Experimental Analysis of Mechanical Property Enhancement of Paper-Pulp-Based Packaging Materials Using Biodegradable Additives

Abstract

:1. Introduction

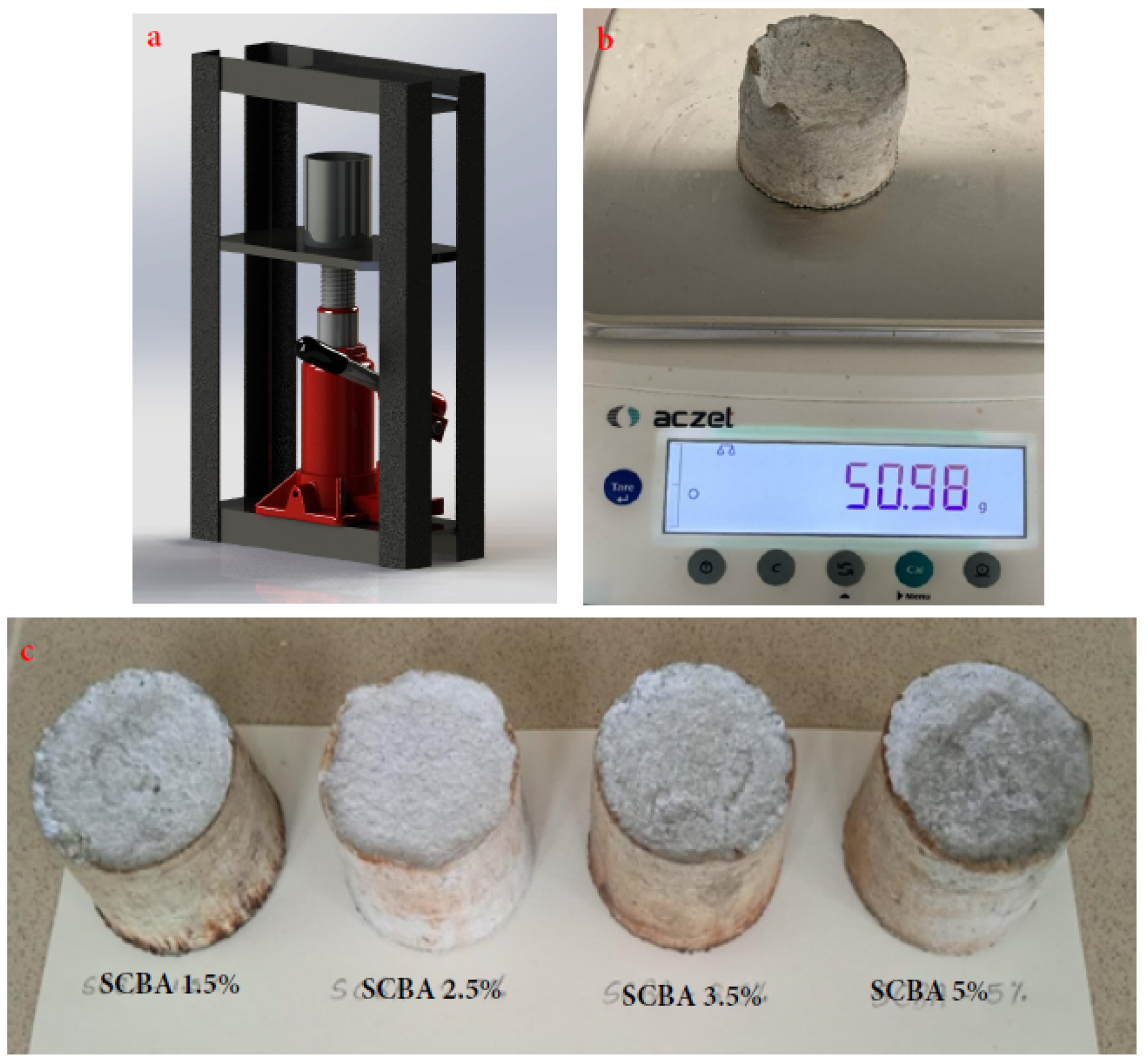

2. Methodology

- Waste papers: Collected internally from the university premises. All collected papers were used to prepare the pulp without undergoing any categorization process.

- Sugarcane bagasse ash: Fly ash was collected from Ethimale Plantation (Pvt) Ltd., located in the Monaragala district of Sri Lanka. The ash sample was sieved to obtain uniform particles with a mesh size of 200 µm.

- Wheat flour: Purchased locally.

- Water: Distilled water was used instead of tap water to prepare samples to minimize the potential effects of minerals mixed in regular water.

