Performance of Environmentally Friendly Concrete Containing Fly-Ash and Waste Face Mask Fibers

Abstract

1. Introduction

2. Materials and Methods

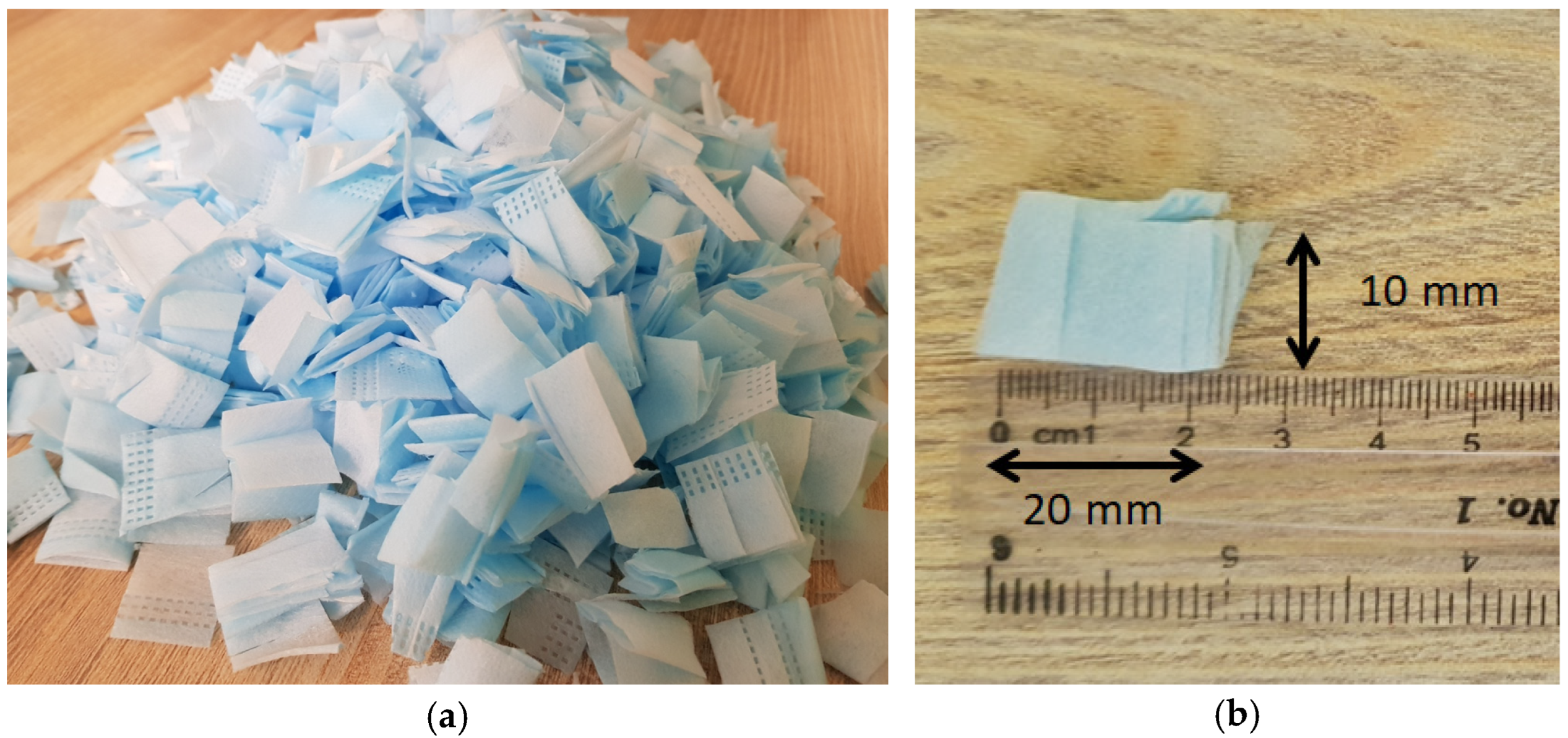

2.1. Materials

2.2. Mix Design, Composition, and Preparation

2.3. Samples Casting and Curing

2.4. Testing Methods

3. Experimental Findings

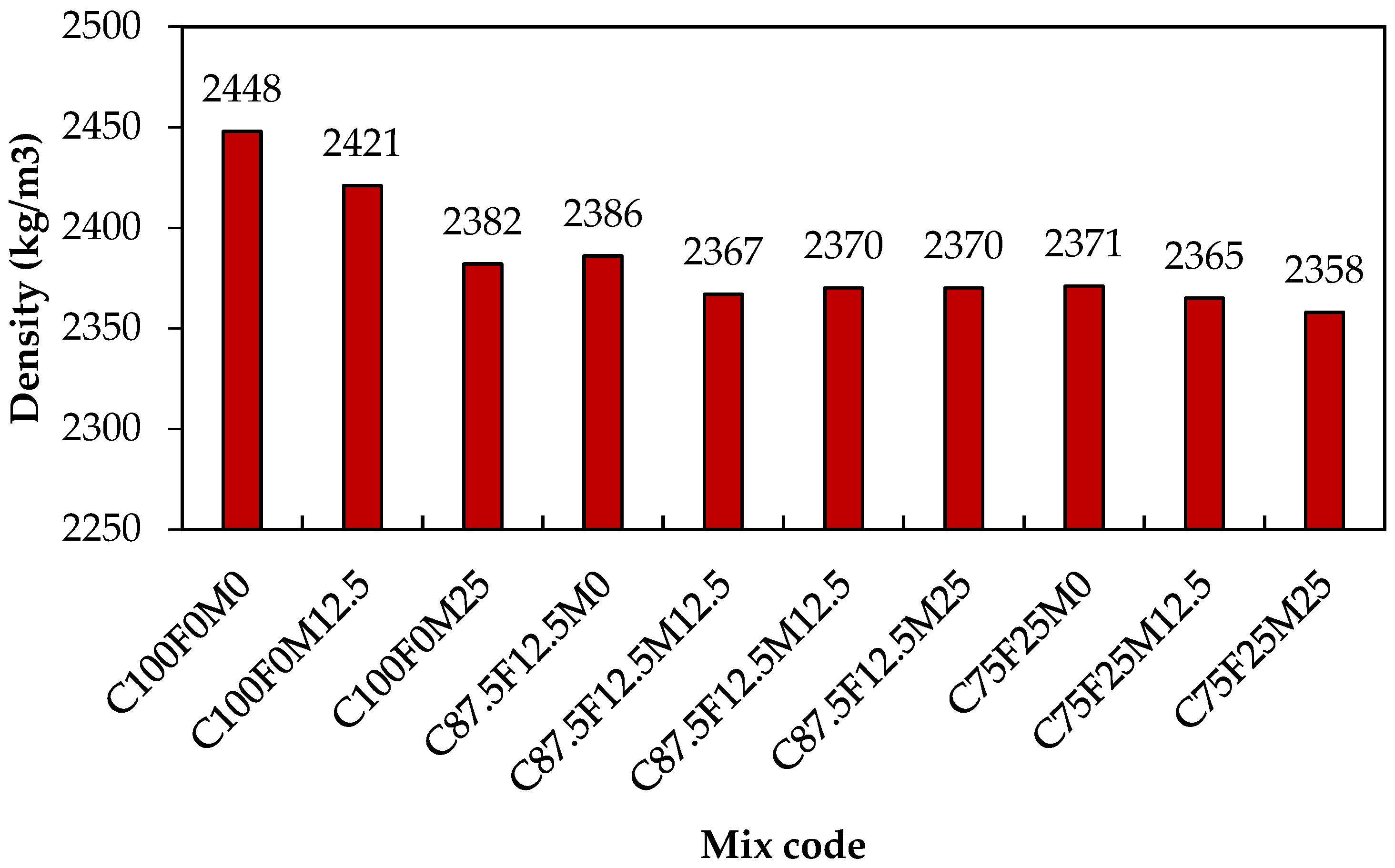

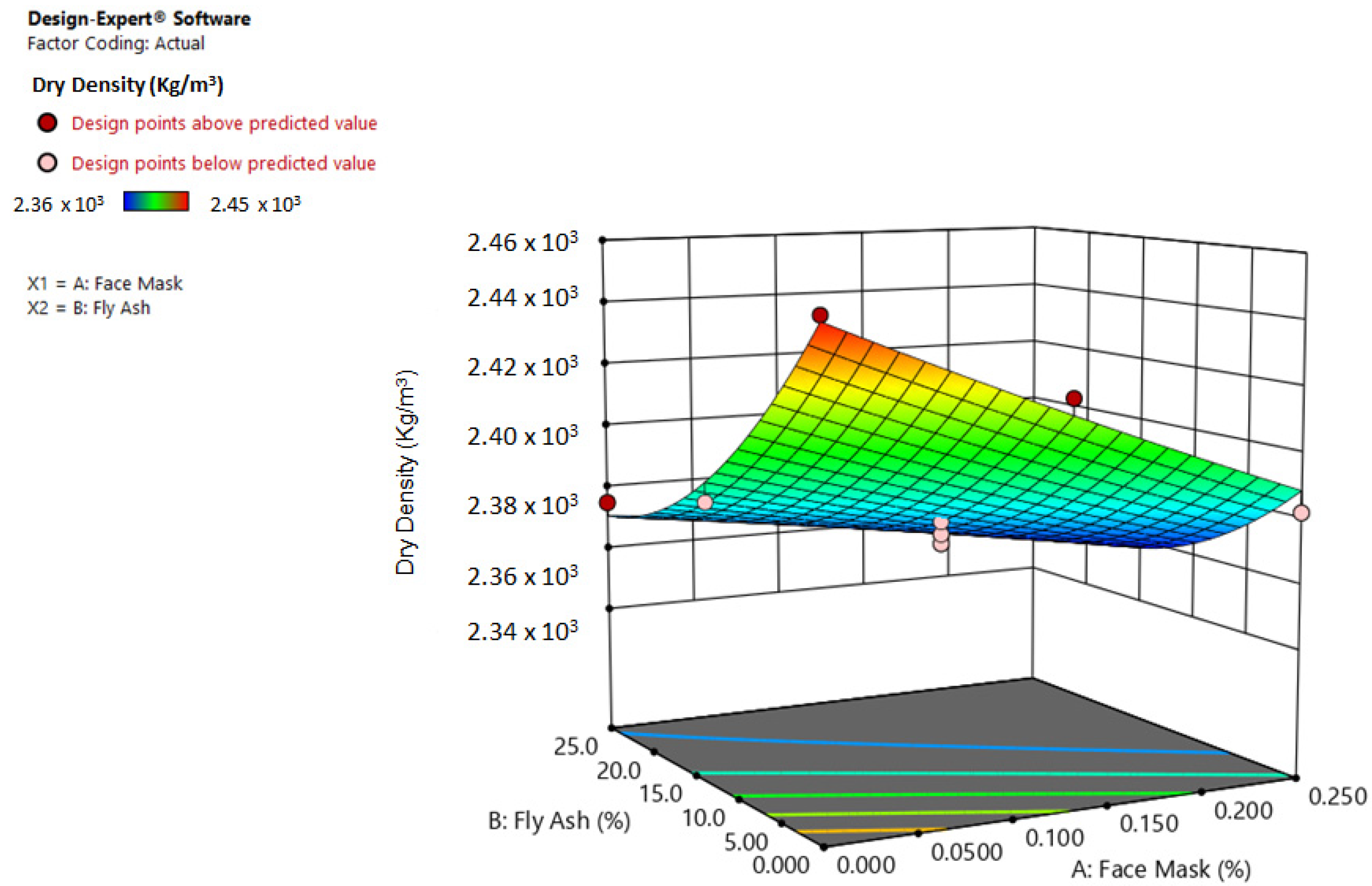

3.1. Dry Density

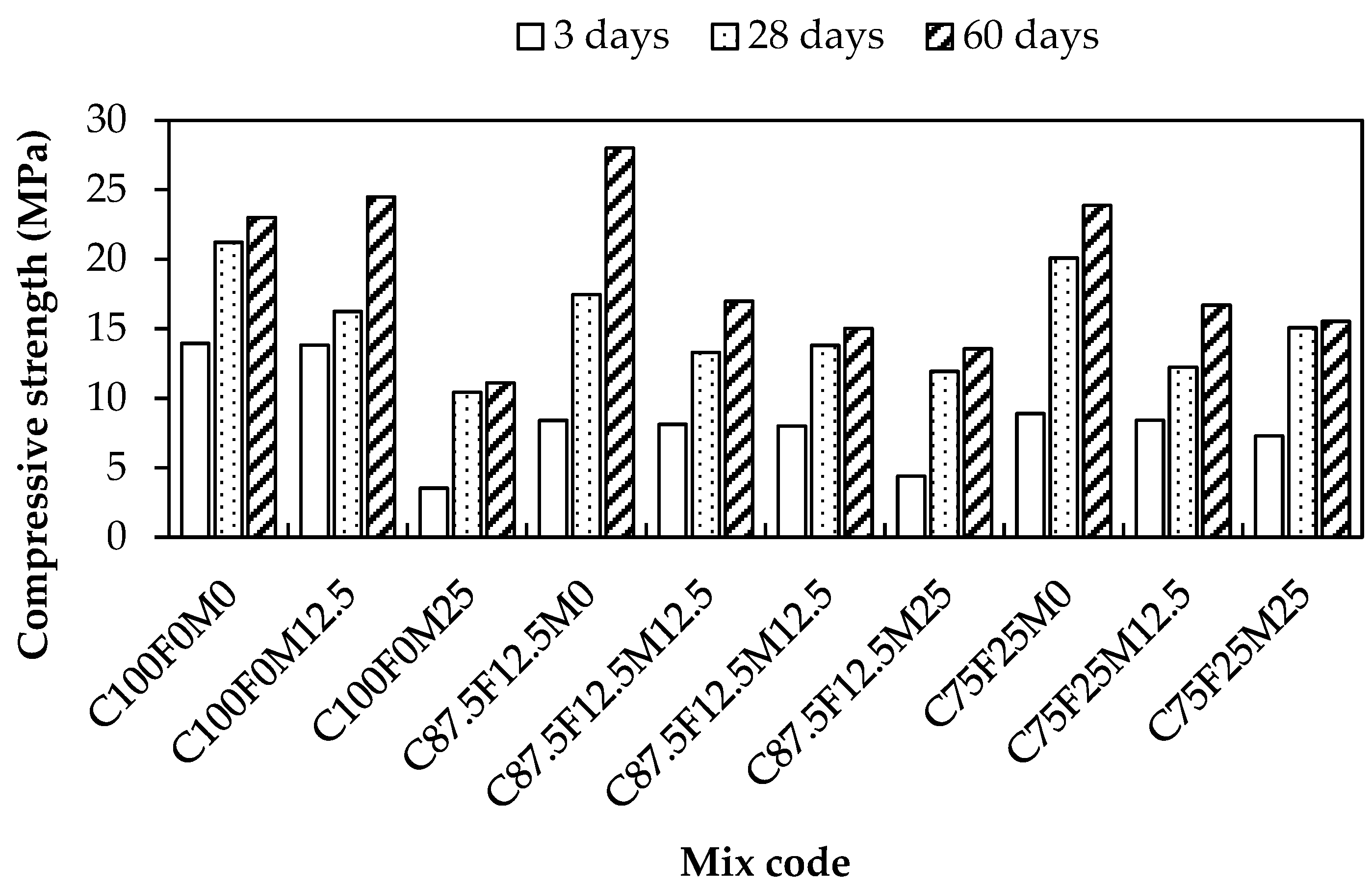

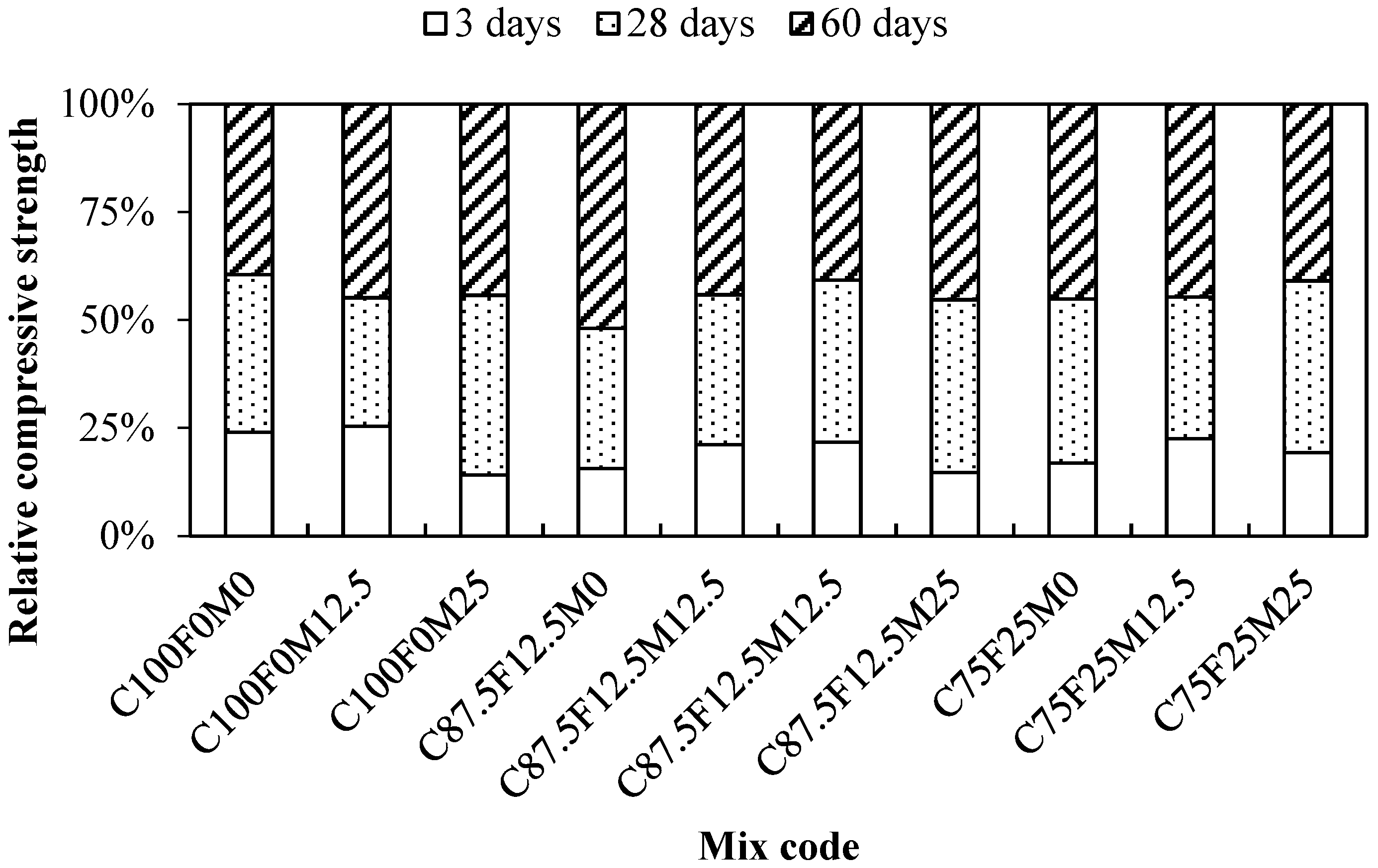

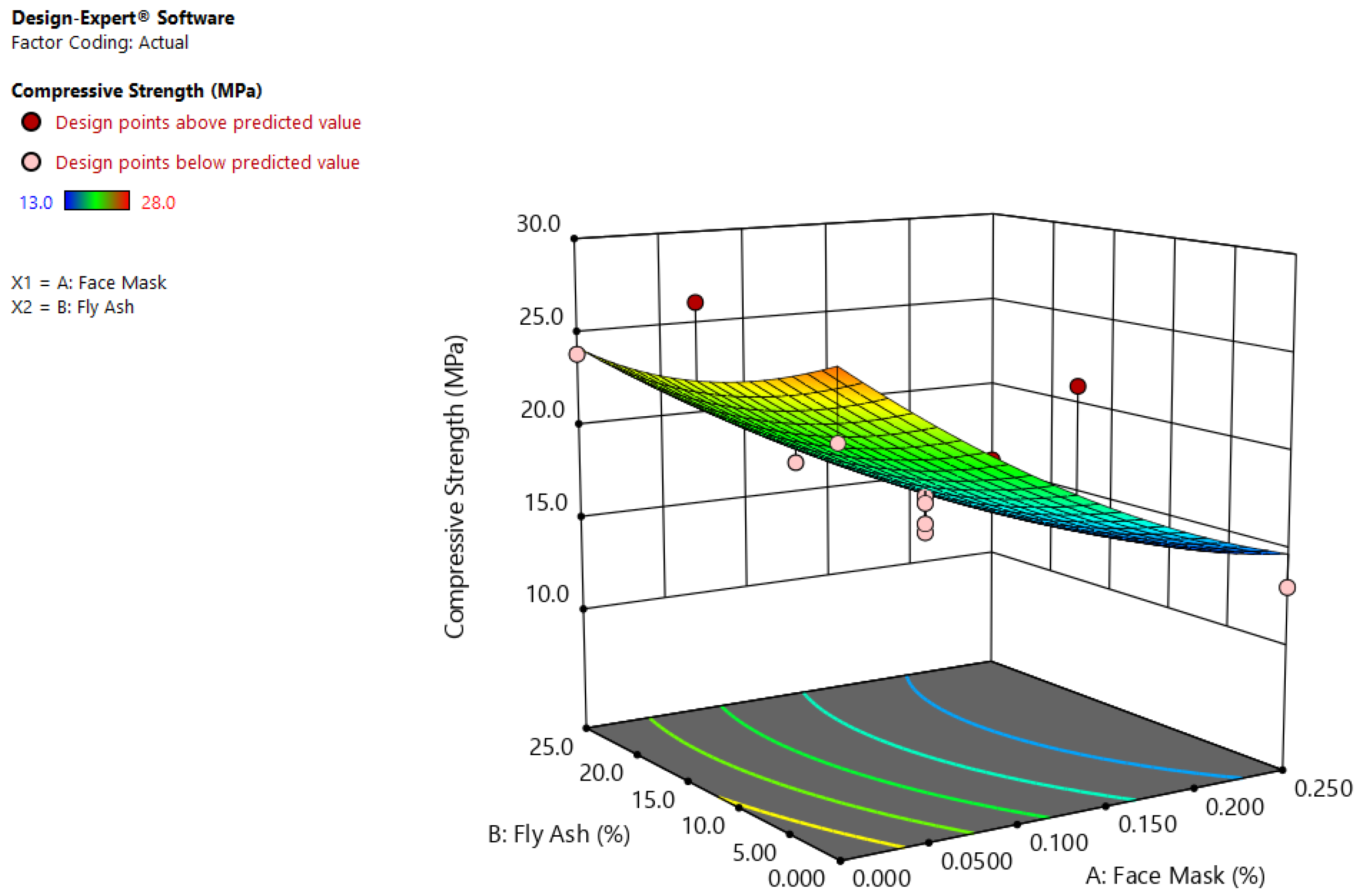

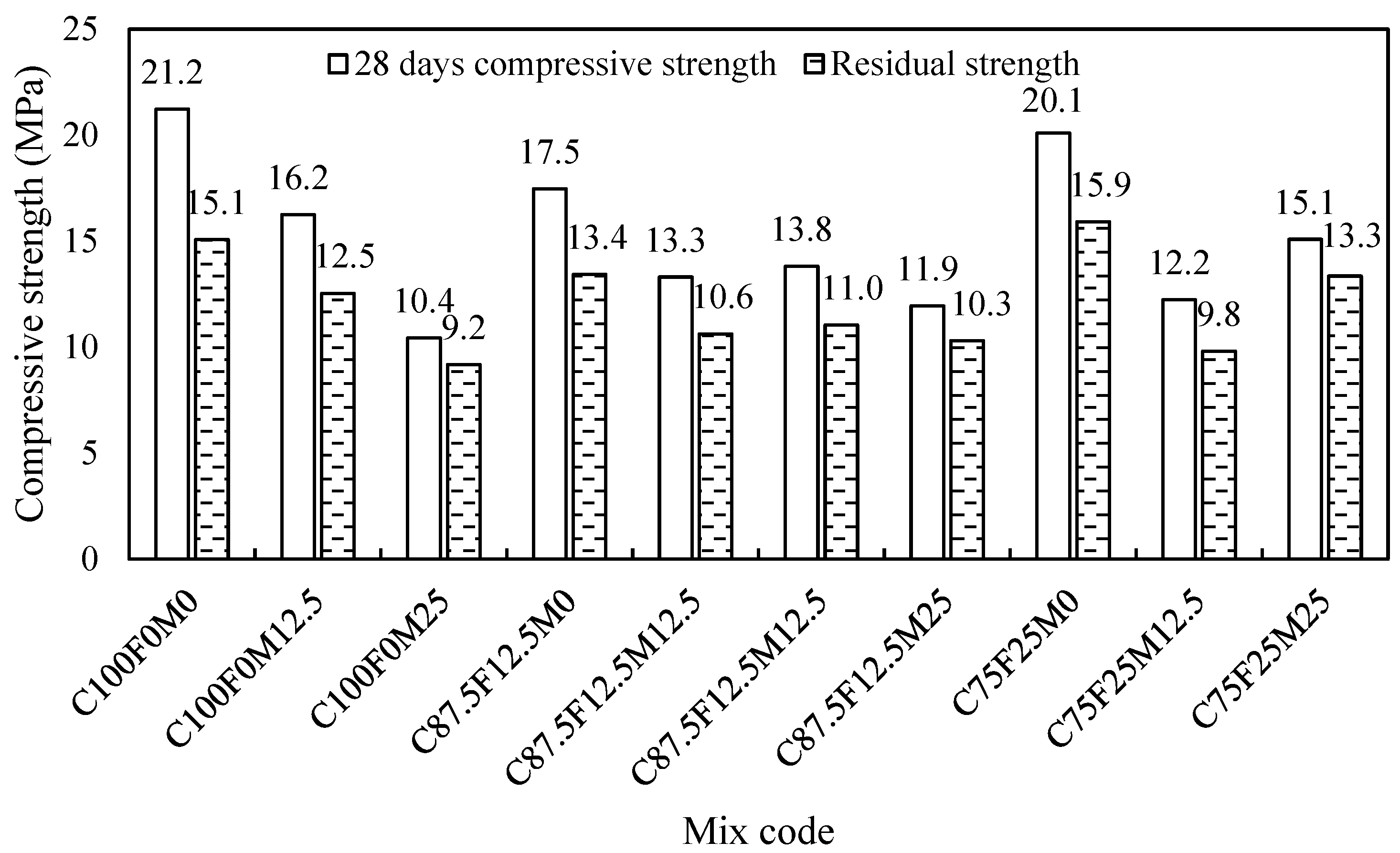

3.2. Compressive Strength

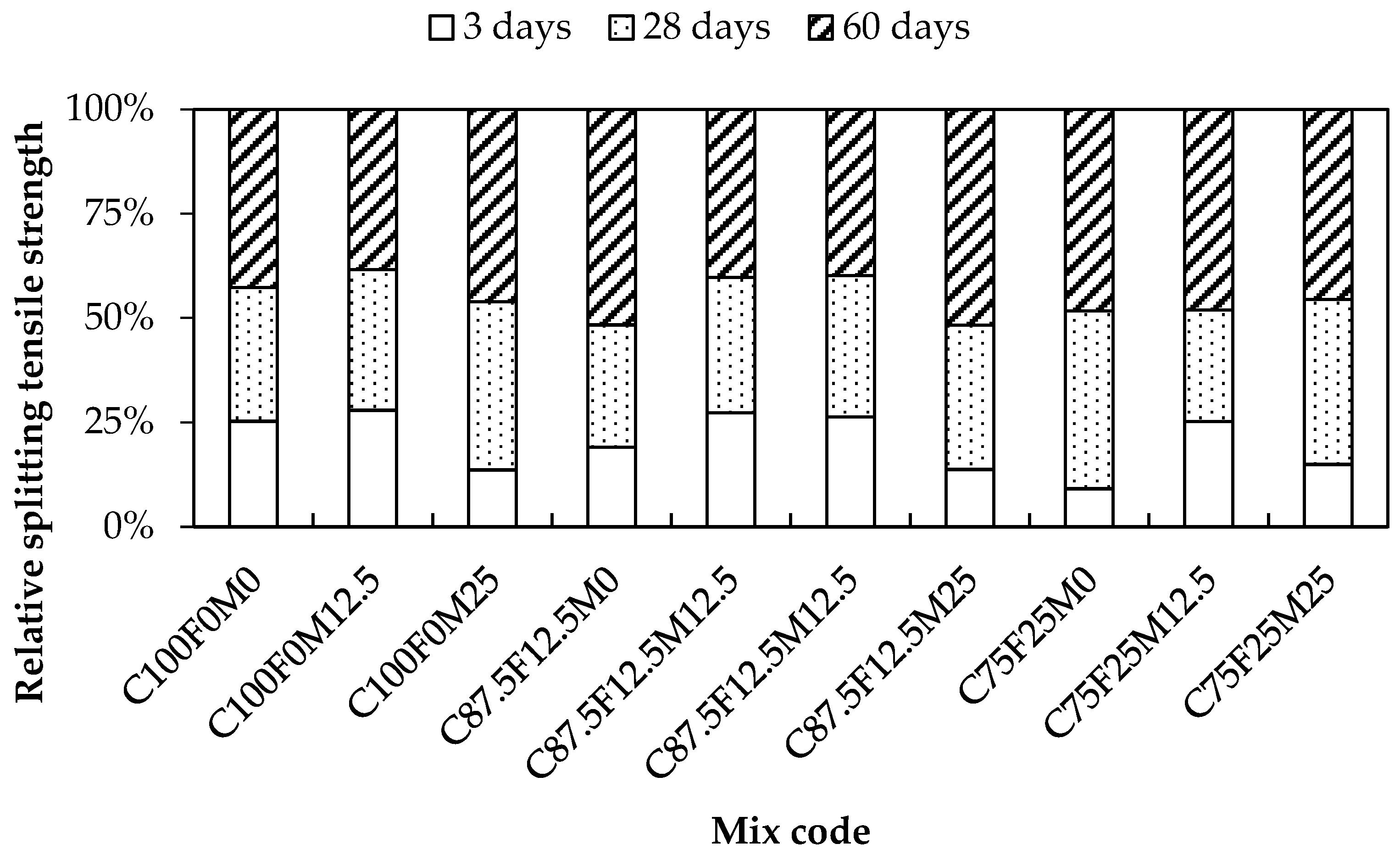

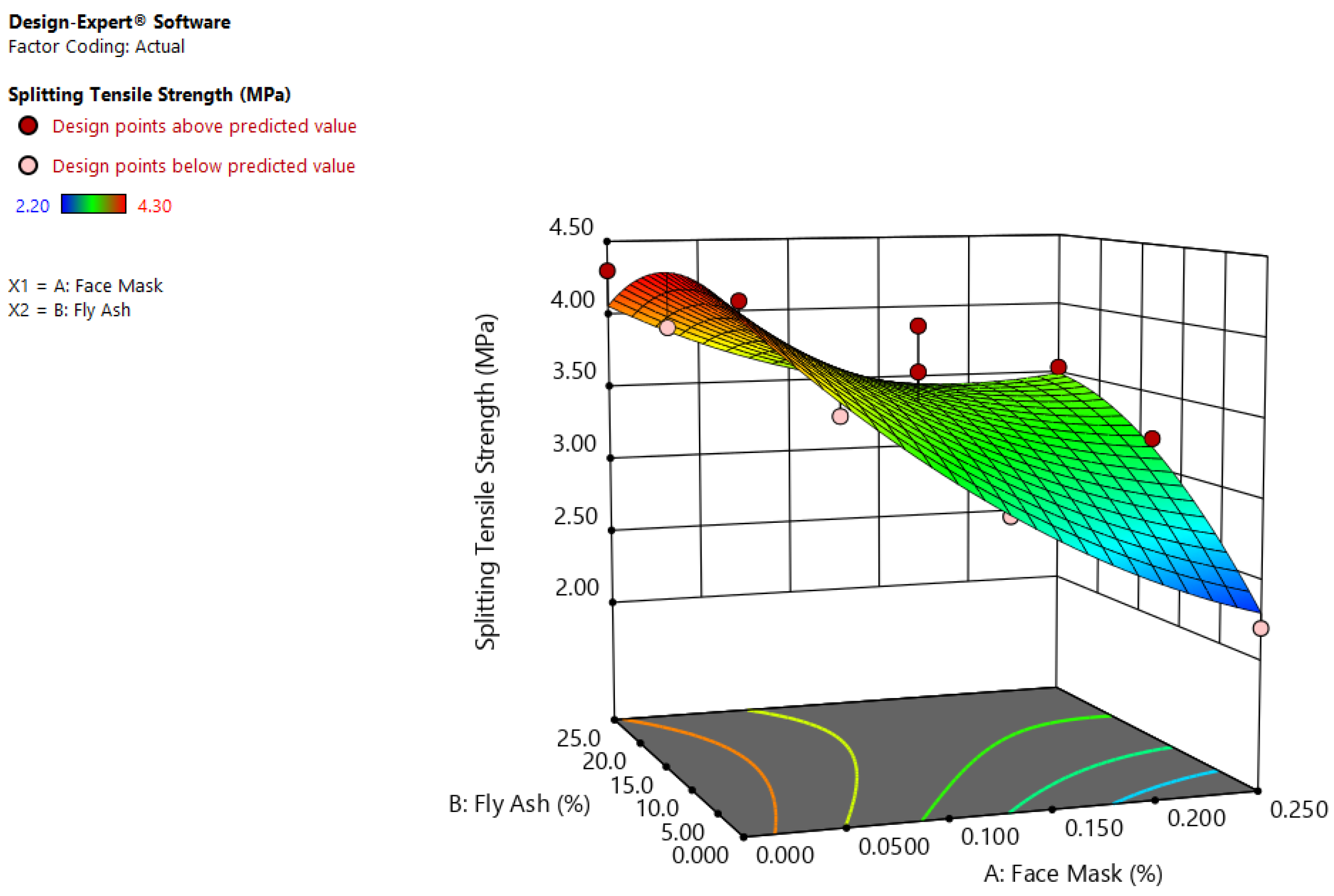

3.3. Splitting Tensile Strength

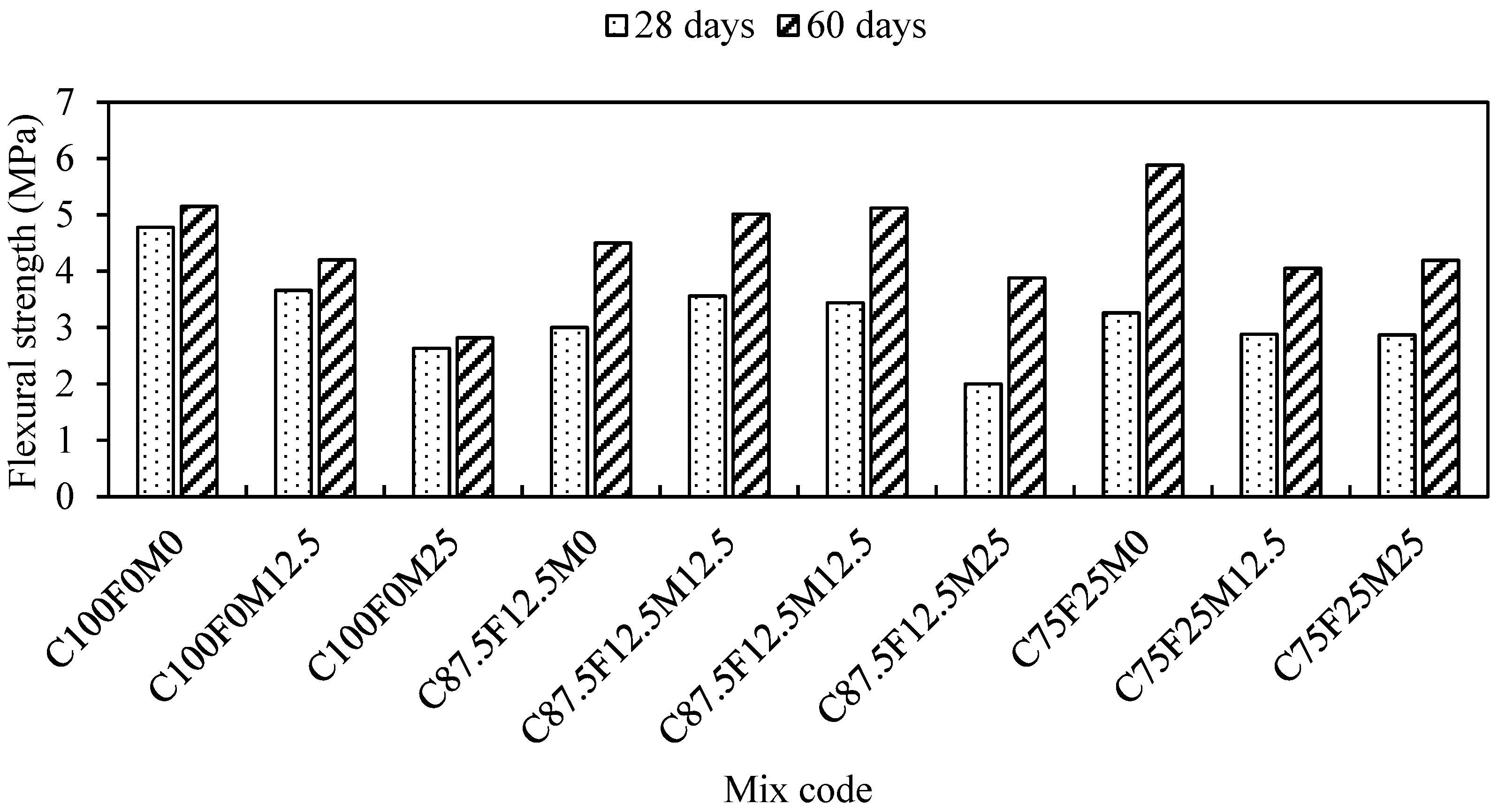

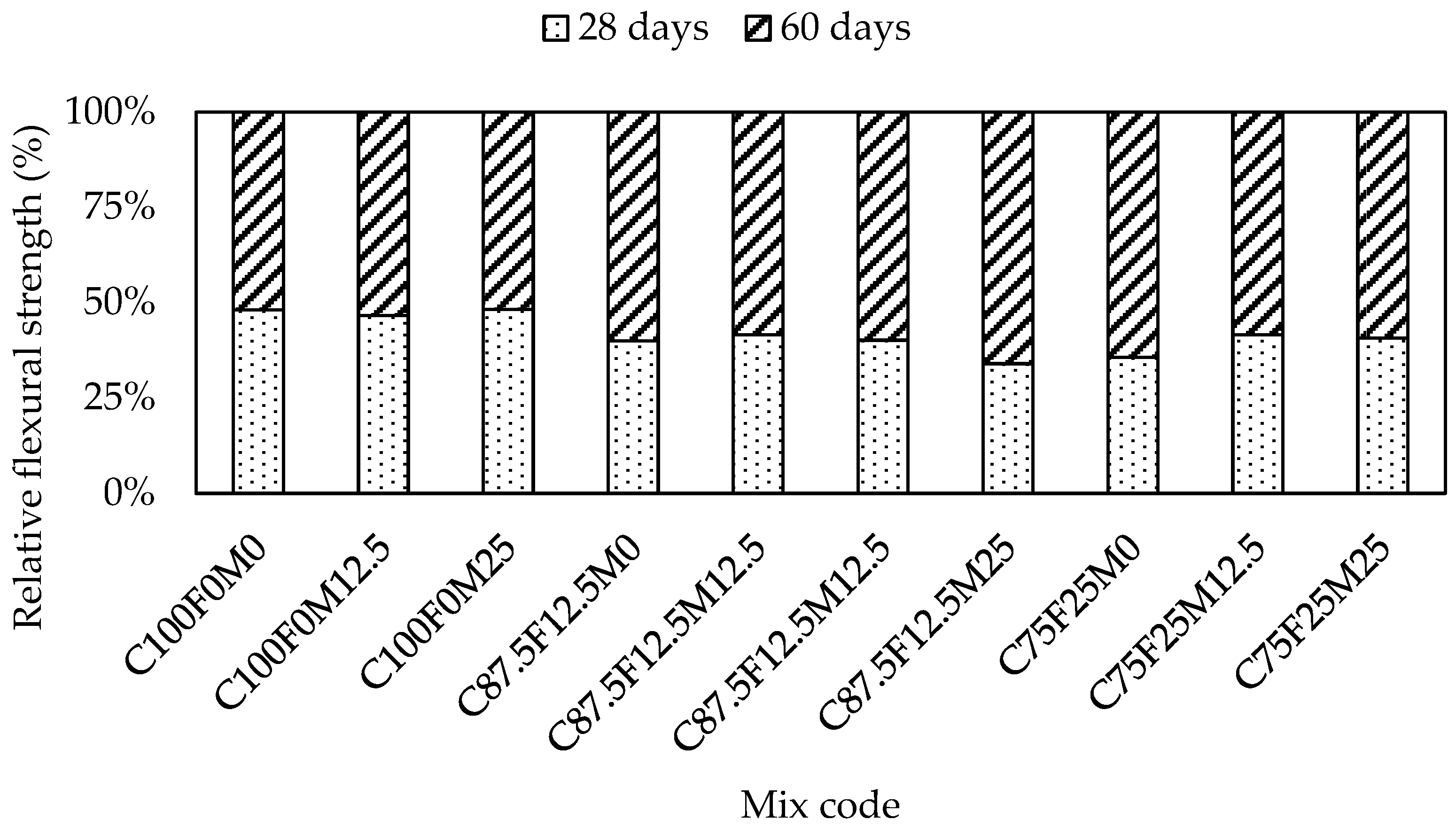

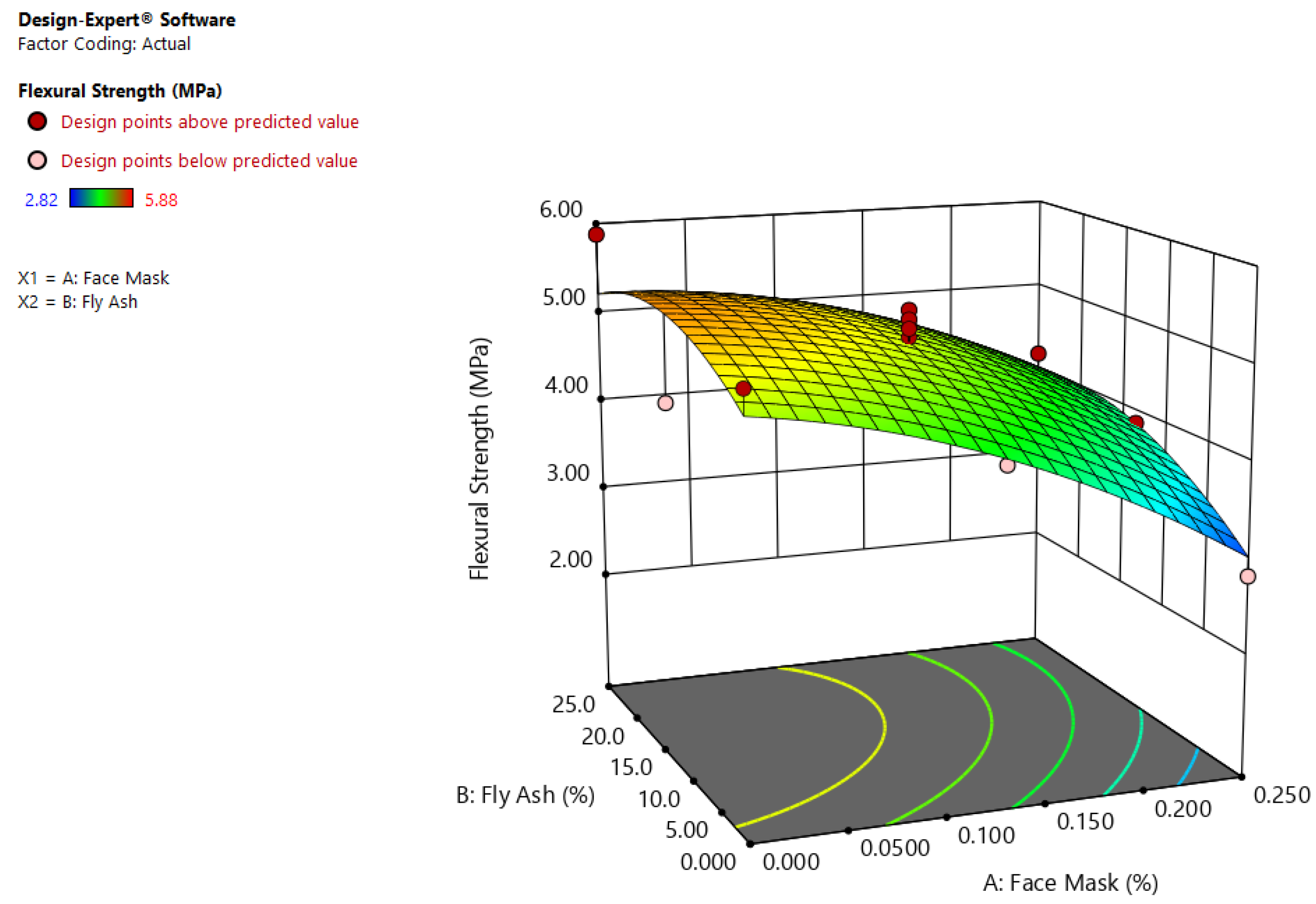

3.4. Flexural Strength

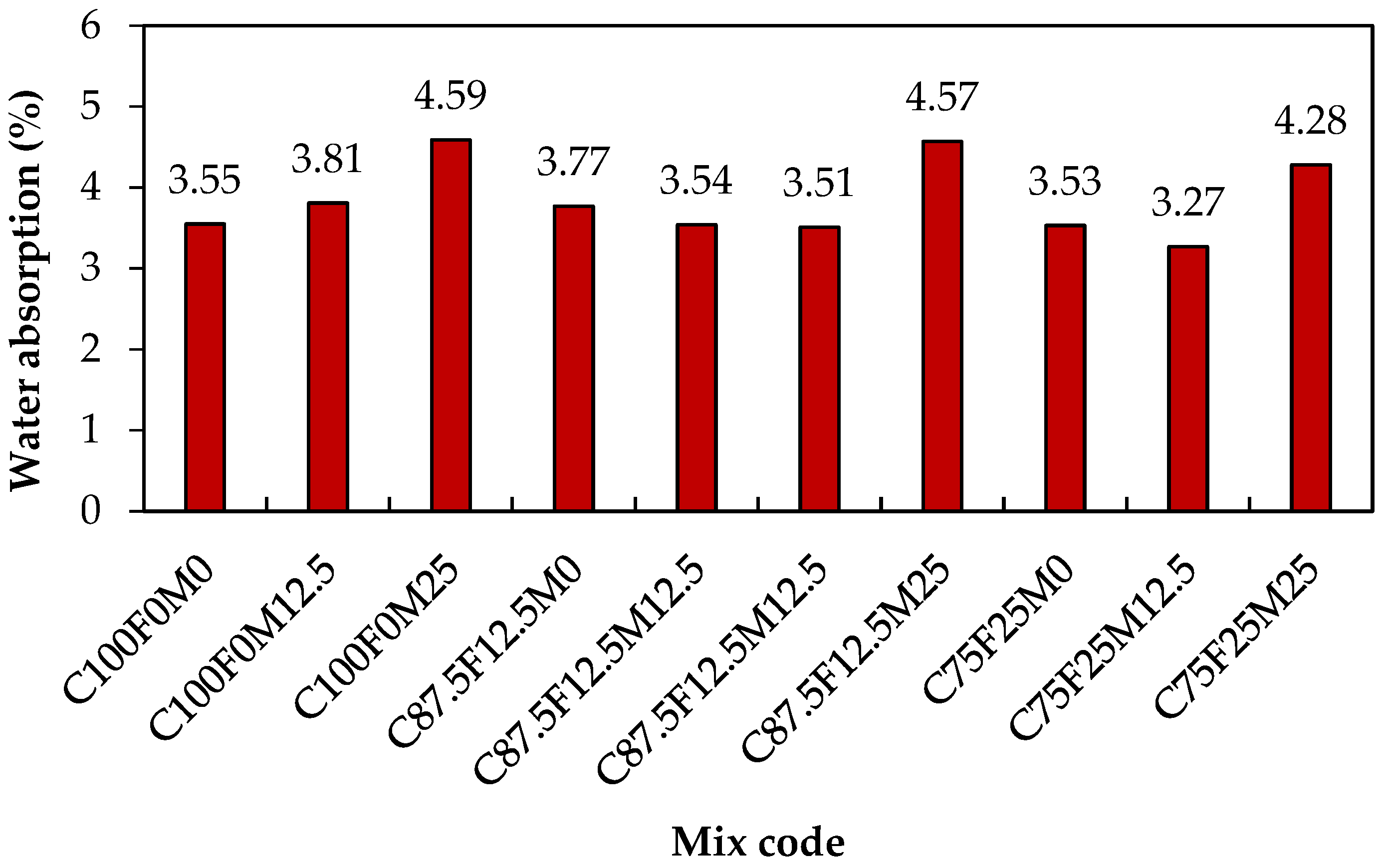

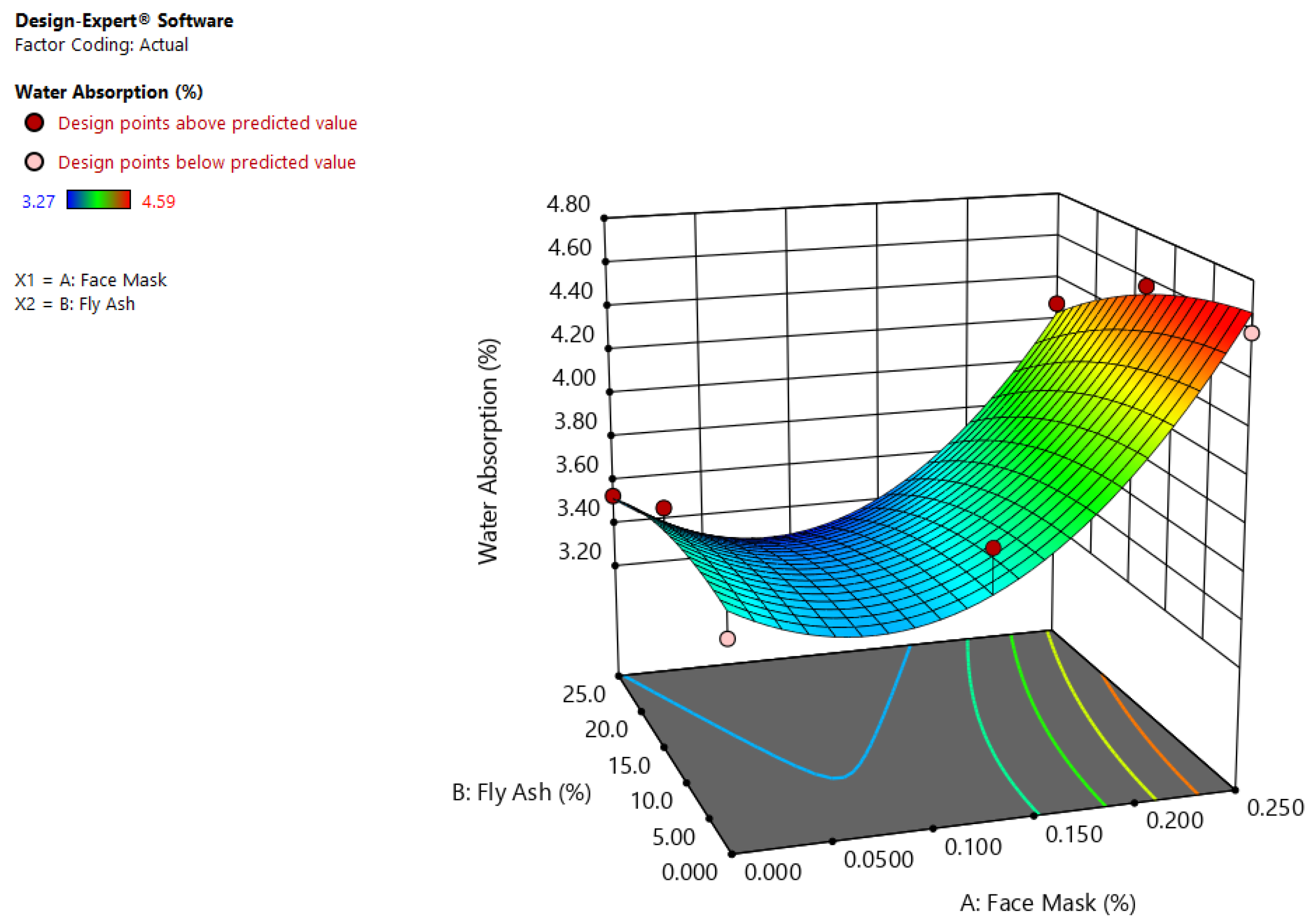

3.5. Water Absorption

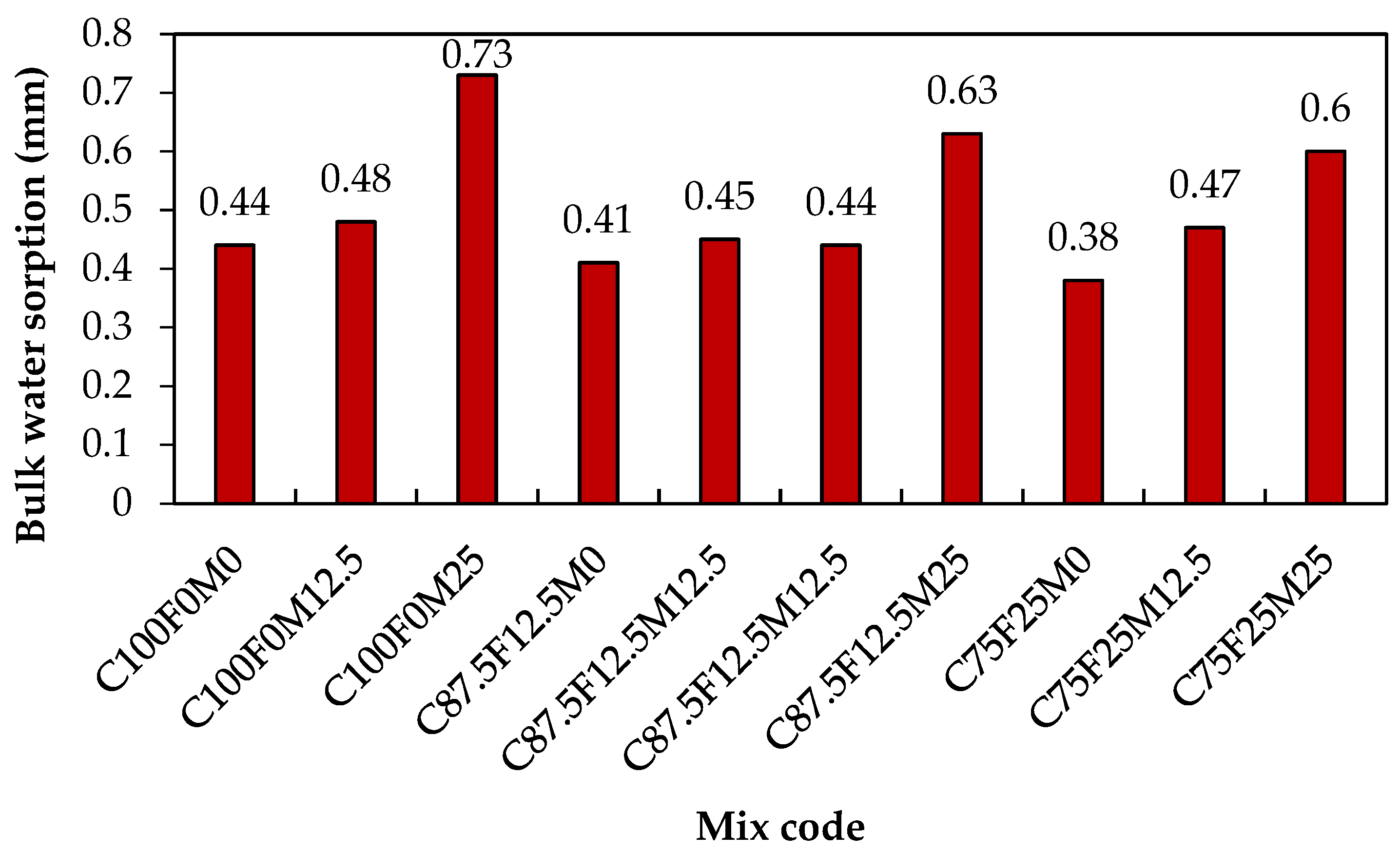

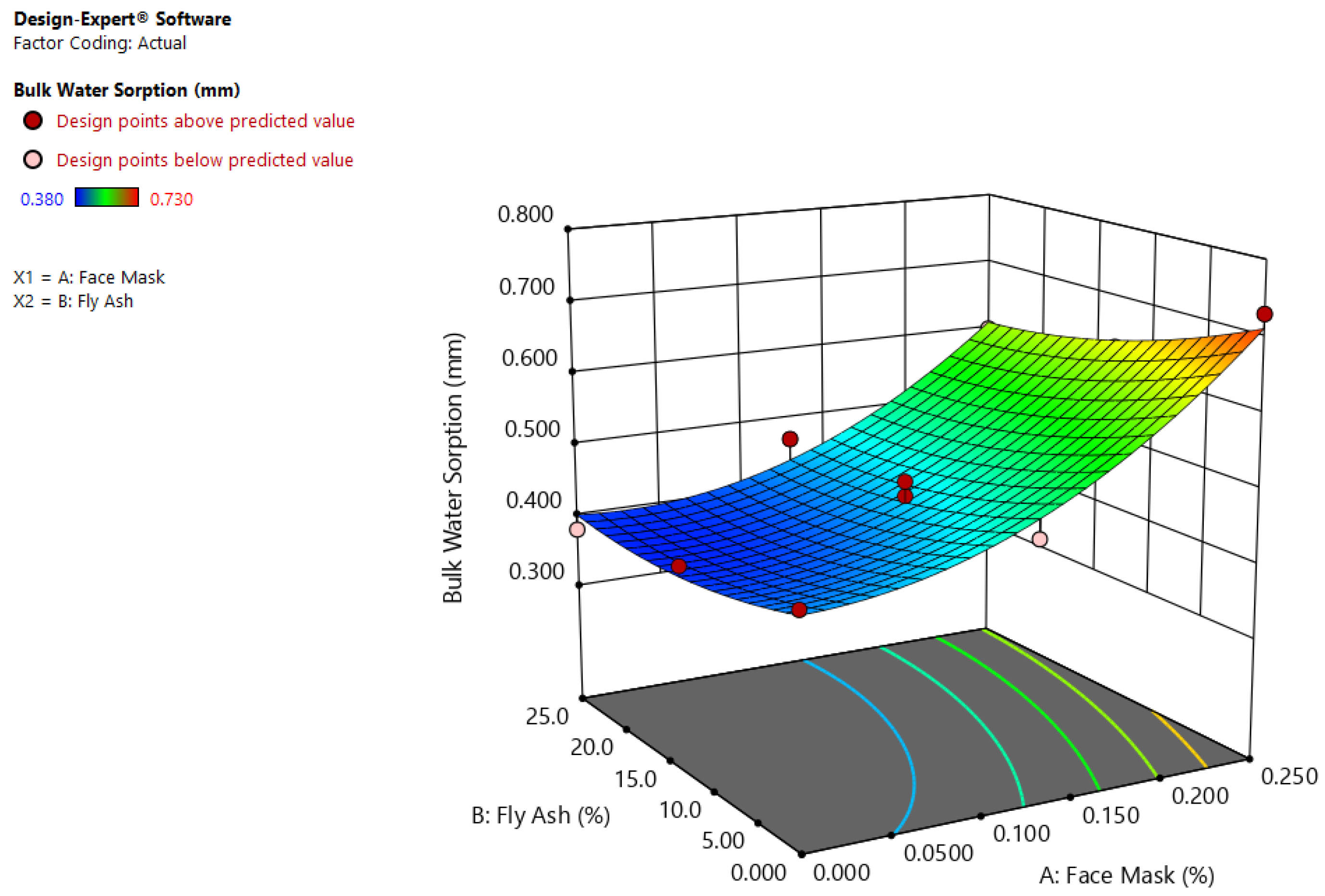

3.6. Bulk Water Sorption

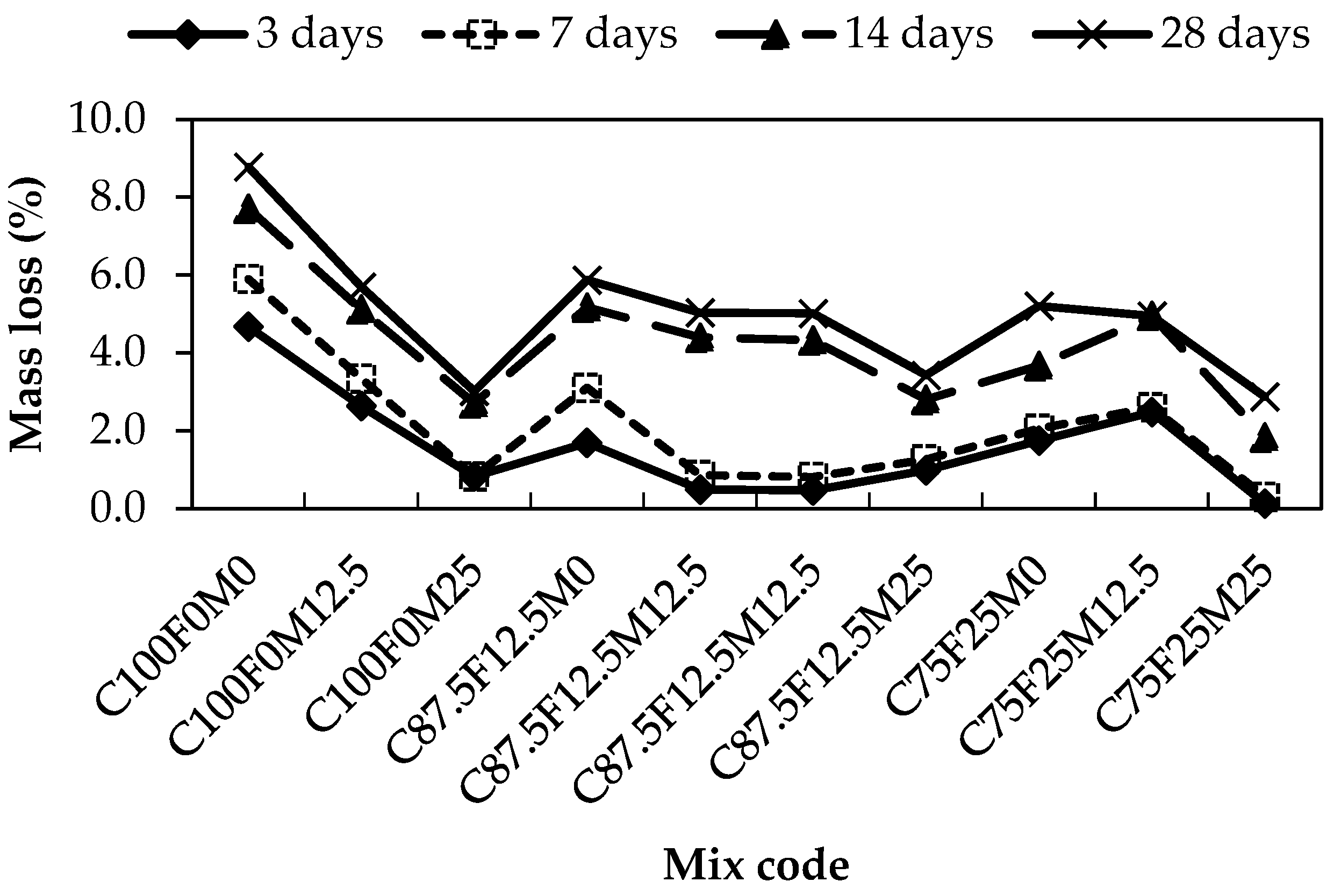

