Hazard Identification and Risk Assessment During Simultaneous Operations in Industrial Plant Maintenance Based on Job Safety Analysis

Abstract

1. Introduction

1.1. Background of Study

- The 2017 Amendment to the Occupational Safety and Health Act: Article 68 mandates appointing a health and safety coordinator to prevent industrial accidents due to work interference when two or more construction projects are carried out at the same location.

- The 2019 Amendment to the Occupational Safety and Health Act: Article 63 expands the obligation of the contractor with respect to safety and health measures from 22 hazardous locations to the entire workplace.

- The 2021 Amendment to the Occupational Safety and Health Act: Article 64 mandates that the timing, content, and safety and health measures of the operations be confirmed for operations carried out at the same location. The Presidential Decree prescribes adjusting the timing and operation in the case of a fire or explosion risk due to work interference.

- System aspects: The Company provides a SIMOPS prediction list and job safety analysis (JSA) by linking an integrated safety and health platform with the enterprise resource planning (ERP) system for work planning. The SIMOPS prediction list is generated based on work dates and equipment classification systems.

- Work planning aspects: Managers from the work planning department, safety managers, and work managers review the SIMOPS predictions in a D-1 meeting before the work begins. Based on the review results, they establish measures such as prohibiting concurrent vertical work, adjusting work execution times, and implementing additional safety measures.

- Work permit aspects: The work permit issuer reviews whether the work is mixed with other teams for upstream, downstream, or interlocking equipment. If SIMOPS are confirmed, the work permit issuer facilitates a toolbox meeting (TBM) during which work supervisors inspect the equipment on-site, identify potential hazards, and establish countermeasures [17].

- Work execution aspects: Workers are invited to a TBM with the operations and equipment supervisors for individual tasks as well as a TBM with the related equipment task supervisors.

