A Comprehensive Review of Sustainability in Natural-Fiber-Reinforced Polymers

Abstract

:1. Introduction

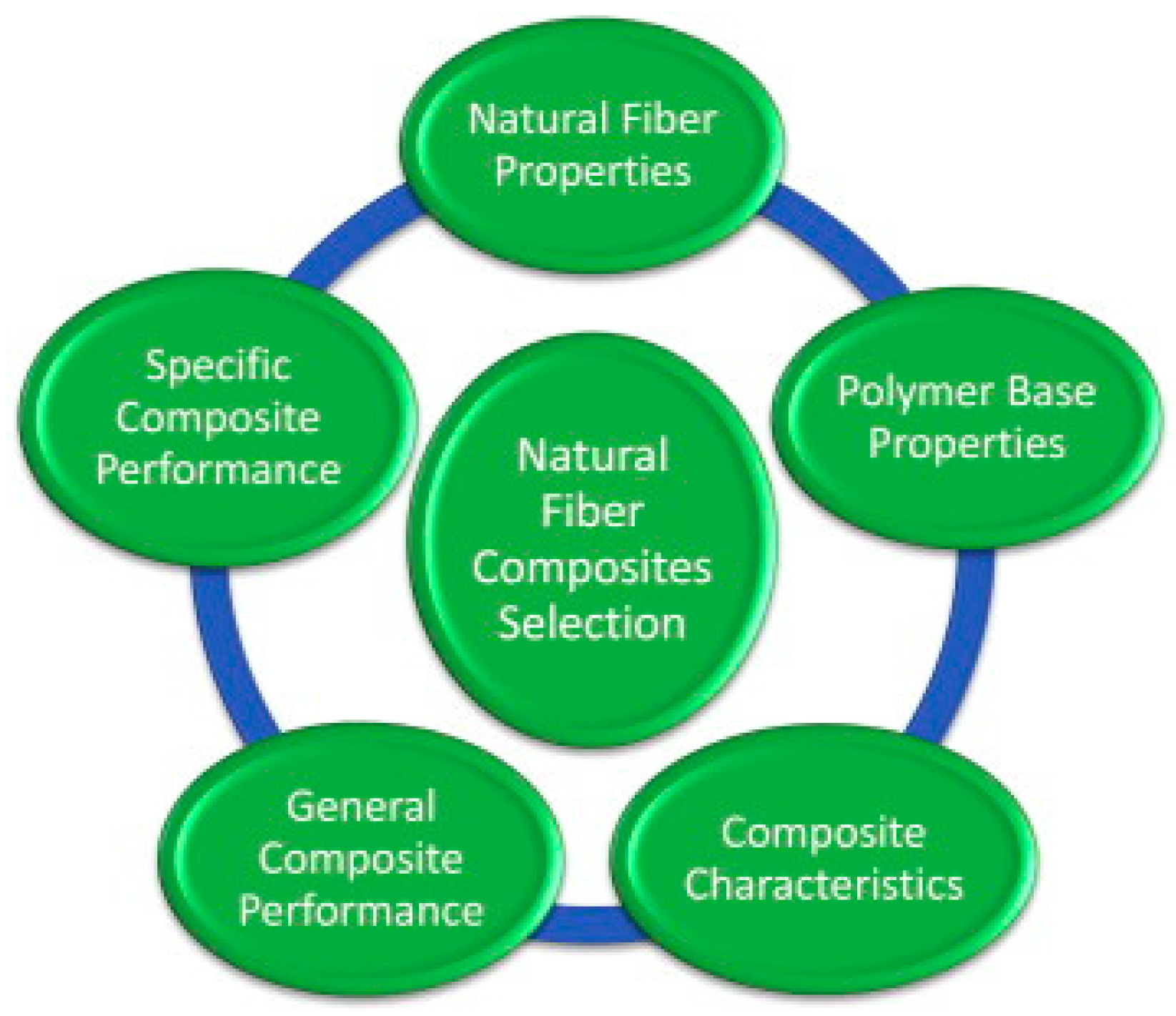

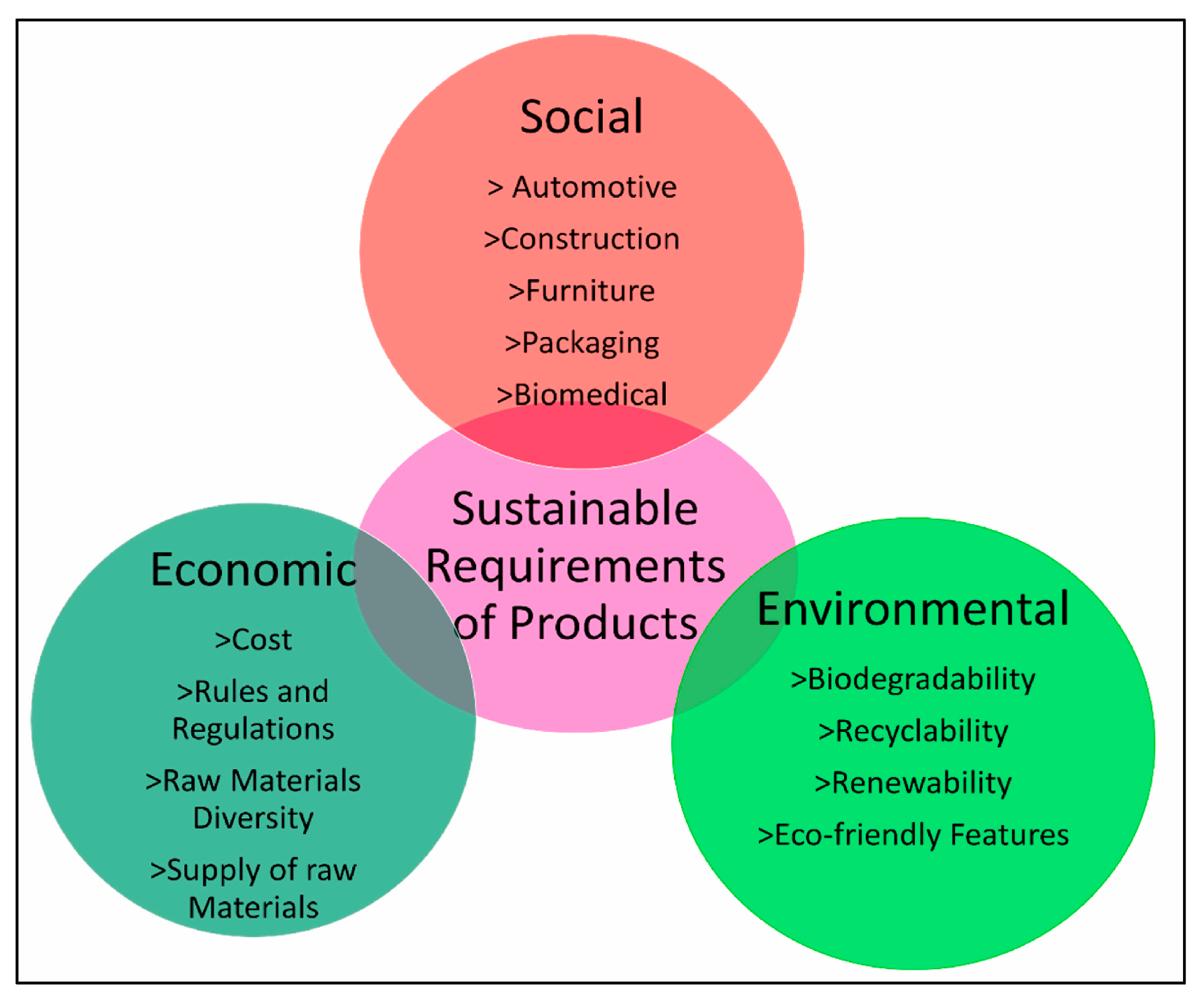

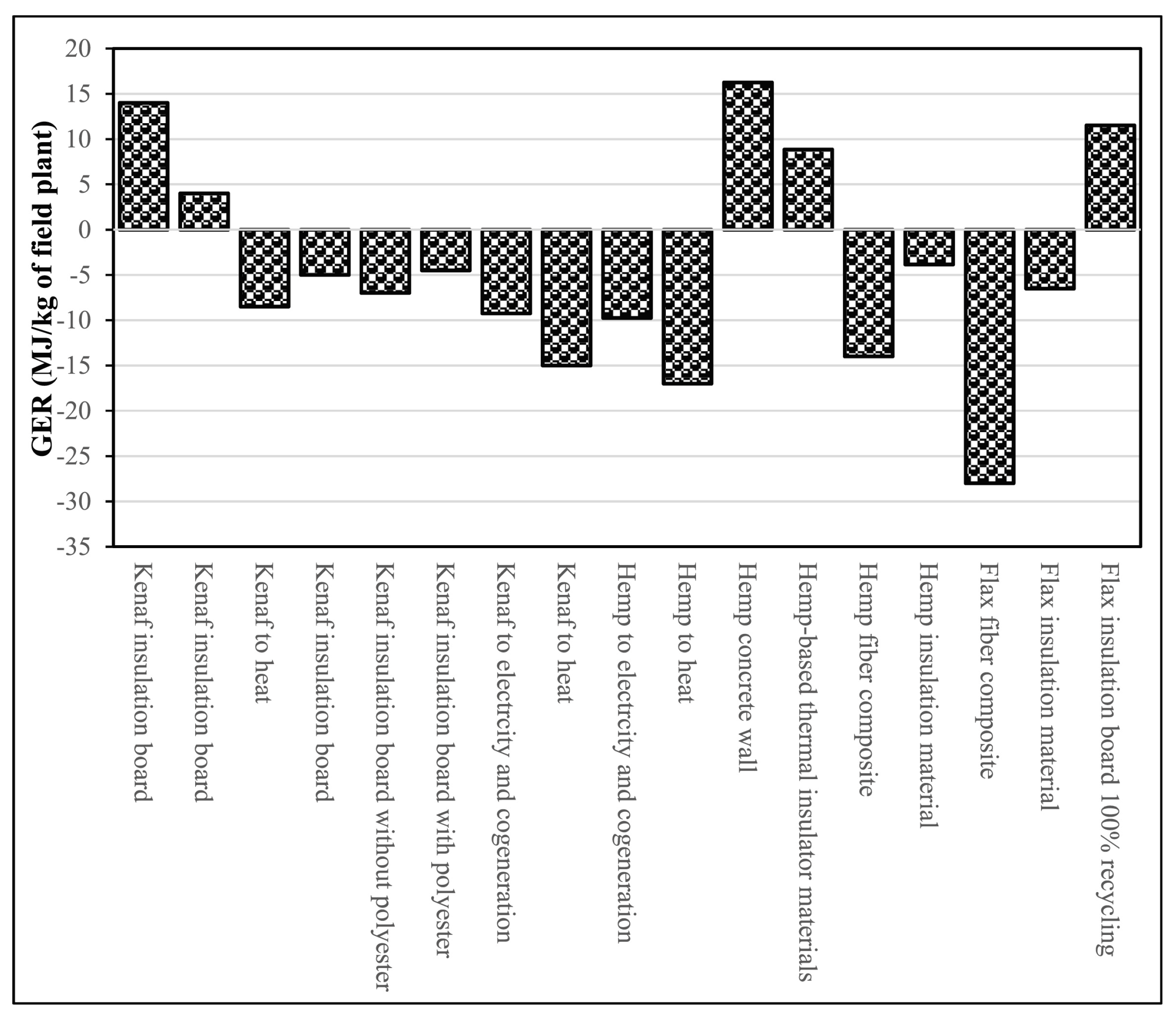

2. Fiber Reinforcement and Its Sustainability

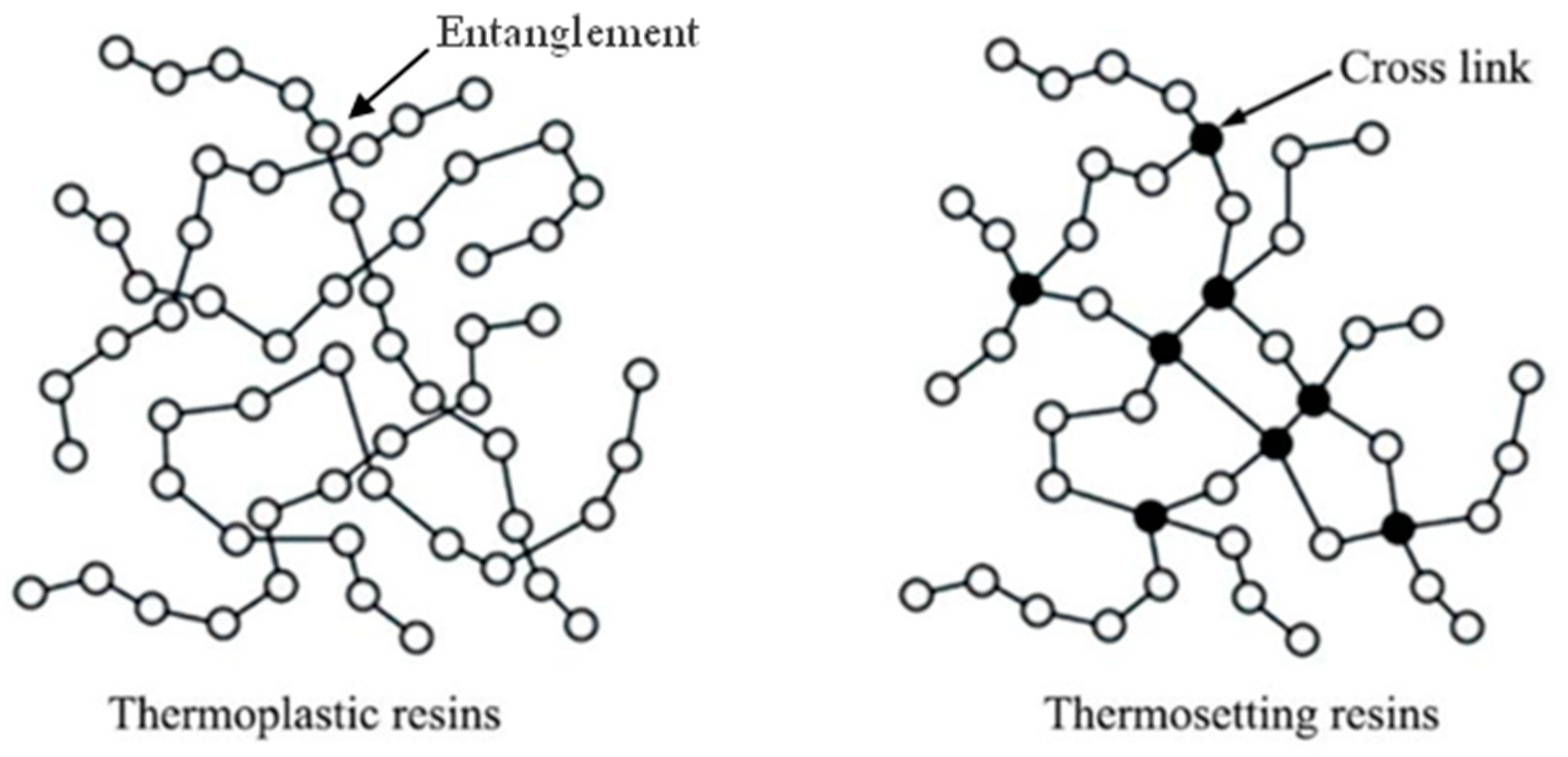

3. Thermoset Matrices and Their Sustainability

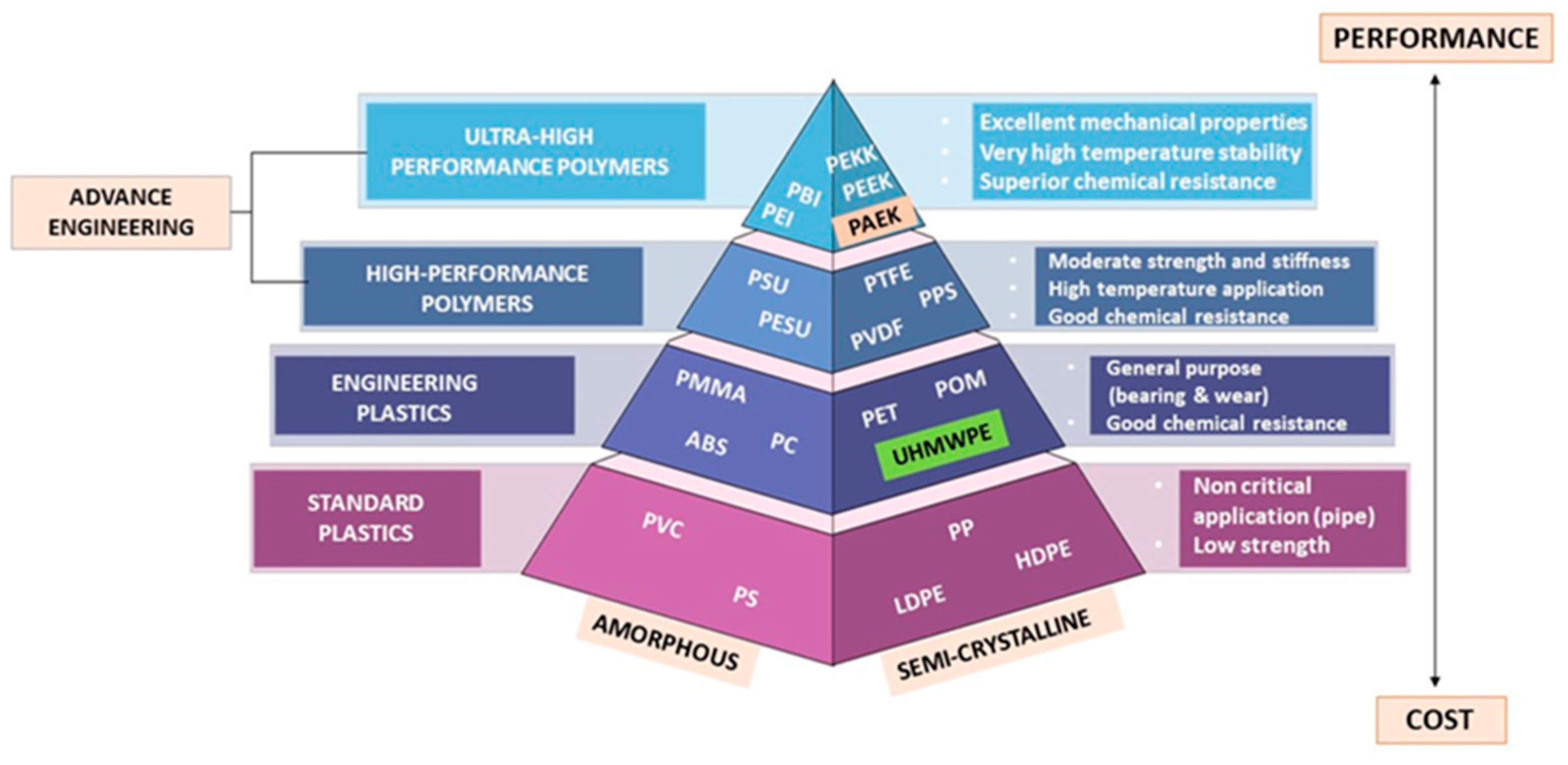

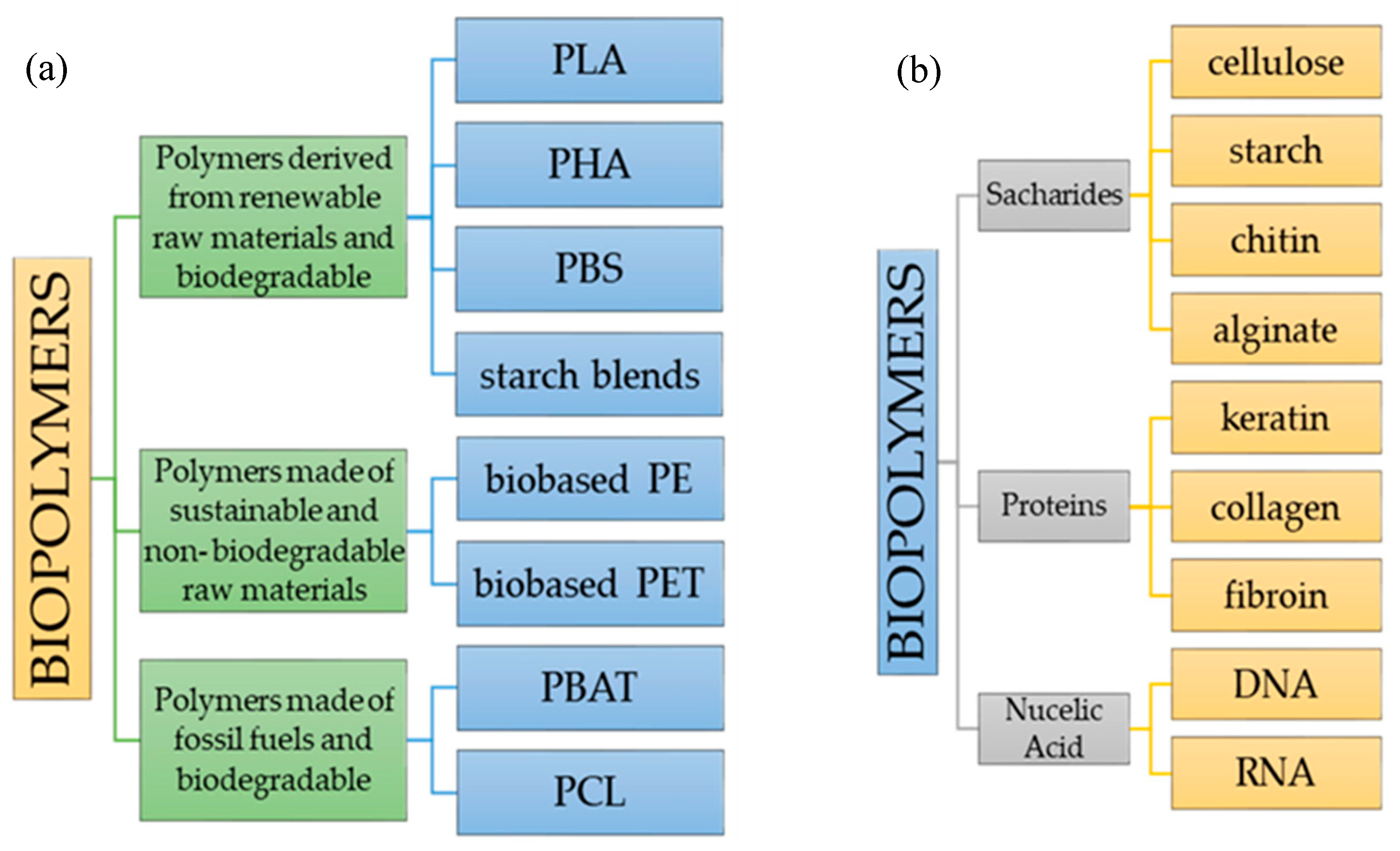

4. Thermoplastic Matrices and Their Sustainability

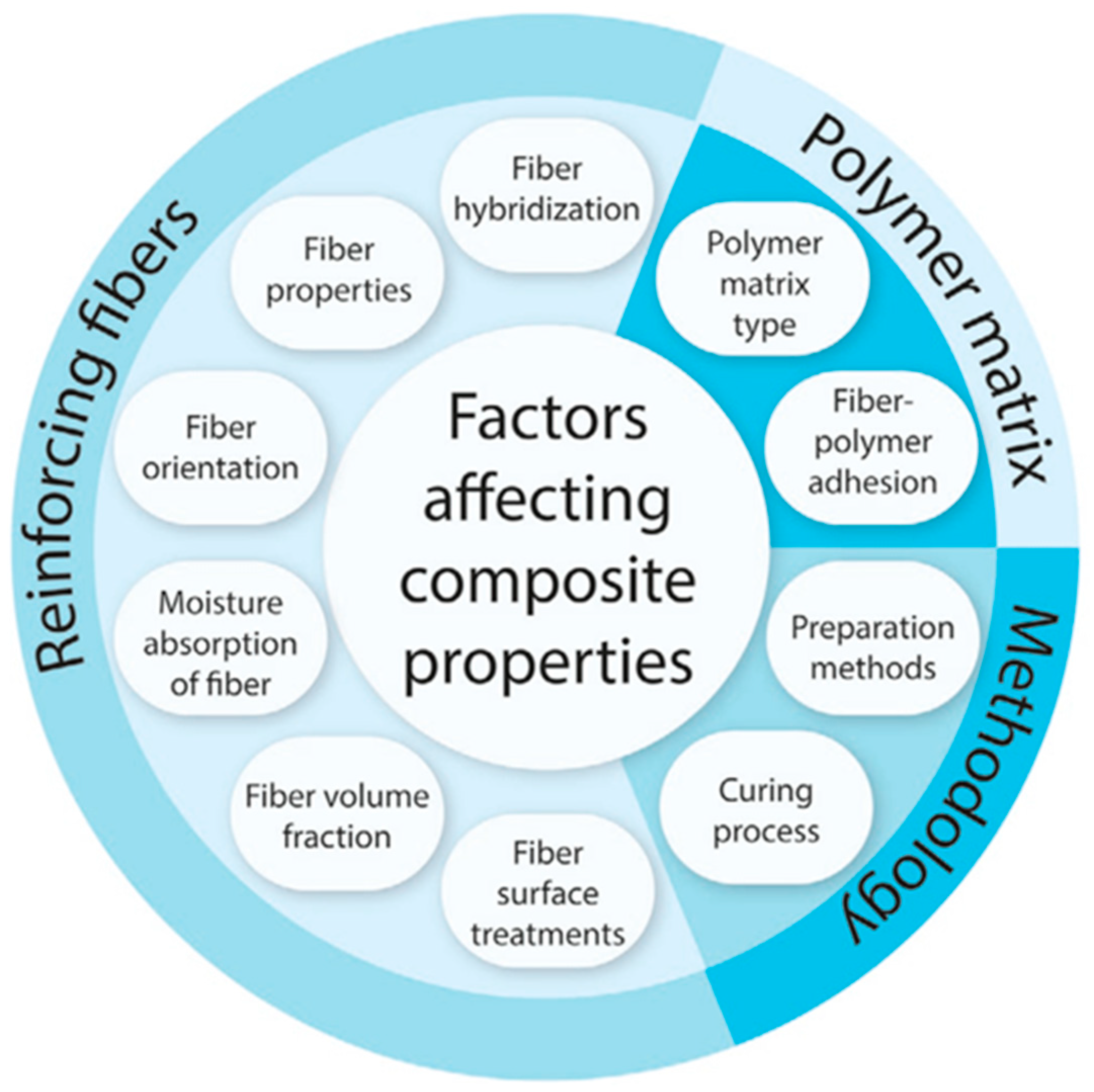

5. Performance of Sustainable Composites

6. Applications of Sustainable Composites

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRC | Fibre-reinforced polymer composites |

| NFRCs | Natural fibre-reinforced composites |

| CNNeWs | Cellulose nanonetworks |

| CNFs | cellulose nanofibrils |

| CNCs | cellulose nanocrystals |

| GER | Gross energy requirement |

