Abstract

The circular economy is a tangible paradigm in response to the unsustainable model of production and consumption of resources in the agri-food system. The circular economy allows for a reduction in the environmental impact through the minimization of food waste or the maximal generation of renewable energy from waste. Despite the relevance, in the extant literature, there are scant indications on how to apply circular business models in agri-food systems. Hence, the paper aims to analyze the circular economy implementation level in the agri-food system in 29 European countries, focusing on specific circular economy strategies. Selected indicators were analyzed to evaluate the level of circular economy implementation in the agri-food system (e.g., production values, energy sharing from renewable sources, and total waste emission) using a Panel data analysis method. The required variables were gained from the global databases within the recent five years (2014–2018). The results reveal an overall lack of circular economy implementation in the agri-food systems among European countries. A set of 12 managerial propositions was suggested to foster the implementation of the circular business models by interacting the recycling, extending, intensifying, and dematerializing strategies with aspects of the production process, waste emission, and renewable energy sharing in the agri-food system.

1. Introduction

The global food system is currently experiencing a multitude of challenges that undermine its future and its ability to satisfy the growing demand for food. Given that the demographic growth is expected to reach 9.1 billion in 2050, feeding the global population will require food production to increase by 60–70% from 2005 levels 25. Ironically, a third of global food production is wasted each year, accounting for 1.3 billion tons lost each year [1]. Furthermore, the food system contributes to other environmental issues like climate change, generating one-quarter of global greenhouse gas emissions and directly impacting biodiversity and ecosystems [2]. At the same time, the food production system also entails numerous socioeconomic problems like labor and food worker issues, as well as negative impacts on vulnerable communities [2,3].

The challenges of the food system appear to be interconnected and self-reinforcing, while their outcomes are causing impact on a global scale, making it challenging to satisfy the growing demand while allowing for a reduction in the impacts [4].

The adoption of the circular economy (CE) paradigm in the agri-food sector has recently received attention in research and academic literature e.g., [5,6] as a potential way to overcome the aforementioned challenges. Specifically, the adoption of circular business models (CBMs) has the potential to help food systems in valorizing resources and waste material, adopting practices like the recovery and recycling of materials along the food supply chain [7]. Additionally, the CE practices within the agri-food sector also hold the potential to improve environmental conditions, enhancing, for instance, soil fertility [8].

However, the existing research has conducted little investigation into the level of implementation of the CE within the agri-food system, and there have been recent calls to conduct a circularity analysis of agri-food companies [9,10]. Moreover, little is known about the enablers and facilitators of CE practices and CBMs within the agri-food industry. Presently, leadership and legislation have been recognized as relevant factors for the adoption of circular strategies, but more research is needed to understand how to apply CE and CBMs in agri-food companies, calling for additional research on the topic [11,12].

The valorization of supply–demand in the global food system is of paramount relevance for worldwide sustainable development. As the world’s population grows, the global food demand will grow significantly, and feeding a world population of 9.1 billion in 2050 will require food production to increase by 60–70% from 2005 levels [13]. On the other hand, a third of global food production is wasted each year, amounting to about 1.3 billion tons [1]. Furthermore, the agri-food system is responsible for almost one-quarter of global greenhouse gas emissions [2], and it is one of the main contributors to global environmental change, entailing many socio-economic negative effects [3] as it encompasses a multitude of actors, elements, and processes, i.e., production, processing, distribution, preparation, consumption, and disposal of food [2].

Thus, the global food system faces several interlinked problems with serious outcomes on the global scale, including growing consumer demand and excessive food waste [4,14]. The adoption of the circular economy (CE) paradigm in the agri-food sector has received attention in research and academic literature e.g., [5,6], specifically for the possible adoption of circular business models (CBMs). CE has the potential to help the agri-food sector by recovering/recycling agri-food waste and might also improve the agri-food supply chain [7], for example, through practices that support the restoration of soil fertility [8].

Although some elements, such as leadership and legislation, have been recognized as enabling factors [15], clear indications on how to apply CE and CBMs in agri-food systems are scant, calling for additional research on the topic [11,12]. Recently, refs. [9,10] encouraged further studies to focus on the interest of agri-food enterprises in a circularity analysis.

Given the above, the present study aims to propose an analysis of the level of CE implementation in the agri-food system at the country level and to provide concrete guidelines for managers and policy-makers who want to contribute to CE in the agri-food system. In more detail, the research aims to answer the following research questions:

RQ1. What is the circular economy implementation level in the agri-food system in European countries?

RQ2. How can the implementation of circular economy practices in the agri-food sector be effectively promoted in European countries?

The remainder of the paper is as follows: After a literature review and development of research hypotheses (Section 2), the methods used for the analysis are presented (Section 3); the results from the empirical investigation are presented (Section 4) and research questions are answered (Section 5); and the conclusions of the study are offered, together with limitations paving the way for future research (Section 6).

2. Literature Background and Hypotheses Development

2.1. Circular Economy and Business Models

Growing in the circular economy in response to the current unsustainable model of production and consumption resources is currently very tangible [10]. The circular economy is a powerful paradigm to address sustainability issues focusing on narrowing and regenerating resource loops [16]. The circular economy is gaining traction in academia, industry, and policy making as an alternative model that minimizes resource depletion, waste, and emissions. This concept is defined as a production and consumption model, which involves sharing, renting, reusing, repairing, renovating, and recycling existing materials and products for as long as possible and reducing waste [10,17].

A business model is a strategic tool for designing business activities as well as for comprehensive, cross-company description and analysis [18]. However, the concept of circularity in business models has emerged with a range of definitions propounded by different scholars [19]. For instance, ref. [20] define circularity as business model strategies suited for the move to a circular economy, and ref. [21] define it as a business model with the conceptual logic for value creation. More recently, ref. [11] proposed the implementation of circularity strategies (i.e., recycling, extending, intensifying, and dematerializing) affecting business model elements (i.e., value proposition, value creation and delivery, and value capture) compiled from the published literature [11,20,22,23]. Furthermore, several circularity strategies exist to reduce the consumption of natural resources and materials and minimize the production of waste, including nine strategies: refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, and recover [24]. In this regard, ref. [24] have noted that a higher level of circularity strategy [25], e.g., refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, and repurpose, in production means that materials remain in the chain for a longer period. However, this definition of the circularity strategy cannot be adapted adequately in the agro-food system [26] because agro-food production has a limited lifetime without the possibility to implement strategies such as reuse, repair, or remanufacture. Hence, our consideration of circularity strategies should be focused on more innovative technologies in circular strategies such as recycling and recovering.

