Abstract

In recent years, the integration of artificial intelligence (AI) into logistics optimization has gained significant attention, particularly concerning sustainability criteria. This article provides an overview of the diverse AI models and algorithms employed in logistics optimization, with a focus on sustainable practices. The discussion covers several techniques, including generative models, machine learning methods, metaheuristic algorithms, and their synergistic combinations with traditional optimization and simulation methods. By employing AI capabilities, logistics stakeholders can enhance decision-making processes, optimize resource utilization, and minimize environmental impacts. Moreover, this paper identifies and analyzes prominent challenges within sustainable logistics, such as reducing carbon emissions, minimizing waste generation, and optimizing transportation routes while considering ecological factors. Furthermore, the paper explores emerging trends in AI-driven logistics optimization, such as the integration of real-time data analytics, blockchain technology, and autonomous systems, which hold immense potential for enhancing efficiency and sustainability. Finally, the paper outlines future research directions, emphasizing the need for further exploration of hybrid AI approaches, robust optimization frameworks, and scalable solutions that accommodate dynamic and uncertain logistics environments.

1. Introduction

Sustainable development is a philosophy of development that aims to meet the needs of the present while protecting the rights of future generations. It seeks to achieve a balance between the society, economy, and environment [1]. The United Nations established the Sustainable Development Goals (SDGs), a framework of global development goals, in 2015, with the aim of achieving a better and sustainable future by 2030. It covers a total of 17 goals in three main areas: social, economic, and environmental. According to the Sustainable Development Goals Report 2024, only of the SDGs are on track, nearly half are making little or average progress, and more than a third are stagnating or even regressing. In modern business, optimizing supply chains is essential for a company’s success and growth [2]. An efficient and optimized supply chain is required to meeting evolving customer demands and staying competitive. At the national level, logistics and supply chain networks are key drivers of overall economic and social development. The World Bank publishes the Logistics Performance Index (LPI), a global indicator used to assess the efficiency and performance of logistics across countries. It reflects the impact of a country’s logistics environment, policies, and investments on logistics efficiency and is an important indicator of international trade and economic development. The index is based on six key dimensions: customs, infrastructure, international shipments, logistics quality and competence, tracking and tracing, and timeliness. The significant and far-reaching impacts of the logistics and transportation industries on social and economic as well as environmental sustainability underscore the importance of integrating sustainable development into logistics and supply chain practices. Logistics optimization, therefore, becomes a relevant endeavor in achieving sustainability goals [3,4]. The aim is to balance operational efficiency with environmental responsibility, a challenge that many authors believe can be addressed through the integration of AI [5,6,7]. AI’s potential to transform supply chain management is significant, enabling companies to forecast demand more accurately, optimize transport routes, and manage inventories in a way that reduces emissions and resource use. This not only enhances efficiency by reducing costs, but also aligns with the broader objective of minimizing the environmental impact of logistics operations [8]. In other words, the utilization of AI in logistics might enable the achievement of sustainability, fundamentally altering the management of supply chains and their environmental footprints.

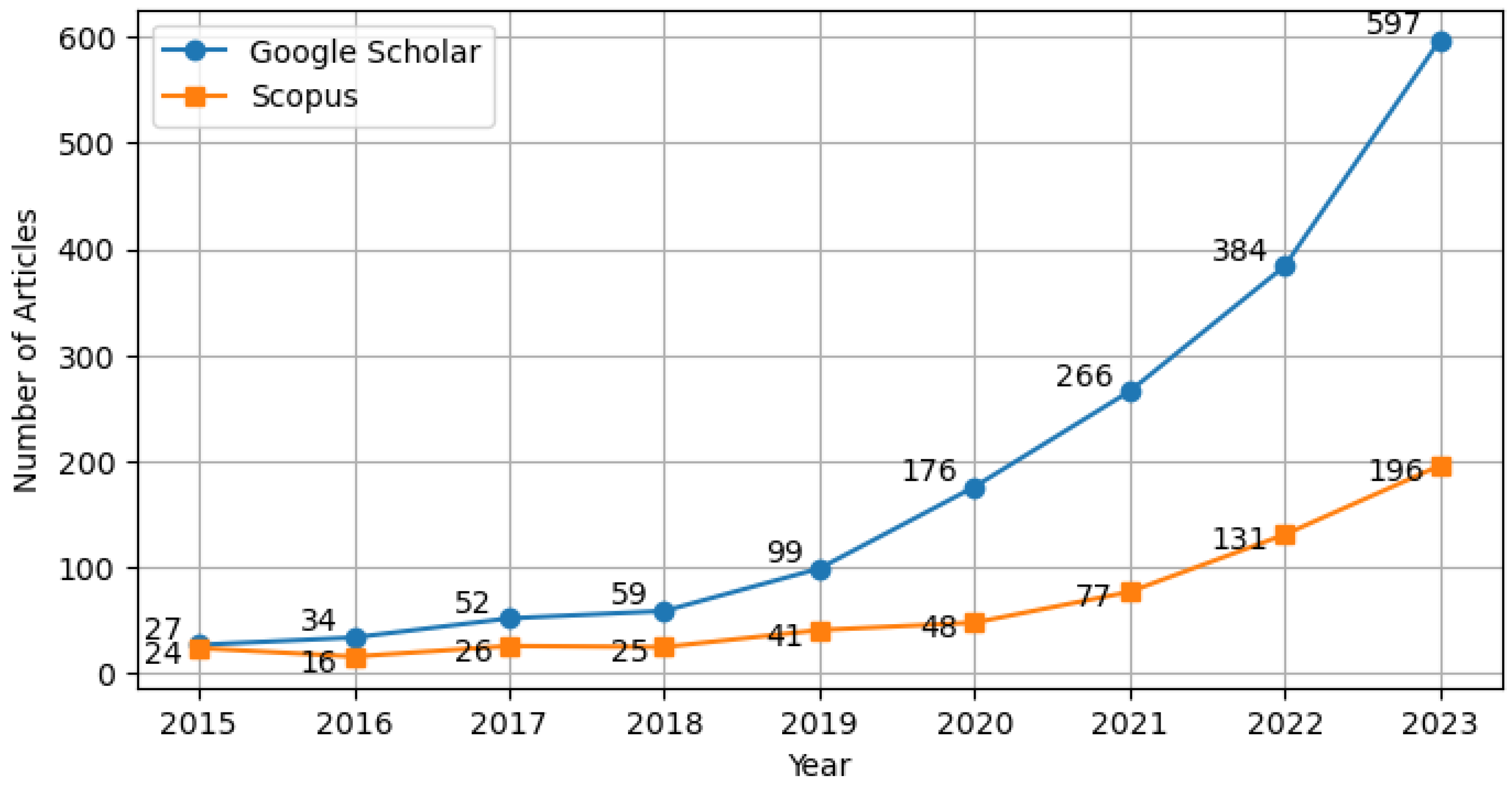

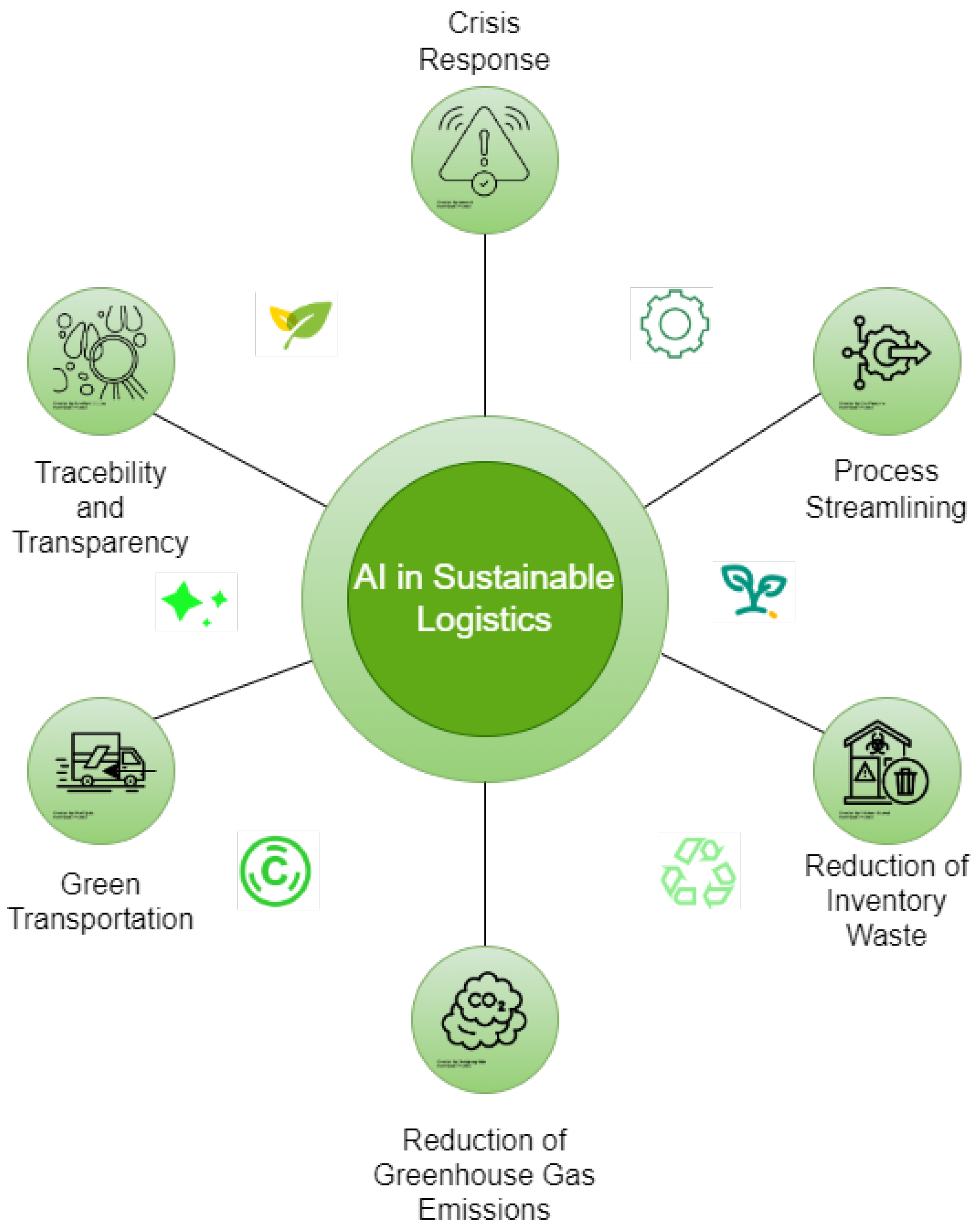

Furthermore, the consistent annual increase in number of academic articles published within the intersecting fields of AI and sustainable logistics reflects a growing research interest. As Figure 1 shows, over recent years, the number of articles including the terms “artificial intelligence” and “logistics” has experienced a noticeable increase in databases such as Google Scholar or Elsevier Scopus.

Figure 1.

Number of publications related to AI and logistics between 2015 and 2023.