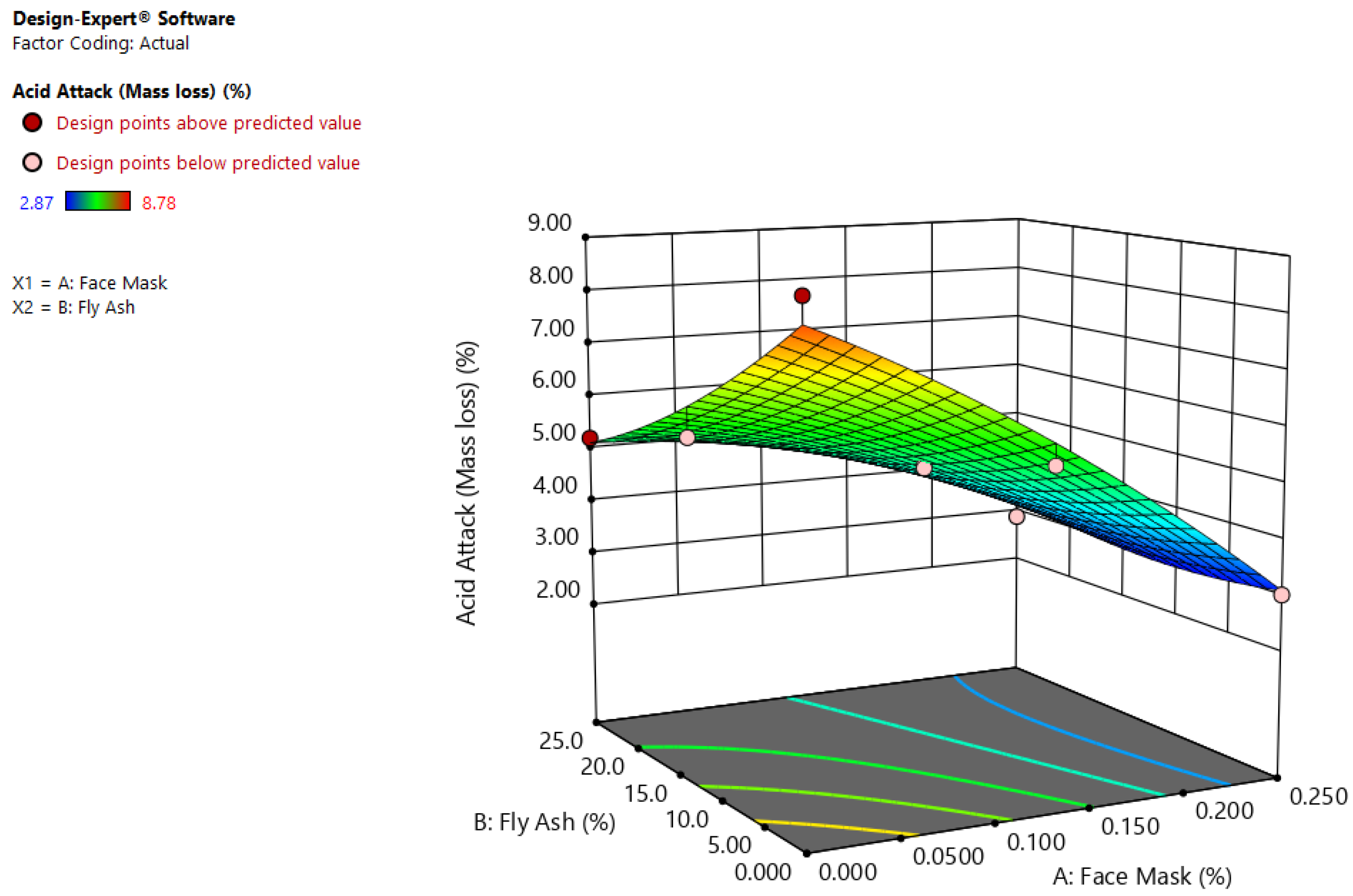

3.7. Resistant to Acid Attach

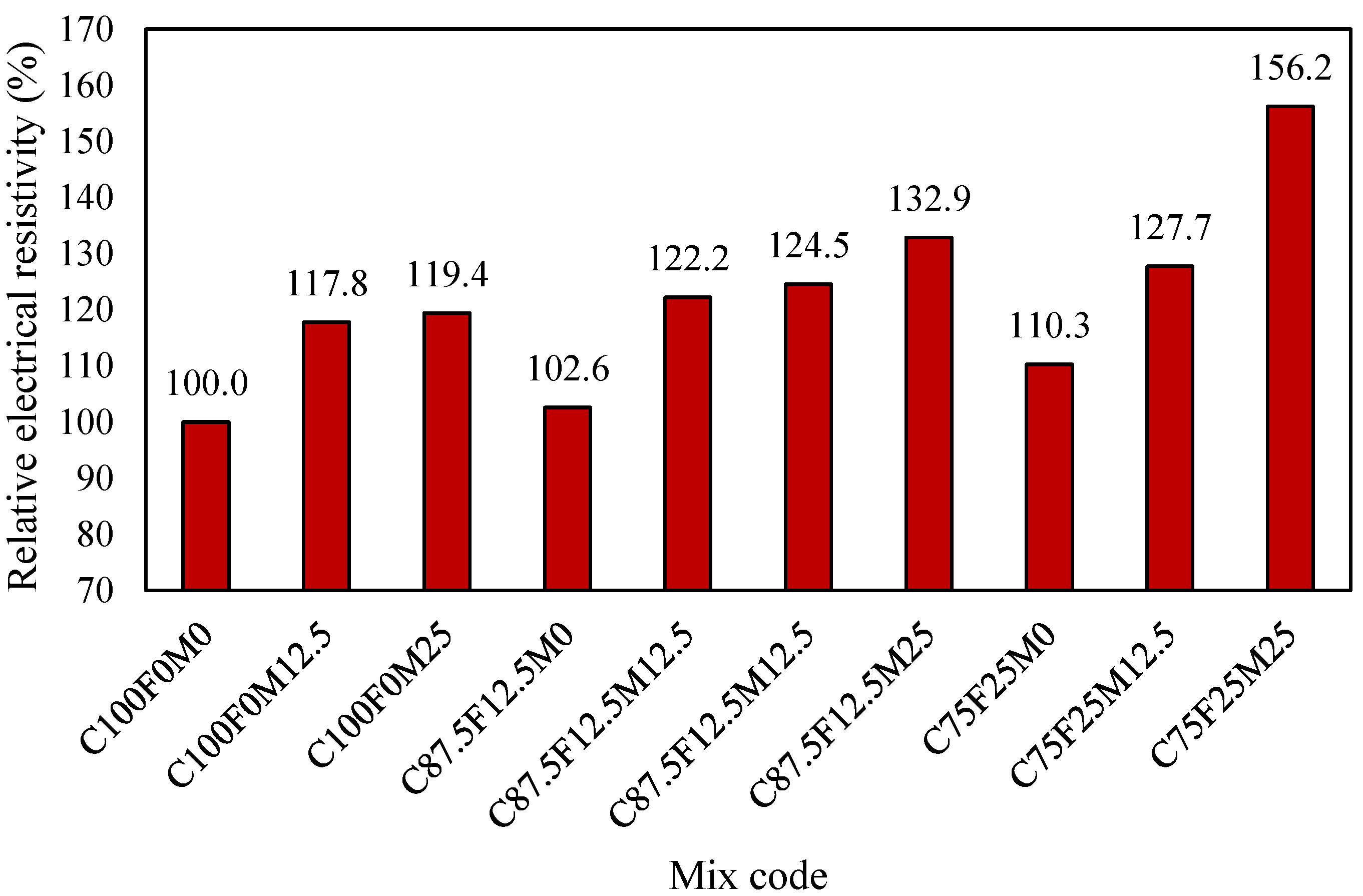

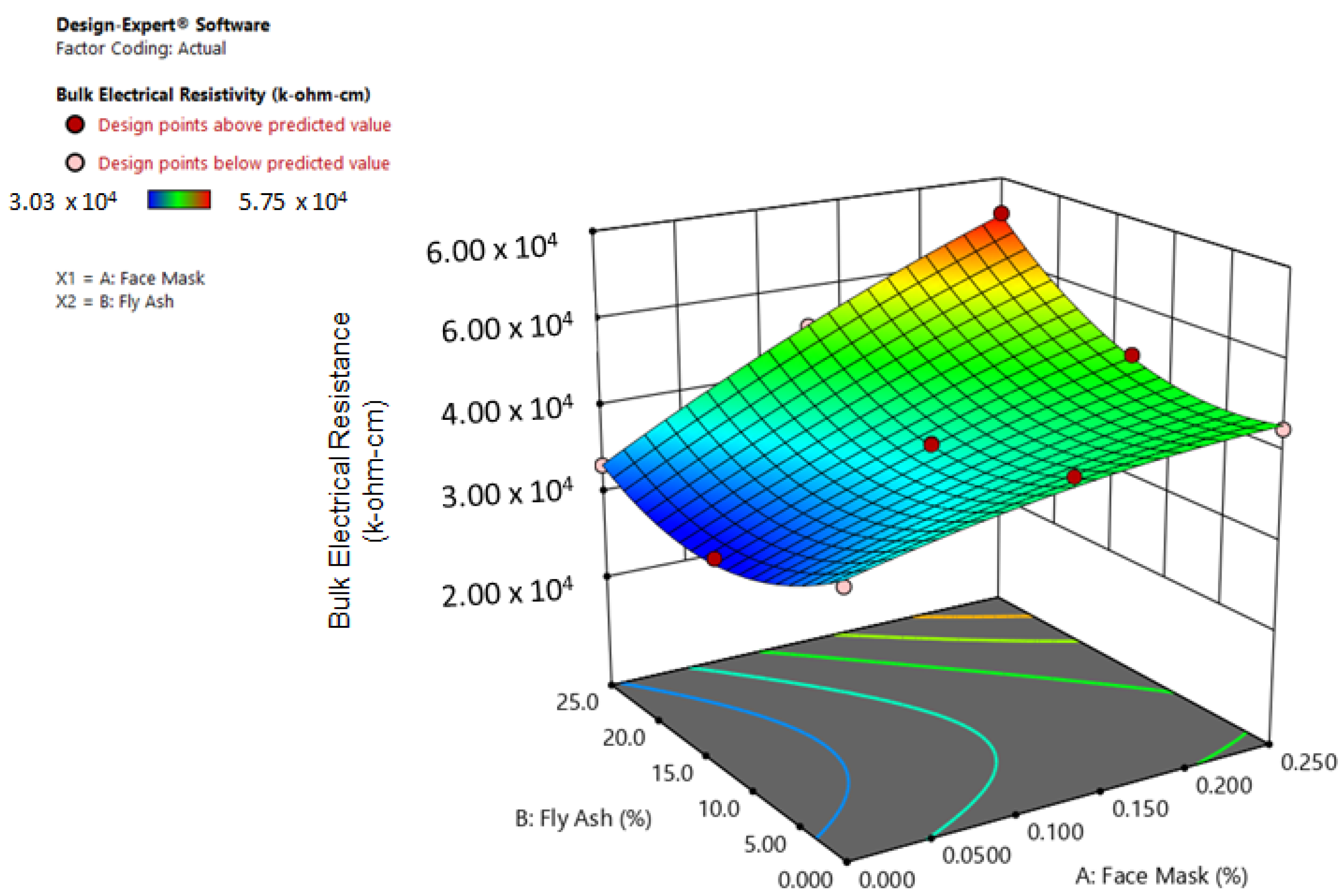

3.8. Bulk Eelectrical Resistivity

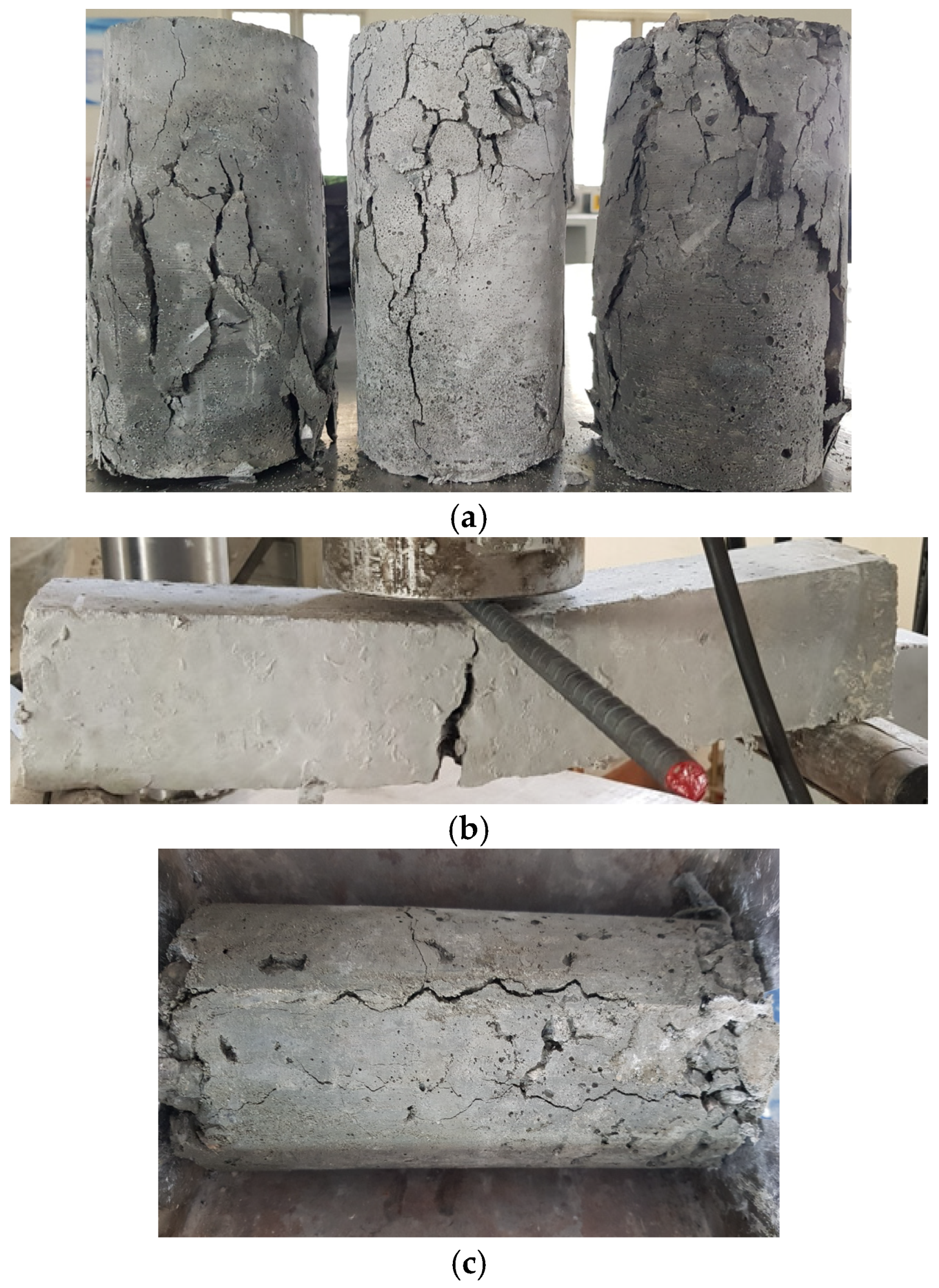

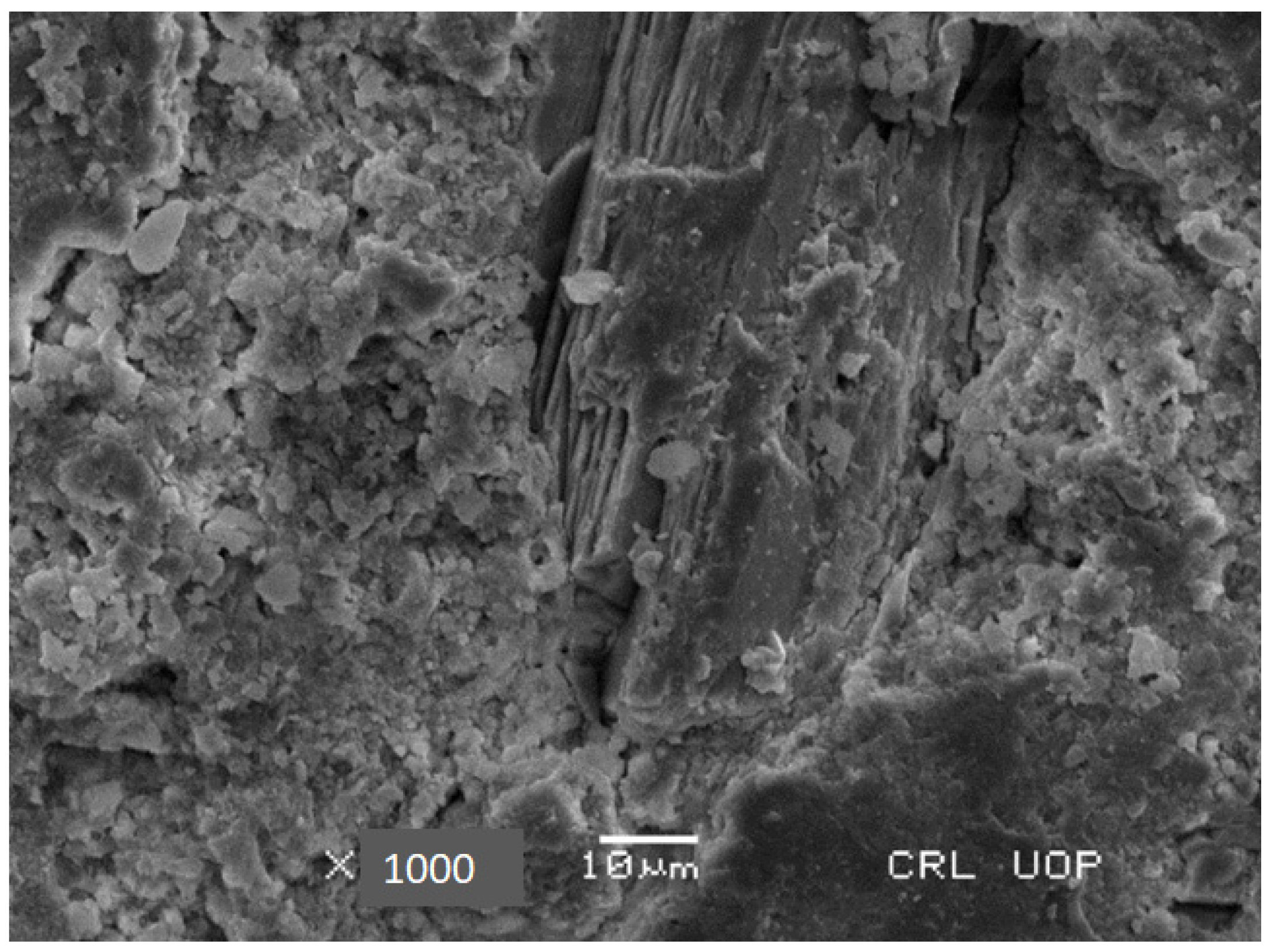

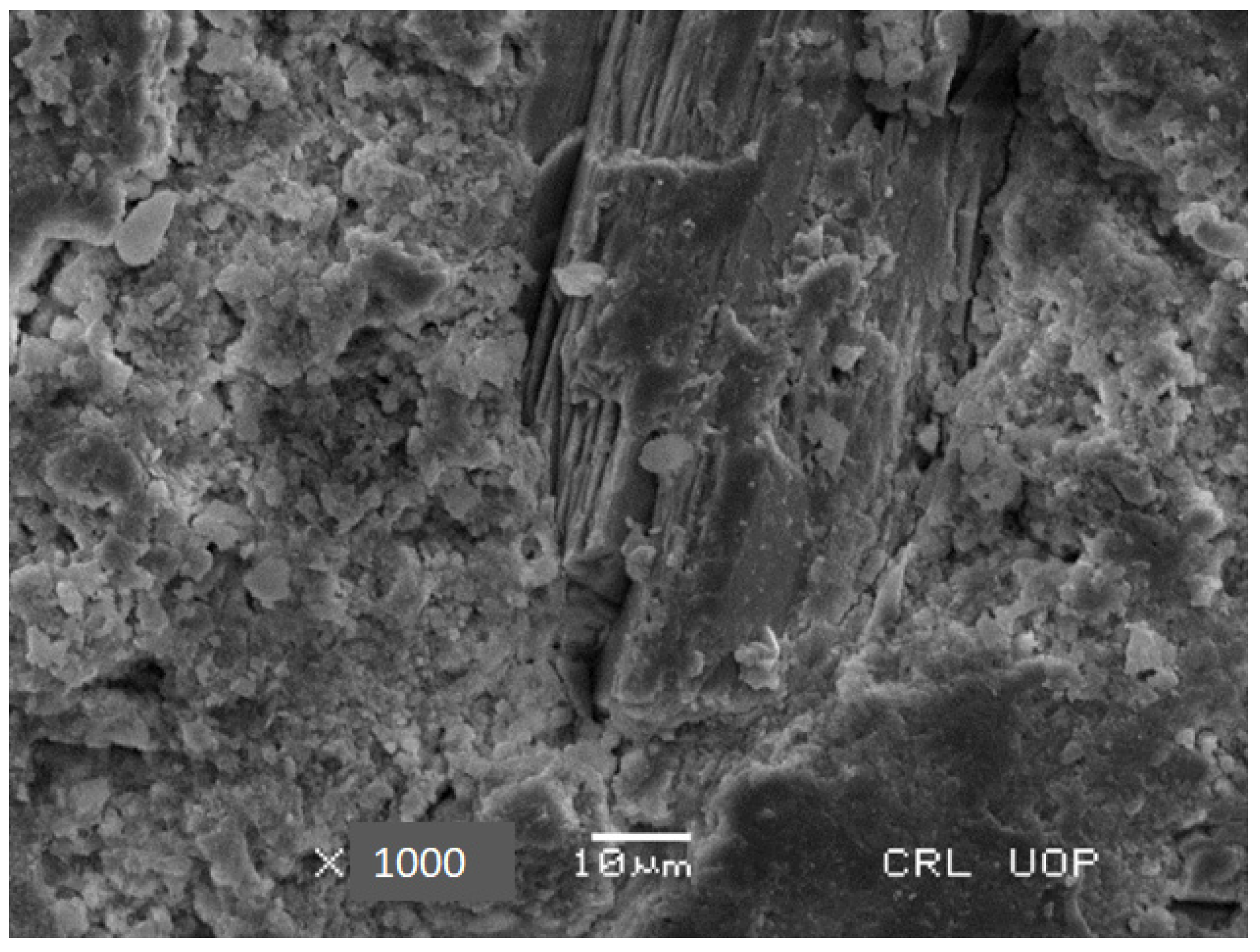

3.9. Microstructural Study of Hardened Concrete

4. Conclusions

- The dry density of the concrete mixes was lowered owing to the incorporation of FA and FM fibers.

- At 3 and 28 days, the compression strength decreased for FA and FM fiber mixes. However, at the later age of 60 days, the compressive strength exhibited enhancements for the mixes containing 0.125% FM fibers as well as for mixes incorporating up to 25% FA.

- FA and FM fibers exhibited lower splitting tensile and flexural strength at 3 and 28 days compared to the control mixture, which tend to improve at a later age of 60 days.

- The enhancement in FM fiber content leads to higher water absorption and bulk water sorption, whereas these values tend to decrease in the case of FA incorporation.

- The addition of FM fibers and FA to the concrete mixes reduced the mass loss when compared to the control mix.

