Abstract

For decades, fossil fuels have been the backbone of reliable energy systems, offering unmatched energy density and flexibility. However, as the world shifts toward renewable energy, overcoming the limitations of intermittent power sources requires a bold reimagining of energy storage and integration. Power-to-X (PtX) technologies, which convert excess renewable electricity into storable energy carriers, offer a promising solution for long-term energy storage and sector coupling. Recent advancements in machine learning (ML) have revolutionized PtX systems by enhancing efficiency, scalability, and sustainability. This review provides a detailed analysis of how ML techniques, such as deep reinforcement learning, data-driven optimization, and predictive diagnostics, are driving innovation in Power-to-Gas (PtG), Power-to-Liquid (PtL), and Power-to-Heat (PtH) systems. For example, deep reinforcement learning has improved real-time decision-making in PtG systems, reducing operational costs and improving grid stability. Additionally, predictive diagnostics powered by ML have increased system reliability by identifying early failures in critical components such as proton exchange membrane fuel cells (PEMFCs). Despite these advancements, challenges such as data quality, real-time processing, and scalability remain, presenting future research opportunities. These advancements are critical to decarbonizing hard-to-electrify sectors, such as heavy industry, transportation, and aviation, aligning with global sustainability goals.

1. Introduction

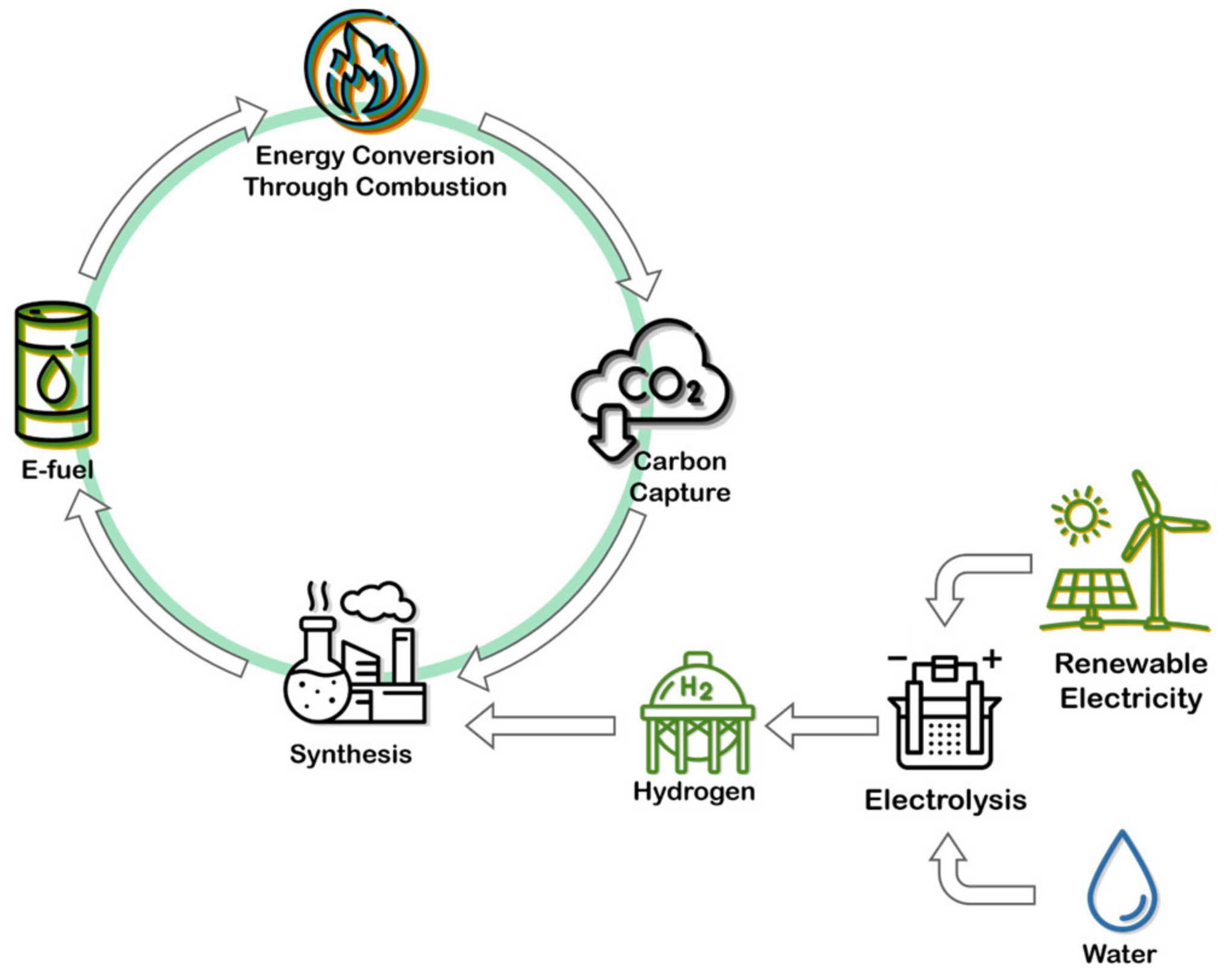

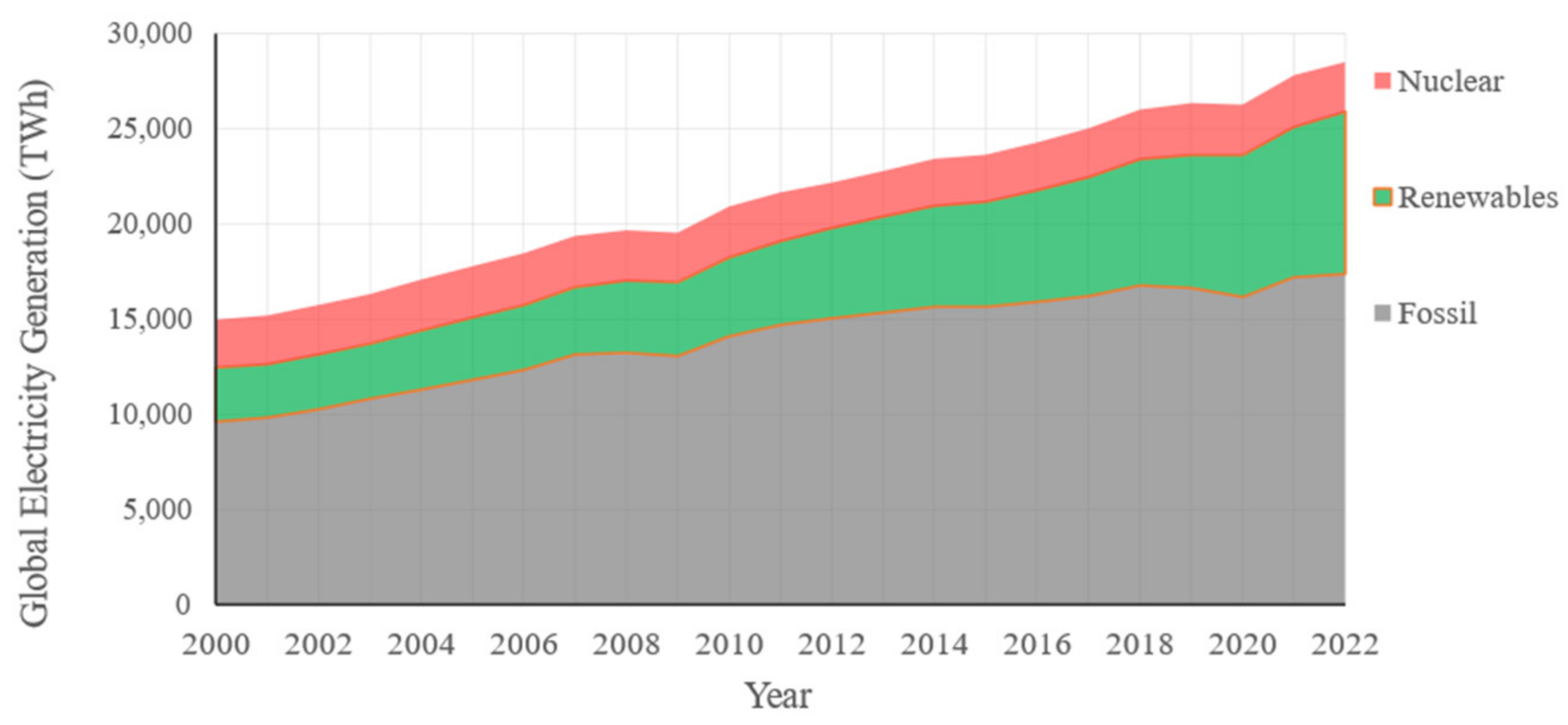

The global energy landscape is transforming, shifting from reliance on fossil fuels to an increased adoption of renewable energy sources. While essential for sustainability, this transition introduces challenges, particularly concerning the intermittent nature of renewable energy sources, such as wind and solar power. Historically, fossil fuels have offered unparalleled reliability and adaptability in meeting the energy demands of various sectors thanks to their high degree of accessibility, flexibility, portability [1,2], and storability with a high density of energy. As shown in Figure 1, fossil fuels have dominated global energy generation for decades, but clean energy sources have steadily increased their share over recent years. However, this progress is still insufficient to fully offset the dependency on fossil fuels.

Fossil fuels have adeptly managed fluctuations in supply and demand, ensuring a balance within the energy systems. However, the variability in renewable energy production necessitates robust solutions to ensure stability in the energy supply, aligning generation with demand across various timescales. The intermittent generation from renewables, characterized by fluctuations ranging from seconds to seasons, presents a significant barrier to their broader implementation. Energy storage systems (ESSs) can play a crucial role in mitigating these fluctuations and achieving a more reliable and consistent energy supply. ESSs help store excess energy generated from renewable sources during times of surplus production, making it available when demand is higher or production is low [3,4]. By smoothing out these supply–demand mismatches, ESSs not only enhance grid stability but also facilitate the integration of renewables into the existing energy infrastructure. This adaptability is crucial for driving the transition toward cleaner energy systems without compromising reliability.

Figure 1.

Annual electricity generation data for 2000–2022 [5].

Figure 1.

Annual electricity generation data for 2000–2022 [5].

Although there are advancements in energy storage, like batteries designed for short-term balancing, the limitations of these solutions become apparent when considering longer-duration storage, as evidenced by their low energy densities and high costs compared to liquid fuels, like diesel, gasoline, or liquid methane [6,7,8]. Also, the geographic disparity between renewable energy sources and major consumption centers further complicates direct electrification efforts.

These challenges underscore the necessity for innovative approaches like Power-to-X (PtX) technologies. While battery systems store electricity directly, PtX extends this by converting energy into other forms, like hydrogen or synthetic fuels, enabling longer-term storage and versatility across different sectors. Together, they provide a comprehensive solution for both short- and long-term energy storage challenges. It is projected that, by 2050, PtX and cogeneration will form the foundation of a resilient, decentralized, and carbon-neutral energy system in Europe [9]. This transformation will empower industries and citizens across the continent to generate clean heat and energy locally, in a manner that is reliable, cost-effective, and efficient.

The development of PtX systems faces a range of challenges across economic, technical, environmental, regulatory, and infrastructural areas. Overcoming these challenges requires collaboration and innovation in various fields, including technological advancements, regulatory adjustments, market growth, and improved modeling approaches [4,10,11,12]. ML plays a crucial role in tackling these issues, particularly as PtX systems become more complex with the integration of renewable energy sources. ML provides effective solutions by simplifying complex optimization tasks, improving predictive and forecasting capabilities, real-time decision-making [13], high-throughput screening and clustering, and simulation acceleration.

While the existing review studies have examined the application of ML in each PtX-related technology area, per se, the literature lacks a holistic overview on how ML can evolve the development of the entire PtX system. Several review studies are found in the literature that have a focus on specific components of PtX and PtX-related systems; for instance, some researchers have provided comprehensive review studies of proton exchange membrane (PEM) electrolyzers, with a particular focus on the integration of ML, to enhance control-oriented modeling, dynamic operation, and control strategies aimed at enhancing system stability and efficiency [14,15,16,17]. Also, Iqbal et al. (2024) [18] conducted an in-depth bibliometric analysis of ML in optimizing hydrogen production through electrochemical methods. Some other have explored recent advancements in environmental, economic, and policy considerations in hydrogen production technologies and the role of ML and data-driven methods [19,20,21].

