Enhancing Dispersive Soil: An Experimental Study on the Efficacy of Microbial, Electrokinetics, and Chemical Approaches

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Apparatus

2.1.1. Dispersive Soil

2.1.2. Additives

2.1.3. Bacterial Solution

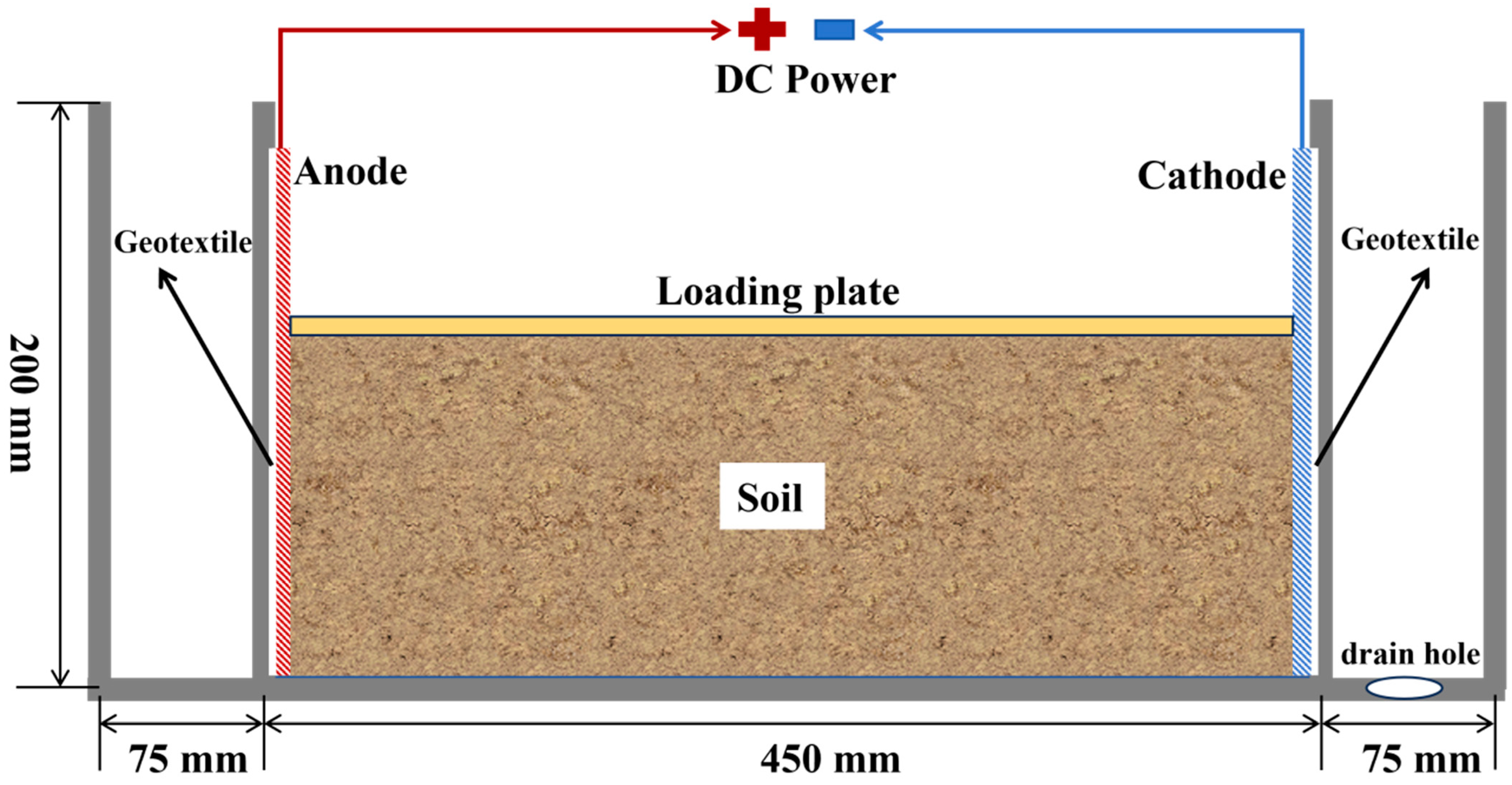

2.1.4. EK Apparatus