1.2. Problem Statement and Research Objectives

1.3. Research Process

2. Literature Review

2.1. Methodologies for Hazard Identification and Risk Assessment in the Construction Sector

2.2. Origins and Limitations of Job Safety Analysis (JSA)

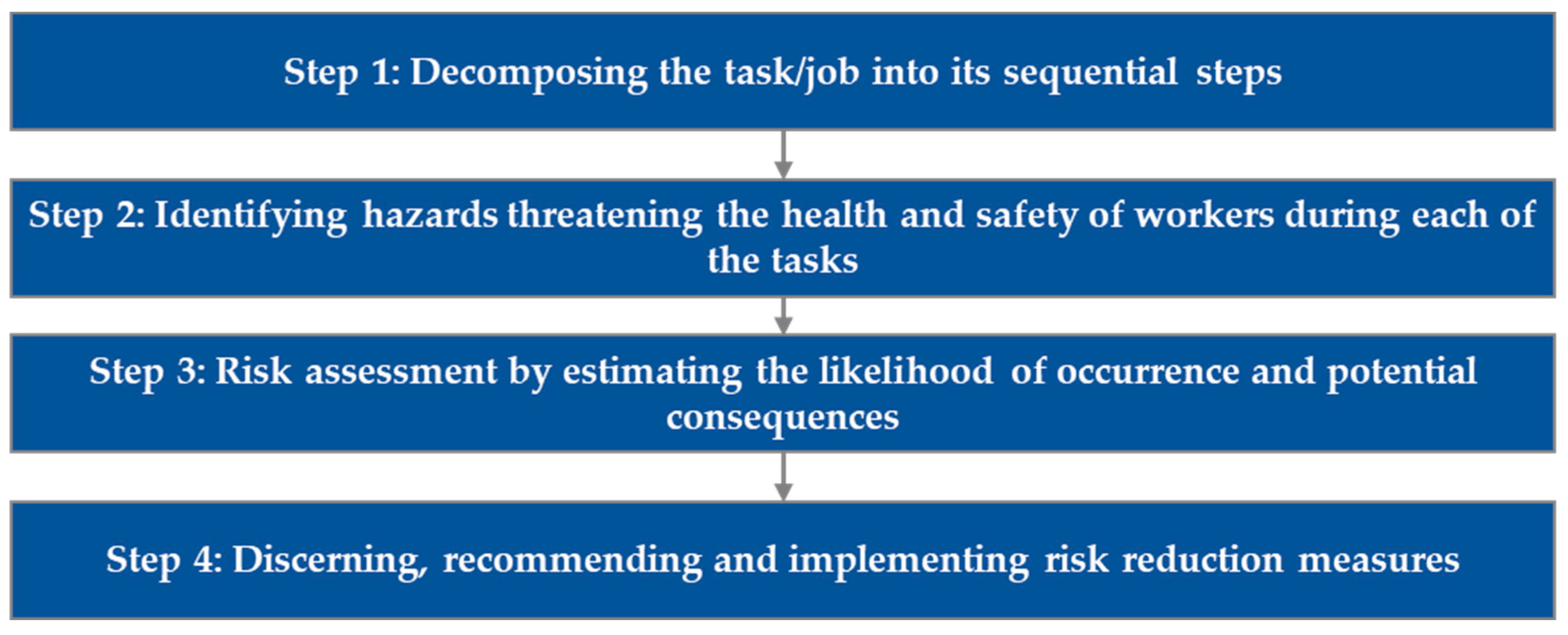

2.3. JSA for Individual Tasks

2.4. JSA for Inter-Task Relationships

2.5. Limitations of Previous Research and Objectives of This Study

3. Hazard Identification in SIMOPS Based on the Zettelkasten Method

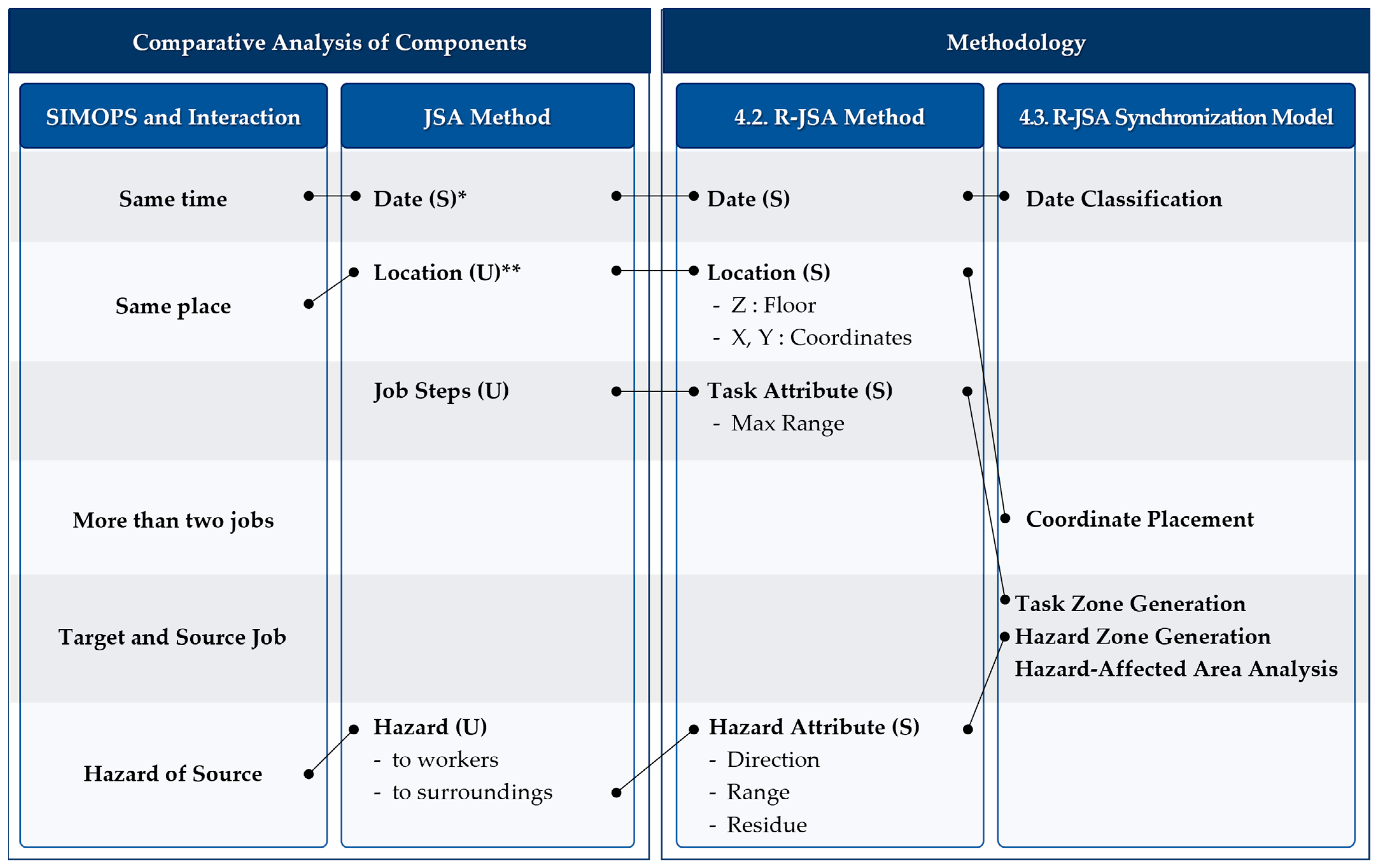

4. Modeling

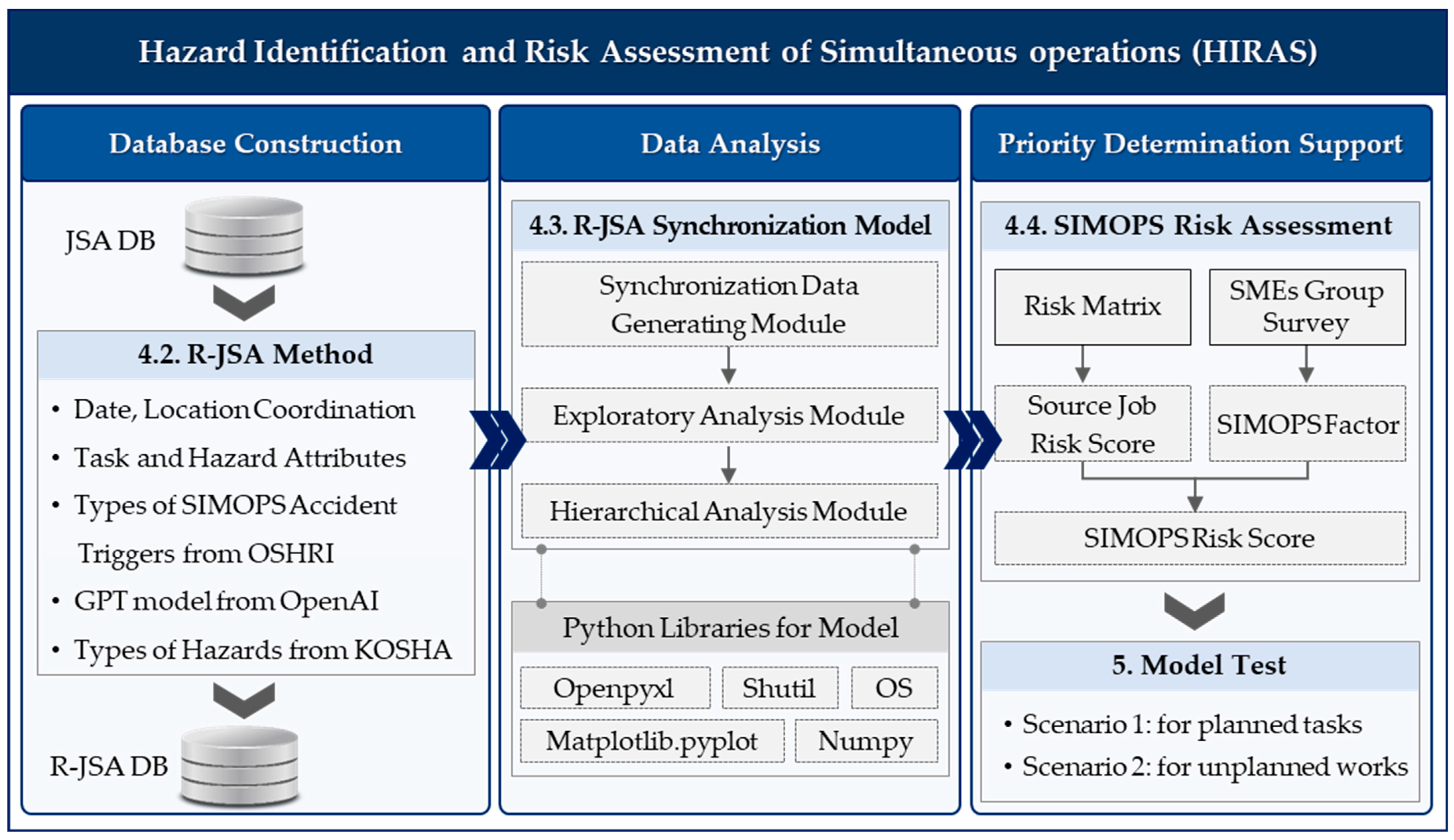

4.1. HIRAS Framework

- R-JSA method: This methodology aims to standardize JSA data to build an open database. Coordinates are assigned to task locations and the attributes of tasks and hazards are structured to standardize the data. Errors in data entry are prevented via quantified hazard classifications, GPT validation, and criteria for hazards that cause accidents during SIMOPS.

- R-JSA synchronization: This model uses data obtained from R-JSA to synchronize hazard information for tasks in a spatially and temporally coordinated manner and analyzes inter-task effects. This analysis involves the generation of synchronized data, exploratory analysis, and hierarchical analysis, which provides a basis for identifying and assessing hazards in SIMOPS.

- S-RA: S-RA focuses on evaluating the identified hazards and determining the priority of actions using the information on the risk level of the source job and the SIMOPS factor derived from expert group discussions.

4.2. Data Structuring Through a Relation-Oriented JSA Method

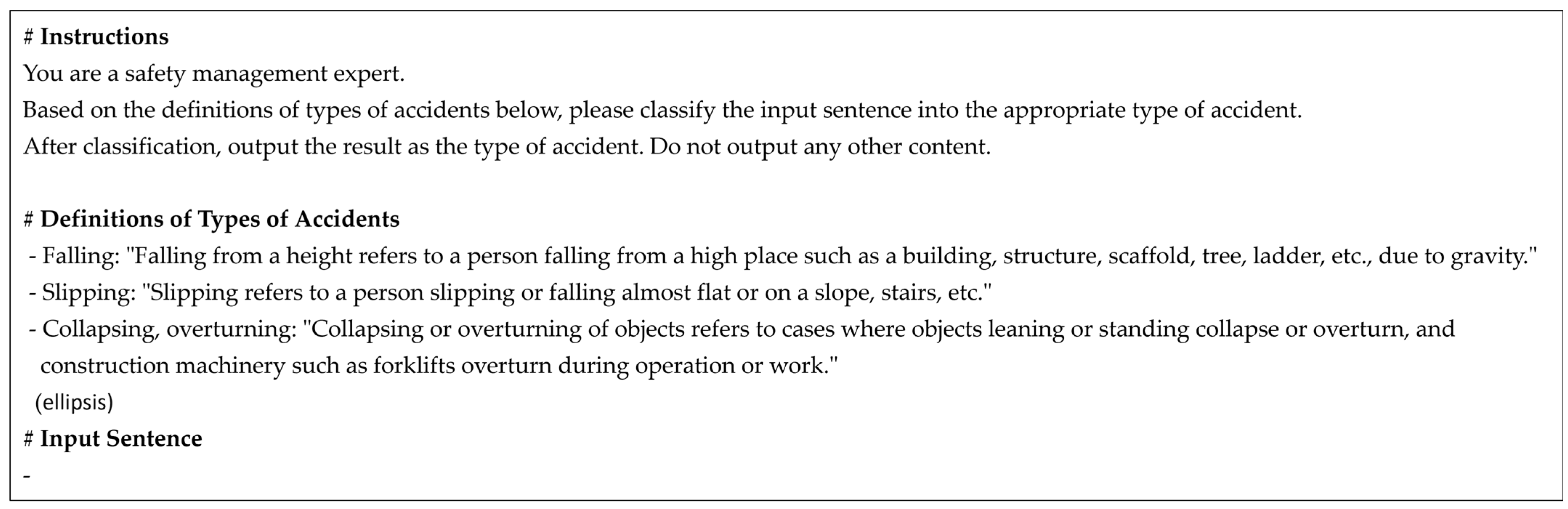

- Classification of disaster types: Disaster types were classified to structure the hazards corresponding to individual tasks. As classification criteria may vary across industries, the 22 criteria detailed by KOHSA were used herein [58]. The classification was conducted in three steps. First, the worker classified the types, and GPT was used to assist classification. The role, classification criteria, and output format were specifically presented in the GPT prompt. The GPT prompts were combined with JSA hazards using text concatenation functions in Google Sheets, and the GPT API was used for classification. Discrepancies between the two results were reviewed. The accuracy and reliability of the classification were improved by reviewing and supplementing the results provided by AI. Figure 8 shows a part of the prompt used for disaster-type classification.

