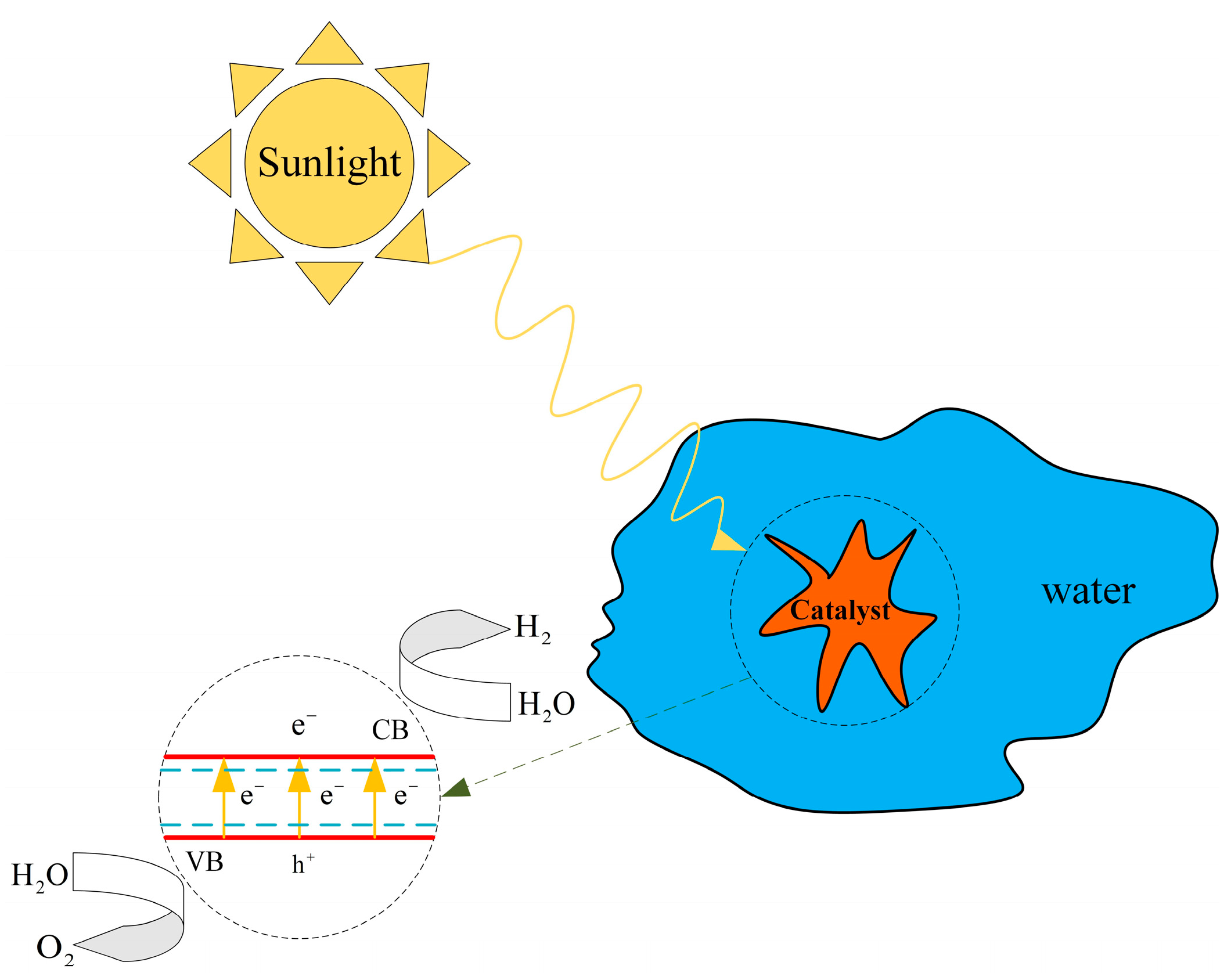

3.1. Photocatalytic Hydrogen Process

3.2. Solar Thermochemical Water Splitting for Hydrogen Production

3.3. Photoelectrochemical Process of Hydrogen

4. Biomass Hydrogen Production Technology

4.1. Thermochemical Conversion of Hydrogen

4.1.1. Pyrolysis Reforming Method

4.1.2. Steam Gasification Method

4.1.3. Supercritical Water Gasification Method

4.2. Microbial Process of Hydrogen

4.2.1. Photo-Fermentation Method

4.2.2. Dark Fermentation Method

4.2.3. Light–Dark Coupling Fermentation Method

4.2.4. Direct Photolysis Method

4.2.5. Indirect Photolysis Method

4.2.6. Cell-Free Synthase Biological Conversion Method

5. Hydrogen Production Technology by Electrolytic Water

5.1. Hydrogen Production by Alkaline Water Electrolysis

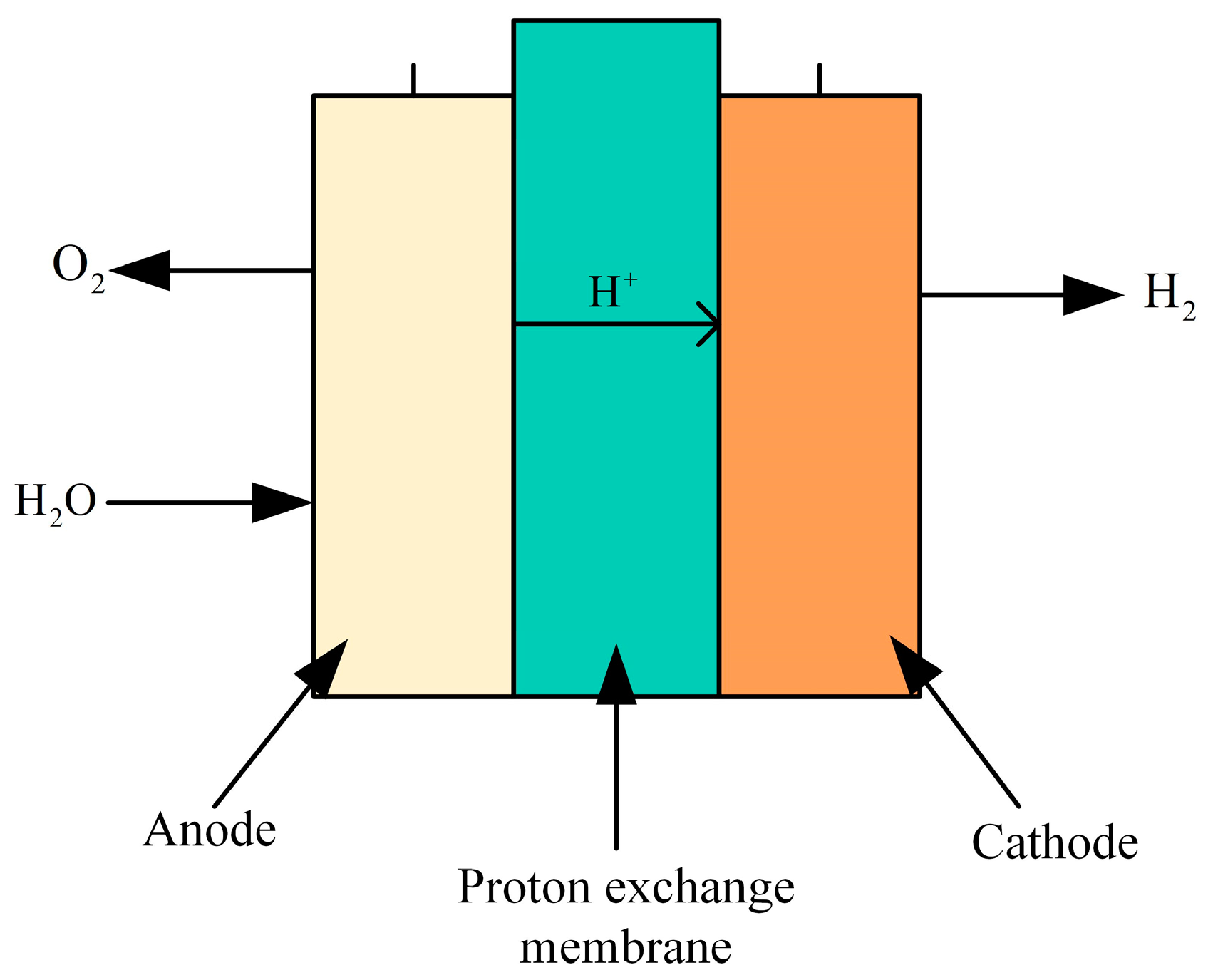

5.2. Proton Exchange Membrane Electrolysis of Water to Produce Hydrogen

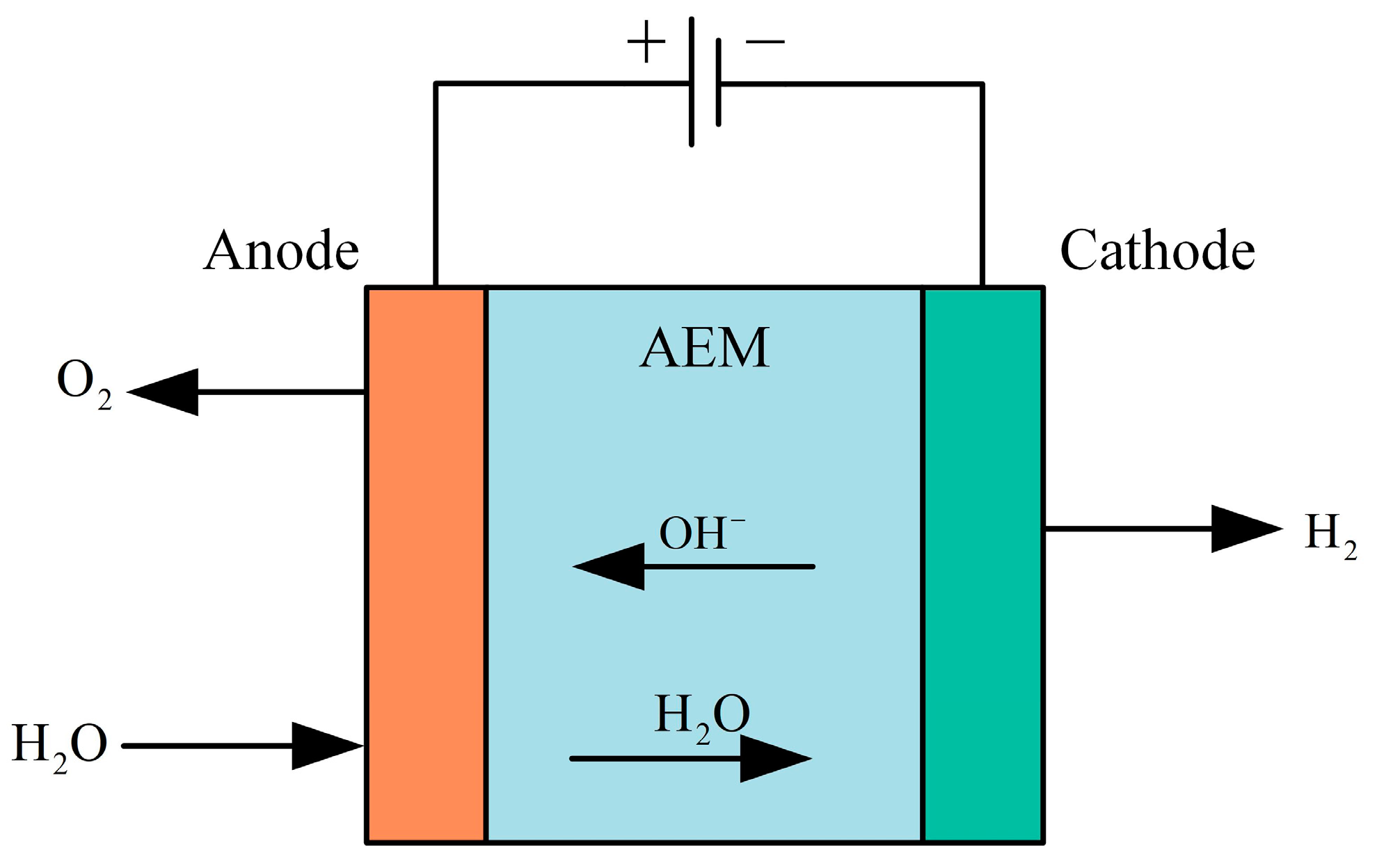

5.3. Anion Exchange Membrane Electrolysis of Water to Produce Hydrogen

5.4. Solid Oxide Electrolysis of Water to Produce Hydrogen

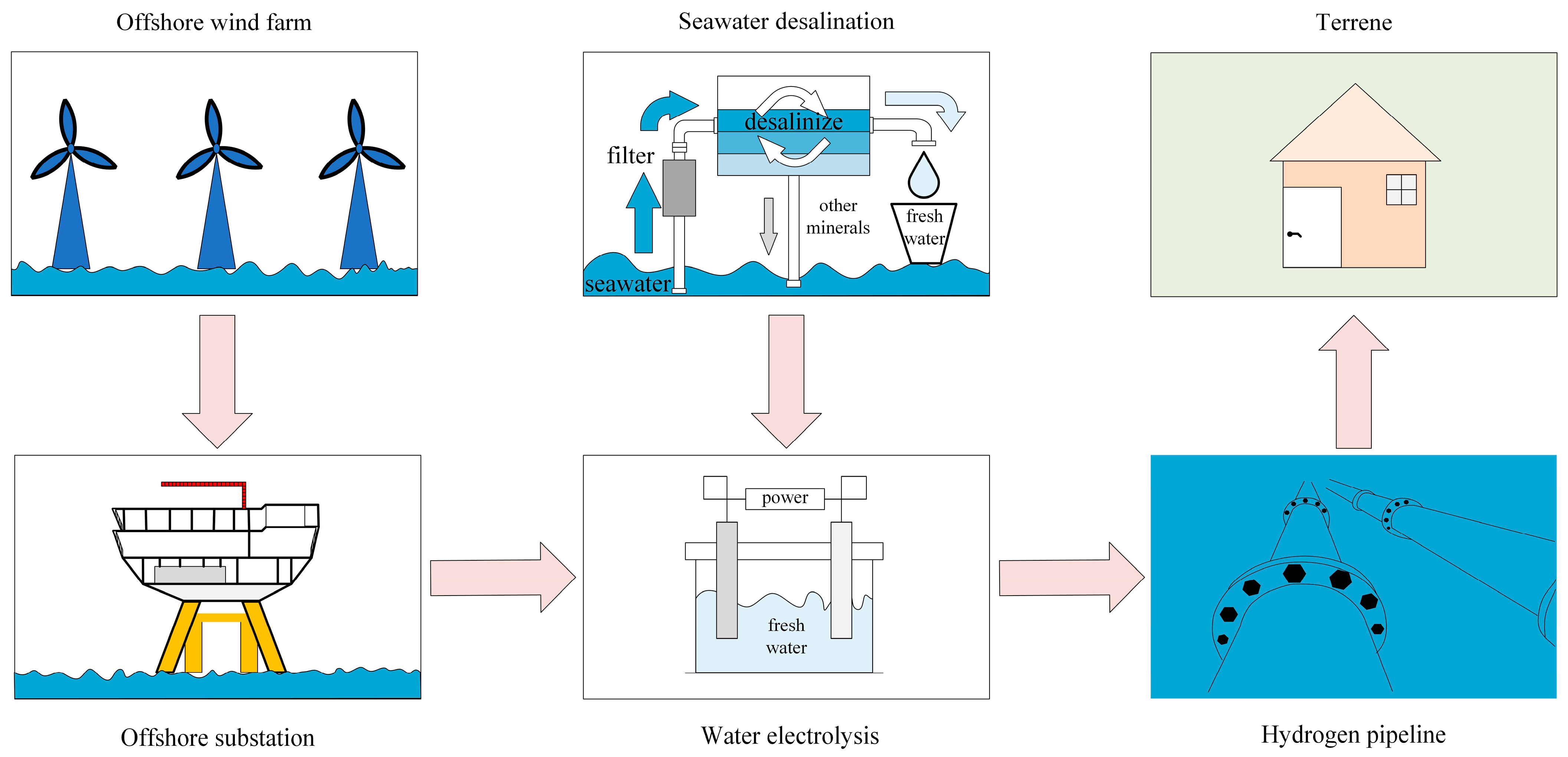

6. Hydrogen Production from Offshore Wind Energy

7. Hydrogen Production from Nuclear Energy

7.1. Methane Steam Reforming

7.2. High-Temperature Steam Electrolysis