Very few review studies are found in the literature that have a particular focus on PtX systems (as a whole) and ML, such as the work by Ullah et al. (2022) [22], which explored the integration of advanced data-driven methodologies, like IoT, big-data analytics, and ML, to optimize PtX operations. They highlight the potential of these technologies to improve sustainability and efficiency by dynamically adjusting operational parameters to manage renewable energy intermittency. They suggest that challenges such as data management, computational demands, and the need for real-time optimization persist. While their work is comprehensive, it lacks sufficient depth in ML applications. Another contribution to this area is the work by Birkner (2017) [23], which, while not a review paper and not recent, discusses the application of big-data tools and neuronal networks in smart energy systems, including PtX technologies. The study highlights the role of ML-driven predictive tools in optimizing PtX operations, particularly in balancing energy generation and improving grid stability.

A review of the existing studies shows that, although considerable research has been conducted on specific components of PtX-related technologies, there remains a notable gap in reviewing works that focus directly on PtX systems as a whole, incorporating explicit references to any member of the PtX family—such as PtG, PtL, PtA, etc.—in combination with ML and data-driven methods. On the other hand, researchers rarely have studied the broad topic of PtX without focusing on a specific type, but the study by Kim et al. (2023) [24] is worth mentioning, where researchers developed a data-driven, reliability-based optimization approach using generative adversarial networks (GANs) to manage renewable uncertainty across grid-assisted PtX systems. This review aims to address that gap by focusing exclusively on studies where the PtX concept, in any of its forms, is paired with ML. Table A1, provided in Appendix A, encompasses recent review papers that have explored specific subjects that can be related to PtX systems, such as green hydrogen production technologies, catalysts, materials, etc.

The present review provides a comprehensive analysis of the role of ML in different types of PtX systems, including PtG, PtL, and PtH. While the two above-mentioned works deliver a very general overview on data-driven methods for operational optimization of PtX systems and take a broader view in sustainable energy practices, the current work distinguishes itself by covering recent advances achieved by ML in different specific types of PtX systems, including technological innovation, optimization, system integration, forecasting, prediction, and strategic environmental and economic analysis.

The overall structure of this article is as follows: After this Introduction, Section 2 outlines the methodology used to identify and classify the relevant literature, including details on keyword selection and search strategy. Section 3 provides a comprehensive review of the concepts and challenges of PtX systems, offering necessary background on different PtX technologies. Section 4 then introduces the core concepts of ML and traces their evolution, laying the groundwork for understanding ML applications in energy systems. The heart of the review is found in Section 5, which explores ML applications in PtX systems through four key categories: (1) machine learning in Power-to-Gas systems, (2) machine learning in Power-to-Liquid systems, (3) advances in sustainable combustion and fuel optimization for next-generation engines, and (4) machine learning in Power-to-Heat. Section 6 discusses the insights gathered from the literature, and finally, Section 7 wraps up the discussion and offers directions for further research on integrating ML into PtX systems.

2. Review Methodology

In the context of applying ML to PtX processes, most research has focused on reviewing specific aspects of PtX in isolation. This body of work mostly encompasses process and technology optimization in Multi-Energy and Integrated Renewable Energy Systems (IRESs) and power networks.

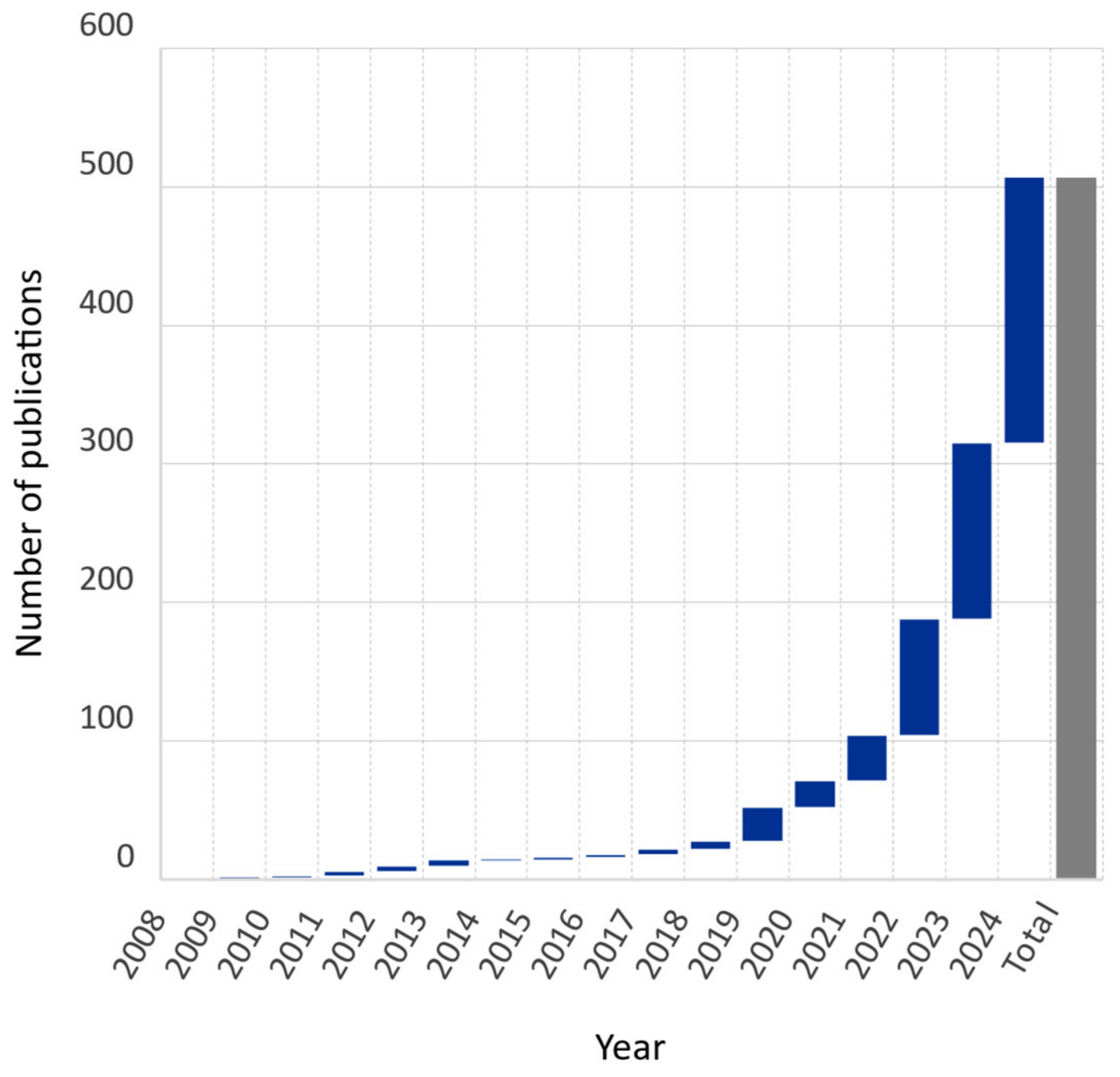

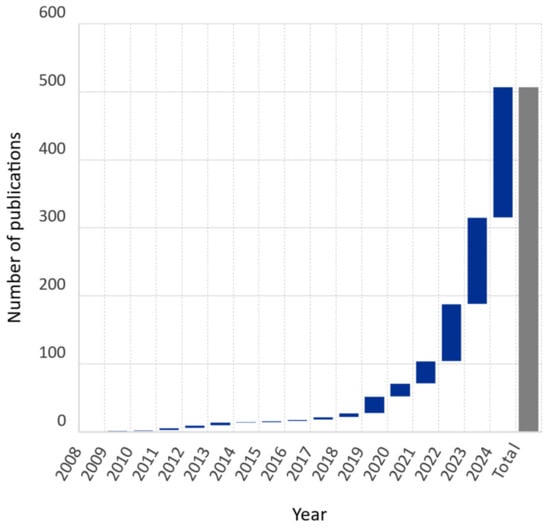

An organized search strategy was employed to explore the relevant literature, utilizing approximately 140 keywords in specifically designed logical queries on Scopus. The search was conducted in stages, systematically covering different categories of studies and discovering the overlaps. This approach aimed to investigate the application of ML methods in the context of PtX and related areas, which began emerging as a growing research area around 2008 due to advancements in ML techniques and increasing interest in PtX solutions for renewable energy integration. A total of 507 peer-reviewed journal articles and review papers published between 2008 and 2024 were identified. Figure 2 illustrates the increasing research interest in this field since 2008. Notably, the total number of studies related to PtX, irrespective of ML applications, exceeds 50,000 papers. However, ML and related keywords were found in only 1.0% of these studies’ title, abstract, and keywords.

Figure 2.

Application of ML in the fields related to PtX process publication trend from Scopus academic search platform.

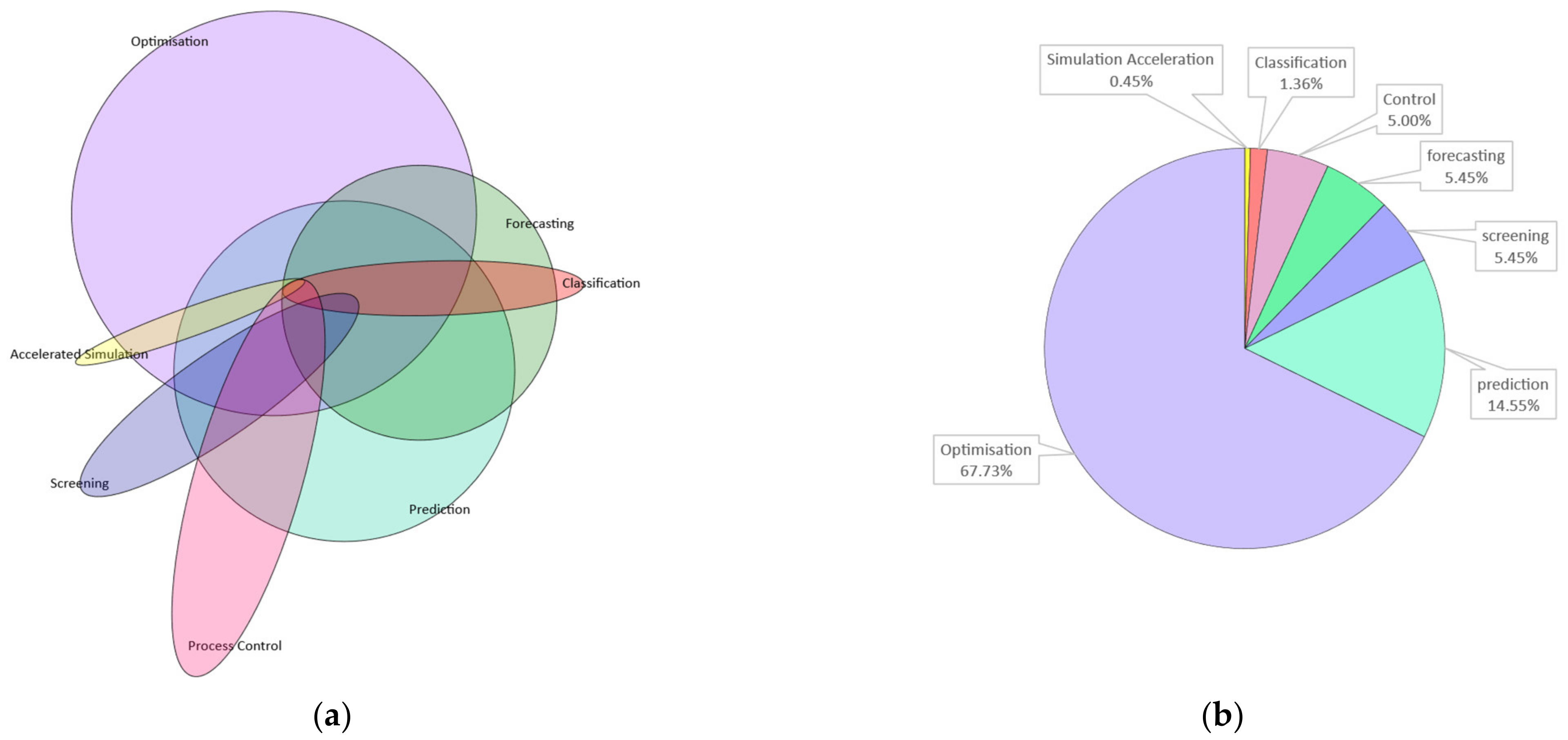

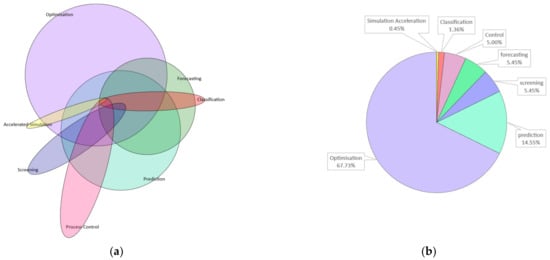

As part of the data-gathering process, and to obtain insightful information, the identified literature was categorized into seven groups based on the primary tasks of ML: prediction, forecasting, classification, screening, optimization, process control, and simulation acceleration. In addition to the frequent interchangeable use of some of these terms—such as prediction and forecasting—in the literature, overlaps exist among them due to the dynamic and innovative nature of ML methods and their diverse applications. An analysis of the frequency of different ML tasks in the PtX field, along with the overlaps, provides valuable insights (see the Venn diagram in Figure 3a). However, in a number of 61 articles from this collection (mostly review papers), no specific ML-based task or method was mentioned in the title, abstract, and keywords area; therefore, they were not categorized under any of these classes.