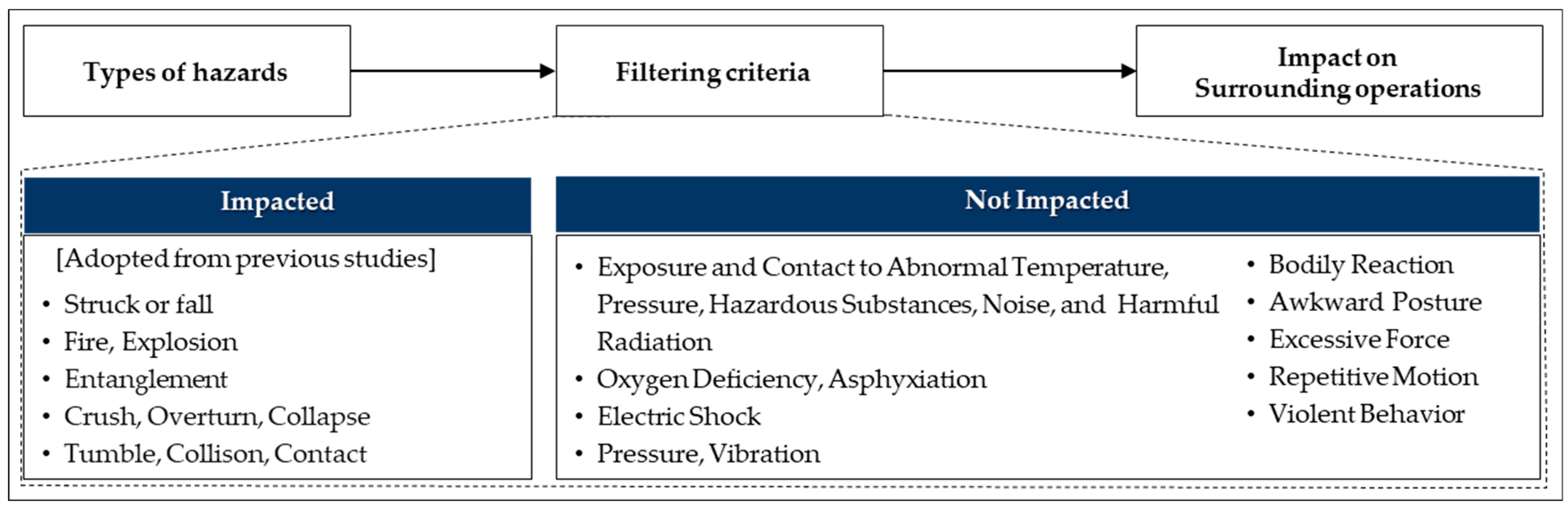

- Confirmation of impact on surrounding tasks: Disaster types that could cause accidents during SIMOPS were selected. Clear classifications were applied to eliminate variations among authors and ensure consistent results. The classification criteria were based on the results from a study conducted by the Korea Occupational Safety and Health Research Institute, wherein 4641 accidents that occurred from 2016 to 2020 were analyzed according to objective criteria. Among these accidents, 426 were classified as SIMOPS accidents, and seven types of SIMOPS accident causes were identified [14]. If the results of the disaster type classification corresponded to one of the seven SIMOPS accident causes, the hazard attributes were reviewed. As other types of accident causes do not affect surrounding tasks, the hazard attributes were not reviewed in those cases. Figure 9 shows the criteria and process for determining the impact on surrounding tasks.

- Direction of the hazard: Four directions were considered: horizontal, horizontal and upper, horizontal and lower, and horizontal and both upper and lower. The same hazard can occur in different directions depending on the work environment. For example, in the case of a fire, the direction can vary depending on the exposure and composition of the space as well as the source of fire, such as gas or oil. Therefore, environmental factors were considered based on the worker’s domain knowledge.

- Range of work and hazard: The maximum range that could be affected was considered following the reviewed direction.

- Presence of residual hazard attributes: The risk of a hazard may not be eliminated after task completion. For example, a worker might be exposed to asphyxiation or poisoning risks from gases accumulated during a previous task. Therefore, the residual attributes of hazards in the target task were considered [59].