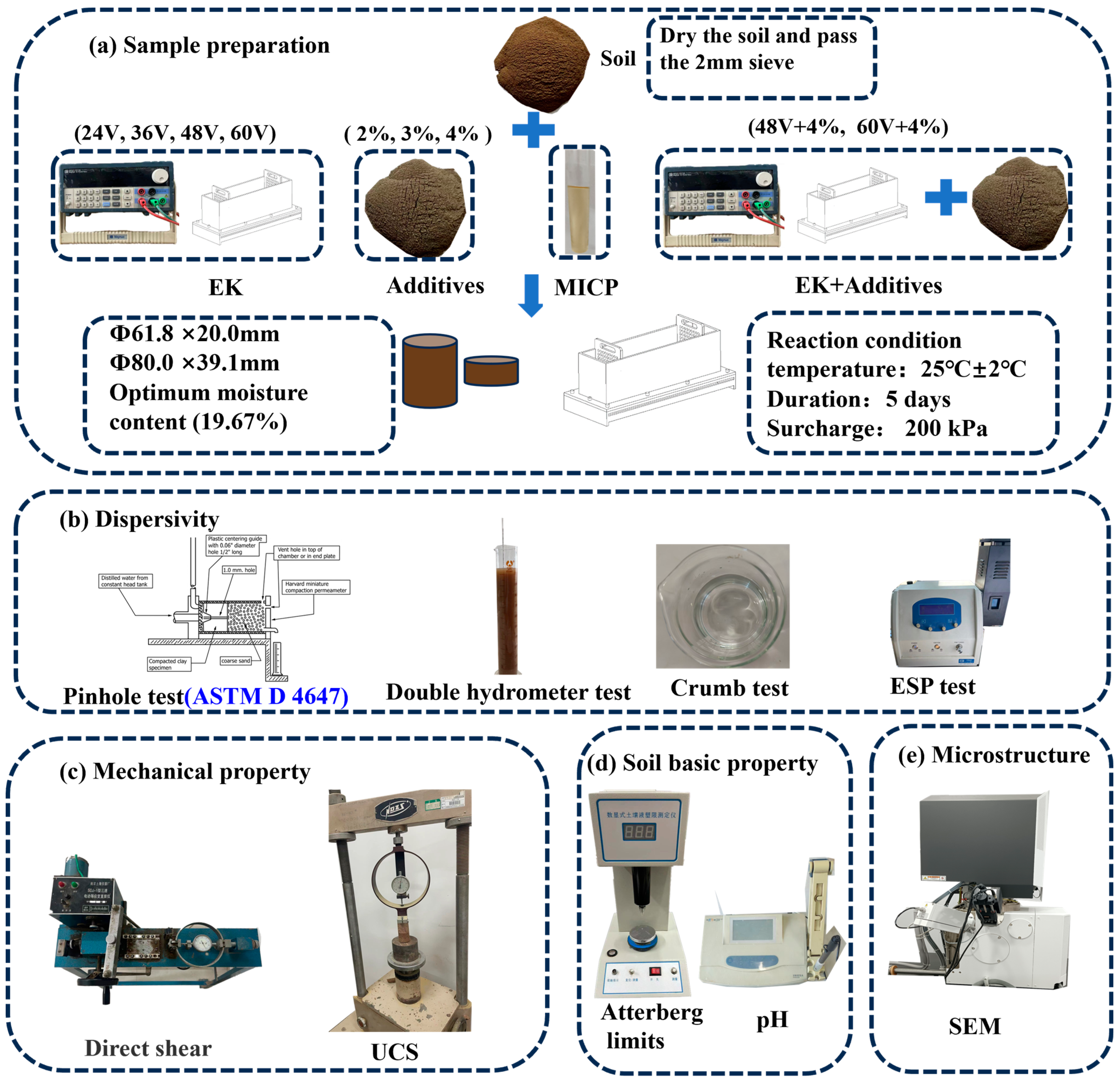

2.2. Sample Preparation

2.3. Methods

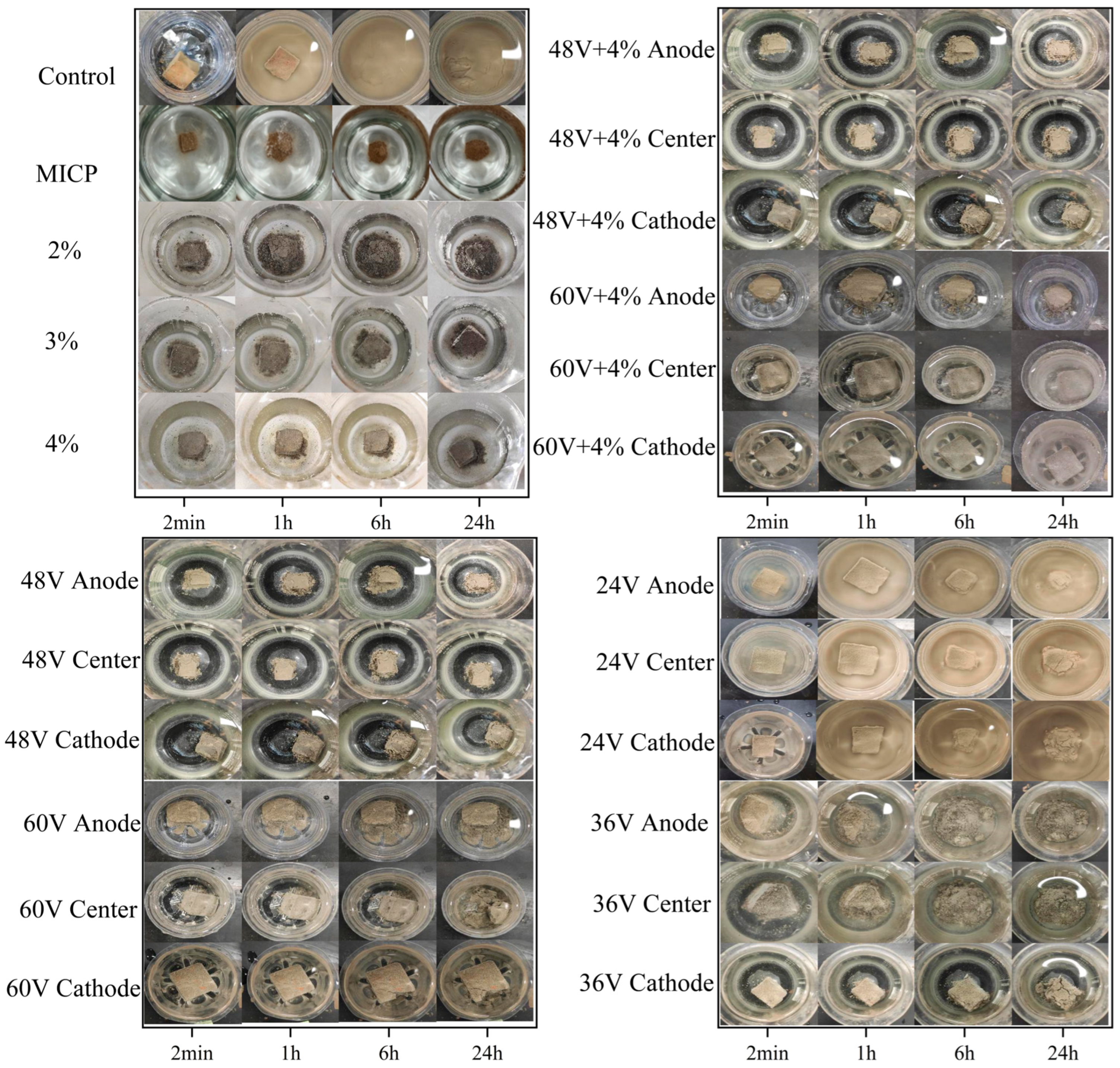

2.3.1. Dispersivity

2.3.2. pH

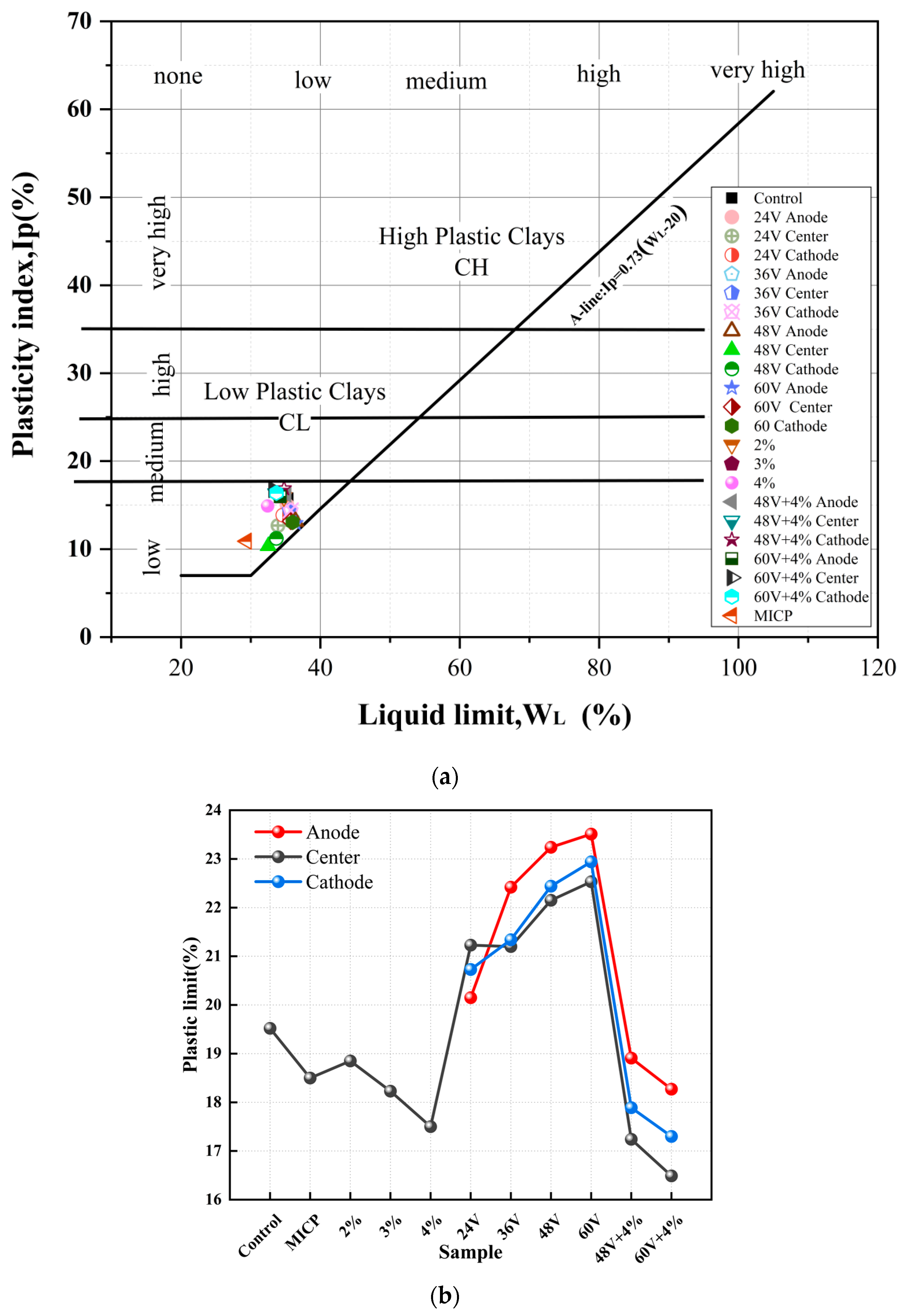

2.3.3. Atterberg Limits

2.3.4. Mechanical Tests

2.3.5. SEM

3. Results and Discussion

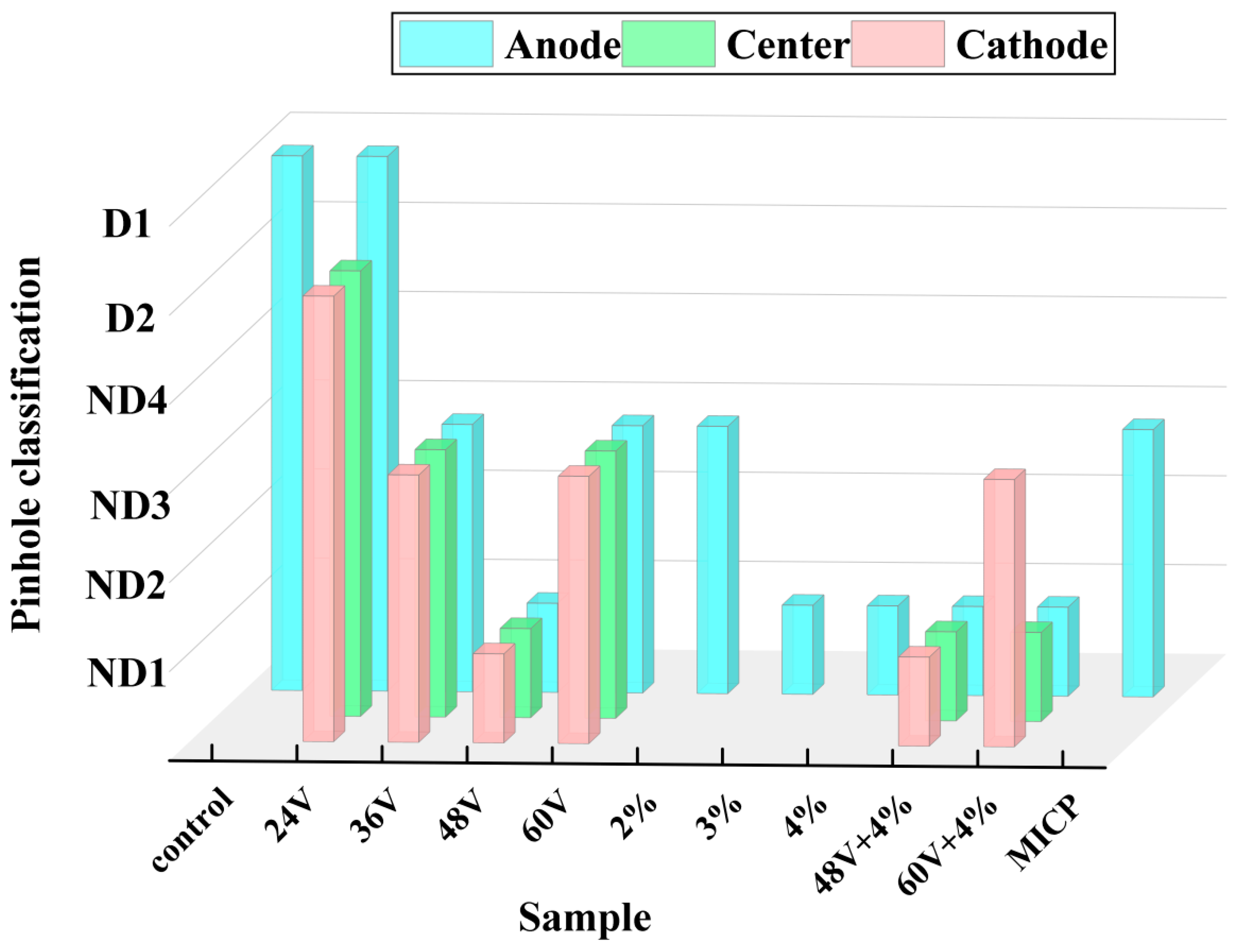

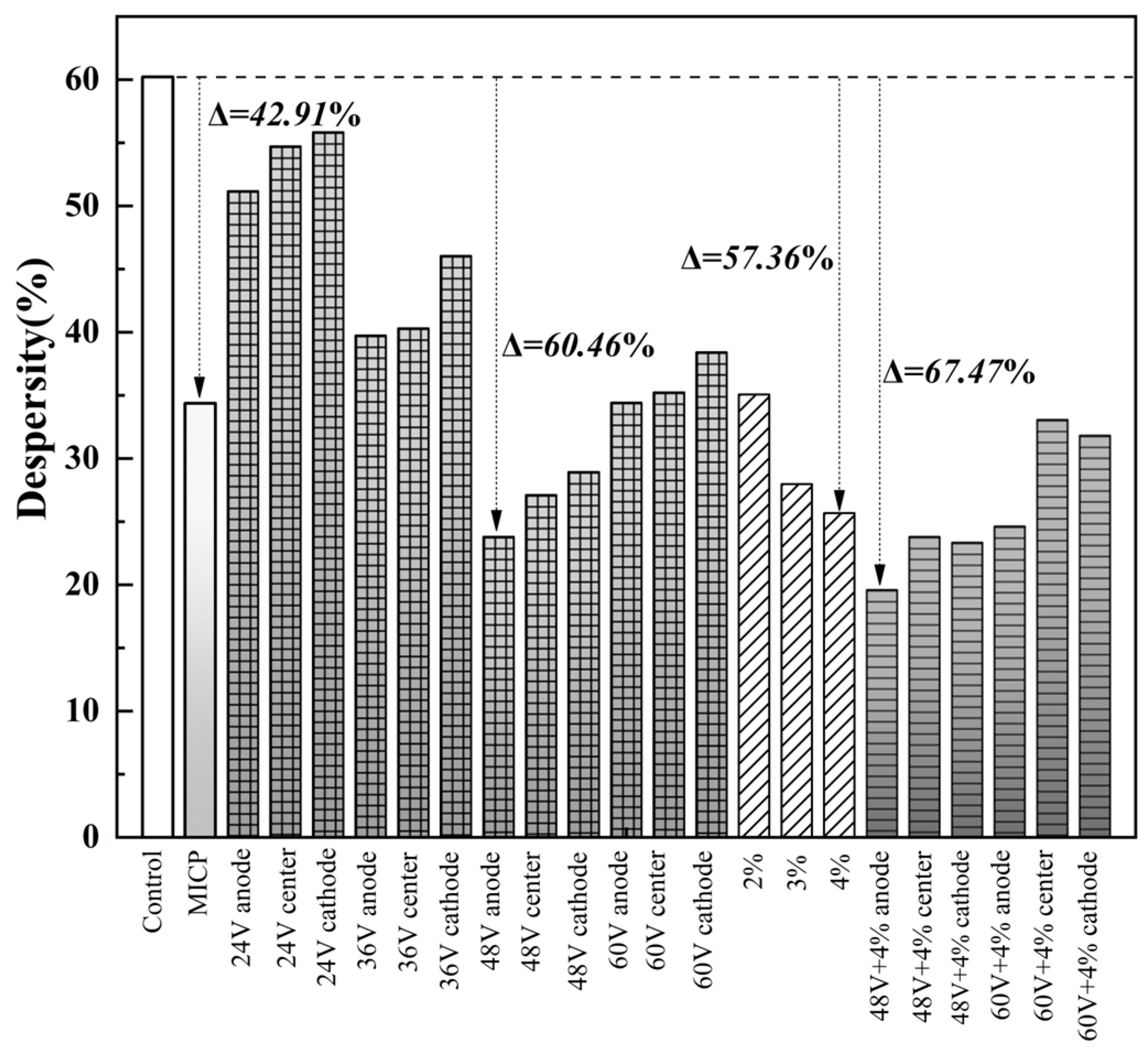