3. Results

3.1. Color and Shape of the Samples

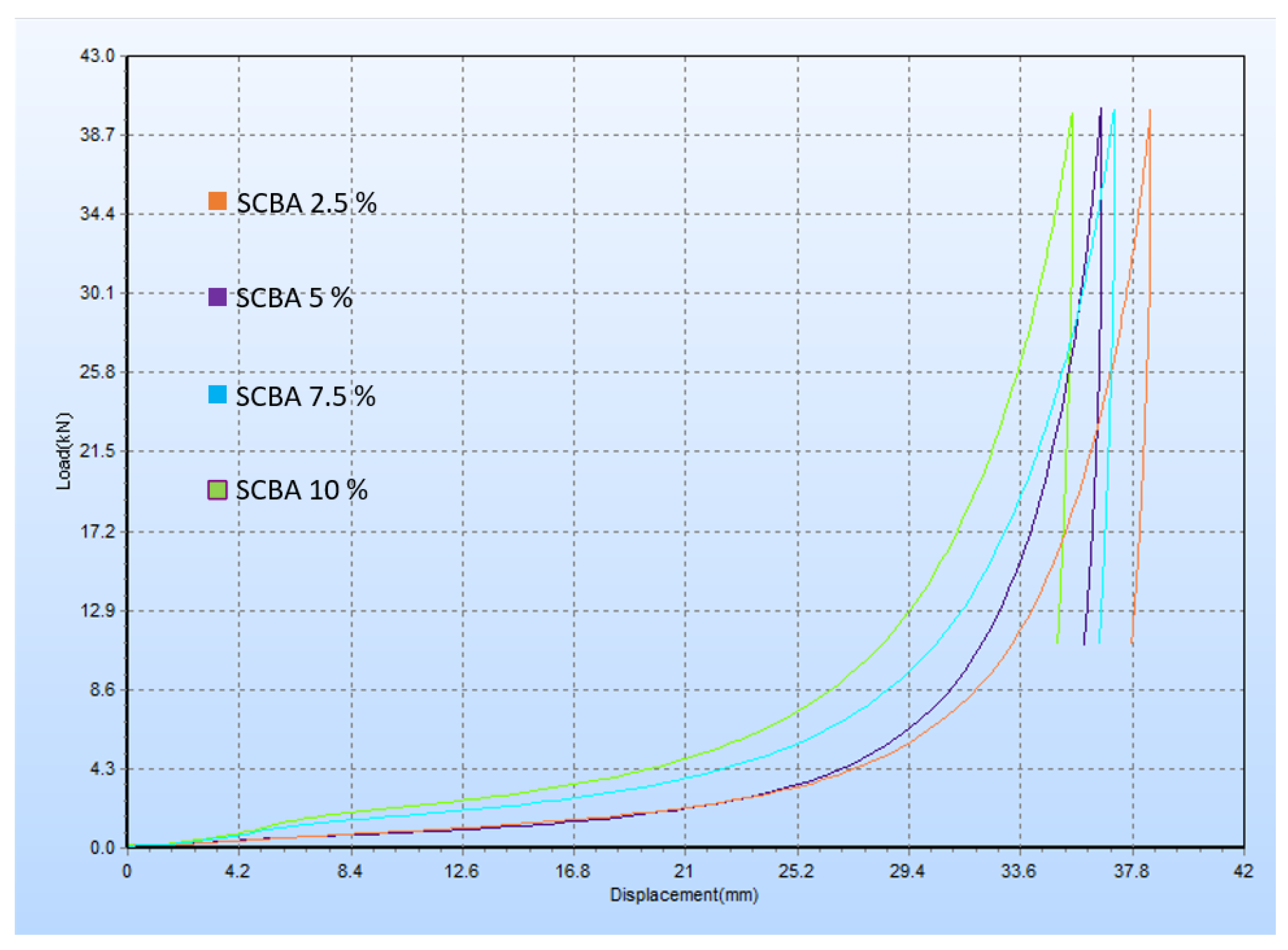

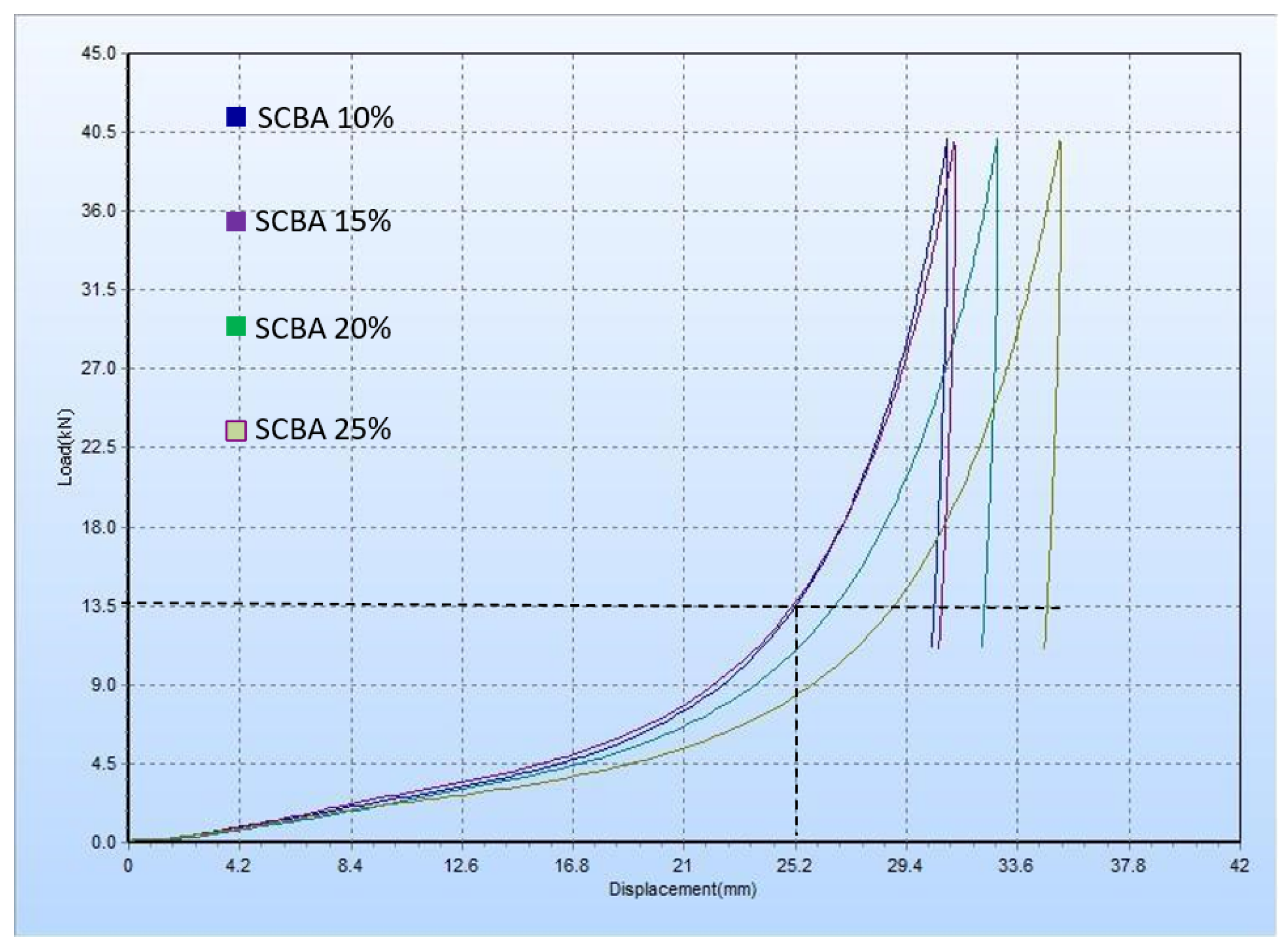

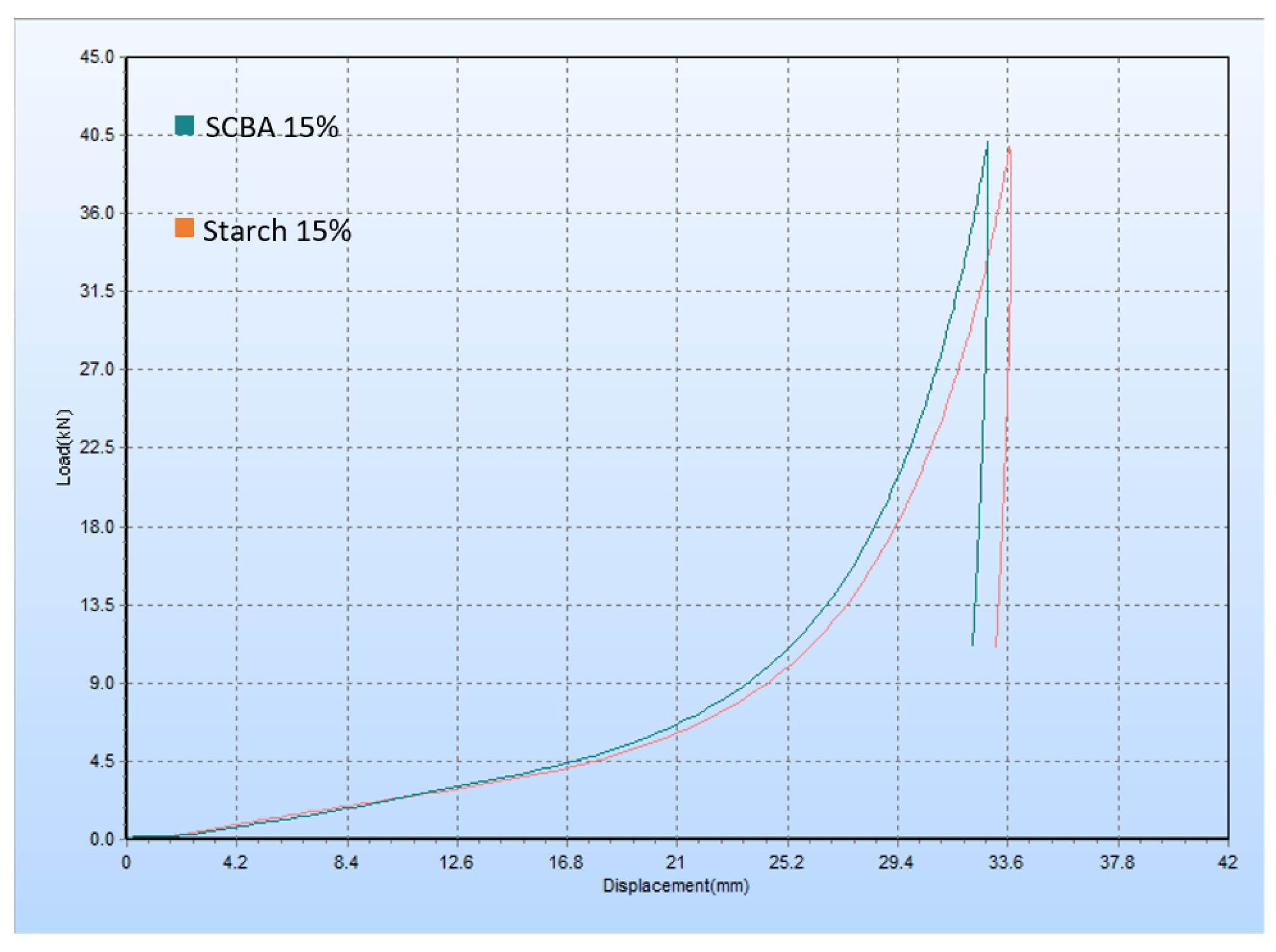

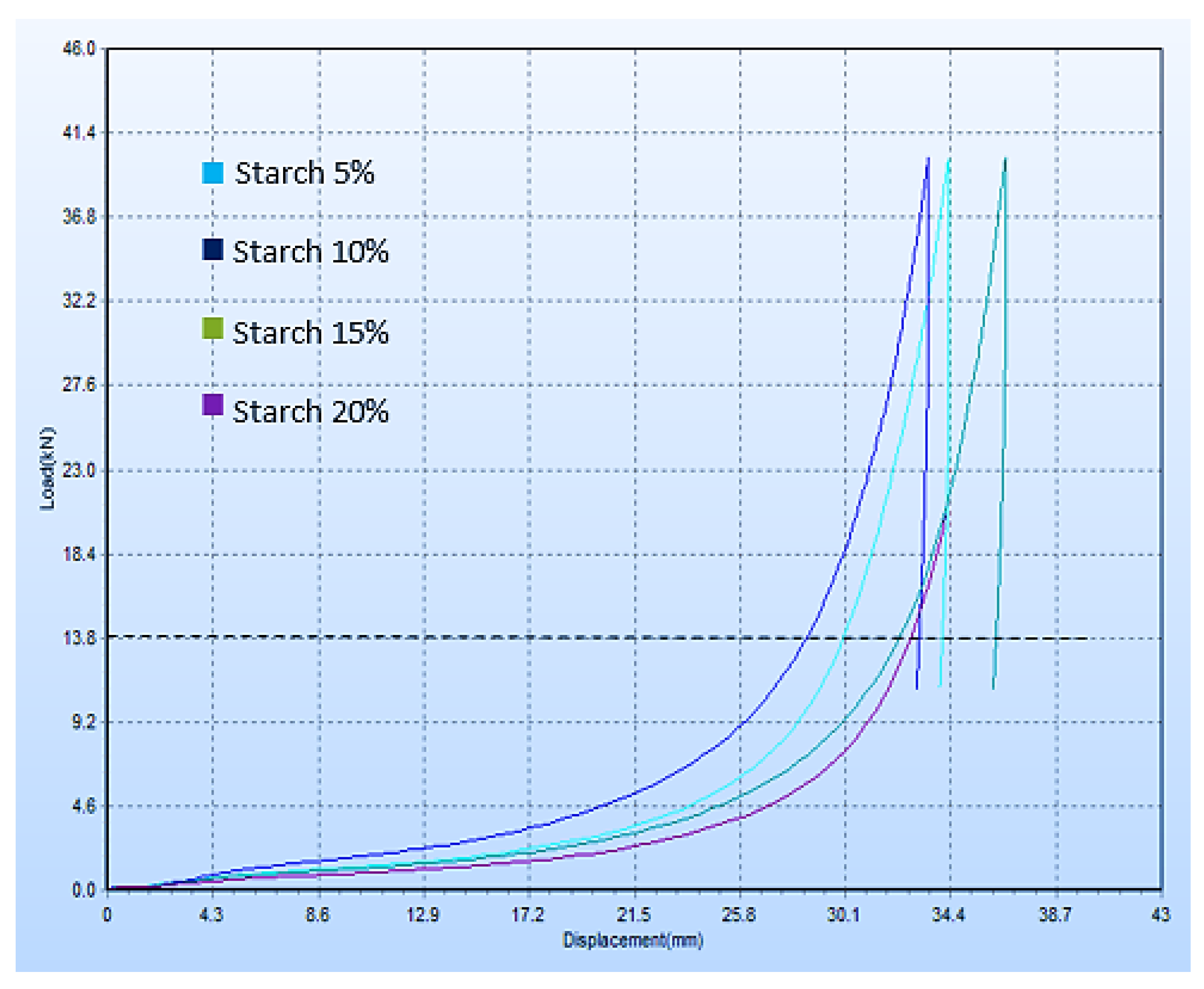

3.2. Compressive Strength Analysis

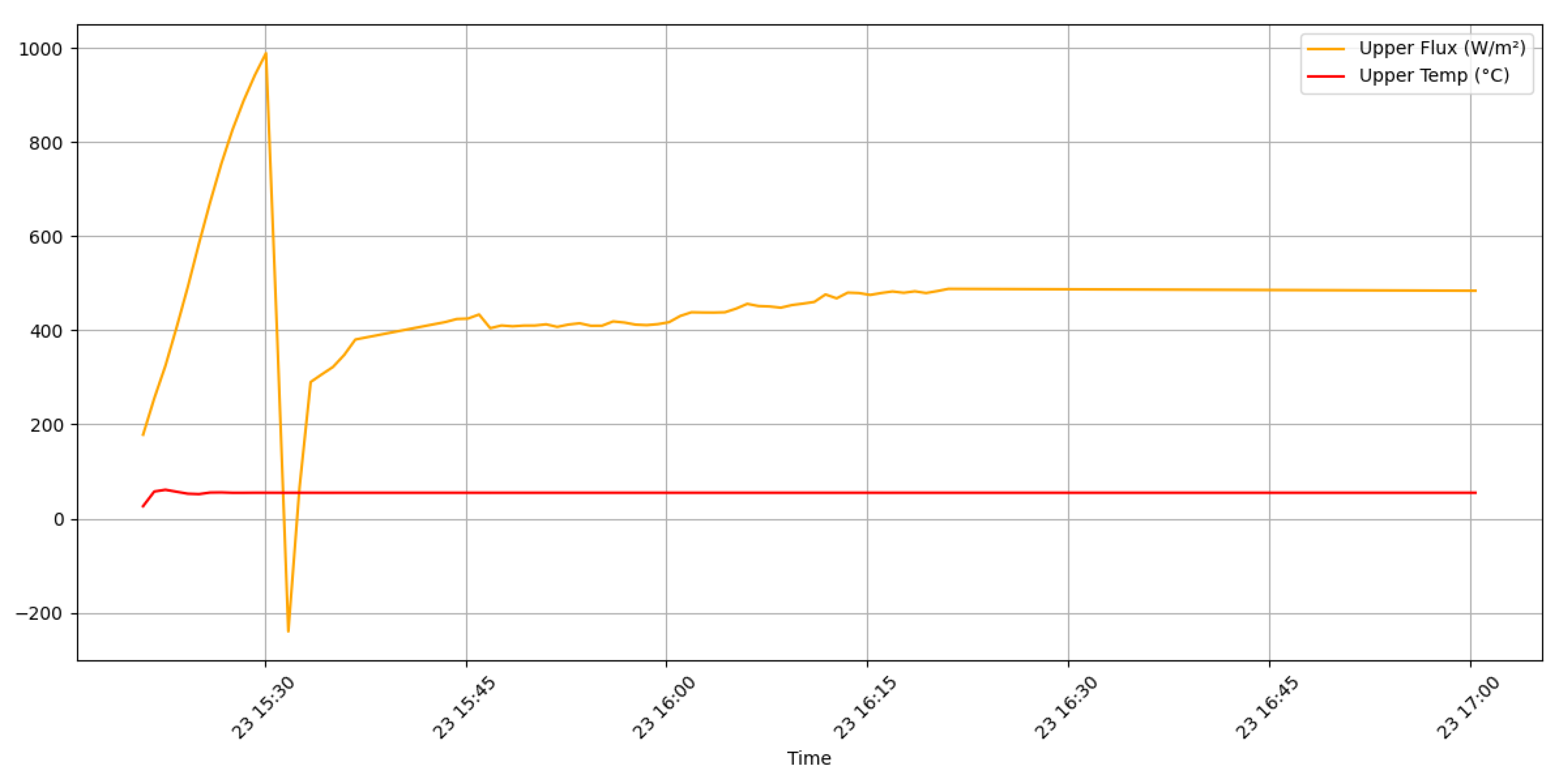

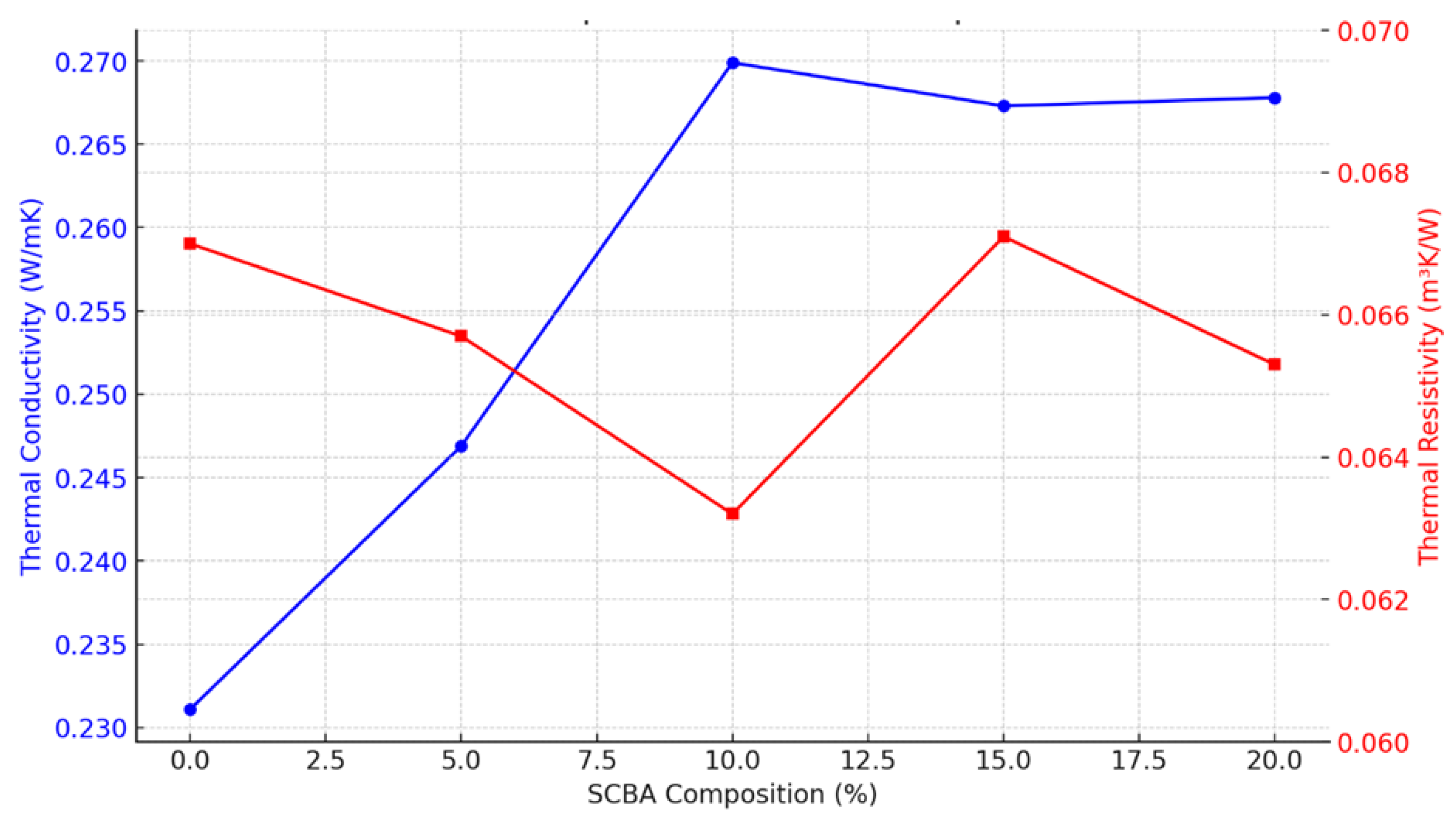

3.3. Thermal Resistivity Analyze

4. Conclusions

- Both SCBA and starch increased the compressive strength of paper composites when added as an additive. The SCBA-based paper pulp composite showed peak compressive strength in higher w% concentration compared to starch.

- There was no significant variation in strength of all compositions under lower compressive loads.

- SCBA performed better than starch as an additive in regards to the compressive strength of paper composite.

- Addition of SCBA resulted in an increase in the thermal conductivity of the paper. pulp material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Materials