1. Introduction

Power Electronics (PE) plays a pivotal role in the energy transition by facilitating the conversion of electrical attributes from renewable energy sources and meeting the demands of modern electrical loads such as E-mobilities and building air conditioning [

1].

However, the lifecycle of Power Electronics impacts the environment significantly, including their high energy consumption, critical raw material consumption, freshwater use, chemical exposure and waste generation [

2,

3]. The sustainable development of PE products is urgently required to reduce the environmental impact throughout their lifecycle and extend their lifetime. Over the past twenty years, at the European level, the constraints and incentives imposed by regulations and standards have has a significant impact on sustainable PE product development. Providing requirements and guiding designers to develop PE products that are more durable, energy- and resource-efficient, repairable, recyclable, and with a preference for recycled materials [

4].

A series of regulations and directives have been introduced with the primary goal of mitigating pollution resulting from production and end-of-life (EoL) management. These measures aim to limit or prohibit the use of toxic substances either during the manufacturing process or directly within static converters.

Notably, the RoHS Directive, first adopted in 2003 (Restriction on Hazardous Substances), and the REACH Regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals), enacted in 2006 [

5,

6], fall within this framework. The RoHS Directive, recognized in the field of Power Electronics, led to the elimination of lead usage in Printed Circuit Board (PCB) soldering [

2].

Beyond the substance level, the WEEE Directive established in 2002 governs the management of Waste from Electrical and Electronic Equipment (WEEE) in each European Union (EU) member state. A decade later, revisions were introduced to address the increasing volume of waste requiring handling. In France, consequently, both the professional and individual WEEE management systems underwent significant changes following the “Law No. 2020-105 of 10 February 2020”, related to the French Anti-Waste Law for a Circular Economy (‘AGEC law’) [

7], which profoundly transformed the framework of Extended Producer Responsibility (EPR) in France (Articles L. 541-10 to L. 541-10-17 and R. 541-86 to R. 541-178 of the Environmental Code).

At the European level, the “New Circular Economy Action Plan (CEAP) (2020)”, adopted by the European Commission identified the circular economy as a crucial strategy for promoting sustainable growth in various industrial sectors [

8]. In an effort to broaden the scope of the Eco-design Directive 2009/125/EC, a framework and a set of mandatory minimum requirements for energy-related products (ErPs), including energy efficiency, have been established [

9]. The European Commission introduced a proposal for the “Eco-design Regulation for Sustainable Products (ESPR)” in March 2022. This proposal aims to establish ecodesign requirements to promote the sustainability, repairability, maintainability, reusability and recycling of ErP, which also encompasses PECs [

10]. Currently, in France, the disassembly of electronic components is gradually becoming a part of the specifications outlined by eco-organizations responsible for facilitating the repair of a growing portion of EEE. This trend is particularly relevant given the increasing emphasis on repairability [

11].

Consequently, the field of PE is profoundly influenced by these legal measures, related to the broader field of ErP. These regulations are driving PE industry towards enhanced sustainability. Simultaneously, the numerous standards arising in the circular economy perspective have been identified as being useful for framing best practices in PE.

To ensure compliance with specific criteria for requirements and the ability to adopt relevant standards for effectively implementing sustainable product development, PE designers need to comprehend the legislative and normative framework well. This understanding is crucial for defining sustainable product specifications and guiding the implementation of sustainable design.

Several studies have examined how regulations and standards impact energy-related product (ErP) sustainable design. For example, Nissen et al. (2007) presented an overview of the status of the WEEE directive and ROHS restrictions for electronics [

12]. Schischke et al. (2008) discussed how the ecodesign directive regulated the energy efficiency of ErPs during their usage [

13]. Hurtado Albir and Carrasco Hernández (2011) explored the impact of the ROHS and REACH regulations on limiting hazardous materials [

2]. Additionally, Bundgaard et al. (2020) and Schischke et al. (2022) looked into how EN4555x contributes to designing products compliant with material efficiency requirements [

14,

15]. These studies are primarily concentrated on specific aspects within the legislative and normative framework for energy-related products (ErPs). However, there is currently no existing literature that offers a comprehensive overview of the legislative and normative framework for sustainable design in ErPs. Furthermore, there is a lack of illumination on how these legislative and normative frameworks are specifically tailored or adapted to the field of PE. Moreover, the precise nature of these standards, their practical utility for PE practitioners, and their limitations remain unclear. There is also a pressing need to explore how the legislative and normative frameworks can evolve to promote absolute sustainability in PE. Thus, our research question is as follows:

How do regulations and related standards support sustainable product development of Power Electronics Converters (PECs), and what are the potential limitations of the current framework?

This article aims to contribute to the existing literature by conducting a comprehensive literature review. Our primary objective is to investigate the regulations and standards that contribute to sustainable development in ErP, with a specific focus on their adaptation and applicability to PE. This article identifies the legislative and normative framework supporting sustainable PE product development, critically assesses the limitations inherent in this framework, and proposes potential avenues for its evolution. To achieve this, the article categorizes environmental indicators and life cycle stages addressed by the framework. Moreover, this article classifies the representative standards that facilitate the PE Product Development Process in terms of circularity evaluation, environmental impact assessment and ecodesign integration. It is important to note that this article exclusively concentrates on the framework developed in France within the context of European-level regulations.

2. Materials and Methods

The review was conducted using the EU Science Hub, EUR-Lex, website of The French Agency for Ecological Transition (ADEME), Ministry of Ecological Transition (France), French Standardization Association (AFNOR), International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC). Two sets of keywords were employed to search the legislative and documents at the intersection of (A) sustainable development: “eco-design” or “environment” or “circular economy” or “sustainability; and (B) “energy-related product” or “power electronics”.

This analysis found 63 references, which include 6 directives, 1 law, 2 regulations, 42 standards and 12 other related references. All the references were collected, organized and analyzed using the following categories of information:

- -

Agency: AFNOR, European Commission, ISO, IEC, European Country, European Committee for Electrotechnical Standardization (CENELEC), United Nations, Industry consortium.

- -

Coverage: French national, European, International.

- -

Type: Standards, Directive, Regulation, Law, Other.

- -

Domain: General/ErP/Power Electronics.

- -

Mandatory: Yes/No.

- -

Life cycle stages addressed: raw material extraction, manufacturing, usage, circular scenarios (repair, reuse, remanufacturing), EoL (recycle, incineration, landfill).

- -

Environmental aspects addressed: energy efficiency, waste quantity, quantity of hazardous substance, raw material consumption, material efficiency, reusability, repairability, remanufacturability, upgradability, recyclability, full environmental impact indicators (ISO 14040 [

16]), PEP Ecopassport [

17] (7 environmental indicators, 17 inventory flow indicators).

- -

Reading priority: Priority read, Average.

Then, the gathered information was organized to establish a legislative and normative framework for ErPs, with a particular focus on the field of PE.