Researchers emphasize the need for cleaner transportation options, sustainable production, and eco-friendly logistics to meet the challenges presented by a growing population and finite natural resources [9]. In this context, AI-based solutions offer the tools necessary for companies to achieve unparalleled advancements in supply chain management. Early implementers of AI in supply chain management have seen significant benefits, reducing logistics expenses by , decreasing stock levels by , and increasing service efficiency by when compared to their less advanced competitors [10]. Given these advancements, the establishment of the SDGs, and the LPI, several research questions arise, as follows:

- How do SDGs relate to the LPI?

- How do the main challenges in sustainable logistics impact the effective implementation of optimization strategies?

- How can AI technologies be implemented in logistics and supply chain management for sustainable development?

- How do emerging trends and best practices in AI-driven logistics optimization improve sustainability in the supply chain?

In order to answer these questions, this research is structured as follows:

Section 2 describes the methodological approach adopted for this review. It highlights a detailed explanation of the correlation analysis methods between sustainable development and logistics, as well as the process and evaluation criteria for reviewing literature on artificial intelligence models and algorithms for logistics optimization. Then, Section 3 emphasizes the importance of sustainability criteria and details the process used to delineate the study, including how the specific SDGs are defined and addressed within the scope of the review. Next, Section 4 provides an overview of AI models and algorithms for logistics optimization and their integration with optimization and simulation methods. It addresses key sustainability issues and challenges, while exploring AI solutions. The section also examines AI integration in logistics, discussing its impact on decision-making, resource optimization, real-world applications, and limitations. Emerging trends and best practices in AI-driven logistics are also explored. Finally, Section 5 concludes the paper by summarizing the key findings from the review.

2. Methodology

The methodology was organized into two main phases: (i) the selection of the most relevant Sustainable Development Goals, with their relationship to logistics determined using correlation analysis; and (ii) identifying the relevant literature on AI in logistics optimization, taking into account the selected SDGs. For the first phase, we used correlation analysis, which is a statistical method used to determine the strength and direction of the relationship between two variables, to help us determine how one variable changes in relation to another. It is commonly employed to identify linear relationships between features and to assess the impact of variables on a target. The formula is expressed in (1), as follows:

where represents the i-th value of variable X, represents the i-th value of variable Y, is the mean of variable X, and is the mean of variable Y.

The Pearson correlation coefficient r ranges from −1 to 1, indicating a positive correlation, a negative correlation, or no correlation. The magnitude of the correlation coefficient indicates the strength of the relationship, with values closer to +1 or −1 representing a stronger association, while values near 0 suggest a weaker or no relationship. In this study, a sample of countries with complete data for Sustainable Development Goals (https://dashboards.sdgindex.org/explorer, accessed on 23 August 2024) and Logistics Performance Index (https://worldpopulationreview.com/country-rankings/logistics-performance-index-by-country, accessed on 23 August 2024) for 2023 was selected, excluding any countries with missing data. Data completeness and analytical accuracy were ensured through this process. By calculating the correlation coefficients between logistics and Sustainable Development Goals, and ranking the results, this method helped to identify which goals were most strongly affected by logistics performance, providing valuable insights for subsequent research.

After delimiting the extent of the research to the SDGs most correlated with logistics, the second phase of the methodology focused on conducting a literature search related to these specific SDGs. The keywords considered were “AI in logistics” “logistics optimization” and “sustainable logistics” The search was then carried out in the ScienceDirect, Springer Link, and Google Scholar databases, limiting the results to journal articles published between 2015 and 2024. For each database, the top 20 relevant articles were selected based on these criteria. This resulted in an initial pool of 180 papers. After compiling this initial pool, duplicates that were present in multiple databases were identified and removed, resulting in 150 unique articles. Then, inclusion and exclusion criteria were applied to these articles. The inclusion criteria included studies focusing on the application of AI, machine learning (ML) or optimization methods within logistics (1), research addressing sustainability in logistics concerning the identified SDGs (2), publications available in full text (3), and articles published in English (4). The exclusion criteria excluded studies not directly related to logistics or the specified SDGs (1), theses (2), dissertations (3), book chapters (4), and non-peer-reviewed articles (5), as well as publications without accessible full texts (6).

Following the application of these criteria, the titles and abstracts of the remaining articles were reviewed, which lead to the exclusion of 50 articles due to irrelevance, incorrect publication type, or language barriers. This left 110 articles for full-text review. During the full-text review, 30 articles were further excluded because they did not sufficiently focus on logistics applications of AI or optimization methods, lacked alignment with the identified SDGs, or had inaccessible full texts despite reasonable efforts to obtain them. A consensus was reached on including 40 articles in the final selection, with any discrepancies between reviewers resolved through discussion to ensure objective selection. An overview of some of the selected papers is presented in Table 1, which includes key details such as the titles, authors, publication years, methodologies applied, application areas, relevant SDGs, and the databases from which they were sourced.

Table 1.

Overview of selected papers on AI and sustainable logistics.

3. Impact of Sustainability on Logistics

Building on the methodology previously outlined, this section explores the correlation between logistics performance and the 17 individual SDGs, as well as the overall SDG score. The results of the analysis are presented, followed by a discussion on the influence of the strongly correlated SDGs on logistics optimization.

3.1. Correlation Analysis Between Sustainable Development and Logistics

A correlation analysis was employed to explore the impact of the LPI on the SDGs. The objective was to measure the linear relationship between LPI and various SDG indicators, identifying which SDG factors were most influenced by changes in logistics performance. The results are summarized in Table 2. Goals with correlation coefficients greater than or less than were selected for analysis.

Table 2.

Correlation coefficients between SDGs and LPI.

As Table 2 shows, there is a strong positive correlation between the LPI and overall SDG index, with a coefficient of , indicating that countries with better logistics performance tend to perform well across sustainable development. Among the individual goals, SDG 9 (industry, innovation, and infrastructure) showed the highest positive correlation with LPI (), highlighting that improved logistics systems enhance industrialization, technological innovation, and infrastructure development. Similarly, SDG 3 (good health and well-being) and SDG 16 (peace, justice, and strong institutions) have high positive correlations of and , respectively, suggesting that efficient logistics contributes to better healthcare access, emergency response systems, and strong governance capacities. However, the analysis also indicated significant negative correlations with SDG 12 (responsible consumption and production) and SDG 13 (climate action) at and , respectively. These findings suggest that, while enhanced logistics can drive economic growth, they may also lead to overconsumption, resource wastage, and environmental challenges, such as increased carbon emissions. Consequently, there is a need to incorporate sustainable practices within logistics systems, such as promoting green logistics, adopting low-emission transportation modes, and utilizing renewable energy sources to mitigate environmental impacts. Policymakers and stakeholders must prioritize sustainable logistics development and international cooperation to balance economic growth with environmental protection, thereby advancing the achievement of the SDGs.

3.2. Influence of Sustainability Criteria on Logistics Optimization

The SDGs and their associated regulations have imposed new requirements on logistics. Logistics optimization enables businesses to meet the growing demand for fast and efficient supply chain operations. This involves effectively planning, organizing, and executing the movement of goods and services in an efficient manner. The influence of the Sustainable Development Goals (specifically, SDG 3, SDG 9, SDG 12, SDG 13, and SDG 16) on logistics optimization is focused on in this study.

Good health and well-being (SDG 3) aims to ensure healthy lives and promote well-being for all ages. Regulations like the Clean Air Act in the United States, European Union (EU) Air Quality Standards, and China’s Green Logistics Promotion Plan push for reduced emissions and pollution, promoting public health. Logistics operations have been identified as significant contributors to greenhouse gas emissions, accounting for of global emissions, as highlighted by the World Economic Forum in 2016 [19]. Reducing emissions by adopting cleaner technologies and optimizing transport routes [20,21] can help logistics companies to minimize their negative impact on public health. Additionally, transportation and warehousing management play a critical role in the timely delivery of medical supplies during health crises, ensuring effective distribution during emergencies. Likewise, effective risk management [22] entails identifying and mitigating risks in the supply chain, such as disruptions in transportation, natural disasters, or geopolitical issues, to ensure the continuity of operations. This capacity strengthens global health systems’ resilience and enhances the industry’s contribution to public well-being.

Industry, innovation, and infrastructure (SDG 9) emphasizes the development of sustainable and resilient infrastructure, promoting inclusive and sustainable industrialization, and fostering innovation. It is supported by initiatives like the Fixing America’s Surface Transportation Act (FAST Act), the Trans-European Transport Network (TEN-T), and China’s Belt and Road Initiative, all of which enhance sustainable transport infrastructure. Logistics relies heavily on robust infrastructure, such as roads, ports, and airports, to ensure the efficient movement of goods. Investments in infrastructure development and the adoption of innovative technologies like smart warehousing, green supply chains, and inventory management enhance the efficiency and sustainability of logistics operations [16,23]. By driving technological advancements and improving connectivity, logistics supports sustainable industrial growth and contributes to economic development.

Responsible consumption and production (SDG 12) focuses on ensuring sustainable consumption and production patterns. It is addressed through policies like the Resource Conservation and Recovery Act (RCRA), the EU’s Circular Economy Action Plan, and China’s Green Supply Chain Initiative, focusing on resource efficiency and waste reduction. Through optimizing transportation and packaging processes, logistics can minimize resource consumption and reduce their environmental footprint. Goyal and Sharma [17] showed that it is also imperative to ensure efficient warehouse layout and design, as well as optimize picking, packing, and shipping processes to streamline operations and reduce cycle times. Additionally, by implementing circular economy principles—such as recycling, reuse, and waste reduction—logistics operations can significantly decrease waste generation, contributing to more sustainable production and consumption practices.