7.3. Thermochemical Cycle

7.3.1. Sulfur Iodine Cycle (S-I Cycle)

7.3.2. Calcium Bromide Cycle (Ca-Br Cycle)

8. Hydrogen Production from Mixed Energy Sources

9. Comparison of Characteristics of Different Green Hydrogen Production Technologies

10. Discussion

10.1. Challenges in Developing Green Hydrogen Production Technology

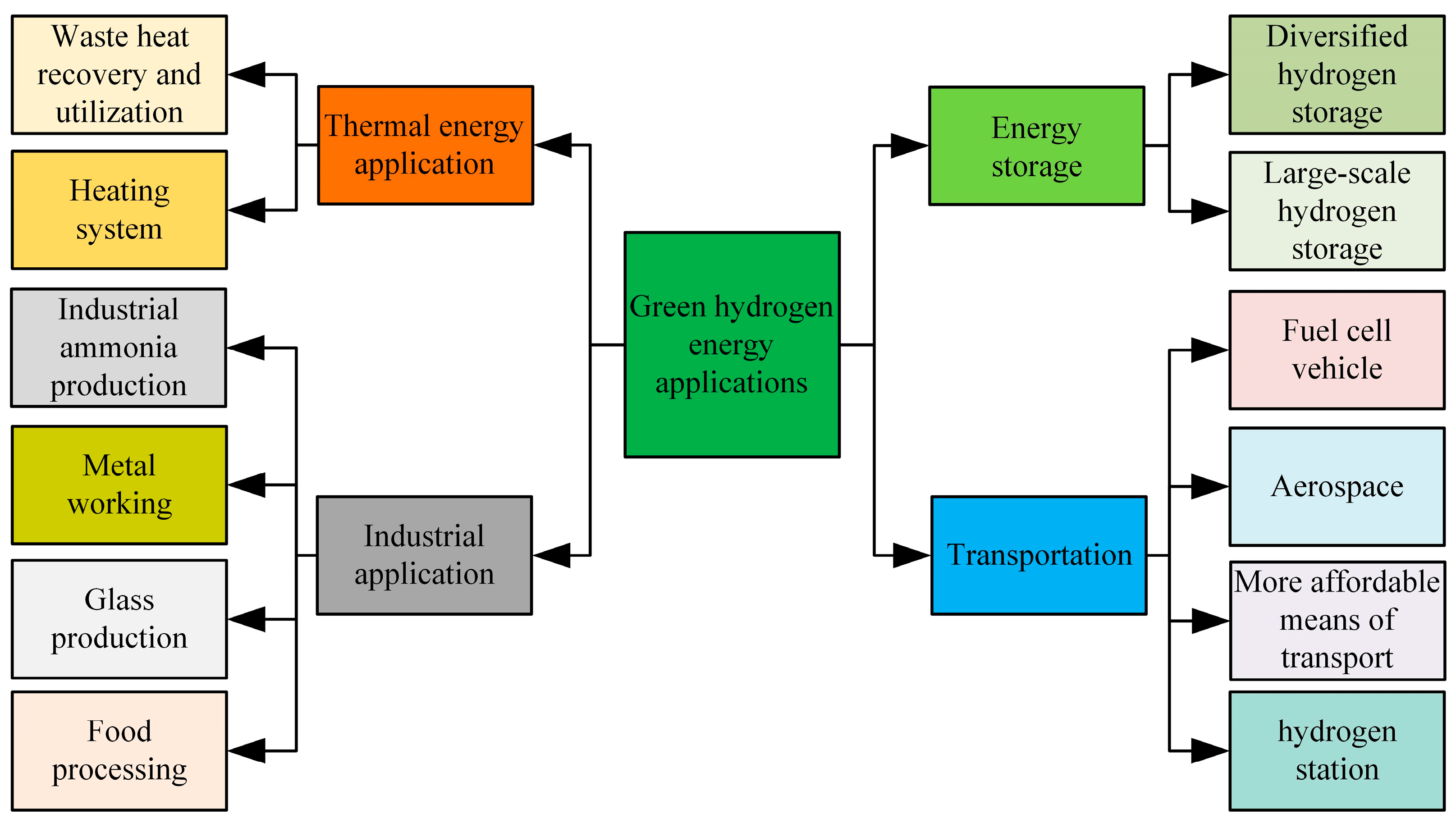

10.2. Application Prospect

10.2.1. Energy Storage

10.2.2. Transportation

10.2.3. Industrial Application

10.2.4. Thermal Energy Application

10.3. Economic Feasibility of Green Hydrogen Technology

11. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zainal, B.S.; Ker, P.J.; Mohamed, H.; Ong, H.C.; Fattah, I.M.R.; Rahman, S.M.A.; Nghiem, L.D.; Mahlia, T.M.I. Recent advancement and assessment of green hydrogen production technologies. Renew. Sustain. Energy Rev. 2024, 189, 113941. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Xu, Z.; Yin, K.; Zhou, Y.; Zhang, J.; Cui, P.; Ma, S.; Wang, Y.; Zhu, Z. A review on renewable energy-based chemical engineering design and optimization. Renew. Sustain. Energy Rev. 2024, 189, 114015. [Google Scholar] [CrossRef]

- Renewables 2021. Available online: https://www.iea.org/reports/renewables-2021 (accessed on 20 June 2024).