In order to enhance accessibility to this compilation of work, an online search tool for this inventory is provided in this paper. This tool aims to assist professionals engaged in the design and development of PE-based products by facilitating efficient search and exploration throughout the 63 references collected and analyzed.

3. Review of Regulative and Normative Constraints for Power Electronics Sustainable Development

According to the review method described above, the identified documents were firstly clustered into two groups: mandatory requirements and facultative guidelines. The life cycle stages addressed and the environmental impact indicators considered by these documents are analyzed.

3.1. Existing Legislative Framework for PEC

The specific legislation governing the ErPs are discussed in this section. Furthermore, the manner in which regulatory provisions applying to PE products are illuminated.

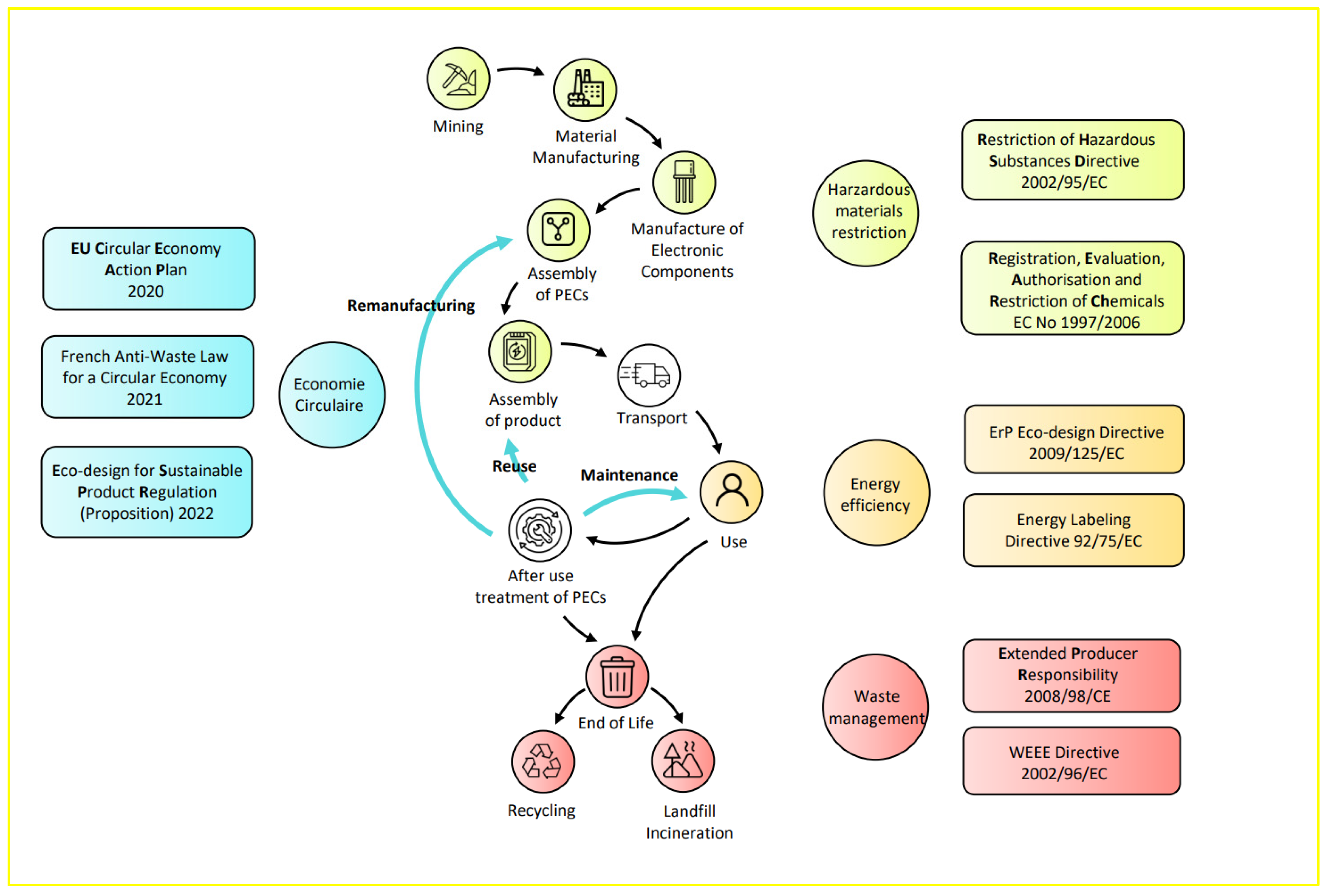

The selected documents were clustered into four distinct sections based on the life cycle stage that they addressed: the raw material extraction and manufacturing of PECs, their usage, circularity options except recycling, and finally, EoL management (

Figure 1).

3.1.1. Regulations on Raw Material Extraction and Manufacturing

Raw material extraction and manufacturing are the first stage of the PEC life cycle. In this stage, significant amounts of resources and energy are consumed, leading to the emissions of greenhouse gases and other pollutants [

10]. The use of toxic and harmful substances in PECs can also have negative impacts on the product’s EoL stage [

2]. When PE-based products are discarded or abandoned, the toxic and harmful substances they contain can pollute the soil, water sources and air [

2]. Many of these substances are known to persist in nature [

18]. They can accumulate in the food chain, ultimately being exposed to humans [

18]. To address these problems, regulations and standards have focused on the limitations of the usage of hazardous substances.

When designing PECs, it is crucial for PE designers to consider the material composition of the components and the chemical substances involved in the manufacturing process. In particular, compliance with the two EU regulations: REACH (EC 1907/2006) and ROHS (Directive 2002/95/EC) [

5,

6] is needed (

Table 1).

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) is a European Union regulation that came into force in 2007 [

5]. It is the main EU law to protect human health and the environment from the risks that can be posed by chemicals. REACH stipulates that chemical substances that exceed 1 ton per year per company must be registered with that information in a central database in the European Chemicals Agency (ECHA) [

5]. The registered substances will be evaluated by the ECHA to clarify the potential risks. Authorization is required for Substances of Very High Concern (SVHCs) that are included in Appendix XIV of the REACH regulation [

5].

To address the specific challenges posed by EEE, which include PECs, there is the RoHS (Restriction of Hazardous Substances) Directive that came into effect in 2006. The RoHS restricts the amount of certain hazardous substances in the manufacture of electrical and electronic products that are sold in the EU market.

Javier Hurtado Albir et al. (2011) provided a list summarizing where these toxic substances can be found in PE components [

2].

Lead (Pb) (0.1%): solder, coatings on component terminations, paints, pigments and driers, PVC as a stabilizer, batteries (not covered by the RoHS Directive).

Mercury (Hg) (0.1%): relays.

Cadmium (Cd) (100 ppm): electroplated coatings, special welding (e.g., in some types of fluxes), contacts, relays and electrical switches, PVC stabilizer, plastic, ceramic pigments, in some ceramic materials.