Research Forum LLC. Biodegradable Materials for Planting Pots. In Materials Research Foundations, 1st ed.; Materials Research Forum LLC: Millersville, PA, USA, 2020; Volume 68, pp. 85–103. [Google Scholar] [CrossRef]

- Shaikh, S.; Yaqoob, M.; Aggarwal, P. An overview of biodegradable packaging in food industry. Curr. Res. Food Sci. 2021, 4, 503–520. [Google Scholar] [CrossRef]

- Dey, A.; Sengupta, P.; Pramanik, N.K.; Alam, T. Paper and other pulp based eco-friendly moulded materials for food packaging applications: A review. J. Postharvest Technol. 2020, 8, 1–21. [Google Scholar]

- Madyira, D.M.; Mabirimisa, T.; Jen, T.-C. Mechanical Performance of Paper Pulp and Wood Glue Composite. In Volume 14: Emerging Technologies; Materials: Genetics to Structures; Safety Engineering and Risk Analysis; American Society of Mechanical Engineers: Tampa, FL, USA, 2017; p. V014T11A026. [Google Scholar] [CrossRef]

- Jurczyk, S.; Musioł, M.; Sobota, M.; Klim, M.; Hercog, A.; Kurcok, P.; Janeczek, H.; Rydz, J. (Bio)degradable Polymeric Materials for Sustainable Future—Part 2: Degradation Studies of P(3HB-co-4HB)/Cork Composites in Different Environments. Polymers 2019, 11, 547. [Google Scholar] [CrossRef]

- Yousif, B.F.; Orupabo, C.; Azwa, Z.N. Characteristics of Kenaf Fiber Immersed in Different Solutions. J. Nat. Fibers 2012, 9, 207–218. [Google Scholar] [CrossRef]

- Hidayat, A.; Tachibana, S. Characterization of polylactic acid (PLA)/kenaf composite degradation by immobilized mycelia of Pleurotus ostreatus. Int. Biodeterior. Biodegrad. 2012, 71, 50–54. [Google Scholar] [CrossRef]

- Dong, Z.; Xu, F.; Ahmed, I.; Li, Z.; Lin, H. Characterization and preservation performance of active polyethylene films containing rosemary and cinnamon essential oils for Pacific white shrimp packaging. Food Control 2018, 92, 37–46. [Google Scholar] [CrossRef]