2.2. Recycling, Agro-Food Industry, and CBMs

CBMs aim to boost recycling and loss prevention of valuable materials [18]. Recycling entails the implementation of a number of end-of-use strategies, such as reuse, repair, and remanufacturing, involving take-back in the value proposition and minimized costs of material acquisition in the value capture of each CBM [11]. To transition to more sustainable development models, the agro-food industry needs to be in line with the principles of the circular economy, particularly to face future challenges by recycling and recovering resources [27,28]. In this regard, restorative or regenerative agro-food systems can imply the creation of opportunities from the use of renewable energy of waste through the superior design of materials, products, systems, and even business models [10].

2.3. Renewable Energy and Waste Emission in Food Production

Renewable energy, as an important pillar of the circular economy, decreases waste generation and the extraction of limited resources. A resource-efficient CBM optimizes production and consumption concerning resource saving (de-materialization), recycling of energy, and reusing (re-materialization) [29]. Also, the recovery of food waste is one of the most important elements in the CBMs to decrease environmental pressure and preservation of values [28]. The current agro-food supply chain is affected by different problems, such as food waste generation. Food waste is one of the targeted areas in the circular economy at the global level, directly linked with environmental, economic, and social impacts [30]. The advantages of circularity approaches are attributable to the reduction in the environmental impact through the minimization of food waste, the reduction in price volatility, and increased generation of renewable energy from wastes [10,31].

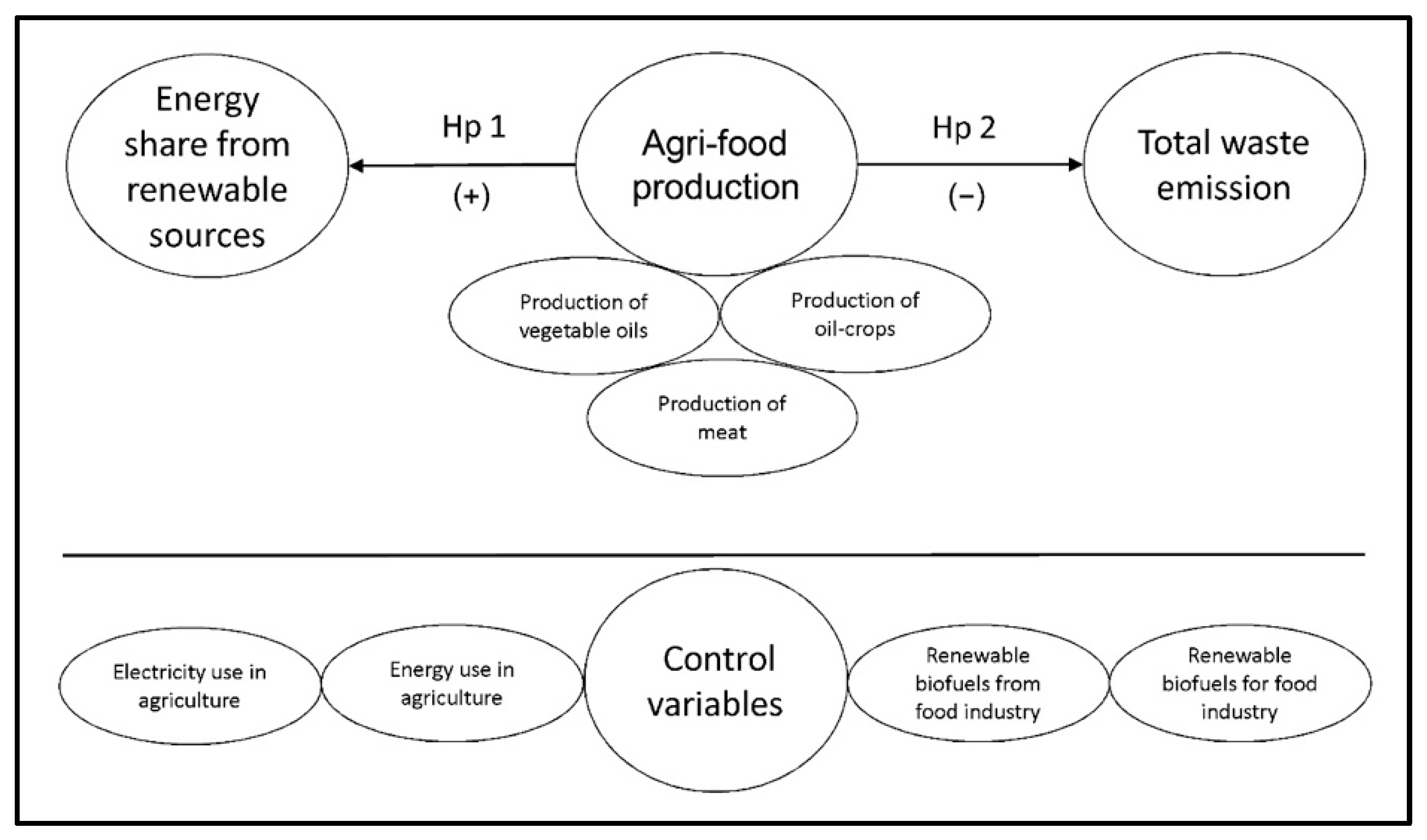

With this background, the research hypotheses are developed based on a research model (Figure 1). Conventionally, the development of higher technologies in agro-food production can result in higher levels of sharing renewable energy, lower waste emissions, and higher efficiency [32]. Inspired by a direct relationship between the sharing of renewable energy and agro-food production, we can confirm the recycling function of circular businesses and the circular economy in the given study area. The vice-versa relationship relates to a significant lack of CBMs within the agro-food system. Furthermore, in a circular economy, a higher level of agro-food production should result in lower waste emissions. Hence, we obtain the following main hypotheses:

Figure 1.

