Optimizing Hempcrete Properties Through Thermal Treatment of Hemp Hurds for Enhanced Sustainability in Green Building

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hemp Hurd Samples

2.2. Lime

2.3. Hempcrete Specimen Preparation

2.4. Formulation and Design of Hempcrete Mixtures

2.5. Proximate Analysis, CHNS Elemental Analysis, and Determination of Bulk Density and Water Absorption

2.6. Thermogravimetric Analysis (TGA)

2.7. SEM Analysis

2.8. Compressive Strength of the Hempcrete Specimens

2.9. Density of the Hempcrete Specimens

2.10. Water Absorption of the Hempcrete Specimens

2.11. Thermal Conductivity of the Hempcrete Specimens

2.12. Data Analysis

3. Results and Discussion

3.1. Proximate Analysis of the Hemp Hurd Samples

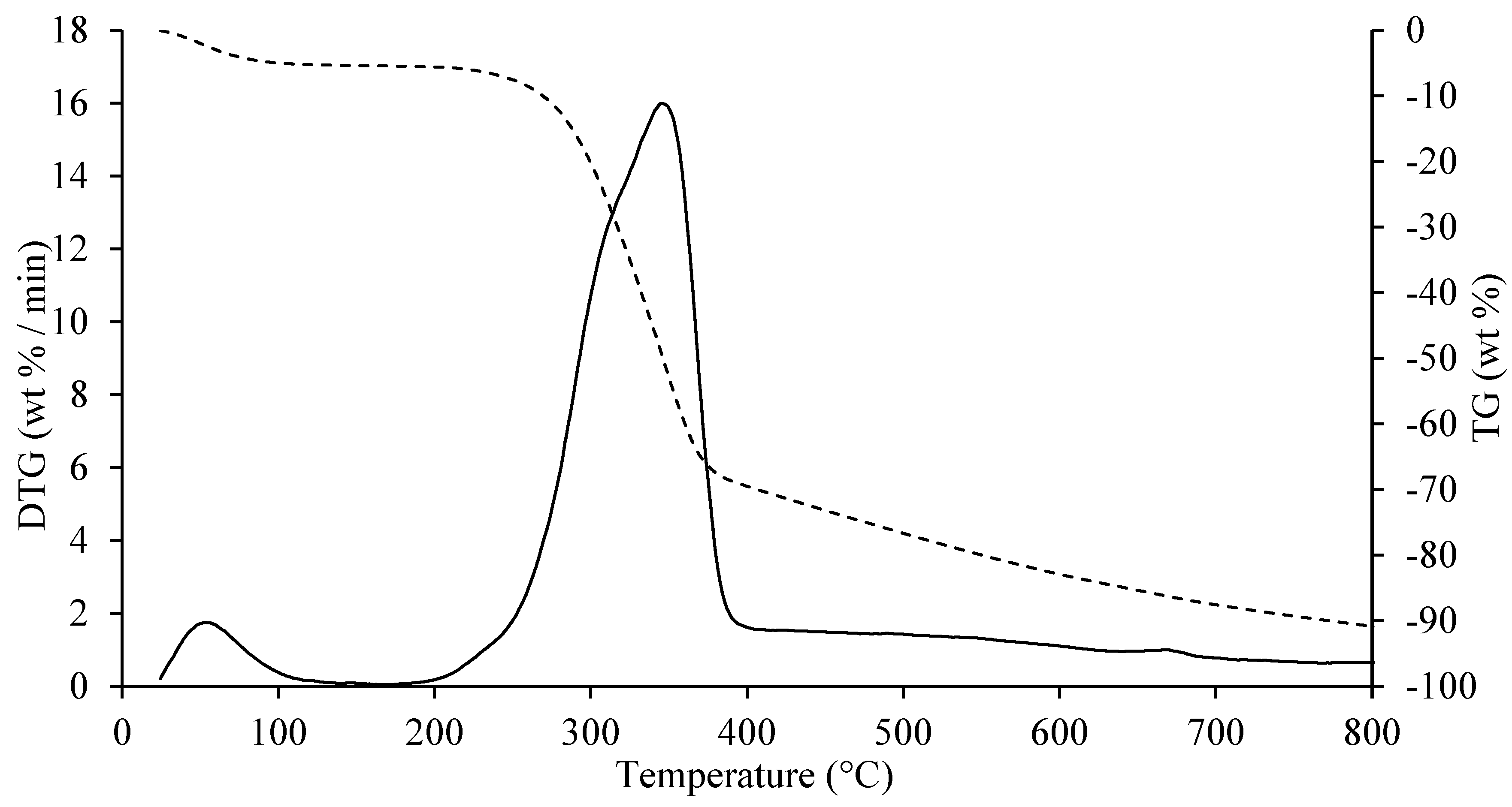

3.2. Thermogravimetric Analysis (TGA) of the Hemp Hurds

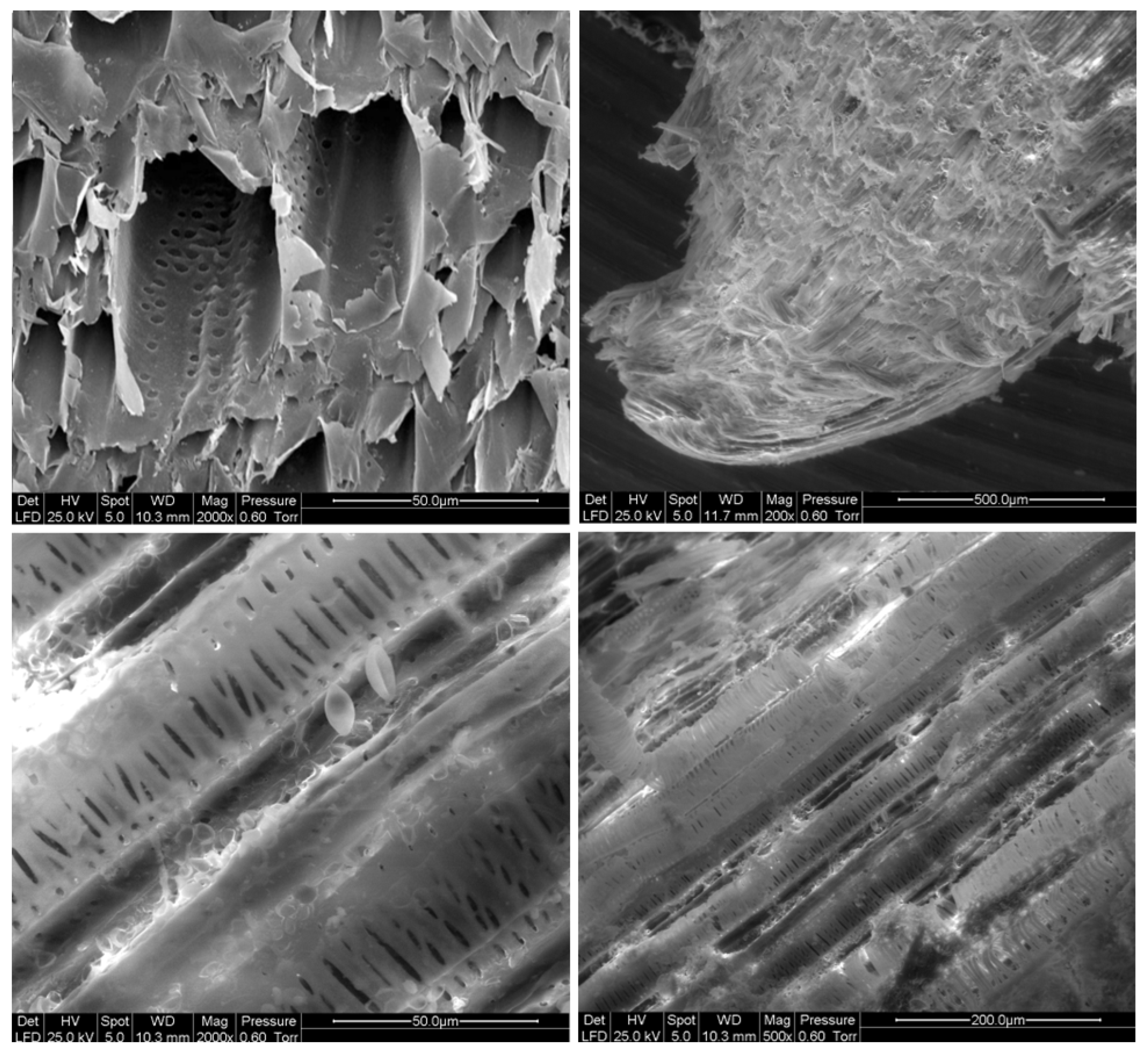

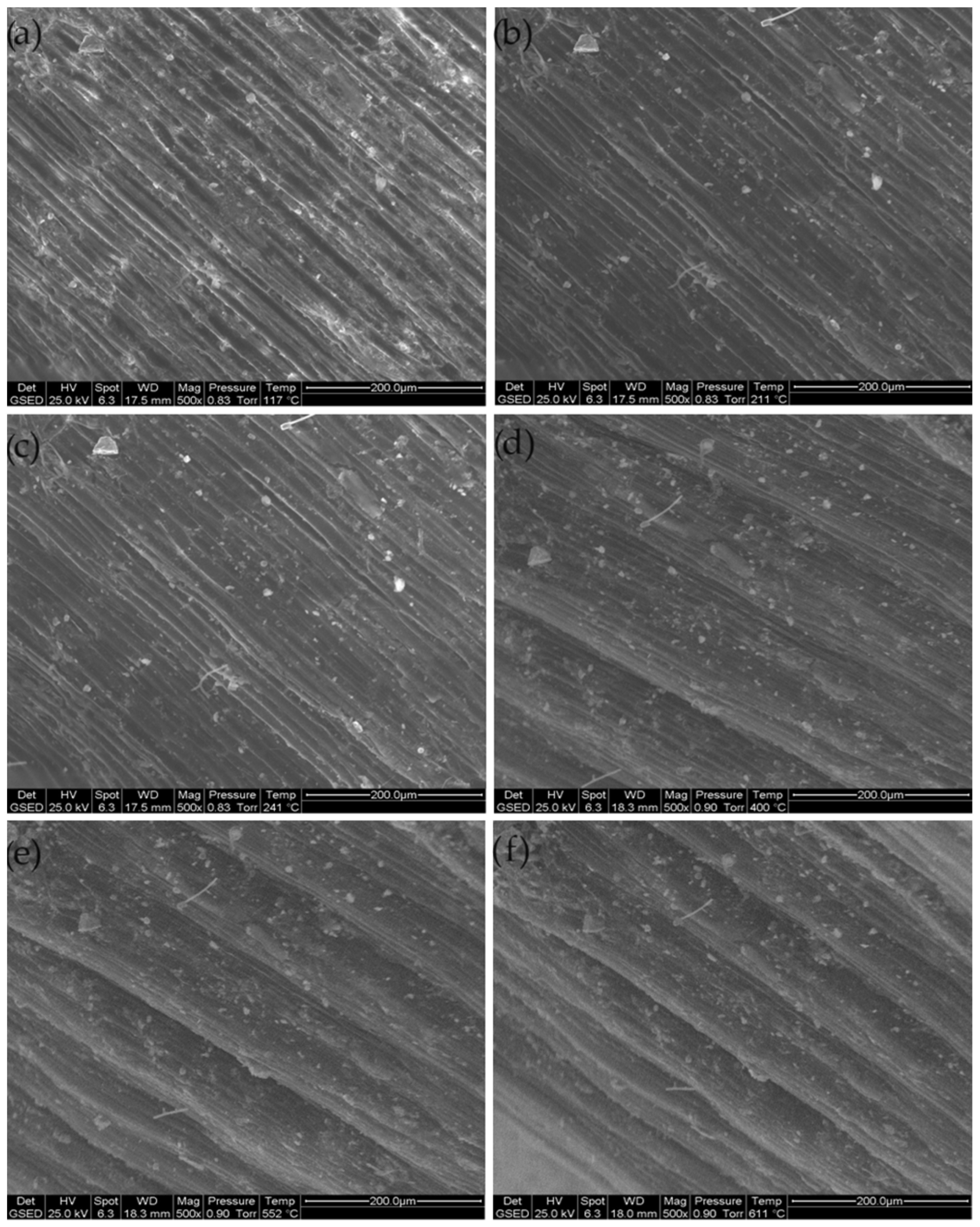

3.3. SEM Analysis

3.4. Hempcrete Properties: Density, Water Absorption, Compressive Strength, and Thermal Conductivity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Traditional and New Applications of Hemp. In Sustainable Agriculture Reviews 42: Hemp Production and Applications; Crini, G., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2020; pp. 37–87. ISBN 978-3-030-41384-2. [Google Scholar]

- Zhao, X.; Wei, X.; Guo, Y.; Qiu, C.; Long, S.; Wang, Y.; Qiu, H. Industrial Hemp—An Old but Versatile Bast Fiber Crop. J. Nat. Fibers 2022, 19, 6269–6282. [Google Scholar] [CrossRef]