- Majeed, K.; Jawaid, M.; Hassan, A.A.B.A.A.; Bakar, A.A.; Khalil, H.A.; Salema, A.A.; Inuwa, I. Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Mater. Des. 2013, 46, 391–410. [Google Scholar] [CrossRef]

- Peighambardoust, S.H.; Peighambardoust, S.J.; Oromiehie, A.; Fasihnia, S.H. Development of novel active polypropylene based packaging films containing different concentrations of sorbic acid. Food Packag. Shelf Life 2018, 18, 87–94. [Google Scholar] [CrossRef]

- Azlin-Hasim, S.; Cruz-Romero, M.C.; Morris, M.A.; Padmanabhan, S.C.; Cummins, E.; Kerry, J.P. The Potential Application of Antimicrobial Silver Polyvinyl Chloride Nanocomposite Films to Extend the Shelf-Life of Chicken Breast Fillets. Food Bioprocess Technol. 2016, 9, 1661–1673. [Google Scholar] [CrossRef]

- Moustafa, H.; El-Wakil, A.E.-A.; Nour, M.T.; Youssef, A.M. Kenaf fibre treatment and its impact on the static, dynamic, hydrophobicity and barrier properties of sustainable polystyrene biocomposites. RSC Adv. 2020, 10, 29296–29305. [Google Scholar] [CrossRef]