- Statistical Yearbook of World Energy 2023. Available online: https://kpmg.com/cn/zh/home/campaigns/2023/10/statistical-review-of-world-energy-2023.html (accessed on 20 June 2024).

- Marouani, I.; Guesmi, T.; Alshammari, B.M.; Alqunun, K.; Alzamil, A.; Alturki, M.; Hadj Abdallah, H. Integration of renewable-energy-based green hydrogen into the energy future. Processes 2023, 11, 2685. [Google Scholar] [CrossRef]

- The Intergovernmental Panel on Climate Change. Climate Change 2022: Impacts, Adaptation and Vulnerability. 2022. Available online: https://www.ipcc.ch/report/ar6/wg2/ (accessed on 20 June 2024).

- Qiu, A.; Sun, Y.; Wang, Y.; Fei, T. Analysis on the development trend of international green technology under the background of carbon neutrality. World Sci-Tech RD 2021, 43, 385. [Google Scholar]

- Olabi, A.G.; Abdelghafar, A.A.; Baroutaji, A.; Sayed, E.T.; Alami, A.H.; Rezk, H.; Abdelkareem, M.A. Large-vscale hydrogen production and storage technologies: Current status and future directions. Int. J. Hydrogen Energy 2021, 46, 23498–23528. [Google Scholar] [CrossRef]

- The National Development and Reform Commission and the National Energy Administration Jointly Issued the “Medium and Long-Term Plan for the Development of Hydrogen Energy Industry (2021–2035)”. Available online: https://www.nea.gov.cn/2022-03/23/c_1310525755.htm (accessed on 20 June 2024).

- Notice on the Issuance of the 14th Five-Year Plan for the Development of Renewable Energy. Available online: http://zfxxgk.nea.gov.cn/2021-10/21/c_1310611148.htm (accessed on 20 June 2024).

- Notice of the National Energy Administration on Issuing the Guiding Opinions on Energy Work in 2024. Available online: http://zfxxgk.nea.gov.cn/2024-03/18/c_1310768578.htm (accessed on 20 June 2024).

- World Class Green Hydrogen Ecological Innovation Zone “Hydrogen Island” Project Released. Available online: https://www.nea.gov.cn/2024-04/01/c_1310769703.htm (accessed on 20 June 2024).

- The National Energy Administration Organized the National Renewable Energy Development and Construction Situation Analysis Meeting in January 2024. Available online: https://www.nea.gov.cn/2024-02/07/c_1310763838.htm (accessed on 20 June 2024).

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market—Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Global Hydrogen Review 2022. Available online: https://www.iea.org/reports/global-hydrogen-review-2022 (accessed on 20 June 2024).

- Ren, Y.; Li, G.; Wang, H.; Bie, Z. China’s Zero-Coal Power System Future. Int. J. Hydrogen Energy 2024, 156, 109748. [Google Scholar] [CrossRef]

- Dincer, I. Green methods for hydrogen production. Int. J. Hydrogen Energy 2012, 37, 1954–1971. [Google Scholar] [CrossRef]

- Squadrito, G.; Maggio, G.; Nicita, A. The green hydrogen revolution. Renew. Energy 2023, 216, 119041. [Google Scholar] [CrossRef]

- Niaz, S.; Manzoor, T.; Pandith, A.H. Hydrogen storage: Materials, methods and perspectives. Renew. Sustain. Energy Rev. 2015, 50, 457–469. [Google Scholar] [CrossRef]

- Fernández-Arias, P.; Antón-Sancho, Á.; Lampropoulos, G.; Vergara, D. On Green Hydrogen Generation Technologies: A Bibliometric Review. Appl. Sci. 2024, 14, 2524. [Google Scholar] [CrossRef]

- Dorel, S.; Lucian, M.; Gheorghe, L.; Cristian, L.G. Green Hydrogen, a Solution for Replacing Fossil Fuels to Reduce CO2 Emissions. Processes 2024, 12, 1651. [Google Scholar] [CrossRef]

- Ge, L.; Zhang, B.; Huang, W.; Li, Y.; Hou, L.; Xiao, J.; Mao, Z.; Li, X. A review of hydrogen generation, storage, and applications in power system. J. Energy Storage 2024, 75, 109307. [Google Scholar] [CrossRef]

- Ham, K.; Bae, S.; Lee, J. Classification and technical target of water electrolysis hydrogen production. J. Energy Chem. 2024, 95, 554–576. [Google Scholar] [CrossRef]

- Arcos, J.M.M.; Santos, D.M. The hydrogen color spectrum: Techno-economic analysis of the available technologies for hydrogen production. Gases 2023, 3, 25–46. [Google Scholar] [CrossRef]

- Sinopec Releases China Energy Outlook 2060 (2024 Edition). Available online: http://edri.sinopec.com/edri/news/com_news/20240109/news_20240109_325732006670.shtml (accessed on 20 June 2024).

- Cheng, G.; Luo, E.; Zhao, Y.; Yang, Y.; Chen, B.; Cai, Y.; Wang, X.; Dong, C. Analysis and prediction of green hydrogen production potential by photovoltaic-powered water electrolysis using machine learning in China. Energy 2023, 284, 129302. [Google Scholar] [CrossRef]

- Deng, Y.; Li, S.; Liu, H.; Zhang, H.; Baeyens, J. Recent Research in Solar-Driven Hydrogen Production. Sustainability 2024, 16, 2883. [Google Scholar] [CrossRef]

- Yu, Q.; Fuxiang, Z. Photocatalytic Water Splitting for Hydrogen Production. Acta Chim. Sin. 2022, 80, 827. [Google Scholar]

- Yan, X.; Xia, M.; Liu, H.; Zhang, B.; Chang, C.; Wang, L.; Yang, G. An electron-hole rich dual-site nickel catalyst for efficient photocatalytic overall water splitting. Nat. Commun. 2023, 14, 1741. [Google Scholar] [CrossRef]

- Thabet, S.M.; Abdelhamid, H.N.; Ibrahim, S.A.; El-Bery, H.M. Boosting photocatalytic water splitting of TiO2 using metal (Ru, Co, or Ni) co-catalysts for hydrogen generation. Sci. Rep. 2024, 14, 10115. [Google Scholar] [CrossRef]

- Andreou, E.K.; Vamvasakis, I.; Armatas, G.S. Efficient Visible Light Photocatalytic Hydrogen Evolution by Boosting the Interfacial Electron Transfer in Mesoporous Mott–Schottky Heterojunctions of CO2P-Modified CdIn2S4 Nanocrystals. ACS Appl. Energy Mater. 2024, 7, 4891–4903. [Google Scholar] [CrossRef]

- Nguyen, V.C.; Sanoe, M.; Putri, N.P.; Lee, Y.L.; Teng, H. Co-catalyst design to control charge transfer and product composition for photocatalytic H 2 production and biomass reforming. Sustain. Energy Fuels 2024, 8, 1412–1423. [Google Scholar] [CrossRef]

- Maulana, F.; Engge, Y.; Nurhuda, M.; Hakim, L.; Juwono, A.M. Boosting Hydrogen Production through Water Splitting: N, Ni, and N-Ni Doped ZnO Photocatalysts. J. Electrochem. Soc. 2024, 171, 046505. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, R.; Zhong, X.; Jiang, F. Preparation and Application of a Novel S-Scheme Nanoheterojunction Photocatalyst (LaNi0.6Fe0.4O3/g-C3N4). ACS Omega 2024, 9, 28422–28436. [Google Scholar] [CrossRef]

- Ma, Z.; Davenport, P.; Saur, G. System and technoeconomic analysis of solar thermochemical hydrogen production. Renew. Energy 2022, 190, 294–308. [Google Scholar] [CrossRef]

- Pérez, A.; Orfila, M.; Díaz, E.; Linares, M.; Sanz, R.; Marugán, J.; Molina, R.; Botas, J.A. Reticulated porous structures of La0.8Al0.2NiO3-δ perovskite for enhanced green hydrogen production by thermochemical water splitting. Catal. Today 2024, 442, 114919. [Google Scholar] [CrossRef]

- Vidal, A.; Gonzalez, A.; Denk, T. A 100 kW cavity-receiver reactor with an integrated two-step thermochemical cycle: Thermal performance under solar transients. Renew. Energy 2020, 153, 270–279. [Google Scholar] [CrossRef]

- Qian, X.; He, J.; Mastronardo, E.; Baldassarri, B.; Wolverton, C.; Haile, S.M. Favorable redox thermodynamics of SrTi0.5Mn0.5O3-δ in solar thermochemical water splitting. Chem. Mat. 2020, 32, 9335–9346. [Google Scholar] [CrossRef]

- Barcellos, D.R.; Sanders, M.D.; Tong, J.; McDaniel, A.H.; O’Hayre, R.P. BaCe0.25Mn0.75O3-δ—A promising perovskite-type oxide for solar thermochemical hydrogen production. Energy Environ. Sci. 2018, 11, 3256–3265. [Google Scholar] [CrossRef]

- Zhang, D.; De Santiago, H.A.; Xu, B.; Liu, C.; Trindell, J.A.; Li, W.; Park, J.; Rodriguez, M.A.; Coker, E.N.; Luo, J. Compositionally complex perovskite oxides for solar thermochemical water splitting. Chem. Mat. 2023, 35, 1901–1915. [Google Scholar] [CrossRef]

- Li, X.; Sun, X.; Song, Q.; Yang, Z.; Wang, H.; Duan, Y. A critical review on integrated system design of solar thermochemical water-splitting cycle for hydrogen production. Int. J. Hydrogen Energy 2022, 47, 33619–33642. [Google Scholar] [CrossRef]

- Chen, S.; Liu, T.; Zheng, Z.; Ishaq, M.; Liang, G.; Fan, P.; Tang, J. Recent progress and perspectives on Sb2Se3-based photocathodes for solar hydrogen production via photoelectrochemical water splitting. J. Energy Chem. 2022, 67, 508–523. [Google Scholar] [CrossRef]

- Maragno, A.R.A.; Morozan, A.; Fize, J.; Pellat, M.; Artero, V.; Charton, S.; Matheron, M. Thermally integrated photoelectrochemical devices with perovskite/silicon tandem solar cells: A modular approach for scalable direct water splitting. Sustain. Energy Fuels 2024, 8, 3726–3739. [Google Scholar] [CrossRef]

- Präg, R.; Kölbach, M.; Abdi, F.F.; Ahmet, I.Y.; Schleuning, M.; Friedrich, D.; van de Krol, R. Photoelectrochemical Properties of CuFeO2 Photocathodes Prepared by Pulsed Laser Deposition. Chem. Mat. 2024, 36, 7764–7780. [Google Scholar] [CrossRef]

- Lee, H.; Lee, C.U.; Yun, J.; Jeong, C.S.; Jeong, W.; Son, J.; Park, Y.S.; Moon, S.; Lee, S.; Kim, J.H.; et al. A dual spin-controlled chiral two-/three-dimensional perovskite artificial leaf for efficient overall photoelectrochemical water splitting. Nat. Commun. 2024, 15, 4672. [Google Scholar] [CrossRef] [PubMed]