| DGEBA | diglycidyl ether of bisphenol A |

| BPA | bisphenol A |

| CANs | covalent adaptable networks |

| LO | linseed oil |

| IFSS | interfacial shear strength |

| HDPE | High-density polyethylene |

| LDPE | Low-density polyethylene |

| PP | polypropylene |

| PMMA | poly-methyl methacrylate |

| PVC | polyvinyl chloride |

| PPSU | polyphenyl sulphone |

| PC | polycarbonate |

| ABS | acrylonitrile butadiene styrene |

| PBT | polybutylene terephtha |

| PET | polyethylene terephthalate |

| PLA | Polylactic acid |

| PHAs | polyhydroxyalkanoates |

| CNWs | nanowhiskers |

References

- Prasad, V.; Joseph, M.A.; Sekar, K. Investigation of mechanical, thermal and water absorption properties of flax fibre reinforced epoxy composite with nano TiO2 addition. Compos. Part A Appl. Sci. Manuf. 2018, 115, 360–370. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Prasad, V.; Sekar, K.; Varghese, S.; Joseph, M.A. Enhancing Mode I and Mode II interlaminar fracture toughness of flax fibre reinforced epoxy composites with nano TiO2. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105505. [Google Scholar] [CrossRef]

- Yakubu, D.; Zaki Abdullah, M.; Sri Melor Megat Yusoff, P. Mechanical Properties of Short and Continuous Kenaf/Pet Fibre Reinforced Polyoxymethylene Composite. Adv. Compos. Lett. 2015, 24, 096369351502400404. Available online: https://journals.sagepub.com/doi/full/10.1177/096369351502400404 (accessed on 29 January 2024).

- Hasan, K.M.F.; Hasan, K.N.A.; Ahmed, T.; György, S.-T.; Pervez, M.N.; Bejó, L.; Sándor, B.; Alpár, T. Sustainable bamboo fiber reinforced polymeric composites for structural applications: A mini review of recent advances and future prospects. Case Stud. Chem. Environ. Eng. 2023, 8, 100362. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Sapuan, S.M. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Ashadujjaman Md Saifullah, A.; Shah, D.U.; Zhang, M.; Akonda, M.; Karim, N.; Sarker, F. Enhancing the mechanical properties of natural jute yarn suitable for structural applications. Mater. Res. Express 2021, 8, 055503. [Google Scholar] [CrossRef]

- Madhu, P.; Sanjay, M.R.; Pradeep, S.; Subrahmanya Bhat, K.; Yogesha, B.; Siengchin, S. Characterization of cellulosic fibre from Phoenix pusilla leaves as potential reinforcement for polymeric composites. J. Mater. Res. Technol. 2019, 8, 2597–2604. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.R.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2020, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Karim, N.; Sarker, F.; Afroj, S.; Zhang, M.; Potluri, P.; Novoselov, K.S. Sustainable and multifunctional composites of graphene-based natural jute fibers. Adv. Sustain. Syst. 2021, 5, 2000228. [Google Scholar] [CrossRef]

- Alves, C.; Ferrão, P.M.C.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B.; Alves, D.E. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Awal, A.; Cescutti, G.; Ghosh, S.B.; Müssig, J. Interfacial studies of natural fibre/polypropylene composites using single fibre fragmentation test (SFFT). Compos. Part A Appl. Sci. Manuf. 2011, 42, 50–56. [Google Scholar] [CrossRef]

- Alliyankal Vijayakumar, A.; Prasad, V.; Kailathuvalappil Kochunny, M. Investigation on the effect of stacking order and hybridization on mechanical and water absorption properties of woven flax/bamboo composites. Polym. Compos. 2022, 43, 5189–5207. [Google Scholar] [CrossRef]

- Kalia, S.; Avérous, L.; Njuguna, J.; Dufresne, A.; Cherian, B.M. Natural Fibers, Bio- and Nanocomposites. Int. J. Polym. Sci. 2011, 2011, e735932. [Google Scholar] [CrossRef]

- Isogai, A. Cellulose Nanofibers: Recent Progress and Future Prospects. JFST 2020, 76, 310–326. [Google Scholar] [CrossRef]