- Nath, M.K. Benefits of Cultivating Industrial Hemp (Cannabis sativa ssp. Sativa)—A Versatile Plant for a Sustainable Future. Chem. Proc. 2022, 10, 14. [Google Scholar] [CrossRef]

- Rehman, M.; Fahad, S.; Du, G.; Cheng, X.; Yang, Y.; Tang, K.; Liu, L.; Liu, F.-H.; Deng, G. Evaluation of Hemp (Cannabis sativa L.) as an Industrial Crop: A Review. Environ. Sci. Pollut. Res. 2021, 28, 52832–52843. [Google Scholar] [CrossRef]

- Muzyczek, M. 4—The Use of Flax and Hemp for Textile Applications. In Handbook of Natural Fibres, 2nd ed.; Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; The Textile Institute Book Series; Woodhead Publishing: Cambridgeshire, UK, 2020; pp. 147–167. ISBN 978-0-12-818782-1. [Google Scholar]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for High-Value Textile Applications: The Effective Long Fiber Yield and Quality of Different Hemp Varieties, Processed Using Industrial Flax Equipment. Ind. Crops Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Ranalli, P.; Venturi, G. Hemp as a Raw Material for Industrial Applications. Euphytica 2004, 140, 1–6. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of Hemp in Textiles, Paper Industry, Insulation and Building Materials, Horticulture, Animal Nutrition, Food and Beverages, Nutraceuticals, Cosmetics and Hygiene, Medicine, Agrochemistry, Energy Production and Environment: A Review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G.; Scaccianoce, G.; Sorrentino, G. Thermal and Structural Properties of a Hemp–Lime Biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

- Qiu, R.; Ren, X.; Fifield, L.S.; Simmons, K.L.; Li, K. Hemp-Fiber-Reinforced Unsaturated Polyester Composites: Optimization of Processing and Improvement of Interfacial Adhesion. J. Appl. Polym. Sci. 2011, 121, 862–868. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp Fiber and Its Composites—A Review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Haque, M.N.; Al-Khaiat, H.; Kayali, O. Strength and Durability of Lightweight Concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

- Thienel, K.-C.; Haller, T.; Beuntner, N. Lightweight Concrete—From Basics to Innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef]

- D’Eusanio, V.; Bertacchini, L.; Marchetti, A.; Mariani, M.; Pastorelli, S.; Silvestri, M.; Tassi, L. Rosaceae Nut-Shells as Sustainable Aggregate for Potential Use in Non-Structural Lightweight Concrete. Waste 2023, 1, 549–568. [Google Scholar] [CrossRef]

- D’Eusanio, V.; Anderlini, B.; Marchetti, A.; Pastorelli, S.; Roncaglia, F.; Ughetti, A. Exploring the Potential of Peach (Prunus persica L.) Nut-Shells as a Sustainable Alternative to Traditional Aggregates in Lightweight Concrete. Multidiscip. J. Eng. Sci. 2023, 2, 22–39. [Google Scholar] [CrossRef]

- Bejan, G.; Bărbuță, M.; Vizitiu, R.Ș.; Burlacu, A. Lightweight Concrete with Waste—Review. Procedia Manuf. 2020, 46, 136–143. [Google Scholar] [CrossRef]

- Samson, G.; Phelipot-Mardelé, A.; Lanos, C. A Review of Thermomechanical Properties of Lightweight Concrete. Mag. Concr. Res. 2017, 69, 201–216. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Rind, T.A.; Sandhu, A.R. Development of Thermal Insulating Lightweight Foamed Concrete Reinforced with Polypropylene Fibres. Arab. J. Sci. Eng. 2020, 45, 4067–4076. [Google Scholar] [CrossRef]

- Jami, T.; Rawtani, D.; Agrawal, Y.K. Hemp Concrete: Carbon-Negative Construction. Emerg. Mater. Res. 2016, 5, 240–247. [Google Scholar] [CrossRef]

- Arehart, J.H.; Nelson, W.S.; Srubar, W.V. On the Theoretical Carbon Storage and Carbon Sequestration Potential of Hempcrete. J. Clean. Prod. 2020, 266, 121846. [Google Scholar] [CrossRef]