- Shabbir, S.A.; Ali, I.; Haris, M.; Latif, H.; Sabah, A.; Alshomrany, A.S.; Bakkour, Y. Bifunctional Co3O4/g-C3N4 Hetrostructures for Photoelectrochemical Water Splitting. ACS Omega 2024, 9, 21450–21458. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Kong, H.; Park, T.; Kim, T.S.; Yang, H.; Yeo, J. Laser-Printed Photoanode: Femtosecond Laser-Induced Crystalline Phase Transformation of WO3 Nanorods for Space-Efficient and Flexible Thin-Film Solar Water-Splitting Cells. Small 2024, 20, 2402051. [Google Scholar] [CrossRef]

- Zhang, X.; Schwarze, M.; Schomäcker, R.; van de Krol, R.; Abdi, F.F. Life cycle net energy assessment of sustainable H2 production and hydrogenation of chemicals in a coupled photoelectrochemical device. Nat. Commun. 2023, 14, 991. [Google Scholar] [CrossRef]

- Osman, A.I.; Deka, T.J.; Baruah, D.C.; Rooney, D.W. Critical challenges in biohydrogen production processes from the organic feedstocks. Biomass Convers. Biorefin. 2020, 13, 8383–8401. [Google Scholar] [CrossRef]

- Lan, P.; Xu, Q.; Zhou, M.; Lan, L.; Zhang, S.; Yan, Y. Catalytic steam reforming of fast pyrolysis bio-oil in fixed bed and fluidized bed reactors. Chem. Eng. Technol. 2010, 33, 2021–2028. [Google Scholar] [CrossRef]

- Yao, D.; Wu, C.; Yang, H.; Hu, Q.; Nahil, M.A.; Chen, H.; Williams, P.T. Hydrogen production from catalytic reforming of the aqueous fraction of pyrolysis bio-oil with modified Ni–Al catalysts. Int. J. Hydrogen Energy 2014, 39, 14642–14652. [Google Scholar] [CrossRef]

- Arandia, A.; Coronado, I.; Remiro, A.; Gayubo, A.G.; Reinikainen, M. Aqueous-phase reforming of bio-oil aqueous fraction over nickel-based catalysts. Int. J. Hydrogen Energy 2019, 44, 13157–13168. [Google Scholar] [CrossRef]

- Bimbela, F.; Ábrego, J.; Puerta, R.; García, L.; Arauzo, J. Catalytic steam reforming of the aqueous fraction of bio-oil using Ni-Ce/Mg-Al catalysts. Appl. Catal. B Environ. 2017, 209, 346–357. [Google Scholar] [CrossRef]

- Brito, J.; Pinto, F.; Ferreira, A.; Soria, M.A.; Madeira, L.M. Steam reforming of biomass gasification gas for hydrogen production: From thermodynamic analysis to experimental validation. Fuel Process. Technol. 2023, 250, 107859. [Google Scholar] [CrossRef]

- Cortazar, M.; Lopez, G.; Alvarez, J.; Amutio, M.; Bilbao, J.; Olazar, M. Advantages of confining the fountain in a conical spouted bed reactor for biomass steam gasification. Energy 2018, 153, 455–463. [Google Scholar] [CrossRef]

- Kargbo, H.O.; Zhang, J.; Phan, A.N. Optimisation of two-stage biomass gasification for hydrogen production via artificial neural network. Appl. Energy 2021, 302, 117567. [Google Scholar] [CrossRef]

- Lysne, A.; Blekkan, E.A. Continuous coke management with Ni and Nico catalysts for bio-syngas tar steam reforming–The switch-SRCG unit. Appl. Catal. O Open 2024, 190, 206943. [Google Scholar] [CrossRef]

- Okoji, A.I.; Taiwo, A.E.; Adeoye, J.B.; Musonge, P.; Makinde, D.O.; Okoji, C.N. Process Integration of Hydrogen Production Using Steam Gasification and Water-Gas Shift Reactions: A Case of Response Surface Method and Machine Learning Techniques. Int. J. Energy Res. 2024, 2024, 6843951. [Google Scholar] [CrossRef]

- Li, T.; Wang, J.; Chen, H.; Li, W.; Pan, P.; Wu, L.; Xu, G.; Chen, H. Performance analysis of an integrated biomass-to-energy system based on gasification and pyrolysis. Energy Convers. Manag. 2023, 287, 117085. [Google Scholar] [CrossRef]

- Kumar, G.; Eswari, A.P.; Kavitha, S.; Kumar, M.D.; Kannah, R.Y.; How, L.C.; Muthukaruppan, G.; Banu, J.R. Thermochemical conversion routes of hydrogen production from organic biomass: Processes, challenges and limitations. Biomass Convers. Biorefin. 2020, 13, 8509–8534. [Google Scholar] [CrossRef]

- Liao, B.; Guo, L.; Lu, Y.; Zhang, X. Solar receiver/reactor for hydrogen production with biomass gasification in supercritical water. Int. J. Hydrogen Energy 2013, 38, 13038–13044. [Google Scholar] [CrossRef]

- Kumar, M.; Oyedun, A.O.; Kumar, A. A comparative analysis of hydrogen production from the thermochemical conversion of algal biomass. Int. J. Hydrogen Energy 2019, 44, 10384–10397. [Google Scholar] [CrossRef]

- Martins, A.H.; Rouboa, A.; Monteiro, E. On the green hydrogen production through gasification processes: A techno-economic approach. J. Clean Prod. 2023, 383, 135476. [Google Scholar] [CrossRef]

- Wu, L.; Qiu, Y.; Liu, F.; Liu, Z.; Chen, B.; Chen, J.; Yi, L.; Chen, B. Optimization of molecular dynamics in hydrogen production through phenol gasification in supercritical water. J. Energy Inst. 2024, 116, 101757. [Google Scholar] [CrossRef]

- Qiu, Y.; Liu, Y.; Fang, C.; Ju, M.; Xia, R.; Wang, Y. Supercritical Water Gasification of Oily Sludge and Its Life Cycle Assessment. BioResources 2024, 19, 2327–2341. [Google Scholar] [CrossRef]

- Dhanya, B.S.; Mishra, A.; Chandel, A.K.; Verma, M.L. Development of sustainable approaches for converting the organic waste to bioenergy. Sci. Total Environ. 2020, 723, 138109. [Google Scholar] [CrossRef]

- Thulasisingh, A.; Ananthakrishnan, K.; Nandakumar, J.; Kannaiyan, S. Fermentative biohydrogen fuel production utilizing wastewater: A review. CLEAN–Soil Air Water 2023, 51, 2300112. [Google Scholar] [CrossRef]

- Hu, C.; Choy, S.Y.; Giannis, A. Evaluation of lighting systems, carbon sources, and bacteria cultures on photofermentative hydrogen production. Appl. Biochem. Biotechnol. 2018, 185, 257–269. [Google Scholar] [CrossRef] [PubMed]

- Sahrin, N.T.; Khoo, K.S.; Masri, A.N.; Rawindran, H.; Tong, W.Y.; Altaf, M.; Sin, J.C.; Lam, S.M.; Bashir, M.J.K.; Lim, J.W. Enhancing microalgal hydrogen production via photo-fermentative modelling with alimentation derived from palm kernel expeller. Int. J. Hydrogen Energy 2024, 72, 388–394. [Google Scholar] [CrossRef]

- Yue, T.; Sun, Y.; Zhang, Q.; Jiang, D.; Zhang, Z.; Zhang, H.; Li, Y.; Zhang, Y.; Zhang, T. Enhancement of biohydrogen production by photo-fermentation of corn stover via visible light catalyzed titanium dioxide/activated carbon fiber. Bioresour. Technol. 2024, 399, 130459. [Google Scholar] [CrossRef]

- Ren, C.; Zhang, S.; Li, Q.; Jiang, Q.; Li, Y.; Gao, Z.; Cao, W.; Guo, L. Pilot composite tubular bioreactor for outdoor photo-fermentation hydrogen production: From batch to continuous operation. Bioresour. Technol. 2024, 401, 130705. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, X.; Yuan, J.; Guo, L. Multidimensional engineering of Rhodobacter sphaeroides for enhanced photo-fermentative hydrogen production. Chem. Eng. J. 2024, 488, 150852. [Google Scholar] [CrossRef]

- Chai, Y.; Lyu, Z.; Du, H.; Li, P.; Ding, S.; Jiang, Y.; Wang, H.; Min, Q.; Du, D.; Lin, Y.; et al. Recent progress on rational design of catalysts for fermentative hydrogen production. SusMat 2022, 2, 392–410. [Google Scholar] [CrossRef]

- Garduño, I.R.; Smith, M.; Baranova, E.; Kinsley, C. Hydrogen production in dark fermentation of a brewery sludge pre-treated with white-rot fungi in submerged culture. Bioresour. Technol. Rep. 2024, 25, 101773. [Google Scholar] [CrossRef]

- Ramprakash, B.; Incharoensakdi, A. Dark fermentative hydrogen production from pretreated garden wastes by Escherichia coli. Fuel. 2022, 310, 122217. [Google Scholar] [CrossRef]

- Rao, R.; Basak, N. Optimization and modelling of dark fermentative hydrogen production from cheese whey by Enterobacter aerogenes 2822. Int. J. Hydrogen Energy 2021, 46, 1777–1800. [Google Scholar] [CrossRef]

- Kovalev, А.A.; Kovalev, D.A.; Panchenko, V.A.; Zhuravleva, E.A.; Laikova, A.A.; Shekhurdina, S.V.; Ivanenko, A.A.; Litty, Y.V. Energy efficiency of hydrogen production during dark fermentation. Int. J. Hydrogen Energy 2024, 87, 171–178. [Google Scholar] [CrossRef]

- Eggers, N.; Giebner, F.; Heinemann, D.; Wagner, M.; Birth-Reichert, T. Improvement of substrate turnover through integrating dark fermentation into existing biogas plants. Biofuels Bioprod. Biorefin. 2024, 18, 855–864. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, X.; Mu, H.; Zhang, X. Biohydrogen production from sewage sludge by sequential dark and photo fermentation. J. Biobased Mater. Bioenergy 2015, 9, 95–100. [Google Scholar] [CrossRef]

- Zagrodnik, R.; Duber, A. Continuous dark-photo fermentative H2 production from synthetic lignocellulose hydrolysate with different photoheterotrophic cultures: Sequential vs. co-culture processes. Energy 2024, 290, 130105. [Google Scholar] [CrossRef]

- Cai, J.; Zhao, Y.; Fan, J.; Li, F.; Feng, C.; Guan, Y.; Wang, R.; Tang, N. Photosynthetic bacteria improved hydrogen yield of combined dark-and photo-fermentation. J. Biotechnol. 2019, 302, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, Z.; Jiang, D.; Jing, Y.; Lu, C.; Zhang, H.; Zhang, Q. Continuous dark and photo biohydrogen production in a baffled bioreactor and electrons distribution analysis. Bioresour. Technol. 2021, 337, 125440. [Google Scholar] [CrossRef] [PubMed]

