Study on Mechanical Properties and Microscopic Mechanism of PVA-Modified Recycled Brick Aggregate Concrete

Abstract

1. Introduction

2. Modification Effect and Mechanism of Recycled Aggregate

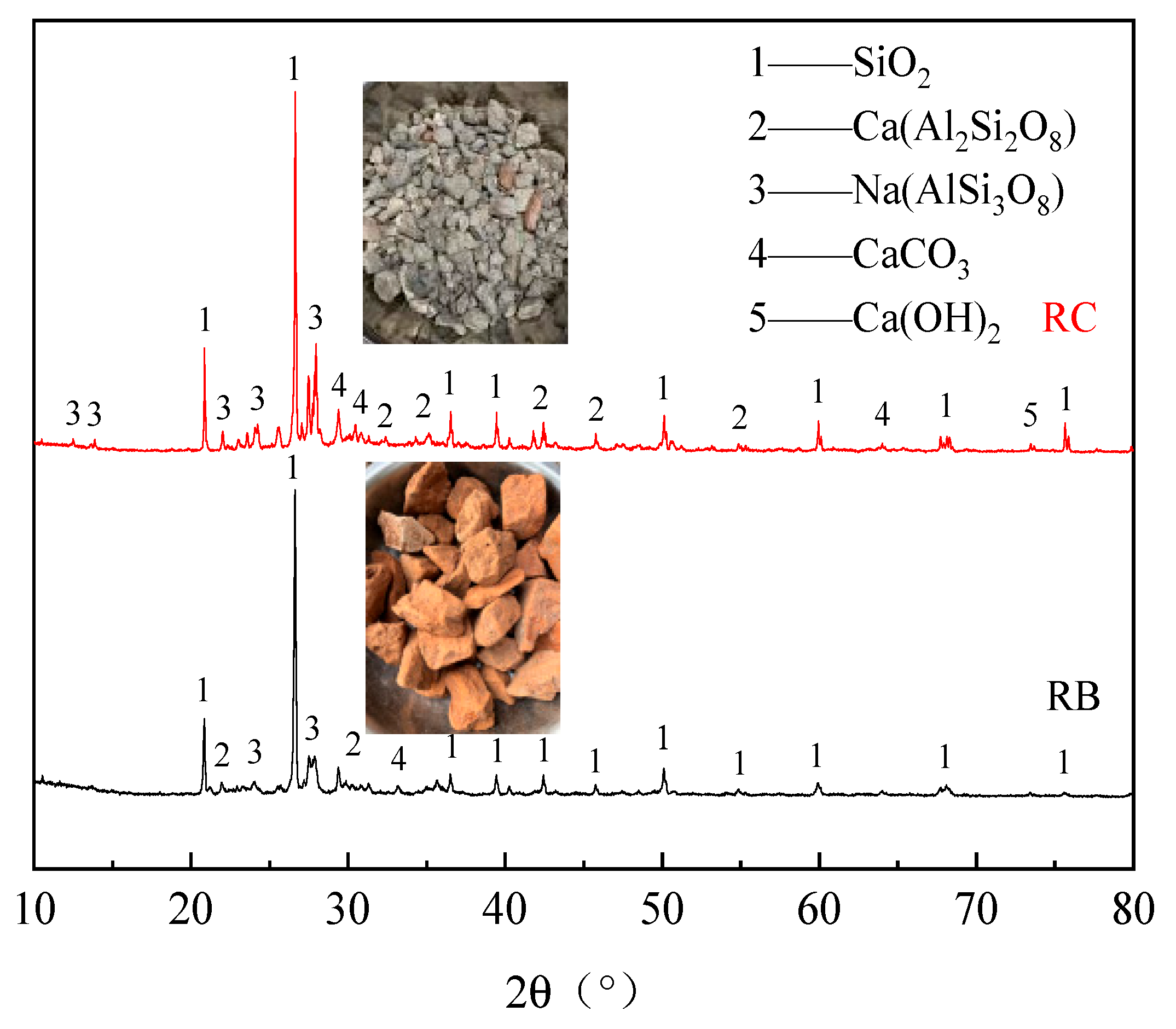

2.1. Raw Materials of Recycled Aggregate

2.2. Preparation Scheme of Modified Recycled Aggregate

- (1)

- According to the design of the three solution concentrations of 1%, 5%, and 10%, respectively, 300 g, 1500 g, or 3000 g of PVA powder was slowly added to 30 kg of tap water to prepare the corresponding concentrations of the PVA solution standby.

- (2)

- The concentration was heated and stirred until the water temperature reached 95 °C, and this temperature was maintained for 30~60 min. The cycle of preparation continued until the solution met the test requirements.