Figure 3.

(a) Distribution and overlap of ML tasks applied in the field of PtX and sustainable energy systems according to the literature (2016–2024). The Venn diagram illustrates the dominant ML tasks (optimization, prediction, and forecasting) and highlights the significant overlap between these categories, as well as their relation to other tasks such as process control, classification, screening, and simulation acceleration. (b) Distribution of unique ML tasks in PtX and sustainable energy systems. The pie chart displays the relative frequency of each ML task, considering only papers that focus exclusively on a single task without overlapping with other categories.

Figure 3a offers a visualized approximation of the extent to which different ML tasks intersect, reflecting their interchangeable use in the literature or their combination in specific research studies. The size of each shape reflects the relative frequency of publications related to each task, while the overlaps show the degree to which certain tasks (or related terms) are used together in the literature. Accordingly, optimization, prediction, and forecasting constitute the majority of ML applications in PtX research, with significant overlap between these categories. Process control, classification, screening, and simulation acceleration are also applied, though to a lesser extent. It is important to note that a vast majority of studies in the field fall under optimization, prediction, and forecasting. Figure 3b presents a pie chart comparing the frequency of each ML task, focusing on unique studies not shared between other categories.

Given the expansive scope of research in this field, this paper will focus on articles and reviews published in peer-reviewed journals after 2020. After applying manual further screening and eligibility criteria over the 507 papers, a total number of 127 papers were identified to include any keywords directly associated with a type of PtX system. Finally, 53 papers were selected as the most relevant for detailed review and included in the reviewing process, using Mendeley Desktop Software Version 1.19.8. Besides these included studies, several other references are cited in this study for their contribution to more general subjects related to sustainable development of energy, PtX, and ML.

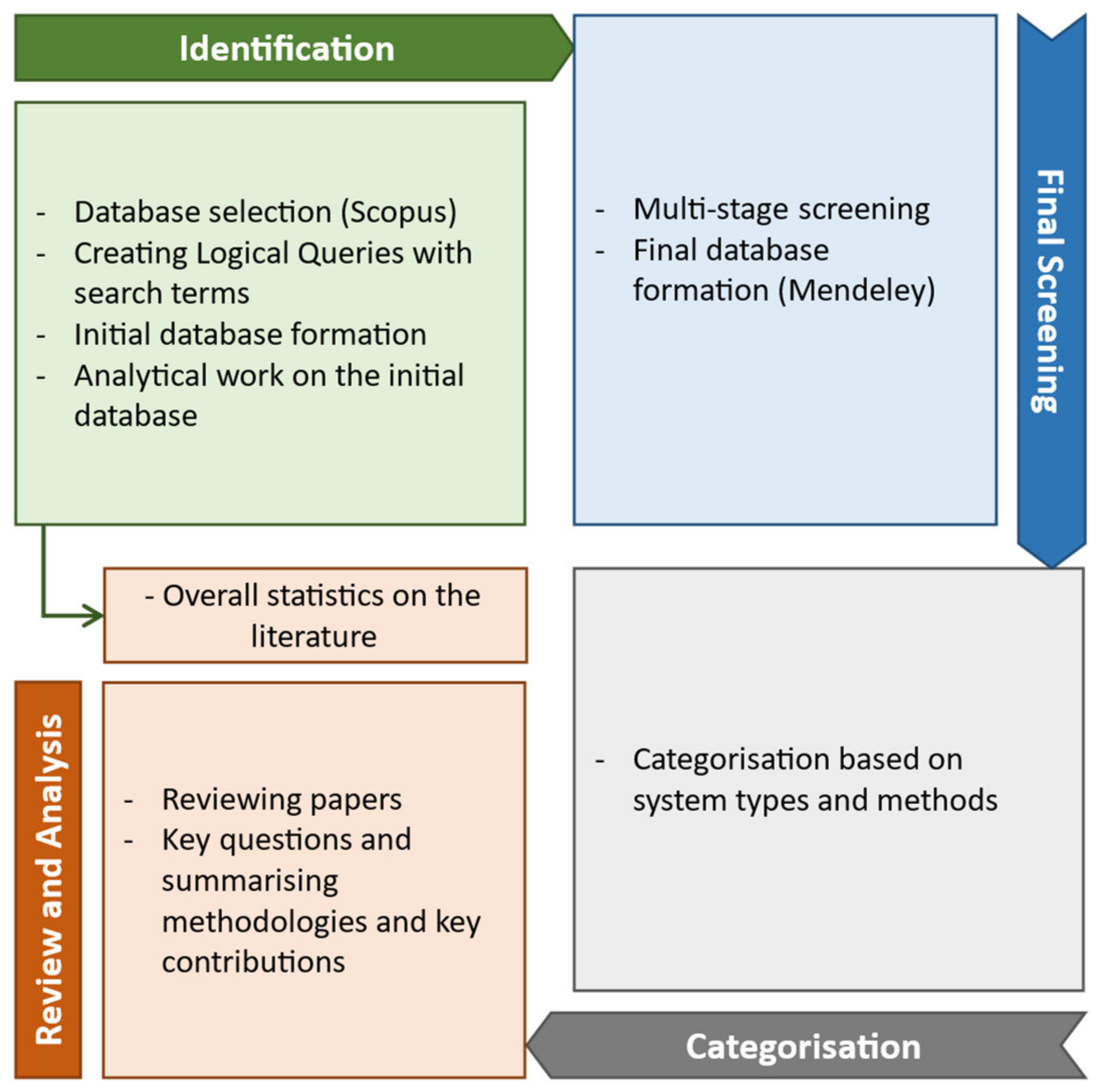

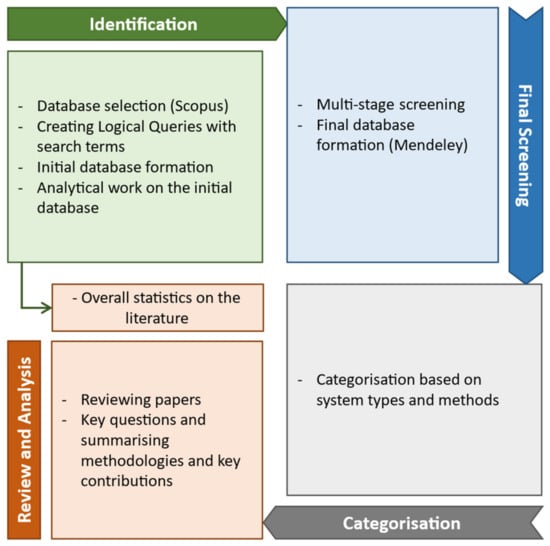

Categorizing studies in a review can be helpful, as it enhances clarity, organization, and depth; helps identify research gaps; facilitates a comparative analysis; and makes the review more accessible and useful for a diverse audience. For the current review, it was performed by exploring each study based on specific key questions:

- What is the main focus area of the study?

- What specific ML techniques are used?

- What application is ML used for?

- What are the main outcomes of the study?

Addressing these questions for each of the included papers would also serve as a critical step to understanding the actual contribution of each study to the literature, through a critical perspective. Figure 4 represents the workflow of this review.

Figure 4.

The strategy for identifying and reviewing the related literature.

3. Power-to-X Systems: Concepts and Challenges

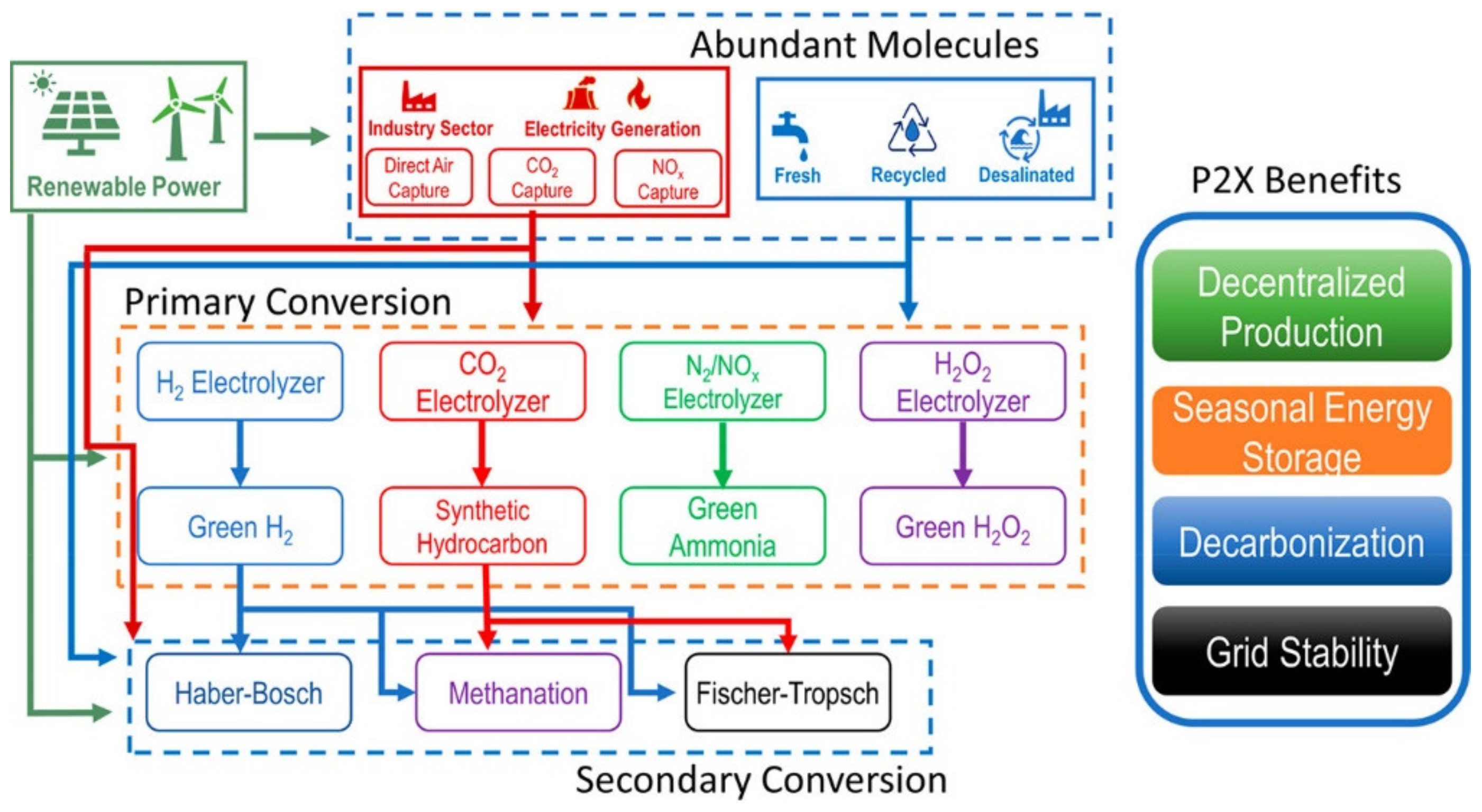

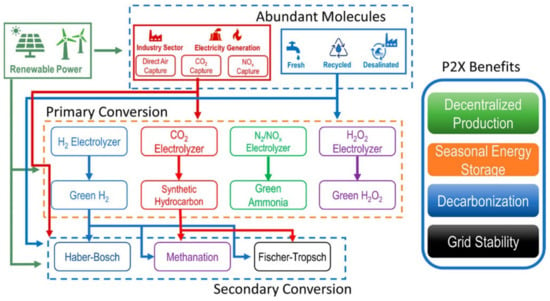

Power-to-X, or PtX, refers to a suite of technologies that convert electrical power, primarily from renewable sources, into different forms of energy carriers or chemical products. This transformation process aims to overcome the limitations of direct electrification and energy storage by enabling the versatile use of renewable energy across various sectors. The “X” in PtX (or P2X) stands for various end products, such as hydrogen (mostly known as P2H2 in the literature); gas (PtG or P2G)—a gaseous energy carrier such as synthetic natural gas, methanol (PtM or P2M); ammonia (PtA or P2A); and other chemicals or fuels (see Figure 5), offering a bridge between renewable energy sources and their broader application in industry, transportation, and beyond. By harnessing excess renewable electricity for the production of these carriers, PtX technologies can play a key role in enhancing energy storage, diversifying energy applications, and facilitating the decarbonization of sectors traditionally reliant on fossil fuels [5]. The flexibility of PtX systems makes them essential for achieving long-term energy sustainability, particularly as global energy demand shifts toward cleaner, more resilient sources.