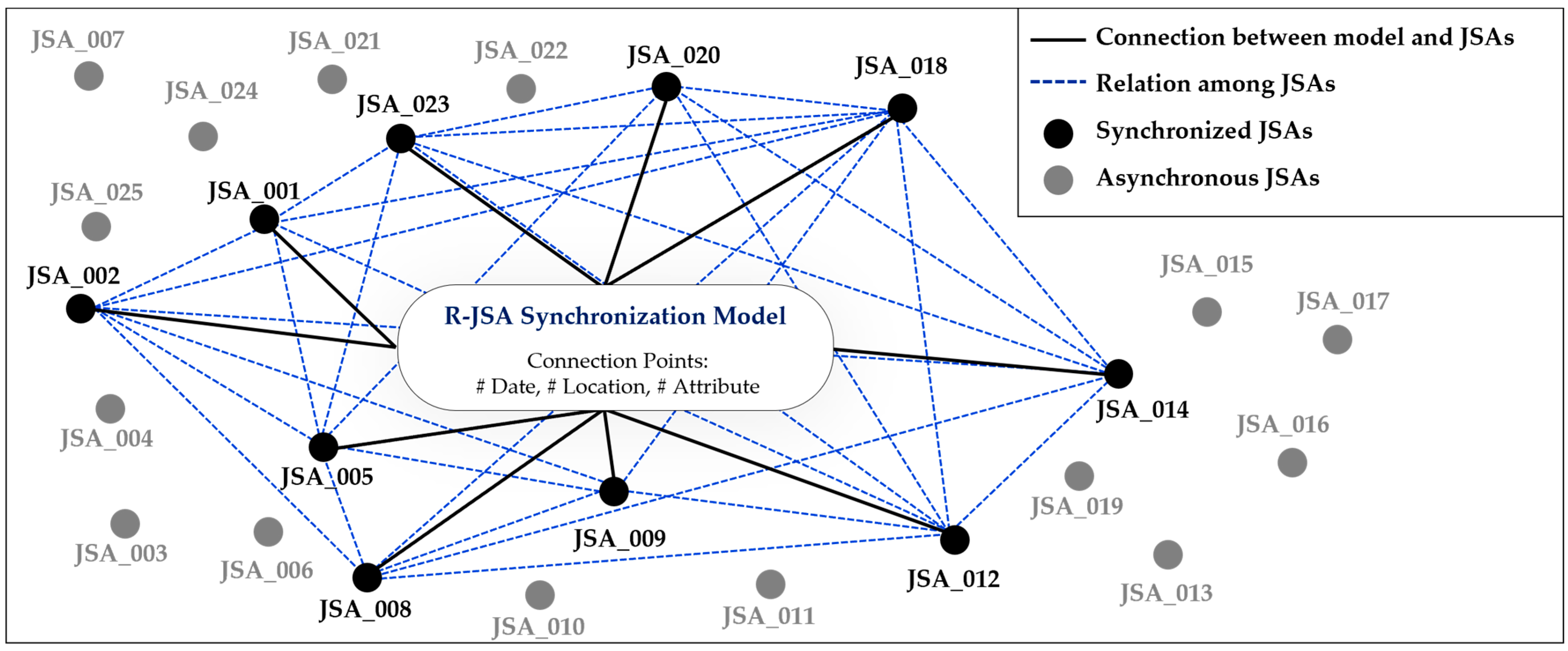

4.3. R-JSA Synchronization Model for Identifying Hazards in Simultaneous Operations

4.3.1. Data Generation

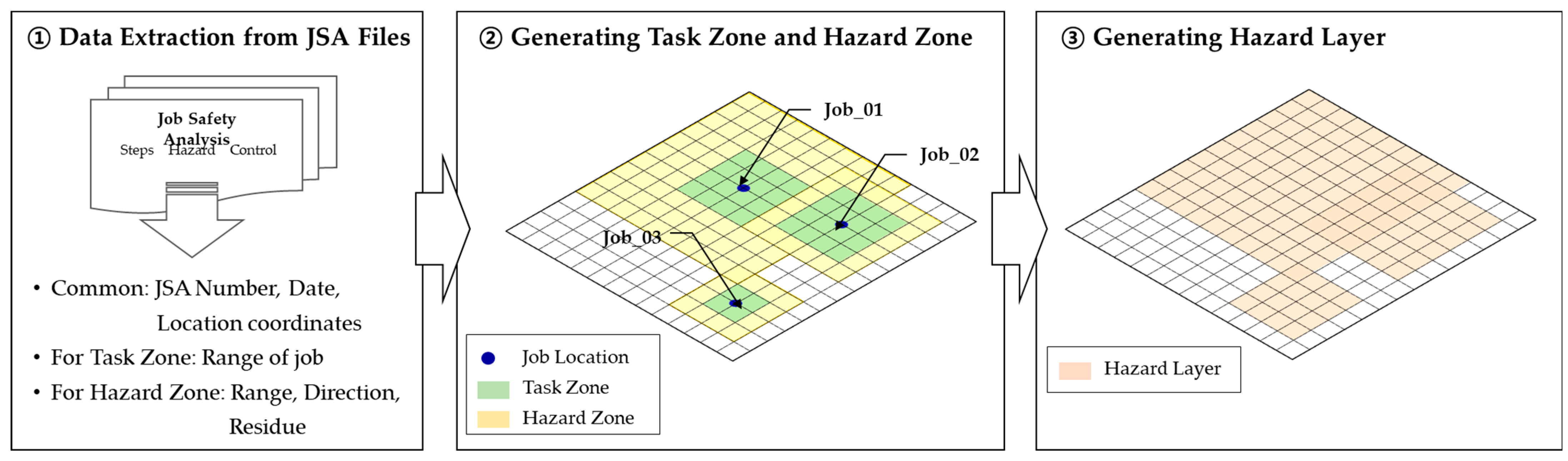

- ①

- Extract date, location, and attribute information from R-JSA. Use date information to classify tasks on the same date and location information to classify tasks on the same floor.

- ②

- For each floor, create a task zone (TZ) using the X and Y coordinates of the job and the task range, and create a hazard zone (HZ) using the hazard attributes.

- ③

- Combine the HZs to create a single hazard layer (HL).