- Rajan, S.T.K.; Nagarajan, K.J.; Balasubramani, V.; Sathickbasha, K.; Sanjay, M.R.; Siengchin, S.; Balaji, A.N. Investigation of mechanical and thermo-mechanical characteristics of silane-treated cellulose nanofibers from agricultural waste reinforced epoxy adhesive composites. Int. J. Adhes. Adhes. 2023, 126, 103492. [Google Scholar] [CrossRef]

- Prasad, V.; Sekar, K.; Joseph, M.A. Chapter 18—Wood fibers, their composites and applications. In Plant Fibers, Their Composites, and Applications; Mavinkere Rangappa, S., Parameswaranpillai, J., Siengchin, S., Ozbakkaloglu, T., Wang, H., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 391–436. [Google Scholar]

- De Araújo, M. 1—Natural and man-made fibres: Physical and mechanical properties. In Fibrous and Composite Materials for Civil Engineering Applications; Fangueiro, R., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 3–28. [Google Scholar]

- Thilagavathi, G.; Pradeep, E.; Kannaian, T.; Sasikala, L. Development of Natural Fiber Nonwovens for Application as Car Interiors for Noise Control. J. Ind. Text. 2010, 39, 267–278. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Islam, M.Z.; Sarker, M.E.; Rahman, M.M.; Islam, M.R.; Ahmed, A.T.M.F.; Mahmud, M.S.; Syduzzaman, M. Green composites from natural fibers and biopolymers: A review on processing, properties, and applications. J. Reinf. Plast. Compos. 2022, 41, 526–557. [Google Scholar] [CrossRef]

- Adekomaya, O.; Jamiru, T.; Sadiku, R.; Huan, Z. A review on the sustainability of natural fiber in matrix reinforcement—A practical perspective. J. Reinf. Plast. Compos. 2016, 35, 3–7. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural fiber reinforced composites: Sustainable materials for emerging applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Jia, W.; Gong, R.H.; Hogg, P.J. Poly (lactic acid) fibre reinforced biodegradable composites. Compos. Part B Eng. 2014, 62, 104–112. [Google Scholar] [CrossRef]

- He, X.; Shi, X.; Chung, C.; Lei, Z.; Zhang, W.; Yu, K. A sustainable manufacturing method of thermoset composites based on covalent adaptable network polymers. Compos. Part B Eng. 2021, 221, 109004. [Google Scholar] [CrossRef]

- Kim, K.-Y.; Ye, L. Interlaminar fracture toughness of CF/PEI composites at elevated temperatures: Roles of matrix toughness and fibre/matrix adhesion. Compos. Part A Appl. Sci. Manuf. 2004, 35, 477–487. [Google Scholar] [CrossRef]

- de Luzuriaga, A.R.; Martin, R.; Markaide, N.; Rekondo, A.; Cabañero, G.; Rodríguez, J.; Odriozola, I. Correction: Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber-reinforced thermoset composites. Mater. Horiz. 2020, 7, 2460–2461. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, Y.; Guo, B.; Zhang, L. Malleable, Mechanically Strong, and Adaptive Elastomers Enabled by Interfacial Exchangeable Bonds. Macromolecules 2017, 50, 7584–7592. [Google Scholar] [CrossRef]

- Zhao, S.; Abu-Omar, M.M. Recyclable and Malleable Epoxy Thermoset Bearing Aromatic Imine Bonds. Macromolecules 2018, 51, 9816–9824. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-Like Malleable Materials from Permanent Organic Networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef]

- Denissen, W.; Rivero, G.; Nicolaÿ, R.; Leibler, L.; Winne, J.M.; Du Prez, F.E. Vinylogous Urethane Vitrimers. Adv. Funct. Mater. 2015, 25, 2451–2457. [Google Scholar] [CrossRef]

- Saitta, L.; Prasad, V.; Tosto, C.; Murphy, N.; Ivankovic, A.; Cicala, G.; Scarselli, G. Characterization of biobased epoxy resins to manufacture eco-composites showing recycling properties. Polym. Compos. 2022, 43, 9179–9192. [Google Scholar] [CrossRef]

- Zhao, X.-L.; Liu, Y.-Y.; Weng, Y.; Li, Y.-D.; Zeng, J.-B. Sustainable Epoxy Vitrimers from Epoxidized Soybean Oil and Vanillin. ACS Sustain. Chem. Eng. 2020, 8, 15020–15029. [Google Scholar] [CrossRef]

- Ng, F.; Couture, G.; Philippe, C.; Boutevin, B.; Caillol, S. Bio-Based Aromatic Epoxy Monomers for Thermoset Materials. Molecules 2017, 22, 149. [Google Scholar] [CrossRef] [PubMed]

- Auvergne, R.; Caillol, S.; David, G.; Boutevin, B.; Pascault, J.-P. Biobased Thermosetting Epoxy: Present and Future. Chem. Rev. 2014, 114, 1082–1115. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Guo, W.; Song, L.; Hu, Y. Intrinsically flame retardant bio-based epoxy thermosets: A review. Compos. Part B Eng. 2019, 179, 107487. [Google Scholar] [CrossRef]

- Boccarusso, L.; Durante, M.; Langella, A. Lightweight hemp/bio-epoxy grid structure manufactured by a new continuous process. Compos. Part B Eng. 2018, 146, 165–175. [Google Scholar] [CrossRef]

- Monteserin, C.; Blanco, M.; Uranga, N.; Sanchez, J.; Laza, J.M.; Vilas, J.L.; Aranzabe, E. Sustainable biobased epoxy thermosets with covalent dynamic imine bonds for green composite development. Polymer 2023, 285, 126339. [Google Scholar] [CrossRef]

- Fei, M.; Liu, W.; Shao, L.; Cao, Y.; Bliss, B.J.; Zhao, B.; Zhang, J. Hemp fiber reinforced dual dynamic network vitrimer biocomposites with direct incorporation of amino silane. Chem. Eng. J. 2024, 480, 148091. [Google Scholar] [CrossRef]

- Kandemir, A.; Longana, M.L.; Hamerton, I.; Eichhorn, S.J. Developing aligned discontinuous flax fibre composites: Sustainable matrix selection and repair performance of vitrimers. Compos. Part B Eng. 2022, 243, 110139. [Google Scholar] [CrossRef]