Figure 5.

Schematics of PtX infrastructure reprinted with permission from [10]. PtX systems primarily begin with electrolysis, where renewable electricity is used to split water into hydrogen and oxygen. This renewable hydrogen can then be applied in secondary processes such as methanation, hydrogenation, and Fischer–Tropsch synthesis to produce hydrocarbon products or ammonia through the Haber–Bosch process, offering a flexible range of outputs. However, additional pathways may also exist depending on the specific PtX technology used.

PtX systems can be broadly categorized into Power-to-Gas (PtG), Power-to-Liquid (PtL), Power-to-Heat (PtH), and Power-to-Chemicals (PtCs), each converting surplus renewable electricity into different energy carriers or products. These systems are essential for energy storage and decarbonization, particularly in hard-to-abate sectors, like industry, transportation, and aviation. Power-to-Fuels (PtFs) is an overarching term that includes both PtG and PtL, focusing on gaseous and liquid fuel production. Electrolysis, especially for hydrogen, is central to most PtX pathways. Though these categories often overlap due to shared technologies, they are differentiated by the specific energy carrier produced and its use. On the other hand, PtX terminology is evolving. The term “Power-to-X” is increasingly used in the literature as an umbrella term for technologies that convert renewable electricity into other energy forms, such as gases, liquids, chemicals, fuels, heat, etc. However, the usage of these terms is indeed somewhat fluid, and there is no strict, universally adopted standard for naming conventions within the PtX framework. This flexibility allows researchers and industries to apply the term in various contexts, leading to some inconsistencies and overlaps in terminology. For example, terms like “Sun-to-Liquid” or “CO2-to-Fuel” emphasize specific inputs (solar energy, CO2) or processes (carbon utilization). Also, terms like PtM (Power-to-Methanol) and PtA (Power-to-Ammonia) emphasis process with specific outputs. These variations reflect the interdisciplinary nature of PtX, allowing flexibility to highlight novel technologies [25]. While PtF often includes PtG and PtL, some processes, like CO2-to-Fuel, specifically focus on converting captured carbon dioxide into fuels, further diversifying the terminology [26]. This evolving usage allows innovation but also highlights the need for clarity across different PtX applications.

The foundational PtX process is P2H2, which uses renewable electricity to electrolyze water into hydrogen and oxygen. The hydrogen can be stored or further converted into other fuels. Two main types of electrolyzers dominate this space: PEM electrolyzers and alkaline electrolyzers. PEM electrolyzers can operate at high efficiencies of around 80%, but they require expensive catalysts, such as platinum, which increases the cost. Alkaline electrolyzers, on the other hand, are less efficient (65–70%) but are more cost-effective and use cheaper materials [27]. Recent research has focused on improving operational flexibility to handle fluctuating renewable energy inputs more effectively [28]. In addition to the widely used PEM and alkaline electrolyzers, other electrolysis methods, such as solid oxide electrolysis (SOE) and Anion Exchange Membrane (AEM) electrolysis offer distinct advantages and challenges. SOE operates at very high temperatures (700–1000 °C), allowing it to achieve efficiencies as high as 70% by utilizing excess industrial heat. This makes it highly efficient for large-scale hydrogen production and particularly useful for applications like Power-to-Syngas, which require both hydrogen and carbon monoxide (CO). However, SOE systems face durability challenges due to material degradation at high temperatures [27]. On the other hand, AEM electrolysis operates in an alkaline environment, using hydroxide ions (OH⁻) to generate hydrogen. Unlike PEM systems, AEM does not require expensive catalysts like platinum, offering a more cost-effective alternative. While still in development, AEM electrolysis holds great potential for lowering costs in decentralized hydrogen production, though membrane durability and efficiency improvements are key hurdles to overcome [29].

PtG systems convert renewable electricity into gaseous fuels such as hydrogen or methane. The primary technology used in PtG is electrolysis, where water is split into hydrogen and oxygen. Hydrogen can then be stored or further combined with captured carbon dioxide (CO2) in a methanation process to produce synthetic natural gas (SNG). This process is particularly useful for long-term storage and can be integrated into existing natural gas infrastructure. PtG systems often utilize alkaline or PEM electrolyzers, with system efficiencies ranging from 60% to 75%, depending on the technology and heat-recovery mechanisms in place [30]. A key challenge is improving the efficiency of the process, especially during the conversion of hydrogen into methane through methanation. Research has focused on optimizing the reaction conditions, such as using solid oxide electrolysis cells (SOECs), which can increase overall system efficiency when the co-electrolysis of water and CO2 is involved [31].

PtL systems convert renewable energy into liquid fuels, like methanol, dimethyl ether, or synthetic gasoline, through electrochemical or thermochemical processes. These liquid fuels are crucial for decarbonizing sectors such as aviation, shipping, and heavy-duty transport, which require high-energy-density fuels. The typical PtL process involves converting CO2 and hydrogen into syngas (a mixture of CO and H2) through the reverse water–gas shift (rWGS) reaction, followed by Fischer–Tropsch synthesis to produce hydrocarbons. The efficiency of PtL processes depends heavily on the integration of key technologies, such as electrolysis, reverse water–gas shift (rWGS) reactions, and Fischer–Tropsch synthesis. For example, research has shown that optimizing the operating conditions of the rWGS reaction (e.g., at 825 °C and 5 bar) can significantly improve PtL system performance, with efficiencies reaching up to 38.7% [32]. Another study indicated that integrating biogas upgrading and SOEC electrolysis with Fischer–Tropsch synthesis can achieve an energy efficiency of over 80% for producing Fischer–Tropsch liquids [33].

Power-to-Fuel (PtF) encompasses both gaseous and liquid fuel production but specifically targets synthetic fuels (referred to as electro-fuels, or e-fuels) that can replace conventional fossil fuels. PtF systems often utilize technologies like Fischer–Tropsch synthesis to convert renewable hydrogen and CO2 into hydrocarbons suitable for transportation fuels. These processes can produce a variety of fuels, such as synthetic natural gas (SNG), methanol, and syncrude (a precursor to gasoline and diesel). The efficiency of PtF systems can vary widely depending on the specific fuel being produced. For example, a study comparing different PtF systems found that the energy efficiency for producing hydrogen through electrolysis can reach up to 94%, while the efficiency drops to around 64% when converting hydrogen into synthetic gasoline [31]. Advances in heat integration and process intensification, such as co-electrolysis of CO2 and H2O, are being investigated to improve overall system performance [34].

PtH focuses on converting renewable electricity into thermal energy, which can then be used for heating purposes or as a high-temperature heat source for industrial processes. PtH systems are highly efficient in converting electricity into heat, often exceeding 95% efficiency, making them a viable option for grid balancing and decarbonizing heating systems. One of the key advantages of PtH systems is their flexibility, as they can be rapidly deployed to stabilize the grid during periods of excess renewable generation. Combined heat and power (CHP) systems are often used in PtH applications, where both electricity and heat are produced from the same energy source. Recent advancements in decentralized micro-CHP systems show promise in reducing transmission losses and improving overall system efficiency [35]. These systems are increasingly being integrated with renewable energy sources to provide flexible, on-demand heat and power for residential and industrial applications.

Overall, the concept of PtX is central to addressing the challenges of integrating renewable energy into our current energy systems. It can provide energy storage, transport, and utilization in forms compatible with existing infrastructure and technologies [36]. P2H2 is identified as the lynchpin of PtX, a foundational step toward the production of sustainable fuels and chemicals that can be used across various sectors, including those that are difficult to decarbonize, such as the industrial sector, heavy transportation, and aviation. The production of hydrogen via electrolysis, utilizing surplus renewable electricity, facilitates the creation of a flexible and responsive energy system capable of accommodating the inherent unpredictability of wind and solar power [37]. Beyond hydrogen, PtX technologies open the door to a broader spectrum of synthetic fuels, such as methanol and ammonia, which not only provide sustainable alternatives but also leverage existing infrastructure and offer practical solutions for deeply entrenched, hard-to-electrify sectors.

Furthermore, the integration of PtX technologies leverages existing natural gas grids and equipment. This integration provides a solution for storing and transporting energy and contributes to the decarbonization of various sectors by providing cleaner alternatives to fossil fuels. PtM and PtA exemplify the potential of PtX to utilize carbon dioxide and nitrogen from the air, turning them into valuable commodities while enhancing the energy system’s flexibility and resilience [4,38,39,40]. As renewable energy scales up, particularly in sectors where direct electrification may not be viable, synthetic fuels emerge as a bridge, enabling the use of established technologies like Internal Combustion Engines (ICEs) in a more sustainable manner.

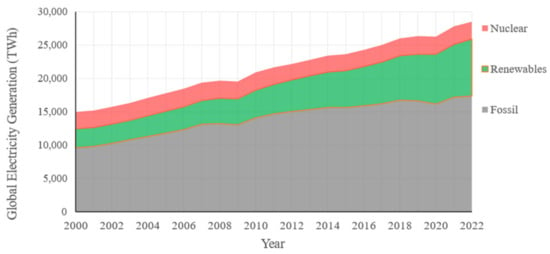

Contrary to the perception that the future of transportation and energy is exclusively electric, ICE technology continues to evolve, presenting a compatible pathway for utilizing synthetic fuels produced via PtX processes. The continuous improvement of the already-mature technology of ICEs, coupled with the strategic incorporation of PtX-derived fuels, also called e-fuels, can facilitate a more inclusive and pragmatic approach toward achieving sustainability in transportation and beyond. This perspective does not discount the potential of electric vehicles but rather highlights the diversity of solutions required to address the complex challenges of the global energy transition [41,42]. As we consider these alternatives, e-fuels stand out as a promising solution. Not only are they capable of powering existing ICEs, but they also offer a carbon-neutral pathway by reintroducing captured carbon into the energy cycle.

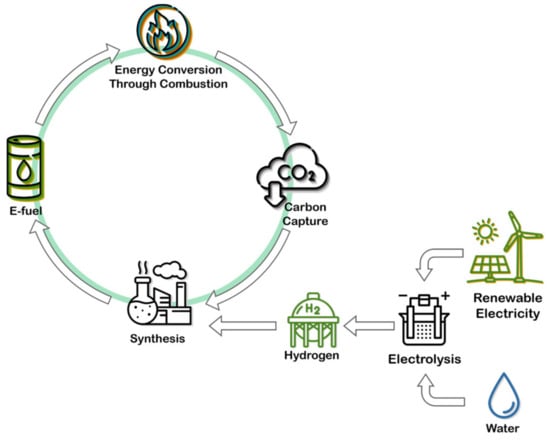

E-fuels are carbon-neutral and renewable because the carbon they contain is sourced directly from the atmosphere, while the chemical energy stored in them comes from renewable resources, like wind or solar power. This process effectively closes the carbon loop, as the CO2 released during combustion is equal to the amount initially captured. In one sense, it can be viewed as reversing the combustion process by using renewable energy to create fuel, thus reintroducing captured carbon into the energy cycle (see Figure 6).

Figure 6.

The carbon-neutral cycle of e-fuels, where CO2 captured from the atmosphere is reused to create fuel using renewable energy, thus closing the carbon loop. Figure adapted from [43].

The development and implementation of PtX technologies represent a critical juncture in the global effort to transition from fossil fuels to a more sustainable, flexible, and resilient energy system. By leveraging the synergy between renewable energy sources, energy storage technologies, and PtX processes, we can overcome the challenges of intermittency and geographical limitations, paving the way for a decarbonized future that still benefits from the proven capabilities of the current infrastructure and well-established technologies, like ICEs.