The research framework.

H1.

A higher level of agro-food production can lead to a higher level of renewable energy from the agro-food system.

H2.

A higher level of agro-food production can lead to a lower level of total waste emissions from the agro-food system.

3. Materials and Methods

3.1. Data Preparation

Our paper statistically employs a panel data analysis, adopted by [33,34] to analyze the lack of CBMs in the current situation of the agro-food system among European countries. A very recent use of panel data analysis to evaluate the circularity rate of the European countries can be observed in the work of [35], revealing the successful role of the method in the analysis of the relationships. The variables required to join the model after the national level are settled on the relevant global databases comprising the [36] and [37], and the required data were gained directly from the databases within the last five years (2014–2018). As mentioned by [38], the databases were considered through the international verified data centers for agro-food and environmental subjects to confirm the relevance and feasibility of the chosen variables of this study in the field of energy balance and agro-food systems comprising production, recycling, and waste categories. Two dependent variables of the “energy share from renewable sources including agro-food system” and “total waste emission from agro-food system” were obtained for the recycling and waste categories. Three variables of “production of meat”, “production of oil crops”, and “production of vegetable oils” were gathered, representing the agro-food production category, and four control variables of the Stata software 14 (“energy use in agriculture”, “electricity use in agriculture”, “renewable biofuels from food industry”, and “use of renewable biofuels for the food industry”) were assumed at the country level, explaining the input variables to avoid any specification errors in the estimated model [39]. Also, the list of case studies (countries) was selected based on the maximum registered countries (European Union countries in addition to the UK) in the database of the European Agri-Food Data Portal without data limitation (Table 1).

Table 1.

The summarized data for all variables in 2014 and in 2018.

The research problem is that currently, there are no sound indicators for the analysis of circularity in the agro-food system. To investigate this state, we used some indicators to analyze the level of circularity in the agro-food system (e.g., production values, energy sharing from renewable sources, and total waste emission) at the country level based on the literature. The study will demonstrate the need for new circularity-based indicators and propositions in the agro-food systems in European countries. The reason that we limited our study to mentioned time-series (2014–2018) is because these are the only existing variables that we could find through databases.

As mentioned by [15], six factors can be classified as causal cases in circularity as general subjects, including leadership, legislation, scarcity of resources, competition pressure, knowledge of circularity practices, and research development. In this way, we need to define dependent variables to gain the critical success factors. For assuming the circularity in waste management, refs. [40,41] has pointed out some indicators to ensure circularity, such as the generation of municipal waste per capita and the recycling rate of the overall packaging. Except for the sound indicators, lack of legislation and lack of government policies are revealed as the most important barriers toward circularity [42], belonging to the development of circular models. Recently, [10]) demonstrated the growing interest of agro-food enterprises in circular transition. As mentioned by [9], with a high level of circularity through a strong partnership approach, the business actors will cooperate with joint instruction to multiply valorization pathways and develop new methods. To cope with such a research stream, our research avenue is selected according to the “circular business model tool” by [11], proposing the implementation of circular strategies (i.e., recycling) affecting business model elements (i.e., value creation and delivery). According to [11], a recycling strategy relates to the recycling of material and energy within the system through reuse, remanufacturing, refurbishing, and recycling. Based on the mentioned construction and value logic, for the consideration previously made regarding the relevance of waste generation along the agro-food supply chain, our research can imply a section by addressing the value creation by recycling, including reprocessing, repairing, retailing, and reverse supply chain [20,43,44]. The research framework is reported in Figure 1.

3.2. Data Analysis

The research stream of panel data modeling deals with complex constructs to test relationships incorporated into an integrated model [45]. Panel models can be assumed to analyze the data series through a random-effect model or a fixed-effect model [46]. Using fixed and random effects in a panel model analysis, the relationship between the dependent variables and each group of independent variables is tested separately to avoid any potential endogeneity. In the panel data analysis, the Hausman test is a specification test for heterogeneity presence based on the difference between the fixed-effect (FE) and random-effect (RE) estimators [47], which is performed using the automatic function within the Stata software. Also, concerning the research method, the very recent use of panel data analysis to evaluate the circularity rate of the European countries can be observed in the work of [35], revealing the successful role of the method in circular analysis.

4. Results

4.1. Data Description

We skimmed the data obtained from the European Agri-Food Data Portal and World Bank dataset. Two samples of raw data for the variables are given in Table 1 for the year 2014 and the year 2018.

Analysis of the raw data shows that Germany, Spain, and France have the highest mean annual production of meat (~100,000 thousand tons), oil crops (~100,000 thousand tons), and vegetable oils (10,000 thousand tons), respectively. The mentioned countries have contributed to over 40–50% of the agri-food production in the European Union.

The highest values of total waste emission from the agri-food system, comprising a mean annual amount of ~3700 tons to a total of ~6500 tons, also belong to Germany, France, and the United Kingdom. The initial facts of high production and high waste emission in the agri-food system reveal that the circular economy of the agri-food system in the mentioned major countries is probably at a low level for the implementation of the related strategies.

Furthermore, we observed that the highest values of energy sharing from renewable sources belong to Iceland, Norway, and Sweden (annually above 50%). The same countries are providing a negligible contribution to agri-food production among the European countries. This outcome shows that the highest energy sharing from renewable sources in some countries, such as Norway, has no connection with its food production system. Hence, this fact is another possible piece of evidence of the weak level of the agri-food system in European countries.

4.2. Panel Data Analysis

The correlation matrix of the indicators was produced initially by panel data analysis to affirm no significant collinearity between the dependent and independent variables [48]. The relationship between the dependent and independent variables was tested using fixed- and random-effect model analysis to avoid any potential endogeneity (Hausman test). The regression coefficients between three categories of agro-food production and renewable energy sharing were produced using Stata (2014–2018), overall revealing no significant relationships (p-value > 0.1) between agro-food production and renewable energy sharing (Table 2). On this basis, the first hypothesis (H1) can be rejected for the given study area (29 European countries) in the respective time interval (2014–2018). This means that the sharing of renewable energy has no direct relation with agro-food production, demonstrating the lack of recycling function of circularity within the agro-food system.