- Niño-Navarro, C.; Chairez, I.; Christen, P.; Canul-Chan, M.; García-Peña, E.I. Enhanced hydrogen production by a sequential dark and photo fermentation process: Effects of initial feedstock composition, dilution and microbial population. Renew. Energy 2020, 147, 924–936. [Google Scholar] [CrossRef]

- Ghimire, A.; Frunzo, L.; Pirozzi, F.; Trably, E.; Escudie, R.; Lens, P.N.L.; Esposito, G. A review on dark fermentative biohydrogen production from organic biomass: Process parameters and use of by-products. Appl. Energy 2015, 144, 73–95. [Google Scholar] [CrossRef]

- Tamburic, B.; Zemichael, F.W.; Maitland, G.C.; Hellgardt, K. Parameters affecting the growth and hydrogen production of the green alga Chlamydomonas reinhardtii. Int. J. Hydrogen Energy 2011, 36, 7872–7876. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Shu, L.; Zhuang, X.; Liu, Y.; Chen, J.; Hu, Z. Sustainable photosynthetic H2-production mediated by artificial miRNA silencing of OEE2 gene in green alga Chlamydomonas reinhardtii. Int. J. Hydrogen Energy 2015, 40, 5609–5616. [Google Scholar] [CrossRef]

- Bechara, R.; Azizi, F.; Boyadjian, C. Process simulation and optimization for enhanced biophotolytic hydrogen production from green algae using the sulfur deprivation method. Int. J. Hydrogen Energy 2021, 46, 14096–14108. [Google Scholar] [CrossRef]

- Chen, J.; Liu, E.; Wang, J.; Liu, H. Mixotrophic cultivation of green algal aggregates boost photobiological hydrogen production. Int. J. Hydrogen Energy 2024, 76, 304–314. [Google Scholar] [CrossRef]

- Chen, J.; Li, Y.; Li, M.; Shi, J.; Wang, L.; Luo, S.; Liu, H. Chemical flocculation-based green algae materials for photobiological hydrogen production. ACS Appl. Bio Mater. 2022, 5, 897–903. [Google Scholar] [CrossRef]

- Delavar, M.A.; Wang, J. Advancing biohydrogen production through indirect photolysis: Insights from numerical simulation using the lattice boltzmann method. Fuel 2024, 376, 132707. [Google Scholar] [CrossRef]

- Ban, S.; Lin, W.; Luo, J. Ca2+ enhances algal photolysis hydrogen production by improving the direct and indirect pathways. Int. J. Hydrogen Energy 2019, 44, 1466–1473. [Google Scholar] [CrossRef]

- Touloupakis, E.; Faraloni, C.; Benavides, A.M.S.; Masojídek, J.; Torzillo, G. Sustained photobiological hydrogen production by Chlorella vulgaris without nutrient starvation. Int. J. Hydrogen Energy 2021, 46, 3684–3694. [Google Scholar] [CrossRef]

- Ban, S.; Lin, W.; Wu, F.; Luo, J. Algal-bacterial cooperation improves algal photolysis-mediated hydrogen production. Bioresour. Technol. 2018, 251, 350–357. [Google Scholar] [CrossRef] [PubMed]

- Hupp, B.; Pap, B.; Farkas, A.; Maróti, G. Development of a microalgae-based continuous starch-to-hydrogen conversion approach. Fermentation 2022, 8, 294. [Google Scholar] [CrossRef]

- Zhang, Y.H.P.; Evans, B.R.; Mielenz, J.R.; Hopkins, R.C.; Adams, M.W.W. High-yield hydrogen production from starch and water by a synthetic enzymatic pathway. PLoS ONE 2007, 2, e456. [Google Scholar] [CrossRef]

- Chi, J.; Yu, H. Water electrolysis based on renewable energy for hydrogen production. Chin. J. Catal. 2018, 39, 390–394. [Google Scholar] [CrossRef]

- David, M.; Ocampo-Martínez, C.; Sánchez-Peña, R. Advances in alkaline water electrolyzers: A review. J. Energy Storage 2019, 23, 392–403. [Google Scholar] [CrossRef]

- Demnitz, M.; Lamas, Y.M.; Barros, R.L.G.; den Bouter, A.L.; van der Schaaf, J.; de Groot, M.T. Effect of iron addition to the electrolyte on alkaline water electrolysis performance. iScience 2024, 27, 108695. [Google Scholar] [CrossRef]

- Zhu, Q.; Yang, P.; Zhang, T.; Yu, Z.; Liu, K.; Fan, H.J. Boosting alkaline water electrolysis by asymmetric temperature modulation. Appl. Phys Lett. 2021, 119, 013901. [Google Scholar] [CrossRef]

- Brauns, J.; Turek, T. Model-based analysis and optimization of pressurized alkaline water electrolysis powered by renewable energy. J. Electrochem. Soc. 2023, 170, 064510. [Google Scholar] [CrossRef]

- Cao, X.; Wang, J.; Zhao, P.; Xia, H.; Li, Y.; Sun, L.; He, W. Hydrogen production system using alkaline water electrolysis adapting to fast fluctuating photovoltaic power. Energies 2023, 16, 3308. [Google Scholar] [CrossRef]

- Shaarawy, H.H.; Hussein, H.S.; Attia, A.; Hawash, S.I. Green hydrogen generation in alkaline solution using electrodeposited Ni-Co-nano-graphene thin film cathode. Environ. Sci. Pollut. Res. 2024, 31, 28719–28733. [Google Scholar] [CrossRef] [PubMed]

- Makhsoos, A.; Kandidayeni, M.; Pollet, B.G.; Boulon, L. A perspective on increasing the efficiency of proton exchange membrane water electrolyzers—A review. Int. J. Hydrogen Energy 2023, 48, 15341–15370. [Google Scholar] [CrossRef]

- Ma, Z.; Witteman, L.; Wrubel, J.A.; Bender, G. A comprehensive modeling method for proton exchange membrane electrolyzer development. Int. J. Hydrogen Energy 2021, 46, 17627–17643. [Google Scholar] [CrossRef]

- Höglinger, M.; Kartusch, S.; Eder, J.; Grabner, B.; Macherhammer, M.; Trattner, A. Advanced testing methods for proton exchange membrane electrolysis stacks. Int. J. Hydrogen Energy 2024, 77, 598–611. [Google Scholar] [CrossRef]

- Padgett, E.; Bender, G.; Haug, A.; Lewinski, K.; Sun, F.; Yu, H.; Cullen, D.A.; Steinbach, A.J.; Alia, S.M. Catalyst layer resistance and utilization in PEM electrolysis. J. Electrochem. Soc. 2023, 170, 084512. [Google Scholar] [CrossRef]

- Zhang, X.L.; Yu, P.C.; Su, X.Z.; Hu, S.J.; Shi, L.; Wang, Y.H.; Yang, P.P.; Gao, F.Y.; Wu, Z.Z.; Chi, L.P.; et al. Efficient acidic hydrogen evolution in proton exchange membrane electrolyzers over a sulfur-doped marcasite-type electrocatalyst. Sci. Adv. 2023, 9, eadh2885. [Google Scholar] [CrossRef] [PubMed]

- Calnan, S.; Bagacki, R.; Bao, F.; Dorbandt, I.; Kemppainen, E.; Schary, C.; Schlatmann, R.; Pehlivan, I.B. Development of various photovoltaic-driven water electrolysis technologies for green solar hydrogen generation. Sol. RRL 2022, 6, 2100479. [Google Scholar] [CrossRef]

- Vincent, I.; Bessarabov, D. Low cost hydrogen production by anion exchange membrane electrolysis: A review. Renew. Sustain. Energy Rev. 2018, 81, 1690–1704. [Google Scholar] [CrossRef]

- Ha, J.S.; Park, Y.; Jeong, J.Y.; Lee, S.H.; Lee, S.J.; Kim, I.T.; Park, S.H.; Jin, H.; Kim, S.M.; Choi, S.; et al. Solar-Powered AEM Electrolyzer via PGM-Free (Oxy)hydroxide Anode with Solar to Hydrogen Conversion Efficiency of 12.44%. Adv. Sci. 2024, 11, 2401782. [Google Scholar] [CrossRef]

- Khataee, A.; Shirole, A.; Jannasch, P.; Krüger, A.; Cornell, A. Anion exchange membrane water electrolysis using Aemion™ membranes and nickel electrodes. J. Mater. Chem. A 2022, 10, 16061–16070. [Google Scholar] [CrossRef]

- Li, K.; Yu, S.; Li, D.; Ding, L.; Wang, W.; Xie, Z.; Park, E.J.; Fujimoto, C.; Cullen, D.A.; Kim, Y.S.; et al. Engineered thin diffusion layers for anion-exchange membrane electrolyzer cells with outstanding performance. ACS Appl. Mater. Interfaces 2021, 13, 50957–50964. [Google Scholar] [CrossRef] [PubMed]

- Kang, X.; Yang, F.; Zhang, Z.; Liu, H.; Ge, S.; Hu, S.; Li, S.; Luo, Y.; Yu, Q.; Liu, Z.; et al. A corrosion-resistant RuMoNi catalyst for efficient and long-lasting seawater oxidation and anion exchange membrane electrolyzer. Nat. Commun. 2023, 14, 3607. [Google Scholar] [CrossRef] [PubMed]

- Corigliano, O.; Pagnotta, L.; Fragiacomo, P. On the technology of solid oxide fuel cell (SOFC) energy systems for stationary power generation: A review. Sustainability 2022, 14, 15276. [Google Scholar] [CrossRef]

- Bui, T.; Lee, D.; Ahn, K.Y.; Kim, Y.S. Techno-economic analysis of high-power solid oxide electrolysis cell system. Energy Convers. Manag. 2023, 278, 116704. [Google Scholar] [CrossRef]

- Jolaoso, L.A.; Asadi, J.; Duan, C.; Kazempoor, P. A novel green hydrogen production using water-energy nexus framework. Energy Convers. Manag. 2023, 276, 116344. [Google Scholar] [CrossRef]

- Liu, H.; Clausen, L.R.; Wang, L.; Chen, M. Pathway toward cost-effective green hydrogen production by solid oxide electrolyzer. Energy Environ. Sci. 2023, 16, 2090–2111. [Google Scholar] [CrossRef]

- Maddaloni, M.; Marchionni, M.; Abbá, A.; Mascia, M.; Tola, V.; Carpanese, M.P.; Bertanza, G.; Artioli, N. Exploring the viability of utilizing treated wastewater as a sustainable water resource for green hydrogen generation using solid oxide electrolysis cells (SOECs). Water 2023, 15, 2569. [Google Scholar] [CrossRef]

- Kumar, S.; Arzaghi, E.; Baalisampang, T.; Garaniya, V.; Abbassi, R. Insights into decision-making for offshore green hydrogen infrastructure developments. Process Saf. Environ. Protect. 2023, 174, 805–817. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Delpisheh, M.; Convery, C.; Niblett, D.; Vinothkannan, M.; Mamlouk, M. Offshore green hydrogen production from wind energy: Critical review and perspective. Renew. Sustain. Energy Rev. 2024, 195, 114320. [Google Scholar] [CrossRef]