- (3)

- The solution was cooled to room temperature, and the aggregate was soaked with it and stirred every 3 h to ensure even soaking. After the soaking was completed, the PVA waste solution was professionally treated before it was discharged into the natural environment, because it will cause some pollution to the environment, and it must be collected and sent to be professionally treated outside the school by the relevant personnel in charge of the school.

- (4)

- The surface of the aggregate was rewashed with water to separate the aggregates from each other when the PVA solution initially solidified.

- (5)

- The aggregate was placed in a well-ventilated and sunny position for complete drying to be used as a backup.

2.3. Test Methods for Basic Physical Properties and Micro-Morphology of Aggregate

2.3.1. Basic Physical Properties Test

- Test for apparent density

- 2.

- Test for water absorption

- 3.

- Test for Crushing Index

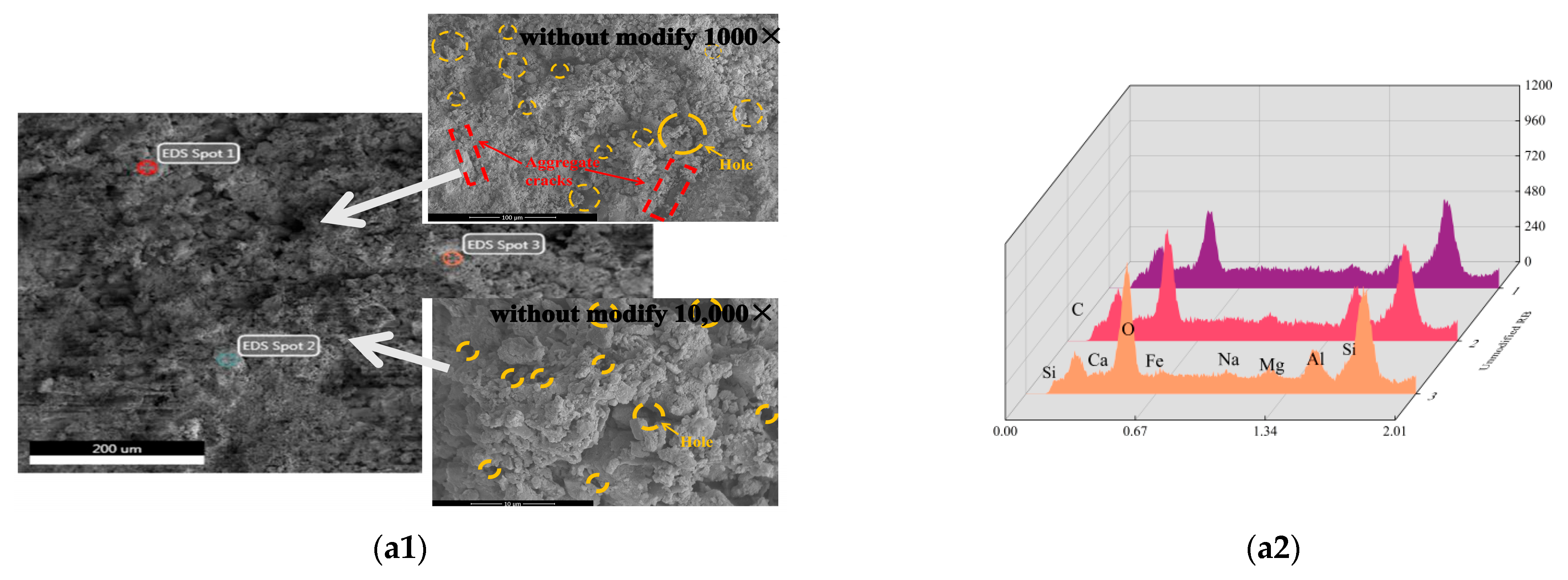

2.3.2. Scanning Electron Microscope