Table 2.

Results of the panel data analysis revealing the production of meat: PM, production of oil crops: PO, and production of vegetable oils: PV and their effects on renewable energy sharing: RE.

From the other side, the regression coefficients between three categories of agro-food production and total waste emission were produced and overall revealed significant relationships (p-value < 0.1) between agro-food production (at least production of meat and vegetable oils) and total waste emission from the agro-food system (Table 3). On this basis, the second hypothesis (H2) can be also rejected for the given study area in the respective time interval (2014–2018). This means that the total waste emission has a direct relation with agro-food production, demonstrating no recycling of renewable bio-fuels from the agro-food system in the study areas. Based on the outputs of the statistical and rejected hypotheses, we can say that the circularity level of the agro-food system in the European countries is low. The full results revealed that the European countries seriously need to implement new circularity-based policies and indicators in the agro-food systems.

Table 3.

Results of the panel data analysis revealing the production of meat: PM, production of oil crops: PO, and production of vegetable oils: PV and their effects on the total waste emission: WE.

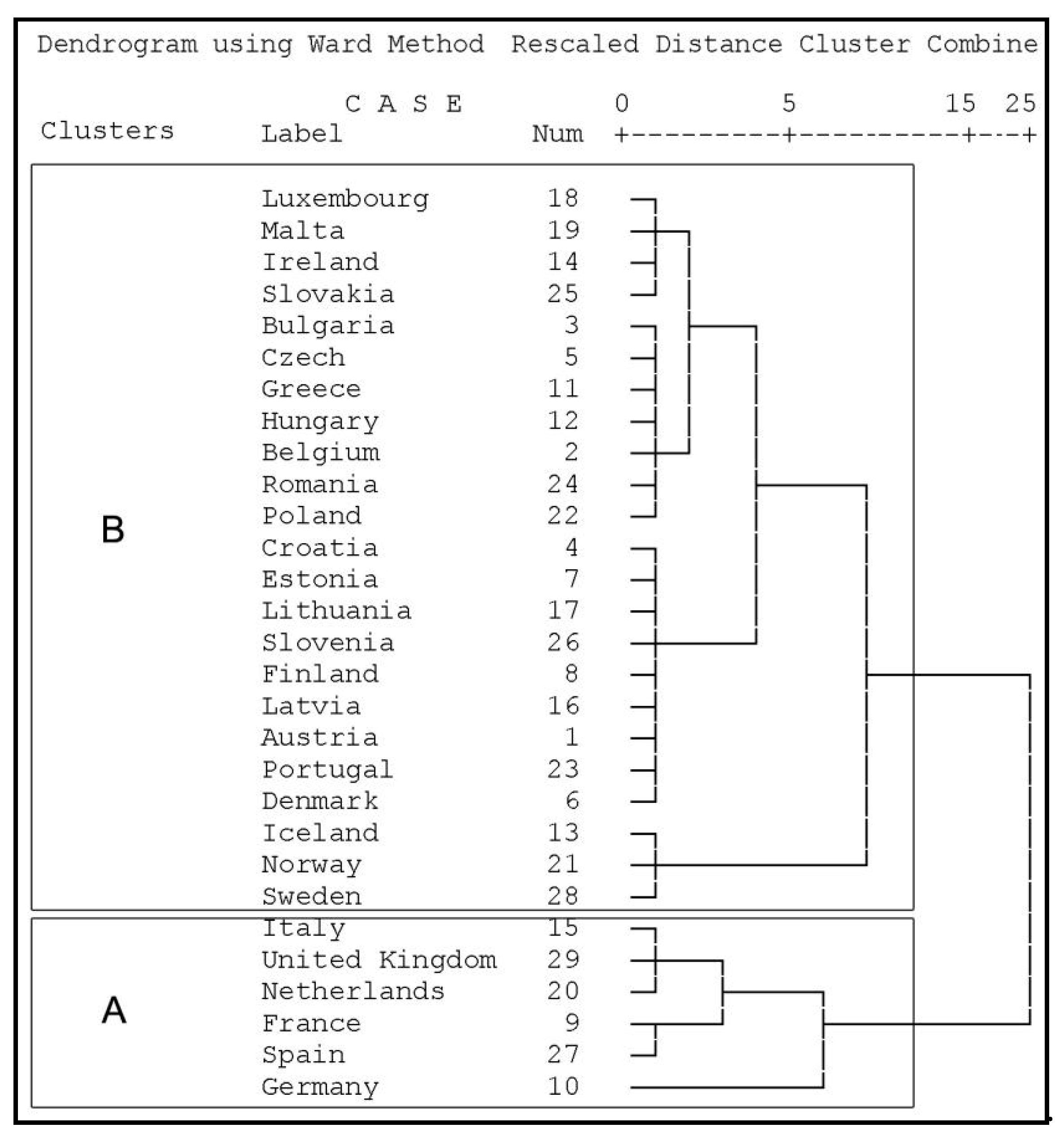

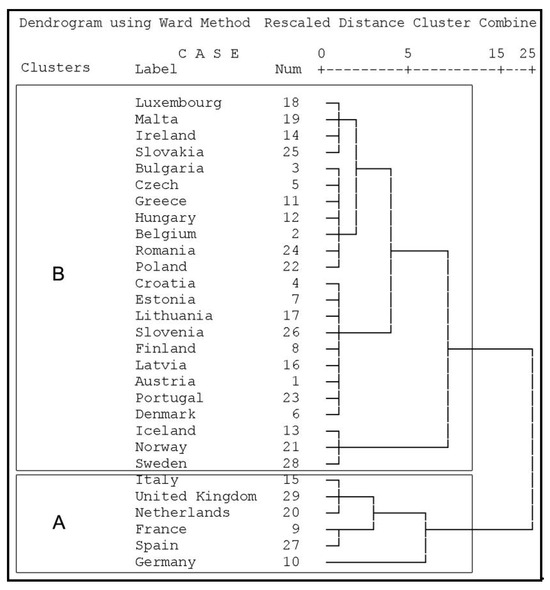

4.3. Hierarchical Clustering

The model confirmed that the sharing of renewable energy (as an indicator of circular economy implication) has no direct relationship with the agri-food system in the given periods and study countries. The findings are aligned with insights derived from the data description, revealing the low level of circular economy implementation in the agri-food system, particularly in Germany and France, which have high rates of agri-food production. On this basis, we can classify the countries using the hierarchical cluster analysis (HCA) approach. The HCA approach is a way to cluster the countries by using Ward’s method and a proximity matrix based on squared Euclidean distance [42]. Based on the interrelated homogeneity of the variables and proximity matrix of the countries (Table 4), the consequent clustering dendrogram (Figure 2) illustrated two main clusters, namely A and B. Cluster A includes six countries, i.e., France, Spain, Germany, Italy, the United Kingdom, and the Netherlands, which, on average, had high values of agri-food production in addition to high amounts of agri-food waste from 2014 to 2018. Cluster B includes other cases, i.e., 23 countries, which, on average, had low values of agri-food production but presented high shares of energy from refinery sources in the agri-food system. Cluster A thus includes countries with critical statuses in the agri-food system and with low levels of circular economy implementation. According to research by [9] focusing on some cases of aforementioned countries such as France, Germany, Italy, and the Netherlands, the conceptual and management insights into circularity levels are still sparse. However, these countries have the largest estimated agricultural bio-energy potential from the agro-food system [32].

Table 4.

Average values of proximity matrix between 29 countries.

Figure 2.

Clustering dendrogram of the countries based on agri-food system (Source: extracted from Stata 14 software).

While the analysis identified that the aforementioned countries have high levels of agri-food production, it is important to acknowledge that specific national policies can significantly influence their circular economy performance. Therefore, future research should explore this matter within the countries to gain a more comprehensive understanding.

5. Discussion

5.1. Circular Economy Implementation Level in the Agri-Food System in European Countries

The first research question depends on the CE implementation level in the agri-food system in European countries. The results of the HCA approach revealed that the critical status in the agri-food system of the Europe region belongs to the six countries of France, Spain, Germany, Italy, the United Kingdom, and the Netherlands, which have weak levels of CE implementation among the study area’s countries.

Therefore, the second research question depends on the promotion of CE implementation in agri-food in European countries. According to [9],, conceptual and management insights into circular economy implementation are still sparse in some European countries, such as France, Germany, Italy, and the Netherlands. However, these countries have the largest estimated agricultural bio-energy potential from the agri-food system [32]. Hence, the promotion of CE implementation in the study area needs to define the propositions for promoting the actual CBMs working in the agri-food sector of the given countries.