- The electrical resistivity of concrete mixes increased with the FM fibers incorporation when related to the control mix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Silva, A.L.P.; Prata, J.C.; Mouneyrac, C.; Barcelò, D.; Duarte, A.C.; Rocha-Santos, T. Risks of Covid-19 Face Masks to Wildlife: Present and Future Research Needs. Sci. Total Environ. 2021, 792, 148505. [Google Scholar] [PubMed]

- Shukla, S.; Khan, R.; Saxena, A.; Sekar, S. Microplastics from face masks: A potential hazard post Covid-19 pandemic. Chemosphere 2022, 302, 134805. [Google Scholar] [PubMed]

- Jiang, H.; Luo, D.; Wang, L.; Zhang, Y.; Wang, H.; Wang, C. A review of disposable facemasks during the COVID-19 pandemic: A focus on microplastics release. Chemosphere 2023, 312, 137178. [Google Scholar] [CrossRef]

- Potluri, P.; Needham, P. Technical Textiles for Protection. In Textiles for Protection; Elsevier: Amsterdam, The Netherlands, 2005; pp. 151–175. [Google Scholar]

- Latifi, M.R.; Biricik, Ö.; Mardani Aghabaglou, A. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Alsadey, S.; Salem, M. Influence of polypropylene fiber on strength of concrete. Am. J. Eng. Res. 2016, 5, 223–226. [Google Scholar]