2.4. Analysis of the Basic Physical Properties of Modified Recycled Aggregate

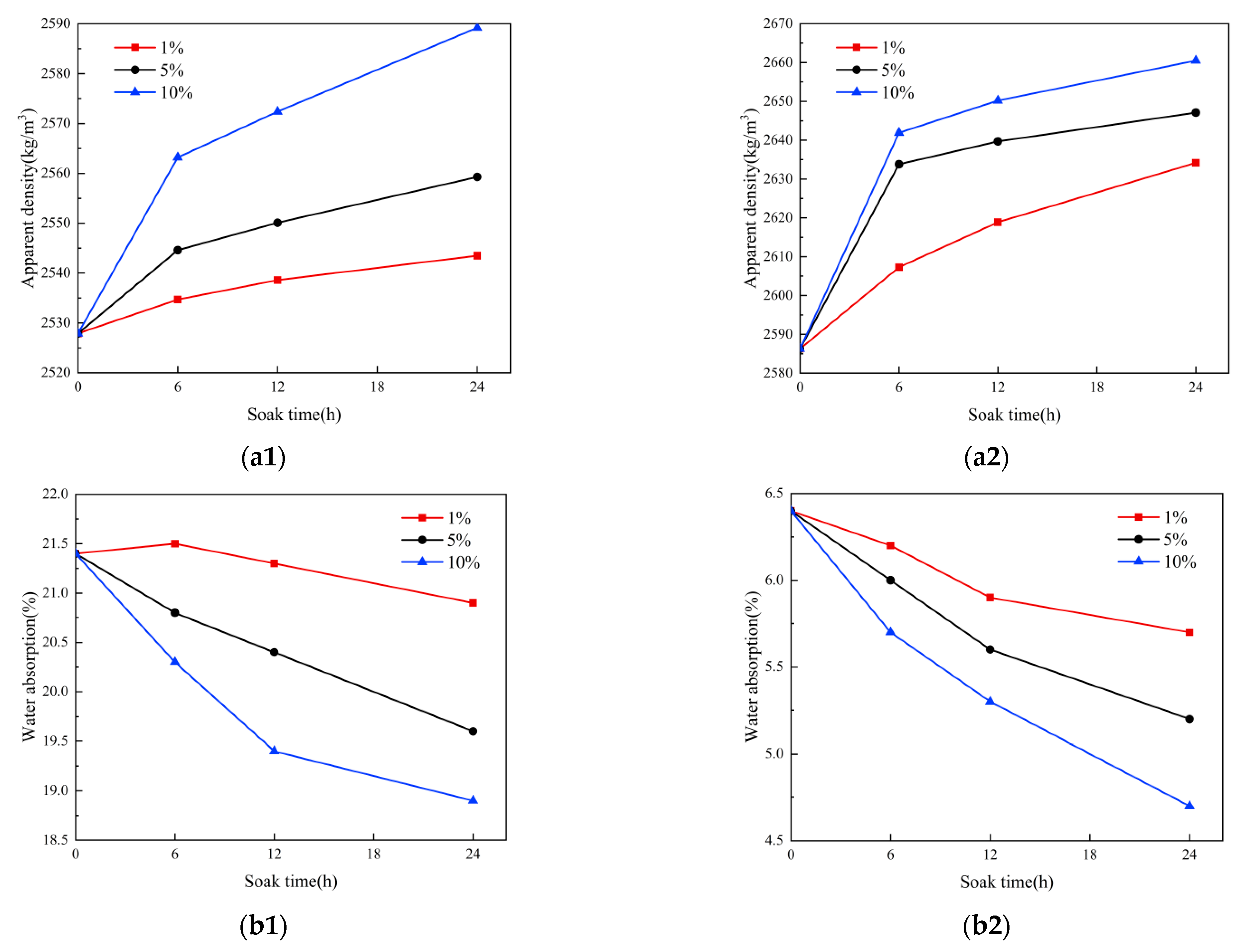

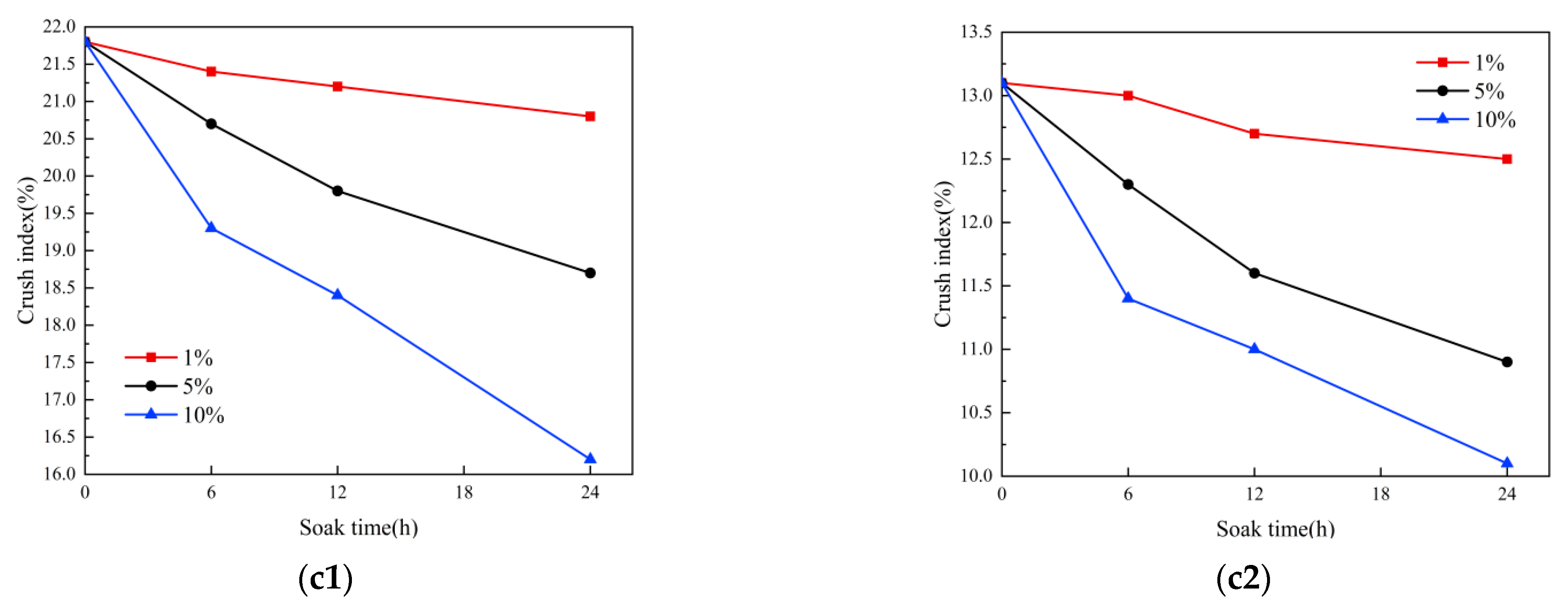

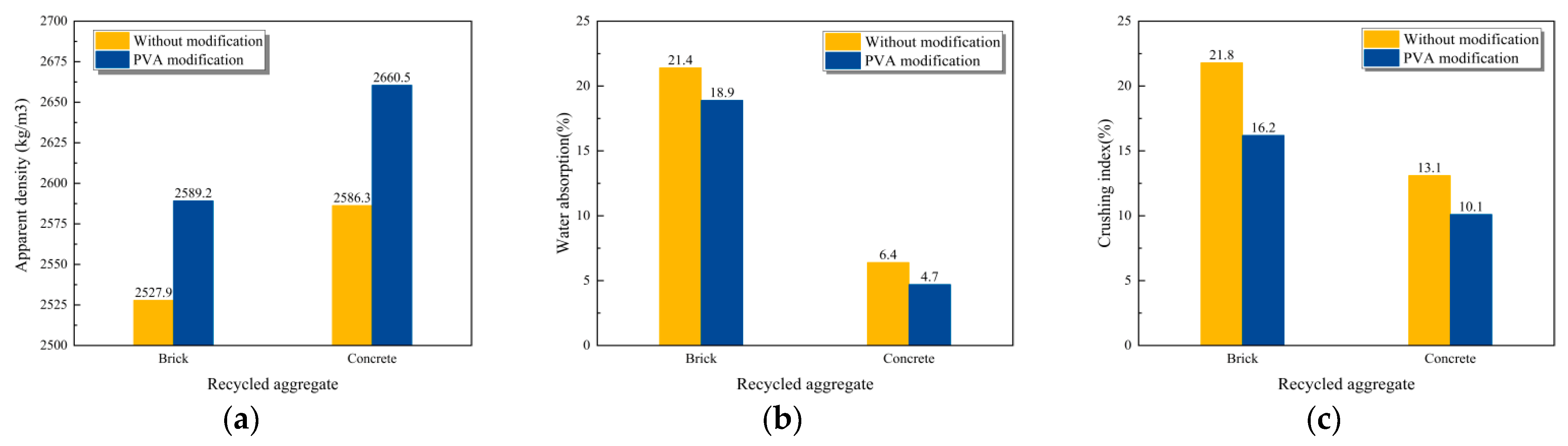

- (1)

- The effect exerted by PVA modification on the apparent density of recycled aggregate (Figure 3(a1,a2)):

- (2)

- The effect exerted by PVA modification on the water absorption of the recycled aggregate (Figure 3(b1,b2)):

- (3)

- The effect of PVA modification on the crushing index of recycled aggregate (Figure 3(c1,c2)):