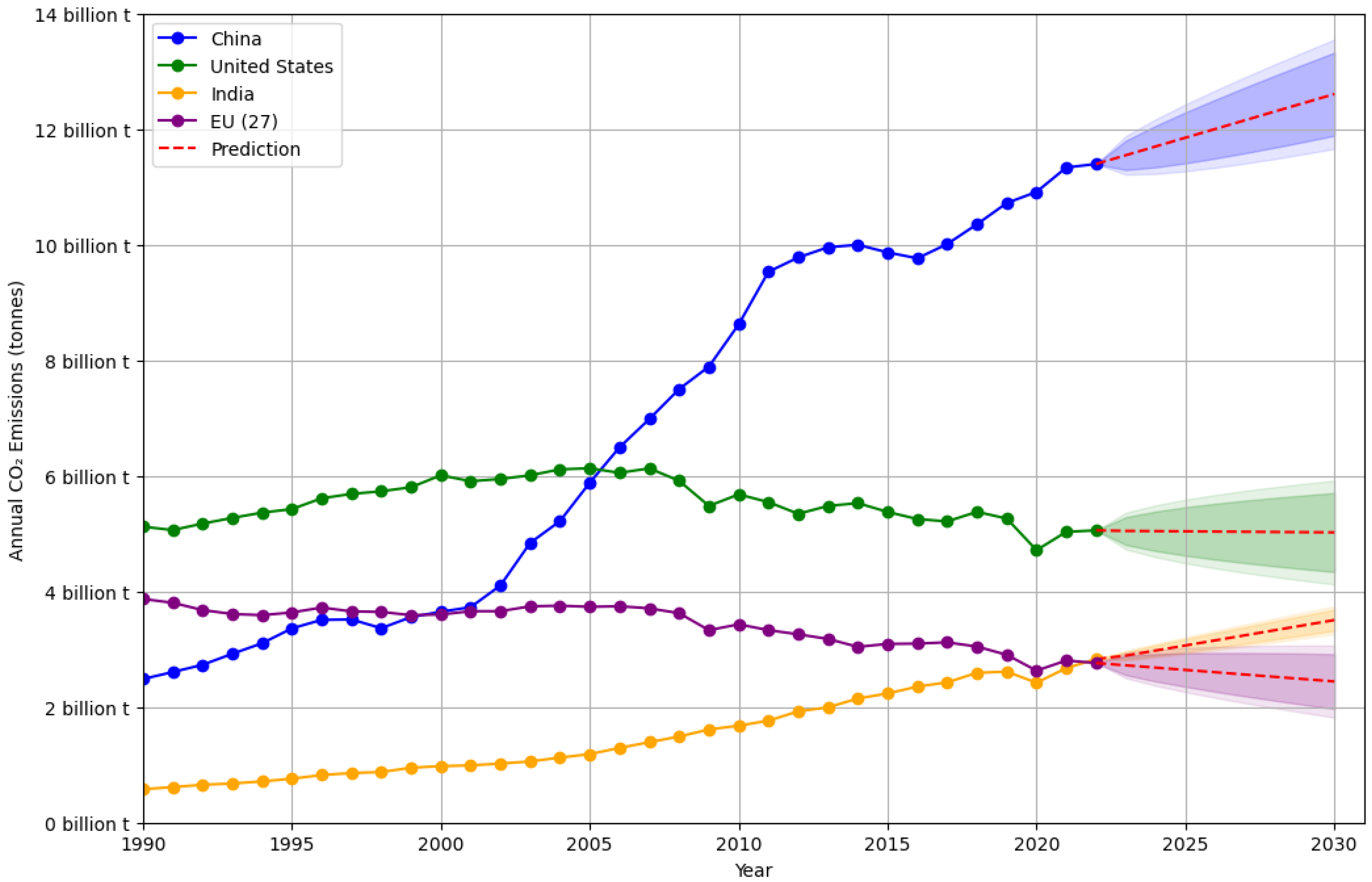

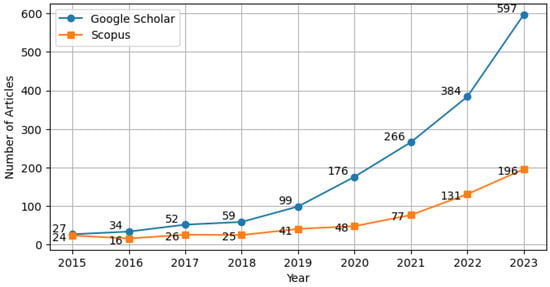

Climate action (SDG 13) calls for urgent measures to combat climate change and its impacts. Carbon dioxide emissions are a major contributor to global climate change. According to data from Our World in Data (https://ourworldindata.org/, accessed on 17 October 2024), global CO2 emissions from fossil fuels and industry have reached a total of billion tonnes. Figure 2 illustrates the annual CO2 emissions from the following four major regions: China, the United States, India, and the European Union (EU), spanning from 1990 to 2022. Projections until 2030 were generated using Holt’s double exponential smoothing, a method specifically designed for time series data that exhibit a trend but lack seasonality [24]. The data reveals several important points, as follows:

Figure 2.

CO2 emissions forecast for China, the United States, India, and the EU-27.

- China has seen a large increase in CO2 emissions since the early 2000s, reaching nearly 12 billion tonnes per year, making it the largest global emitter. Despite this, China has committed to climate action with a target to peak carbon emissions by 2030 and achieve carbon neutrality by 2060 [25].

- The United States has maintained high but relatively stable emission levels, with a slight decline over the past decade. Currently, U.S. emissions stand at approximately 5 billion tonnes annually. Together, China and the United States are responsible for almost half of global CO2 emissions [26].

- India has shown a steady growth in emissions, surpassing 3 billion tonnes per year. As an emerging economy, India’s emissions trajectory is expected to continue rising.

- The 27 member states of the European Union (EU-27) have successfully reduced their emissions over the past three decades, currently emitting around billion tonnes per year. The European Climate Law mandates that Europe achieve climate neutrality by 2050, with an intermediate target of reducing net greenhouse gas emissions by at least by 2030 compared to 1990 levels [27].

These trends highlight the need for strong climate policies and global cooperation, especially among the largest emitters. In the logistics sector, key activities like manufacturing, packaging, transportation, and procurement contribute significantly to the overall carbon footprint, estimated to be 80–90% [28]. Using low-carbon technologies, like electric vehicles [29] and renewable energy [30], can greatly reduce emissions. Additionally, including climate change strategies in logistics operations, such as risk management and emergency response, can help the industry be more resilient to climate-related risks [23]. These efforts not only reduce climate change but also make logistics businesses more sustainable and competitive.

Lastly, peace, justice, and strong institutions (SDG 16) focuses on promoting peaceful and inclusive societies, providing access to justice, and building accountable and transparent institutions. They are promoted through laws like the Foreign Corrupt Practices Act (FCPA) from the United States, the EU’s General Data Protection Regulation (GDPR), and China’s Anti-Unfair Competition Law, fostering transparency and ethical practices in global supply chains. The global nature of the logistics industry exposes it to challenges such as corruption, fraud, and unfair competition. By enhancing transparency, accountability, and ethical standards, logistics can reduce corruption and ensure fair trade practices [31,32]. Establishing strong legal and institutional frameworks helps improve supply chain credibility and efficiency, thereby supporting global peace and prosperity.

4. Findings

With global concerns about climate change, resource depletion, and social well-being growing in recent years, sustainable logistics, as an integral part of realizing global connectivity, is critical to addressing environmental challenges, mitigating climate change, and increasing resilience. AI, with its ability to process data autonomously to generate predictions or prescriptions, is recognized as a powerful tool to help achieve the Sustainable Development Goals [33,34]. This section provides insights into AI-driven approaches in sustainable logistics, explores the effectiveness of AI in sustainable logistics, and investigates the potential benefits and limitations of AI integration in logistics operations.

4.1. Top Issues Driving Sustainable Logistics

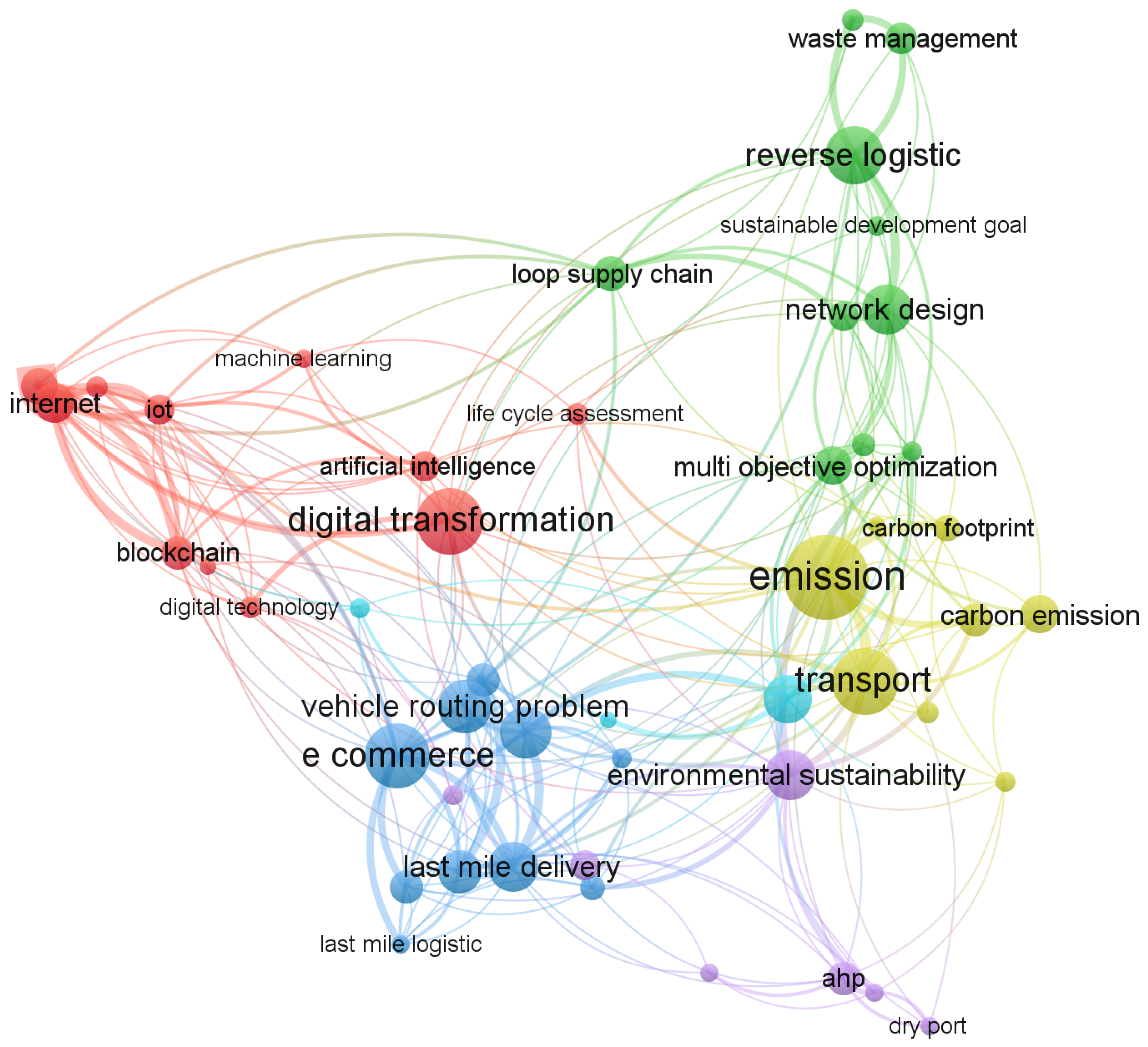

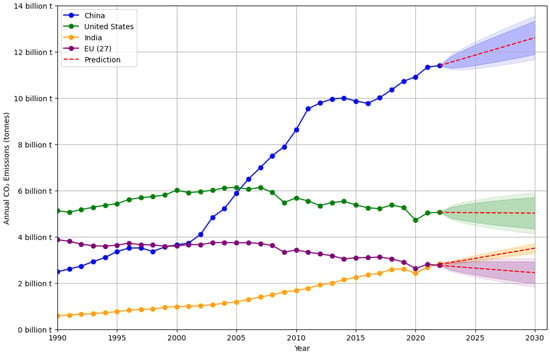

In order to achieve the SDGs, logistics needs to improve its overall efficiency, reduce costs, and minimize its environmental impact, in order to become sustainable logistics. The hot topics in sustainable logistics research are analyzed in this section. Figure 3 presents the strength of the associations between the keywords of 1362 publications related to sustainable logistics between 2019 and 2023 and was made using VOSviewer, which is a scientific literature data visualization and analysis tool. The results indicate different degrees of association and attributes through the color shades of the nodes and the colors themselves. Notice that, in recent years, the most relevant research topics have been emissions, vehicle routing problems, waste management, digital transformation, and environmental sustainability.

