Modest Method for Estimating CO2 Emissions from Container Handling Equipment at Ports

Abstract

1. Introduction

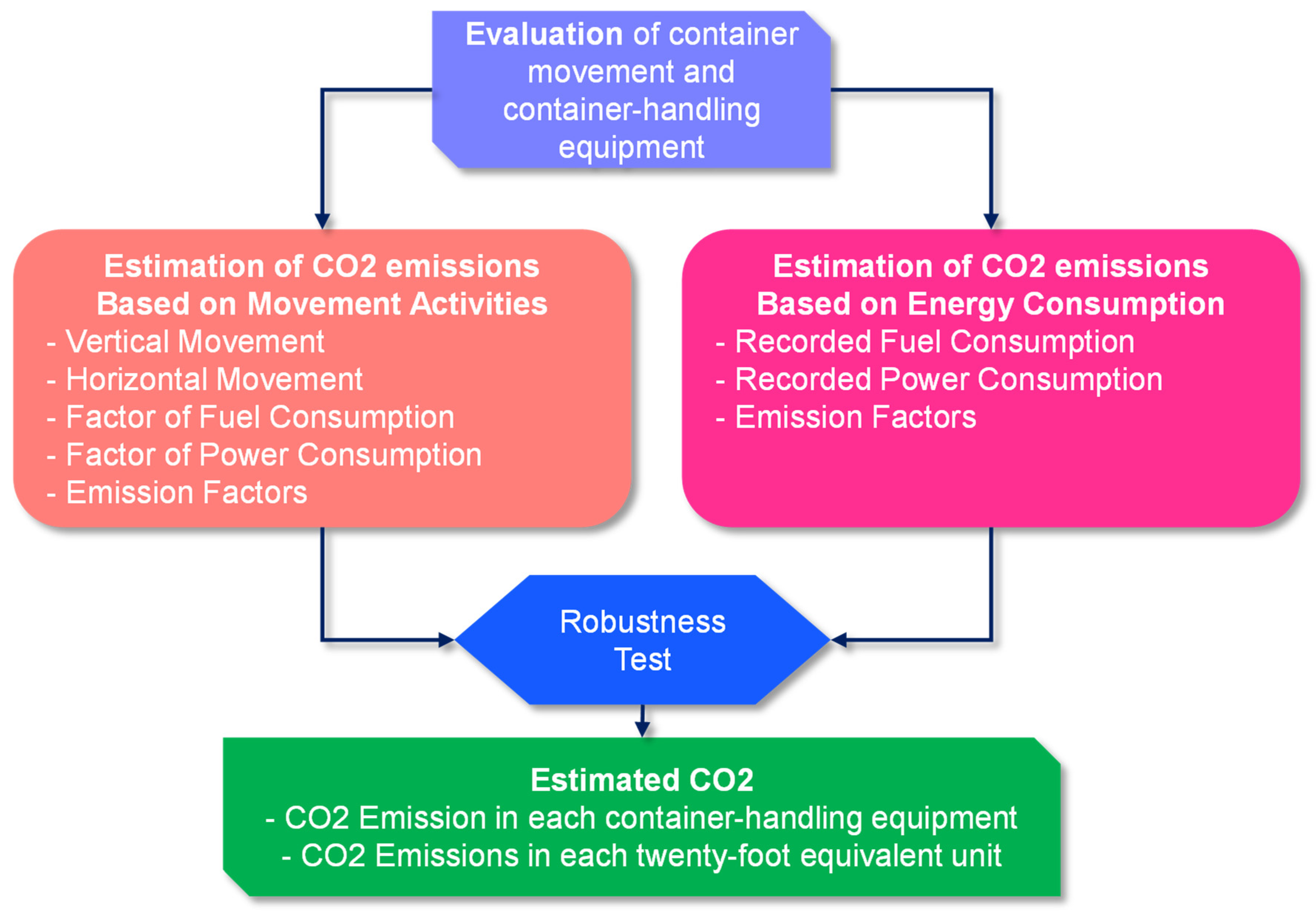

2. Methodology

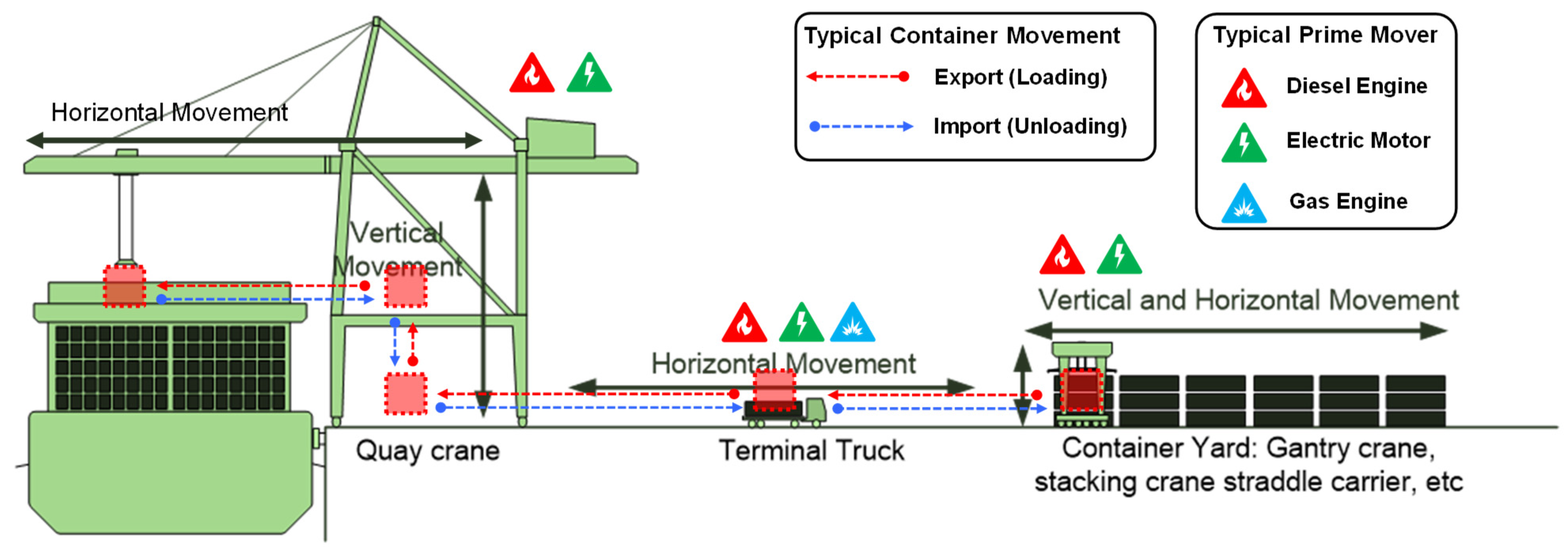

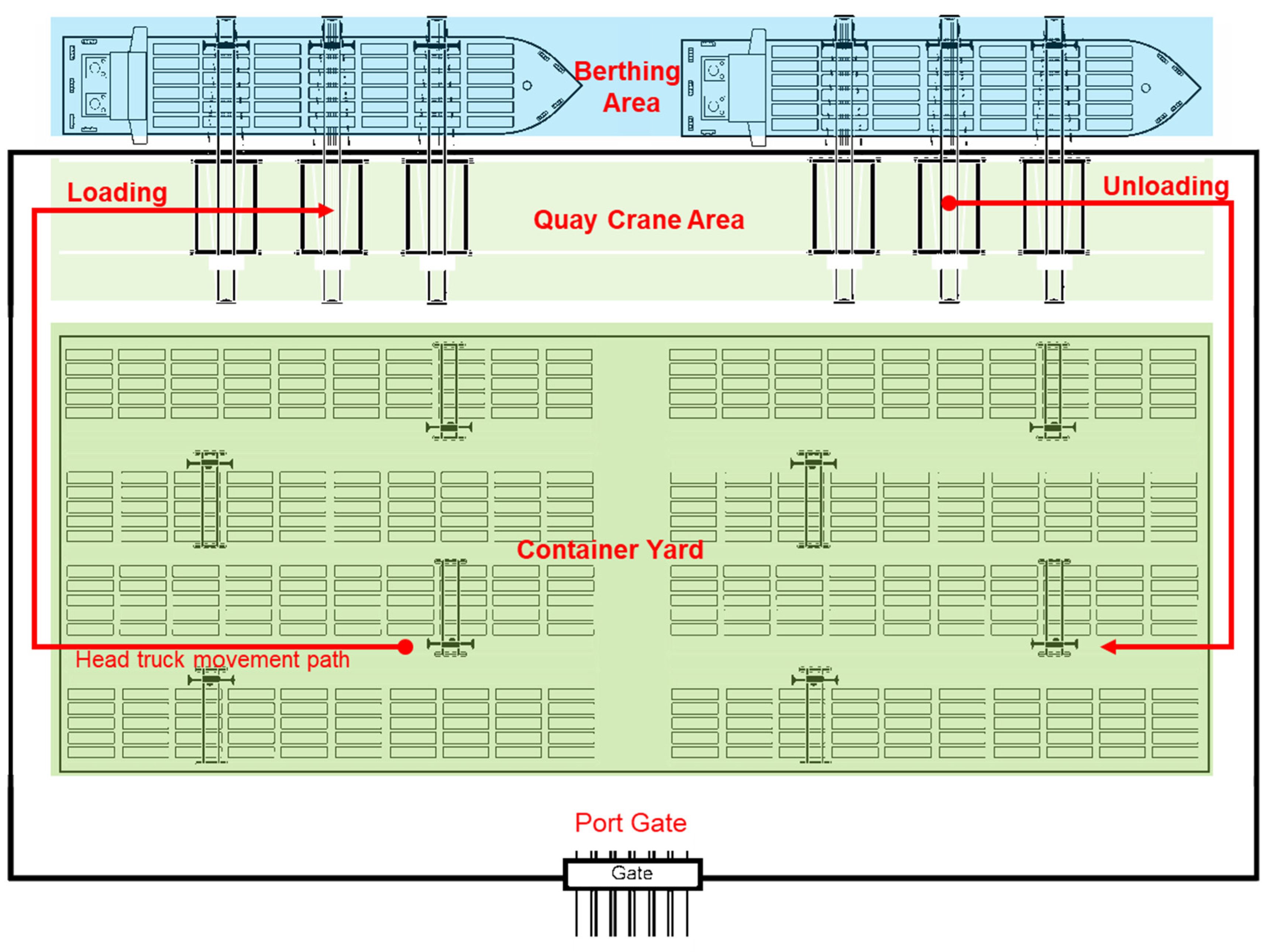