- Kumar, V.; Ramadoss, R.; G.S, R. A Study Report on Carbon Sequestration by Using Hempcrete. Mater. Today Proc. 2021, 45, 6369–6371. [Google Scholar] [CrossRef]

- Arehart, J.H.; Hart, J.; Pomponi, F.; D’Amico, B. Carbon Sequestration and Storage in the Built Environment. Sustain. Prod. Consum. 2021, 27, 1047–1063. [Google Scholar] [CrossRef]

- Galván-Ruiz, M.; Hernández, J.; Baños, L.; Noriega-Montes, J.; Rodríguez-García, M.E. Characterization of Calcium Carbonate, Calcium Oxide, and Calcium Hydroxide as Starting Point to the Improvement of Lime for Their Use in Construction. J. Mater. Civ. Eng. 2009, 21, 694–698. [Google Scholar] [CrossRef]

- Yadav, M.; Saini, A. Opportunities & Challenges of Hempcrete as a Building Material for Construction: An Overview. Mater. Today Proc. 2022, 65, 2021–2028. [Google Scholar] [CrossRef]

- Nguyen, T.-T.; Picandet, V.; Amziane, S.; Baley, C. Influence of Compactness and Hemp Hurd Characteristics on the Mechanical Properties of Lime and Hemp Concrete. Eur. J. Environ. Civ. Eng. 2009, 13, 1039–1050. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A Review of the Properties of Hemp Concrete for Green Building Applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Stevulova, N.; Cigasova, J.; Estokova, A.; Terpakova, E.; Geffert, A.; Kacik, F.; Singovszka, E.; Holub, M. Properties Characterization of Chemically Modified Hemp Hurds. Materials 2014, 7, 8131–8150. [Google Scholar] [CrossRef]

- Bokhari, S.M.Q.; Chi, K.; Catchmark, J.M. Structural and Physico-Chemical Characterization of Industrial Hemp Hurd: Impacts of Chemical Pretreatments and Mechanical Refining. Ind. Crops Prod. 2021, 171, 113818. [Google Scholar] [CrossRef]

- Heinze, T. Cellulose: Structure and Properties. In Cellulose Chemistry and Properties: Fibers, Nanocelluloses and Advanced Materials; Rojas, O.J., Ed.; Springer: Cham, Switzerland, 2016; pp. 1–52. ISBN 978-3-319-26015-0. [Google Scholar]

- Ebringerová, A.; Hromádková, Z.; Heinze, T. Hemicellulose. In Polysaccharides I: Structure, Characterization and Use; Heinze, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1–67. ISBN 978-3-540-31583-4. [Google Scholar]

- Jędrzejczak, P.; Collins, M.N.; Jesionowski, T.; Klapiszewski, Ł. The Role of Lignin and Lignin-Based Materials in Sustainable Construction—A Comprehensive Review. Int. J. Biol. Macromol. 2021, 187, 624–650. [Google Scholar] [CrossRef]

- Van Balen, K.; Van Gemert, D. Modelling Lime Mortar Carbonation. Mater. Struct. 1994, 27, 393–398. [Google Scholar] [CrossRef]

- Shih, S.-M.; Ho, C.-S.; Song, Y.-S.; Lin, J.-P. Kinetics of the Reaction of Ca(OH)2 with CO2 at Low Temperature. Ind. Eng. Chem. Res. 1999, 38, 1316–1322. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted Pre-Treatment of Hemp Bast Fibres for Optimal Performance in Biocomposite Materials: A Review. Ind. Crops Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical Treatments on Plant-Based Natural Fibre Reinforced Polymer Composites: An Overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Moonart, U.; Utara, S. Effect of Surface Treatments and Filler Loading on the Properties of Hemp Fiber/Natural Rubber Composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Prasad, B.M.; Sain, M.M. Mechanical Properties of Thermally Treated Hemp Fibers in Inert Atmosphere for Potential Composite Reinforcement. Mater. Res. Innov. 2003, 7, 231–238. [Google Scholar] [CrossRef]

- Stevulova, N.; Estokova, A.; Cigasova, J.; Schwarzova, I.; Kacik, F.; Geffert, A. Thermal Degradation of Natural and Treated Hemp Hurds under Air and Nitrogen Atmosphere. J. Therm. Anal. Calorim. 2017, 128, 1649–1660. [Google Scholar] [CrossRef]