5.2. Fostering the Circular Economy Implementation in Agri-Food in European Countries

For overcoming the critical status of implementation of a circular economy in the European agri-food system, CBMs can be considered drivers of the flow of technical and biological circularity in the products, components, and materials, leading to reduced process wastes [16]. In CBMs, we should help to find innovative solutions for the environmental challenges in the agri-food system using a policy-based set of propositions. This means focusing on the guiding lines to circular, flexible, and zero-waste bio-refineries and integrating biomass, bio-fuel, biomaterials, and bio-energy cycles [49].

Using the extracted variables from the datasets and based on the model projected by [11], we proposed a set of three agri-food aspects, i.e., agri-food production, total waste emission, and renewable energy sharing, to analyze the existence of the circular economy implementation level in the agri-food systems of selected EU countries. The statistical results confirmed no significant relationship (p-value > 0.1) between agri-food production and renewable energy (rejecting the first hypothesis H1) and a direct relationship between the total waste emission and agri-food production (rejecting the second hypothesis H2). Overall, the results demonstrate the lack of CE implementations in agri-food CBMs within the agri-food system in the study areas.

Suggestions and insights are thus needed to foster the implementation of a circular economy in the specific context of an investigation, as well as circular-oriented business solutions to improve the existing linear models [50,51]. From this line, we here suggest propositions to improve the implementation of CBMs in the European agri-food system. As noted by [9], the circular economy in the agri-food system is facing common challenges such as climate-change sensitivity or increasing urbanization, resulting in uncertainties about changing legislation, laws, and regulations on the valorization pathways. Hence, managerial propositions of the circular economy should tackle the mentioned challenges by supporting the implementation of CBMs in the agri-food sector. For this purpose, we designed a matrix matching the four circular strategies suggested by [11], namely extending, intensifying, dematerializing, and recycling, with three agri-food aspects, namely food production, waste emission, and energy sharing.

As for the considered strategies [11], the extending strategy implies the extended use of products through long-lasting design, maintenance, and repair; the intensifying strategy implies the sharing economy and public uses; the dematerializing strategy describes the provision of product utility using digitalized service and software solutions; and the recycling strategy relates to the recycling of material and energy within the system. Considering the agri-food system, the production process involves a set of chaining segments e.g., agricultural production and harvest, post-harvest operations, storage, packing, and processing to retail [52]; food waste is one of the substantial issues directly related to production and consumption [30]; and renewable energy decreases waste generation and the extraction of limited resources [10].

The intersections of strategies and aspects led to the identification of 12 managerial propositions, reported in Table 5. Propositions are indeed needed to promote CBMs [21] and can be used to establish a dialogue between national policymakers and practitioners.

Table 5.

Propositions in the agri-food CBMs.

- Enhancing durability of agri-food products [EP].

To enhance the durability of agri-food products, we propose extending product lifespans through improving aspects of their production and consumption process, such as packaging and storage. This aligns with the production process aspect, as it aims to optimize the food supply chain from farm to fork, as suggested by [53] and [54].

- 2.

- Innovative transport tracking and service management [IP].

To optimize transport and logistics, innovative transport tracking and service management are proposed. This strategy aligns with the production process aspect as it also reduces waste and increases efficiency through the supply chain, as was suggested by [55] and [11].

- 3.

- Digitalization to generate end-of-life packing process [DP].

This strategy is proposed to leverage digital technology to optimize the end-of-life packing process. By implementing this proposition, we can enable the recycling of valuable resources efficiency. This strategy aims to reduce the physical aspect of packaging materials, as suggested by [56] and [57].

- 4.

- Biodegradable materials in agri-food packing [RP].