- Hassan, A.; ElNemr, A.; Goebel, L.; Koenke, C. Effect of hybrid polypropylene fibers on mechanical and shrinkage behavior of alkali-activated slag concrete. Constr. Build. Mater. 2024, 411, 134485. [Google Scholar] [CrossRef]

- Dharan, D.S.; Lal, A. Study the effect of polypropylene fiber in concrete. Int. Res. J. Eng. Technol. 2016, 3, 616–619. [Google Scholar]

- Sun, Z.; Xu, Q. Microscopic, physical and mechanical analysis of polypropylene fiber reinforced concrete. Mater. Sci. Eng. A 2009, 527, 198–204. [Google Scholar] [CrossRef]

- Haq, I.U.; Elahi, A.; Nawaz, A.; Shah SA, Q.; Ali, K. Mechanical and durability performance of concrete mixtures incorporating bentonite, silica fume, and polypropylene fibers. Constr. Build. Mater. 2022, 345, 128223. [Google Scholar] [CrossRef]

- Zaman, A.B.; Shahzada, K.; Tayyab, N.M. Mechanical properties of polypropylene fibers mixed cement-sand mortar. J. Appl. Eng. Sci. 2019, 17, 116–125. [Google Scholar] [CrossRef]

- Karahan, O.; Atiş, C.D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Win, T.T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar]

- Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Roychand, R.; Zhang, G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021, 296, 126460. [Google Scholar] [CrossRef] [PubMed]

- Avudaiappan, S.; Cendoya, P.; Arunachalam, K.P.; Maureira-Carsalade, N.; Canales, C.; Amran, M.; Parra, P.F. Innovative use of single-use face mask fibers for the production of a sustainable cement mortar. J. Compos. Sci. 2023, 7, 214. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W. Effective recycling of disposable medical face masks for sustainable green concrete via a new fiber hybridization technique. Constr. Build. Mater. 2022, 344, 128245. [Google Scholar] [CrossRef]

- Koniorczyk, M.; Bednarska, D.; Masek, A.; Cichosz, S. Performance of concrete containing recycled masks used for personal protection during coronavirus pandemic. Constr. Build. Mater. 2022, 324, 126712. [Google Scholar] [CrossRef]

- Wang, F.; Luo, X.; Hai, Y.; Yu, C. Experimental investigation of face mask fiber-reinforced fully recycled coarse aggregate concrete. Constr. Build. Mater. 2024, 447, 138141. [Google Scholar] [CrossRef]

- Miah, M.J.; Pei, J.; Kim, H.; Sharma, R.; Jang, J.G.; Ahn, J. Property assessment of an eco-friendly mortar reinforced with recycled mask fiber derived from COVID-19 single-use face masks. J. Build. Eng. 2023, 66, 105885. [Google Scholar] [CrossRef]

- Rodsin, K.; Joyklad, P.; Hussain, Q.; Mohamad, H.; Buatik, A.; Zhou, M.; Chaiyasarn, K.; Nawaz, A.; Mehmood, T.; Elnemr, A. Behavior of steel clamp confined brick aggregate concrete circular columns subjected to axial compression. Case Stud. Constr. Mater. 2022, 16, e00815. [Google Scholar] [CrossRef]

- Liao, Y.; Cai, Z.; Deng, F.; Ye, J.; Wang, K.; Tang, S. Hydration behavior and thermodynamic modelling of ferroaluminate cement blended with steel slag. J. Build. Eng. 2024, 97, 110833. [Google Scholar] [CrossRef]

- Liao, Y.; Yao, J.; Deng, F.; Li, H.; Wang, K.; Tang, S. Hydration behavior and strength development of supersulfated cement prepared by calcined phosphogypsum and slaked lime. J. Build. Eng. 2023, 80, 108075. [Google Scholar] [CrossRef]

- Thomas, M.D.A. Optimizing the Use of Fly Ash in Concrete; Portland Cement Association: Skokie, IL, USA, 2007; Volume 5420. [Google Scholar]

- Yao, G.; Cui, T.; Zhang, J.; Wang, J.; Lyu, X. Effects of mechanical grinding on pozzolanic activity and hydration properties of quartz. Adv. Powder Technol. 2020, 31, 4500–4509. [Google Scholar] [CrossRef]

- Ghelich, R.; Jahannama, M.R.; Abdizadeh, H.; Torknik, F.S.; Vaezi, M.R. Central composite design (CCD)-Response surface methodology (RSM) of effective electrospinning parameters on PVP-B-Hf hybrid nanofibrous composites for synthesis of HfB2-based composite nanofibers. Compos. Part B Eng. 2019, 166, 527–541. [Google Scholar] [CrossRef]

- Ezeagu, C.A.; Agbo-Anike, O.J. Experimental Investigation Using Design Expert Software for Lightweight Concrete Production with Sawdust as Partial Replacement for fine Aggregates. Niger. J. Eng. 2020, 27, 9–16. [Google Scholar]

- ASTM C192/C192M; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- Siddique, R. Performance characteristics of high-volume Class F fly ash concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Nawaz, A.; Julnipitawong, P.; Krammart, P.; Tangtermsirikul, S. Effect and limitation of free lime content in cement-fly ash mixtures. Constr. Build. Mater. 2016, 102, 515–530. [Google Scholar] [CrossRef]

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM Standards: West Conshohocken, PA, USA, 2013.