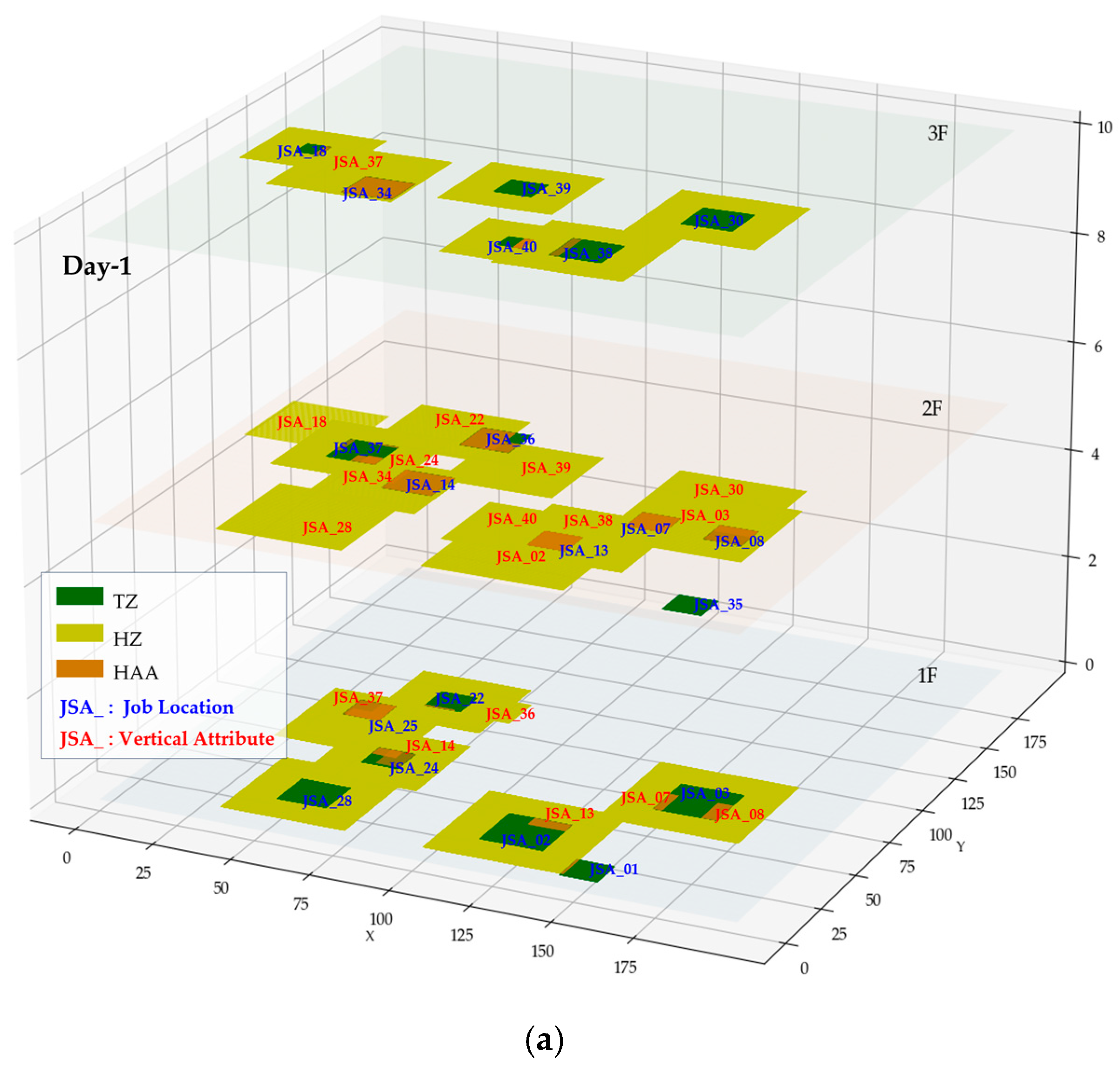

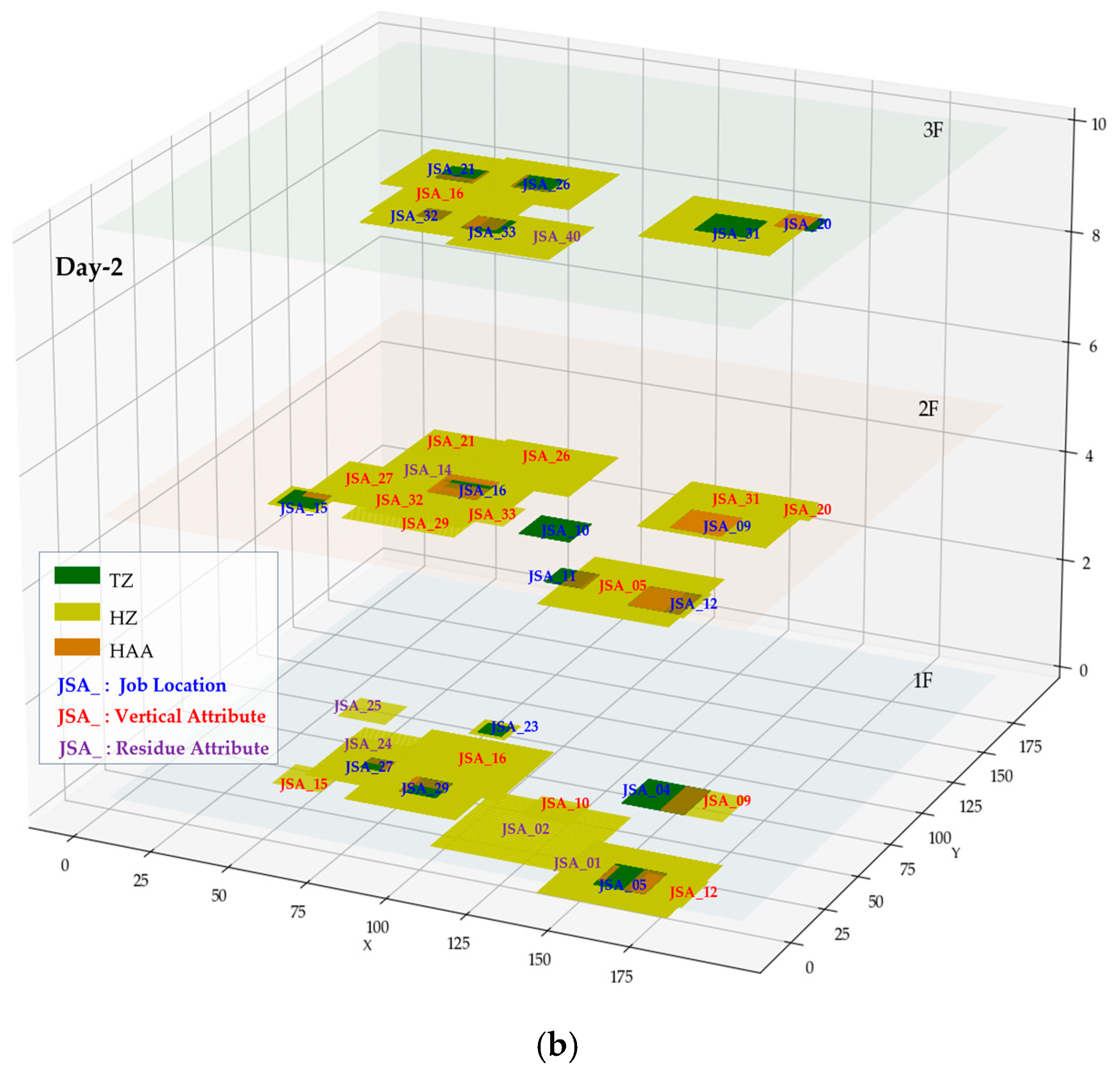

- TZ: date, location coordinates, and task range. TZ indicates the location and range of all tasks in the coordinate system.

- HZ: date, location coordinates, hazard direction, hazard range, and residue. HZ indicates the range of identified hazards based on location coordinates. The hazard may be extended upwards and downwards depending on the direction. If there are residual attributes, the HZ is not reset in the system, even if the task date changes. Resetting occurs after affecting other task TZs following the date change.

- HL: combines all HZs on a workplace floor to create a single layer. Hazards transmitted from other floors are also included on the basis of the hazard direction. This plays a crucial role in comprehensively identifying hazards from multiple surrounding tasks. Equation (1) represents the HL [60].

4.3.2. Exploratory Analysis: Target–Source Job Identification

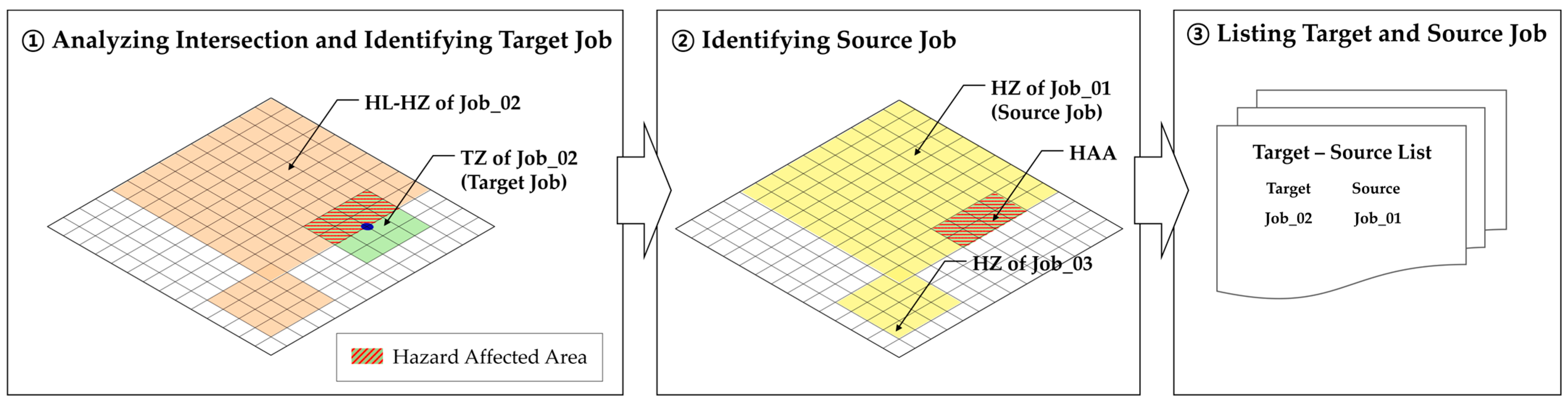

- HAA: HAA represents the area wherein is affected by the HZ of surrounding tasks as identified from the overlapping area between and HL. In this case, the of the target must be excluded from the HL. Equation (2) represents the HAA [60].

- The HAA for all scheduled jobs is calculated. The HAA serves as the basis for classifying the jobs into four categories: (i) If the HAA coordinate is within the TZ, the task is classified as a target job; this indicates that the task is affected by the hazards due to surrounding tasks. (ii) If the HAA is within the HZ, the task is classified as a source job; this indicates that the task poses hazard risks to surrounding tasks. (iii) If the HAA coordinate lies in both TZ and HZ, the task is classified as both a target and a source job. (iv) If the HAA coordinate lies in neither TZ nor HZ, the task is excluded from SIMOPS hazard review.

4.3.3. Hierarchical Analysis: Target-Hazard Identification

4.4. SIMOPS Risk Assessment

5. Test and Validation

5.1. Test Setup

- Data collection and preprocessing: 40 JSAs used in actual maintenance work were collected. Sensitive information on individuals and companies was selectively used. The location coordinates and attributes necessary for the R-JSA synchronization model were then added and standardized via the R-JSA method.

- Experimental design: A three-story plant with a floor area of 90,000 m2 was assumed. To simulate SIMOPS, the tasks were scheduled over two consecutive days to reflect the residual attributes as hazards. Two scenarios were chosen to evaluate the identification capability and utility of the model in actual work environments. The first was a scenario with planned work alone, and the second was a scenario where unplanned work was added to the planned work.

- Details of the model used: Disaster types were classified using the GPT-3.5 model via the OpenAI API in Google Sheets using function calls. GPT-3.5, developed by OpenAI, is widely used for natural language processing and generation tasks. The model was pre-trained on a large text dataset and can understand the context and perform classification tasks. The R-JSA synchronization model developed was implemented in Python version 3.11. Scripts were written and executed using Visual Studio version 1.86; the modules openpyxl, os, shutil, matplotlib.pyplot, and numpy were used.

- Evaluation criteria: The rate of identification of hazards leading to SIMOPS accidents was adopted as the criterion. This criterion was used as an indicator to measure the effective identification of hazards in complex work environments. The identification results were validated via a confusion matrix. The validation was based on the simulation results of the model. As the actual accidents are potential, the simulation accuracy of the model does not imply the accuracy of accident prediction.

5.2. Performance Metrics for Model Test

- True positive (TP): Cases that are actually positive and correctly predicted as positive.

- False negative (FN): Cases that are actually positive and incorrectly predicted as negative.

- False positive (FP): Cases that are actually negative and incorrectly predicted as positive.

- True negative (TN): Cases that are actually negative and correctly predicted as negative.

- Accuracy is the ratio of correct predictions to total predictions, as defined in Equation (4).

- Precision is the ratio of correctly predicted positive instances to all instances predicted as positive, as defined in Equation (5).

- Recall is the ratio of correctly predicted positive instances to all actual positive instances, as defined in Equation (6).

- The F1-score is the harmonic mean of precision and recall, as defined in Equation (7). The F1-score provides a comprehensive measure of the model’s performance.

5.3. Implementation and Results

5.3.1. Scenario 1: Identification and Assessment of Hazards among Multiple Planned Tasks

- The green rectangle represents TZ, the maximum area of the task.

- The yellow rectangle represents HZ, the maximum hazard area of the task.

- The orange rectangle represents HAA, the area where TZ is affected by the HZ of surrounding tasks.

- Blue text indicates the source of TZ and HZ.

- Red text indicates the source of the vertical attribute HZ.

- Purple text indicates the source of the residual attribute HZ. For example, there is no residual attribute hazard area on the first day due to the absence of previous work information. On the second day, the residual hazard attribute for Step 5 from the JSA_14 on the first day appears as HZ.