Figure 3.

Network visualization and association strengths of keywords from sustainable logistics studies.

With the increasing prosperity of global trade and the continuous growth of logistics activities, greenhouse gas emissions generated during transport have become an environmental issue that cannot be ignored. This not only contributes to the trend of global warming, but also has an impact on the operating costs and reputation of logistics companies. Reducing emissions is a key measure for sustainable logistics, as shown in Figure 3, where it can be seen that transportation and carbon emissions have attracted a great deal of attention. The transport sector’s primary reliance on fossil fuel-powered vehicles is the main sources of carbon emissions from logistics operations [11]. One major development in this regard is the use of electric vehicles for urban distribution. The rise of e-commerce and the increased demand for last-mile delivery has made electric vehicles effective in reducing carbon footprints, especially in urban logistics operations [29]. In addition, the use of route optimization techniques, such as clustered logistics and optimized routes, have made a significant contribution to sustainable transport [12]. Additionally, logistics activities produce various types of waste. For instance, packaging has led to the over-consumption of resources, environmental pollution, ecological damage, and an increased energy demand, due to their extensive use of disposable materials and generation of large quantities of waste [30]. Minimizing the waste generated during logistics operations requires multifaceted measures, including sustainable packaging materials, reverse logistics, and waste management. Li et al. [13] proposed a hybrid discrete artificial bee colony algorithm for solving the location allocation problem in reverse logistics network systems.

With the rise of the e-commerce industry, vehicle routing problems and last-mile delivery have attracted widespread attention which is a critical task for sustainable logistics. Burinskiene et al. [14] conducted an extensive simulation analysis and found that optimizing transportation routes within the warehouse can reduce warehouse waste by approximately . Innovative solutions such as parcel lockers [15], reception boxes and pick-up points [35], and drones [36] effectively improve the efficiency of last-mile deliveries, thereby reducing the carbon footprint. Digital transformation facilitates greater supply chain transparency and collaboration. Tijan et al. [31] state that blockchain technology can guarantee transparency in logistics and supply chain management by creating immutable records of transactions and asset movements. Consequently, this enhances the ability to track products and reduces occurrences of deceit. Additionally, the utilization of RFID technology in IoT devices has also facilitated the instantaneous monitoring of goods [32].

4.2. Key Challenges in Achieving Sustainable Logistics

The green logistics framework by McKinnon et al. [1] illustrates the complex relationship between logistics activities and their environmental impacts and costs. This subsection uses the framework to identify the main challenges in sustainable logistics and examine key strategies to address them, such as reducing carbon emissions, minimizing waste, and optimizing transportation routes. Furthermore, the role of AI in overcoming these challenges is also explored. The key challenges are categorized into four groups: (i) uncertainty; (ii) network complexity; (iii) logistics collaboration; and (iv) the need for technological innovation. Table 3 summarizes these challenges and their sources within sustainable logistics.

Table 3.

Challenges in sustainable logistics.

Uncertainty is a complex and multidimensional challenge in the field of sustainability logistics. It involves not only volatility on the demand side and complexity on the supply side, but also the unpredictability of technological advances and the volatility of regulations and policies. Demand-side and supply-side uncertainties have always been central challenges in logistics and supply chain management [37]. Additionally, delays, demand changes/lack of information, delivery constraints, and insufficient supply chain integration are the main sources of logistics uncertainty [38]. Dat et al. [37] optimized the waste electrical and electronic products (WEEPs) model by considering the characteristics of each type of waste in different recycling processes. Focusing on the perishability of food products, Soysal et al. [39] examined the inventory pathway problem for multiple suppliers and customers, and the results showed that horizontal cooperation between suppliers led to better energy savings and cost reductions. However, these challenges in the context of sustainability are further amplified by the development of new technologies and changes in regulations and policies. The introduction of new technologies has brought efficiency gains and environmental sustainability to the logistics industry, but it has also triggered challenges in terms of technology investment and staff training [40]. Legislative and regulatory uncertainty is also one of the challenges. The case study presented in Abbasi and Nilsson [41] revealed that companies are reluctant to take risks in terms of increasing investment in clean transportation and seeking cleaner alternatives due to the lack of clear and long-term guidance from regulators.

The logistics network design problem (LNDP) is a crucial issue in the field of supply chain management and logistics. It involves making decisions about the number, location, and capacity of facilities, as well as the flow of products in a logistics system. A well-organized logistics network is crucial to the sustainable development of enterprises and society, as it can improve transportation efficiency, reduce operating costs, minimize environmental pollution, and enhance the resilience of the supply chain. Research by You and Wang [42] has shown that the field of sustainable logistics network design is confronted with a multifaceted set of challenges that encompass the comprehensive integration of environmental and social objectives, the management of uncertainty and risk, and the expansion of industry applications. First, the three pillars of sustainable development are social, economic, and environmental, but current models tend to focus excessively on single environmental indicators such as economic efficiency and greenhouse gas emissions, ignoring important social aspects such as equity and worker welfare. However, the lack of indicators for social assessment makes their inclusion in the network a serious challenge. Secondly, the treatment of uncertainty and risk within existing models is insufficient, affecting the reliability and robustness of decision-making [43]. To make more holistic decisions under conditions of uncertainty, there is a need to employ enhanced multi-objective methodologies that balance the trade-offs between environmental, social, and economic objectives. Furthermore, despite advancements in specific sectors like manufacturing and retail, the universality and practicality of models could be improved by testing and validating them across a broader range of industries [42]. For instance, Yang et al. [44] showed that certain areas are at the forefront of technology while others are falling behind, due to the performance disparity at the city level.

The study of Soysal et al. [39] suggested that horizontal collaboration between suppliers can lead to better energy savings and cost reductions. Digital transformation facilitates greater logistics collaboration. In the era of Logistics 4.0, advanced technologies like the internet of things (IoT), blockchain, and AI are playing a significant role in enhancing collaboration in logistics and various other domains [45]. However, achieving collaboration in sustainable logistics is not without obstacles. An important obstacle is the matter of data privacy and security. According to Soumpenioti and Panagopoulos [46], the growing use of digital technology in logistics has led to heightened worries regarding the protection and confidentiality of data. The biggest issue is balancing transparency with protecting sensitive information from unwanted access. The diversity of logistics systems and the variability of logistics businesses also present substantial obstacles to attaining transparency throughout the supply chain. According to McGrath et al. [47], the presence of different systems creates obstacles that prevent the smooth sharing of data and transparency among stakeholders. The ever-changing nature of the logistics business requires a sustainable management strategy that can effectively respond to market uncertainties and the numerous adverse circumstances that come with transportation operations.

The logistics industry faces the challenge of increasing efficiency, reducing costs, and minimizing environmental impact. In order to meet these challenges, logistics companies and related organizations need to continuously develop and apply new technologies and innovative approaches. These include the adoption of green packaging technologies [30], optimizing transport routes [14], the promotion of electric and hybrid vehicles [29], and the establishment of shared logistics platforms [45]. However, the application of technology and innovation to sustainable logistics faces challenges such as high research and development costs, problems with technology adaptation, difficulties in transforming enterprises, and regulatory and competitive market pressures [48]. In addition, inadequate infrastructure makes it difficult to implement new technologies [49]. For example, Ewedairo et al. [50] showed that challenges facing urban freight last-mile logistics include the difficulty of adapting existing road networks and urban loading and unloading facilities to the increase in freight traffic, as well as space and access constraints. Overcoming these challenges requires multiple efforts, among them managing policy support, financial assistance, technological innovation, education and training, etc.

4.3. Integration of AI in Sustainable Logistics

The evolving complexity of global logistics has created a demand for sophisticated optimization techniques. Extensive data and continuously improving computing power have enhanced the ability of AI to process large amounts of information and derive actionable insights that enable the improvement of traditional logistics practices [33]. This subsection provides an overview of different AI models and algorithms for logistics optimization and explores the potential benefits and limitations of AI integration in logistics operations, taking into account the sustainable challenges found in the previous subsection.