2.1. Evaluation of Container Movement and Cargo Handling Equipment at Container Ports

2.2. CO2 Emission Estimation Method Based on Container Movement

2.3. CO2 Emission Estimation Method Based on Recorded Energy Consumption

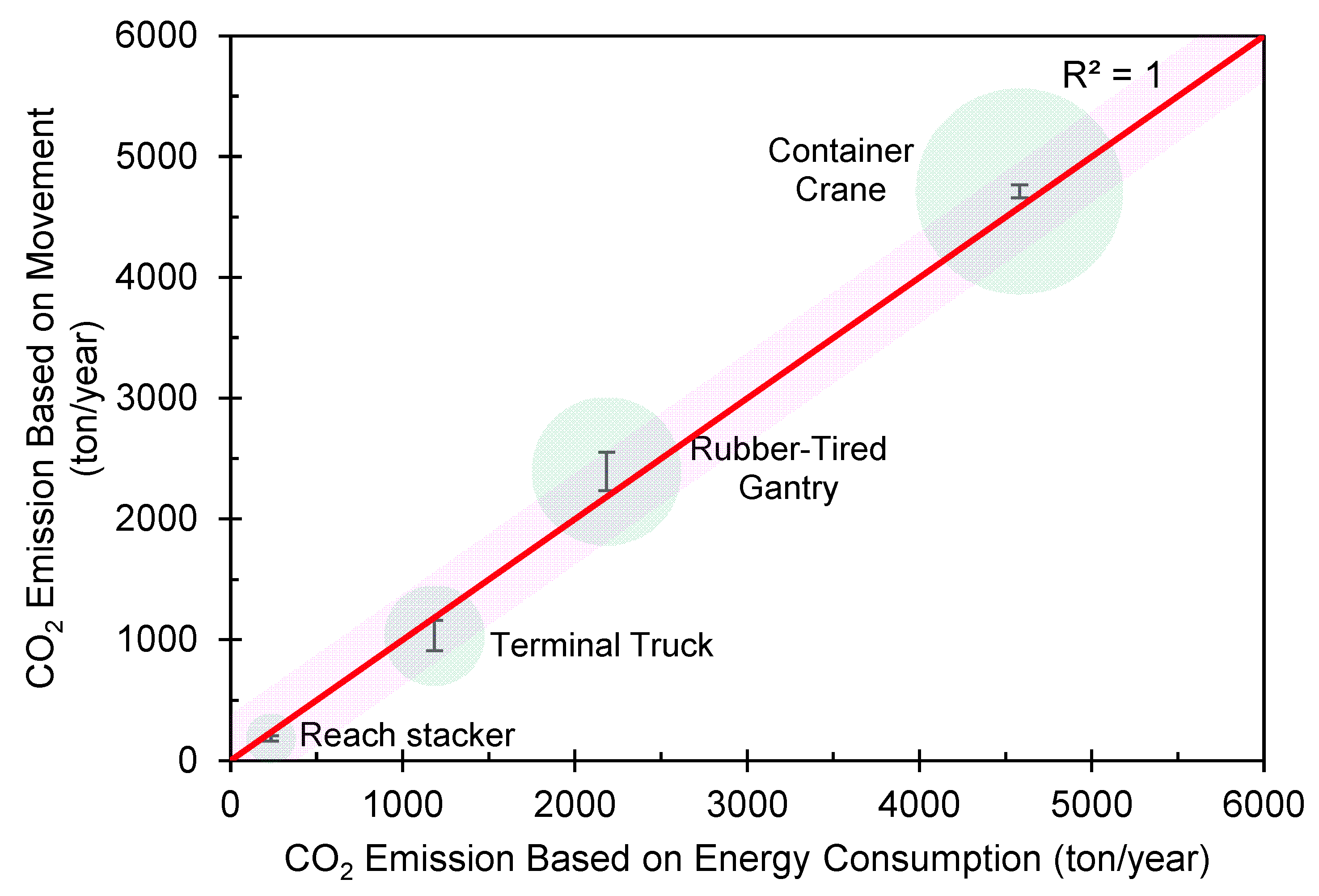

2.4. Robustness Test

2.5. Case Study of Typical Container Port Operation

3. Results and Discussions

3.1. Estimation of Results of CO2 Emissions

3.2. Robustness of the Proposed Models

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walker, T.R.; Adebambo, O.; Feijoo, M.C.; Elhaimer, E.; Hossain, T.; Edwards, S.J.; Morrison, C.E.; Romo, J.; Sharma, N.; Taylor, S.; et al. Environmental Effects of Marine Transportation. In World Seas: An Environmental Evaluation Volume III: Ecological Issues and Environmental Impacts; Academic Press: Cambridge, MA, USA, 2019; pp. 505–530. [Google Scholar] [CrossRef]