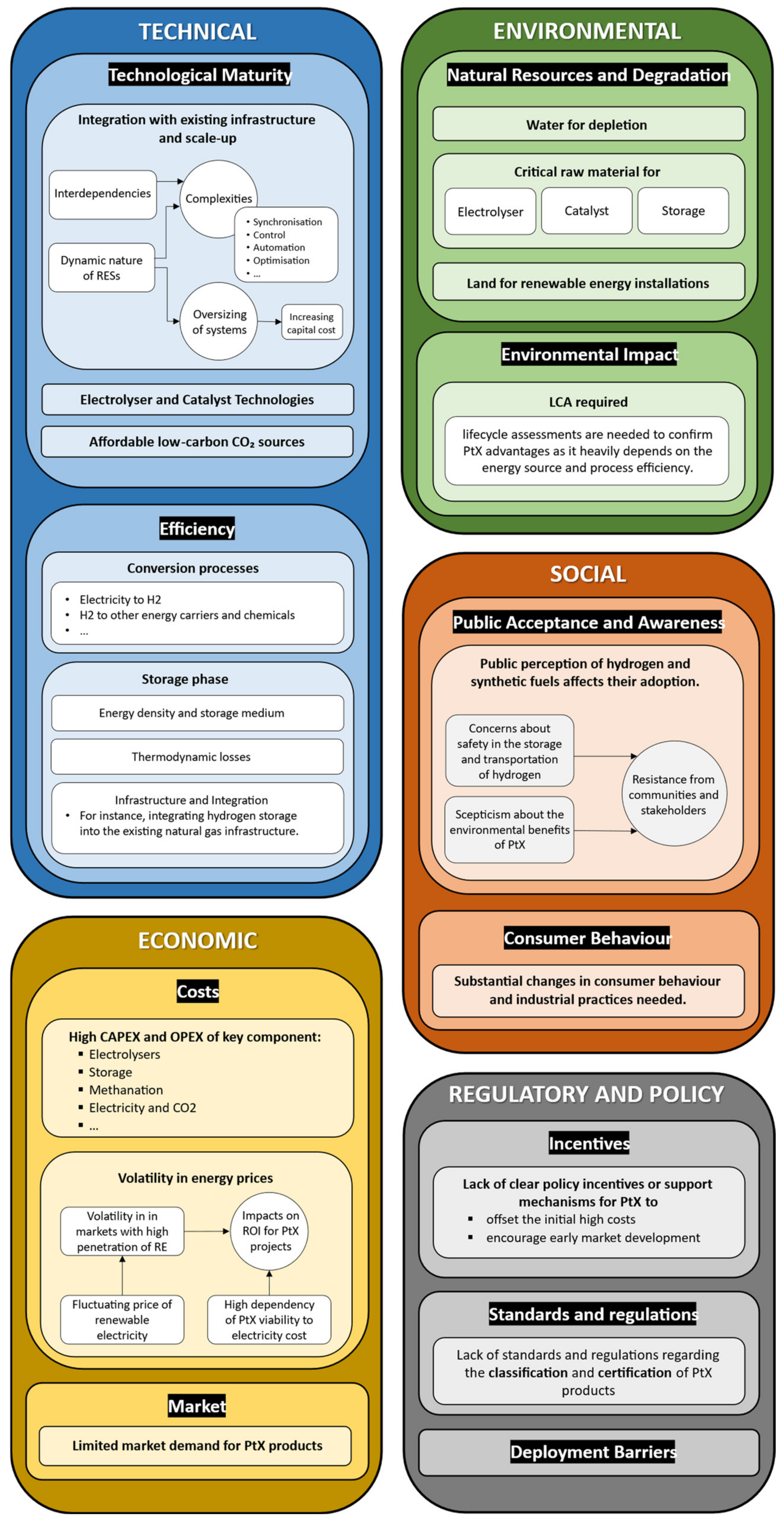

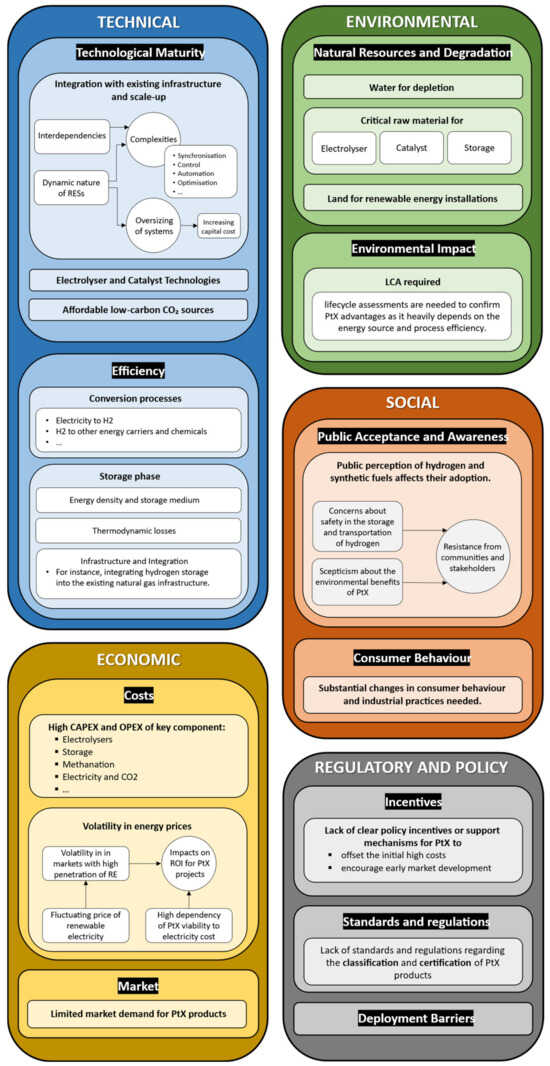

What Key Challenges Impede PtX Systems’ Progress?

The progression of PtX systems is impeded by multifaceted challenges that span economic, technical, environmental, regulatory, and infrastructural domains. A quick review of these challenges is presented in Figure 7. The economic barriers are particularly pronounced, with high capital and operational costs, especially in the absence of sufficient government incentives. These economic challenges are exacerbated by the high costs associated with renewable electricity and hydrogen storage [4,10,11,12].

Figure 7.

Existing challenges in developing PtX systems.

Technically, the maturity of PtX technologies varies, with some systems, like solid oxide electrolyzer cells (SOECs), still in the early stages of development [27]. In addition, the technical scalability of PtX technologies is hampered by the limited availability of critical raw materials, such as platinum group metals, which are essential for electrolysis processes [12]. The integration of these technologies into existing infrastructures is complex, particularly when coupled with the fluctuating nature of renewable energy sources, which demand dynamic flexibility that many current systems cannot adequately provide [44,45]. This challenge is compounded by the issues of thermal instability and catalyst degradation that arise when operating PtX processes dynamically to match the fluctuating supply of renewable energy, which can complicate the maintenance of consistent product quality [34]. Additionally, the effective utilization of by-products and waste heat, a potential efficiency booster, remains underexplored, further limiting the overall effectiveness of PtX systems [11].

Environmental challenges also pose significant barriers, particularly in the sourcing and storage of CO2 and the environmental impact of electrolyzer operations, which raise concerns about water depletion and other forms of degradation. Furthermore, the substantial water demand for hydrogen production via electrolysis, though currently considered manageable in some regions, must be carefully monitored as PtX scales up globally [12]. In fact, electrolysis for hydrogen generation consumes vast amounts of water and electricity, and as PtX systems expand, water depletion and other forms of environmental degradation, such as resource-intensive material production for electrolysis and catalytic systems, could exacerbate the situation [46]. Additionally, CO2 storage and sourcing present significant challenges, with the availability of low-carbon or carbon-neutral CO2 being a crucial factor in ensuring the overall sustainability of these systems. The environmental impacts are closely tied to the type of electricity used, with renewable sources substantially lowering the carbon footprint, while fossil-based electricity significantly undermines the carbon-reducing potential of PtX [26]. Moreover, the lack of widely adopted sustainability metrics and comprehensive environmental assessments hampers a full understanding of the implications of PtX technologies, particularly within hybrid renewable energy systems (HRESs) [27,47]. Life-cycle assessments (LCAs) are essential to confirm the advantages of PtX systems, as their benefits are highly dependent on energy source, process efficiency, and indirect emissions from material and energy input. LCAs reveal that while PtX systems can reduce land use and water consumption compared to traditional methods, significant challenges remain in achieving large-scale sustainability [48]. Therefore, a holistic view of PtX technologies’ environmental impact, including indirect emissions and resource consumption, is essential for scaling up these systems in a sustainable manner.

Regulatory constraints, such as strict standards for natural gas and hydrogen blending, further limit the integration of PtX products into existing energy networks [11]. The lack of a cohesive, application-neutral regulatory framework for PtX technologies presents a significant barrier to their deployment and scaling. Regulatory gaps and the absence of supportive niche markets complicate the commercialization of PtX systems [49]. The market for PtX products is still developing, and the reliance on public funding shows the current lack of economic viability and the need for greater market acceptance and infrastructure development to support the widespread commercialization of PtX systems.

Infrastructural challenges, including geographical variability and the scalability of PtX projects, complicate the large-scale deployment of these technologies. Furthermore, implementing PtX processes in remote locations with high renewable energy potential but limited infrastructure adds to the operational challenges, leading to increased costs and complexity [34]. The transition to decentralized energy systems introduces additional complexities in ensuring stability and security, which are critical for the sustainable operation of PtX technologies [11,27].

Limitations in current modeling and optimization approaches often lead to oversimplifications that fail to capture the real-world complexities of PtX systems. The need for multi-objective optimization that considers not only economic factors but also environmental and operational safety metrics is crucial for accurately assessing and improving the performance of these technologies [11]. Without addressing these diverse factors, the potential for PtX systems to meaningfully contribute to decarbonization efforts may be hindered.

Addressing these intertwined challenges requires a concerted and innovative effort across multiple sectors, including technological innovation, regulatory reform, market development, and enhanced modeling techniques. ML can be a critical enabler in addressing the multifaceted challenges of integrating PtX technologies into existing energy systems. As PtX systems grow in complexity, particularly with the integration of renewable energy sources, ML offers robust solutions by converting complex optimization tasks into manageable processes, enhancing predictive accuracy and real-time decision-making [13]. Its ability to integrate diverse data sources and optimize energy storage is indispensable for maintaining system stability and efficiency in increasingly decentralized and cyber–physical energy networks [50].

4. ML: Concepts, Evolution, and Impact

ML is a pivotal branch of artificial intelligence (AI) that focuses on enabling computer systems to learn from data, identify patterns, and make decisions with minimal human intervention. Unlike traditional programming, where specific instructions are coded, ML algorithms develop their own logic based on input data, allowing them to adapt and improve over time [51]. ML can be understood as the scientific study of mathematical algorithms and models designed to generate complex rules based on data, thereby automating tasks that would otherwise require human intelligence. These algorithms are categorized by learning styles—such as supervised, unsupervised, and reinforcement learning—and by their function, including classification, regression, and clustering. Deep learning, a subset of ML, specifically focuses on learning data representations through multiple layers of processing, further expanding the capabilities of ML [52]. As ML algorithms have become more advanced, they have revolutionized various industries by solving complex problems and driving innovation, making ML indispensable in the modern technological landscape [53]. The versatility of ML algorithms, combined with their capacity for continuous learning and optimization, have proven their critical role in advancing technology [54].

The essential elements of ML include representation, which refers to the set of classifiers or the language that a computer system understands to interpret data; evaluation, which involves assessing the model’s accuracy and effectiveness in making predictions or classifications; and optimization, the process of improving the model’s performance by finding the best parameters or methods that yield the highest evaluation scores. These components are crucial for enabling ML algorithms to learn from data, make predictions, and adapt over time without explicit programming [51,52].

ML is broadly categorized into three main types: supervised learning, unsupervised learning, and reinforcement learning. Supervised learning involves training algorithms on labeled datasets, enabling them to predict outcomes or classify data based on known input–output pairs [52]. This approach is widely used in industries like automotive manufacturing for predictive maintenance, where algorithms can forecast component failures by analyzing historical data [54]. Unsupervised learning, on the other hand, deals with unlabeled data, using techniques like clustering and dimensionality reduction to identify hidden patterns or group similar items, which is particularly useful in quality control and process [51,52] through trial and error, making it ideal for optimizing complex processes in dynamic environments such as manufacturing and supply chain logistics [53,54]. These types of ML, along with deep learning, a subset focused on learning data representations through multiple layers, are integral to advancing automation, efficiency, and innovation in various technological and industrial domains [52].

While deep learning (DL) is a subset of ML, this paper examines a broader range of ML techniques, including both traditional methods and DL, to capture the diverse applications in PtX systems. Traditional ML techniques, such as reinforcement learning, genetic algorithms, and data-driven optimization, are particularly effective in tasks like process control, predictive maintenance, and resource management, where interpretability and computational efficiency are key. DL, while powerful for more complex data and high-dimensional data (such as images or complex sequences), may not always be necessary for optimizing PtX systems. Therefore, our focus includes both simpler ML methods and DL, as appropriate for each task.

The evolution of ML has profoundly impacted industries, particularly within the framework of Industry 4.0, where it has become essential for optimizing processes, enhancing automation, and enabling data-driven decision-making. Initially, the integration of ML faced challenges, such as data scarcity and technological limitations, but advancements in deep learning and other algorithms have gradually overcome these barriers, leading to widespread industrial applications. ML now plays a crucial role in sectors like smart manufacturing and petrochemicals, where it drives real-time process optimization, predictive maintenance, and energy-efficiency improvements. As research continues to advance, ML is poised to further revolutionize industries by addressing challenges related to data quality and scalability, solidifying its role as a key driver of innovation and efficiency in the modern industrial landscape [53,54,55,56]. As these technologies mature, industries are increasingly leveraging ML not just for operational efficiency but also for more strategic applications, such as long-term sustainability goals and predictive market shifts. This trajectory shows the growing importance of AI-driven solutions in maintaining a competitive edge in the evolving industrial landscape.