- Ismail-Fitry, M.R.; Ainun, Z.M.A.; Hanani, Z.A.N.; Syahida, S.N. Effects of palm wax on the physical, mechanical and water barrier properties of fish gelatin films for food packaging application. Food Packag. Shelf Life 2020, 23, 100437. [Google Scholar] [CrossRef]

- Panda, F.P.E.S.K.; Ashraf, P.M.; Varghese, T.O.; Bindu, J. Polylactic acid/chitosan films for packaging of Indian white prawn (Fenneropenaeus indicus). Int. J. Biol. Macromol. 2018, 117, 1002–1010. [Google Scholar] [CrossRef]

- Sánchez-Safont, E.L.; Aldureid, A.; Lagaron, J.M.; Pérez, P.G.; Cabedo, L. Biocomposites of different lignocellulosic wastes for sustainable food packaging applications. Compos. Part Eng. 2018, 145, 215–225. [Google Scholar] [CrossRef]

- Miao, L.; Walton, W.C.; Wang, L.; Li, L.; Wang, Y. Characterization of polylactic acids-polyhydroxybutyrate based packaging film with fennel oil, and its application on oysters. Food Packag. Shelf Life 2019, 22, 100388. [Google Scholar] [CrossRef]

- Hasanpour Ardekani-Zadeh, A.; Hosseini, S.F. Electrospun essential oil-doped chitosan/poly(ϵ-caprolactone) hybrid nanofibrous mats for antimicrobial food biopackaging exploits. Carbohydr. Polym. 2019, 233, 115108. [Google Scholar] [CrossRef] [PubMed]

- Vytejckova, S.; Vapenka, L.; Hradecky, J. Testing of polybutylene succinate based films for poultry meat packaging. Polym. Test. 2017, 60, 357–364. [Google Scholar] [CrossRef]

- Perdana, M.I.; Ruamcharoen, J.; Panphon, M.L.S. Antimicrobial activity and physical properties of starch/chitosan film incorporated with lemongrass essential oil and its application. LWT 2021, 141, 110934. [Google Scholar] [CrossRef]

- Padil, V.V.T.; Senan, C.; Wacławek, S.; Cerník, M.; Agarwal, S.; Varma, R.S. Bioplastic Fibers from Gum Arabic for Greener Food Wrapping Applications. ACS Sustain. Chem. Eng. 2019, 7, 5900–5911. [Google Scholar] [CrossRef]

- Tolesa, S.M.C.G.N.; Workneh, T.S. Biodegradable Food Packaging Materials and Prospects of the Fourth Industrial Revolution for Tomato Fruit and Product Handling. Adv. Mater. Sci. Eng. 2020, 2020, 8879101. [Google Scholar] [CrossRef]

- Akkarapongtrakul, A.; Julphunthong, P.; Nochaiya, T. Setting time and microstructure of Portland cement-bottom ash–sugarcane bagasse ash pastes. Monatshefte Für Chem.-Chem. Mon. 2017, 148, 1355–1362. [Google Scholar] [CrossRef]

- Patil, C.; Kalburgi, P.B.; Patil, M.B.; Prakash, K.B. An Investigation on the Micro Structural and Elemental Composition of Sugarcane Bagasse Ash Blended Concrete using SEM and EDS Technique. Int. J. Eng. Manuf. 2018, 8, 54–66. [Google Scholar] [CrossRef]

- Prabhath, N.; Kumara, B.S.; Vithanage, V.; Samarathunga, A.I.; Seww, I.N.; Damruwan, H.G.H.; Lewangamage, S.; Koswattage, K.R. Investigation of Pozzolanic Properties of Sugarcane Bagasse Ash for Commercial Applications. ACS Omega 2023, 8, 12052–12061. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Weragoda, V.S.C.; Kaushalya, R.A.N.C.; Dhanushka, M.K.D.T.; Samarasekara, A.M.P.B. Development of Biodegradable Packaging Materials Using Polylactic Acid (PLA) and Locally Extracted Starch. In Proceedings of the 2019 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 3–5 July 2019. [Google Scholar] [CrossRef]

- Amaraweera, S.M.; Gunathilake, C.; Gunawardene, O.H.; Dassanayake, R.S.; Fern, O.N.M.; Wanninayaka, D.B.; Rajapaksha, S.M.; Manamperi, A.; Gangoda, M.; Manchanda, A.; et al. Preparation and Characterization of Dual-Modified Cassava Starch-Based Biodegradable Foams for Sustainable Packaging Applications. ACS Omega 2022, 7, 19579–19590. [Google Scholar] [CrossRef]

- Semple, K.E.; Zhou, C.; Rojas, O.J.; Nkeuwa, W.N.; Dai, C. Moulded pulp fibers for disposable food packaging: A state-of-the-art review. Food Packag. Shelf Life 2022, 33, 100908. [Google Scholar] [CrossRef]

- García-Guzmán, L.; Cabrera-Barjas, G.; Soria-Hernández, C.G.; Castaño, J.; Guadarrama-Lezama, A.Y.; Rodríguez Llamazares, S. Progress in Starch-Based Materials for Food Packaging Applications. Polysaccharides 2022, 3, 136–177. [Google Scholar] [CrossRef]

- Kasiviswanathan, K.S. Utilisation of Bagasse For Paper Making—An Overview; Seshasayee Pap. ADd Boards Ltd.: Alampalayam, India, 1998; Volume 10, pp. 9–14. [Google Scholar]

- Huerta, E.; Corona, J.E.; Oliva, A.I.; Aviles, F.; Gonzalez-Hernandez, J. Universal testing machine for mechanical properties of thin materials. Rev. Mex. Fis. 2010, 56, 317–322. [Google Scholar]

- Samarasekara, A.M.P.B.; Senavirathne, H.V.H.H.; Sandaruwan, A.H.W.O. Preparation of biodegradable polymer materials using agricultural waste. In Proceedings of the International Forestry and Environment Symposium, Nugegoda, Sri Lanka, 16–17 November 2012; p. 1. [Google Scholar]

- Uthpala, T.G.G.; Navaratne, S.B.; Thibbotuwawa, A.; Jayasinghe, M.; Wanigasinghe, R.S. Agricultural By-Product Proteins: Emerging Source for Packaging Applications. Int. J. Food Sci. Agric. 2021, 5, 355–362. [Google Scholar] [CrossRef]