- Kundu, K.; Chatterjee, A.; Bhattacharyya, T.; Roy, M.; Kaur, A. Thermochemical Conversion of Biomass to Bioenergy: A Review; Springer: Berlin/Heidelberg, Germany, 2018; pp. 235–268. ISBN 978-981-10-7517-9. [Google Scholar]

- Collet, F.; Pretot, S. Thermal Conductivity of Hemp Concretes: Variation with Formulation, Density and Water Content. Constr. Build. Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Picandet, V.; Carre, P.; Lecompte, T.; Amziane, S.; Baley, C. Effect of Compaction on Mechanical and Thermal Properties of Hemp Concrete. Eur. J. Environ. Civ. Eng. 2010, 14, 545–560. [Google Scholar] [CrossRef]

- Abdellatef, Y.; Khan, M.A.; Khan, A.; Alam, M.I.; Kavgic, M. Mechanical, Thermal, and Moisture Buffering Properties of Novel Insulating Hemp-Lime Composite Building Materials. Materials 2020, 13, 5000. [Google Scholar] [CrossRef]

- Isaac, R.A. AOAC: Official Methods of Analysis (Volume 1); Association of Official Analytical Chemists, Inc.: Washington, DC, USA, Chapter 3; 1990; pp. 40–63. [Google Scholar]

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absoprtion of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D5334-08; Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. ASTM International, American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- D’Eusanio, V.; Malferrari, D.; Marchetti, A.; Roncaglia, F.; Tassi, L. Waste By-Product of Grape Seed Oil Production: Chemical Characterization for Use as a Food and Feed Supplement. Life 2023, 13, 326. [Google Scholar] [CrossRef]

- D’Eusanio, V.; Lezza, A.; Anderlini, B.; Malferrari, D.; Romagnoli, M.; Roncaglia, F. Technological Prospects of Biochar Derived from Viticulture Waste: Characterization and Application Perspectives. Energies 2024, 17, 3421. [Google Scholar] [CrossRef]

- Johnson, C.M. Differential Scanning Calorimetry as a Tool for Protein Folding and Stability. Arch. Biochem. Biophys. 2013, 531, 100–109. [Google Scholar] [CrossRef]

- Ojeda-Galván, H.J.; Hernández-Arteaga, A.C.; Rodríguez-Aranda, M.C.; Toro-Vazquez, J.F.; Cruz-González, N.; Ortíz-Chávez, S.; Comas-García, M.; Rodríguez, A.G.; Navarro-Contreras, H.R. Application of Raman Spectroscopy for the Determination of Proteins Denaturation and Amino Acids Decomposition Temperature. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2023, 285, 121941. [Google Scholar] [CrossRef]

- Şen, D.; Gökmen, V. Kinetic Modeling of Maillard and Caramelization Reactions in Sucrose-Rich and Low Moisture Foods Applied for Roasted Nuts and Seeds. Food Chem. 2022, 395, 133583. [Google Scholar] [CrossRef]

- Weiss, I.M.; Muth, C.; Drumm, R.; Kirchner, H.O.K. Thermal Decomposition of the Amino Acids Glycine, Cysteine, Aspartic Acid, Asparagine, Glutamic Acid, Glutamine, Arginine and Histidine. BMC Biophys. 2018, 11, 2. [Google Scholar] [CrossRef]

- Salema, A.A.; Ting, R.M.W.; Shang, Y.K. Pyrolysis of Blend (Oil Palm Biomass and Sawdust) Biomass Using TG-MS. Bioresour. Technol. 2019, 274, 439–446. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic Biomass Pyrolysis Mechanism: A State-of-the-Art Review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Li, K.; Du, W.; Lu, K.; Zhang, Y. Thermal Interaction Analysis of Isolated Hemicellulose and Cellulose by Kinetic Parameters during Biomass Pyrolysis. Energy 2020, 195, 117010. [Google Scholar] [CrossRef]

- Carrier, M.; Loppinet-Serani, A.; Denux, D.; Lasnier, J.-M.; Ham-Pichavant, F.; Cansell, F.; Aymonier, C. Thermogravimetric Analysis as a New Method to Determine the Lignocellulosic Composition of Biomass. Biomass Bioenergy 2011, 35, 298–307. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chin, T.; Liang, D.T.; Chen, H.; Zheng, C. Thermogravimetric Analysis−Fourier Transform Infrared Analysis of Palm Oil Waste Pyrolysis. Energy Fuels 2004, 18, 1814–1821. [Google Scholar] [CrossRef]