To promote sustainable packing processes, we propose the adoption of biodegradable materials in agri-food products. This strategy aligns with the recycling aspect, minimizing environmental impact and returning materials to the natural cycle, as suggested by [34,41,58]. Additionally, the use of biodegradable materials leads to cost reduction and value being added to the agri-food system, as highlighted by [10].

- 5.

- Cascading reuse to organic feedstock farms [EW].

To improve waste management and the circular economy, we proposed cascading the reuse to organic feedstock farms. This results in the creation of new products and applications within the agri-food system, as suggested by [43]. This strategy aligns with minimizing waste emissions and maximizing resource recovery.

- 6.

- Advanced system for handling agri-food waste [IW].

We proposed to implement an advanced system for monitoring and handling agri-food waste. This strategy aligns with maximizing the value and minimizing the environmental impacts of waste. As suggested by [9], these systems help to create value from agri-food waste and improve sustainability.

- 7.

- Consumer education and demand rationalization [DW].

This strategy is proposed to educate consumers about sustainable consumption practices and acceptance of dematerialized agri-food packing solutions. It aligns with minimizing the material footprint of products [59]. As suggested by [60], increasing consumer awareness can lead suitable consumption patterns.

- 8.

- Zero-waste bio-refinery process [RW].

To reduce waste emissions, we propose implementing a zero-waste bio-refinery process. This strategy aligns with the recycling aspect as it aims to convert waste to energy. As described by [9], the bio-refinery process can use a variety of technologies to recover marketable energy from agri-food production, consumption, and waste management, such as bio-fuels and bio-materials.

- 9.

- Refurbishing and retrofitting bio-fuel plants [EE].

To promote renewable energy, we proposed refurbishing and retrofitting bio-fuel plants to enhance their efficiency and sustainability. This strategy aligns with the extending aspect, as it aims to maximize the lifetime. As suggested by [9], this can reduce environmental impact and promote sustainable energy production.

- 10.

- Retailing energy from the agri-food system [IE].

This strategy is proposed for the utilization of renewable energy in the agri-food system. It aims to optimize energy use and reduce external energy sources, as suggested by [54].

- 11.

- Technologies to create marketable renewable energy [DE].

To promote the dematerialization of energy production, we propose the development of technologies to create marketable renewable energy from agri-food waste. This strategy aims to utilize renewable energy sources. Technologies, particularly in the production process, can add value and contribute to a more sustainable future, as suggested by [9].

- 12.

- Integrating biomass, bio-fuel, biomaterials, and bio-energy cycles [RE].

To promote a circular economy in the agri-food system, we propose integrating biomass, bio-fuel, biomaterials, and bio-energy cycles. This strategy aims to recover valuable resources from waste. As suggested by [19] and [9], bio-refineries can play an important role in this process and maximize the added value along three pillars of sustainability: environment, economy, and society, along with minimizing waste.

To further illustrate the practical application of these circular economy strategies in the agri-food system, it can be considered to encourage producers to design longer-lasting and recyclable packaging; provide agricultural equipment for producers to reduce resource consumption and costs and minimize food waste; promote ordering and food delivery by using digital platforms to reduce packaging waste and optimize logistics; and manage agricultural waste for conversion into valuable products. These examples can highlight the potential of circular economy strategies to address challenges in the agri-food system.

6. Implications

6.1. Theoretical Implications

The current study provides several implications. Hence, the theoretical implication calls for broader knowledge in the agro-food system when dealing with business models and circularity analysis, which is especially important for CBMs to create added value tracking [19]. The current paper theoretically contributes to the literature on two types of research by recent scholars. The first implication involves approaching the problem of circularity measurement at the national level, which is not observed in the agro-food system [12,61]. The second implication is complementing specific findings and models in agro-food literature streams proposed by [10] and [9] using statistical analysis and a policy-based framework.

6.2. Managerial Implications

Our paper will provide at least two main implications. First, it is relevant for managerial practice, as it outlines a policy framework that adheres to circularity in the agro-food system and makes these practices applicable for CBMs. The findings of the research can improve the circular economy in different countries and call for a dialogue between national policy-makers and business stockholders, which was noted by [56,60]. Second, the theoretical implication calls for a broader knowledge of the agro-food system dealing with business models and circularity analysis, which is especially important for CBMs to create added value tracking [19].

7. Conclusions

The present study contributes to a better understanding of the level of circular economy adoption in the agri-food system in Europe and paves the way for further implementation by presenting a set of managerial propositions. The research shows several implications. As for academia, it calls for a broader knowledge of the agri-food system dealing with CBMs and circular economy. The current paper theoretically contributes to the literature on two types of recent scholarly research. The first implication is analyzing the level of circular economy implementation, especially selecting appropriate indicators at the national level (food production, waste, and energy sharing). The second implication is complementing specific findings and models in agri-food literature streams proposed by [10] and [9] using statistical analysis and a set of managerial propositions.

Concerning practitioners, propositions are offered to adhere to a circular economy in the agri-food system; they can be proactive in adopting the mentioned propositions to reduce and modify agri-food waste, linking to the circular economy through flows of agri-food production and renewable bio-refinery energy.

The main limitation of this study depends on the availability of datasets for required variables and indicators at the country level of circularity analysis. It seems that, to address this issue, we need to prepare a broader set of raw and re-analyzed variables and indicators at different scales from different databases. Another limitation relates to the construction of the propositions. In the current study, we considered only one framework to propose the managerial propositions, while in future research, a broader set of strategic models could be created to obtain comprehensive policy-based recommendations. Moreover, future research can consider the circularity analysis of agri-food indicators directly in the CBM levels. Our research can pave the way for more research at the national level regarding the lack of CE implementations in agri-food CBMs, which can be considered for further studies to make the applicable governmental propositions.

Another limitation concerns the methodological approach. We adopted a quantitative approach in order to understand the relationships between the indicators. Future studies could use quantitative approaches by using interviews to better explain the implications by defining several propositions.

The third limitation is that we only focused on the food industry. Although, through our investigation, we attempted to fill existing gaps in the literature, future research could make a comparison between two sectors (e.g., the fashion sector) to better describe the finding and also to report on this compression among selected EU countries.