In PtX systems, several advanced ML techniques play a critical role in optimizing complex, multi-variable processes, such as energy conversion, storage, and resource management. Among these, deep reinforcement learning (DRL), neural networks (NNs), and genetic algorithms (GAs) stand out for their potential to enhance system efficiency, minimize environmental impact, and improve overall process automation. In the following, we provide additional technical depth on these techniques, exploring their underlying mechanisms and how they contribute to the optimization of PtX systems.

4.1. Deep Reinforcement Learning (DRL)

DRL combines reinforcement learning (RL) and deep neural networks (DNNs) to handle complex, high-dimensional decision-making tasks. In DRL, an agent interacts with an environment modeled as a Markov Decision Process (MDP), which consists of states, actions, rewards, and transitions. The agent learns an optimal policy that maximizes cumulative rewards over time by navigating through different states based on its interactions. The key technical aspect of DRL is the Q-learning algorithm, where the Q-value function maps state–action pairs to the expected cumulative rewards. When scaled to complex environments with large state–action spaces (such as in PtX systems where energy management or optimization across multiple variables is required), a deep neural network (DNN) is used to approximate the Q-value function, known as the Deep Q-Network (DQN) [57].

A critical feature of the DQN is the experience replay buffer, which stores the agent’s interactions and samples them randomly to train the network. This process reduces the correlation between consecutive training examples, improving convergence. Furthermore, DQN uses a target network to stabilize training by holding a fixed set of weights for the Q-value approximator during multiple updates [58]. In more advanced versions of DRL, such as Double DQN and Dueling DQN, additional techniques are used to improve the stability and accuracy of learning. In PtX applications, DRL can help optimize real-time decisions regarding energy storage, resource allocation, and system controls. Given the stochastic nature of energy systems, DRL can continuously learn from system feedback and adjust operations for optimal efficiency.

4.2. Neural Networks (NNs)

Neural networks (NNs) are composed of layers of neurons that model complex, non-linear relationships between inputs and outputs. The architecture of a neural network includes input layers, hidden layers, and output layers. Each neuron in the hidden layers applies a non-linear activation function (such as ReLU or Sigmoid) to the weighted sum of inputs it receives from the previous layer, enabling the network to approximate intricate functions. A key technical element in NNs is backpropagation, a process where the network’s prediction error is calculated and propagated backward through the layers to update the weights using gradient descent. In deep neural networks (DNNs), which contain many hidden layers, backpropagation, combined with stochastic gradient descent (SGD), is used to optimize the network’s weights [59].

In PtX systems, NNs are crucial for predictive modeling, such as forecasting energy demand, predicting system failures, and optimizing the conversion processes (e.g., hydrogen production or CO2 capture). More sophisticated architectures, like convolutional neural networks (CNNs) and recurrent neural networks (RNNs), are used for processing spatial and temporal data respectively, providing robust models for dynamic energy systems [60].

4.3. Genetic Algorithms (GAs)

Genetic algorithms (GAs) are a population-based search heuristic inspired by the process of natural selection. GAs work by evolving a population of potential solutions through genetic operators, such as selection, crossover, and mutation. A fitness function evaluates each candidate solution, and the best-performing solutions are selected to “reproduce” the next generation by combining parts of two parent solutions (crossover) or randomly altering parts of a solution (mutation) [61]. One of the advantages of GAs is their ability to solve optimization problems where the solution space is large and complex, and where gradient information is unavailable or unreliable (as in many PtX processes). GAs are particularly useful for multi-objective optimization problems, such as minimizing energy consumption, costs, and emissions in PtX processes, while maximizing efficiency. GAs have also been applied to optimize the topology of neural networks, evolving architectures that perform better in specific applications [62]. For PtX systems, GAs can help optimize process parameters, such as temperature, pressure, or material flow, in energy-conversion processes, like PtM or P2H2. By evaluating and iterating through various configurations, GAs enable the discovery of optimal setups that are difficult to find through manual tuning or traditional optimization methods.

5. Power-to-X and Machine Learning: A Promising Team-Up

As explored, ML has been successfully used to accelerate the discovery and optimization of materials, particularly catalysts, essential for scaling PtX technologies and reducing dependency on scarce raw materials. It also enhances predictive modeling to manage fluctuating renewable energy inputs, ensuring seamless system integration and energy management. Economically, ML supports strategic planning and analysis by simulating cost-effective scenarios and improving market viability. Finally, ML plays a crucial role in conducting comprehensive environmental impact assessments, optimizing processes to minimize environmental impacts, and ensuring the sustainable development of PtX systems. Together, these capabilities position ML as a cornerstone in advancing PtX technologies toward a more efficient, reliable, and sustainable future.

The structure of this section, which forms the main body of the review, is designed to provide a focused analysis of how ML and data-driven methods enhance various PtX processes, with each subsection dedicated to a different PtX technology—PtG, Power-to-Liquid, sustainable combustion, and PtH. This structure allows for a clear, thematic exploration of ML’s role in optimizing each technology, starting with more established processes, like PtG, and progressing to more niche applications, like PtH.

5.1. Machine Learning and Power-to-Gas Systems

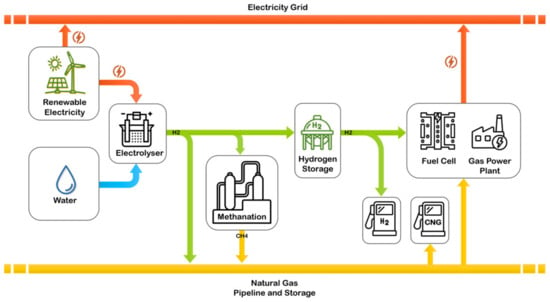

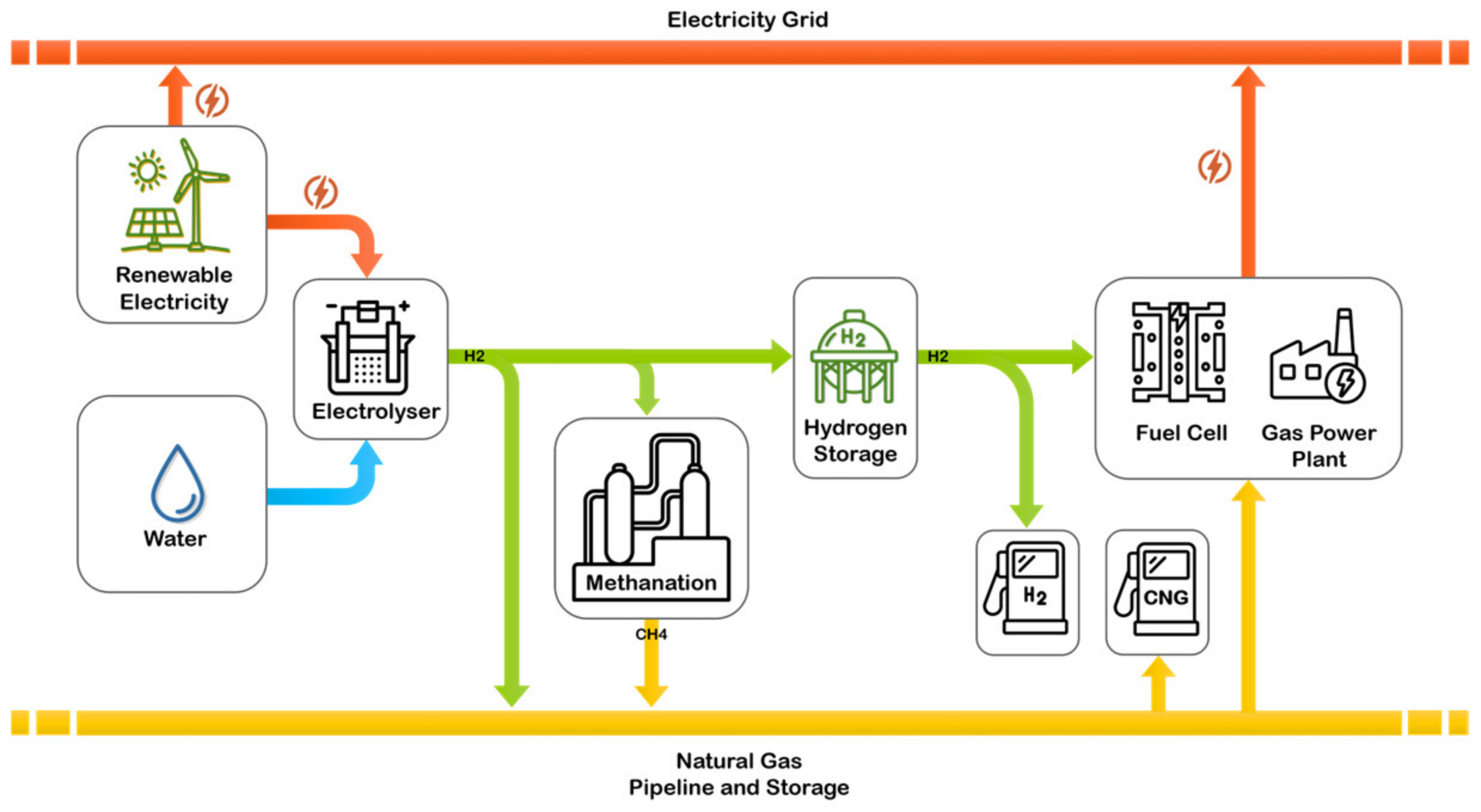

The increasing integration of renewable energy sources into power systems has driven the development of PtX technologies, particularly PtG, which converts surplus renewable power into storable forms, like hydrogen or methane. Figure 8 represents a schematic of PtG system.

PtG systems are a technology designed to store surplus renewable energy by converting it into hydrogen or synthetic natural gas (SNG) through electrolysis and methanation processes. In these systems, excess electricity, particularly from intermittent renewable sources like wind or solar, is used to produce hydrogen via water electrolysis. The hydrogen can be stored directly, injected into the natural gas grid, or further converted into SNG by combining it with captured CO2. PtG systems offer long-term energy-storage solutions and can provide flexibility to power grids, reduce wind and solar curtailment, and enhance the integration of renewable energy. Additionally, PtG systems can support ancillary services to the electricity grid, such as frequency and voltage regulation, and facilitate the decarbonization of sectors such as transportation, heating, and industry [63,64]. They also allow the existing natural gas infrastructure to be used for hydrogen transport and storage, reducing capital investment needs. While PtG systems are still emerging, they show great potential in the transition to a sustainable, low-carbon energy, while ensuring that excess renewable energy is never wasted but instead utilized for further decarbonization of hard-to-abate sectors.

As the complexity of energy systems grows, ML and data-driven methods are becoming central to optimizing the efficiency, flexibility, and resilience of PtX systems. This section synthesizes insights from several research papers that examine the role of ML in advancing PtG technologies, focusing on the applications of these methods to enhance operational decision-making, uncertainty management, and multi-energy integration.

Figure 8.

Simplified schematic of a PtG system, adapted from [65].

Figure 8.

Simplified schematic of a PtG system, adapted from [65].

5.1.1. Coordinating PtG in Multi-Energy Systems

A major theme in PtX research is the use of ML to coordinate the interaction between multiple energy carriers—electricity, heat, gas, and hydrogen—particularly in systems that integrate PtG. Y. Zhang et al. (2022) [66] emphasize the need for data-driven robust optimization to manage the interplay between wind and solar energy outputs in electric–gas networks. Their model employs data-driven robust optimization (DDRO) techniques to process historical data on renewable generation and create a Minimum Volume Enclosing Ellipsoid (MVEE) uncertainty set, allowing the system to optimize dispatch decisions with reduced conservatism. Similarly, Z. Yang and Jiang (2024) [67] proposed a two-step scheme for multi-energy systems (MESs) integrating PtG to mitigate renewable-energy curtailment by converting excess wind and solar energy into natural gas. MLs, specifically deep neural networks, are trained using historical data to optimize real-time decision-making in electricity–heat demand response (DR), significantly reducing charging costs and improving system security amidst uncertainties in renewable energy supply.