- Hosoya, T.; Kawamoto, H.; Saka, S. Cellulose–Hemicellulose and Cellulose–Lignin Interactions in Wood Pyrolysis at Gasification Temperature. J. Anal. Appl. Pyrolysis 2007, 80, 118–125. [Google Scholar] [CrossRef]

- Zhao, C.; Jiang, E.; Chen, A. Volatile Production from Pyrolysis of Cellulose, Hemicellulose and Lignin. J. Energy Inst. 2017, 90, 902–913. [Google Scholar] [CrossRef]

- Yeo, J.Y.; Chin, B.L.F.; Tan, J.K.; Loh, Y.S. Comparative Studies on the Pyrolysis of Cellulose, Hemicellulose, and Lignin Based on Combined Kinetics. J. Energy Inst. 2019, 92, 27–37. [Google Scholar] [CrossRef]

| Proportions (vol%) | |||

|---|---|---|---|

| Formulation | Hemp Hurd | Lime | Water |

| A | 80 | 12 | 8 |

| B | 75 | 15 | 10 |

| C | 65 | 20 | 15 |

| Sample | AD | 120 | 160 | 200 | 240 | 280 |

|---|---|---|---|---|---|---|

| Moisture (wt%) | 9.96 ± 0.23 a | 5.80 ± 0.14 b | 3.61 ± 0.33 c | 1.32 ± 0.19 d | 0.758 ± 0.072 e | 0.581 ± 0.080 e |

| Protein (wt%) | 2.25 ± 0.09 a | 1.53 ± 0.08 b | 1.60 ± 0.08 bc | 1.90 ± 0.15 c | 2.22 ± 0.13 a | 2.63 ± 0.14 d |

| Lipids (wt%) | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| Ash (wt%) | 1.10 ± 0.01 a | 1.16 ± 0.05 a | 1.50 ± 0.05 b | 1.92 ± 0.06 c | 2.80 ± 0.15 d | 3.72 ± 0.12 e |

| C (wt%) | 46.2 ± 1.9 a | 47.3 ± 1.0 a | 47.9 ± 0.2 a | 48.0 ± 0.1 a | 50.9 ± 0.2 b | 52.4 ± 0.4 b |

| H (wt%) | 5.82 ± 0.11 ab | 5.68 ± 0.13 ab | 5.85 ± 0.07 b | 5.84 ± 0.14 ab | 5.65 ± 0.15 ab | 5.53 ± 0.05 a |

| N (wt%) | 0.35 ± 0.03 ac | 0.24 ± 0.04 b | 0.26 ± 0.02 a | 0.32 ± 0.05 abc | 0.35 ± 0.04 abc | 0.42 ± 0.03 c |

| S (wt%) | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| O# (wt%) | 46.5 ± 2.0 a | 45.6 ± 0.8 a | 44.5 ± 0.2 a | 43.9 ± 0.2 a | 40.3 ± 0.5 b | 38.0 ± 0.6 b |

| Bulk density (g/mL) | 0.117 ± 0.002 a | 0.114 ± 0.003 ab | 0.108 ± 0.004 bc | 0.106 ± 0.001 cd | 0.103 ± 0.001 cde | 0.098 ± 0.001 e |

| Water absorption (%) | 263 ± 2 a | 262 ± 3 ab | 255 ± 4 b | 245 ± 2 c | 232 ± 2 d | 191 ± 3 e |

| Region | To (°C) | Tm (°C) | Tc (°C) | Δm wt% | Thermally Activated Processes |

|---|---|---|---|---|---|

| I | 24.6 | 53.2 | 120.5 | 5.22 | Removal of moisture and VOCs. |

| II | 120.5 | - | 210.3 | 0.480 | Removal of bound water, NH3 from protein denaturation, low-boiling VOCs, and loss of CO and CO2. |

| III | 210.3 | 345.6 | 415.3 | 64.9 | Protein degradation, removal of reaction and constitutional water, low-boiling VOCs, decarboxylation of acids with CO2 loss, degradation of polysaccharides, plasticization, and pseudo-vitrification of the sample. |

| IV | 415.3 | - | 700.2 | 16.9 | Removal of reaction water, and weak reactions related to slow volatilization of CO2 and carbon residues. |

| V | 700.2 | - | 814.8 | 3.75 | Volatilization of carbon residues (C20–C40 fragments) |

| Density (14 d) (kg/m3) | Density (28 d) (kg/m3) | Water Absorption (%) | Compressive Strength (kPa) | Thermal Conductivity (W/mK) | |