4.3.1. AI for Solving Sustainable Logistics Challenges

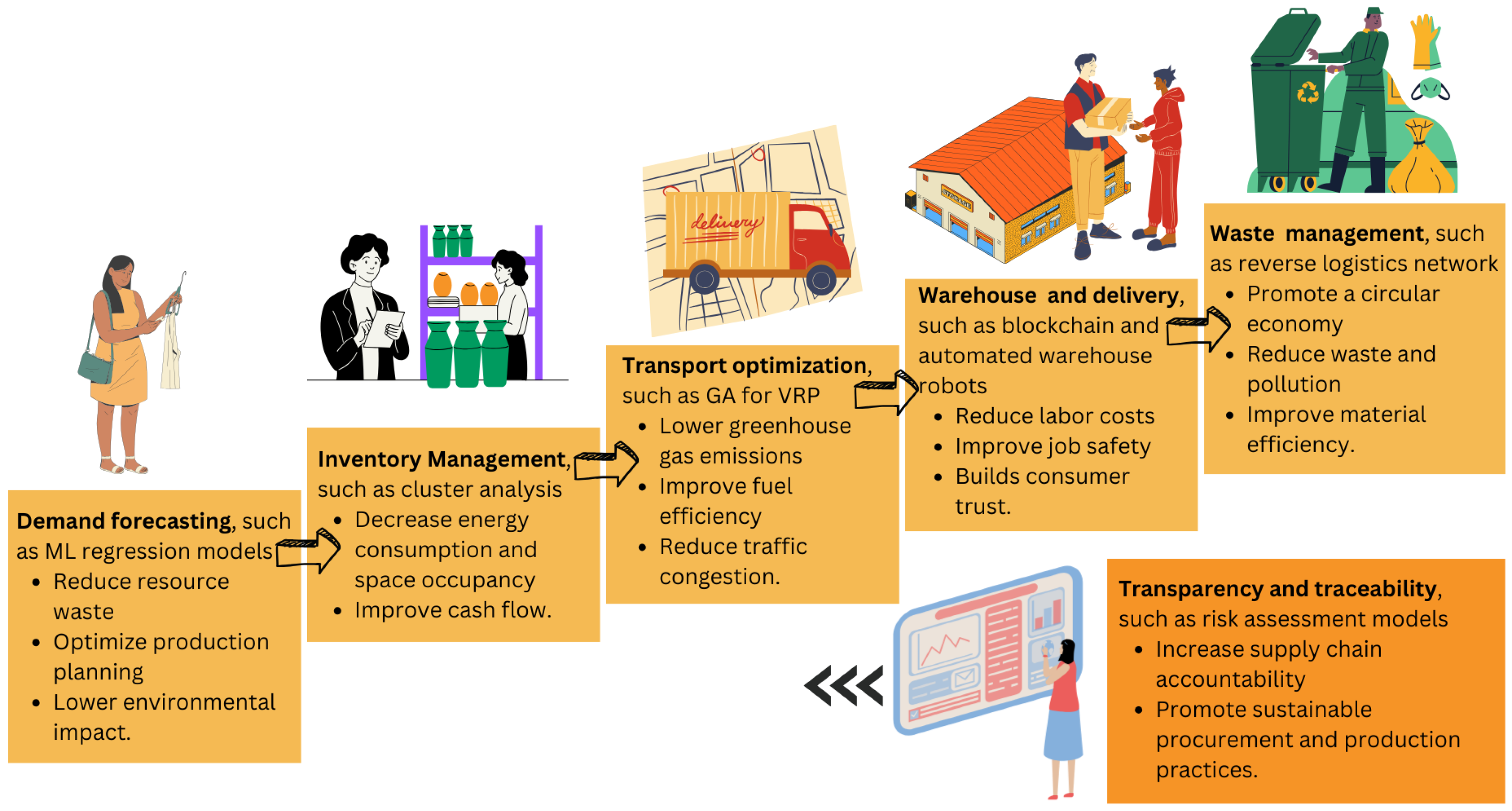

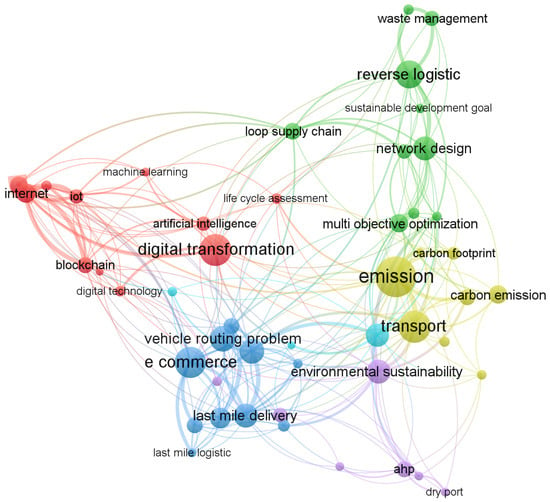

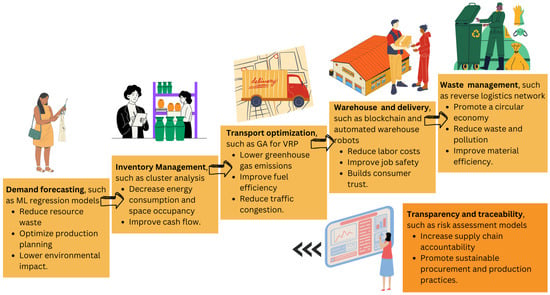

In the field of sustainable logistics, AI can help in addressing challenges such as reducing uncertainty, optimizing network structure, enhancing supply chain transparency, and improving overall efficiency. The functions of AI at each stage of sustainable logistics are illustrated in Figure 4.

Figure 4.

AI in sustainable logistics.

Pal [51] illustrated how AI-powered predictive analytics plays a crucial role in helping logistics organizations to accurately predict demand and optimize inventory levels. This not only reduces waste but also ensures the effective utilization of resources, hence promoting sustainability. Cui et al. [52] utilized a rich dataset consisting of detailed operational and retailer information for each product to develop a data-driven model for predicting returns at the retailer, product type, and cycle level. In addition, AI assesses potential risks and provides early warnings, enabling organizations to adjust their strategies in response to possible supply chain disruptions.

Emergencies such as COVID-19 provided new objectives for logistics systems in order to meet various economic needs in times of crisis and uncertainty. Companies utilize AI-based innovations to provide a wide range of solutions that allow them to address the complexity of activities, increase efficiency, and ensure sustainable financial growth and resource utilization [33,53]. AI and, in particular, ML help supply chain operators to quickly make informed decisions on streamlining processes and quickly identifying inefficiencies, in order to reduce them [18,54]. Furthermore, organizations that use AI-driven technologies to optimize aspects of the supply chain, such as demand forecasting, energy management, and waste reduction, can improve operational efficiency while achieving cost savings and a reduced ecological footprint [34]. The benefits of AI-driven demand forecasting, customer behavior analysis, and supply chain network design support more rational production planning, purchasing, inventory management, and transportation scheduling, directly easing environmental strain. AI-driven forecasting also reduces the need for excessive safety stock, particularly for perishable items. Additionally, economies of scale from bundling goods promote a shift to more eco-friendly transportation modes. By refining supply chain networks, AI further boosts transportation efficiency, directly reducing environmental impacts [33].

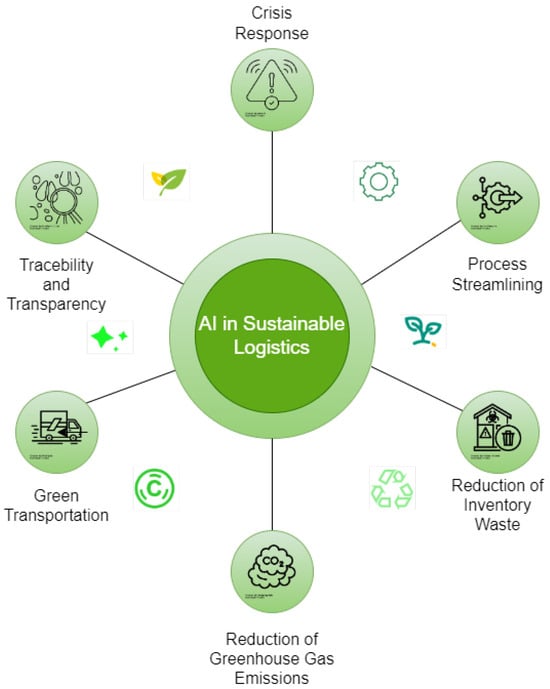

AI also improves logistics traceability and transparency, allowing companies to monitor carbon emissions and enhance accountability. This is supported by AI-driven supplier auditing and selection tools from providers like EcoVadis (https://ecovadis.com/, accessed on 17 October 2024) and Intelex (https://www.intelex.com/, accessed on 17 October 2024), which offer sustainability insights based on vast datasets across multiple dimensions [33]. The ways in which AI intelligence-driven approaches can improve sustainable logistics are summarized in Figure 5.

Figure 5.

AI-driven approaches to enhancing sustainable logistics.

Modern logistics optimization relies on various AI models and algorithms to address complex operational challenges. Zaher and Bányai [55] showed the rapid progress in the research for the development of metaheuristic algorithms in logistics, and Boute and Udenio [33] summarized the opportunities that AI brings to logistics. ML, a subset of AI, can be applied to all aspects of logistics optimization. Supervised learning predicts factors like demand, arrival times, customs throughput, and downtime. Unsupervised learning identifies patterns for customer clustering and market basket analysis. Reinforcement learning determines the best action based on current conditions, supporting multi-source replenishment and multi-modal shipping decisions [33]. Singh et al. [56] found that supervised learning solves most logistics problems, including multi-modal transportation, demand uncertainty, and user behavior. In addition, AI-driven metaheuristic approaches provide promising solutions for sustainable logistics systems. These approaches demonstrate the potential to address difficulties linked to transparency by utilizing advanced analytical and predictive capabilities. For instance, Zhang et al. [57] developed a ML-based risk assessment model using historical data to assess risks in the strawberry cold chain, achieving an average accuracy of . Others AI models and algorithms found in the recent literature are shown in Table 4, where GA refers to genetic algorithms, PSO refers to particle swarm optimization, IWO refers to invasive weed optimization, CDAP refers to the Cross-Dock Door Assignment Problem, and ACO refers to ant colony optimization. These methods have been instrumental in advancing efficient solutions to complex problems in supply chain management and transportation systems. Each entry details the algorithmic approach employed, the problem it addresses, and the main contributions of the authors.

Table 4.

Supply chain and logistics optimization algorithms.

4.3.2. Real-World Applications: Case Studies

Case studies offer valuable insights and lessons derived from real-world scenarios of AI integration on logistics and supply chain operations. Tsolakis et al. [67] introduced a case study quantifying the environmental benefits of different types of automated guided vehicles (AGVs) associated with routing schemes using the Europe’s port of Piraeus. They showed how the implementation of smart logistics significantly reduced the total distance traveled by the loaded AGVs by and improved the environmental impact of approximately of the loaded vehicles. Zubovich [68] discussed a case study where more than 350,000 trucks were fitted with IoT sensors to monitor conditions, analyze, and troubleshoot. The Swedish automaker Volvo has used IoT and AI to reduce the time it takes to repair trucks by and to diagnose them by , maximizing the vehicle’s travel time through more proactive and efficient maintenance. Shinkarenko [69] provided a case study regarding the California-based company Plus. This company has developed enhanced trucks with self-driving systems that can perform stop-and-go traffic, pass other vehicles, change lanes, and other things that need to be handled on the road with the help of a proprietary multimodal sensor system that notably optimizes fuel usage and saves about in energy costs. This company has partnered with some of the largest companies in the industry, including IVECO, FAW, and Amazon. Pourhejazy et al. [70] employed an evolutionary algorithm to incorporate sustainability into the optimization of fuel logistics networks. Through testing at a Korean company, they demonstrated that decentralization could significantly enhance the sustainability of logistics networks. Optimizing transport routes also reduced distances, times, and fuel consumption. For instance, Okyere et al. [71] improved a high-cost transportation system using a genetic algorithm (GA), lowering costs by and saving USD million. Real-time tracking ensures product traceability, and Tijan et al. [31] highlighted AI’s ability to manage large logistics data efficiently, enabling better decision-making. This feature is essential for dynamic routing and scheduling to minimize delays and decrease the environmental impact of logistics operations.

In real-world logistics optimization, various AI techniques are applied and combined. An improved multi-objective particle swarm-based algorithm was proposed by Yang et al. [62] and proved to be effective as an inventory control method for reverse logistics in shipping e-commerce. Scalar methods and evolutionary algorithms can handle vehicle routing problems with several conflicting objectives or performance measures in real-life last-mile logistics [72]. AI and data analytics capabilities have enabled flexible and intelligent logistics handling. AGVs have become smarter and more widely used in different applications in production areas such as material handling, assembly lines, etc. [67,73]. A powerful solution based on the long short-term memory (LSTM) model was proposed by Issaoui et al. [74] and verified to be effective in optimizing resource allocation and enhancing task scheduling in logistics frameworks. Tufano et al. [75] presented a real-world environment application of unsupervised learning clustering algorithms to collect data available to third-party logistics providers through input datasets, defining product families to assign workloads to processing resources represented by a third-party logistics packaging plant in the automotive industry. Businesses are using applications such as chatbots in daily operations to develop data collection and inventory methods, improving purchasing efficiency and market forecasting while addressing key challenges in logistics operations [76]. Although current generative language models are not yet able to solve highly complex problems, their strong understanding of logistics systems and the rapid advancements in natural language processing suggest that frameworks based on models like GPT-4 may soon overcome limitations related to model parameters, training data, and contextual understanding, enabling solutions for increasingly complex logistics challenges in the near future [77].