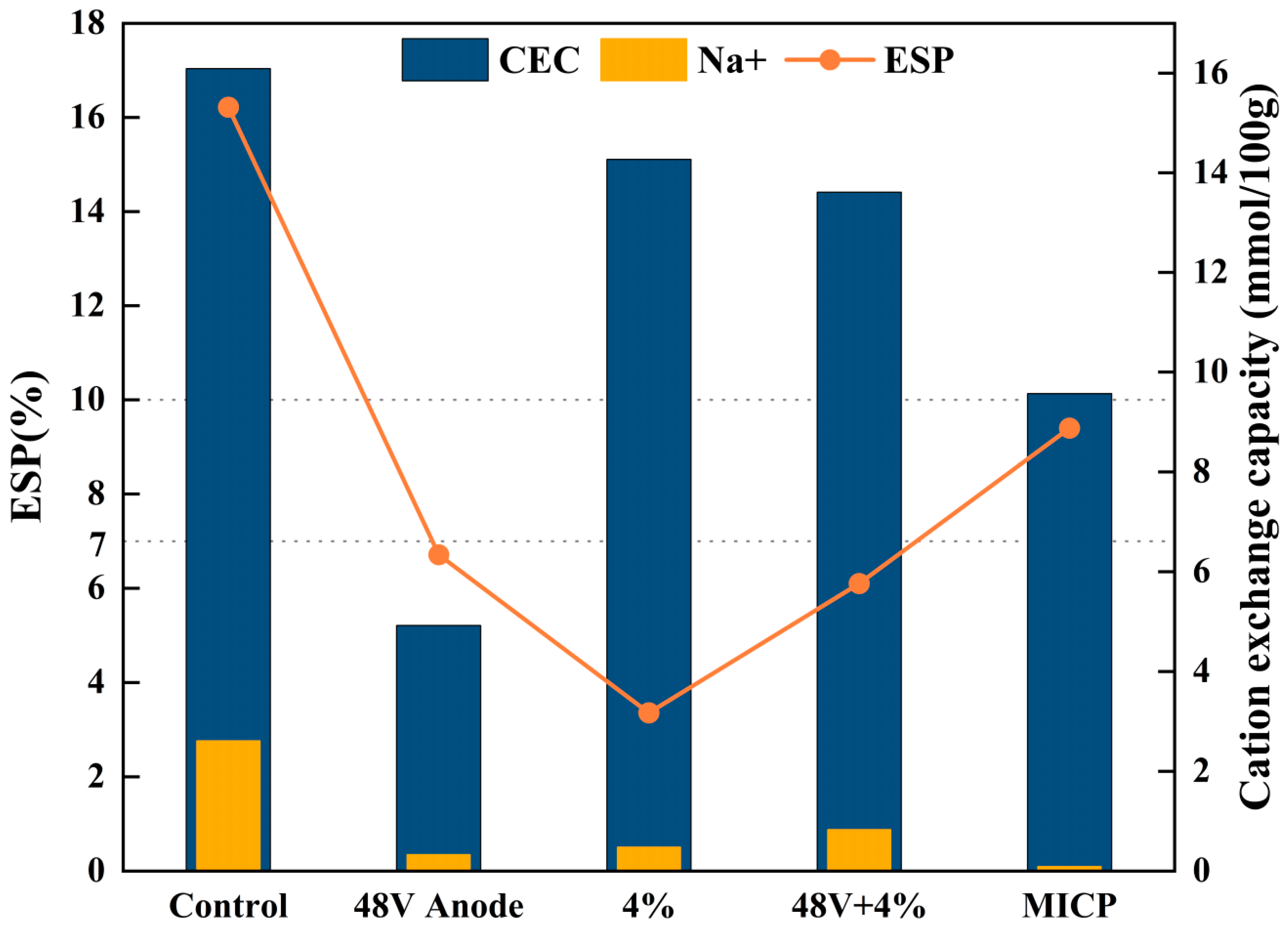

3.1. Dispersivity

3.2. pH and CaCO3

3.3. Atterberg Limits

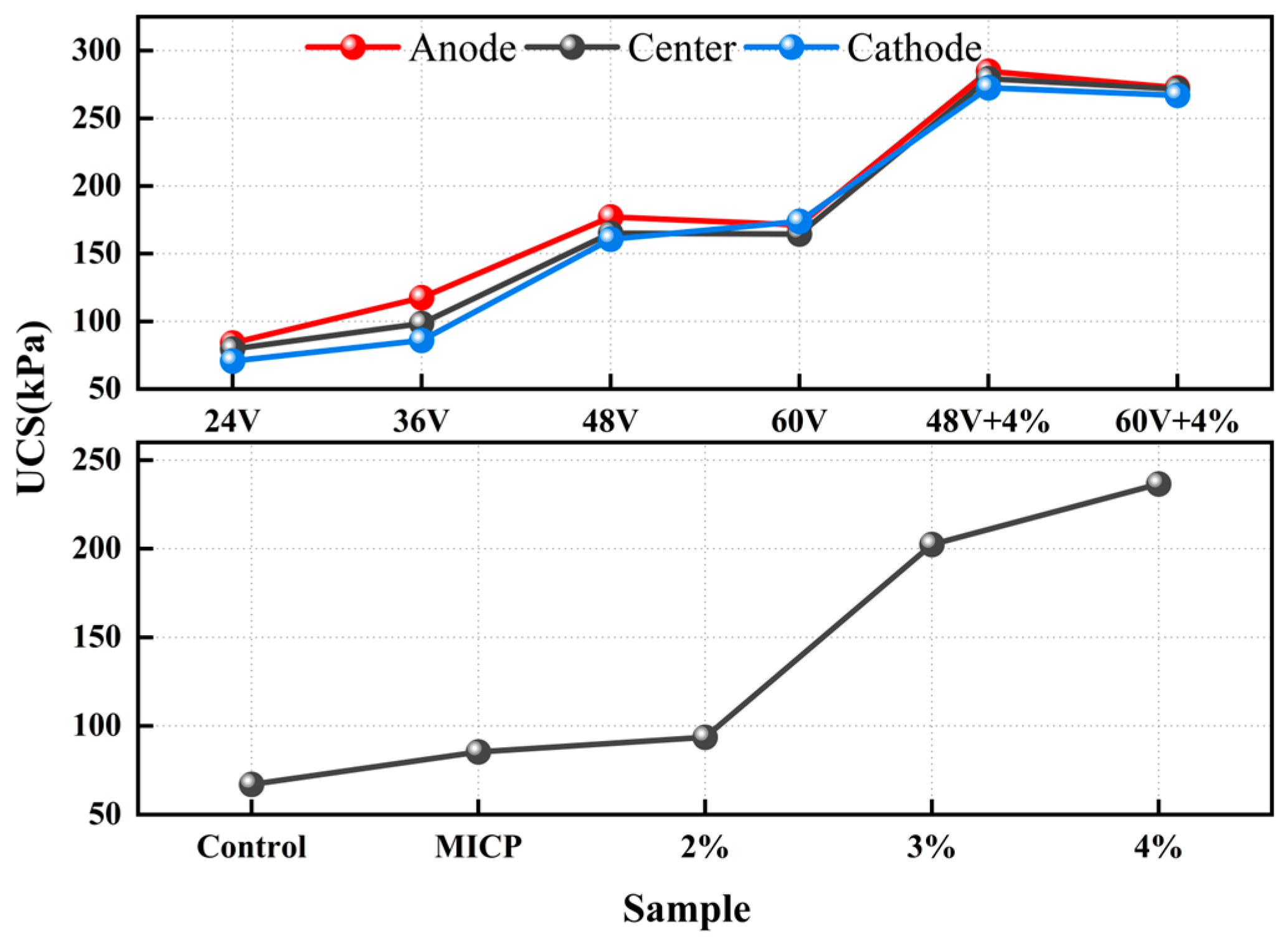

3.4. Mechanical Property

3.4.1. UCS

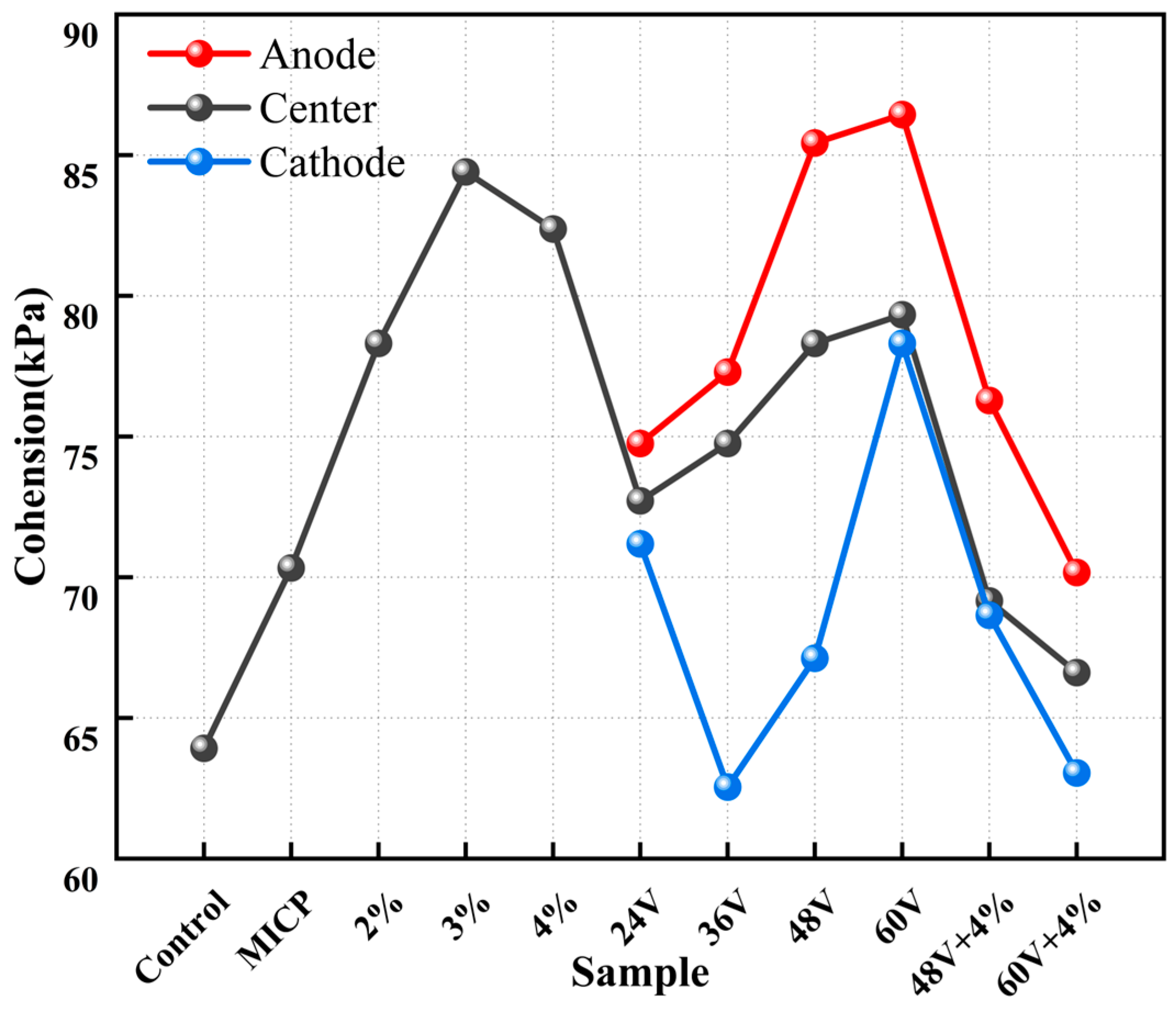

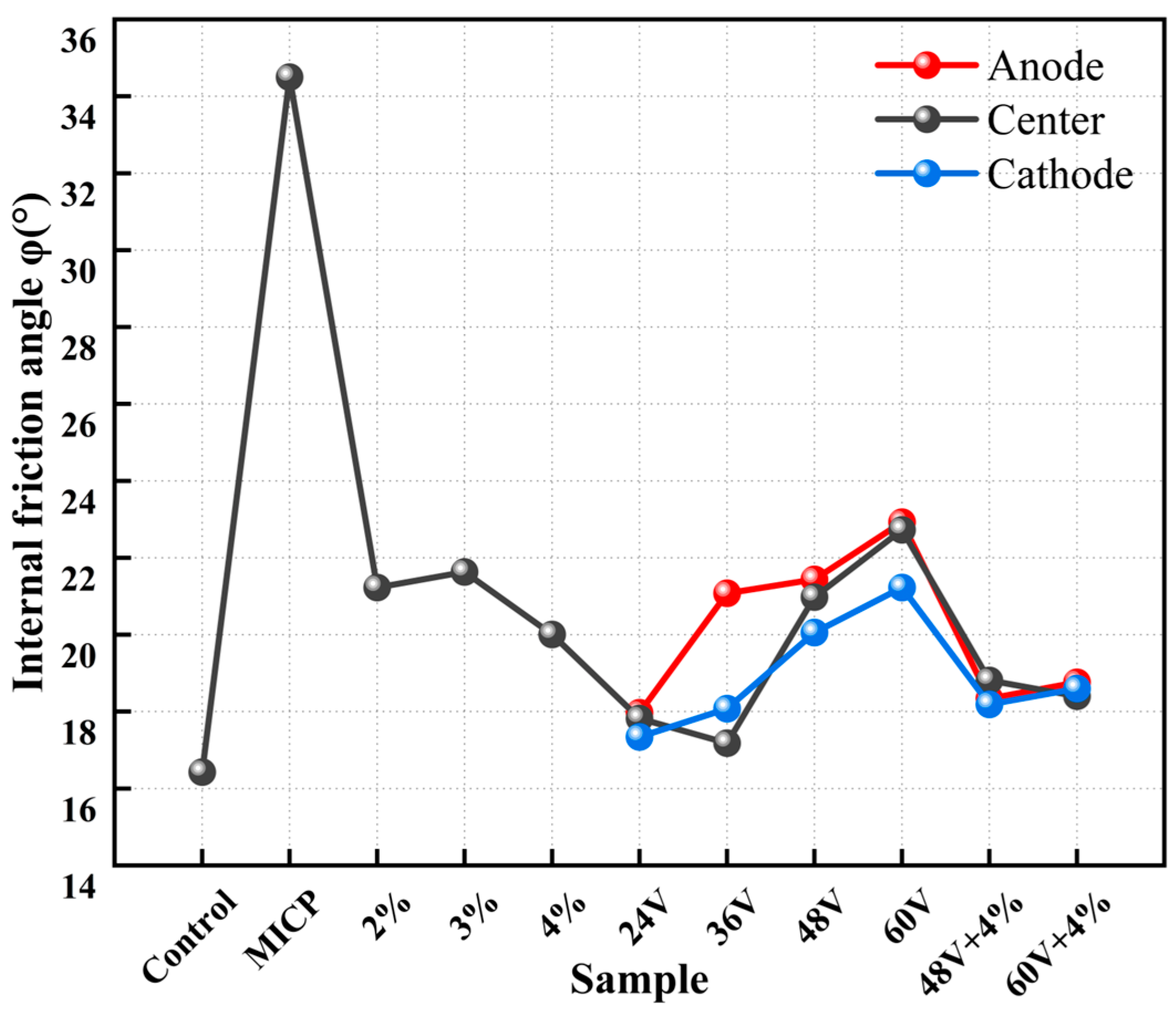

3.4.2. Direct Shearing Test

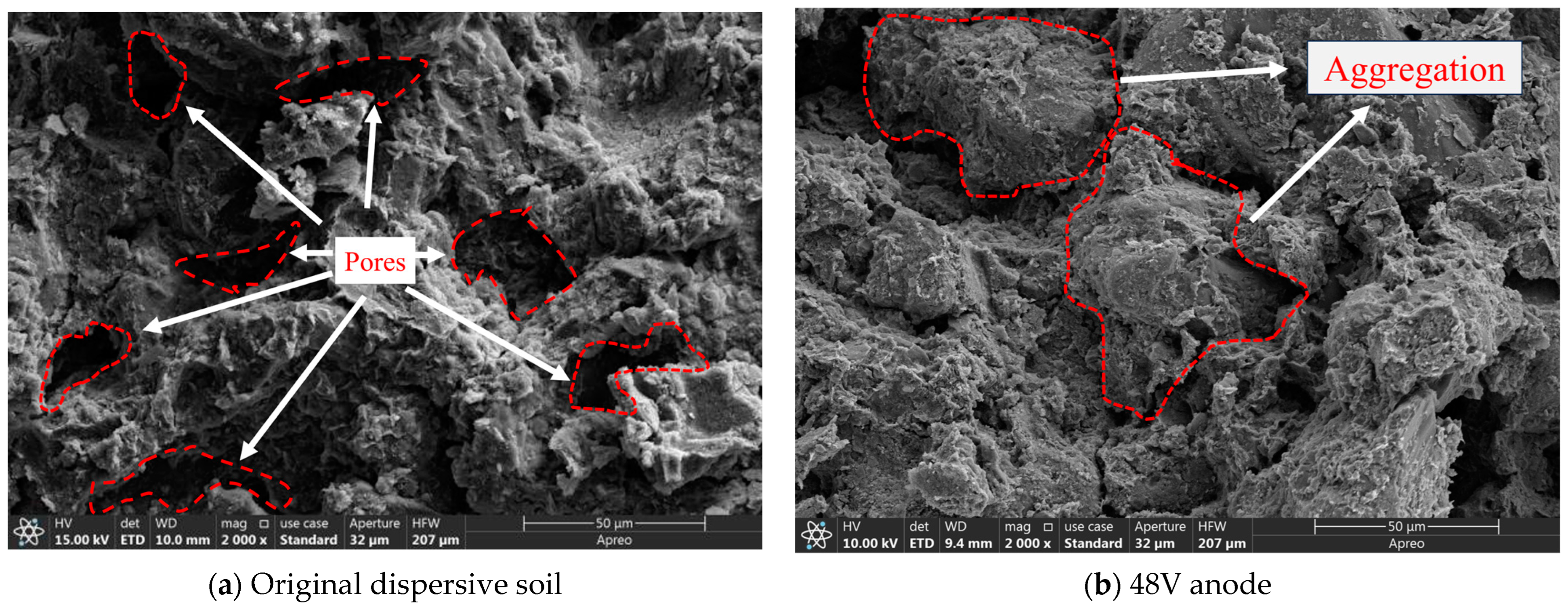