|---|---|---|---|---|---|

| AAD | 397 ± 10 ah | 309 ± 11 a | 121.1 ± 13.3 a | 318 ± 13 a | 0.047 ± 0.007 a |

| A120 | 401 ± 19 abh | 312 ± 14 a | 118.3 ± 3.7 a | 331 ± 19 a | 0.057 ± 0.009 ab |

| A160 | 400 ± 11 ach | 298 ± 9 a | 116.1 ± 17.0 ab | 325 ± 28 a | 0.063 ± 0.004 abc |

| A200 | 365 ± 12 ad | 281 ± 11 ab | 90.3 ± 9.5 bc | 383 ± 16 ab | 0.072 ± 0.002 bcd |

| A240 | 328 ± 16 de | 240 ± 15 bc | 72.9 ± 8.8 cd | 466 ± 22 cd | 0.080 ± 0.001 cde |

| A280 | 308 ± 8 e | 225 ± 20 c | 63.9 ± 7.0 d | 515 ± 31 cd | 0.081 ± 0.002 cde |

| BAD | 452 ± 17 bfh | 382 ± 17 di | 114.5 ± 7.4 ab | 334 ± 22 a | 0.088 ± 0.007 de |

| B120 | 467 ± 22 fgh | 400 ± 5 dhi | 114.2 ± 5.0 ab | 452 ± 42 bc | 0.089 ± 0.011 de |

| B160 | 432 ± 32 h | 379 ± 13 di | 104.2 ± 9.4 abce | 375 ± 32 a | 0.096 ± 0.007 e |

| B200 | 421 ± 21 h | 362 ± 16 de | 80.9 ± 6.3 cde | 498 ± 32 cd | 0.118 ± 0.007 f |

| B240 | 358 ± 15 ae | 321 ± 18 ae | 67.6 ± 5.7 cf | 511 ± 11 cd | 0.134 ± 0.006 fg |

| B280 | 328 ± 8 de | 298 ± 22 a | 58.7 ± 7.9 d | 540 ± 26 d | 0.142 ± 0.008 gh |

| CAD | 506 ± 14 gi | 469 ± 10 f | 104.8 ± 6.8 ab | 512 ± 18 cd | 0.121 ± 0.005 f |

| C120 | 497 ± 14 fi | 451 ± 26 fg | 103.5 ± 5.5 ab | 513 ± 19 cd | 0.128 ± 0.007 fg |

| C160 | 491 ± 9 fi | 443 ± 16 fh | 95.5 ± 8.8 abc | 532 ± 18 d | 0.137 ± 0.002 fgh |

| C200 | 485 ± 14 fi | 438 ± 11 fh | 76.7 ± 10.0 bcd | 677 ± 12 e | 0.149 ± 0.007 gi |

| C240 | 474 ± 18 fi | 432 ± 17 fh | 62.1 ± 7.2 df | 777 ± 22 f | 0.156 ± 0.005 hi |

| C280 | 449 ± 19 cfh | 418 ± 17 gi | 52.4 ± 6.3 df | 829 ± 26 f | 0.166 ± 0.003 i |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Eusanio, V.; Rivi, M.; Malferrari, D.; Marchetti, A. Optimizing Hempcrete Properties Through Thermal Treatment of Hemp Hurds for Enhanced Sustainability in Green Building. Sustainability 2024, 16, 10404. https://doi.org/10.3390/su162310404

D’Eusanio V, Rivi M, Malferrari D, Marchetti A. Optimizing Hempcrete Properties Through Thermal Treatment of Hemp Hurds for Enhanced Sustainability in Green Building. Sustainability. 2024; 16(23):10404. https://doi.org/10.3390/su162310404

Chicago/Turabian StyleD’Eusanio, Veronica, Mirco Rivi, Daniele Malferrari, and Andrea Marchetti. 2024. "Optimizing Hempcrete Properties Through Thermal Treatment of Hemp Hurds for Enhanced Sustainability in Green Building" Sustainability 16, no. 23: 10404. https://doi.org/10.3390/su162310404

APA StyleD’Eusanio, V., Rivi, M., Malferrari, D., & Marchetti, A. (2024). Optimizing Hempcrete Properties Through Thermal Treatment of Hemp Hurds for Enhanced Sustainability in Green Building. Sustainability, 16(23), 10404. https://doi.org/10.3390/su162310404