Moreover, Helo and Hao [78] presented an analysis of AI’s practical applications within various aspects of supply chain and operations management. They exemplified a case of transition from traditional manual processes to AI-driven solutions in a manufacturing and distribution company, focusing on the configuration, pricing, and quoting process. The implementation of AI in this context aimed to automate the quotation process, reduce manual labor, and enhance the accuracy of documents provided to customers. Another case focused on the use of AI for quality control in a food production facility. The company employed deep neural networks for real-time visual inspection of packaging processes [78]. This AI-driven approach enabled the reduction of waste and the enhancement of the overall quality control process. By training the AI system on various product features and defects, the company was able to automate the quality assurance process, allowing human inspectors to concentrate on more strategic tasks. Another relevant case study of application of AI was described by Shinkarenko [69]. Kortical (https://kortical.com/, accessed on 17 October 2024), a London software development company, worked with the team at the National Healthcare Service Blood and Transplant (NHSBT) to develop a demand-planning system for blood products with a short shelf-life, in order to forecast demand for 40 blood products across 15 distribution centers. NHSBT used Kortical’s ML-based tool, built by analyzing large amounts of historical supply data, to predict platelet supply, resulting in a reduction in expired platelets and a reduction in costly temporary shipments. More examples of AI-driven logistic optimization across different sectors are summarized in Table 5.

Table 5.

Summary of AI applications in various sectors.

4.3.3. Limitations of AI Integration in Logistics Operations

Some potential limitations also exist for AI integration in logistics. At present, sustainability may be seen more as a positive side effect on logistics operations in the beginning stages of AI applications in the supply chain. Measuring the impact of AI solutions on sustainability is not yet a priority for some companies because of barriers including lack of integration between systems and processes, the need for advanced technologies and analytics, the development of data governance frameworks, and changes in the organization of the company. Likewise, in the absence of government intervention, the incentive to invest in sustainable AI models depends on the financial complementarity of operational benefits [33,83]. The use of AI by big business to improve productivity and efficiency may not yet outweigh the increase in profitability in terms of reducing environmental impacts, when considering the growth in demand and consumption stimulated by productivity and efficiency improvements [84]. In addition, the widespread adoption of AI and the requirement for computerized equipment to accelerate natural resource extraction have been criticized by some political economists as justification for transnational corporations’ exaggerated claims that the gains of AI contribute to environmental sustainability [84].

4.4. Emerging Trends and Best Practices

After analyzing the integration of AI in sustainable logistics and real-world applications in logistics operations, in this subsection, emerging trends and best methodologies in AI-driven approaches will be discussed.

4.4.1. Current and Future Trends in AI-Driven Logistics Optimization

Abduljabbar et al. [85] highlighted two major trends in AI-driven logistics: (i) the use of AI for optimizing corporate decision-making and resource allocation, particularly in addressing demand forecasting and roadway constraints; and (ii) the development of connected and autonomous vehicles to enhance efficiency and safety on highways. These trends reflect a broader shift towards employing AI technologies to tackle complex logistical challenges and improve operational outcomes. Emerging technologies such as blockchain, reverse logistics, and data analytics are also gaining prominence within the logistics arena. Blockchain, for instance, offers enhanced transparency and efficiency in supply chain management, while reverse logistics focuses on the movement of goods back through the supply chain to capture value and reduce waste [86]. Real-time data analytics, powered by advancements in big data processing and storage solutions, are enabling logistics companies to optimize route planning, reduce fuel consumption, and minimize greenhouse gas emissions [87]. It is also worth mentioning the emergence of green logistics, which aims to reduce total costs associated with economic and environmental challenges. This is driven by the fact that present logistics strategies are unsustainable in the long term [88]. In this sense, the concept of reverse logistics is relevant, which emphasizes the movement of goods from their consumption point back to previous stages in the supply chain for the purposes of re-capturing value, re-manufacturing, proper disposal, costs savings, etc. [86].

Another emerging trend is the use of real-time data analytics within logistics. The logistics sector is facing challenges related to the continuous generation of big amounts of unstructured data from diverse sources, including road and vehicle sensors, log files, GPS systems, and traffic cameras [89]. This proliferation of data sources presents a significant challenge for traditional data processing methods, emphasizing the need for advanced analytical solutions to analyze real-time traffic information [90]. Furthermore, this increase in data availability requires better computational capabilities and storage solutions. It also shows the inadequacy of current data processing strategies, due to the dependence on outdated data processing methods [91]. As a result, traditional logistics information systems are not equipped to efficiently manage the constant flow of information from sensors in real-time. In this context, solutions like Apache Hadoop emerge as a frequently employed solution for big data analytics across various industries, including logistics and transportation, because of its distributed storage and parallel processing for handling vast datasets efficiently [89].

Given these challenges, logistics companies are using data to predict delays by using information from accidents and traffic jams found on social media to analyze and predict delays as they happen [91]. This skill to forecast delays right away complements the benefits of using software like Apache Hadoop, Spark, and Storm and lets businesses quickly change their plans, like updating routes instantly in order to avoid possible delays or bottlenecks, making them work more smoothly and respond faster to any issues [79]. In this topic, Chen et al. [90] present an innovative data-centric strategy for enhancing logistics through the utilization of real-time traffic data. Their goal is to improve the precision of freight travel time predictions, thereby increasing freight logistics’ reliability. They propose the gradient boosting partitioned regression tree for forecasting stochastic travel times. Following the trend of data analytics and AI in logistics, it is also relevant to mention blockchain technology. The adoption of this technology within logistics and supply chain management enables a higher level of transparency, reliability, and operational efficiency in logistics frameworks. As noted by Khan et al. [92], blockchain technology allows transactions that are both secure and transparent, reducing the need for intermediaries and lowering transaction costs. It also enables the monitoring of products throughout their journey, from the sourcing of the materials to the delivery of the final product [31]. In recent years, researchers have concentrated on the implementation of blockchain technology in areas like supply chain finance, supply chain management, and logistics [93]. For its implementation in the latter, Abeyratne and Monfared [94] proposed a distributed, decentralized logistic system that uses blockchain technologies to collect and manage the most important data of every product throughout its life cycle using barcode or QR code tags, being this a unique digital identifier that links a physical product to its virtual identity on the network.

4.4.2. Best Practices and Methodologies

Over time, tools from various scientific areas (e.g., business intelligence and operations research, among others) have been instrumental for logistics managers to make decisions based on data and have promoted the optimization of supply chains [95]. However, despite these advances, designing supply chains that are efficient and robust remains a challenge, especially given the complexity and dynamic diversity of these systems [96]. For this reason, it is important to consider different options for implementing AI solutions in logistics operations, depending on the nature of the problem. Peffers et al. [97] explained a design science methodology which focuses on information systems development and research through a practical, solution-oriented approach. The described methodology is based on a process of six interconnected steps, which are as follows: (i) the identification of the problem; (ii) the determination of the objectives of the proposed solution; (iii) the design and development of the solution; (iv) the demonstration of the solution in an operational environment; (v) the evaluation of the impact and effectiveness of the solution; and (vi) the dissemination of the results and knowledge gained. This structured approach is essential for effectively addressing complex challenges, especially in areas such as logistics, where technology-based solutions can offer significant improvements in efficiency and sustainability. In their paper, Zhu et al. [98] argued that adopting advanced technologies in logistics can achieve optimization that boots operational efficiency by up to , while simultaneously reducing the costs associated with these operations by around , compared to more traditional logistics approaches.

Following the line of previous sections, which emphasized the importance of sustainability criteria in logistics decision-making, Ali et al. [99] validated through various hypotheses that the adoption of sustainable practices in logistics has a positive relationship with low-carbon performance, which in turn contributes significantly to the development of sustainable societies. In addition, Uygun and Dede [100] introduced a framework of dimensions with corresponding criteria to assess companies’ green supply chain management activities more precisely. This framework was utilized to rank companies based on their green supply chain management practices, providing a detailed analysis of each firm’s performance in sustainable logistics operations. The dimensions and their criteria are detailed in Table 6, offering a structured approach to ensure that AI implementations in logistics are in line with sustainable practices.

Table 6.

Dimensions and related criteria of green supply chain management.

5. Conclusions and Future Research

This paper has analyzed the integration of AI in sustainable logistics optimization, exploring various facets including key challenges, emerging trends, best practices, and real-world case studies. Through a comprehensive analysis, several key conclusions can be drawn.

Firstly, the following question has been addressed: How do SDGs relate to the LPI? This study has demonstrated that the Logistics Performance Index (LPI) is strongly correlated with the Sustainable Development Goals (SDGs). A higher logistics performance positively impacts various SDGs, such as SDG 9 (industry, innovation, and infrastructure), SDG 3 (good health and well-being), and SDG 16 (peace, justice, and strong institutions). However, there are significant challenges in aligning logistics performance with SDG 12 (responsible consumption and production) and SDG 13 (climate action), where negative correlations were identified. This indicates that, while improved logistics efficiency can drive economic development and institutional strengthening, it may also contribute to environmental degradation unless sustainability practices are integrated into logistics operations. This finding underscores the need for logistics stakeholders to prioritize green logistics, low-emission transportation modes, and the adoption of renewable energy sources, in order to ensure that improvements in logistics do not come at the expense of environmental sustainability.

Secondly, the main challenges in sustainable logistics were identified, and their impact on the effective implementation of optimization strategies was analyzed. These challenges include demand and supply uncertainties, complex logistics network architectures, issues with logistics collaboration, and the need for technological innovation. These factors can affect the application of optimization strategies, requiring tailored approaches such as optimizing transportation routes, adopting renewable energy sources, reducing carbon emissions, minimizing waste generation, and enhancing supply chain transparency. These insights address the question: How do the main challenges in sustainable logistics impact the effective implementation of optimization strategies? Thirdly, the integration of AI technologies into logistics and supply chain management was explored, highlighting how these technologies contribute to sustainable development. AI-driven approaches offer significant potential in optimizing decision-making processes, enhancing resource utilization, and improving operational efficiency across various aspects of logistics operations. Implementing predictive analytics for demand forecasting, optimizing inventory levels, real-time risk assessment, and transportation route optimization are key AI applications that support sustainability. Real-world case studies highlighted the practical applications and benefits of AI in logistics, providing valuable examples of how AI-driven solutions can drive positive outcomes and contribute to the advancement of sustainable logistics practices. These case studies ranged from supply chain optimization to operational efficiency improvements, showcasing significant cost savings, waste reduction, and enhanced accuracy in demand forecasting. This addresses the question: How can AI technologies be implemented in logistics and supply chain management to enhance sustainable development?

Finally, the emerging trends and best practices in AI-driven logistics optimization were examined, highlighting how they improve sustainability in the supply chain. Trends such as the adoption of AI for logistics optimization, real-time data analytics, and the implementation of blockchain technology can redefine sustainable logistics by enhancing efficiency and reducing environmental impacts. Best practices, such as adopting green logistics principles, integrating reverse logistics to capture value and reduce waste, and utilizing advanced data analytics for real-time traffic management, contribute to these improvements. These insights address the question: How do emerging trends and best practices in AI-driven logistics optimization improve sustainability in the supply chain?