Hexavalent chromium (CrVI) (0.1%): passivation coatings on metals, corrosion-resistant paintings.

Polybrominated biphenyls (PBBs) (0.1%) and Polybrominated diphenyl ethers (PBDEs) (1000 ppm): plastics.

To comply with the REACH and RoHS regulations, PE designers must carefully select components and manufacturing processes that comply with the restrictions. This requires implementing appropriate measures to minimize the use of hazardous substances, as well as the use of safer alternatives wherever possible.

For instance, alternative RoHS directive-conforming components that can be used in a PEC are as follows:

Silver oxide/cadmium contacts should be replaced by silver oxide/tin contacts, with a good performance at low voltage, although they wear faster at high voltages;

Chrome passivation has several options, most of them are less effective as inhibitors of corrosion in uncoated metals;

Mercury switches can be replaced by gold contact switches, but mercury offers a contact free of fluctuations, and the operative life is significantly greater;

PBDE flame retardants can be exchanged with others, but this might clash with fire regulations. Once PBDE is used, the plastic part cannot be recycled anymore.

Table 1.

Regulations and standards addressing the usage of hazardous substances.

Table 1.

Regulations and standards addressing the usage of hazardous substances.

| Reference | Title |

|---|

| RoHS directive (Directive 2002/95/EC) [6] | RoHS (Restriction of Hazardous Substances) Directive |

| REACH (EC 1907/2006) [5] | REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) |

3.1.2. Regulations on Usage Stage

Enhancing the energy efficiency of PECs during their operation holds the key to significantly mitigating energy losses over varying usage periods, given their core function of energy conversion.

Table 2 presents regulations focusing on the environmental performance of energy-related products (ErPs) during the usage stage. As a response to this imperative, the Eco-design Directive 2009/125/EC [

9] has been established, setting forth mandatory minimum threshold requirements for designing Energy-using Products (EuPs), with a focal point on the energy efficiency indicator. Consequently, products failing to meet these specified thresholds face exclusion from the EU market, resulting in progressively diminished competitiveness for those demonstrating lower energy performance, as graphically depicted in

Figure 2.

To encourage manufacturers to create more energy-efficient products, Directive 92/75/EC [

19], requires standard information labels on seven types of household appliances (e.g., refrigerators, washing machines, dishwashers, ovens, water heaters, lighting sources, air-conditioning appliances) showing their energy consumption and resource usage (graded from class A to G). This energy efficiency labeling enables customers to make informed choices and promotes the development of products with enhanced energy efficiency, as depicted in

Figure 2 [

20].

Directive 92/75/EC [

19] was repealed by Directive 2010/30/EU [

21] on 19 May 2010, which extend the scope to provide information on the energy consumption of energy-related products in general (e.g., lighting products, heating and cooling equipment, consumer electronics). Directive 2010/30/EU [

21] was amended by Directive 2017/1369/EU [

22], which introduced new labeling requirements for energy-related products. The new labeling requirements include a revised energy efficiency scale from A to G, replacing the previous A+++ to D scale [

23]. The new scale is designed to be more intuitive and easier to understand for consumers. The new energy labels have been implemented in France since 2021 for five types of appliances (e.g., dishwashers, washing machines, refrigerators, blisters, televisions and screens) [

24]. This dynamic “energy label” system encapsulates critical information regarding the principal functional aspects corresponding to each product category, thereby influencing energy efficiency evaluations.

Table 2.

Regulations focusing on the environmental performance of Energy-related Products (ErPs) during the usage stage.

Table 2.

Regulations focusing on the environmental performance of Energy-related Products (ErPs) during the usage stage.

| Reference | Title |

|---|

| Directive 2009/125/CE [9] | Establishing a framework for the setting of ecodesign requirements for energy-related products |

| Directive 92/75/CEE [19] | Indication by labelling and standard product information for the consumption of energy and other resources by household appliances |

| Directive 2010/30/EU [21] | Indication by labelling and standard product information of the consumption of energy and other resources by energy-related products |

| Directive 2017/1369/EU [20] | Setting a framework for energy labelling |

3.1.3. Regulations around Circularity Scenario

The circular economy is an economic framework that prioritizes minimizing waste and maximizing resource usage through closed-loop systems. The concept of circularity encompasses various scenarios, including refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle and recover [

25]. The regulations surrounding the circular economy aim to promote material circularity and encourage the reintroduction of the residual value of materials in the product’s value chain, presented in

Table 3. In 2020, the European commission published a new CEAP (2020); this action plan promotes the use of secondary materials in product manufacturing [

8], and will increase their traceability.

Announced in the New Consumer Agenda and the CEAP, the “Right to Repair” is a new Directive proposal by the European Commission that aims to empower consumers with enhanced rights to repair their goods, instead of replacing them [

26]. This directive seeks to tackle the barriers that hinder consumers from accessing repair services or obtaining necessary information, such as limited availability or transparency. By promoting the availability and accessibility of repair services, the directive expects to promote a circular economy and minimize waste.

To integrate the circularity requirements into the product design stage, the European Commission proposed a regulation in March 2022, establishing a framework for Eco-design Requirements for Sustainable Products (ESPR) [

10]. This proposal is strategically designed to broaden the horizon of the eco-design directive 2009/125/EC. It aims to extend the ecodesign directive’s scope from a singular focus on energy efficiency in the use phase to various aspects of material efficiency, such as product upgradability, repairability, maintenance and refurbishment [

10].

At the French national level, the French AGEC law (Anti-Gaspillage pour une Economie Circulaire) [

7], enacted in 2020, aims to reduce waste and foster a circular economy by transitioning the French economy to a more circular model, rather than relying on a linear take–make–use–dispose approach. According to the AGEC law, the French Repairability Index (FRI) [

27] has been introduced to regulate EEE. This index sets a score out of ten that indicates how easily a product can be repaired. It is mandatory for several electronic and electric products, including mobile phones, computers and washing machines. However, it is not currently mandatory for PEC. The introduction of the FRI aims to encourage manufacturers to consider repairability at the design stage and make consumers aware of repair options when purchasing a device. By 2026, France aims to increase the proportion of repaired electronic and electric products from 40% to 60%. These measures ultimately promote a more sustainable approach to consumption and production [

28].

Table 3.

Regulations promoting material circularity.

Table 3.