- Li, P.; Hao, C.; Wang, H.; He, T.; Shu, T.; Li, C.; Yu, L.; Yan, N. Eco-friendly recyclable high performance ramie yarn reinforced polyimine vitrimer composites. Chem. Eng. J. 2023, 457, 141341. [Google Scholar] [CrossRef]

- Vijayakumar, A.A.; James, N.; Prasad, V.; Divakaran, M.; Kochunny, M.K. Tribological and thermogravimetric performance of flax/bamboo hybrid composites for gear applications: Influence of the stacking sequence. Polym. Compos. 2023, 44, 1038–1053. [Google Scholar] [CrossRef]

- Passaro, A.; Corvaglia, P.; Manni, O.; Barone, L.; Maffezzoli, A. Processing-properties relationship of sandwich panels with polypropylene-core and polypropylene-matrix composite skins. Polym. Compos. 2004, 25, 307–318. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Huang, J.; Lin, N.; Ahmad, I.; Mariano, M.; Dufresne, A.; Thomas, S.; Gałęski, A. Recent developments in nanocellulose-based biodegradable polymers, thermoplastic polymers, and porous nanocomposites. Prog. Polym. Sci. 2018, 87, 197–227. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Seidlitz, H.; Krenz, J.; Goracy, K.; Urbaniak, M.; Rösch, J.J. Recycling of Carbon Fiber Reinforced Composite Polymers—Review—Part 2: Recovery and Application of Recycled Carbon Fibers. Polymers 2020, 12, 3003. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Mavinkere Rangappa, S.; Siengchin, S.; Puttegowda, M.; Thiagamani, S.M.K.; Hemath Kumar, M.; Oladijo, O.P.; Fiore, V.; Moure Cuadrado, M.M. Sustainable recycling technologies for thermoplastic polymers and their composites: A review of the state of the art. Polym. Compos. 2022, 43, 5831–5862. [Google Scholar] [CrossRef]

- Zol, S.M.; Alauddin, M.S.; Said, Z.; Mohd Ghazali, M.I.; Hao-Ern, L.; Mohd Farid, D.A.; Zahari, N.A.H.; Al-Khadim, A.H.A.; Abdul Aziz, A.H. Description of Poly(aryl-ether-ketone) Materials (PAEKs), Polyetheretherketone (PEEK) and Polyetherketoneketone (PEKK) for Application as a Dental Material: A Materials Science Review. Polymers 2023, 15, 2170. [Google Scholar] [CrossRef]

- Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer matrix-natural fiber composites: An overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Qin, X.; Richard, F.; Batiot, B.; Rogaume, T. Modeling study of pyrolysis of charring composite materials in the fire scenario-A short literature review. Polym. Degrad. Stab. 2023, 218, 110577. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Sutera, F.; Gulino, E.; Morreale, M. Degradation and Recycling of Films Based on Biodegradable Polymers: A Short Review. Polymers 2019, 11, 651. [Google Scholar] [CrossRef]

- Vincent, G.A.; De Bruijn, T.A.; Wijskamp, S.; Abdul Rasheed, M.I.; Van Drongelen, M.; Akkerman, R. Shredding and sieving thermoplastic composite scrap: Method development and analyses of the fibre length distributions. Compos. Part B Eng. 2019, 176, 107197. [Google Scholar] [CrossRef]

- Karayannidis, G.P.; Achilias, D.S. Chemical Recycling of Poly(ethylene terephthalate). Macromol. Mater. Eng. 2007, 292, 128–146. [Google Scholar] [CrossRef]

- Matsumura, S. Enzyme-Catalyzed Synthesis and Chemical Recycling of Polyesters. Macromol. Biosci. 2002, 2, 105–126. [Google Scholar] [CrossRef]

- Rahimi, A.; García, J.M. Chemical recycling of waste plastics for new materials production. Nat. Rev. Chem. 2017, 1, 0046. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Qureshi, M.S.; Oasmaa, A.; Pihkola, H.; Deviatkin, I.; Tenhunen, A.; Mannila, J.; Minkkinen, H.; Pohjakallio, M.; Laine-Ylijoki, J. Pyrolysis of plastic waste: Opportunities and challenges. J. Anal. Appl. Pyrolysis 2020, 152, 104804. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable compatibilized polymer blends for packaging applications: A literature review. J. Appl. Polym. Sci. 2018, 135, 45726. [Google Scholar] [CrossRef]

- Sarasini, F. Thermoplastic biopolymer matrices for biocomposites. In Biocomposites for High-Performance Applications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 81–123. [Google Scholar]

- Madej-Kiełbik, L.; Gzyra-Jagieła, K.; Jóźwik-Pruska, J.; Dziuba, R.; Bednarowicz, A. Biopolymer Composites with Sensors for Environmental and Medical Applications. Materials 2022, 15, 7493. [Google Scholar] [CrossRef] [PubMed]

- Morreale, M.; Liga, A.; Mistretta, M.C.; Ascione, L.; Mantia, F.P.L. Mechanical, Thermomechanical and Reprocessing Behavior of Green Composites from Biodegradable Polymer and Wood Flour. Materials 2015, 8, 7536–7548. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material valorisation of amorphous polylactide. Influence of thermo-mechanical degradation on the morphology, segmental dynamics, thermal and mechanical performance. Polym. Degrad. Stab. 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Scaffaro, R.; Morreale, M.; Mirabella, F.; La Mantia, F.P. Preparation and Recycling of Plasticized PLA. Macromol. Mater. Eng. 2011, 296, 141–150. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of multi-extruded poly(lactic acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

- Badia, J.D.; Ribes-Greus, A. Mechanical recycling of polylactide, upgrading trends and combination of valorization techniques. Eur. Polym. J. 2016, 84, 22–39. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- La Mantia, F.P.; Mistretta, M.C.; Morreale, M. Recycling and Thermomechanical Degradation of LDPE/Modified Clay Nanocomposites. Macromol. Mater. Eng. 2014, 299, 96–103. [Google Scholar] [CrossRef]

- Ashik, K.P.; Sharma, R.S. A Review on Mechanical Properties of Natural Fiber Reinforced Hybrid Polymer Composites. J. Miner. Mater. Charact. Eng. 2015, 3, 420. [Google Scholar] [CrossRef]

- Joseph, P.V.; Joseph, K.; Thomas, S. Effect of processing variables on the mechanical properties of sisal-fiber-reinforced polypropylene composites. Compos. Sci. Technol. 1999, 59, 1625–1640. [Google Scholar] [CrossRef]