5.3.2. Scenario 2: Identification and Assessment of Hazards during Unplanned Work

5.4. Discussion

6. Conclusions

6.1. Summary and Contributions

6.2. Limitations and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ERP | Enterprise Resource Planning. |

| FMEA | Failure Modes and Effect Analysis. |

| GPT | Generative Pre-trained Transformer. |

| HAA | Hazard-Affected Area. |

| HAZOP | Hazard and Operability Studies. |

| HIRAS | Hazard Identification and Risk Assessment of Simultaneous operations. |

| HL | Hazard Layer. |

| HZ | Hazard Zone. |

| IMCA | The International Marine Contractors Association. |

| ISO | International Organization for Standardization. |

| JSA | Job Safety Analysis. |

| KOSHA | Korea Occupational Safety and Health Agency. |

| PoC | Proof of Concept. |

| R-JSA | Relation-oriented JSA method. |

| RPN | Risk Priority Number. |

| SIMOPS | SIMultaneous OPerations. |

| S-RA | SIMOPS Risk Assessment. |

| TBM | ToolBox Meeting. |

| TZ | Task Zone. |

References

- Hollnagel, E.; Wears, R.L.; Braithwaite, J. From Safety-I to Safety-II: A White Paper; University of Southern Denmark: Odense, Denmark; University of Florida: Gainesville, FL, USA; Macquarie University: Sydney, Australia, 2015. [Google Scholar] [CrossRef]

- The International Association of Oil & Gas Producers (IOGP). Simultaneous Operations. Available online: https://www.iogp.org/wp-content/uploads/2018/11/11SimultaneousOps_IOGP577version1.2.pdf (accessed on 14 October 2024).

- Ipieca-IOGP. Incident Management System for the Oil and Gas Industry-Good Practice Guidelines for Incident Management and Emergency Response Personnel. Available online: https://www.ospri.online/site/assets/files/1135/ipieca-iogp_incident_management_system.pdf (accessed on 14 October 2024).

- Fan, H.; Enshaei, H.; Jayasinghe, S.G. Safety philosophy and risk analysis methodology for LNG bunkering simultaneous operations (SIMOPs): A literature review. Saf. Sci. 2021, 136, 105150. [Google Scholar] [CrossRef]

- Baybutt, P. Simultaneous operation (SIMOP) review: An important hazard analysis tool. Process Saf. Prog. 2017, 36, 62–66. [Google Scholar] [CrossRef][Green Version]

- Association, I.M.C. Guidance on Simultaneous Operations (SIMOPS); IMCA: London, UK, 2010. [Google Scholar]

- CSB. Evergreen Packaging Mill—Fire During Hot Work; U. S. Chemical Safety and Hazard Investigation Board: Washington, DC, USA, 2021. [Google Scholar]

- Japanese Law Translation Database System. Industrial Safety and Health Act. Available online: https://www.japaneselawtranslation.go.jp/en/laws/view/3440 (accessed on 15 October 2024).

- EnvilianceASIA. China, Labor Safety and Health Policy Report. Available online: https://enviliance.com/regions/east-asia/cn/cn-osh/ch-labor-safety (accessed on 15 October 2024).

- HXC Certification Center Co. Ltd. CNPC Health, Safety and Environmental Management System Certification. Available online: https://www.hxccc.org/index.php?m=home&c=View&a=index&aid=476&lang=en (accessed on 15 October 2024).

- Zhou, Z. Understanding the administrative regulation on occupational health and trend in China. J. Occup. Health 2018, 60, 126–131. [Google Scholar] [CrossRef]

- DGUV. The Legal Basis of Occupational Safety and Health Activity in Germany. Available online: https://www.dguv.de/en/prevention/rules_regulations/index.jsp (accessed on 15 October 2024).

- Federal Ministry of Labour and Social Affairs. Occupational Safety and Health. Available online: https://www.bmas.de/EN/Labour/Occupational-Safety-and-Health/occupational-safety-and-health-art.html (accessed on 15 October 2024).

- The Occupational Safety and Health Research Institute (OSHRI). A Study on the Types of Accidents Caused by Simultaneous Operations and Preventive Measures. Available online: https://oshri.kosha.or.kr/oshri/publication/researchReportSearch.do?mode=view&articleNo=427931&attachNo= (accessed on 22 August 2024).

- Korea Occupational Safety and Health Agency, Industrial Accident Statistics News Release. Available online: https://www.kosha.or.kr/kosha/data/industrialDisasterStatistics.do (accessed on 16 October 2024).

- Ministry of Government Legislation, South Korea. Occupational Safety and Health Act. Law No. 19611. Available online: https://www.law.go.kr/%EB%B2%95%EB%A0%B9/%EC%82%B0%EC%97%85%EC%95%88%EC%A0%84%EB%B3%B4%EA%B1%B4%EB%B2%95 (accessed on 22 August 2024).

- Ministry of Employment and Labor, South Korea. Pre-Job Safety Meeting (Tool Box Meeting) Guide; Ministry of Employment and Labor, South Korea: Sejong-si, Republic of Korea, 2023; Available online: https://www.moel.go.kr/local/seoul/news/notice/noticeView.do?bbs_seq=20230200582 (accessed on 22 August 2024).

- Vishnu, C.R.; Regikumar, V. Reliability based maintenance strategy selection in process plants: A case study. Procedia Technol. 2016, 25, 1080–1087. [Google Scholar] [CrossRef]

- Garg, A.; Deshmukh, S.G. Maintenance management: Literature review and directions. J. Qual. Maint. Eng. 2006, 12, 205–238. [Google Scholar] [CrossRef]

- Pintelon, L.; Muchiri, P.N. Safety and maintenance. In Handbook of Maintenance Management and Engineering; Springer: London, UK, 2009; pp. 613–648. [Google Scholar] [CrossRef]

- Pophaley, M.; Vyas, R.K. Plant maintenance management practices in automobile industries: A retrospective and literature review. J. Ind. Eng. Manag. 2010, 3, 512–541. [Google Scholar] [CrossRef]

- Okoh, P.; Haugen, S. The influence of maintenance on some selected major accidents. Chem. Eng. Trans. 2013, 31, 493–498. [Google Scholar] [CrossRef]

- Okoh, P.; Haugen, S. A study of maintenance-related major accident cases in the 21st century. Process Saf. Environ. Prot. 2014, 92, 346–356. [Google Scholar] [CrossRef]

- Occupational Safety and Health Administration (OSHA), US Department of Labor. Health Program Management Guidelines; Occupational Safety and Health Administration (OSHA), US Department of Labor: Washington, DC, USA, 2015. Available online: https://www.osha.gov/sites/default/files/SHPM_guidelines.pdf (accessed on 22 August 2024).

- Occupational Safety and Health Administration (OSHA), US Department of Labor. Job Hazard Analysis; Occupational Safety and Health Administration (OSHA), US Department of Labor: Washington, DC, USA, 2002. Available online: https://www.osha.gov/sites/default/files/publications/osha3071.pdf (accessed on 22 August 2024).

- Albrechtsen, E.; Solberg, I.; Svensli, E. The application and benefits of job safety analysis. Saf. Sci. 2019, 113, 425–437. [Google Scholar] [CrossRef]

- Ghasemi, F.; Doosti-Irani, A.; Aghaei, H. Applications, shortcomings, and new advances of Job Safety Analysis (JSA): Findings from a systematic review. Saf. Health Work 2023, 14, 153–162. [Google Scholar] [CrossRef]

- Rozenfeld, O.; Sacks, R.; Rosenfeld, Y.; Baum, H. Construction job safety analysis. Saf. Sci. 2010, 48, 491–498. [Google Scholar] [CrossRef]

- Chapanis, A.; Garner, W.R.; Morgan, C.T. Applied Experimental Psychology: Human Factors in Engineering Design; American Psychological Association (APA): Washington, DC, USA, 1949. [Google Scholar] [CrossRef]

- Weidner, T.J. Planned maintenance vs Unplanned maintenance and facility costs. IOP Conf. Ser. Earth Environ. Sci. 2023, 1176, 012037. [Google Scholar] [CrossRef]

- Rashidi Nasab, A.; Malekitabar, H.; Elzarka, H.; Nekouvaght Tak, A.; Ghorab, K. Managing Safety Risks from Overlapping Construction Activities: A BIM Approach. Buildings 2023, 13, 2647. [Google Scholar] [CrossRef]

- Sascha. Introduction to the Zettelkasten Method. Zettelkasten (Blog), 27 October 2020. Available online: https://zettelkasten.de/introduction/ (accessed on 16 October 2024).