- Jayasinghe, J.A.S.C. The Influence of Green Packaging, Green Campaigns and Green Attitude on Green Behavioural Intentions of Consumers: Evidence from Sri Lanka. FGS—Colombo J.-Multi-Discip. Res. 2022, 6, 1. [Google Scholar] [CrossRef]

- Galpaya, C.; Induranga, A.; Vithanage, V.; Mantilaka, P.; Koswattage, K.R. Comparative Study on the Thermal Properties of Engine Oils and Their Nanofluids Incorporating Fullerene-C60, TiO2 and Fe2O3 at Different Temperatures. Energies 2024, 17, 732. [Google Scholar] [CrossRef]

- Induranga, A.; Galpaya, C.; Vithanage, V.; Koswattage, K.R. Thermal Properties of TiO2 Nanoparticle-Treated Transformer Oil and Coconut Oil. Energies 2024, 17, 49. [Google Scholar] [CrossRef]

- Perera, K.Y.; Jaiswal, A.K.; Jaiswal, S. Biopolymer-Based Sustainable Food Packaging Materials: Challenges, Solutions, and Applications. Foods 2023, 12, 2422. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wu, Z.; Li, A.; Chen, N.; Rao, J.; Zeng, Q. Nanocellulose Composite Films in Food Packaging Materials: A Review. Polymers 2024, 16, 423. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Gaikwad, K.K.; Lee, M.; Lee, Y.S. Temperature-Regulating Materials for Advanced Food Packaging Applications: A Review. Food Meas. 2018, 12, 588–601. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, S.; Wang, F.; Wang, L. Advances in Research of Molded Pulp for Food Packaging. J. Renew. Mater. 2023, 11, 3831–3846. [Google Scholar] [CrossRef]

- Siti Halipah, I. Thermal Performance of Oil Palm Fibre and Paper Pulp as the Insulation Materials. UNIMAS E-J. Civ. Eng. 2014, 5, 22–28. [Google Scholar]

- Basyigit, C.; Özel, C. Thermal insulation properties of expanded polystyrene as construction and insulating materials. In Proceedings of the 15th Symposium on Thermophysical Properties, Boulder, CO, USA, 22–27 June 2003. [Google Scholar]

- Chen, M.; Li, L.; Zhao, P.; Wang, S.; Lu, L. Paper sludge functionalization for achieving fiber-reinforced and low thermal conductivity calcium silicate insulating materials. J. Therm. Anal. Calorim. 2019, 136, 493–503. [Google Scholar] [CrossRef]

- Mujtaba, M.; Lipponen, J.; Ojanen, M.; Puttonen, S.; Vaittinen, H. Trends and challenges in the development of bio-based barrier coating materials for paper/cardboard food packaging; A review. Sci. Total Environ. 2022, 851, 158328. [Google Scholar] [CrossRef]

- Wang, K.; Yang, L.; Kucharek, M. Investigation of the effect of thermal insulation materials on packaging performance. Packag. Technol. Sci. 2020, 33, 227–236. [Google Scholar] [CrossRef]

- Wolska, W.; Małachowska, E. Paper recycling as an element of sustainable development. Ann. WULS For. Wood Technol. 2023, 123, 66–75. [Google Scholar] [CrossRef]

- Patil, G.D.; Jadhav, P.; Joshi, G.M. Role of Inorganic Fillers in Nanocomposites for Food Packaging. In Nanotechnology Horizons in Food Process Engineering; Apple Academic Press: Palm Bay, FL, USA, 2023. [Google Scholar]

- Ke, Y.; Li, J.; Yan, X.; Xiong, Z. Research Progress on the Activity Stimulation of Lithium Slag in Concrete. Sustainability 2024, 16, 9549. [Google Scholar] [CrossRef]

- Reis, W.F.; Barreto, C.G.; Capelari, M.G.M. Circular Economy and Solid Waste Management: Connections from a Bibliometric Analysis. Sustainability 2023, 15, 15715. [Google Scholar] [CrossRef]

- de Oliveira, D.M.; de Bomfim, A.S.C.; Benini, K.C.C.d.C.; Cioffi, M.O.H.; Voorwald, H.J.C.; Rodrigue, D. Waste Paper as a Valuable Resource: An Overview of Recent Trends in the Polymeric Composites Field. Polymers 2023, 15, 426. [Google Scholar] [CrossRef] [PubMed]

- Ozola, Z.; Vesere, R.; Kalnins, S.; Blumberga, D. Paper Waste Recycling. Circular Economy Aspects. Environ. Clim. Technol. 2019, 23, 260–273. [Google Scholar] [CrossRef]

- Standard Test Method for Determining Compressive Resistance of Shipping Containers, Components, and Unit Loads. Available online: https://www.astm.org/d0642-20.html (accessed on 11 October 2024).

- “TAPPI T 804 Compression” SGS-IPS Testing. Available online: https://ipstesting.com/find-a-test/tappi-test-methods/tappi-t-804-compression/ (accessed on 11 October 2024).

- ISO 1924-2:2008; Paper and Board—Determination of Tensile Properties Part 2: Constant Rate of Elongation Method (20 mm/min). ISO: Geneva, Switzerland, 2008. Available online: https://www.iso.org/standard/41397.html (accessed on 11 October 2024).

- Elmendorf Tear ASTM D1922. Available online: https://www.intertek.com/polymers-plastics/testlopedia/elmendorf-tear-astm-d1922/ (accessed on 11 October 2024).

- Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. Available online: https://www.astm.org/d0790-17.html (accessed on 11 October 2024).