Integration of Combined Cooling, Heating, and Power (CCHP) systems with PtG in multi-energy system has been a key strategy in enhancing the flexibility and reliability of multi-energy systems, according to the literature. This combination leverages renewable energy to meet diverse energy needs—electricity, heating, cooling, and gas—while addressing the uncertainties inherent in wind and solar power. Yang et al. (2023) [68] proposed a two-stage framework that combines CCHP, PtG, and carbon capture, optimizing system operations through ML models that generate predictive scenarios based on historical energy imbalances. This approach improves multi-energy coordination at the regional scale, balancing cost and reliability. Siqin et al. (2022) [69] focus on a PtG-CCHP microgrid, where uncertainties in wind and solar generation are tackled using a Wasserstein metric in their DRO model. By integrating PtG with CCHP, they enhance system flexibility and reliability, much like Yang’s regional framework but applied at a smaller scale. In a similar vein, L. Wang et al. (2024) [70] introduced a novel Power-to-Gas-to-Power (PtG-PtP) system driven by the Allam cycle, which integrates carbon capture and water desalination into PtG processes. By combining exergy analysis with ML techniques like artificial neural networks (ANNs) and multi-objective optimization, their system maximizes energy and water production efficiencies while reducing emissions, highlighting a novel approach for multi-energy system design in PtG technologies. Also, L. Li et al. (2022) [71] propose a 100% renewable island energy system integrating PtG, biogas; Combined Cooling, Heating, and Power (CCHP); and desalination technologies to meet electricity, heating, cooling, gas, and fresh-water demand under extreme weather conditions. The model utilizes agent-based modeling (ABM) for energy-demand prediction and employs multi-objective optimization to design and optimize system dispatch using k-means clustering. The results show that, compared to battery storage, PtG reduces annual costs by 2.5%, while extreme weather resilience is improved through enhanced biogas and desalination capacities, demonstrating the system’s economic and environmental benefits.

Mansouri et al. (2023) [36] integrated real-time IoT data with a deep learning framework using a Long Short-Term Memory (LSTM) neural network to predict energy demand and dynamically adjust energy supply, including PtG in multi-energy microgrids. This enables systems to quickly adapt to fluctuations in market prices and renewable energy availability. Also, Olanlari et al. (2022) [37] used ML to optimize multi-energy virtual power plants (MEVPPs), coordinating PtG, energy storage, and renewables through an Epsilon-constraint method and a fuzzy satisfying approach. This maximized profits while meeting emissions targets, with ML predicting market prices and demand fluctuations to adjust strategies. Meanwhile, Qi et al. (2022) [72] enhanced system reliability by integrating a Power-to-Methane (PtCH4) system with Liquid CO2 Energy Storage (LCES), balancing renewable energy supply and demand. Zhong et al. (2024) [73] further improved operational flexibility by introducing a PtM system combining solid oxide electrolysis cells (SOECs) and a methanation reactor, optimizing off-design performance to enhance efficiency.

5.1.2. Deep Reinforcement Learning for Dynamic Optimization

The dynamic nature of renewable energy generation requires real-time decision-making, and deep reinforcement learning (DRL) has proven to be particularly effective in handling such challenges. Liang et al. (2024) [74] and B. Zhang et al. (2023) [75] both apply DRL algorithms to PtG systems, integrating them with carbon capture technologies.

Liang et al. (2024) [74] implemented a Twin Delayed Deep Deterministic Policy Gradient (TD3) algorithm to dynamically optimize energy flows in complex systems, providing stability and adaptability through continuous action spaces. B. Zhang et al. (2023) [75] enhanced this approach by using a Soft Actor–Critic (SAC) algorithm with prioritized experience replay, improving learning efficiency and enabling quicker adaptation to fluctuations in renewable generation and market prices. Similarly, Cui et al. (2023) [76] applied the SAC algorithm to optimize electricity–gas–heat coupling in low-carbon microgrids, incorporating PtG and Organic Rankine Cycle (ORC) technologies. Wen and Aziz (2023) [77] further explored energy hub scheduling using a modified double-deep Q-network, comparing Power-to-Gas-to-Power (PtX2P) and Biomass-to-Gas-to-Power (B2X2P), with B2X2P proving more profitable but PtX2P offering greater flexibility. Finally, Monfaredi et al. (2023) [78] introduced a multi-agent deep reinforcement learning (MA-DRL) method to optimize energy management in microgrids, improving coordination of renewable energy resources and reducing both operational costs and carbon emissions.

These studies collectively demonstrate the effectiveness of advanced reinforcement learning algorithms, such as TD3, SAC, and multi-agent DRL, in optimizing energy flows and improving the operational flexibility of multi-energy systems. By incorporating real-time adaptability and advanced coordination of energy resources, these methods not only enhance system efficiency but also reduce operational costs and carbon emissions, making them vital for managing the complexities of renewable energy integration in PtG systems and multi-energy microgrids.

5.1.3. Predictive Diagnostics in PtG Systems

In addition to optimization, ML enhances the reliability of PtG systems through predictive diagnostics. Zaveri et al. (2023) [79] developed a ML-based diagnostic model for proton exchange membrane fuel cells (PEMFCs), used in PtG systems to produce hydrogen. By employing supervised learning algorithms, including advanced regression techniques, such as support vector machine, decision tree regression, random forest regression, and artificial neural network, they detect early signs of PEMFC malfunction, such as dehydration or flooding. The predictive capabilities of these models improve system reliability and reduce downtime, ensuring the consistent production of hydrogen in PtG applications. Ma et al. (2022) [80] also focus on PEMFC systems integrated with PtG, but in the context of hybrid energy systems that address renewable uncertainty. Their study applies wavelet transform–neural network to optimize PEMFC operations under fluctuating renewable inputs, ensuring that energy storage and hydrogen production remain stable. The integration of PEMFC and PtG, supported by ML, enables these systems to balance renewable energy variability effectively.

ML improves the reliability of PtG systems, particularly through predictive diagnostics for PEMFCs, as demonstrated by Zaveri et al. (2023) [79], who used various supervised learning algorithms to detect early signs of malfunction. Additionally, the wavelet transform–neural network approach by Ma et al. (2022) [80] ensures stable PEMFC operations in hybrid systems by balancing renewable energy fluctuations. These advancements ensure consistent hydrogen production and enhance the operational stability of PtG systems.

5.1.4. Market Integration and Carbon Capture in PtG Systems

ML has also been applied to optimize PtG systems in the context of market operations, particularly in integrating carbon trading mechanisms and electricity markets. Researchers has attempted to make PtG systems economically viable in competitive market environments by applying ML; X. Zheng et al. (2021) [81] proposed a stochastic co-optimization model for power–gas systems in day-ahead markets. Their model integrates PtG technologies and uses ML-based methods, such as Gaussian Process Regression (GPR), to predict electricity and gas prices. Also, Janke et al. (2020) [82] explored bidding strategies for PtX systems in day-ahead electricity markets, utilizing an artificial neural network (ANN) to forecast electricity prices and develop a price-independent order (PIO) strategy. While PIO helps avoid expensive, carbon-intensive electricity during peak loads, it results in fewer operating hours and higher hydrogen production costs compared to a price-dependent order (PDO), which proved to have 10.9% lower levelized hydrogen costs.

Li et al. (2023) [83] extended the application of ML to near-zero carbon emission power (NZCEP) plants, integrating PtG and CCS to optimize both energy production and carbon capture under carbon trading mechanisms. Their use of a k-means clustering algorithm simplified carbon pricing scenarios and optimized operations based on real-time carbon price signals. Similarly, Wu and Li (2023) [84] incorporated PtG into hydrogen-based integrated energy systems with CCS, utilizing a Wasserstein-based DRO model and ML predictions to manage fluctuations in renewable generation and carbon prices. This approach efficiently converts surplus renewable energy into hydrogen while capturing and storing carbon emissions. Lastly, Janke et al. (2020) [82] focused on optimizing P2H2 systems by developing a price-independent order (PIO) bidding strategy for the electricity market. Supported by ANN, this strategy improved electricity price forecasting and reduced hydrogen production costs by avoiding peak demand periods. Despite the price-dependent order (PDO) strategy offering lower levelized costs overall, PIO proved effective under volatile market conditions, providing a valuable tool for plant operations. Together, these advancements highlight how ML and advanced strategies can enhance the efficiency and adaptability of PtG systems in various operational contexts.

5.1.5. Handling Uncertainty with Data-Driven Robust Optimization

Uncertainty management is a recurring theme across many of these studies, regardless of the specific focus. Whether managing renewable energy variability or dealing with market price fluctuations, ML is central to building models that can anticipate and respond to unpredictability. The use of distributionally robust optimization (DRO) by Siqin et al. (2022) [69], Yang et al. (2023) [68], and L. Zheng et al. (2024) [85] showcases how robust models can mitigate risks associated with wind and solar generation. Similarly, deep reinforcement learning (DRL), as used by Liang et al. (2024) [74] and B. Zhang et al. (2023) [75], allows for real-time adaptation to fluctuating energy supply and demand. In predictive diagnostics, Zaveri et al. (2023) [79] and Ma et al. (2022) [80] demonstrate how ML can anticipate failures in PEMFCs, improving system stability.

Also, Fan et al. (2023) [86] developed a two-stage distributionally robust optimization (TSDRO) model for integrated energy system groups (IESGs), focusing on energy sharing and carbon transfer under wind and photovoltaic power uncertainties. The model utilizes kernel density estimation (KDE) and the Wasserstein metric to construct fuzzy uncertainty sets, achieving a balance between robustness and economic efficiency. Similarly, Gao et al. (2022) [87] introduced a data-driven DDRO model for urban integrated energy systems, focusing on wind-power uncertainty. They employed techniques such as KDE and the Wasserstein metric to improve resource utilization and system robustness in PtG applications.

The application of ML in PtG systems has addressed key challenges, such as optimizing energy flows, managing uncertainty, and integrating multi-energy systems. Studies utilizing techniques like deep reinforcement learning, distributionally robust optimization, and predictive diagnostics have demonstrated improvements in system flexibility, reliability, and operational efficiency. The studies, however, could not be limited to the proposed categorization as the applications of ML could be so diverse and innovative, still related to the field. For example, Lakhmi et al. (2024) [88] presented another use of ML in process monitoring, focusing on a gas sensor array designed to control PtX processes. Using both linear models (Partial Least Squares) and non-linear models (ANNs), they showed that ANN models provided more accurate predictions for methane concentrations, offering superior performance for process control applications.

Furthermore, ML has shown potential in enhancing market integration and handling renewable energy variability. The literature, as summarized in the Table 1, suggests that as PtG systems grow more complex, ML will be crucial in advancing their capabilities to meet future energy demands and decarbonization goals.

Table 1.

Key findings from the recent literature on ML and PtG systems.

5.2. Machine Learning and Power-to-Liquid Systems

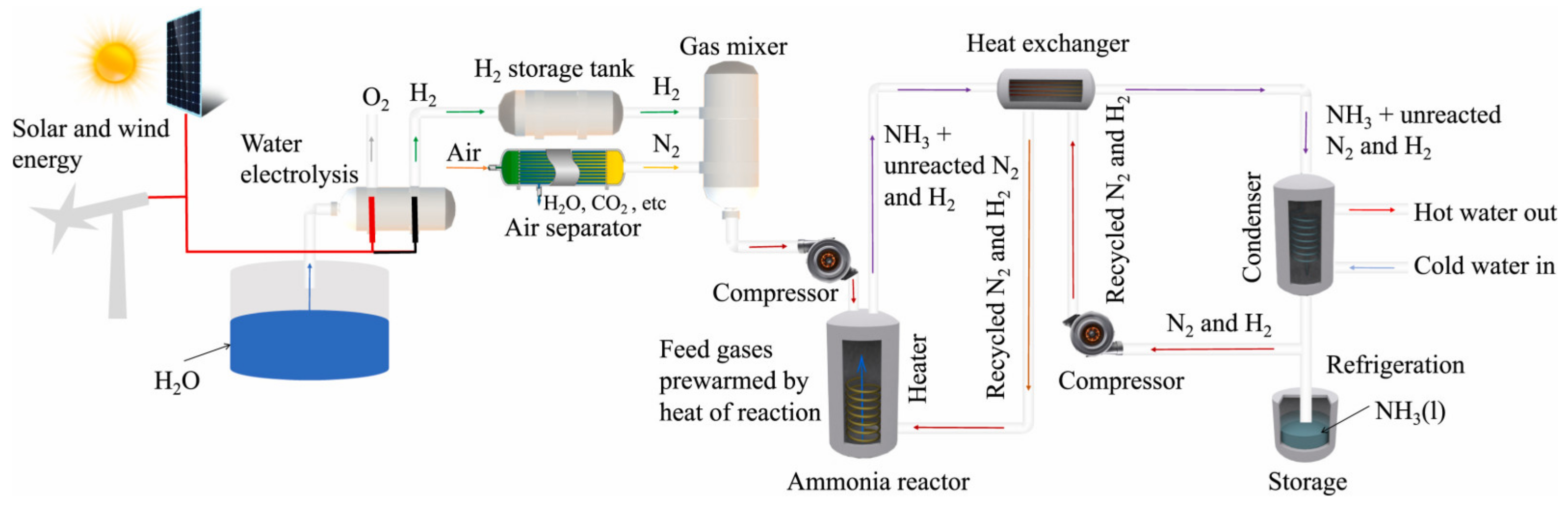

PtL systems are an innovative approach to converting renewable energy into liquid fuels, utilizing surplus electricity to synthesize hydrocarbons, methanol, and ammonia. These processes typically involve using renewable electricity for water electrolysis to produce hydrogen, which is then combined with captured CO2 in processes like Fischer–Tropsch synthesis to create carbon-neutral fuels, such as methanol or synthetic diesel. Ammonia is also increasingly produced in PtL systems, serving as a carbon-free hydrogen carrier with advantages in storage and transportation. Recent advancements, such as plasma-assisted ammonia synthesis, enhance the efficiency of ammonia production at lower temperatures and pressures, reducing the energy footprint [89,90]. PtL fuels can be seamlessly integrated into existing fuel infrastructure, supporting decarbonization in sectors like aviation, shipping, and heavy industry. These systems offer flexibility in fuel production while helping close the carbon cycle by using captured CO2 or nitrogen, making them a key solution for achieving net-zero emissions in hard-to-abate sectors.