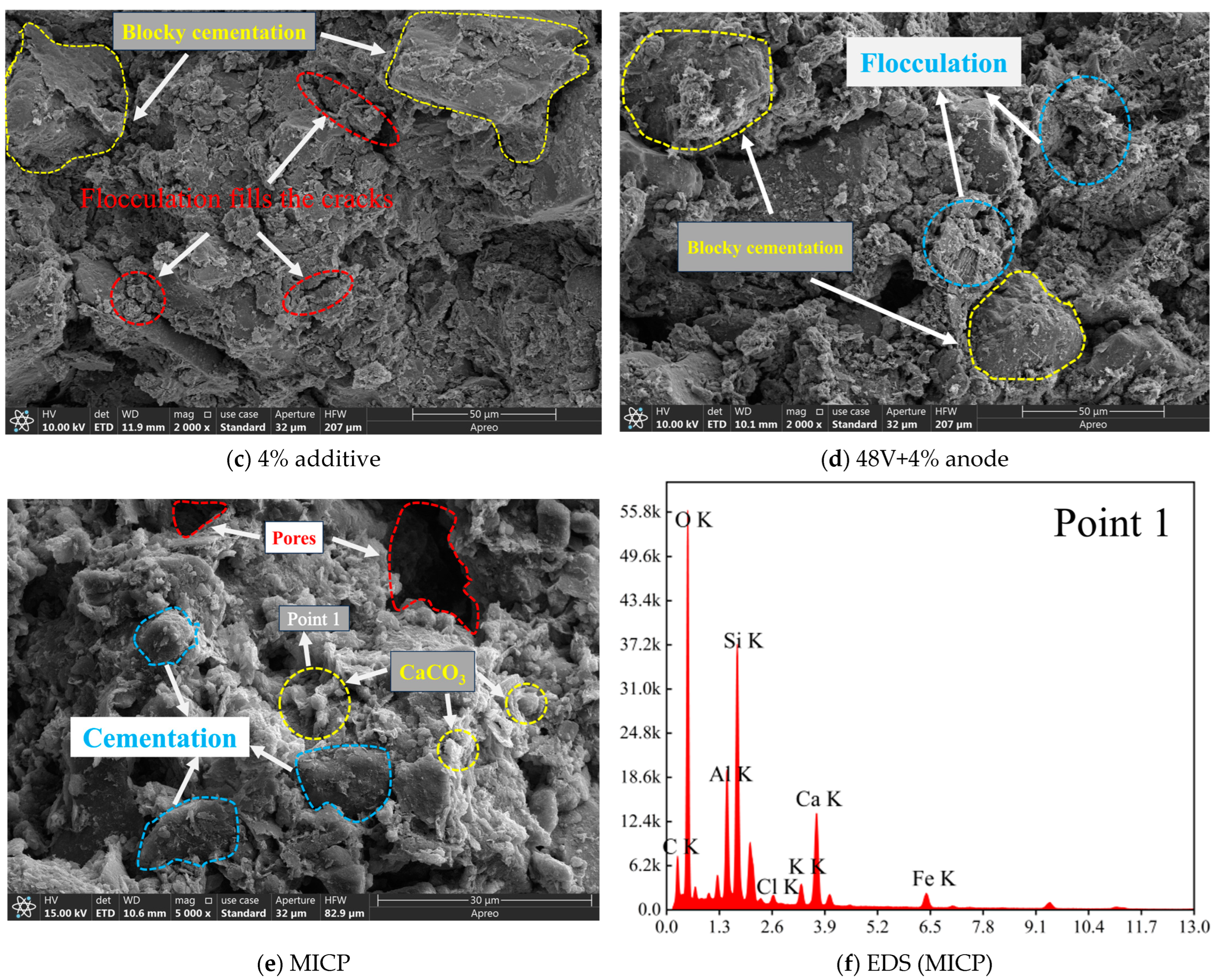

3.5. Microstructure and Mechanism

4. Conclusions

- (1)

- Reduction in Dispersivity: All four methods (MICP, additives, EK, and their combination) effectively reduced soil dispersivity, with the combined method showing the most significant improvement.

- (2)

- Mechanical Property Enhancement: The combination of EK treatment and additives led to a substantial increase in Unconfined Compressive Strength (UCS) by approximately 325%. This method outperformed MICP, EK, and additives alone. MICP had the most significant effect on the internal friction angle, followed by EK, with enhanced effects observed near the anode.

- (3)

- Chemical and Structural Changes: EK treatment reduced Na⁺concentration and pH through ion migration and hydrolysis. The additives, rich in Ca2⁺, facilitated ion exchange, reduced the double electric layer thickness, and contributed to the formation of hydration products, enhancing soil strength through cementation.

- (4)

- MICP Limitations: Although the MICP treatment produces the highest calcium carbonate content, it does not lead to the most significant improvement in the dispersivity of dispersive soil. Reducing dispersivity with this method may necessitate the consideration of various other factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Turgut, A.; Isik, N.S.; Kasapoglu, K.E. Investigation of factors affecting the dispersibility of clays and estimation of dispersivity. Bull. Eng. Geol. Environ. 2016, 76, 1051–1073. [Google Scholar] [CrossRef]

- Shoghi, H.; Ghazavi, M.; Ganjian, N. Pilot-scale electrokinetic treatment of dispersive soil and feasibility study of sodium ion transport across the soil by electric field relocation. Arab. J. Geosci. 2019, 12, 765. [Google Scholar] [CrossRef]

- Gutiérrez, F.; Desir, G.; Gutiérrez, M. Causes of the catastrophic failure of an earth dam built on gypsiferous alluvium and dispersive clays (Altorricón, Huesca Province, NE Spain). Environ. Geol. 2003, 43, 842–851. [Google Scholar] [CrossRef]

- Fatima, B.; Alshameri, B.; Hassan, W.; Maqsood, Z.; Jamil, S.M.; Madun, A. Sustainable incorporation of Plaster of Paris kiln dust for stabilization of dispersive soil: A potential solution for construction industry. Constr. Build. Mater. 2023, 397, 132459. [Google Scholar] [CrossRef]

- Yuan, X.; Wang, X.; Chen, H.; Shi, Z.; Shi, B.; Niu, C. A Study on the Durability of Dispersive Soils Improved by Alum in Western Jilin Province of China. Geofluids 2021, 2021, 3795958. [Google Scholar] [CrossRef]

- Fan, H.; Kong, L. Empirical equation for evaluating the dispersivity of cohesive soil. Can. Geotech. J. 2013, 50, 989–994. [Google Scholar] [CrossRef]

- Abbaslou, H.; Hadifard, H.; Ghanizadeh, A.R. Effect of cations and anions on flocculation of dispersive clayey soils. Heliyon 2020, 6, e03462. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Song, Y.; Fu, R.; Lu, C.; Liu, H. Experimental Study on the Comprehensive Identification and Improvement of Dispersive Soil in Western Jilin Province, China. Geofluids 2021, 2021, 6267212. [Google Scholar] [CrossRef]

- McElroy, C.H. The use of chemical additives to control the erosive behavior of dispersed clays. In Proceedings of the Symposium on Engineering Aspects of Soil Erosion, Dispersive Clays, and Loess, Atlantic City, NJ, USA, 29 April 1987. [Google Scholar]

- Zhang, L.; Qiu, W.; Yang, X.; Fan, H.; Zhang, S.; Zhang, A. Dispersivity Identification and Modification with Lime of Soil in Huaaopao’s Water Conservancy Project. Geotech. Geol. Eng. 2022, 40, 5347–5359. [Google Scholar] [CrossRef]

- Türköz, M.; Savaş, H.; Tasci, G. The effect of silica fume and lime on geotechnical properties of a clay soil showing both swelling and dispersive features. Arab. J. Geosci. 2018, 11, 735. [Google Scholar] [CrossRef]

- Mohanty, S.; Roy, N.; Singh, S.P.; Sihag, P. Strength and durability of flyash, GGBS and cement clinker stabilized dispersive soil. Cold Reg. Sci. Technol. 2021, 191, 103358. [Google Scholar] [CrossRef]

- Shoghi, H.; Ghazavi, M.; Ganjian, N. The effects of chemical admixtures and physical factors on the treatment of dispersive soils. Arab. J. Geosci. 2017, 10, 486. [Google Scholar] [CrossRef]

- Hassan, W.; Alshameri, B.; Haider, A.; Maqsood, Z.; Jamil, S.M.; Shahzad, A. A novel technique for the construction industry to mitigate dispersibility and internal erosion problems of sodium rich clays by using Water-Soluble potassium rich ions material. Constr. Build. Mater. 2023, 400, 132780. [Google Scholar] [CrossRef]

- Fattah, M.Y.; Ismael, R.H.; Aswad, M.F. Dispersion characteristics of MgO-treated dispersive clay. Arab. J. Geosci. 2021, 14, 605. [Google Scholar] [CrossRef]

- Abbasi, N.; Farjad, A.; Sepehri, S. The Use of Nanoclay Particles for Stabilization of Dispersive Clayey Soils. Geotech. Geol. Eng. 2017, 36, 327–335. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Zhao, W.; Jiang, X.; Chen, Y.; Hou, J.; Wang, Y.; Yan, Z.; Zhu, H. Influence of multi-scale fiber on residual compressive properties of a novel rubberized concrete subjected to elevated temperatures. J. Build. Eng. 2023, 65, 105750. [Google Scholar] [CrossRef]

- Lu, D.; Shi, X.; Zhong, J. Understanding the role of unzipped carbon nanotubes in cement pastes. Cem. Concr. Compos. 2022, 126, 104366. [Google Scholar] [CrossRef]

- Zhao, G.; Wu, T.; Ren, G.; Zhu, Z.; Gao, Y.; Shi, M.; Ding, S.; Fan, H. Reusing waste coal gangue to improve the dispersivity and mechanical properties of dispersive soil. J. Clean. Prod. 2023, 404, 136993. [Google Scholar] [CrossRef]

- Zhao, G.; Xie, S.; Zhang, Z.; Ren, G.; Ding, Y.; Wu, T.; Ding, S.; Shi, M.; Fan, H. Engineering properties optimization of dispersive soil by calcium silicate waste—The role of steel-making slag. J. Environ. Manag. 2024, 365, 121563. [Google Scholar] [CrossRef]

- Zhao, G.; Yan, D.; Ren, G.; Zhu, Z.; Wu, T.; Ding, S.; Shi, M.; Fan, H. Influence of ground granulated blast furnace slag on the dispersivity and mechanical property of dispersive soil. Constr. Build. Mater. 2023, 409, 134036. [Google Scholar] [CrossRef]

- Li, T.; Zhu, Z.; Wu, T.; Ren, G.; Zhao, G. A potential way for improving the dispersivity and mechanical properties of dispersive soil using calcined coal gangue. J. Mater. Res. Technol. 2024, 29, 3049–3062. [Google Scholar] [CrossRef]

- Xu, X.; Lei, H.; Wang, Q.; Yuan, X.; Guo, L.; Yu, Z. Polyaluminum chloride (PAC) modification of dispersive soil: A comprehensive study on dispersivity, mechanical properties, and microscale mechanisms. Constr. Build. Mater. 2024, 425, 135890. [Google Scholar] [CrossRef]

- Moravej, S.; Habibagahi, G.; Nikooee, E.; Niazi, A. Stabilization of dispersive soils by means of biological calcite precipitation. Geoderma 2018, 315, 130–137. [Google Scholar] [CrossRef]

- Li, C.; Shi, G.Y.; Wu, H.M.; Wang, C.; Gao, Y. Experimental study on bio-mineralization for dispersed soil improvement based on enzyme induced calcite precipitate technology. Rock Soil Mech 2021, 42, 333–342. [Google Scholar] [CrossRef]

- Tang, C.-S.; Yin, L.-Y.; Jiang, N.-J.; Zhu, C.; Zeng, H.; Li, H.; Shi, B. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: A review. Environ. Earth Sci. 2020, 79, 94. [Google Scholar] [CrossRef]

- Ouhadi, V.; Goodarzi, A. Assessment of the stability of a dispersive soil treated by alum. Eng. Geol. 2006, 85, 91–101. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S.; Puppala, A.J. Engineering properties and microstructural characteristics of foundation silt stabilized by lignin-based industrial by-product. KSCE J. Civ. Eng. 2016, 20, 2725–2736. [Google Scholar] [CrossRef]

- Vakili, A.H.; Ghasemi, J.; bin Selamat, M.R.; Salimi, M.; Farhadi, M.S. Internal erosional behaviour of dispersive clay stabilized with lignosulfonate and reinforced with polypropylene fiber. Constr. Build. Mater. 2018, 193, 405–415. [Google Scholar] [CrossRef]

- Joga, J.R.; Varaprasad, B.J. Effect of xanthan gum biopolymer on dispersive properties of soils. World J. Eng. 2020, 17, 563–571. [Google Scholar] [CrossRef]

- Jayasekera, S. Electrokinetics to Modify Strength Characteristics of Soft Clayey Soils: A Laboratory Based Investigation. Electrochim. Acta 2015, 181, 39–47. [Google Scholar] [CrossRef]

- Abdullah, W.; Al-Abadi, A. Cationic–electrokinetic improvement of an expansive soil. Appl. Clay Sci. 2010, 47, 343–350. [Google Scholar] [CrossRef]

- Vakili, A.H.; Kaedi, M.; Mokhberi, M.; bin Selamat, M.R.; Salimi, M. Treatment of highly dispersive clay by lignosulfonate addition and electroosmosis application. Appl. Clay Sci. 2018, 152, 1–8. [Google Scholar] [CrossRef]

- Sihag, P.; Suthar, M.; Mohanty, S. Estimation of UCS-FT of Dispersive Soil Stabilized with Fly Ash, Cement Clinker and GGBS by Artificial Intelligence. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 45, 901–912. [Google Scholar] [CrossRef]

- D 4647-20; Test Methods for Identification and Classification of Dispersive Clay Soils by the Pinhole Test. ASTM: West Conshehoken, PA, USA, 2020.

- D 4221; Standard Test Methods for Determining Dispersive Characteristics of Clayey Soils by the Crumb Test. ASTM: West Conshehoken, PA, USA, 2021.

- D 6572; Test Method for Dispersive Characteristics of Clay Soil by Double Hydrometer. ASTM: West Conshehoken, PA, USA, 2018.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. China Planning Publishing House: Beijing, China, 2019.

- D 2487-17; ASTM Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM: West Conshehoken, PA, USA, 2017.

- Lauchnor, E.; Topp, D.; Parker, A.; Gerlach, R. Whole cell kinetics of ureolysis by S porosarcina pasteurii. J. Appl. Microbiol. 2015, 118, 1321–1332. [Google Scholar] [CrossRef]

- Zhao, Y.; Xiao, Z.; Lv, J.; Shen, W.; Xu, R. A Novel Approach to Enhance the Urease Activity of Sporosarcina pasteurii and its Application on Microbial-Induced Calcium Carbonate Precipitation for Sand. Geomicrobiol. J. 2019, 36, 819–825. [Google Scholar] [CrossRef]

- Li, C.; Yao, D.; Liu, S.; Zhou, T.; Bai, S.; Gao, Y.; Li, L. Improvement of Geomechanical Properties of Bio-remediated Aeolian Sand. Geomicrobiol. J. 2017, 35, 132–140. [Google Scholar] [CrossRef]

- Khodaparast, M.; Rajabi, A.M.; Moein, B.; Bazargan, J. Identifying dispersive soils by modification of chemical criterion, validated based on data from Northwest and Central Iran. Arab. J. Geosci. 2021, 14, 1695. [Google Scholar] [CrossRef]

- Singh, B.; Gahlot, P.; Purohit, D. Dispersive soils-characterization, problems and remedies. Int. J. Eng. Technol. 2018, 5, 2478–2484. [Google Scholar]

- Xin, Y.; Zheng, Y.-X.; Yu, Y.-X. Density functional theory study on ion adsorption and electroosmotic flow in a membrane with charged cylindrical pores. Mol. Phys. 2015, 114, 2328–2336. [Google Scholar] [CrossRef]

- Chorom, M.; Rengasamy, P.; Murray, R. Clay dispersion as influenced by pH and net particle charge of sodic soils. Soil Res. 1994, 32, 1243–1252. [Google Scholar] [CrossRef]

- Sumner, M.E. Sodic soils—New perspectives. Soil Res. 1993, 31, 683–750. [Google Scholar] [CrossRef]

- Suarez, D.L.; Rhoades, J.D.; Lavado, R.; Grieve, C.M. Effect of pH on Saturated Hydraulic Conductivity and Soil Dispersion. Soil Sci. Soc. Am. J. 1984, 48, 50–55. [Google Scholar] [CrossRef]

- Oades, J.M. Soil organic matter and structural stability: Mechanisms and implications for management. Plant Soil 1984, 76, 319–337. [Google Scholar] [CrossRef]

- Goldberg, S.; Forster, H. Flocculation of reference clays and arid-zone soil clays. Soil Sci. Soc. Am. J. 1990, 54, 714–718. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; John Wiley & Sons, Inc.: Toronto, ON, Canada, 2005; pp. 251–320. [Google Scholar]

- Micic, S.; Shang, J.Q.; Lo, K.Y.; Lee, Y.N.; Lee, S.W. Electrokinetic strengthening of a marine sediment using intermittent current. Can. Geotech. J. 2001, 38, 287–302. [Google Scholar] [CrossRef]

| Index | Value |

|---|---|

| Water content (%) | 19.80 |

| Density (g/cm3) | 2.05 |

| Liquid limit (%) | 35.30 |

| Plastic limit (%) | 19.50 |

| Plasticity index | 15.80 |

| Specific gravity | 2.72 |

| Sand % (>0.075 mm) | 8.22 |

| Silt % (0.075~0.005 mm) | 48.59 |

| Clay % (<0.005 mm) | 43.19 |

| Soil type | CL |

| pH | 8.73 |

| Optimum water content (%) | 19.67 |

| Composition | Value |

|---|---|

| Ca (OH)2 | 60% |

| Fe, FeO, and SiO2 | 20% |

| CaSO4·2H2O | 10% |

| CaO, MgO, MnO, and Al2O3 | 10% |

| Medium | Composition (g/L) | ||||||

|---|---|---|---|---|---|---|---|

| Peptone | Beef Extract | Urea | NiCl | (NH4)2SO4 | Yeast | Agar | |

| A | 5 | 3 | 20 | 0.02 | |||

| B | 0.02 | 20 | 20 | ||||

| Solid | 5 | 3 | 10 | 0.02 | 15 | ||

| Test Type | Mixing Ratio (%) | Electric Potential (V) | Duration (Days) | Surcharge (kPa) |

|---|---|---|---|---|

| Control | 0 | 0 | 5 | 200 |

| EK | 0 | 24 | ||

| 0 | 36 | |||

| 0 | 48 | |||

| 0 | 60 | |||

| Additives | 2 | 0 | ||

| 3 | 0 | |||

| 4 | 0 | |||

| EK and Additives | 4 | 48 | ||

| 4 | 60 | |||

| MICP | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Zhu, R.; Zhao, F.; Zhao, Y. Enhancing Dispersive Soil: An Experimental Study on the Efficacy of Microbial, Electrokinetics, and Chemical Approaches. Sustainability 2024, 16, 10425. https://doi.org/10.3390/su162310425

Liu P, Zhu R, Zhao F, Zhao Y. Enhancing Dispersive Soil: An Experimental Study on the Efficacy of Microbial, Electrokinetics, and Chemical Approaches. Sustainability. 2024; 16(23):10425. https://doi.org/10.3390/su162310425

Chicago/Turabian StyleLiu, Pinghui, Ruimeng Zhu, Feiyan Zhao, and Yang Zhao. 2024. "Enhancing Dispersive Soil: An Experimental Study on the Efficacy of Microbial, Electrokinetics, and Chemical Approaches" Sustainability 16, no. 23: 10425. https://doi.org/10.3390/su162310425

APA StyleLiu, P., Zhu, R., Zhao, F., & Zhao, Y. (2024). Enhancing Dispersive Soil: An Experimental Study on the Efficacy of Microbial, Electrokinetics, and Chemical Approaches. Sustainability, 16(23), 10425. https://doi.org/10.3390/su162310425