- Leahy, P.; McKeogh, E.; Murphy, J.; Cummins, V. Development of a viability assessment model for hydrogen production from dedicated offshore wind farms. Int. J. Hydrogen Energy 2021, 46, 24620–24631. [Google Scholar]

- Durakovic, G.; del Granado, P.C.; Tomasgard, A. Powering Europe with North Sea offshore wind: The impact of hydrogen investments on grid infrastructure and power prices. Energy 2023, 263, 125654. [Google Scholar] [CrossRef]

- Hill, S.J.P.; Bamisile, O.; Hatton, L.; Staffell, I.; Jansen, M. The cost of clean hydrogen from offshore wind and electrolysis. J. Clean. Prod. 2024, 445, 141162. [Google Scholar] [CrossRef]

- Sorrenti, I.; Rasmussen, T.B.H.; Xydis, G.; Enevoldsen, P.; You, S. Correlations between component size green hydrogen demand and breakeven price for energy islands. Renew. Sustain. Energy Rev. 2023, 183, 113439. [Google Scholar] [CrossRef]

- Rogeau, A.; Vieubled, J.; de Coatpont, M.; Nobrega, P.A.; Erbs, G.; Girard, R. Techno-economic evaluation and resource assessment of hydrogen production through offshore wind farms: A European perspective. Renew. Sustain. Energy Rev. 2023, 187, 113699. [Google Scholar] [CrossRef]

- Groenemans, H.; Saur, G.; Mittelsteadt, C.; Lattimer, J.; Xu, H. Techno-economic analysis of offshore wind PEM water electrolysis for H2 production. Curr. Opin. Chem. Eng. 2022, 37, 100828. [Google Scholar] [CrossRef]

- Kubo, S. The roles of nuclear energy in hydrogen production. Engineering 2021, 16, 16–20. [Google Scholar] [CrossRef]

- Mendrela, P.; Stanek, W.; Simla, T. Sustainability assessment of hydrogen production based on nuclear energy. Int. J. Hydrogen Energy 2024, 49, 729–744. [Google Scholar] [CrossRef]

- Pruvost, F.; Cloete, S.; del Pozo, C.A.; Zaabout, A. Blue, green, and turquoise pathways for minimizing hydrogen production costs from steam methane reforming with CO2 capture. Energy Convers. Manag. 2022, 274, 116458. [Google Scholar] [CrossRef]

- Garcia-Villalva, R.; Biset-Peiró, M.; Alarcón, A.; Bacariza, C.; Murcia-López, S.; Guilera, J. Comparison of methane reforming routes for hydrogen production using dielectric barrier discharge plasma-catalysis. Int. J. Hydrogen Energy 2024, 59, 1367–1375. [Google Scholar] [CrossRef]

- Lee, S.; Kim, H.S.; Park, J.; Kang, B.M.; Cho, C.H.; Lim, H.; Won, W. Scenario-based techno-economic analysis of steam methane reforming process for hydrogen production. Appl. Sci. 2021, 11, 6021. [Google Scholar] [CrossRef]

- Ingale, G.U.; Kwon, H.M.; Jeong, S.; Park, D.; Kim, W.; Bang, B.; Lim, Y.I.; Kim, S.W.; Kang, Y.B.; Mun, J. Assessment of Greenhouse Gas Emissions from Hydrogen Production Processes: Turquoise Hydrogen vs. Steam Methane Reforming. Energies 2022, 15, 8679. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Giuliano, A.; Carapellucci, R.; Gallucci, K.; Cipollone, R. Experimental Characterization and Energy Performance Assessment of a Sorption-Enhanced Steam–Methane Reforming System. Processes 2021, 9, 1440. [Google Scholar] [CrossRef]

- Agnolin, S.; Di Felice, L.; Tanaka, A.P.; Tanco, M.L.; Ververs, W.J.; Gallucci, F. Intensification of hydrogen production: Pd–Ag membrane on tailored hastelloy-X filter for membrane-assisted steam methane reforming. Processes 2023, 12, 40. [Google Scholar] [CrossRef]

- Vostakola, M.F.; Ozcan, H.; El-Emam, R.S.; Horri, B.A. Recent advances in high-temperature steam electrolysis with solid oxide electrolysers for green hydrogen production. Energies 2023, 16, 3327. [Google Scholar] [CrossRef]

- Frick, K.; Wendt, D.; Talbot, P.; Rabiti, C.; Boardman, R. Technoeconomic assessment of hydrogen cogeneration via high temperature steam electrolysis with a light-water reactor. Appl. Energy 2022, 306, 118044. [Google Scholar] [CrossRef]

- Yildiz, B.; Kazimi, M.S. Efficiency of hydrogen production systems using alternative nuclear energy technologies. Int. J. Hydrogen Energy 2006, 31, 77–92. [Google Scholar] [CrossRef]

- Loreti, G.; Facci, A.L.; Ubertini, S. Combining renewable sources towards negative carbon emission hydrogen. Int. J. Hydrogen Energy 2023, 48, 20875–20888. [Google Scholar] [CrossRef]

- Norman, E.A.; Maestre, V.M.; Ortiz, A.; Ortiz, I. Steam electrolysis for green hydrogen generation. State of the art and research perspective. Renew. Sustain. Energy Rev. 2024, 202, 114725. [Google Scholar] [CrossRef]

- Kim, T.; Lee, W.Y.; Seo, S.H.; Oh, S.D.; Kwak, H.Y. Energy, Exergy and Thermoeconomic Analyses on Hydrogen Production Systems Using High-Temperature Gas-Cooled and Water-Cooled Nuclear Reactors. Energies 2023, 16, 8090. [Google Scholar] [CrossRef]

- Özkaya, M.; Acır, A.; Yalçın, Ş. Investigation of the hydrogen production of the PACER fusion blanket integrated with Fe–Cl thermochemical water splitting cycle. Nucl. Eng. Technol. 2023, 55, 4287–4294. [Google Scholar] [CrossRef]

- Juárez-Martínez, L.C.; Espinosa-Paredes, G.; Vázquez-Rodríguez, A.; Romero-Paredes, H. Energy optimization of a Sulfur–Iodine thermochemical nuclear hydrogen production cycle. Nucl. Eng. Technol. 2021, 53, 2066–2073. [Google Scholar] [CrossRef]

- Kong, R.; Chen, L.; Xia, S.; Li, P.; Ge, Y. Minimization of entropy generation rate in hydrogen iodide decomposition reactor heated by high-temperature helium. Entropy 2021, 23, 82. [Google Scholar] [CrossRef] [PubMed]

- Qian, X.; Jung, S. Computational design of H2SO4 decomposer combined with SOFC for thermochemical hydrogen production. Int. J. Energy Res. 2021, 45, 16576–16591. [Google Scholar] [CrossRef]

- Wang, Q.; Macián-Juan, R. Design and analysis of an iodine-sulfur thermochemical cycle-based hydrogen production system with an internal heat exchange network. Int. J. Energy Res. 2022, 46, 11849–11866. [Google Scholar] [CrossRef]

- Zhang, J.; Ling, B.; He, Y.; Zhu, Y.; Wang, Z. Experimental Study of the Characteristics of HI Distillation in the Thermochemical Iodine–Sulfur Cycle for Hydrogen Production. Processes 2024, 12, 1768. [Google Scholar] [CrossRef]

- Simpson, M.F.; Utgikar, V.; Sachdev, P.; McGrady, C. A novel method for producing hydrogen based on the Ca–Br cycle. Int. J. Hydrogen Energy 2007, 32, 505–509. [Google Scholar] [CrossRef]

- Lee, M.S.; Goswami, D.Y.; Stefanakos, E.K. Immobilization of calcium oxide solid reactant on a yttria fabric and thermodynamic analysis of UT-3 thermochemical hydrogen production cycle. Int. J. Hydrogen Energy 2009, 34, 745–752. [Google Scholar] [CrossRef]

- Sarker, A.K.; Azad, A.K.; Rasul, M.G.; Doppalapudi, A.T. Prospect of green hydrogen generation from hybrid renewable energy sources: A review. Energies 2023, 16, 1556. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Rezazadeh, A. Hydrogen fuel and electricity generation from a new hybrid energy system based on wind and solar energies and alkaline fuel cell. Energy Rep. 2021, 7, 2594–2604. [Google Scholar] [CrossRef]

- Song, Y.; Mu, H.; Li, N.; Shi, X.; Zhao, X.; Chen, C.; Wang, H. Techno-economic analysis of a hybrid energy system for CCHP and hydrogen production based on solar energy. Int. J. Hydrogen Energy 2022, 47, 24533–24547. [Google Scholar] [CrossRef]

- Abdolmaleki, L.; Jahanbin, A.; Berardi, U. Net-zero energy management through multi-criteria optimizations of a hybrid solar-hydrogen energy system for a laboratory in Toronto, Canada. Energy Build. 2024, 312, 114186. [Google Scholar] [CrossRef]

- Su, W.; Li, Q.; Zheng, W.; Han, Y.; Yu, Z.; Bai, Z.; Han, Y. Enhancing wind-solar hybrid hydrogen production through multi-state electrolyzer management and complementary energy optimization. Energy Rep. 2024, 11, 1774–1786. [Google Scholar] [CrossRef]

- Baral, S.; Šebo, J. Techno-economic assessment of green hydrogen production integrated with hybrid and organic Rankine cycle (ORC) systems. Heliyon 2024, 10, e25742. [Google Scholar] [CrossRef]

- Yang, T.; Yan, X.; Cai, W.; Luo, H.; Xu, N.; Tong, L.; Yan, F.; Chahine, R.; Xiao, J. Parametric Study and Optimization of Hydrogen Production Systems Based on Solar/Wind Hybrid Renewable Energies: A Case Study in Kuqa, China. Sustainability 2024, 16, 896. [Google Scholar] [CrossRef]

- Megia, P.J.; Vizcaíno, A.J.; Calles, J.A.; Carrero, A. Hydrogen production technologies: From fossil fuels toward renewable sources. A Mini Review. Energy Fuels 2021, 35, 16403–16415. [Google Scholar] [CrossRef]

- Dash, S.K.; Chakraborty, S.; Elangovan, D. A brief review of hydrogen production methods and their challenges. Energies 2023, 16, 1141. [Google Scholar] [CrossRef]

- Yang, L.; Wang, S.; Zhang, Z.; Lin, K.; Zheng, M. Current development status, policy support and promotion path of China’s green hydrogen industries under the target of carbon emission peaking and carbon neutrality. Sustainability 2023, 15, 10118. [Google Scholar] [CrossRef]

- Rey, J.; Segura, F.; Andújar, J.M. Green Hydrogen: Resources Consumption, Technological Maturity, and Regulatory Framework. Energies 2023, 16, 6222. [Google Scholar] [CrossRef]