Regulations promoting material circularity.

| Reference | Title |

|---|

CEAP (COM/2020/98)

[8] | A new Circular Economy Action Plan For a cleaner and more competitive Europe |

Directive 2002/96/EC

[29] | WEEE (Waste Electrical and Electronic Equipment) Directive |

AGEC Law (2020)

[7] | French Anti-Waste Law for a Circular Economy |

R2R Directive 2023/0083(COD)

[30] | Right to Repair Directive (Proposal) |

ESPR

[10] | Eco-design Requirements for Sustainable Products (Proposal) |

3.1.4. Regulations for End-of-Life Management

Initially introduced in 2003 and revised in 2012, the WEEE Directive 2012/19/EU aimed to improve the prevention, reuse, recycling and recovery of electronic waste in Europe [

31] (

Table 4). In 2018, the directive was revised to promote the recovery of valuable secondary raw materials, ensure efficient resource use and further reduce waste [

14]. Regarding EoL treatments, PECs can contain components and substances that require special disposal or recovery procedures to prevent environmental damage. In line with the WEEE Directive 2012/19/EU [

31], the following substances, preparations or components must be disposed of or recovered separately from other WEEE:

Capacitors (containing polychlorinated biphenyls/polychlorinated terphenyls);

Components containing mercury;

Batteries;

PCBs (with a surface greater than 10 cm2);

Components containing toner, ink and liquids;

Plastic containing brominated flame retardants;

Components containing asbestos or asbestos waste;

Cathode ray tubes;

Components containing CFC, HCFC, HFC and HC;

Gas discharge lamps;

External electric cables;

Components containing refractory ceramic fibers;

Components containing radioactive substances;

Electrolyte capacitors (height > 25 mm, diameter > 25 mm).

PECs can contain some of these components, particularly capacitors, PCBs with a surface greater than 10 cm2, electrolyte capacitors and external electric cables. Depending on the design and application, they may also contain batteries at the system level. It is essential to have or to recover these components appropriately to align with the Waste Framework Directive 2008/98/EC.

One of the key principles of the WEEE Directive is the EPR (Extended Producer Responsibility), which financially obligates producers to collect, treat, recover and dispose of WEEE [

32]. This incentivizes producers to design more easily reused, recycled and recovered products and encourages a circular economy approach. However, the implementation of the WEEE Directive and EPR principles varies across Member States. For instance, France has introduced its own AGEC law to encourage manufacturers to adopt more sustainable practices [

7].

Table 4.

Regulations addressing EoL management.

Table 4.

Regulations addressing EoL management.

| Reference | Title |

|---|

Directive 2012/19/EU

[31] | WEEE (Waste Electrical and Electronic Equipment) Directive |

EPR (2008/98/EC)

[33] | Extended Producer Responsibility |

To address the need for the proper management of end-of-life disposal and the recycling of the products, many countries have established EPR schemes. Under these schemes, producers are required to financially contribute to the management of their products at their EoL, rather than relying on citizens to pay for waste collection and management through taxes. EPR schemes take various forms depending on the product category and country, but typically involve the establishment of a governing body (e.g., eco-organism in the case of France) responsible for managing the scheme and collecting fees from producers [

11]. These fees are used to cover the expenses involved in the collection, transportation and treatment of WEEE, including PECs [

34]. Furthermore, the AGEC Law in France aims to promote the reuse of products by creating a “solidarity reuse fund” that supports organizations and structures such as waste sorting, recovery and recycling centers that enable the reuse of products [

28]. In addition, waste collection points should be set up in a way that preserves the reusability of collected e-waste, which is partially addressed in TS 50625-4 [

35].

3.2. Facultative Guidelines for PEC Ecodesign

The mentioned legislation applies across different stages of the PEC’s entire lifecycle, with a focus on environmental impact indicators, material circularity, waste management and other relevant aspects. Notably, a significant 80% of the environmental impacts originate during the design phase [

36]. This emphasizes the crucial necessity for designers to integrate these essential factors that influence product sustainability directly into the functional design and development processes. This section presents standards supporting sustainable design for PECs, categorized into three groups: material circularity assessment, environmental performance evaluation and ecodesign integration in the design process.

3.2.1. Material Circularity Assessment

Under CEAP, the EN 4555X series of standards were developed to provide generic material efficiency standards for ecodesign under standardization mandate M/543 [

14] (

Table 5). EN 45552-EN 45557 [

37,

38,

39,

40] focus on the evaluation methods for a product’s ability to be used for a long time, repaired, reused, remanufactured, upgraded and recycled. EN 45558:2019 provides guidelines for critical raw material declaration, while EN 45559:2019 indicates the method for providing information related to material efficiency aspects [

41,

42]. The product-specific standards for PECs are currently being developed, following the guidance provided by the EN 4555X [

14] series. This approach aims to align with the understanding of various material efficiency aspects within distinct product groups [

14].

In addition to the EN standards, the IEC/TR 62635 [

43] directives provide a comprehensive approach for calculating the recyclability and recoverability rates of electrical and electronic equipment, including PECs.

EN 50614 [

44] was developed to provide requirements for preparing WEEE for reuse. This standard specifies procedures for the collection, sorting and treatment of WEEE to promote their reuse.

Table 5.

Regulations and standards promoting material circularity.

Table 5.

Regulations and standards promoting material circularity.

| Reference | Title |

|---|

EN 45552:2020

[37] | General method for the assessment of the durability of energy-related products |

EN 45553:2020

[38] | General method for the assessment of the ability to remanufacture energy-related products |

EN 45554:2020

[39] | General methods for the assessment of the ability to repair, reuse and upgrade energy-related products |

EN 45555:2019

[40] | General methods for assessing the recyclability and recoverability of energy-related products |

EN 45556:2019

[45] | General method for assessing the proportion of reused components in energy-related products |

EN 45557:2020

[46] | General method for assessing the proportion of recycled material content in energy-related products |

EN 45558:2019

[41] | General method to declare the use of critical raw materials in energy-related products |

EN 45559:2019

[42] | Methods for providing information relating to material efficiency aspects of energy-related products |

IEC/TR 62635

[43] | Guidelines for end-of-life information provided by manufacturers and recyclers and for recyclability rate calculation of electrical and electronic equipment |

3.2.2. Environmental Performance Evaluation

Standards for environmental performance evaluation allows PE designers to make informed choices and take appropriate measures to reduce or prevent negative environmental impacts. Life Cycle Analysis (LCA) is a standardized and mature systems-oriented analytical tool that provides a life cycle perspective for assessing the potential impacts of products or services [

16]. The standards provide guidelines for conducting an LCA and are presented in the

Table 6. The international reference program PEP Ecopassport

® was developed for environmental declarations specifically for EEE products [

17]. PEP Ecopassport

® establishes rules for certifying type III environmental declaration (ISO14,025). PEP Ecopassport

® Program provides Product Category Rules (PCRs) and Product Specific Rules (PSRs) to conduct LCAs for electrical product families, for instance PSR0010—Uninterruptible Power Systems (UPSs) that can be used as an example for PECs [

47]. There is mutual recognition between PEP Ecopassport

® and other European associations that maintain the same level of data quality. Equivalent rules will be adopted at the European level when products become subject to mandatory Environmental and Social Performance Reporting (ESPR).