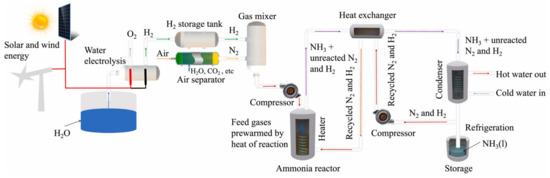

Green ammonia is emerging as a key hydrogen carrier due to its high hydrogen content, low flammability, and established transport infrastructure, making it vital for industries such as fertilizers and fuel cells. Its potential to reduce energy consumption and emissions is significant. Catalytic decomposition using nickel-based catalysts is noted for its cost-effectiveness in large-scale hydrogen production, and ML aids in optimizing these catalysts by simulating reaction mechanisms [91,92]. Recent advancements in green ammonia synthesis emphasize its role in sustainable energy due to its low-carbon footprint and compatibility with renewable energy sources. Deng et al. (2024) [92] proposed a physics-informed sparse identification model for optimizing reactor design, enhancing ammonia yield using a bald-eagle search algorithm. Similarly, Zeng et al. (2023) [93] employed plasma catalysis under low-temperature pulsed plasmas, optimizing parameters through a Bayesian neural network to improve energy efficiency. These studies collectively advance green ammonia synthesis by integrating ML and optimization techniques to boost yield and sustainability. A schematic of green ammonia synthesis process is shown in Figure 9.

Figure 9.

Schematic of green ammonia synthesis process. Reprinted with permission from [92].

Power-to-Ammonia (PtA) technology provides a practical solution for converting surplus renewable energy into ammonia, a fuel that is both storable and transportable, offering a means to enhance the stability of multi-energy systems. In recent research, PtA is being integrated into energy hubs that combine renewable power sources with advanced energy storage and management systems. These hubs are optimized to address the intermittent nature of renewable energy by converting it into green ammonia, which can later be used for power generation or other applications. In this context, studies have focused on designing energy-efficient, cost-effective solutions to improve the operation of PtA systems within multi-energy hubs, particularly in terms of energy conversion efficiency and system scalability [94,95]. Innovations in PtA system integration are not only improving energy efficiency but also unlocking new strategies for managing complex energy flows in real-time. By leveraging advanced optimization algorithms, such as deep reinforcement learning, these systems are becoming increasingly adept at responding to the variability of renewable energy, as demonstrated by recent studies.

In their study, Xiong et al. (2023) [94] propose a coordinated energy management strategy for a renewable-powered multi-energy hub that incorporates PtA technology. Their system employs a multi-agent deep reinforcement learning (DRL) algorithm to optimize energy flow, ensuring that the hub can efficiently handle fluctuating renewable energy inputs, such as wind and solar. The use of the DRL algorithm significantly enhances the hub’s ability to minimize operational costs and carbon dioxide emissions, while also maximizing ammonia production. On the other hand Qi et al. (2022) [95] presented a different approach by proposing an energy hub that integrates PtA with liquid air energy storage (LAES) technology. Their system is designed to co-produce green ammonia and electricity, using a surrogate-based optimization method to achieve cost-optimal configurations. By combining LAES with PtA, the system enhances its flexibility and performance, allowing it to store excess renewable energy and generate power on demand.

Ammonia-fueled solid oxide fuel cells (SOFCs) offer the ability to directly convert ammonia into electricity with high efficiency and lower carbon emissions. These systems are particularly attractive due to ammonia’s high energy density and ease of storage compared to hydrogen. However, challenges remain in optimizing their performance, particularly in managing the high temperatures generated during ammonia decomposition and improving overall system efficiency. Yanchen Lai et al. (2023) [96] have addressed this by investigating the thermal management of ammonia-fueled tubular SOFCs, focusing on the impact of ammonia cracking reactions within the fuel cell. Their study develops a thermal management model, proposing pre-reforming techniques and optimized reaction activation energy to improve temperature distribution and reduce thermal stress. Meanwhile, Y. Du et al. (2023) [97] propose a novel SOFC and rotary engine system, integrating hydrogen regeneration to enhance part-load performance. Using a data-driven model, they optimize the system’s efficiency, showing significant improvements in energy output, particularly at partial loads.

While ammonia has gained significant attention in PtL technologies, PtL systems are versatile and can produce a variety of fuels, including hydrogen, methanol, and hydrocarbons. Recent research has focused on optimizing these systems using ML and advanced optimization techniques to enhance their efficiency and flexibility. For example, Ahbabi Saray et al. (2024) [98] developed a system that produces both liquid hydrogen and ammonia using renewable energy, employing artificial neural networks (ANNs) and genetic algorithms (GAs) for optimization. Their system not only efficiently balances the production of hydrogen and ammonia but also addresses multiple energy needs, such as cooling and freshwater generation. Also, Zhao et al. (2024) [99] focus on hydrogen production through solar-assisted methanol steam reforming, optimizing key operational factors using a GA–Back Propagation Neural Network (GA-BPNN) model. Expanding PtL beyond ammonia and hydrogen, Mohammad Nezhad et al. (2024) [100] optimized a Fischer–Tropsch process for hydrocarbon fuel production in small-scale PtL plants. Using surrogate models and genetic algorithms, they enhance the efficiency of the fuel production system, which offers a compact and localized energy storage solution. The key findings related to ML applications in Power-to-Liquid Systems are summarized in Table 2.

Table 2.

Key findings from the recent literature on machine learning and Power-to-Liquid systems.

5.3. Advances in Sustainable Combustion and Fuel Optimization for Next-Generation Engines

The transition to sustainable combustion will depend heavily on the interplay between hydrogen and carbon-based fuels, each offering unique advantages and challenges. Hydrogen’s potential as a clean fuel is promising due to its versatility and low carbon footprint, but its combustion presents technical hurdles, such as flame instability and nitrogen oxide emissions. Meanwhile, carbon-based fuels, especially those derived from renewable sources, provide higher energy densities, making them indispensable for sectors like aviation. However, their reliance on carbon capture and the complexity of their combustion processes necessitate advanced computational methods, including ML, for optimizing fuel efficiency and minimizing emissions. As highlighted by Pitsch (2024) [101], both hydrogen- and carbon-based fuels require innovative approaches in fuel technology and computational modeling to drive the transition toward sustainable combustion.

To fully leverage hydrogen’s potential as a clean fuel, its production and distribution systems must be optimized. In particular, managing hydrogen refueling stations is critical, where fluctuating demand and integration with renewable energy sources create operational challenges. Huy et al. (2024) [102] address this issue by implementing Generative Adversarial Imitation Learning (GAIL) to optimize real-time energy management, improving decision-making by mimicking expert strategies to balance hydrogen production with electricity generation.

ML’s role in combustion modeling is equally crucial, particularly for hydrogen- and carbon-based fuels. Traditional computational models struggle with non-linear interactions like flame instability, but ML offers a solution by enhancing combustion simulations with data-driven approaches. As Pitsch (2024) [101] notes, integrating ML with physics-based models is essential for optimizing fuel design, enhancing combustion efficiency, and reducing emissions. Expanding on this, Kale et al. (2023) [103] explored the stability of hydrogen–CNG-powered vehicles, using advanced control techniques such as MIMO system models and transfer functions to ensure operational feasibility in hybrid fuel systems. Building on this, Sadeq et al. [104] developed machine-learning models for predicting flame radius evolution and turbulent flame speeds in gas-to-liquid (GTL) fuel combustion. These models demonstrated superior accuracy and efficiency compared to traditional CFD methods, offering insights that can optimize the performance of alternative fuels like GTL in sustainable combustion systems. The use of ML to model complex combustion dynamics further highlights its potential for improving fuel efficiency and reducing emissions in next-generation fuels, including hydrogen and biofuels.

Recent advancements in engine design further underscore the importance of ML in combustion systems. Sapra et al. (2024) [105] applied computational fluid dynamics (CFD) and Gaussian Process Regression (GPR) to optimize piston-bowl geometries for energy-assisted compression ignition using low-cetane sustainable aviation fuel blends. This integration significantly reduces ignition delays and improves fuel efficiency, particularly under high-altitude and high-load conditions. Similarly, Narayanan et al. (2024) [106] developed the Misfire-Integrated Gaussian Process (MInt-GP) emulator to enhance control systems for jet fuels with varying cetane numbers, offering up to 80 times faster computation than traditional CFD methods, thus reducing the cost and time associated with engine control system training.

Finally, ML plays a key role in evaluating the environmental impact of alternative fuels. Ahmed et al. (2023) [107] used supervised ML models, including random forest, decision tree, and XGBoost, to assess the life-cycle impact of offshore vessels powered by LNG and green ammonia. The study found that green ammonia-powered vessels exhibited lower global warming potential and emissions compared to conventional fuels, with XGBoost outperforming other models in predictive accuracy, providing a robust framework for environmental impact assessments.

Sustainable Aviation Fuel (SAF)

Production of sustainable liquid fuels can be classified under PtL processes. According to L. Yang et al. (2023) [108], who presented a comprehensive framework to quantify CO2 emissions from China’s civil aviation industry up to 2050 by using a combination of Backpropagation Neural Network (BPNN) and Monte Carlo simulations, addressing the uncertainties in future aviation demand and policy changes is crucial for meeting decarbonization goals. Their analysis shows that while sustainable aviation fuels (SAFs) are pivotal to reducing emissions, achieving carbon neutrality by 2050 will require SAFs to account for up to 70% of aviation fuel. In addition to SAF adoption, innovations in aircraft technology, carbon capture methods, and carbon trading mechanisms will be essential to offset emissions and meet global targets. This highlights the growing role of ML in not only forecasting emissions but also optimizing the integration of SAFs into the aviation fuel mix.

In line with these findings, F. Wang and Rijal (2024) [109] further explored the potential of sustainable aviation fuels by focusing on strained hydrocarbons and cycloalkanes as promising SAF candidates due to their high energy density and efficient combustion properties. Their study employed ML techniques such as quantum chemistry-based simulations and neural networks to optimize molecular structures, enhancing fuel stability, energy density, and combustion efficiency. They emphasized the importance of addressing production challenges, providing a detailed technoeconomic assessment based on life-cycle assessment (LCA) and production cost models, which evaluate the scalability and economic viability of SAF production. While their results show that these SAFs offer significant performance advantages, scaling up production remains a challenge due to high initial costs.

The key findings related to the applications of ML in sustainable aviation fuels are summarized in Table 3.

Table 3.

Key findings from the recent literature on the applications of ML in sustainable aviation fuel (SAF).

5.4. Machine Learning and Power-to-Heat

PtH systems convert excess electricity, typically from renewable sources like wind or solar, into heat, which can be used for space heating and industrial processes or stored in district heating systems. These systems help balance electricity grids by utilizing surplus energy during periods of high renewable generation and low demand. PtH technologies, such as electric boilers and heat pumps, can be integrated into district heating networks, providing flexibility by shifting energy between the electricity and heat sectors. Furthermore, as highlighted in recent studies, such as the one by Liu et al. (2023) [110], buildings themselves can offer flexibility services to the grid by integrating PtH systems with model predictive control and leveraging thermal inertia. This allows buildings to modulate energy consumption in response to fluctuating energy prices and renewable availability, further enhancing grid stability. By replacing fossil fuel-based heat production, PtH technologies contribute to decarbonization and reduce greenhouse gas emissions in the heating sector. Studies have shown that PtH systems can significantly reduce wind and solar curtailment and lower operational costs for energy systems, especially when integrated with thermal storage [111,112].