- Morales-España, G.; Hernández-Serna, R.; Tejada-Arango, D.A.; Weeda, M. Impact of large-scale hydrogen electrification and retrofitting of natural gas infrastructure on the European power system. Int. J. Electr. Power Energy Syst. 2024, 155, 109686. [Google Scholar] [CrossRef]

- Du, Z.; Dai, Z.; Yang, Z.; Zhan, C.; Chen, W.; Cao, M.; Thanh, H.V.; Soltanian, M.R. Exploring hydrogen geologic storage in China for future energy: Opportunities and challenges. Renew. Sustain. Energy Rev. 2024, 196, 114366. [Google Scholar] [CrossRef]

- Butt, F.K.; Cao, C.; Wan, Q.; Li, P.; Idrees, F.; Tahir, M.; Khan, W.S.; Ali, Z.; Zapata, M.J.M.; Safdar, M.; et al. Synthesis, evolution and hydrogen storage properties of ZnV2O4 glomerulus nano/microspheres: A prospective material for energy storage. Int. J. Hydrogen Energy 2014, 39, 7842–7851. [Google Scholar] [CrossRef]

- Tarasov, B.P.; Fursikov, P.V.; Volodin, A.A.; Bocharnikov, M.S.; Shimkus, Y.Y.; Kashin, A.M.; Yartys, V.A.; Lototskyy, M.V. Metal hydride hydrogen storage and compression systems for energy storage technologies. Int. J. Hydrogen Energy 2021, 46, 13647–13657. [Google Scholar] [CrossRef]

- Jayaprabakar, J.; Hari, N.S.S.; Badreenath, M.; Anish, M.; Joy, N.; Prabhu, A.; Rajasimman, M.; Kumar, J.A. Nano materials for green hydrogen production: Technical insights on nano material selection, properties, production routes and commercial applications. Int. J. Hydrogen Energy 2024, 52, 674–686. [Google Scholar] [CrossRef]

- Ledwaba, K.; Karimzadeh, S.; Jen, T.C. Emerging borophene two-dimensional nanomaterials for hydrogen storage. Mater. Today Sustain. 2023, 22, 100412. [Google Scholar] [CrossRef]

- Durkin, K.; Khanafer, A.; Liseau, P.; Stjernström-Eriksson, A.; Svahn, A.; Tobiasson, L.; Andrade, T.S.; Ehnberg, J. Hydrogen-Powered Vehicles: Comparing the Powertrain Efficiency and Sustainability of Fuel Cell versus Internal Combustion Engine Cars. Energies 2024, 17, 1085. [Google Scholar] [CrossRef]

- Marksel, M.; Prapotnik Brdnik, A. Comparative Analysis of Direct Operating Costs: Conventional vs. Hydrogen Fuel Cell 19-Seat Aircraft. Sustainability 2023, 15, 11271. [Google Scholar] [CrossRef]

- Franco, A.; Giovannini, C. Routes for Hydrogen Introduction in the Industrial Hard-to-Abate Sectors for Promoting Energy Transition. Energies 2023, 16, 6098. [Google Scholar] [CrossRef]

- Bedakhanian, A.; Maleki, A.; Haghighat, S. Multi-objective optimization of a cogeneration system based on solar energy for clean hydrogen, cooling, and electricity production. Mater. Today Sustain. 2024, 54, 103990. [Google Scholar] [CrossRef]

- Rad, H.N.; Ghasemi, A.; Marefati, M. Cost and environmental analysis and optimization of a new and green three-level waste heat recovery-based cogeneration cycle: A comparative study. Heliyon 2024, 10, e29087. [Google Scholar]

- Vives, A.M.V.; Wang, R.; Roy, S.; Smallbone, A. Techno-economic analysis of large-scale green hydrogen production and storage. Appl. Energy 2023, 346, 121333. [Google Scholar] [CrossRef]

- Frowijn, L.S.F.; van Sark, W.G. Analysis of photon-driven solar-to-hydrogen production methods in the Netherlands. Sustain. Energy Technol. Assess. 2021, 48, 101631. [Google Scholar] [CrossRef]

- Lui, J.; Paul, M.C.; Sloan, W.; You, S. Techno-economic feasibility of distributed waste-to-hydrogen systems to support green transport in Glasgow. Int. J. Hydrogen Energy 2022, 47, 13532–13551. [Google Scholar] [CrossRef]

- Liponi, A.; Baccioli, A.; Ferrari, L. Feasibility analysis of green hydrogen production from wind. Int. J. Hydrogen Energy 2023, 48, 37579–37593. [Google Scholar] [CrossRef]

- Matute, G.; Yusta, J.M.; Naval, N. Techno-economic model and feasibility assessment of green hydrogen projects based on electrolysis supplied by photovoltaic PPAs. Int. J. Hydrogen Energy 2023, 48, 5053–5068. [Google Scholar] [CrossRef]

- Armoo, E.A.; Mohammed, M.; Narra, S.; Beguedou, E.; Agyenim, F.B.; Kemausuor, F. Achieving Techno-Economic Feasibility for Hybrid Renewable Energy Systems through the Production of Energy and Alternative Fuels. Energies 2024, 17, 735. [Google Scholar] [CrossRef]

- Hasan, T.; Emami, K.; Shah, R.; Hassan, N.M.S.; Anderson, J.; Thomas, D.; Louis, A. A study on green hydrogen-based isolated microgrid. Energy Rep. 2022, 8, 259–267. [Google Scholar] [CrossRef]

| Time | Nation | Strategy/Planning | Key Content |

|---|---|---|---|

| 2022 | China | Mid- to Long-Term Plan for the Development of the Hydrogen Energy Industry (2021–2035) | By 2025, a comprehensive hydrogen energy industry development system and policy environment will be established. The production of hydrogen from renewable energy sources is expected to reach between 100,000 and 200,000 tons annually, about 0.303~0.606% of total hydrogen production in China, contributing to a reduction of 1 to 2 million tons of carbon dioxide emissions per year, about 0.1% to 0.2% of total carbon emissions. By 2030, a well-established system for technological innovation in the hydrogen energy industry, along with a clean energy hydrogen production and supply system, will be in place. By 2035, a robust hydrogen energy industry system will be developed, with a significant increase in the proportion of renewable energy-based hydrogen production in terminal energy consumption, thereby playing a crucial role in supporting the green energy transition and development. |

| 2022 | China | 14th Five-Year Plan for Renewable Energy Development | By 2025, the total consumption of renewable energy will reach approximately 1 billion tons of standard coal. During the 14th Five-Year Plan period, renewable energy accounted for over 50% of the growth in primary energy consumption. The annual renewable energy generation is about 3.3 trillion kilowatt hours. The total share of renewable energy consumption in China has reached about 33%, and the share of non-hydroelectric consumption of renewable energy has reached about 18%. The utilization rate of renewable resources remains at a reasonable level. The scale of non-electricity utilization such as geothermal energy heating, biomass heating, biomass fuel, and solar thermal utilization has reached over 60 million tons of standard coal. |

| 2024 | China | Guiding Opinions on Energy Work for 2024 | We will vigorously promote the green and low-carbon energy transition, pursue the dual-carbon goal, and ensure the sustained high-quality development of clean energy. By leveraging scientific and technological innovation, we aim to foster new growth drivers and enhance research, development, and innovation in energy technologies. We will deepen reform and openness, improve energy management efficiency, promote international cooperation, and further integrate with the global market. The goal is set to achieve energy production equivalent to 4.98 billion tons of standard coal by 2024, which includes the stable increase in the production of coal, crude oil, and natural gas, as well as the enhancement of installed power generation capacity and overall electricity production. Concurrently, the focus will be on optimizing the energy structure, improving quality, and enhancing efficiency. |

| Time | Nation | Strategy/Planning | Key Content |

|---|---|---|---|

| 2019 | Japan | Hydrogen/Fuel Cell Strategic Roadmap (2019) | By 2025, hydrogen fuel cell vehicle sales are projected to reach 200,000 units, with an anticipated increase to 800,000 units by 2030. The strategy includes diversifying hydrogen production through fossil fuel-based methods (utilizing carbon capture and storage technology), renewable energy sources, and the long-term goal of importing liquid hydrogen. Additionally, investments in research and development for hydrogen and fuel cell technologies are to be increased, focusing on enhancing energy efficiency, reducing costs, and improving safety. |

| 2020 | European Union | Eu Hydrogen Strategy | Efforts to accelerate green hydrogen production will be intensified by 2030, aiming to significantly boost production and utilization. This includes installing at least 40 GW of renewable hydrogen electrolysis facilities and producing up to 10 million tons of renewable hydrogen during this period. Plans also include developing a transmission and distribution network suited for hydrogen energy, such as retrofitting existing natural gas pipelines and establishing a cross-border hydrogen transmission network. The use of hydrogen will be encouraged across various industries, particularly in heavy industries (such as steel and chemicals) and sectors like transportation, where electrification is challenging. |

| 2020 | America | Hydrogen Energy Development Plan (2020–2030) | A comprehensive strategic framework is proposed for hydrogen research, development, and demonstration over the next decade and beyond. The goal is to reduce the cost of producing clean hydrogen energy from renewable, nuclear, and thermal sources by 80%, targeting USD 1/kg within the next 10 years. The Clean Hydrogen Center aims to produce over 3 million tons of clean hydrogen annually, contributing nearly a third of the U.S. 2030 clean hydrogen production target while reducing end-use carbon dioxide emissions by an estimated 25 million tons per year. |

| 2021 | Japan | Sixth Energy Basic Plan (2021) | The plan is to achieve carbon neutrality, or net zero greenhouse gas emissions, by 2050. The potential of hydrogen and ammonia in achieving carbon reduction targets was highlighted, and plans were made to expand the introduction and use of these energy sources. It is planned to improve energy efficiency in the industrial, transport, and residential sectors to reduce overall energy consumption. The plan is to ensure a stable supply of energy while reducing dependence on fossil fuels. |

| 2023 | America | U.S. National Clean Hydrogen Strategy and Roadmap | By 2030, 2040, and 2050, the clean hydrogen market space is 10/20/50 million tons, respectively; Put forward short-, medium-, and long-term hydrogen energy development goals; The cost of hydrogen in 2031 is down to USD 1/kg; Deploying clean hydrogen would reduce U.S. carbon emissions by about 10 percent in 2050 from 2005 levels, among other things. |

| 2020 | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | 2055 | 2060 | |

|---|---|---|---|---|---|---|---|---|---|

| Total hydrogen supply/ million tons | 31.73 | 37.15 | 38.10 | 42.64 | 49.01 | 58.07 | 67.87 | 74.09 | 85.80 |

| Energy ratio for hydrogen production | 3% | 3% | 3% | 5% | 7% | 9% | 12% | 14% | 18% |

| Type | Principle of Hydrogen Production | Advantage | Shortcoming | Application Phase |