- Standard Test Method for Evaluating the Resistance to Thermal Transmission by the Guarded Heat Flow Meter Technique. Available online: https://www.astm.org/e1530-19.html (accessed on 11 October 2024).

| Name | Properties | Tensile Strength (MPa) | References |

|---|---|---|---|

| LDPE film (low-density polyethylene) | Stiff | 21.98 | [8,9] |

| Strong | |||

| Tough | |||

| Resistant to chemical and moisture | |||

| PP film (Polypropylene) | Harder | ~48 | [9,10] |

| Denser | |||

| Transparent | |||

| Resistant to heat and chemicals | |||

| PVC film (Polyvinyl Chloride) | Stiff | 3.56 | [9,11] |

| Medium strong and transparent material | |||

| Resistant to chemicals grease and oil | |||

| Good flow | |||

| PS Film (Polystyrene) | Clear | ~22.95 | [9,12] |

| Hard and brittle material | |||

| Foaming produces an opaque | |||

| Rigid | |||

| Lightweight material with impact protection and thermal insulation properties |

| Name | Properties | Tensile Strength (MPa) | References |

|---|---|---|---|

| Fish gelatin film | Excellent film-forming ability | 9.08 | [13] |

| High binding potential with water and emulsifying properties | |||

| Edible, poor strength, durability, and low barrier effects | |||

| PLA (polylactide) | Good mechanical strength, biocompatibility, abundance | 43.19 | [14] |

| Brittleness, low thermal stability, and low barrier properties | |||

| PHB (Polyhydroxybutyrate) | Excellent moisture barrier and excellent mechanical performance | 40 | [15] |

| Crystallinity, biocompatibility, and is naturally compostable | |||

| PLA/PHB film | 41.20 | [16] | |

| Chitosan/PCL (Polycaprolactone) fibrous mat | Great biocompatible, biodegradable, low-set processing temperature (60 °C) | 14 | [17] |

| Low barrier properties and lack of mechanical strength | |||

| PBSA/(90 wt.% PBS + 10 wt.% PBSA) film PBS (Polybutylene Succinate) | Good processability and thermal stability, and chemical resistance | 28.97 | [18] |

| Mechanical properties similar to PE and PP materials | |||

| Cassava starch/chitosan | 8.98 | [19] | |

| PVA/gum Arabic polyvinyl alcohol (PVA) | Higher barrier properties Good thermal stability | 16.10 | [20] |

| Additives | Source | Properties | References |

|---|---|---|---|

| Paper | Wood, Cotton | Very good retention of elastic modulus in flexure with heating | [28] |

| Bamboo, Straw | Good moisture absorption | ||

| Water vapor permeability increased | |||

| Corn | Antioxidant capacity increased | ||

| Starch | Potato starch | Increase apparent density values | [29] |

| Rice starch | Enhance the resistance to ultraviolet and thermal aging | ||

| Increase the food shelf life | |||

| Bagasse | Sugarcane | Strength properties (burst factor and breaking length are comparable due to better bonding characteristics.) | [30] |

| Optical properties (brightness stability is higher and opacity is lower) Printability is superior |

| Sample | Water 90% ((V ± 0.5) × 10−3 L) | Paper ((W ± 0.5) × 10−3 kg) | Percentage of Paper (%) | SCBA ((W ± 0.5) × 10−3 kg) | Percentage of SCBA (%) |

|---|---|---|---|---|---|

| 1 | 450 | 45.00 | 90 | 5.00 | 10 |

| 2 | 450 | 42.50 | 85 | 7.50 | 15 |

| 3 | 450 | 40.00 | 80 | 10.00 | 20 |

| 4 | 450 | 37.50 | 75 | 12.50 | 25 |

| Sample | Water 90% ((V ± 0.5) × 10−3 L) | Paper ((W ± 0.5) × 10−3 kg) | Percentage of Paper (%) | Starch ((W ± 0.5) × 10−3 kg) | Percentage of Starch (%) |

|---|---|---|---|---|---|

| 1 | 450.0 | 42.50 | 85.00 | 7.50 | 15.00 |

| 2 | 450.0 | 43.75 | 87.50 | 6.25 | 12.50 |

| 3 | 450.0 | 45.00 | 90.00 | 5.00 | 10.00 |

| 4 | 450.0 | 46.25 | 92.50 | 3.75 | 7.50 |

| Sample | Water 90% ((V ± 0.5) × 10−3 L) | SCBA (Constant) ((W ± 0.5) × 10−3 kg) | SCBA Percentage (%) | Paper ((W ± 0.5) × 10−3 kg) | Paper Percentage (%) | Starch ((W ± 0.5) × 10−3 kg) | Starch Percentage (%) |

|---|---|---|---|---|---|---|---|

| 1 | 450.0 | 5.00 | 10 | 42.50 | 85 | 2.50 | 5 |

| 2 | 450.0 | 5.00 | 10 | 40.00 | 80 | 5.00 | 10 |

| 3 | 450.0 | 5.00 | 10 | 37.50 | 75 | 7.50 | 15 |

| 4 | 450.0 | 5.00 | 10 | 35.00 | 70 | 10.00 | 20 |

| SCBA Composition | Thermal Conductivity (W/mK) | Thermal Resistivity (m3K/W) |

|---|---|---|

| 0% (Pure paper pulp) | 0.2311 | 0.0670 |

| 5% | 0.2469 | 0.0657 |

| 10% | 0.2699 | 0.0632 |

| 15% | 0.2673 | 0.0671 |

| 20% | 0.2678 | 0.0653 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samarathunga, A.I.; Kulasooriya, W.G.C.M.; Sewwandi, H.M.D.U.; Vithanage, V.; Induranga, A.; Kumara, B.S.; Koswattage, K. Experimental Analysis of Mechanical Property Enhancement of Paper-Pulp-Based Packaging Materials Using Biodegradable Additives. Sustainability 2024, 16, 10310. https://doi.org/10.3390/su162310310

Samarathunga AI, Kulasooriya WGCM, Sewwandi HMDU, Vithanage V, Induranga A, Kumara BS, Koswattage K. Experimental Analysis of Mechanical Property Enhancement of Paper-Pulp-Based Packaging Materials Using Biodegradable Additives. Sustainability. 2024; 16(23):10310. https://doi.org/10.3390/su162310310

Chicago/Turabian StyleSamarathunga, Amalka Indupama, Watagoda Gedara Chathura Madusanka Kulasooriya, Horawala Mahawaththage Dona Umesha Sewwandi, Vimukthi Vithanage, Ashan Induranga, Buddhika Sampath Kumara, and Kaveenga Koswattage. 2024. "Experimental Analysis of Mechanical Property Enhancement of Paper-Pulp-Based Packaging Materials Using Biodegradable Additives" Sustainability 16, no. 23: 10310. https://doi.org/10.3390/su162310310

APA StyleSamarathunga, A. I., Kulasooriya, W. G. C. M., Sewwandi, H. M. D. U., Vithanage, V., Induranga, A., Kumara, B. S., & Koswattage, K. (2024). Experimental Analysis of Mechanical Property Enhancement of Paper-Pulp-Based Packaging Materials Using Biodegradable Additives. Sustainability, 16(23), 10310. https://doi.org/10.3390/su162310310