2.5. Effect of Chemical Solution on Microstructure of Recycled Aggregate

3. Analysis of Basic Mechanical Properties of Modified Recycled Brick Aggregate Concrete

3.1. Raw Materials

3.2. Mixing Proportion Design

3.3. Specimen Preparation

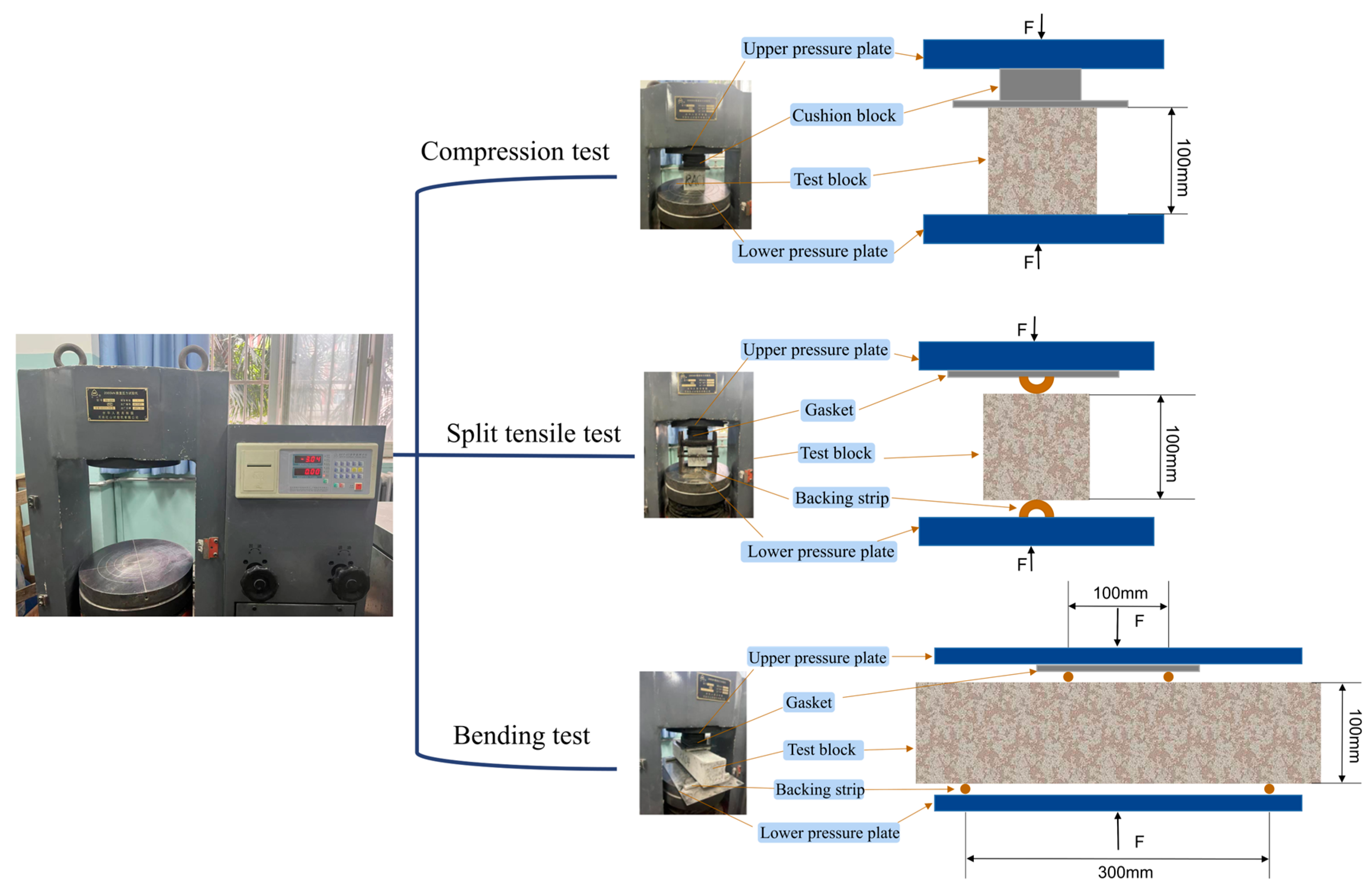

3.4. Mechanical Strength Test

3.4.1. Compression Test

3.4.2. Bending Test

3.4.3. Splitting Tensile Test

4. Analysis of Modification Mechanism of Recycled Brick-Concrete Aggregate Concrete

4.1. Test Method

4.1.1. Nuclear Magnetic Test

- (1)

- Cylindrical specimens with a diameter of 100 mm and a height of 50 mm are prepared by sampling from the cured test blocks using a core drilling tool (see Figure 13a).

- (2)

- The specimens are placed in a concrete vacuum water retention machine for 8 h of vacuum water retention. Typically, the vacuum pressure is set to 0.1 MPa. Subsequently, the test block is immersed in distilled water for 24 h to ensure complete saturation.

- (3)

- Prior to the NMR analysis test (Figure 13b), the surface water on the test block is wiped off, and the specimen is covered with cling film to prevent water loss, which could affect the accuracy of the test signal. The specimen is then positioned in the NMR radio frequency detection signal coil, and the NMR relaxation measurement is carried out using the MacroMR12-150H-I NMR analysis system.