The current framework for conducting LCAs on PE systems (including study objectives, scope, life cycle inventory, and impact assessment) lacks the necessary precision to ensure consistent estimations among various parties. As a result, comparing products becomes challenging, especially when there are variations in the functional unit. Additionally, the selection of indicators and calculation methods for impact assessments is left to the discretion of the LCA analysts, leading to potentially significant variations in results. To address these challenges, the international working group TC111 WG15 is currently developing the IEC 63,366 standard titled, “Product category rules for LCA of electrical and electronic products and systems”. The aim is to establish clearer guidelines for conducting LCA within the field of electrotechnology, ensuring a more consistent and standardized approach.

3.2.3. Ecodesign Integration

The mentioned criteria and evaluation system for sustainable PECs become effective only when integrated into the Product Development Process (PDP) of PECs.

Table 7 presents the standards that offer guidance for aiding companies in implementing an ecodesign approach within the PDP. The ecodesign methods and tools that can assist PE designers in integrating environmental considerations alongside traditional design factors such as performance and cost [

53], towards reducing environmental impacts throughout the product life cycle [

54].

Specifically for the PE field, the European standard EN 50598 [

57] specifies ecodesign requirements for electrical drive systems, motor starters, Power Electronics and their applications in machine drives. Built upon the Eco-design Directive [

9], EN 50598:2015 [

57] is divided into three parts, outlining test and measurement methods for assessing compliance with international efficiency classes (IE classes) (

Table 8). The first two parts of this standard have been repealed and replaced by the international standards IEC 61800-9 for power drive systems with variable speed drives [

58,

59].

In accordance with the “classic” ecodesign process, the standard EN 50598-3, in effect since 2015, specifies relevant requirements for PE practitioners, referring to product categories and the contents of environmental declarations related to Complete Drive Modules (CDMs) used in motor-driven applications (i.e., loads driven by motors) for low-voltage applications (less than 1000 V) with power ranges from 0.12 kW up to 1000 kW throughout their entire life cycle. This standard provides practical guidelines for Power Electronics designers to implement ecodesign principles in their activities. It starts by describing the principal elements of ecodesign, including two types of environmental declaration (Type II and Type III) (

Table 9). It also defines ecodesign requirements that highlight aspects that Power Electronics designers should consider, such as the constitutive materials and substances used, energy efficiency during the use phase and potential environmental impacts during all life cycle stages, from manufacturing to EoL. The standards indicated the environmental indicators should be evaluated and declared: climate change (measured in kg CO

2-eq), ozone depletion (measured in kg CFC-115), the creation of photochemical ozone (measured in kg NMVOC), terrestrial acidification (measured in kg SO

2), freshwater eutrophication (measured in kg P), human toxicity (measured in kg 1,4-DB), terrestrial ecotoxicity (measured in kg 1,4-DB), mineral depletion (measured in kg Fe) and fossil fuel depletion (measured in kg) [

57]. A CENELEC (European Committee for Electrotechnical Standardization) working group TC22X is presently in the process of updating the EN 50598-3 standard. The goal is to establish specific PE rules based on EN 63,366 as generic requirements.

4. A Collaborative Online Inventory Framework for Up-to-Date Review of Legislative and Normative Constraints

The 63 related documents contributing to legislative and normative frameworks have been gathered in an Excel file and shared online (

Figure 3) (VIVAE website accessed on 5 December 2023,

https://g2elab.grenoble-inp.fr/fr/recherche/projet-vivae-contenus-techniques). In the inventory, documents are characterized by parameters such as agency, coverage, mandatory status, type, domain, lifecycle addressed, environmental aspects addressed and priority for review. These parameters enable users to effectively search and evaluate relevant documents based on specific criteria.

This inventory can preliminarily support professionals involved in Power Electronics-based product design and development, such as designers, R&D professionals and researchers. However, it can also support those working on sustainable development and the circular economy within the company. Although the specific PE field is the main target, any private or public organization operating in the broader domain of electrical engineering can also benefit from the documents provided in this inventory.

This inventory is designed to be flexible, meaning that the database is not fixed and can be easily updated. This flexibility enables the opportunity for contributors to aid in the development, enrichment or consolidation of the data made available to everyone. For instance, if researchers, industrialists or policy-makers come across or are developing new legislation and standards that have not yet been included in the current database, they can contribute by contacting the owners of the inventory or updating their own version, since it can be downloaded.

This seeker tool facilitates the establishment of the PE product specification, ensuring compliance with regulations and standards in the aspect of sustainability. It helps PE designers discern specific constraints applicable to the PE product specification, and determine the standardized evaluation method for analyzing these defined constraints.

The overview of environmental legislation for ErPs and PE provided by the inventory sheds light on the existing limitations within the current regulatory framework. Subsequent sections delve into a detailed discussion of these identified limitations and associated challenges.

5. Discussion: Limitations and Challenges Related to the Current Legislative and Normative Constraints Addressed for Power Electronics Sustainable Product Development

5.1. Absence of Constraints on Environmental Performance

The state of the art of the current regulatory landscape in the field of PE reveals several notable aspects. Firstly, existing standards and regulations do not impose any requirements on the characteristics and “environmental performance” of energy conversion devices beyond minimum efficiency levels and standby power consumption. These standards are primarily focused on minimizing the electrical energy dissipated during device usage [

9]. The ecodesign directive has drawn criticism for its exclusive emphasis on energy efficiency during the usage phase [

14]. However, it falls short in addressing material efficiency and various environmental impacts throughout a product’s extended lifecycle. In the case of EN 50598-3, it only defines performance classification in terms of energy efficiency and associated power losses during the usage phase. When it comes to environmental life cycle impact indicators and EoL performance, the standard only requires manufacturers to provide relevant information.

To make the standards for assessing the environmental impact of PE systems more stringent, a shift from relative limits (which are not mandatory) to absolute limits (which would be mandatory) is suggested. Such a shift towards absolute limits would have practical implications. It could lead to removing products with the poorest environmental performance (in addition to considering energy efficiency) from the market. Moreover, based on the “absolute limits”, a standardized ranking system could be set up. The ranking system would provide clear guidance to PE designers in designing products that minimize negative environmental impacts throughout their life cycle.

The absolute limits would be based on a specific set of indicators representing significant environmental effects of the PE system’s life cycle. This set could align with the indicators already identified by the EN 50598-3 standard [

57].

However, implementing the concept of absolute limits requires careful consideration. It necessitates a democratic discussion beforehand to determine what should be considered as a “threshold value” not to be surpassed for specific categories of PE products.

These considerations are connected to the concept of “Absolute Sustainability” in LCA [

65]. While challenging, this approach involves thinking about physical boundaries beyond which Earth’s ecosystems could shift into unpredictable and irreversible states. The concept of absolute limits draws from the framework of planetary boundaries [

66]. Building on this framework, Bjørn et al. (2015) established limits for LCA indicators based on ecosystem capacity [

65]. For instance, to keep the global average surface temperature below 2 °C, greenhouse gas emissions should remain below 985 kg of CO

2 equivalent per person per year [

65]. Transitioning from this global limit to specific product categories while considering sector-specific boundaries requires exploring different scaling principles, all of which should be rooted in the concept of a functional unit.

5.2. Horizontal Material Efficiency Standards Have Not Been Adapted for PE

5.2.1. The EN4555X Standard Family Remains Generic

EN4555X standard family provides generic methods and criteria for the assessment of the durability of energy-related products, and ErPs’ ability to be repaired, reused, upgraded, remanufactured, recycled and recovered.

Patra (2021), however, pointed out the lack of application of these generic horizontal standards EN4555X to unique energy-related products such as Power Electronics drives [

67]. The current literature-based design guidelines are excessively general. The specific application of the EN4555X standard’s circularity criteria for PECs requires a further specification and adaptation to be incorporated in the conceptual stage design requirements. The product-related and support-related criteria and their qualification criteria need to be adapted regarding different system levels of PECs. This aspect is currently being addressed by the CENELEC Working Group TC22X, aiming to adapt EN4555X to the Power Electronics (PE) system.

5.2.2. Limitations of the Current French Repairability Index for Supporting PE Designers

To propose to stakeholders a useful framework for evaluating product repairability, the development of a standardized and more technical repairability index for PECs becomes essential. This index would consist of distinct categories and criteria that could be assessed and given varying importance to calculate a potential repairability score. These categories would cover factors such as resilience against malfunctions, product documentation and identification, diagnostic capabilities, ease of repair, the replacement of components and requalification [

68].

By taking into account elements like potential safety component integration, the simplicity of diagnostics, the availability of product information, modular design, standardized components, and the accessibility of parts, this theoretical index aims to empower stakeholders to make more informed decisions regarding repair and maintenance. Moreover, the index could potentially consider factors like the estimated time required for procedures, the complexity of component removal, the required expertise level, the availability of repair services, and the compatibility with other products.

Introducing such a standardized repairability index could potentially enhance transparency, streamline repair processes, and encourage the development of PECs that are not only more repairable but also built for long-lasting durability.

5.3. Unclear Methodology and Lack of Industrial Interests for Integrating Ecodesign Criteria into the PE Design Process

The current standards do not provide a comprehensive methodology to effectively integrate environmental impact assessment and material efficiency evaluation into the distinct stages of the PE design process, including tasks like conversion topology design, hardware selection, and 3D layout.

Moreover, the general ecodesign integration standards fail to specify the methodology and tools required for monitoring the relevant criteria in the context of the PE design process. This gap raises questions about the specific stage at which these criteria should be measured, what criteria should be considered, and how these criteria should be measured effectively.

This research gap poses challenges for PE professionals aiming to implement ecodesign in their R&D projects and to evaluate the ecodesign maturity of their design process. Consequently, it becomes challenging to monitor effectively and to optimize the sustainable performance of the PEC within the design process.

Moreover, the current cost-driven product development model is a barrier to convince industries to adopt ecodesign methodologies and implement ecodesign criteria in the PE design process. Striking a compromise between cost and environmental considerations becomes challenging in the absence of industrial interests.

6. Conclusions

This article aimed to offer the scientific community in the field of PE as well as electrical engineering a comprehensive assessment of the regulations associated with ecodesign and circular economy in Europe, with a specific focus in France.

Currently, the research is primarily focused on the broad field of ErPs. However, there is relatively limited discussion regarding how these regulatory frameworks are tailored to specific product categories. This gap is particularly noticeable in the field of PE. PECs are crucial equipment in a diverse range of electronic and electrotechnic/electrical products. However, there is an absence of comprehensive and detailed literature that investigates how sustainable regulations affect the development of PE products and how related standards contribute to promoting ecodesign for PE products. Therefore, this paper’s unique contribution lies in examining sustainability regulations and standards applicable to the PE domain, simultaneously analyzing how these standards support sustainable PE product design.

The findings present a legislative and normative framework that serves as a guide for PE practitioners seeking to integrate ecodesign practices within industrial contexts. The legislative framework encompasses regulations for ensuring compliance across various stages of the product life cycle—from raw material extraction and manufacturing to usage, circularity scenarios and EoL management. Complementing this, the normative framework establishes standardized guidelines for evaluating environmental impacts, assessing material circularity, and effectively integrating ecodesign principles. The compiled online inventory (VIVAE website accessed on 5 December 2023,

https://g2elab.grenoble-inp.fr/fr/recherche/projet-vivae-contenus-techniques) (

Figure 3) facilitates further exploration for PE professionals by providing an analysis tool of the existing regulatory and normative framework. This inventory provides the specifications in France. From the perspective of extending this framework to different European countries through this collaborative online inventory, the authors invite other stakeholders to incorporate the implementation of European directives into their national laws and the specific standards developed.

Through this analysis, certain gaps in regulations and standards become apparent. Firstly, the absence of constraints on environmental performance necessitates the establishment of absolute limits for LCA indicators and a ranking system to address this shortcoming. Secondly, while horizontal material efficiency standards exist, they require adaptation with suitable granularity to align with the specific needs of PE industrial design. Thirdly, the PE design process lacks a coherent methodology for integrating ecodesign criteria into the activities of PE designers. Lastly, an incentive regulatory method is required to stimulate the industry to actively integrate ecodesign requirements. To tackle these challenges, it is crucial for general standards to incorporate the industrial design context of PE. By doing so, relevant tools can be developed, allowing stakeholders to assess the maturity of their ecodesign process and effectively monitor the sustainable performance of their products during the design phase.

Author Contributions

Conceptualization, L.F., T.T.R., M.R. and J.-C.C.; methodology, L.F., T.T.R., M.R. and J.-C.C.; validation, L.F., T.T.R., M.R., J.M. and J.-C.C.; formal analysis, L.F., T.T.R., M.R., J.M. and J.-C.C.; data curation, L.F. and T.T.R.; writing—original draft preparation, L.F. and T.T.R.; writing—review and editing, L.F., T.T.R., M.R., J.M. and J.-C.C.; visualization, L.F. and T.T.R.; supervision, M.R. and J.-C.C.; funding acquisition, M.R., J.M. and J.-C.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the French National Research Agency (ANR) under the project ANR-21-CE10-0010-01.

Data Availability Statement

Conflicts of Interest

Author Julien Melot was employed by the company Eaton Industries France. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Sandelic, M.; Peyghami, S.; Sangwongwanich, A.; Blaabjerg, F. Reliability Aspects in Microgrid Design and Planning: Status and Power Electronics-Induced Challenges. Renew. Sustain. Energy Rev. 2022, 159, 112127. [Google Scholar] [CrossRef]

- Javier Hurtado Albir, F.; Antonio Carrasco Hernández, J. Environmental Aspects of Manufacturing and Disposal of Power Electronics Equipment. EPE J. 2011, 21, 5–13. [Google Scholar] [CrossRef]

- Pirson, T.; Delhaye, T.P.; Pip, A.G.; Le Brun, G.; Raskin, J.-P.; Bol, D. The Environmental Footprint of IC Production: Review, Analysis, and Lessons from Historical Trends. IEEE Trans. Semicond. Manuf. 2023, 36, 56–67. [Google Scholar] [CrossRef]

- European Commission. Overview of EU Measures to Make Sustainable Products the Norm in the EU. Available online: https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/sustainable-products/about-sustainable-products_en (accessed on 11 January 2024).

- REACH. Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), Establishing a European Chemicals Agency, Amending Directive 1999/45/EC and Repealing Council Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94 as Well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC; European Union: Brussels, Belgium, 2006; Volume 396. [Google Scholar]

- RoHS Directive. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/rohs-directive_en (accessed on 22 June 2022).

- French Ministry of Ecological Transition. A French Act of Law against Waste and for a Circular Economy. Available online: https://circulareconomy.europa.eu/platform/en/strategies/french-act-law-against-waste-and-circular-economy (accessed on 25 May 2023).

- CEAP. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020.

- 2009/125/EC; Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products (Text with EEA Relevance). European Union: Brussels, Belgium, 2009; Volume 285.

- Directorate-General for Environment. Proposal for Ecodesign for Sustainable Products Regulation. Available online: https://environment.ec.europa.eu/publications/proposal-ecodesign-sustainable-products-regulation_en (accessed on 4 October 2022).

- French Ministry of Ecological Transition. General Framework for Extended Producer Responsibility Channels. Available online: https://www.ecologie.gouv.fr/cadre-general-des-filieres-responsabilite-elargie-des-producteurs (accessed on 30 November 2023).

- Nissen, N.F.; Stobbe, L.; Schischke, K.; Muller, J.; Reichl, H. European Environmental Legislation-Insights into the EuP Process. In Proceedings of the 2007 32nd IEEE/CPMT International Electronic Manufacturing Technology Symposium, San Jose, CA, USA, 3–5 October 2007; pp. 325–331. [Google Scholar]

- Schischke, K.; Nissen, N.F.; Stobbe, L. Energy Efficiency Meets Ecodesign—Technology Impacts of the European EuP Directive. In Proceedings of the 2008 IEEE International Symposium on Electronics and the Environment, San Francisco, CA, USA, 19–22 May 2008; pp. 1–6. [Google Scholar]

- Bundgaard, A.M.; Huulgaard, R.D. The Role of Standards in Support of Material Efficiency Requirements under the Ecodesign Directive. J. Clean. Prod. 2023, 385, 135599. [Google Scholar] [CrossRef]

- Schischke, K.; Berwald, A.; Dimitrova, G.; Rückschloss, J.; Nissen, N.F.; Schneider-Ramelow, M. Durability, Reparability and Recyclability: Applying Material Efficiency Standards EN 4555x to Mobile Phones and Tablet Computers. Procedia CIRP 2022, 105, 619–624. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- PEP Ecopassport. Available online: http://www.pep-ecopassport.org/ (accessed on 12 January 2024).

- Allsopp, M.; Costner, P.; Johnston, P. Incineration and Human Health: State of Knowledge of the Impacts of Waste Incinerators on Human Health (Executive Summary). Environ. Sci. Pollut. Res. 2001, 8, 141–145. [Google Scholar] [CrossRef] [PubMed]

- 92/75/CEE; Directive 92/75/CEE du Conseil, du 22 Septembre 1992, Concernant L’indication de la Consommation des Appareils Domestiques en Énergie et en Autres Ressources par Voie D’étiquetage et D’informations Uniformes Relatives Aux Produits. European Union: Brussels, Belgium, 1992; Volume 297.

- European Commission COMMISSION DELEGATED REGULATION (EU) …/... Supplementing Regulation (EU) 2017/1369 of the European Parliament and of the Council with Regard to Energy Labelling of Electronic Displays and Repealing Commission Delegated Regulation (EU) No 1062/2010; European Union: Brussels, Belgium, 2019.

- 2010/30/EU DIRECTIVE 2010/30/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 19 May 2010 on the Indication by Labelling and Standard Product Information of the Consumption of Energy and Other Resources by Energy-Related Products. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX%3A32010L0030 (accessed on 30 November 2023).

- Proposal for a DIRECTIVE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL on Common Rules Promoting the Repair of Goods and Amending Regulation (EU) 2017/2394, Directives (EU) 2019/771 and (EU) 2020/1828; European Union: Brussels, Belgium, 2023.

- European Parliament. Review of the Energy Efficiency Labelling Directive 2010/30/EU|Legislative Train Schedule. Available online: https://www.europarl.europa.eu/legislative-train/theme-industry-research-and-energy-itre/file-energy-efficiency-labelling-review (accessed on 30 November 2023).

- France Government. A New Energy Label for Household Equipment. Available online: https://www.gouvernement.fr/actualite/une-nouvelle-etiquette-energie-pour-l-equipement-de-la-maison (accessed on 22 May 2023).

- Potting, J.; Hekkert, M.P.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Assessment Agency: Dutch, The Netherlands, 2017. [Google Scholar]

- European Commission. Right to Repair: Making Repair Easier for Consumers. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_1794 (accessed on 24 August 2023).

- French Ministry of Ecological Transition. Indice de Réparabilité. Available online: https://www.ecologie.gouv.fr/indice-reparabilite (accessed on 26 May 2023).

- EMF France’s Anti-Waste and Circular Economy Law. Available online: https://ellenmacarthurfoundation.org/circular-examples/frances-anti-waste-and-circular-economy-law (accessed on 24 August 2023).

- European Commission. Directive 2002/96/EC of the European Parliament and of the Council of 27 January 2003 on Waste Electrical and Electronic Equipment (WEEE); Joint Declaration of the European Parliament, the Council and the Commission Relating to Article 9; European Union: Brussels, Belgium, 2003; Volume 037.

- European Commission. Procedure File: 2023/0083(COD)|Legislative Observatory|European Parliament. Available online: https://oeil.secure.europarl.europa.eu/oeil/popups/ficheprocedure.do?reference=2023/0083(COD)&l=en (accessed on 23 January 2024).

- European Commission. Directive 2012/19/UE du Parlement Européen et du Conseil du 4 juillet 2012 Relative aux Déchets D’équipements Électriques et Électroniques (DEEE) Texte Présentant de L’intérêt Pour l’EEE; European Union: Brussels, Belgium, 2012; Volume 197.

- Atasu, A.; Subramanian, R. Extended Producer Responsibility for E-Waste: Individual or Collective Producer Responsibility? Prod. Oper. Manag. 2012, 21, 1042–1059. [Google Scholar] [CrossRef]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance); European Union: Brussels, Belgium, 2008; Volume 312.

- Domingo, L.; Melchor, D. Designing out Waste: Which Levelers for Local Authorities? Procedia CIRP 2022, 105, 535–540. [Google Scholar] [CrossRef]

- TS 50625 TS 50625-4:2017. Available online: https://www.boutique.afnor.org/en-gb/standard/pd-clc-ts-5062542017/collection-logistics-treatment-requirements-for-weee-specification-for-the-/eu148550/227711 (accessed on 30 November 2023).

- Directorate-General for Energy (European Commission); Directorate-General for Enterprise and Industry (European Commission). Ecodesign Your Future: How Ecodesign Can Help the Environment by Making Products Smarter; Publications Office of the European Union: Luxembourg, 2012; ISBN 978-92-79-25145-0.

- NF EN 45552; General Method for the Assessment of the Durability of Energy-Related Products. AFNOR Publishing: Paris, France, 2020.

- NF EN 45553; General Method for Assessing the Ability of an Energy-Related Product to Be Remanufactured. AFNOR Publishing: Paris, France, 2020.

- NF EN 45554; General Methods for the Assessment of the Ability to Repair, Reuse and Upgrade Energy-Related Products. AFNOR Publishing: Paris, France, 2020.

- NF EN 45555; General Methods for Assessing the Recyclability and Recoverability of Energy-Related Products. AFNOR Publishing: Paris, France, 2019.

- NF EN 45558; General Method to Declare the Use of Critical Raw Materials in Energy-Related Products. AFNOR Publishing: Paris, France, 2019.

- NF EN 45559; Methods for Providing Information Relating to Material Efficiency Aspects of Energy-Related Products. AFNOR Publishing: Paris, France, 2019.

- IEC TR 62635:2012; Guidelines for End-of-Life Information Provided by Manufacturers and Recyclers and for Recyclability Rate Calculation of Electrical and Electronic Equipment. International Electrotechnical Commission: Geneva, Switzerland, 2012.

- NF EN 50614; Requirements for the Preparing for Re-Use of Waste Electrical and Electronic Equipment. AFNOR Publishing: Paris, France, 2020.

- NF EN 45556; General Method for Assessing the Proportion of Reused Components in Energy-Related Products. AFNOR Publishing: Paris, France, 2020.

- NF EN 45557; General Method for Assessing the Proportion of Recycled Materials Content in Energy-Related Products. AFNOR Publishing: Paris, France, 2020.

- PEP Ecopassport PSR0010-Uninterruptible Power Supply (UPS). Available online: http://www.pep-ecopassport.org/create-a-pep/produce-a-lca/ (accessed on 24 August 2023).

- ISO 14031:2021; Environmental Management—Environmental Performance Evaluation—Guidelines. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO/TR 14047:2012; Environmental Management—Life Cycle Assessment—Illustrative Examples on How to Apply ISO 14044 to Impact Assessment Situations. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO/TS 14072:2014; Environmental Management—Life Cycle Assessment—Requirements and Guidelines for Organizational life Cycle Assessment. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 14067:2018; Carbon Footprint of Products. International Organization for Standardization: Geneva, Switzerland, 2018.

- Johansson, G. Success Factors for Integration of Ecodesign in Product Development: A Review of State of the Art. Environ. Manag. Health 2002, 13, 98–107. [Google Scholar] [CrossRef]

- ISO/TR 14062:2002; Environmental Management—Integrating environmental Aspects into Product Design and Development. International Organization for Standardization: Geneva, Switzerland, 2002.

- ISO 14006:2020; Environmental Management Systems—Guidelines for Incorporating Ecodesign. International Organization for Standardization: Geneva, Switzerland, 2002.

- ISO 14009:2020; Environmental Management Systems—Guidelines for Incorporating Material Circulation in Design and Development. International Organization for Standardization: Geneva, Switzerland, 2002.

- NF EN 50598-3; Ecodesign for Power Drive Systems, Motor Starters, Power Electronics and Their Driven Applications—Part 3: Quantitative Eco Design Approach through Life Cycle Assessment Including Product Category Rules and the Content of Environmental Declarations. AFNOR Publishing: Paris, France, 2015.

- IEC 61800-9-1:2017; Adjustable Speed Electrical Power Drive Systems—Part 9-1: Ecodesign for Power Drive Systems, Motor Starters, Power Electronics and Their Driven Applications—General Requirements for Setting Energy Efficiency Standards for Power Driven Equipment Using The Extended Product Approach (EPA) and Semi Analytic Model (SAM). International Electrotechnical Commission: Geneva, Switzerland, 2017.

- IEC 61800-9-2:2017; Adjustable Speed Electrical Power Drive Systems (PDS)—Part 9-2: Ecodesign for Motor Systems—Energy Efficiency Determination and Classification. International Electrotechnical Commission: Geneva, Switzerland, 2017.

- IEC 62474; Material Declaration for Products of and for the Electrotechnical Industry. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- NF EN 50581; Technical Documentation for the Assessment of Electrical and Electronic Products with Respect to the Restriction of Hazardous Substances. AFNOR Publishing: Paris, France, 2013.

- ISO 14020:2022; Environmental Statements and Programmes for Products—Principles and General Requirements. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 14021:2016/Amd 1:2021; Environmental Labels and Declarations—Self-Declared Environmental Claims (Type II Environmental Labelling). International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 14025:2020; Environmental labels and declarations Type I environmental labelling—Principles and Procedures. International Organization for Standardization: Geneva, Switzerland, 2020.

- Bjørn, A.; Hauschild, M.Z. Introducing Carrying Capacity-Based Normalisation in LCA: Framework and Development of References at Midpoint Level. Int. J. Life Cycle Assess. 2015, 20, 1005–1018. [Google Scholar] [CrossRef]

- Persson, L.; Carney Almroth, B.M.; Collins, C.D.; Cornell, S.; de Wit, C.A.; Diamond, M.L.; Fantke, P.; Hassellöv, M.; MacLeod, M.; Ryberg, M.W.; et al. Outside the Safe Operating Space of the Planetary Boundary for Novel Entities. Environ. Sci. Technol. 2022, 56, 1510–1521. [Google Scholar] [CrossRef] [PubMed]

- Patra, M. European Ecodesign Material Efficiency Standardization Overview for Circular Economy Aspects in Motor and Power Drive Systems. In Energy Efficiency in Motor Systems; Bertoldi, P., Ed.; Springer International Publishing: Cham, Switzerland, 2021; pp. 231–242. [Google Scholar]

- Romano, T.T.; Fang, L.; Rio, M.; Alix, T.; Melot, J.; Serrano, F.; Dray, A.; Lefranc, P.; Lembeye, Y.; Perry, N.; et al. Évaluation de la Démontabilité des Convertisseurs Électroniques de Puissance Pour une Circularité Améliorée; SYMPOSIUM DE GENIE ELECTRIQUE SGE: Lille, France, 2023. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).