- ASTM C39/C39M; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM C496/C496M; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C293/C293M; Standard Test Method for Flexural Strength of Concrete. ASTM Standards: West Conshohocken, PA, USA, 2016.

- ASTM C1757; Standard Test Method for Determination of One-Point, Bulk Water Sorption of Dried Concrete. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM C267; Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes. ASTM Standards: West Conshohocken, PA, USA, 2001.

- ASTM C1760; Standard Test Method for Bulk Electrical Conductivity of Hardened Concrete. ASTM Standards: West Conshohocken, PA, USA, 2012.

- Akid, A.S.M.; Hossain, S.; Munshi, M.I.U.; Elahi, M.M.A.; Sobuz, M.H.R.; Tam, V.W.Y.; Islam, M.S. Assessing the influence of fly ash and polypropylene fiber on fresh, mechanical and durability properties of concrete. J. King Saud Univ. Eng. Sci. 2021, 35, 474–484. [Google Scholar]

- Ahmad, J.; Majdi, A.; Babeker Elhag, A.; Deifalla, A.F.; Soomro, M.; Isleem, H.F.; Qaidi, S. A step towards sustainable concrete with substitution of plastic waste in concrete: Overview on mechanical, durability and microstructure analysis. Crystals 2022, 12, 944. [Google Scholar] [CrossRef]

- Puertas, F.; Amat, T.; Fernández-Jiménez, A.; Vázquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- Choi, Y.; Yuan, R.L. Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem. Concr. Res. 2005, 35, 1587–1591. [Google Scholar] [CrossRef]

- Alhozaimy, A.M.; Soroushian, P.; Mirza, F. Mechanical properties of polypropylene fiber reinforced concrete and the effects of pozzolanic materials. Cem. Concr. Compos. 1996, 18, 85–92. [Google Scholar] [CrossRef]

- Huang, W.-H. Improving the properties of cement–fly ash grout using fiber and superplasticizer. Cem. Concr. Res. 2001, 31, 1033–1041. [Google Scholar] [CrossRef]

- Zhang, M.H.; Mirza, J.; Malhotra, V.M. Mechanical properties and freezing and thawing durability of polypropylene fiber-reinforced shotcrete incorporating silica fume and high volumes of fly ash. Cem. Concr. Aggreg. 1999, 21, 117–125. [Google Scholar] [CrossRef]

- Alaj, A.; Krelani, V.; Numao, T. Effect of class F fly ash on strength properties of concrete. Civ. Eng. J. 2023, 9, 2249–2258. [Google Scholar] [CrossRef]

- Susanti, E.; Istiono, H.; Komara, I.; Pertiwi, D.; Septiarsilia, Y.; Syahputra, F.K. Effect of fly ash to water-cement ratio on the characterization of the concrete strength. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1010, 012035. [Google Scholar] [CrossRef]

- Mondal, S.K.; Clinton, C.; Ma, H.; Kumar, A.; Okoronkwo, M.U. Effect of Class C and Class F Fly Ash on Early-Age and Mature-Age Properties of Calcium Sulfoaluminate Cement Paste. Sustainability 2023, 15, 2501. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of fly ash on Portland cement systems: Part I. Low-calcium fly ash. Cem. Concr. Res. 1999, 29, 1727–1736. [Google Scholar] [CrossRef]

- Geng, Z.; Tang, S.; Wang, Y.; He, Z.; Wu, K.; Wang, L. Stress relaxation properties of calcium silicate hydrate: A molecular dynamics study. J. Zhejiang Univ. Sci. A 2024, 25, 97–115. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Zhou, S.; Tang, S.; Lu, X. Investigation of microstructure of CSH and micro-mechanics of cement pastes under NH4NO3 dissolution by 29Si MAS NMR and microhardness. Measurement 2021, 185, 110019. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Esmaeili, M.; Ghahari, S.-A.; Najafi, M.H. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Bagherzadeh, R.; Sadeghi, A.-H.; Latifi, M. Utilizing polypropylene fibers to improve physical and mechanical properties of concrete. Text. Res. J. 2012, 82, 88–96. [Google Scholar] [CrossRef]

- Amjad, H.; Ahmad, F.; Qureshi, M.I. Enhanced mechanical and durability resilience of plastic aggregate concrete modified with nano-iron oxide and sisal fiber reinforcement. Constr. Build. Mater. 2023, 401, 132911. [Google Scholar] [CrossRef]

- Zhang, X.; Yin, R.; Chen, Y.; Lou, C. Experimental study on the axial tensile properties of polypropylene fiber reinforced concrete. Sci. Rep. 2023, 13, 16383. [Google Scholar] [CrossRef]

- Bagherzadeh, R.; Pakravan, H.R.; Sadeghi, A.-H.; Latifi, M.; Merati, A.A. An investigation on adding polypropylene fibers to reinforce lightweight cement composites (LWC). J. Eng. Fibers Fabr. 2012, 7, 155892501200700400. [Google Scholar] [CrossRef]

- Ibrahim, Y.A.; Hasan, A.H.; Maroof, N.R. Effects of polypropylene fiber content on strength and workability properties of concrete. Polytech. J. 2019, 9, 3. [Google Scholar]

- Ras, M. Effect of polypropylene fibers on the mechanical properties of normal concrete. JES J. Eng. Sci. 2006, 34, 1049–1059. [Google Scholar]

- Aly, T.; Sanjayan, J.G.; Collins, F. Effect of polypropylene fibers on shrinkage and cracking of concretes. Mater. Struct. 2008, 41, 1741–1753. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Ghavami, K.; Sanjuán, M.A.; England, G.L. Free, restrained and drying shrinkage of cement mortar composites reinforced with vegetable fibres. Cem. Concr. Compos. 2005, 27, 537–546. [Google Scholar] [CrossRef]

- Peled, A.; Guttman, H.; Bentur, A. Treatments of polypropylene fibres to optimize their reinforcing efficiency in cement composites. Cem. Concr. Compos. 1992, 14, 277–285. [Google Scholar] [CrossRef]

- Mazaheripour, H.; Ghanbarpour, S.; Mirmoradi, S.H.; Hosseinpour, I. The effect of polypropylene fibers on the properties of fresh and hardened lightweight self-compacting concrete. Constr. Build. Mater. 2011, 25, 351–358. [Google Scholar] [CrossRef]

- Rahmani, T.; Kiani, B.; Sami, F.; Fard, B.N.; Farnam, Y.; Shekarchizadeh, M. Durability of glass, polypropylene and steel fiber reinforced concrete. In Proceedings of the International Conference on Durability of Building Materials and Components, Porto, Portugal, 12–15 April 2011; pp. 12–15. [Google Scholar]

- Sengul, O. Use of electrical resistivity as an indicator for durability. Constr. Build. Mater. 2014, 73, 434–441. [Google Scholar] [CrossRef]

- Azarsa, P.; Gupta, R. Electrical resistivity of concrete for durability evaluation: A review. Adv. Mater. Sci. Eng. 2017, 2017, 8453095. [Google Scholar] [CrossRef]

- Araújo, C.C.; Meira, G.R. Correlation between concrete strength properties and surface electrical resistivity. Rev. IBRACON Estrut. E Mater. 2021, 15, e15103. [Google Scholar] [CrossRef]

- Balestra, C.E.T.; Reichert, T.A.; Savaris, G. Concrete Electrical Resistivity as a Durability and Service Life Parameter for Reinforced Concrete Structures. In Durability of Concrete Structures; Springer: Berlin/Heidelberg, Germany, 2021; pp. 51–61. [Google Scholar]

- Layssi, H.; Ghods, P.; Alizadeh, A.R.; Salehi, M. Electrical resistivity of concrete. Concr. Int. 2015, 37, 41–46. [Google Scholar]

| Factor | Code | Levels (%) | ||

|---|---|---|---|---|

| Low (−1) | Mean | High (+1) | ||

| Face mask (FM) | X1 | 0 | 0.125 | 0.25 |

| Fly ash | X2 | 0 | 12.5 | 25 |

| Mix No. | Mix Code | Cement (kg) | Fly Ash (kg) | Sand (kg) | Coarse Aggregates (kg) | Water (kg) | Face Masks (% by Concrete Volume) |

|---|---|---|---|---|---|---|---|

| 1 | C100F0M0 | 400 | 0 | 600 | 1200 | 200 | 0 |

| 2 | C100F0M12.5 | 400 | 0 | 600 | 1200 | 200 | 0.125 |

| 3 | C100F0M25 | 400 | 0 | 600 | 1200 | 200 | 0.25 |

| 4 | C87.5F12.5M0 | 350 | 50 | 600 | 1200 | 200 | 0 |

| 5 | C87.5F12.5M12.5 | 350 | 50 | 600 | 1200 | 200 | 0.125 |

| 6 | C87.5F12.5M12.5 | 350 | 50 | 600 | 1200 | 200 | 0.125 |

| 7 | C87.5F12.5M25 | 350 | 50 | 600 | 1200 | 200 | 0.25 |

| 8 | C75F25M0 | 300 | 100 | 600 | 1200 | 200 | 0 |

| 9 | C75F25M12.5 | 300 | 100 | 600 | 1200 | 200 | 0.125 |

| 10 | C75F25M25 | 300 | 100 | 600 | 1200 | 200 | 0.25 |

| Test | ASTM Standard | Sample Shape | Sample Dimensions (mm) | Test Age (Days) |

|---|---|---|---|---|

| Density of hardened concrete | ASTM C642 [32] | Cylinder | 100 × 200 | 60 |

| Compressive strength test | ASTM C39/C39 [33] | Cylinder | 100 × 200 | 3, 28, 60 |

| Splitting tensile strength test | ASTM C496 [34] | Cylinder | 100 × 200 | 3, 28, 60 |

| Flexural strength test | ASTM C293 [35] | Prism beam | 100 × 100 × 500 | 28, 60 |

| Water absorption test | ASTM C642 [32] | Cylinder | 100 × 200 | 60 |

| Bulk water sorption test | ASTM C1757 [36] | Cylindrical disk | 100 × 50 | 60 |

| Acid resistance test | ASTM C267 [37] | Cylinder | 100 × 200 | 3, 7, 14, 28 |

| Bulk electrical resistivity | ASTM C1760 [38] | Cylinder | 100 × 200 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nawaz, A.; Khan, A.M.; Jirasakjamroonsri, A.; Saingam, P.; Ejaz, A.; Hussain, Q.; Mohamad, H.; Thansirichaisree, P. Performance of Environmentally Friendly Concrete Containing Fly-Ash and Waste Face Mask Fibers. Sustainability 2024, 16, 10385. https://doi.org/10.3390/su162310385

Nawaz A, Khan AM, Jirasakjamroonsri A, Saingam P, Ejaz A, Hussain Q, Mohamad H, Thansirichaisree P. Performance of Environmentally Friendly Concrete Containing Fly-Ash and Waste Face Mask Fibers. Sustainability. 2024; 16(23):10385. https://doi.org/10.3390/su162310385

Chicago/Turabian StyleNawaz, Adnan, Ameer Murad Khan, Amorntep Jirasakjamroonsri, Panumas Saingam, Ali Ejaz, Qudeer Hussain, Hisham Mohamad, and Phromphat Thansirichaisree. 2024. "Performance of Environmentally Friendly Concrete Containing Fly-Ash and Waste Face Mask Fibers" Sustainability 16, no. 23: 10385. https://doi.org/10.3390/su162310385

APA StyleNawaz, A., Khan, A. M., Jirasakjamroonsri, A., Saingam, P., Ejaz, A., Hussain, Q., Mohamad, H., & Thansirichaisree, P. (2024). Performance of Environmentally Friendly Concrete Containing Fly-Ash and Waste Face Mask Fibers. Sustainability, 16(23), 10385. https://doi.org/10.3390/su162310385