Finally, a future research line in this field involves the development of AI algorithms tailored specifically for logistics applications. By focusing on improving demand forecasting models, optimization algorithms for route planning and scheduling, and predictive analytics for supply chain management, researchers can provide logistics operators with more accurate, efficient, and sustainable decision-making tools. Additionally, investigating the integration of IoT devices with AI systems offers an opportunity to enhance real-time monitoring, tracking, and decision-making in logistics operations. Another important area for future research is the exploration of sustainable last-mile delivery solutions based on AI. With the rise of e-commerce and urbanization, the last-mile delivery segment has become a critical focus for logistics companies seeking to minimize their environmental footprint. AI-driven solutions such as autonomous delivery vehicles, drone delivery systems, and crowd-shipping platforms can contribute to the development of more sustainable and efficient last-mile delivery networks. These conclusions provide a comprehensive overview of how AI can be leveraged to achieve sustainability in logistics, and they outline a path for future research.

Author Contributions

Conceptualization, A.A.J.; methodology, A.A.J.; investigation, W.C., Y.M., N.F. and C.O.; writing—original draft preparation, W.C., Y.M., N.F. and C.O.; writing—review and editing, A.A.J.; supervision, A.A.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been partially funded by the Investigo Program of the Generalitat Valenciana (INVEST/2023/304), Coca-Cola Europacific Partners, and the Spanish Ministry of Science and Innovation (PID2022-138860NB-I00 and RED2022-134703-T).

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- McKinnon, A.; Browne, M.; Whiteing, A.; Piecyk, M. Green Logistics: Improving the Environmental Sustainability of Logistics; Kogan Page Publishers: London, UK, 2015. [Google Scholar]

- Annosi, M.C.; Brunetta, F.; Bimbo, F.; Kostoula, M. Digitalization within food supply chains to prevent food waste. Drivers, barriers and collaboration practices. Ind. Mark. Manag. 2021, 93, 208–220. [Google Scholar] [CrossRef]

- Matantseva, O.Y.; Spirin, I.; Ulitskaya, N.; Kazantsev, I. Logistic as a Tool to Achieve Sustainable Development Goals. In Proceedings of the Second Conference on Sustainable Development: Industrial Future of Territories (IFT 2021), Yekaterinburg, Russia, 24 September 2021; Atlantis Press: Amsterdam, The Netherlands, 2021; pp. 196–201. [Google Scholar]

- Chauhan, C.; Kaur, P.; Arrawatia, R.; Ractham, P.; Dhir, A. Supply chain collaboration and sustainable development goals (SDGs). Teamwork makes achieving SDGs dream work. J. Bus. Res. 2022, 147, 290–307. [Google Scholar] [CrossRef]

- Canhoto, A.I.; Clear, F. Artificial intelligence and machine learning as business tools: A framework for diagnosing value destruction potential. Bus. Horizons 2020, 63, 183–193. [Google Scholar] [CrossRef]

- Dirican, C. The impacts of robotics, artificial intelligence on business and economics. Procedia-Soc. Behav. Sci. 2015, 195, 564–573. [Google Scholar] [CrossRef]

- Soni, N.; Sharma, E.K.; Singh, N.; Kapoor, A. Artificial intelligence in business: From research and innovation to market deployment. Procedia Comput. Sci. 2020, 167, 2200–2210. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar] [CrossRef]

- Delmonico, D.V.D.G.; Bezerra, B.S. A systematic literature review on sustainable logistics. Lat. Am. J. Manag. Sustain. Dev. 2020, 5, 47–57. [Google Scholar] [CrossRef]

- Alicke, K.; Knut, D.; Görner, S.; Mori, L.; Rebuffel, P.; Reiter, S.; Samek, R. Succeeding in the AI Supply-Chain Revolution. 2021. Available online: https://www.mckinsey.com/industries/metals-and-mining/our-insights/succeeding-in-the-ai-supply-chain-revolution (accessed on 17 October 2024).

- Tang, S.; Wang, W.; Yan, H.; Hao, G. Low carbon logistics: Reducing shipment frequency to cut carbon emissions. Int. J. Prod. Econ. 2015, 164, 339–350. [Google Scholar] [CrossRef]

- Islam, M.A.; Gajpal, Y.; ElMekkawy, T.Y. Mixed fleet based green clustered logistics problem under carbon emission cap. Sustain. Cities Soc. 2021, 72, 103074. [Google Scholar] [CrossRef]

- Li, J.Q.; Wang, J.D.; Pan, Q.K.; Duan, P.Y.; Sang, H.Y.; Gao, K.Z.; Xue, Y. A hybrid artificial bee colony for optimizing a reverse logistics network system. Soft Comput. 2017, 21, 6001–6018. [Google Scholar] [CrossRef]

- Burinskiene, A.; Lorenc, A.; Lerher, T. A simulation study for the sustainability and reduction of waste in warehouse logistics. Int. J. Simul. Model. 2018, 17, 485–497. [Google Scholar] [CrossRef]

- Iwan, S.; Kijewska, K.; Lemke, J. Analysis of Parcel Lockers’ Efficiency as the Last Mile Delivery Solution—The Results of the Research in Poland. Transp. Res. Procedia 2016, 12, 644–655. [Google Scholar] [CrossRef]

- Granillo-Macías, R. Inventory management and logistics optimization: A data mining practical approach. LogForum 2020, 16, 535–547. [Google Scholar] [CrossRef]

- Goyal, N.; Sharma, M.A. Impact of warehouse management system in a supply chain. Int. J. Dev. Stud. 2016, 8, 38–45. [Google Scholar]

- Haleem, A.; Javaid, M.; Khan, I.H.; Mohan, S. Significant Applications of Artificial Intelligence Towards Attaining Sustainability. J. Ind. Integr. Manag. 2023, 8, 489–520. [Google Scholar] [CrossRef]

- Weinelt, B. World Economic Forum White Paper Digital Transformation of Industries: In Collaboration with Accenture. 2016. Available online: https://www.netscout.com/digital-transformation-realtime-information-platform/jim/data/pdf/jim/world-economic-forum-digital-transformation-of-industries.pdf (accessed on 22 August 2024).

- Masson, R.; Trentini, A.; Lehuédé, F.; Malhéné, N.; Péton, O.; Tlahig, H. Optimization of a city logistics transportation system with mixed passengers and goods. EURO J. Transp. Logist. 2017, 6, 81–109. [Google Scholar] [CrossRef]

- Yan, Q.; Zhang, Q. The optimization of transportation costs in logistics enterprises with time-window constraints. Discret. Dyn. Nat. Soc. 2015, 2015, 365367. [Google Scholar] [CrossRef]

- Choi, T.M.; Chiu, C.H.; Chan, H.K. Risk management of logistics systems. Transp. Res. Part E Logist. Transp. Rev. 2016, 90, 1–6. [Google Scholar] [CrossRef]

- de la Torre, R.; Corlu, C.G.; Faulin, J.; Onggo, B.S.; Juan, A.A. Simulation, optimization, and machine learning in sustainable transportation systems: Models and applications. Sustainability 2021, 13, 1551. [Google Scholar] [CrossRef]

- Woodward, W.A.; Sadler, B.P.; Robertson, S. Time Series for Data Science: Analysis and Forecasting; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar]

- Liu, Z.; Deng, Z.; He, G.; Wang, H.; Zhang, X.; Lin, J.; Qi, Y.; Liang, X. Challenges and opportunities for carbon neutrality in China. Nat. Rev. Earth Environ. 2022, 3, 141–155. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. CO2 Emissions. Our World in Data 2020. Available online: https://ourworldindata.org/co2-emissions (accessed on 17 October 2024).

- Bäckstrand, K. Towards a climate-neutral union by 2050? The European green deal, climate law, and green recovery. In Routes to a Resilient European Union: Interdisciplinary European Studies; Springer: Berlin/Heidelberg, Germany, 2022; pp. 39–61. [Google Scholar]

- Bairamzadeh, S.; Pishvaee, M.S.; Saidi-Mehrabad, M. Multiobjective robust possibilistic programming approach to sustainable bioethanol supply chain design under multiple uncertainties. Ind. Eng. Chem. Res. 2016, 55, 237–256. [Google Scholar] [CrossRef]

- Schöder, D.; Ding, F.; Campos, J.K. The impact of e-commerce development on urban logistics sustainability. Open J. Soc. Sci. 2016, 4, 1–6. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, Z. Green packaging management of logistics enterprises. Phys. Procedia 2012, 24, 900–905. [Google Scholar] [CrossRef]

- Tijan, E.; Aksentijević, S.; Ivanić, K.; Jardas, M. Blockchain technology implementation in logistics. Sustainability 2019, 11, 1185. [Google Scholar] [CrossRef]

- Wang, R.; Tsai, W.T.; He, J.; Liu, C.; Li, Q.; Deng, E. Logistics management system based on permissioned blockchains and RFID technology. In Proceedings of the 2019 International Conference on Computer, Network, Communication and Information Systems (CNCI 2019), Qingdao, China, 27–29 March 2019; Atlantis Press: Amsterdam, The Netherlands, 2019; pp. 426–432. [Google Scholar]

- Boute, R.N.; Udenio, M. AI in logistics and supply chain management. In Global Logistics and Supply Chain Strategies for the 2020s: Vital Skills for the Next Generation; Springer: Berlin/Heidelberg, Germany, 2022; pp. 49–65. [Google Scholar]

- Gupta, C.P.; Kumar, V.R.; Khurana, A. Artificial Intelligence integration with the supply chain, making it green and sustainable. In Proceedings of the 2023 7th International Conference on Electronics, Materials Engineering & Nano-Technology (IEMENTech), Kolkata, India, 18–20 December 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–5. [Google Scholar]

- Kedia, A.; Kusumastuti, D.; Nicholson, A. Acceptability of collection and delivery points from consumers’ perspective: A qualitative case study of Christchurch city. Case Stud. Transp. Policy 2017, 5, 587–595. [Google Scholar] [CrossRef]

- Ha, Q.M.; Deville, Y.; Pham, Q.D.; Hà, M.H. On the min-cost Traveling Salesman Problem with Drone. Transp. Res. Part C Emerg. Technol. 2018, 86, 597–621. [Google Scholar] [CrossRef]

- Dat, L.Q.; Truc Linh, D.T.; Chou, S.Y.; Yu, V.F. Optimizing reverse logistic costs for recycling end-of-life electrical and electronic products. Expert Syst. Appl. 2012, 39, 6380–6387. [Google Scholar] [CrossRef]

- Peng, H.; Shen, N.; Liao, H.; Xue, H.; Wang, Q. Uncertainty factors, methods, and solutions of closed-loop supply chain—A review for current situation and future prospects. J. Clean. Prod. 2020, 254, 120032. [Google Scholar] [CrossRef]

- Soysal, M.; Bloemhof-Ruwaard, J.M.; Haijema, R.; van der Vorst, J.G. Modeling a green inventory routing problem for perishable products with horizontal collaboration. Comput. Oper. Res. 2018, 89, 168–182. [Google Scholar] [CrossRef]