- Notteboom, T.; Pallis, A.; Rodrigue, J.-P. Port Economics, Management and Policy; Routledge: London, UK, 2022. [Google Scholar] [CrossRef]

- Neves, R.A.; Lopes, A.; Naveira, C.; Rodrigues, N.; Silveira, R.B.; Guimarães, T.; Filardi, F.; Santos, L.N. Socio-economic impacts of a maritime industrial development area (MIDA) model in Latin America: The case of the Açu Port-Industrial Complex. WMU J. Marit. Aff. 2022, 21, 351–368. [Google Scholar] [CrossRef]

- Tokuslu, A. Estimating greenhouse gas emissions from ships on four ports of Georgia from 2010 to 2018. Environ. Monit. Assess. 2021, 193, 385. [Google Scholar] [CrossRef] [PubMed]

- International Maritime Organization (IMO). IMO’s Work to Cut GHG Emissions from Ships. Available online: https://www.imo.org/en/MediaCentre/HotTopics/Pages/Cutting-GHG-emissions.aspx (accessed on 11 November 2024).

- Romano, A.; Yang, Z. Decarbonisation of shipping: A state of the art survey for 2000–2020. Ocean Coast. Manag. 2021, 214, 105936. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Huzaifi, M.H.; Sirait, S.J.; Prayoga, P.H.N. Evaluation of CO₂ emissions and energy use with different container terminal layouts. Sci. Rep. 2021, 11, 5476. [Google Scholar] [CrossRef]

- Ros Chaos, S. The Transport and Environmental Impacts of Cruise Ships: Application to the Case of the Port of Barcelona. Ph.D. Thesis, Departament d’Enginyeria Civil i Ambiental, Universitat Politècnica de Catalunya (UPC), Barcelona, Spain, 2020. Available online: http://hdl.handle.net/2117/340974 (accessed on 11 November 2024). [CrossRef]

- Azarkamand, S.; Wooldridge, C.; Darbra, R.M. Review of initiatives and methodologies to reduce CO2 emissions and climate change effects in ports. Int. J. Environ. Res. Public Health 2020, 17, 3858. [Google Scholar] [CrossRef]

- Azarkamand, S. Development of a Standardized Tool to Calculate Carbon Footprint in Ports. Ph.D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2021. Available online: https://upcommons.upc.edu/handle/2117/360344 (accessed on 11 November 2024).

- Misra, A.; Panchabikesan, K.; Ayyasamy, E.; Ramalingam, V. Sustainability and Environmental Management for Ports. In International Solutions to Sustainable Energy, Policies and Applications; River Publishers: Aalborg, Denmark, 2020; pp. 303–320. [Google Scholar]

- Roh, S.; Thai, V.V.; Jang, H.; Yeo, G.T. The best practices of port sustainable development: A case study in Korea. Marit. Policy Manag. 2023, 50, 254–280. [Google Scholar] [CrossRef]

- Yang, Y.C.; Chang, W.M. Impacts of electric rubber-tired gantries on green port performance. Res. Transp. Bus. Manag. 2013, 8, 67–76. [Google Scholar] [CrossRef]

- Lee, H.; Park, D.; Choo, S.; Pham, H.T. Estimation of the Non-Greenhouse Gas Emissions Inventory from Ships in the Port of Incheon. Sustainability 2020, 12, 8231. [Google Scholar] [CrossRef]

- Chen, S.; Meng, Q.; Jia, P.; Kuang, H. An operational-mode-based method for estimating ship emissions in port waters. Transp. Res. Part D Transp. Environ. 2021, 101, 103080. [Google Scholar] [CrossRef]

- Iris, Ç.; Lam, J.S.L. A review of energy efficiency in ports: Operational strategies, technologies and energy management systems. Renew. Sustain. Energy Rev. 2019, 112, 170–182. [Google Scholar] [CrossRef]