- Crossley, R.; Schubel, P.; Stevenson, A. Furan matrix and flax fibre as a sustainable renewable composite: Mechanical and fire-resistant properties in comparison to phenol, epoxy and polyester. J. Reinf. Plast. Compos. 2014, 33, 58–68. [Google Scholar] [CrossRef]

- Cruz-Ramos, C.A. Natural Fiber Reinforced Thermoplastics. In Mechanical Properties of Reinforced Thermoplastics; Clegg, D.W., Collyer, A.A., Eds.; Springer: Dordrecht, The Netherlands, 1986; pp. 65–81. [Google Scholar]

- Zaman, H.U.; Beg, M. Preparation, structure, and properties of the coir fiber/polypropylene composites. J. Compos. Mater. 2014, 48, 3293–3301. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Mathew, A.P.; Oksman, K. Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion. Compos. Sci. Technol. 2010, 70, 1742–1747. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Ninomiya, K.; Abe, M.; Tsukegi, T.; Kuroda, K.; Omichi, M.; Takada, K.; Noguchi, M.; Tsuge, Y.; Ogino, C.; Taki, K.; et al. Ionic liquid pretreatment of bagasse improves mechanical property of bagasse/polypropylene composites. Ind. Crops Prod. 2017, 109, 158–162. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Newman, R.H.; Le Guen, M.J.; Battley, M.A.; Carpenter, J.E.P. Failure mechanisms in composites reinforced with unidirectional Phormium leaf fibre. Compos. Part A Appl. Sci. Manuf. 2010, 41, 353–359. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T.; Selke, S.E.; Harte, B.R.; Hinrichsen, G. Natural Fibers, Biopolymers, and Biocomposites: An Introduction. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Bekmezci, M.; Ay, H.; Sen, F. Chapter 7—Green composite materials and their applications. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Inamuddin, T.A., Alrooqi, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 159–182. [Google Scholar]

- Pokharel, A.; Falua, K.J.; Babaei-Ghazvini, A.; Acharya, B. Biobased Polymer Composites: A Review. J. Compos. Sci. 2022, 6, 255. [Google Scholar] [CrossRef]

- Bagheri, M.; Validi, M.; Gholipour, A.; Makvandi, P.; Sharifi, E. Chitosan nanofiber biocomposites for potential wound healing applications: Antioxidant activity with synergic antibacterial effect. Bioeng. Transl. Med. 2022, 7, e10254. [Google Scholar] [CrossRef]

- Santi, R.; Garrone, P.; Iannantuoni, M.; Del Curto, B. Sustainable Food Packaging: An Integrative Framework. Sustainability 2022, 14, 8045. [Google Scholar] [CrossRef]

- Sulyman, M.; Haponiuk, J.; Formela, K. Utilization of Recycled Polyethylene Terephthalate (PET) in Engineering Materials: A Review. IJESD 2016, 7, 100–108. [Google Scholar] [CrossRef]

- Laria, J.G.; Gaggino, R.; Kreiker, J.; Peisino, L.E.; Positieri, M.; Cappelletti, A. Mechanical and processing properties of recycled PET and LDPE-HDPE composite materials for building components. J. Thermoplast. Compos. Mater. 2023, 36, 418–431. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D.; Wambua, P.; Chapple, S.A.; Klems, T.; Doecker, M.; Goulain, M.; Erasmus, L.D. Bio-based structural composite materials for aerospace applications. In Proceedings of the 2nd SAIAS Symposium, Stellenbosch, South Africa, 14–16 September 2008. [Google Scholar]

- Bari, E.; Sistani, A.; Morrell, J.J.; Pizzi, A.; Akbari, M.R.; Ribera, J. Current Strategies for the Production of Sustainable Biopolymer Composites. Polymers 2021, 13, 2878. [Google Scholar] [CrossRef] [PubMed]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Mishra, T.; Mandal, P.; Rout, A.K.; Sahoo, D. A state-of-the-art review on potential applications of natural fiber-reinforced polymer composite filled with inorganic nanoparticle. Compos. Part C Open Access 2022, 9, 100298. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

| Fibres | Density (g cm−3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) |

|---|---|---|---|---|

| Flax | 1.4–1.5 | 345–1500 | 27–39 | 2.7–3.2 |

| Hemp | 1.47 | 550–900 | 38–70 | 1.6–4 |

| Jute | 1.3–1.49 | 393–800 | 13–26.5 | 1.16–1.5 |

| Kenaf | 1.5–1.6 | 350–930 | 40–53 | 1.6 |

| Ramie | 1.5–1.6 | 400–938 | 61.4–128 | 1.2–3.8 |

| Sisal | 1.45 | 468–700 | 9.4–22 | 3.7–4.3 |

| Pineapple | 1.52–1.56 | 170–1627 | 60–82 | 2.4 |

| Banana | 1.30–1.35 | 529–914 | 27–32 | 3 |

| Coir | 1.25–1.50 | 175 | 4–6.02 | 30 |

| Basalt | 2.65 | 1.8–2.5 | 80–93 | 3.1 |

| E-glass | 2.55 | 2000–3500 | 70–73 | 2.5–3.7 |

| S-glass | 2.5 | 4570 | 86 | 2.5 |

| Carbon | 1.4 | 4000 | 230–240 | 1.4–1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prasad, V.; Alliyankal Vijayakumar, A.; Jose, T.; George, S.C. A Comprehensive Review of Sustainability in Natural-Fiber-Reinforced Polymers. Sustainability 2024, 16, 1223. https://doi.org/10.3390/su16031223

Prasad V, Alliyankal Vijayakumar A, Jose T, George SC. A Comprehensive Review of Sustainability in Natural-Fiber-Reinforced Polymers. Sustainability. 2024; 16(3):1223. https://doi.org/10.3390/su16031223

Chicago/Turabian StylePrasad, Vishnu, Amal Alliyankal Vijayakumar, Thomasukutty Jose, and Soney C. George. 2024. "A Comprehensive Review of Sustainability in Natural-Fiber-Reinforced Polymers" Sustainability 16, no. 3: 1223. https://doi.org/10.3390/su16031223

APA StylePrasad, V., Alliyankal Vijayakumar, A., Jose, T., & George, S. C. (2024). A Comprehensive Review of Sustainability in Natural-Fiber-Reinforced Polymers. Sustainability, 16(3), 1223. https://doi.org/10.3390/su16031223