- (4)

- The software of the analytical instrument inverts the NMR data, and post-processing is conducted to obtain relevant data such as the T2 relaxation time to analyze the pore structure properties of the aggregate concrete made from recycled bricks.

4.1.2. Scanning Electron Microscope Test

4.1.3. Microhardness Test

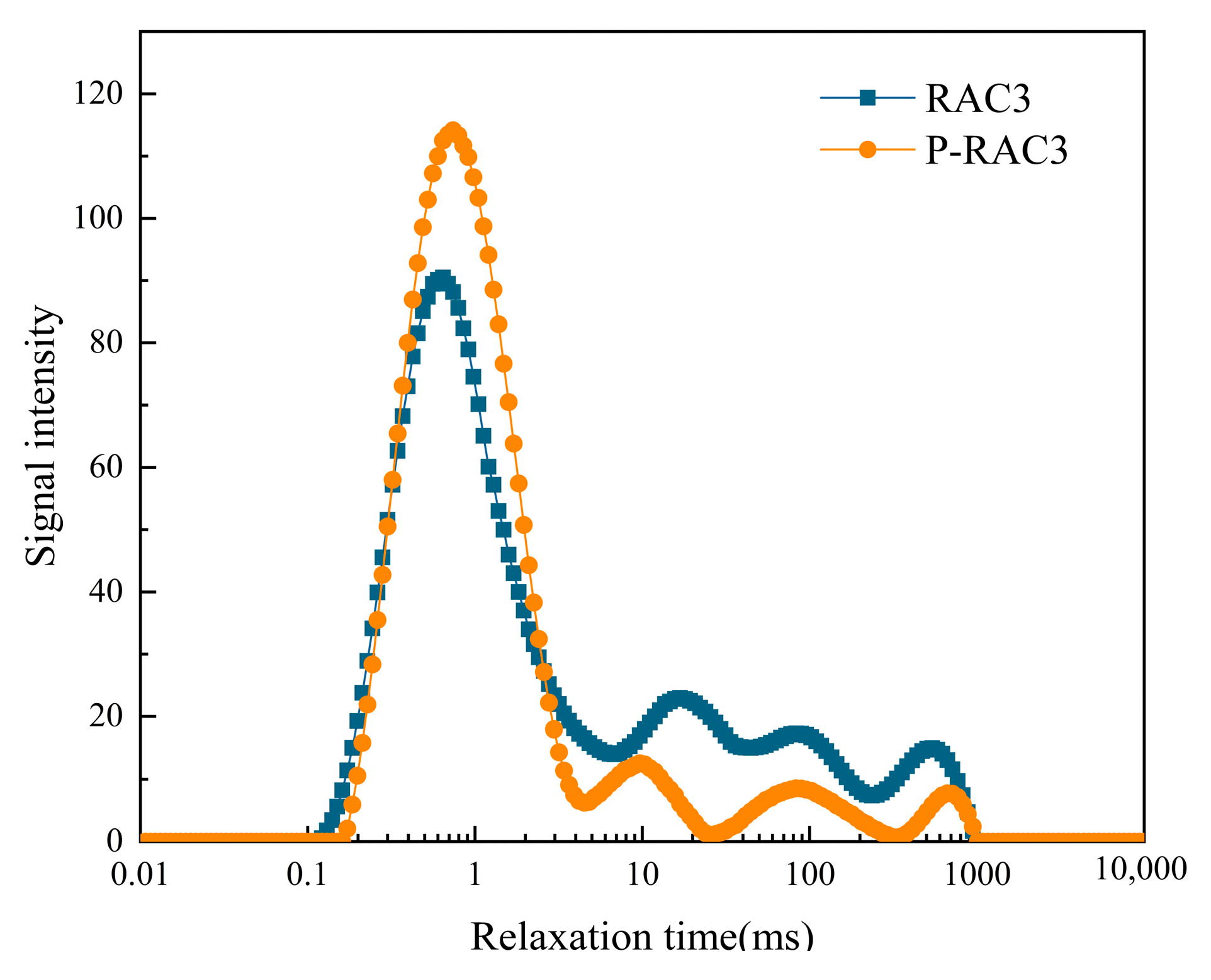

4.2. Analysis of Pore Structure of Recycled Brick Aggregate Concrete

4.2.1. The Principle of Nuclear Magnetic Resonance Testing Pore Structure

4.2.2. T2 Relaxation Spectrum

4.2.3. Pore Size Distribution and Pore Level Ratio

4.3. Micro-Morphology Analysis of Recycled Brick-Concrete Aggregate Concrete

4.4. Microhardness Analysis of Interfacial Transition Zone of Recycled Brick-Concrete Aggregate Concrete

5. Conclusions

- (1)

- This method is most effective for modifying recycled brick aggregate and recycled concrete aggregate when the recycled aggregate is submerged in a 10% PVA solution for 24 h. This improves the quality of the aggregate and amends the aggregate’s inherent defects. It particularly reduces the rate at which the recycled aggregate significantly absorbs water. The water absorption rate of recycled brick aggregate is reduced by 12%, and the water absorption rate of recycled concrete aggregate is reduced by 27%.

- (2)

- The modification mechanism of the PVA solution on recycled brick aggregate and recycled concrete aggregate involves the formation of a PVA film on the surface of the recycled aggregate. This film not only repairs the microcracks of the recycled aggregate but also fills its pores. Furthermore, the PVA solution can penetrate the aggregate during soaking, effectively improving the internal pore structure of the recycled aggregate.

- (3)

- With an increase in the brick-concrete ratio, the compressive strength, bending strength, and splitting tensile strength of unmodified and PVA solution-modified RAC initially increase and then decrease, peaking when the brick–concrete ratio is 1:1. The compressive strength increases most notably at a brick–concrete ratio of 1:1, the bending strength increases most at a 7:3 ratio, and the splitting tensile strength improves the most at a brick–concrete ratio of 0:1.

- (4)

- The goal of modification is to improve the mechanical properties of RAC by increasing the number of transition holes and decreasing the proportion of macropores. When the aggregate was modified with a PVA solution, the proportion of harmless and less harmful pores increased, while the proportion of harmful and very harmful pores decreased. This demonstrates that the PVA-solution modification process can effectively enhance the material’s pore structure.

- (5)

- Due to the unique adhesive properties of the polymer in PVA, the polymer network structure can bond with the cement hydration products to form a hard coating structure. Simultaneously, the mutual penetration between cement hydration products and polymer films enhances the structural morphology of the ITZ in recycled brick aggregate concrete.

- (6)

- PVA solution modification can effectively reduce the ITZ thickness between RC and new mortar, old mortar and new mortar, and RB and new mortar.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Weizhong, F.; Yu, P.; Dan, W. Quantitative research on the policy of construction waste recycling under the background of “double carbon”. Constr. Econ. 2022, 43 (Suppl. S1), 562–565. [Google Scholar]

- Wang, Y.; Li, H.; Gou, W.; Shi, S. Research on the willingness to use construction waste recycling products in the context of non-waste cities. J. Arid. Land Resour. Environ. 2020, 34, 86–90. [Google Scholar]

- He, J.; Zhong, W.; Zhang, Y.; Zhang, S.; Ji, X. China’s Construction Waste Recycling Analysis Based on Material Flow and Whole Process Management. Environ. Eng. 2018, 36, 102–107. [Google Scholar]

- Gyurkó, Z.; Jankus, B.; Fenyvesi, O.; Nemes, R. Sustainable applications for utilization the construction waste of aerated concrete. J. Clean. Prod. 2019, 230, 430–444. [Google Scholar] [CrossRef]

- Xu, Z. Research on the current situation and countermeasures of construction waste resource management. Constr. Mater. Decor. 2018, 182. [Google Scholar] [CrossRef]

- Yao, W. Preparation and Properties of Recycled Concrete from Construction Waste. Master’s Thesis, Jilin University, Changchun, China, 2016. [Google Scholar]

- Li, Y. Experimental study on the preparation of high performance recycled concrete from construction waste. Fly Ash Compr. Util. 2013, 17–20. [Google Scholar] [CrossRef]

- Bai, B. Research and Application of Key Technologies of Construction Waste Recycled Concrete Structure System. Shanxi Province, Xi’an University of Architecture and Technology, Xi’an, China, 2012. Available online: https://kns.cnki.net/kcms2/article/abstract?v=4j1cDaxzFAl0ta73HHdhIrRL51z1uYeZiwkwbKE_ry6375yM2U_yV9dvxzY5NYAj4NvVWS-nmoeZTOzyc4dsPm1vDq5VaFd1oPewgStJd0is_tE5p3e7rjNTAW3MYnDR866SSShkOwrhqBhoKuj38A==&uniplatform=NZKPT&language=CHS (accessed on 17 October 2023).

- González, M.D.; Plaza Caballero, P.; Fernández, D.B.; Jordán Vidal, M.M.; Del Bosque, I.F.S.; Medina Martínez, C. The Design and Development of Recycled Concretes in a Circular Economy Using Mixed Construction and Demolition Waste. Materials 2021, 14, 4762. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Frías, M.; De Rojas, M.S. Effect of the constituents (asphalt, clay materials, floating particles and fines) of construction and demolition waste on the properties of recycled concretes. Constr. Build. Mater. 2015, 79, 22–23. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Lan, Y. The latest progress and review of recycled concrete technology. Concrete 2003, 10, 17–20. [Google Scholar]

- Chen, Y.; Cao, B. Development of recycled concrete at home and abroad. Foreign Build. Mater. Sci. Technol. 2004, 25, 4–6. [Google Scholar]

- Zhu, P.; Wang, X.; Zhou, J.; He, X. Green high performance recycled concrete research main progress and development trend. In Proceedings of the First National Recycled Concrete Research and Application of Academic Exchange, Shanghai, China, July 2008; pp. 106–116. [Google Scholar]

- Zhu, C.; Zhao, W.; Yu, W.; Liu, C. Basic mechanical properties and constitutive model of recycled brick-concrete aggregate concrete. Acta Mater. Compos. Sin. 2024, 41, 899–911. [Google Scholar] [CrossRef]

- Liu, C.; Yu, W.; Liu, H.; Hu, T.F.; Hu, H.M. Study on mechanical properties and failure mechanism of recycled brick aggregate concrete. Mater. Rep. 2021, 35, 13025–13031. [Google Scholar]

- Ye, W. Research and application prospects of recycled brick aggregate concrete. Brick Tile 2018, 35–36. [Google Scholar] [CrossRef]

- Yang, N.; Wang, C.; Zhao, M. Recycled aggregate strengthening technology research. New Build. Mater. 2011, 38, 45–47. [Google Scholar]

- Kou, S.C.; Poon, C.S. Properties of concrete prepared with PVA-impregnated recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 649–654. [Google Scholar] [CrossRef]

- Zhao, Z. Study on the Modification of Recycled Aggregate and the Preparation Process of Concrete; Jinan University: Jinan, China, 2013. [Google Scholar]

- Fan, X.; Xu, Y. Reinforcement test of recycled aggregate. Shanghai Build. Mater. 2005, 22–23. [Google Scholar] [CrossRef]

- Du, T.; Li, H.; Wu, X. Experimental study on strengthening recycled aggregate concrete. New Build. Mater. 2002, 6–8. [Google Scholar] [CrossRef]

- Fan, Y.; Niu, H.; Zhang, X. Experimental study on nano-SiO2 modified recycled concrete. Concrete 2017, 92–95. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, P.; Xu, H.; Ma, M.; Tao, H. Experimental study on strengthening recycled aggregate based on microbial mineralization deposition. J. Zhejiang Sci. Tech Univ. Nat. Sci. 2020, 43, 122–129. [Google Scholar]

- GB/T 25177-2010; Recycled Coarse Aggregate for Concrete. National Standards of People's Republic of China: Beijing, China, 2011.

- GB/T 14685-2022; Pebble and Crushed Stone for Construction. National Standards of People's Republic of China: Beijing, China, 2022.

- Qiu, J.; Zhou, Y.; Guan, X.; Zhu, M. The influence of fly ash content on ITZ microstructure of coal gangue concrete. Constr. Build. Mater. 2021, 298, 123562. [Google Scholar] [CrossRef]

- Zhu, M.; Qiu, J.; Chen, J. Effect and mechanism of coal gangue concrete modification by basalt fiber. Constr. Build. Mater. 2022, 328, 126601. [Google Scholar] [CrossRef]

- GB/T 14684-2001; Sand for Building. China Construction Industry Press: Beijing, China, 2011.

- GB/T 50081-2002; Standard for Test Methods of Mechanical Properties of Ordinary Concrete. China Academy of Building Research: Beijing, China, 2003.

- JGJ/T 443-2018; Technical Standard for Recycled Concrete Structures. Beijing University of Technology: Beijing, China, 2018.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. National Standards of People's Republic of China: Beijing, China, 2019.

- Liu, T.; Wang, Y.; Zhou, K.; Gao, F.; Xie, S. Research on the mechanical properties and NMR characteristics of cement mortar during freeze-thaw cycles. Adv. Civ. Eng. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Heijden, G.; Pel, L.; Adan, O. Fire spalling of concrete, as studied by NMR. Cem. Concr. Res. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Pop, A.; Badea, C.; Ardelean, I. The effects of different superplasticizers and water-to-cement ratios on the hydration of gray cement using T2-NMR. Appl. Magn. Reson. 2013, 44, 1223–1234. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, Y.; Wei, X.; Jia, H.; Yan, R. Investigation on meso-debonding process of the sandstone–concrete interface induced by freeze–thaw cycles using NMR technology. Constr. Build. Mater. 2020, 252, 118962. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, W.; Peng, Y.; Tang, S.; Wang, L.; Shi, Y.; Li, Y.; Wang, Y.; Geng, Z.; Wu, K. