The Use of Plastic Waste as Replacement of Coarse Aggregate in Concrete Industry

Abstract

:1. Introduction

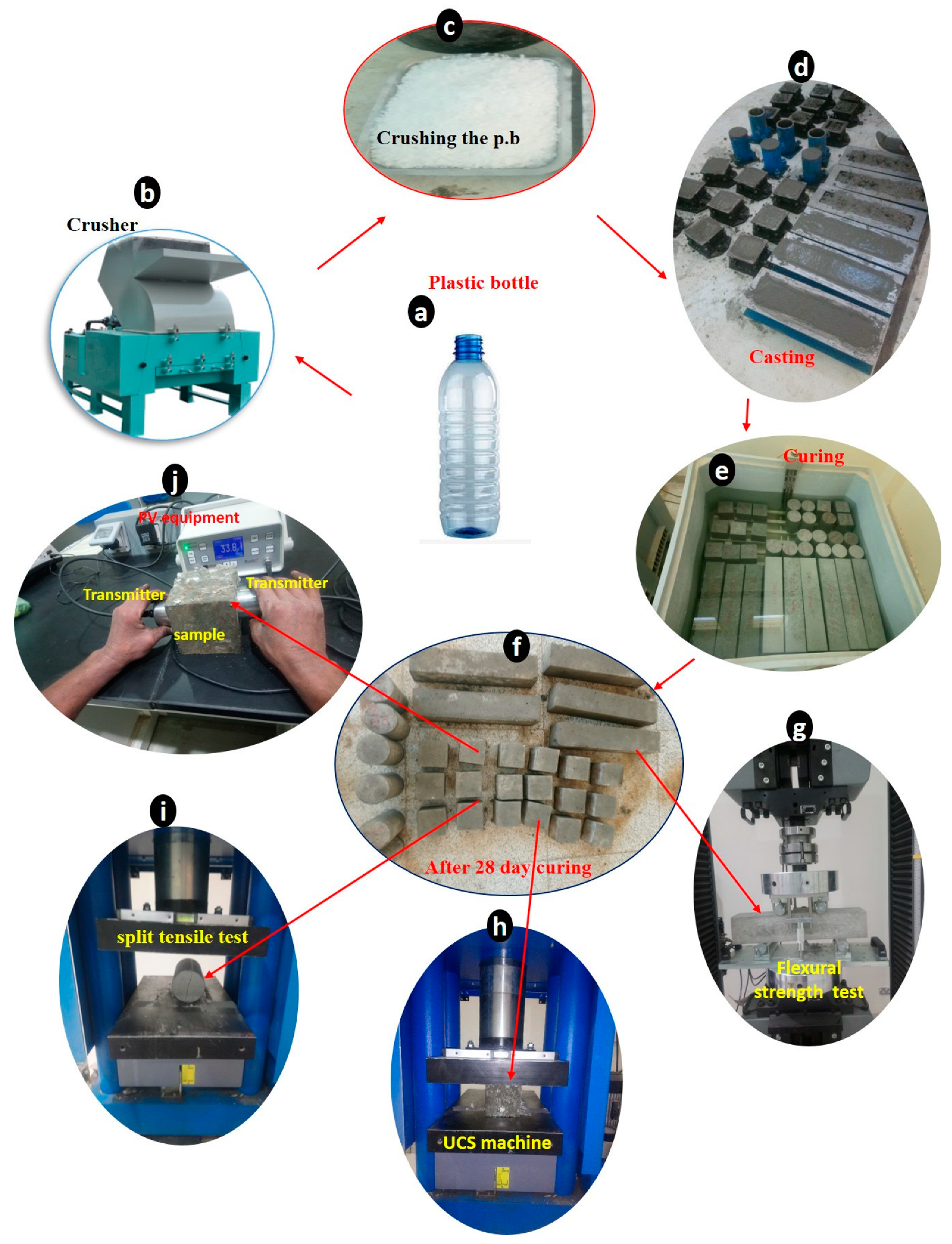

2. Literature Review

3. Materials and Methods

3.1. General

- Samples of concrete mixtures of partially replaced coarse aggregate with (2.5%, 5%, 7.5%, 10%, and 12.5%) PW and other samples of CC concrete according to British specifications were prepared (Table 1);

- The consistency-testing program was implemented in accordance with British Standard BS 1881 [13]. This program was conducted to identify the mechanical properties of concrete, such as compressive, tensile, and split strength, and then compare them with their counterparts in CC concrete.

3.2. PW Preparation

3.3. Experimental Program

4. Results and Discussion

4.1. Workability of the Fresh PW Concrete

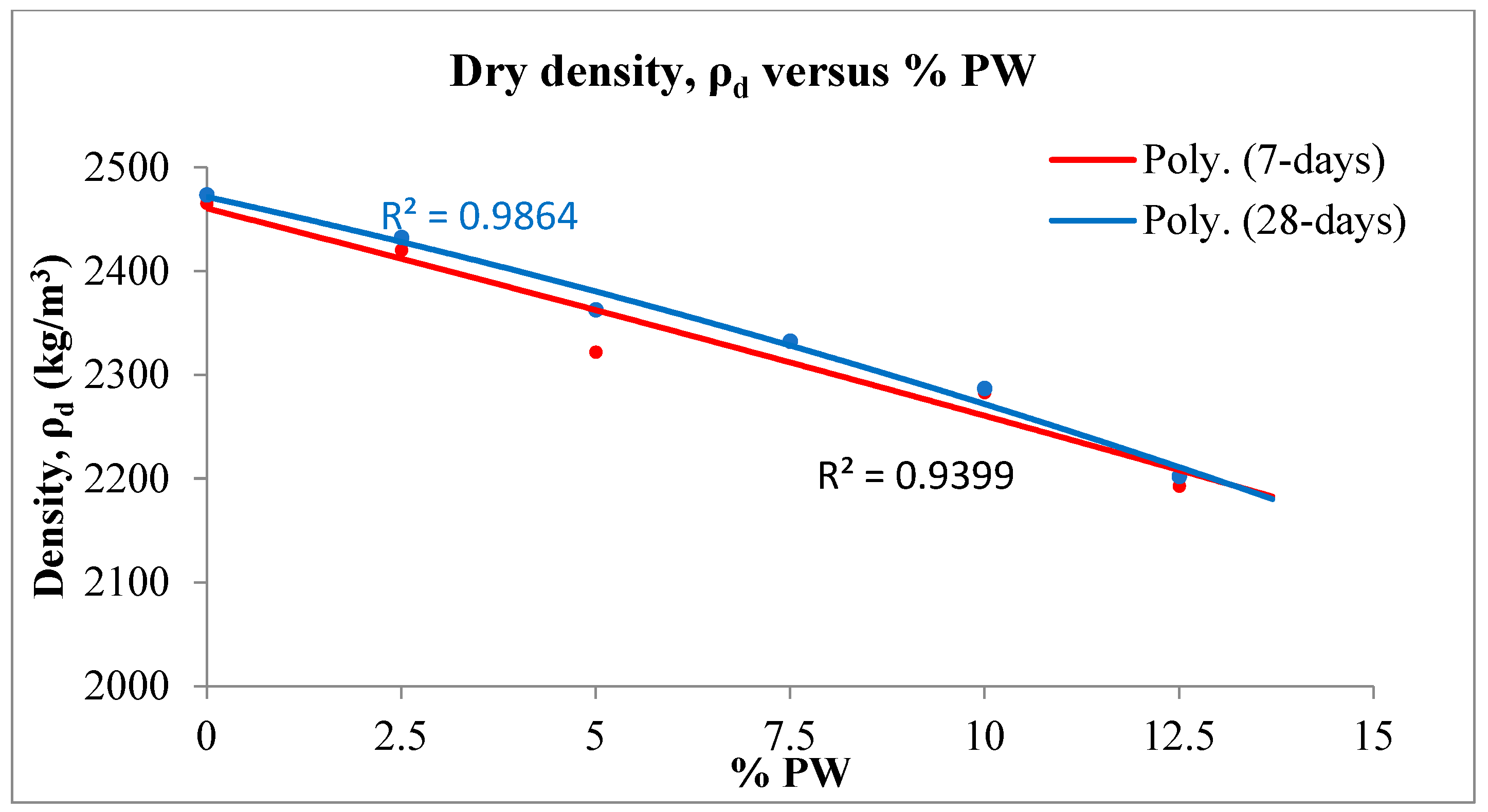

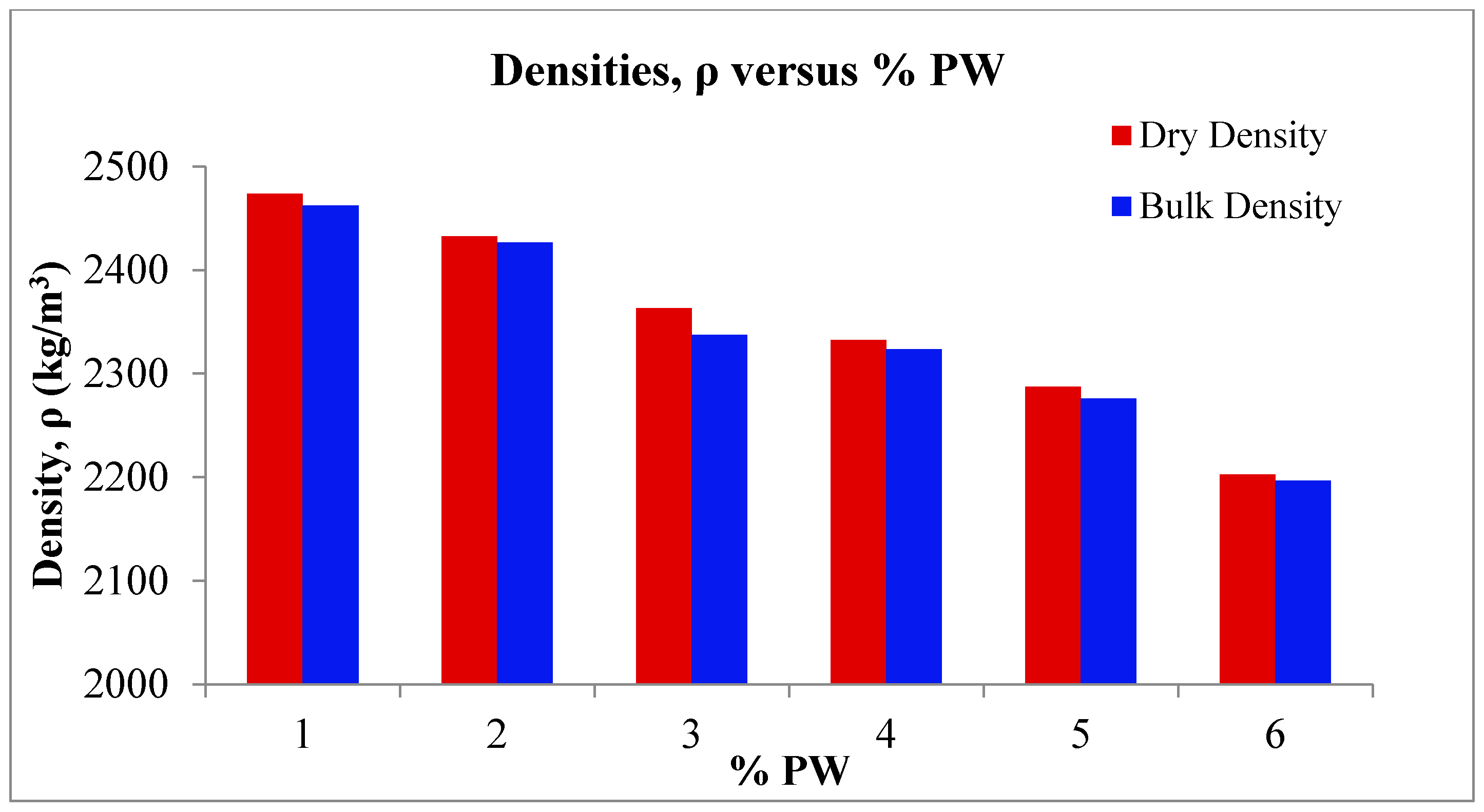

4.2. Density of the Hardened PW Concrete

4.3. Strength of PW Concrete

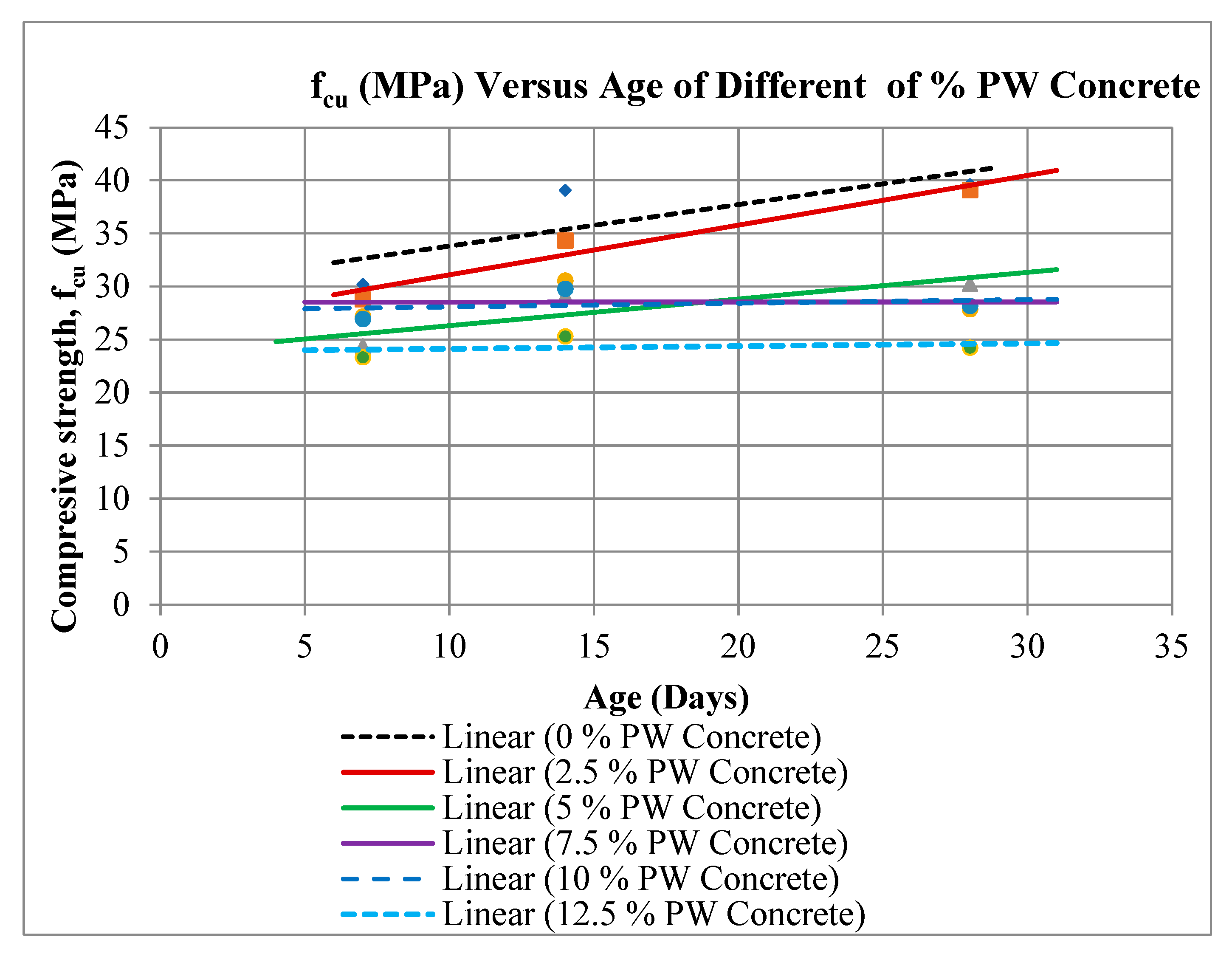

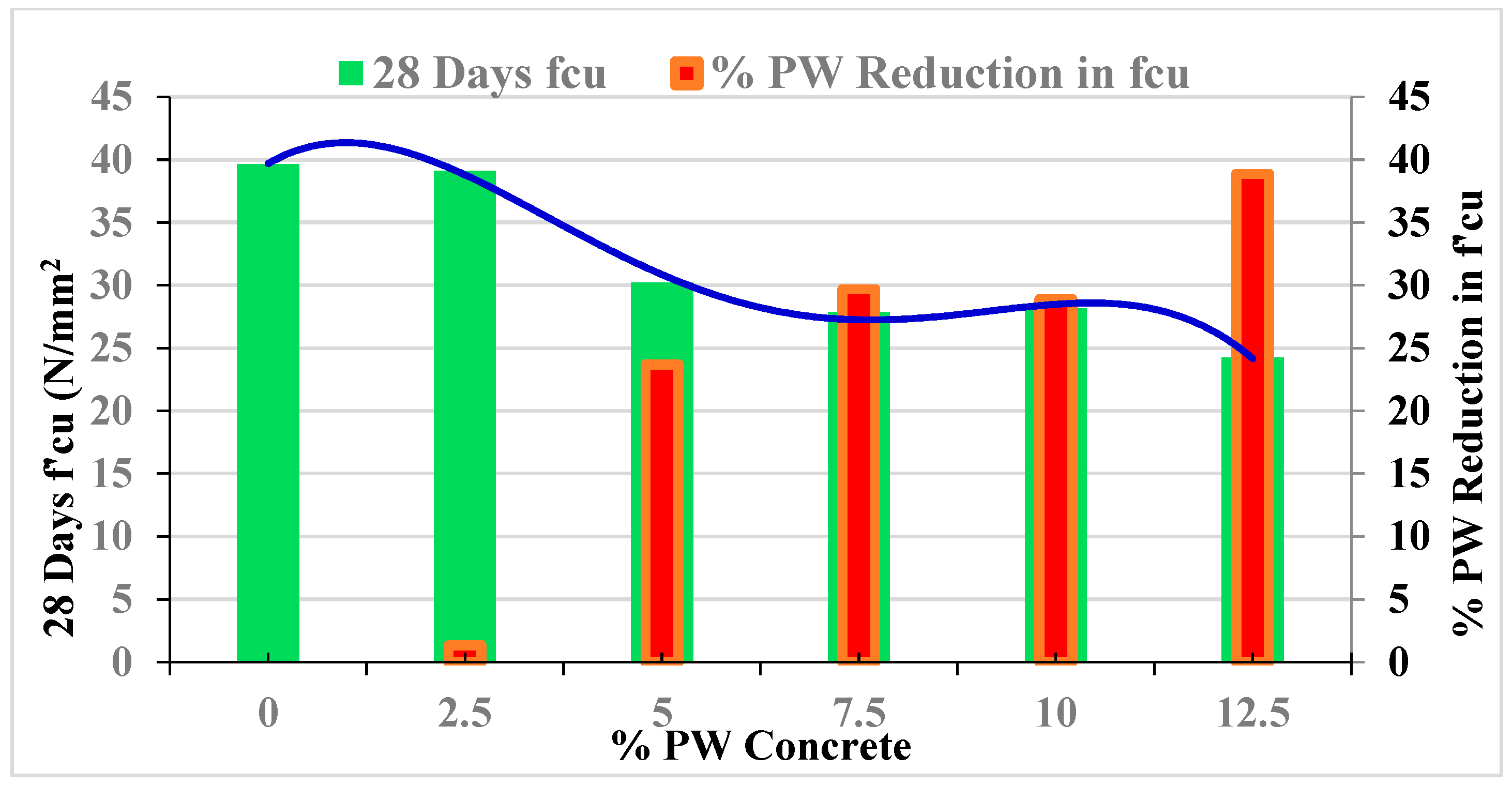

4.3.1. Compressive Strength

4.3.2. Flexural Strength

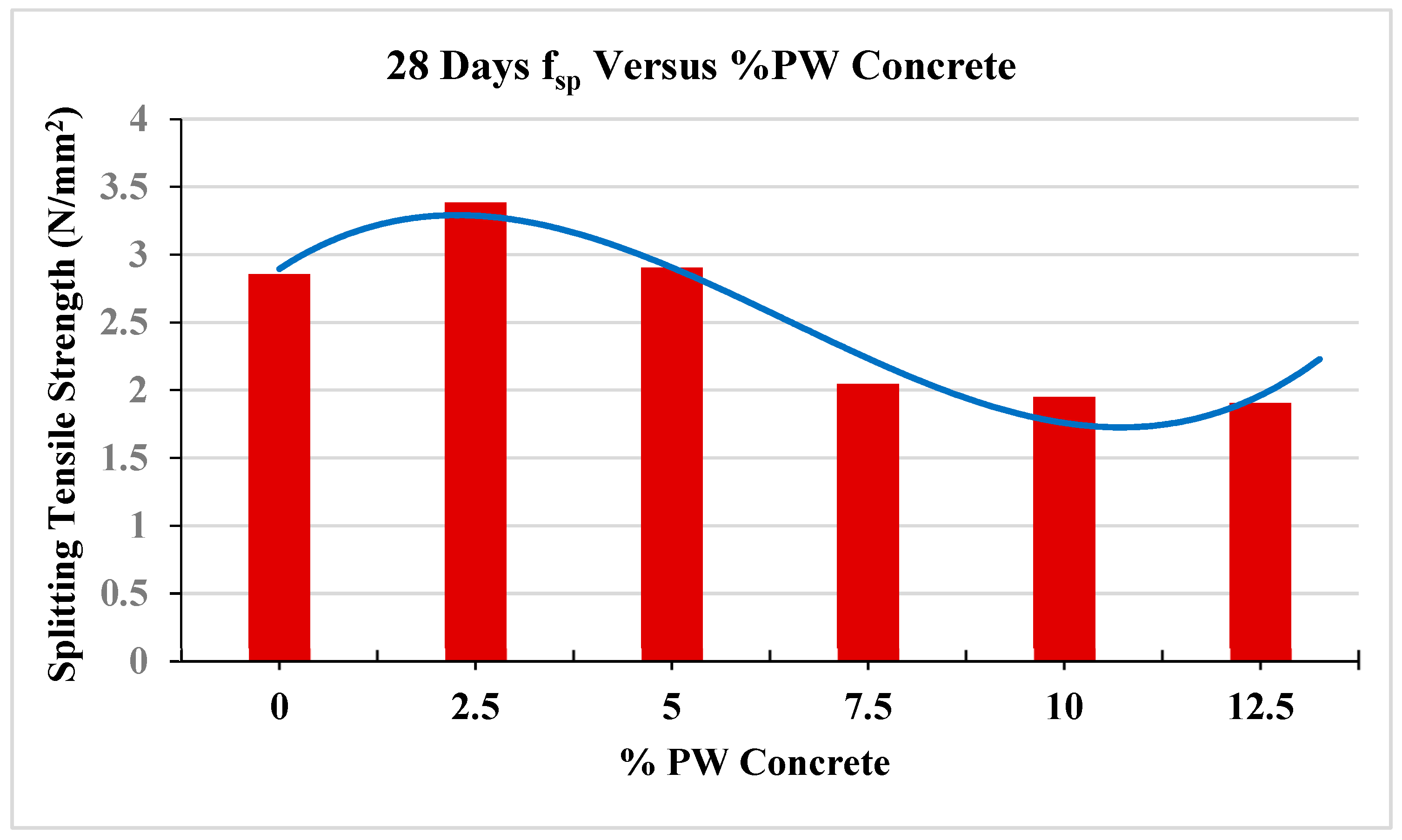

4.3.3. Splitting Tensile Strength

5. Conclusions and Recommendations

- The decrease in the slump value of fresh concrete increases as the percentage of PW partially replaced by the coarse aggregate increases, as the drop values for the CC and 12.5% PW concrete were 100 mm and 10 mm, respectively;

- The value of the decrease in the density of concrete increases with the increase in the proportion of coarse aggregate replaced by PW. The dry density of 2.5% PW concrete decreased by 1% from the density of CC, while the maximum decrease in density was 11% for the 12.5% PW concrete. There is no significant difference between the dry density and bulk density of concrete produced at all of its age stages, regardless of the percentage of PW that replaces the aggregate and regardless of the age stage;

- The compressive strength of the produced concrete decreases as the percentage of aggregates replaced with PW increases. It was found that the decrease in strength does not exceed 1% for concrete with 2.5% PW compared to the strength of CC, while the strength of concrete with 5% PW decreases by 24%;

- Replacing aggregates with any amount of PW reduces concrete’s flexural strength. In any case, this decrease is consistent with the results of previous studies. However, the flexural strength is not significantly affected when replacing coarse aggregate with PW up to 2.5%;

- The splitting tensile strength of concrete decreases significantly and steadily when the aggregate is replaced with PW, by more than 2.5%. Otherwise, the tensile strength of the concrete will be enhanced;

- Therefore, PW concrete can maintain its strength when PW is used in small quantities (up to 2.5%) and is suitable for structural applications. However, beyond this limit, it is more appropriate for non-structural uses;

- To predict the strength of concrete according to the % PW replacement of coarse aggregate for a given age, it is recommended to derive a mathematical model to achieve this.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agarwal, S.P.; Samdani, K.L.; Singhvi, B.S.; Shekhawat, R.S.; Arora, R.P. Plastic Waste Management-An Indian Perspective. Glob. J. Eng. Appl. Sci. 2012, 2, 56–61. [Google Scholar]

- Kule, S. Assessing the Effect of Partial Replacement of Coarse Aggregate in Concrete with Recycled Plastic-Waste Palates. Reg. No. BSCE/43968/143/DU. 2018. Available online: http://hdl.handle.net/20.500.12306/2281 (accessed on 1 January 2024).

- Osubor, S.O.; Salam, K.A.; Audu, T.M. Effect of flaky plastic particle size and volume used as partial replacement of gravel on compressive strength and density of concrete mix. J. Environ. Prot. 2019, 10, 711–721. [Google Scholar] [CrossRef]

- Sau, D.; Shiuly, A.; Hazra, T. Utilization of plastic waste as replacement of natural aggregates in sustainable concrete: Effects on mechanical and durability properties. Int. J. Environ. Sci. Technol. 2023, 21, 2085–2120. [Google Scholar] [CrossRef] [PubMed]

- Manjunath, B.A. Partial replacement of E-plastic waste as coarse-aggregate in concrete. Procedia Environ. Sci. 2016, 35, 731–739. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamal, A.; Mazher, K.M.; Umer, W.; Iqbal, M. Performance Evaluation of Plastic Concrete Modified with E-Waste Plastic as a Partial Replacement of Coarse Aggregate. Materials 2021, 15, 175. [Google Scholar] [CrossRef]

- Botchway, D.N.-L.; Bentil, J.; Henaku, C.Y. Effect of Partial Replacement of Coarse Aggregate with Electronic Waste Plastic in Light Weight Concrete. J. Manag. Sci. Eng. Res. 2022, 5, 38–44. [Google Scholar] [CrossRef]

- Kayentao, D.; Tamboura, M.; Diarra, A.P.; Traore, M.F.; Coulibaly, A.; Toure, A.S.; Daou, K. Modified Concrete Using Polyethylene Terephthalate Plastic Waste as a Partial Replacement for Coarse Aggregate. Open J. Appl. Sci. 2023, 13, 896–909. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Tota-Maharaj, K.; Adeleke, B.O.; Nounu, G. Effects of waste plastics as partial fine-aggregate replacement for reinforced low-carbon concrete pavements. Int. J. Sustain. Eng. 2022, 15, 192–207. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Li, X.-M.; Zhang, J.; Lin, J.-X. A review on the influence of recycled plastic aggregate on the engineering properties of concrete. J. Build. Eng. 2023, 79, 107787. [Google Scholar] [CrossRef]

- Edmund TS, J.; Hon, C.J.; Hejazi, F.; Jaafar, M.S. Waste plastic as partial replacement for aggregates-a review. IOP Conf. Ser. Earth Environ. Sci. 2019, 357, 012018. [Google Scholar] [CrossRef]

- BS 1881; Testing Concrete. Methods for Analysis of Hard Concrete. British Standards Institute: London, UK, 1881.

- BS 882-1992 (w/d 2004); Specification for Aggregate from Natural Sources for Concrete. British Standards Institute: London, UK, 2004.

- BS 1881-102:1983; Testing Concrete, Method for Determination of Slump. British Standards Institute: London, UK, 1983.

- BS 1881-125:1986; Testing Concrete—Part 125: Methods for Mixing and Sampling Fresh Concrete in the Laboratory. British Standards Institute: London, UK, 1986.

- BS 1881-116:1983; Testing Concrete, Method for Determination of Com Pressive Strength of Concrete Cubes. British Standards Institute: London, UK, 1983.

- BS 1881-117:1983; Testing Concrete, Method for Determination of Tensile Splitting Strength. British Standards Institute: London, UK, 1983.

- BS 1881-118:1983; Testing Concrete, Method for Determination of Flexural Strength. British Standards Institute: London, UK, 1983.

- Mohamedsalih, M.A.; El Aal, A.K.A.; Radwan, A.E.; Abdullah, G.M.S.; Al Saiari, M. Feasibility of Najran rocks crushing waste as manufactured sand in the sustainable concrete industry in the Kingdom of Saudi Arabia. Int. J. Geotech. Eng. 2023, 17, 519–529. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of different forms of waste plastic in concrete—A review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Ling, T.-C.; Mo, K.H. Functions and impacts of plastic/rubber wastes as eco-friendly aggregate in concrete—A review. Constr. Build. Mater. 2019, 240, 117869. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Zafar, I. Plastic-based sustainable synthetic aggregate in Green Lightweight concrete—A review. Constr. Build. Mater. 2021, 292, 123321. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2006, 27, 1870–1876. [Google Scholar] [CrossRef]

- Pezzi, L.; De Luca, P.A.; Vuono, D.; Chiappetta, F.; Nastro, A. Concrete Products with Waste’s Plastic Material (Bottle, Glass, Plate). Mater. Sci. Forum 2006, 514–516, 1753. [Google Scholar] [CrossRef]

- Al-Manaseer, A.A.; Dalal, T.R. Concrete containing plastic aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2007, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

| %PW | Vp m/s | ρd Kg/m3 | ρsat Kg/m3 | ρim Kg/m3 | ρb Kg/m3 | fcu MPa |

|---|---|---|---|---|---|---|

| 2.5 | 4.993 | 2433 | 2448 | 1446 | 2426 | 39 |

| 5 | 4.699 | 2363 | 2379 | 1368 | 2337 | 30 |

| 7.5 | 4.626 | 2333 | 2348 | 1344 | 2323 | 28 |

| 10 | 4.646 | 2287 | 2301 | 1296 | 2276 | 28 |

| 12.5 | 4.468 | 2202 | 2217 | 1215 | 2196 | 24 |

| CC | 4.756 | 2474 | 2491 | 1487 | 2462 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamedsalih, M.A.; Radwan, A.E.; Alyami, S.H.; Abd El Aal, A.K. The Use of Plastic Waste as Replacement of Coarse Aggregate in Concrete Industry. Sustainability 2024, 16, 10522. https://doi.org/10.3390/su162310522

Mohamedsalih MA, Radwan AE, Alyami SH, Abd El Aal AK. The Use of Plastic Waste as Replacement of Coarse Aggregate in Concrete Industry. Sustainability. 2024; 16(23):10522. https://doi.org/10.3390/su162310522

Chicago/Turabian StyleMohamedsalih, Moustafa Abdulrahim, Ahmed E. Radwan, Saleh H. Alyami, and Ahmed K. Abd El Aal. 2024. "The Use of Plastic Waste as Replacement of Coarse Aggregate in Concrete Industry" Sustainability 16, no. 23: 10522. https://doi.org/10.3390/su162310522

APA StyleMohamedsalih, M. A., Radwan, A. E., Alyami, S. H., & Abd El Aal, A. K. (2024). The Use of Plastic Waste as Replacement of Coarse Aggregate in Concrete Industry. Sustainability, 16(23), 10522. https://doi.org/10.3390/su162310522