Author Contributions

F.K.: conceptualization, methodology, software, validation, data curation; E.C.: conceptualization, validation, writing—original draft preparation, writing—review and editing, project administration; R.K.: methodology, software. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from the individual participants included in the study.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon request.

Acknowledgments

We thank the anonymous reviewers for their technical suggestions on data interpretations.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Huho, J.M.; Kosonei, R.C.; Musyimi, P.K. Sociodemographic Determinants of Households’ Food Wastein Garissa Sub County, Kenya. Bp. Int. Res. Crit. Inst. J. 2020, 3, 932–946. [Google Scholar]

- Crippa, M.; Solazzo, E.; Guizzardi, D.; Ferrario, F.M.; Tubiello, F.N.; Leip, A. Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food 2021, 2, 198–209. [Google Scholar] [CrossRef]

- FAO. The Future of Food and Agriculture—Trends and Challenges; UN Food and Agriculture Organization: Rome, Italy, 2017. [Google Scholar]

- Esposito, M.; Tse, T.; Soufani, K. Introducing a circular economy: New thinking with new managerial and policy implications. Calif. Manag. Rev. 2018, 60, 5–19. [Google Scholar] [CrossRef]

- Bruins, M.E.; Sanders, J.P. Small-scale processing of biomass for biorefinery. Biofuels Bioprod. Biorefin. 2012, 6, 135–145. [Google Scholar] [CrossRef]

- Barakat, A.; de Vries, H.; Rouau, X. Dry fractionation process as an important step in current and future lignocellulose biorefineries: A review. Bioresour. Technol. 2013, 134, 362–373. [Google Scholar] [CrossRef]

- Verstraete, W.; Clauwaert, P.; Vlaeminck, S.E. Used water and nutrients: Recovery perspectives in a “pantarhei” context. Bioresour. Technol. 2016, 215, 199–208. [Google Scholar] [CrossRef]

- Zucchella, A.; Previtali, P. Circular business models for sustainable development: A “waste is food” restorative ecosystem. Bus. Strategy Environ. 2018, 28, 274–285. [Google Scholar] [CrossRef]

- Donner, M.; Gohier, R.; de Vries, H. A new circular business model typology for creating value from agro-waste. Sci. Total Environ. 2020, 716, 137065. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Pieroni, M.P.P.; Pigosso, D.C.A.; Soufani, K. Circular business models: A review. J. Clean. Prod. 2020, 277, 123741. [Google Scholar] [CrossRef]

- Urbinati, A.; Franzò, S.; Chiaroni, D. Enablers and Barriers for Circular Business Models: An empirical analysis in the Italian automotive industry. Sustain. Prod. Consum. 2021, 27, 551–566. [Google Scholar] [CrossRef]

- Henry, R.C.; Engström, K.; Olin, S.; Alexander, P.; Arneth, A.; Rounsevell, M.D.A. Food supply and bioenergy production within the global cropland planetary boundary. PLoS ONE 2018, 13, e0194695. [Google Scholar] [CrossRef] [PubMed]

- Esposito, B.; Sessa, M.; Sica, R.D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector. A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Kumar, A.; Ali, S.M.; Paul, S.K.; Sultana, R.; Rezaei, J. Critical success factors for a circular economy: Implications for business strategy and the environment. Bus. Strategy Environ. 2020, 29, 3611–3635. [Google Scholar] [CrossRef]

- Bocken, N.M.; Ritala, P. Six ways to build circular business models. J. Bus. Strategy 2021, 43, 184–192. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Vladimirova, D.; Evans, S. Sustainable business model innovation: A review. J. Clean. Prod. 2018, 198, 401–416. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Business models for industrial symbiosis: A taxonomy focused on the form of governance. Resour. Conserv. Recycl. 2019, 146, 114–126. [Google Scholar] [CrossRef]

- Kanda, W.; Geissdoerfer, M.; Hjelm, O. From circular business models to circular business ecosystems. Bus. Strategy Environ. 2021, 30, 2814–2829. [Google Scholar] [CrossRef]

- Bocken, N.M.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the business models for circular economy—Towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Richardson, J. The business model: An integrative framework for strategy execution. Strat. Chang. 2008, 17, 133–144. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Policy Report of Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017. [Google Scholar]

- Kyriakopoulos, G.L.; Kapsalis, V.C.; Aravossis, K.G.; Zamparas, M.; Mitsikas, A. Evaluating circular economy under a multi parametric approach: A technological review. Sustainability 2019, 11, 6139. [Google Scholar] [CrossRef]

- Muradin, M.; Joachimiak-Lechman, K.; Foltynowicz, Z. Evaluation of Eco-Efficiency of Two Alternative Agricultural Biogas Plants. Appl. Sci. 2018, 8, 2083. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M.; Salehabadi, A.; Nafchi, A.M.; Uthaya, U.S.; Khalil, H.P.S.A. Biodegradable green packaging with antimicrobial functions based on the bioactive compounds from tropical plants and their by-products. Trends Food Sci. Technol. 2020, 100, 262–277. [Google Scholar] [CrossRef]

- Poponi, S.; Arcese, G.; Pacchera, F.; Martucci, O. Evaluating the transition to the circular economy in the agri-food sector: Selection of indicators. Resour. Conserv. Recycl. 2022, 176, 105916. [Google Scholar] [CrossRef]

- Tariq Majeed, M.; Luni, T. Renewable Energy, Circular Economy Indicators and Environmental Quality: A Global Evidence of 131 Countries with Heterogeneous Income Groups. Pak. J. Commer. Soc. Sci. 2022, 14, 866–912. [Google Scholar]

- Chiaraluce, G.; Bentivoglio, D.; Finco, A. Circular Economy for a Sustainable Agri-Food Supply Chain: A Review for Current Trends and Future Pathways. Sustainability 2021, 13, 9294. [Google Scholar] [CrossRef]

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef]

- Popp, J.; Lakner, Z.; Rákos, M.; Fári, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Dora, M. Collaboration in a circular economy: Learning from the farmers to reduce food waste. J. Enterp. Inf. Manag. 2019, 33, 769–789. [Google Scholar]

- Jafari-sadeghi, V.; Garcia-perez, A.; Candelo, E.; Couturier, J. Exploring the impact of digital transformation on technology entrepreneurship and technological market expansion: The role of technology readiness, exploration and exploitation. J. Bus. Res. 2021, 124, 100–111. [Google Scholar] [CrossRef]

- Kostakis, I.; Tsagarakis, K. The role of entrepreneurship, innovation and socioeconomic development on circularity rate: Empirical evidence from selected European countries. J. Clean. Prod. 2022, 348, 131267. [Google Scholar] [CrossRef]

- World Bank. World Development Indicators Archived by Online Public Web Resource of World Data Dank. 2020. Available online: https://databank.worldbank.org/source/world-development-indicators (accessed on 2 October 2024).