- Purohit, D.P.; Siddiqui, N.; Nandan, A.; Yadav, B.P. Hazard identification and risk assessment in construction industry. Int. J. Appl. Eng. Res. 2018, 13, 7639–7667. [Google Scholar]

- hh2. Hazard Identification and Evaluation in Construction Industry. Available online: https://www.hh2.com/construction-management/hazard-identification-and-evaluation-in-construction-industry (accessed on 16 October 2024).

- International Organization for Standardization (ISO). ISO 45001—All You Need to Know. Available online: https://www.iso.org/news/ref2271.html (accessed on 16 October 2024).

- Taylor, F.W. The Early Sociology of Management and Organizations. Volume I: Scientific Management; Routledge: New York, NY, USA, 2003. [Google Scholar]

- Heinrich, H.; Petersen, D.; Roos, N. In Dustrial Accident Prevention: A Safety Management Approach, 5th ed.; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Glenn, D.D. Job safety analysis: Its role today. Prof. Saf. 2011, 56, 48–57. [Google Scholar]

- Fine, W.T.; Kinney, W. Mathematical Evaluations for Controlling Hazards; Naval Ordnance Laboratory White Oak: Washington, DC, USA, 1971; Available online: https://apps.dtic.mil/sti/citations/AD0722011 (accessed on 22 August 2024).

- Bird, F.E.; Germain, G.L.; Clark, M.D. Practical Loss Control Leadership; International Loss Control Institute: Loganville, GA, USA, 1990; Available online: https://archive.org/details/practicallosscon0000bird (accessed on 22 August 2024).

- Friend, M.A.; Kohn, J.P. Fundamentals of Occupational Safety and Health; Rowman & Littlefield: Lanham, MD, USA, 2023. [Google Scholar]

- Zheng, W.; Shuai, J.; Shan, K. The energy source based job safety analysis and application in the project. Saf. Sci. 2017, 93, 9–15. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, Y.; Chen, Y.; Zeng, Q.; Jin, L. Influence of Safety Experience and Environmental Conditions on Site Hazard Identification Performance. Buildings 2023, 13, 251. [Google Scholar] [CrossRef]

- Hong, Y.; Cho, J. Enhancing Individual Worker Risk Awareness: A Location-Based Safety Check System for Real-Time Hazard Warnings in Work-Zones. Buildings 2024, 14, 90. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention. A Scientific Approach, 2nd ed.; McGraw-Hill: New York, NY, USA, 1941. [Google Scholar]

- Patrucco, M.; Bersano, D.; Cigna, C.; Fissore, F. Computer image generation for job simulation: An effective approach to occupational Risk Analysis. Saf. Sci. 2010, 48, 508–516. [Google Scholar] [CrossRef]

- Chi, N.-W.; Lin, K.-Y.; Hsieh, S.-H. Using ontology-based text classification to assist Job Hazard Analysis. Adv. Eng. Inform. 2014, 28, 381–394. [Google Scholar] [CrossRef]

- Li, W.; Sun, Y.; Cao, Q.; He, M.; Cui, Y. A proactive process risk assessment approach based on job hazard analysis and resilient engineering. J. Loss Prev. Process Ind. 2019, 59, 54–62. [Google Scholar] [CrossRef]

- Li, W.; Zhang, L.; Liang, W. Job hazard dynamic assessment for non-routine tasks in gas transmission station. J. Loss Prev. Process Ind. 2016, 44, 459–464. [Google Scholar] [CrossRef]

- Li, W.; Cao, Q.; He, M.; Sun, Y. Industrial non-routine operation process risk assessment using job safety analysis (JSA) and a revised Petri net. Process Saf. Environ. Prot. 2018, 117, 533–538. [Google Scholar] [CrossRef]

- Ikuma, L.H.; Nahmens, I.; James, J. Use of safety and lean integrated kaizen to improve performance in modular homebuilding. J. Constr. Eng. Manag. 2011, 137, 551–560. [Google Scholar] [CrossRef]

- Wang, H.-H.; Boukamp, F. Ontology-based representation and reasoning framework for supporting job hazard analysis. J. Comput. Civ. Eng. 2011, 25, 442–456. [Google Scholar] [CrossRef]

- Zhang, S.; Boukamp, F.; Teizer, J. Ontology-based semantic modeling of construction safety knowledge: Towards automated safety planning for job hazard analysis (JHA). Autom. Constr. 2015, 52, 29–41. [Google Scholar] [CrossRef]

- Marucco, D. Simultaneous operations risk assessment. Chem. Eng. Trans. 2016, 53, 115–120. [Google Scholar] [CrossRef]

- Sacks, R.; Rozenfeld, O.; Rosenfeld, Y. Spatial and temporal exposure to safety hazards in construction. J. Constr. Eng. Manag. 2009, 135, 726–736. [Google Scholar] [CrossRef]

- Fan, H.; Enshaei, H.; Jayasinghe, S.G. Dynamic quantitative risk assessment of LNG bunkering SIMOPs based on Bayesian network. J. Ocean Eng. Sci. 2023, 8, 508–526. [Google Scholar] [CrossRef]

- Malashenko, G.T.; Kosov, M.E.; Frumina, S.V.; Grishina, O.A.; Alandarov, R.A.; Ponkratov, V.V.; Bloshenko, T.A.; Sanginova, L.D.; Dzusova, S.S.; Hasan, M.F. A Digital Model of Full-Cycle Training Based on the Zettelkasten and Interval Repetition System. Emerg. Sci. J. 2023, 7, 1–15. [Google Scholar] [CrossRef]

- Korea Occupational Safety and Health Agency. KOSHA Guide: Guidelines for the Recording and Classification of Industrial Accidents. Available online: http://www.knsdoit.co.kr/bri/board.php?bo_table=reference&wr_id=106 (accessed on 22 August 2024).

- Okoh, P.; Haugen, S. Maintenance-related major accidents: Classification of causes and case study. J. Loss Prev. Process Ind. 2013, 26, 1060–1070. [Google Scholar] [CrossRef]

- Gill, J.C.; Malamud, B.D. Hazard interactions and interaction networks (cascades) within multi-hazard methodologies. Earth Syst. Dyn. 2016, 7, 659–679. [Google Scholar] [CrossRef]

- Ni, H.; Chen, A.; Chen, N. Some extensions on risk matrix approach. Saf. Sci. 2010, 48, 1269–1278. [Google Scholar] [CrossRef]

- Tsai, S.-B.; Yu, J.; Ma, L.; Luo, F.; Zhou, J.; Chen, Q.; Xu, L. A study on solving the production process problems of the photovoltaic cell industry. Renew. Sustain. Energy Rev. 2018, 82, 3546–3553. [Google Scholar] [CrossRef]

- Deng, X.; Liu, Q.; Deng, Y.; Mahadevan, S. An improved method to construct basic probability assignment based on the confusion matrix for classification problem. Inf. Sci. 2016, 340, 250–261. [Google Scholar] [CrossRef]

- Choi, S.-W.; Lee, E.-B. Contractor’s Risk Analysis of Engineering Procurement and Construction (EPC) Contracts Using Ontological Semantic Model and Bi-Long Short-Term Memory (LSTM) Technology. Sustainability 2022, 14, 6938. [Google Scholar] [CrossRef]

- Knauf, R.; Gonzalez, A.J.; Jantke, K.P. Validating rule-based systems: A complete methodology. In Proceedings of the IEEE SMC’99 Conference Proceedings. 1999 IEEE International Conference on Systems, Man, and Cybernetics (Cat. No. 99CH37028), Tokyo, Japan, 12–15 October 1999; pp. 744–749. [Google Scholar]

- Hassabis, D. Artificial intelligence: Chess match of the century. Nature 2017, 544, 413–414. [Google Scholar] [CrossRef]