- He, J.; Huang, Y.; Yan, W.; Wang, S. Integrated internal truck, yard crane and quay crane scheduling in a container terminal considering energy consumption. Expert. Syst. Appl. 2015, 42, 2464–2487. [Google Scholar] [CrossRef]

- Yao, L.; Ng, A.K.; Liu, B.; Li, D.; Feng, L. A study on multiple types of yard cranes rescheduling in ports considering carbon emission. Marit. Policy Manag. 2024, 7, 1–35. [Google Scholar] [CrossRef]

- Sha, M.; Zhang, T.; Lan, Y.; Zhou, X.; Qin, T.; Yu, D.; Chen, K. Scheduling optimization of yard cranes with minimal energy consumption at container terminals. Comput. Ind. Eng. 2017, 113, 704–713. [Google Scholar] [CrossRef]

- Zeng, Y.; Yuan, X.; Hou, B. Analysis of Carbon Emission Reduction at the Port of Integrated Logistics: The Port of Shanghai Case Study. Sustainability 2023, 15, 10914. [Google Scholar] [CrossRef]

- Yang, Y.C. Operating strategies of CO2 reduction for a container terminal based on carbon footprint perspective. J. Clean. Prod. 2017, 141, 472–480. [Google Scholar] [CrossRef]

- Yu, H.; Ge, Y.E.; Chen, J.; Luo, L.; Tan, C.; Liu, D. CO₂ emission evaluation of yard tractors during loading at container terminals. Transp. Res. D Transp. Env. 2017, 53, 17–36. [Google Scholar] [CrossRef]

- Tan, C.; Qin, T.; He, J.; Wang, Y.; Yu, H. Yard space allocation of container port based on dual cycle strategy. Ocean Coast. Manag. 2024, 247, 106915. [Google Scholar] [CrossRef]

- 2006 IPCC Guidelines for National Greenhouse Gas Inventories—IPCC n.d. Available online: https://www.ipcc.ch/report/2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 24 January 2024).

- Geerlings, H.; van Duin, R. A new method for assessing CO2 -emissions from container terminals: A promising approach applied in Rotterdam. J. Clean. Prod. 2011, 19, 657–666. [Google Scholar] [CrossRef]

- Martínez-Moya, J.; Vazquez-Paja, B.; Gimenez Maldonado, J.A. Energy efficiency and CO2 emissions of port container terminal equipment: Evidence from the Port of Valencia. Energy Policy 2019, 131, 312–319. [Google Scholar] [CrossRef]

- Hasan, K.R.; Zhang, W.; Shi, W. A Sustainable Port-Hinterland Container Transport System: The Simulation-Based Scenarios for CO2 Emission Reduction. Sustainability 2023, 15, 9444. [Google Scholar] [CrossRef]

- Rijsenbrij, J.C.; Wieschemann, A. Automation and electric drives: A powerful union for sustainable container terminal design. In Handbook of Terminal Planning; Operations Research/Computer Science Interfaces Series; Springer: Berlin/Heidelberg, Germany, 2020; pp. 101–123. [Google Scholar] [CrossRef]

- Vlahopoulos, D.; Bouhouras, A.S. Solution for RTG crane power supply with the use of a hybrid energy storage system based on literature review. Sustain. Energy Technol. Assess. 2022, 52, 102351. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). IPCC Guidelines for National Greenhouse Gas Inventories. Intergovernmental Panel on Climate Change (IPCC). 2006. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/ (accessed on 19 November 2024).

- Ministry of Energy and Mineral Resources (ESDM RI). Greenhouse Gas (GHG) Emission Factor for the National Power Grid System. 2019. Available online: https://gatrik.esdm.go.id/assets/uploads/download_index/files/96d7c-nilai-fe-grk-sistem-ketenagalistrikan-tahun-2019.pdf (accessed on 11 November 2024).