|---|---|---|---|---|

| Photocatalytic process of hydrogen | Hydrogen production by decomposing water under light using photocatalysts. | Simple device; low cost. | Inefficient hydrogen production. | Laboratory research phase. |

| Solar thermochemical water splitting for hydrogen production | Hydrogen production from solar pyrolytic water. | The principle is simple, the technology is mature, and the hydrogen production efficiency is high. | High cost; poor long-term stability of the material. | Preliminary demonstration phase. |

| The photoelectrochemical process of hydrogen | The use of photoelectric chemical cells to convert solar energy directly into chemical energy, which drives the separation of water into hydrogen and oxygen. | Low cost; rapid charge transfer in electrochemical reactions. | The operation is complicated, and the electrode material is not easy to find. | Laboratory research phase. |

| Type | Principle of Hydrogen Production | Advantage | Shortcoming | Application Phase |

|---|---|---|---|---|

| Pyrolysis reforming process | The gaseous components of biomass pyrolysis products are reformed by reacting with water vapor to produce hydrogen. | High hydrogen production efficiency; rich source of raw materials; easy to obtain. | Easy tar clogging; catalyst deactivation. | Industrial demonstration and initial commercialization phase. |

| Steam gasification process | Biomass is directly converted into hydrogen-rich gas by reacting with water vapor at high temperatures. | Hydrogen production efficiency is high; more economical. | Tar is produced as a by-product during gasification. | |

| Supercritical water gasification | Biomass is directly vaporized into hydrogen-rich gas in a supercritical water environment. | High conversion rate, high hydrogen content, and no by-products such as tar and coke. | High equipment requirements and high cost. | |

| Photo-fermentation | Photosynthetic bacteria are used to break down organic substrates under light to produce hydrogen. | Wide source of raw materials; high hydrogen production. | The lighting conditions are strict and are easily affected by the type and concentration of organic substrates. | Laboratory research and preliminary demonstration phase. |

| Dark fermentation | Using anaerobic bacteria to break down organic matter in dark conditions, hydrogen gas is produced. | Low cost; fast hydrogen production rate; easy to large-scale production. | Prone to toxic by-products. | |

| The light–dark coupling fermentation method | Combining light and dark fermentation. | Improved hydrogen production and conversion efficiency; intermediates such as organic acids are effectively utilized. | Control complexity and fine control. It is difficult to maintain the stability of the coexistence of two kinds of fermentation microorganisms. | |

| Direct photolysis | Photosynthetic organisms such as cyanobacteria and some green algae are used to produce hydrogen through photosynthesis under light conditions. | Direct use of solar energy; the process is simple; no need to add external organic substrates; rich resources. | Low hydrogen production efficiency and oxygen generation will inhibit hydrogenase activity. | |

| Indirect photolysis | Photosynthesis produces carbohydrates, which decompose to produce hydrogen under dark conditions. | The separation of hydrogen and oxygen reduces the inhibition of oxygen to hydrogenase and indirectly improves the efficiency of hydrogen production. | The process is complex, requiring two stages of light and darkness; conversion efficiency is limited by the efficiency with which carbohydrates are produced and broken down. | |

| Cell-free synthase biological conversion method | Use of hydrogenases and other related enzymes derived from microorganisms. | Simple operation; high hydrogen production efficiency. | Higher cost. | Laboratory research and preliminary demonstration phase. |

| Type | Diaphragm Material | Operating Temperature /°C | Efficiency /% | Current Density /A cm−2 | Application Phase | Merits and Demerits |

|---|---|---|---|---|---|---|

| AWE | Asbestos, polyphenylene sulfide | ≤90 | 60~80 | 0.2~0.5 | Large-scale industrialization | Simple, mature, high reliability; however, the current density is low, the electrolyte is corrosive, and the maintenance cost is high. |

| PEM | Perfluorosulfonic acid membrane | ≤80 | 80~90 | 1.0~4.0 | Initial commerce | High efficiency, high current density, and high hydrogen production purity, but the service life is low. |

| AEM | Anion exchange membrane | ≤60 | 70~90 | 0.8~2.0 | laboratory | Simple operation, good stability, high current density, but the cost is high. |

| SOE | Solid oxide | ≥800 | 85~100 | 1.0~10.0 | laboratory | High efficiency but high material requirements, low stability. |

| Type | Principle of Hydrogen Production | Advantage | Shortcoming | Application Phase | |

|---|---|---|---|---|---|

| Methane steam reforming | Hydrogen and carbon dioxide are produced through the reaction of methane with water vapor at high temperature and pressure. | Reduced fossil fuel use and high efficiency. | Complex process; high equipment cost. | Laboratory to demonstration project phase. | |

| High-temperature steam electrolysis | Hydrogen production by electrolysis of high-temperature water vapor. | Significantly lower power consumption and improved energy efficiency in electrolyzing water at high temperatures. Suitable for large-scale hydrogen production. | High-temperature operation requires high levels of materials and equipment, increasing costs and maintenance difficulties. | Laboratory to demonstration project phase. | |

| Thermochemical cycle | S-I cycle | First sulfur dioxide, iodine, and water react to form hydrogen iodide and sulfuric acid, and then hydrogen iodide decomposes at high temperatures to form hydrogen. | Increased energy efficiency by utilizing high-temperature thermal energy directly from nuclear reactors without relying on electricity. | Complex processes involving multi-step reactions require efficient chemical reactors and materials. | Laboratory research phase. |

| Ca-Br Cycle | Calcium oxide is regenerated from calcium bromide at high temperatures, and then calcium oxide reacts with hydrogen bromide to form hydrogen. | ||||

| Green Hydrogen Production Technology | Advantage | Shortcoming | Application Phase | ||

|---|---|---|---|---|---|

| Solar water splitting technology for hydrogen production | Photocatalytic process of hydrogen | Simple material acquisition; simple device; low cost. | The electron-hole pair recombination has low hydrogen production efficiency. | Laboratory research phase. | |

| Solar thermochemical water splitting for hydrogen production | Simple principle; mature technology; high hydrogen production efficiency. | High cost; poor long-term stability of the material. | Preliminary demonstration phase. | ||

| Photoelectrochemical process of hydrogen | Low cost; rapid charge transfer in electrochemical reactions. | The operation is complicated, and the electrode material is not easy to find. | Laboratory research phase. | ||

| Biomass hydrogen production technology | Hydrogen by thermochemical conversion | Pyrolysis reforming process | High hydrogen production efficiency; rich source of raw materials; easy to obtain. | Easy tar clogging; catalyst deactivation. | Industrial demonstration and initial commercialization phase. |

| Steam gasification process | Hydrogen production efficiency is high; more economical. | Tar is produced as a by-product during gasification. | |||

| Supercritical water gasification | High conversion rate, high hydrogen content, and no by-products such as tar and coke. | High equipment requirements and high cost. | |||

| Biomass hydrogen pro-duction technology | Microbial hydrogen process | Photo-fermentation | Wide source of raw materials; high hydrogen production. | The lighting conditions are strict and are easily affected by the type and concentration of organic substrates. | Laboratory re-search and preliminary demonstration phase. |

| Dark fermentation | Low cost, fast hydrogen production rate, easy to large-scale production. | Prone to toxic by-products. | |||

| The light–dark coupling fermentation method | Improved hydrogen production and conversion efficiency; intermediates such as organic acids are effectively utilized. | Control complexity and fine control. It is difficult to maintain the stability of the coexistence of two kinds of fermentation microorganisms. | |||

| Direct photolysis | Direct use of solar energy; the process is simple; no need to add external organic substrates; rich resources. | Low hydrogen production efficiency and oxygen generation will inhibit hydrogenase activity. | |||

| Indirect photolysis | The separation of hydrogen and oxygen reduces the inhibition of oxygen to hydrogenase and indirectly improves the efficiency of hydrogen production. | The process is complex, requiring two stages of light and darkness; conversion efficiency is limited by the efficiency with which carbohydrates are produced and broken down. | |||

| Cell-free synthase biological conversion method | Simple operation; high hydrogen production efficiency. | Higher cost. | |||

| Water electrolysis technology for hydrogen production | AWE hydrogen production | Mature technology; high reliability. | Low current density; corrosive electrolyte; high maintenance costs. | Mature industrial application. | |

| PEM hydrogen production | High efficiency; high current density; high purity hydrogen production. | Low service life. | Initial commercialization phase. | ||

| AEM hydrogen production | Simple operation; good stability; high current density. | High cost. | Laboratory re-search and preliminary demonstration phase. | ||

| SOE hydrogen production | High efficiency; high material requirements. | Low stability. | Laboratory re-search phase. | ||

| Hydrogen production from offshore wind | Effectively address the space and environmental constraints of onshore wind power and can be integrated with existing offshore wind facilities. | The construction and maintenance cost is high, the technology is complex, the marine environment is greatly affected, and the equipment has high corrosion resistance requirements. | Demonstration project phase. | ||

| Hydrogen production from nuclear energy | Methane steam reforming | Use heat energy; reduce fossil fuels; improve efficiency. | Complicated process; higher equipment cost. | Lab to demonstration project stage. | |

| High-temperature steam electrolysis | Under high-temperature conditions, the power consumption of electrolytic water is significantly reduced and the energy efficiency is improved. Suitable for large-scale hydrogen production. | High-temperature operation requires high materials and equipment, increasing the cost and maintenance difficulty. | Lab to demonstration project stage. | ||

| Thermochemical cycle | S-I cycle | It does not rely on electricity and directly uses the high-temperature heat energy of the nuclear reactor to improve energy efficiency. | The reaction process is complex, involves multi-step reactions, and requires efficient chemical reactors and materials. | Laboratory re-search phase. | |

| Ca-Br Cycle | |||||

| Hydrogen production from mixed energy sources | By combining solar, wind, nu-clear, and other forms of energy, the overall stability and efficiency of the system are improved. We can make full use of the advantages of various energy sources to achieve a diversified energy supply. | Technology integration is complex, and system construction and maintenance costs are high, involving a variety of energy conversion and storage technologies; the coordination of various energy forms should be considered. | Demonstration project and initial commercialization phase. | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuluhong, A.; Chang, Q.; Xie, L.; Xu, Z.; Song, T. Current Status of Green Hydrogen Production Technology: A Review. Sustainability 2024, 16, 9070. https://doi.org/10.3390/su16209070

Tuluhong A, Chang Q, Xie L, Xu Z, Song T. Current Status of Green Hydrogen Production Technology: A Review. Sustainability. 2024; 16(20):9070. https://doi.org/10.3390/su16209070

Chicago/Turabian StyleTuluhong, Ayiguzhali, Qingpu Chang, Lirong Xie, Zhisen Xu, and Tengfei Song. 2024. "Current Status of Green Hydrogen Production Technology: A Review" Sustainability 16, no. 20: 9070. https://doi.org/10.3390/su16209070

APA StyleTuluhong, A., Chang, Q., Xie, L., Xu, Z., & Song, T. (2024). Current Status of Green Hydrogen Production Technology: A Review. Sustainability, 16(20), 9070. https://doi.org/10.3390/su16209070