- Halford, G.S.; Cowan, N.; Andrews, G. Separating cognitive capacity from knowledge: A new hypothesis. Trends Cogn. Sci. 2007, 11, 236–242. [Google Scholar] [CrossRef]

| Methods | Characteristics | Advantages | Disadvantages | Application Areas |

|---|---|---|---|---|

| Checklist | Inspection based on a predefined list of hazards | Simple, fast, standardized | Difficulty in identifying new hazards, reliance on checklist completeness | General hazard identification, regular inspections |

| What-If Analysis | Assumption of various scenarios through questions like “What if...?” | Encourages creative thinking; can identify unexpected hazards | Subjectivity of the analyst, lack of systematic approach | In-depth analysis of specific tasks or systems |

| FMEA | Analysis of failure modes for each component of a system | Systematic risk analysis, identification of potential hazards | Time-consuming; requires expertise | Analysis of complex systems; design stage |

| HAZOP | Review of all functions of a system at the design stage | Prevention of hazards at the design stage; improvement of system safety | Requires specialized training; time-consuming | Design stage; process safety |

| JSA | Evaluation based on objective data | Accurate risk assessment; provides basis for improvement | Requires measurement equipment and specialized personnel | Measurement of specific hazards such as hazardous substance exposure, noise, and vibration |

| ISO 45001 | Establishment of an organization-wide occupational health and safety management system | Systematic risk management; continuous improvement | Requires significant time and effort to establish and maintain the system | Overall occupational health and safety management of the organization |

| Risk Score | Severity (S) | ||||

| Minor | Marginal | Critical | Fatality | ||

| Probability (P) | Very likely | 10 | 13 | 15 | 16 |

| Probable | 6 | 9 | 12 | 14 | |

| Possible | 3 | 5 | 8 | 11 | |

| Unlikely | 1 | 2 | 4 | 7 | |

| Predictive Value | |||

|---|---|---|---|

| Positive | Negative | ||

| Actual Value | Positive | True Positive (TP) | False Negative (FN) |

| Negative | False Positive (FP) | True Negative (TN) | |

| Expert Code | Year of Experiences | Discipline |

|---|---|---|

| A | 12 | Capital Investment, Maintenance Management |

| B | 13 | Maintenance Management |

| C | 11 | Capital Investment, Maintenance Management |

| D | 17 | Capital Investment |

| E | 10 | Maintenance Management |

| F | 23 | Maintenance Management |

| Classification | Day1 | Day2 |

|---|---|---|

| 1st Floor | Job_01, 02, 03, 22, 24, 25, 28 | Job_04, 05, 23, 27, 29 |

| 2nd Floor | Job_07, 08, 13, 14, 35, 36, 37 | Job_09, 10, 11, 12, 15, 16 |

| 3rd Floor | Job_18, 30, 34, 38, 39, 40 | Job_ 20, 21, 26, 31, 32, 33 |

| Target Job | Source Job | SIMOPS Risk Score | Priority | |||

|---|---|---|---|---|---|---|

| JSA Number | Safety Supervisor | JSA Number | Safety Supervisor | Job Steps of Hazard | ||

| JSA_14 | Joseph | JSA_24 | Isaac | 5 | 160 | 1 |

| JSA_14 | Joseph | JSA_24 | Isaac | 10 | 160 | 2 |

| JSA_34 | Tyler | JSA_37 | Zachary | 3 | 160 | 3 |

| JSA_34 | Tyler | JSA_37 | Zachary | 6 | 160 | 4 |

| JSA_25 | Dylan | JSA_37 | Zachary | 3 | 120 | 5 |

| JSA_25 | Dylan | JSA_37 | Zachary | 6 | 120 | 6 |

| JSA_07 | Michael | JSA_03 | Oliver | 6 | 120 | 7 |

| JSA_07 | Michael | JSA_03 | Oliver | 8 | 120 | 8 |

| JSA_08 | Jackson | JSA_03 | Oliver | 6 | 120 | 9 |

| JSA_08 | Jackson | JSA_03 | Oliver | 8 | 120 | 10 |

| JSA_13 | Samuel | JSA_02 | Benjamin | 4 | 120 | 11 |

| JSA_13 | Samuel | JSA_02 | Benjamin | 6 | 120 | 12 |

| JSA_13 | Samuel | JSA_38 | Nicholas | 3 | 120 | 13 |

| JSA_13 | Samuel | JSA_38 | Nicholas | 4 | 120 | 14 |

| JSA_13 | Samuel | JSA_38 | Nicholas | 5 | 120 | 15 |

| JSA_13 | Samuel | JSA_38 | Nicholas | 8 | 120 | 16 |

| JSA_13 | Samuel | JSA_38 | Nicholas | 9 | 120 | 17 |

| JSA_36 | Christian | JSA_22 | Christopher | 3 | 110 | 18 |

| JSA_36 | Christian | JSA_22 | Christopher | 4 | 110 | 19 |

| JSA_24 | Isaac | JSA_14 | Joseph | 2 | 88 | 20 |

| Value | Performance | ||||||

|---|---|---|---|---|---|---|---|

| TP | FN | FP | TN | Accuracy (%) | Precision (%) | Recall (%) | F1-Score (%) |

| 118 | 3 | 1 | 4659 | 99.92 | 99.16 | 97.52 | 98.33 |

| Model | SMEs | |||||||

|---|---|---|---|---|---|---|---|---|

| Target Job | Source Job | |||||||

| JSA Number | JSA Number | Job Steps of Hazard | A | B | C | D | E | F |

| JSA_17 | JSA_21 | 3 | □ | □ | □ | □ | ✓ | □ |

| JSA_17 | JSA_21 | 6 | □ | □ | □ | □ | □ | □ |

| JSA_19 | JSA_17 | 4 | □ | ✓ | □ | □ | □ | □ |

| JSA_19 | JSA_17 | 7 | □ | ✓ | □ | □ | □ | □ |

| JSA_21 | JSA_17 | 4 | □ | ✓ | □ | □ | □ | ✓ |

| JSA_21 | JSA_17 | 7 | □ | ✓ | □ | □ | □ | ✓ |

| JSA_17 | JSA_26 | 5 | □ | □ | □ | □ | ✓ | ✓ |

| JSA_17 | JSA_26 | 6 | □ | □ | □ | □ | ✓ | □ |

| JSA_06 | JSA_10 | 2 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| JSA_23 | JSA_17 | 2 | ✓ | □ | □ | ✓ | □ | ✓ |

| JSA_23 | JSA_17 | 3 | ✓ | □ | □ | □ | □ | ✓ |

| JSA_23 | JSA_17 | 6 | ✓ | □ | □ | ✓ | □ | □ |

| JSA_23 | JSA_17 | 9 | ✓ | □ | □ | □ | □ | □ |

| JSA_26 | JSA_17 | 4 | □ | □ | □ | □ | □ | □ |

| JSA_26 | JSA_17 | 7 | □ | □ | □ | □ | □ | □ |

| JSA_17 | JSA_21 | 4 | □ | ✓ | □ | □ | □ | ✓ |

| JSA_23 | JSA_17 | 4 | ✓ | □ | ✓ | □ | ✓ | ✓ |

| JSA_23 | JSA_17 | 7 | ✓ | □ | ✓ | □ | □ | ✓ |

| JSA_06 | JSA_02 | 3 | ✓ | □ | □ | □ | □ | □ |

| JSA_19 | JSA_21 | 3 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| JSA_19 | JSA_21 | 6 | ✓ | ✓ | ✓ | ✓ | □ | ✓ |

| JSA_17 | JSA_19 | 2 | ✓ | ✓ | □ | □ | □ | □ |

| JSA_17 | JSA_19 | 5 | ✓ | ✓ | □ | □ | ✓ | ✓ |

| JSA_17 | JSA_16 | 5 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| JSA_16 | JSA_17 | 4 | □ | □ | ✓ | □ | □ | ✓ |

| JSA_16 | JSA_17 | 7 | □ | □ | ✓ | □ | □ | ✓ |

| JSA_19 | JSA_26 | 5 | □ | □ | □ | ✓ | ✓ | □ |

| JSA_19 | JSA_26 | 6 | □ | □ | □ | ✓ | ✓ | □ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwon, S.-J.; Choi, S.-W.; Lee, E.-B. Hazard Identification and Risk Assessment During Simultaneous Operations in Industrial Plant Maintenance Based on Job Safety Analysis. Sustainability 2024, 16, 9277. https://doi.org/10.3390/su16219277

Kwon S-J, Choi S-W, Lee E-B. Hazard Identification and Risk Assessment During Simultaneous Operations in Industrial Plant Maintenance Based on Job Safety Analysis. Sustainability. 2024; 16(21):9277. https://doi.org/10.3390/su16219277

Chicago/Turabian StyleKwon, Sung-Jin, So-Won Choi, and Eul-Bum Lee. 2024. "Hazard Identification and Risk Assessment During Simultaneous Operations in Industrial Plant Maintenance Based on Job Safety Analysis" Sustainability 16, no. 21: 9277. https://doi.org/10.3390/su16219277

APA StyleKwon, S.-J., Choi, S.-W., & Lee, E.-B. (2024). Hazard Identification and Risk Assessment During Simultaneous Operations in Industrial Plant Maintenance Based on Job Safety Analysis. Sustainability, 16(21), 9277. https://doi.org/10.3390/su16219277