- European Commission. European Agri-Food Data Archived by European Commission. 2021. Available online: https://agridata.ec.europa.eu/extensions/DataPortal/home.html (accessed on 2 October 2024).

- Zuin, V.G.; Ramin, L.Z. Review: Green and sustainable separation of natural products from agro-industrial waste: Challenges, potentialities, and perspectives on emerging. Top. Curr. Chem. 2018, 376, 3. [Google Scholar] [CrossRef]

- Sewpersadh, N.S. An examination of CEO power with board vigilance as a catalyst for firm growth in South Africa. Meas. Bus. Excell. 2019, 23, 377–395. [Google Scholar] [CrossRef]

- Corrado, S.; Sala, S. Food waste accounting along global and European food supply chains: State of the art and outlook. Waste Manag. 2018, 79, 120–131. [Google Scholar] [CrossRef]

- Luttenberger, L.R. Waste management challenges in transition to circular economy—Case of Croatia. J. Clean. Prod. 2020, 256, 120495. [Google Scholar] [CrossRef]

- Khatami, F.; Scuotto, V.; Krueger, N.; Cantino, V. The influence of the entrepreneurial ecosystem model on sustainable innovation from a macro-level lens. Int. Entrep. Manag. J. 2021, 18, 1419–1451. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M. A review and typology of circular economy business model patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef]

- Vermeulen, W. Self governance for sustainable global supply chains: Can it deliver the impacts needed? Bus. Strategy Environ. 2015, 24, 73–85. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Smith, D.; Reams, H.; Hair, J.F., Jr. Partial least squares structural equation modeling (PLS-SEM): A useful tool for family business researchers. J. Fam. Bus. Strategy 2014, 5, 105–115. [Google Scholar] [CrossRef]

- Dogan, E.; Chishti, M.Z.; Alavijeh, N.K.; Tzeremes, P. The roles of technology and Kyoto Protocol in energy transition towards COP26 targets: Evidence from the novel GMM-PVAR approach for G-7 countries. Technol. Forecast. Soc. Chang. 2022, 181, 121756. [Google Scholar] [CrossRef]

- Baltagi, B.H. Panel Data and Difference-in-Differences Estimation. In Encyclopedia of Health Economics; Elsevier: Amsterdam, The Netherlands, 2014; pp. 425–433. [Google Scholar] [CrossRef]

- Ratner, B. The correlation coefficient: Its values range between +1/−1, or do they? J. Target. Meas. Anal. Mark. 2009, 17, 139–142. [Google Scholar] [CrossRef]

- Andrade, E.P.; Bonmati, A.; Esteller, L.J.; Brunn, S.; Jensen, L.S.; Meers, E.; Anton, A. Selection and application of agri-environmental indicators to assess potential technologies for nutrient recovery in agriculture. Ecol. Indic. 2022, 134, 108471. [Google Scholar] [CrossRef]

- Christensen, C. The Innovator’s Dilemma. When New Technologies Cause Great Firms to Fail; Harvard Business Review Press: Brighton, MA, USA, 2016. [Google Scholar]

- Hofmann, F.; Erben, M.J. Organizational transition management of circular business model innovations. Bus. Strategy Environ. 2019, 29, 2770–2788. [Google Scholar] [CrossRef]

- FAO. The State of Food and Agriculture 2019. Moving Forward on Food Loss and Waste Reduction; UN Food and Agriculture Organization: Rome, Italy, 2019; Available online: https://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 2 October 2024).

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring how usage-focused business models enable circular economy through digital technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Balkenende, R. Opportunities and challenges in IoT-enabled circular business model implementation—A case study. Resour. Conserv. Recycl. 2020, 16, 105047. [Google Scholar] [CrossRef]

- Parida, V.; Sjödin, D.; Reim, W. Reviewing literature on digitalization, business model innovation, and sustainable industry: Past achievements and future promises. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.V.; Witjes, S. The circular economy: New or Refurbished as CE 3.0?—Exploring Controversies in the Conceptualization of the Circular Economy through a Focus on History and Resource Value Retention Options. Resour. Conserv. Recycl. 2018, 135, 246–264. [Google Scholar] [CrossRef]

- Uçar, E.; Le Dain, M.A.; Joly, I. Digital Technologies in Circular Economy Transition: Evidence from Case Studies. Procedia CIRP 2020, 90, 133–136. [Google Scholar] [CrossRef]

- Rabnawaz, M.; Wyman, I.; Auras, R.; Cheng, S. A roadmap towards green packaging: The current status and future outlook for polyesters in the packaging industry. Green Chem. 2017, 19, 4737–4753. [Google Scholar] [CrossRef]

- Weerawardena, J.; McDonald, R.E.; Sullivan Mort, G. Sustainability of nonprofit organizations: An empirical investigation. J. World Bus. 2010, 45, 346–356. [Google Scholar] [CrossRef]

- Perito, M.A.; Di Fonzo, A.; Sansone, M.; Russo, C. Consumer acceptance of food obtained from olive by-products: A survey of Italian consumers. Br. Food J. 2019, 122, 212–226. [Google Scholar] [CrossRef]

- Palmié, M.; Boehm, J.; Lekkas, C.-K.; Parida, V.; Wincent, J.; Gassmann, O. Circular business model implementation: Design choices, orchestration strategies, and transition pathways for resource-sharing solutions. J. Clean. Prod. 2021, 280, 124399. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).