- Huzaifi, M.H.; Budiyanto, M.A.; Sirait, S.J. Study on the carbon emission evaluation in a container port based on energy consumption data. Evergreen 2020, 7, 97–103. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Huzaifi, M.H.; Sirait, S.J. Estimating of CO2 Emissions in a container port based on modality movement in the terminal area. Int. J. Technol. 2019, 10, 1618–1625. [Google Scholar] [CrossRef]

- Papaioannou, V.; Pietrosanti, S.; Holderbaum, W.; Becerra, V.M.; Mayer, R. Analysis of energy usage for RTG cranes. Energy 2017, 125, 337–344. [Google Scholar] [CrossRef]

- Kastner, M.; Jahn, C. Impact of Rubber-Tired Gantry Crane Dimension on Container Terminal Productivity. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2022; Volume 13557, pp. 74–88. [Google Scholar] [CrossRef]

| Independent Variable | Dependent Variable | |

|---|---|---|

| Evaluation of container movement and cargo handling equipment. | ype of equipment (quay crane, terminal truck, and gantry crane) | CO2 emissions from equipment |

| CO2 emission estimation method based on container movement. | Number of movements, energy consumption variables for diesel and electricity, average distance traveled | Total CO2 emissions |

| CO2 emission estimation method based on recorded energy consumption. | Total recorded energy consumption from diesel and electrical sources CO2 emission factors for diesel and electrical sources | Total CO2 emissions |

| Distance calculations and layout considerations. | Terminal layout Type of movement (vertical, horizontal) | Travel distance (used for CO2 estimation) |

| Distance traveled by terminal trucks. | Container stacking area, dock area, and layout details | Distance traveled by terminal trucks |

| Terminal Characteristic | Container Terminal |

|---|---|

| Layout type | Parallel layout |

| Throughput | 526,039 TEUs/year |

| Wharf Data | |

| Length | 950 m |

| Width | 31 m |

| Depth | −10 m |

| Container Yard | |

| Area | 124,847 m2 |

| Capacity | 14,988 TEUs |

| Ground slot | 3342 TEUs |

| Reefer | 144 |

| Amount of Equipment | |

| Quay crane | 10 |

| RTG | 25 |

| Truck | 40 |

| Case Study | CO2 Emissions | Reference |

|---|---|---|

| Current study | 15.6 kg/TEU | |

| Rotterdam Shortsea Terminal, The Netherlands | 9.3 kg/TEU | [25] |

| Noatum Container Terminal, Valencia, Spain | 11.5 kg/TEU | [26] |

| Port of Vigo, Spain | 14.1 kg/TEU | [8] |

| Hanno Terminals, The Netherlands | 24.0 kg/TEU | [25] |

| Chittagong Container Terminal, Bangladesh | 26.5 kg/TEU | [27] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Budiyanto, M.A.; Ichfari, F.; Shinoda, T. Modest Method for Estimating CO2 Emissions from Container Handling Equipment at Ports. Sustainability 2024, 16, 10293. https://doi.org/10.3390/su162310293

Budiyanto MA, Ichfari F, Shinoda T. Modest Method for Estimating CO2 Emissions from Container Handling Equipment at Ports. Sustainability. 2024; 16(23):10293. https://doi.org/10.3390/su162310293

Chicago/Turabian StyleBudiyanto, Muhammad Arif, Faril Ichfari, and Takeshi Shinoda. 2024. "Modest Method for Estimating CO2 Emissions from Container Handling Equipment at Ports" Sustainability 16, no. 23: 10293. https://doi.org/10.3390/su162310293

APA StyleBudiyanto, M. A., Ichfari, F., & Shinoda, T. (2024). Modest Method for Estimating CO2 Emissions from Container Handling Equipment at Ports. Sustainability, 16(23), 10293. https://doi.org/10.3390/su162310293