- Bachofner, M.; Lemardelé, C.; Estrada, M.; Pagès, L. City logistics: Challenges and opportunities for technology providers. J. Urban Mobil. 2022, 2, 100020. [Google Scholar] [CrossRef]

- Abbasi, M.; Nilsson, F. Developing environmentally sustainable logistics: Exploring themes and challenges from a logistics service providers’ perspective. Transp. Res. Part D Transp. Environ. 2016, 46, 273–283. [Google Scholar] [CrossRef]

- You, F.; Wang, B. Life cycle optimization of biomass-to-liquid supply chains with distributed–centralized processing networks. Ind. Eng. Chem. Res. 2011, 50, 10102–10127. [Google Scholar] [CrossRef]

- Elia, J.A.; Baliban, R.C.; Floudas, C.A. Nationwide energy supply chain analysis for hybrid feedstock processes with significant CO2 emissions reduction. AIChE J. 2012, 58, 2142–2154. [Google Scholar] [CrossRef]

- Yang, J.; Tang, L.; Mi, Z.; Liu, S.; Li, L.; Zheng, J. Carbon emissions performance in logistics at the city level. J. Clean. Prod. 2019, 231, 1258–1266. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Ali, A.; Jehangir, M.; Hassan, N.; Bae, J. A model for understanding the mediating association of transparency between emerging technologies and humanitarian logistics sustainability. Sustainability 2022, 14, 6917. [Google Scholar] [CrossRef]

- Soumpenioti, V.; Panagopoulos, A. AI Technology in the Field of Logistics. In Proceedings of the 2023 18th International Workshop on Semantic and Social Media Adaptation & Personalization (SMAP) 18th International Workshop on Semantic and Social Media Adaptation & Personalization (SMAP 2023), Limassol, Cyprus, 25–26 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- McGrath, P.; McCarthy, L.; Marshall, D.; Rehme, J. Tools and technologies of transparency in sustainable global supply chains. Calif. Manag. Rev. 2021, 64, 67–89. [Google Scholar] [CrossRef]

- Stucki, T. Which firms benefit from investments in green energy technologies?—The effect of energy costs. Res. Policy 2019, 48, 546–555. [Google Scholar] [CrossRef]

- Bosona, T. Urban Freight Last Mile Logistics—Challenges and Opportunities to Improve Sustainability: A Literature Review. Sustainability 2020, 12, 8769. [Google Scholar] [CrossRef]

- Ewedairo, K.; Chhetri, P.; Jie, F. Estimating transportation network impedance to last-mile delivery: A Case Study of Maribyrnong City in Melbourne. Int. J. Logist. Manag. 2018, 29, 110–130. [Google Scholar] [CrossRef]

- Pal, S. Integrating AI in sustainable supply chain management: A new paradigm for enhanced transparency and sustainability. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 2979–2984. [Google Scholar] [CrossRef]

- Cui, H.; Rajagopalan, S.; Ward, A.R. Predicting product return volume using machine learning methods. Eur. J. Oper. Res. 2020, 281, 612–627. [Google Scholar] [CrossRef]

- Allioui, H.; Allioui, A.; Mourdi, Y. AI-Based Logistics Solutions to Tackle COVID-19 Pandemic and Ensure a Sustainable Financial Growth. In Advanced AI and Internet of Health Things for Combating Pandemics; Springer: Berlin/Heidelberg, Germany, 2023; pp. 359–382. [Google Scholar]

- krishna Vaddy, R. Artificial intelligence (AI) and machine learning driving efficiency and automation in supply chain Transportation. Int. J. Manag. Educ. Sustain. Dev. 2023, 6, 1–20. [Google Scholar]

- Zaher, A.M.; Bányai, T. Analytical review on the modern optimization algorithms in logistics. Adv. Logist. Syst.-Theory Pract. 2020, 14, 25–31. [Google Scholar]

- Singh, A.; Wiktorsson, M.; Hauge, J.B. Trends in machine learning to solve problems in logistics. Procedia CIRP 2021, 103, 67–72. [Google Scholar] [CrossRef]

- Zhang, G.; Li, G.; Peng, J. Risk assessment and monitoring of green logistics for fresh produce based on a support vector machine. Sustainability 2020, 12, 7569. [Google Scholar] [CrossRef]

- Fathi, M.; Ghobakhloo, M. Enabling mass customization and manufacturing sustainability in industry 4.0 context: A novel heuristic algorithm for in-plant material supply optimization. Sustainability 2020, 12, 6669. [Google Scholar] [CrossRef]

- Deng, S.; Li, Y.; Guo, H.; Liu, B. Solving a Closed-Loop Location-Inventory-Routing Problem with Mixed Quality Defects Returns in E-Commerce by Hybrid Ant Colony Optimization Algorithm. Discret. Dyn. Nat. Soc. 2016, 2016, 6467812. [Google Scholar] [CrossRef]

- Atabaki, M.S.; Mohammadi, M.; Naderi, B. Hybrid genetic algorithm and invasive weed optimization via priority based encoding for location-allocation decisions in a three-stage supply chain. Asia-Pac. J. Oper. Res. 2017, 34, 1750008. [Google Scholar] [CrossRef]

- Bányai, T.; Illés, B.; Gubán, M.; Gubán, A.; Schenk, F.; Bányai, A. Optimization of just-in-sequence supply: A flower pollination algorithm-based approach. Sustainability 2019, 11, 3850. [Google Scholar] [CrossRef]

- Yang, W.; Xie, Q.; Li, M. Inventory control method of reverse logistics for shipping electronic commerce based on improved multi-objective particle swarm optimization algorithm. J. Coast. Res. 2018, 83, 786–790. [Google Scholar] [CrossRef]

- Chen, L.; Ma, M.; Sun, L. Heuristic swarm intelligent optimization algorithm for path planning of agricultural product logistics distribution. J. Intell. Fuzzy Syst. 2019, 37, 4697–4703. [Google Scholar] [CrossRef]

- Tarhini, A.; Yunis, M.; Chamseddine, M. Natural Optimization Algorithms for the Cross-Dock Door Assignment Problem. IEEE Trans. Intell. Transp. Syst. 2016, 17, 2324–2333. [Google Scholar] [CrossRef]

- Santis, R.; Montanari, R.; Vignali, G.; Bottani, E. An adapted ant colony optimization algorithm for the minimization of the travel distance of pickers in manual warehouses. Eur. J. Oper. Res. 2018, 267, 120–137. [Google Scholar] [CrossRef]

- Brajevic, I.; Ignjatovic, J. An upgraded firefly algorithm with feasibility-based rules for constrained engineering optimization problems. J. Intell. Manuf. 2019, 30, 2545–2574. [Google Scholar] [CrossRef]

- Tsolakis, N.; Zissis, D.; Papaefthimiou, S.; Korfiatis, N. Towards AI driven environmental sustainability: An application of automated logistics in container port terminals. Int. J. Prod. Res. 2022, 60, 4508–4528. [Google Scholar] [CrossRef]

- Zubovich, N. IoT Supply Chain: Real-Life Use Cases & Challenges. Available online: https://sumatosoft.com/blog/iot-supply-chain (accessed on 12 March 2024).

- Shinkarenko, A. Machine Learning in Logistics: Technology Breakdown & 10 Use Cases. Available online: https://www.itransition.com/machine-learning/logistics (accessed on 12 March 2024).

- Pourhejazy, P.; Kwon, O.K.; Lim, H. Integrating sustainability into the optimization of fuel logistics networks. KSCE J. Civ. Eng. 2019, 23, 1369–1383. [Google Scholar] [CrossRef]

- Okyere, S.; Yang, J.; Adams, C.A. Optimizing the Sustainable Multimodal Freight Transport and Logistics System Based on the Genetic Algorithm. Sustainability 2022, 14, 11577. [Google Scholar] [CrossRef]

- Giuffrida, N.; Fajardo-Calderin, J.; Masegosa, A.D.; Werner, F.; Steudter, M.; Pilla, F. Optimization and machine learning applied to last-mile logistics: A review. Sustainability 2022, 14, 5329. [Google Scholar] [CrossRef]

- Qi, B.; Yang, Q.; Zhou, Y. Application of AGV in intelligent logistics system. In Proceedings of the Fifth Asia International Symposium on Mechatronics (AISM 2015), Guilin, China, 7–10 October 2015; IET: London, UK, 2015; pp. 1–5. [Google Scholar]

- Issaoui, Y.; Khiat, A.; Bahnasse, A.; Ouajji, H. An advanced LSTM model for optimal scheduling in smart logistic environment: E-commerce case. IEEE Access 2021, 9, 126337–126356. [Google Scholar] [CrossRef]

- Tufano, A.; Accorsi, R.; Manzini, R. Machine learning methods to improve the operations of 3PL logistics. Procedia Manuf. 2020, 42, 62–69. [Google Scholar] [CrossRef]

- Singh, K.; Goyal, S.; Bedi, P. The Role of Artificial Intelligence and Machine Learning in Supply Chain Management and its Task Model. In Proceedings of the 2020 3rd International Conference on Intelligent Sustainable Systems (ICISS), Thoothukudi, India, 3–5 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 616–621. [Google Scholar]

- Jackson, I.; Ivanov, D.; Dolgui, A.; Namdar, J. Generative artificial intelligence in supply chain and operations management: A capability-based framework for analysis and implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Prod. Plan. Control 2022, 33, 1573–1590. [Google Scholar] [CrossRef]

- Reyes, S.; Patel, M. Big Data and Predictive Analytics for Optimized Supply Chain Management and Logistics. Sage Sci. Rev. Appl. Mach. Learn. 2024, 7, 10–21. [Google Scholar]

- Amazon Web Services. Amazon Robotics Case Study. 2024. Available online: https://aws.amazon.com/solutions/case-studies/amazon-robotics-case-study/ (accessed on 17 October 2024).

- Nataraj, S.; Alvarez, C.; Sada, L.; Juan, A.A.; Panadero, J.; Bayliss, C. Applying statistical learning methods for forecasting prices and enhancing the probability of success in logistics tenders. Transp. Research Proc. 2020, 47, 529–536. [Google Scholar] [CrossRef]

- Zen Robotics. How to Robotize Your Waste Sorting. 2024. Available online: https://www.terex.com/zenrobotics/how-to-robotize/Overview (accessed on 17 October 2024).

- Faccenda, G. Measuring the Sustainability Impact of Artificial Intelligence in Logistics: A Case Study Analysis. 2021. Available online: https://www.politesi.polimi.it/retrieve/d8c483a6-80fb-4c81-b237-e628338484ca/2023_05_Faccenda.pdf (accessed on 17 October 2024).

- Dauvergne, P. Is artificial intelligence greening global supply chains? Exposing the political economy of environmental costs. Rev. Int. Political Econ. 2022, 29, 696–718. [Google Scholar] [CrossRef]

- Abduljabbar, R.; Dia, H.; Liyanage, S.; Bagloee, S.A. Applications of artificial intelligence in transport: An overview. Sustainability 2019, 11, 189. [Google Scholar] [CrossRef]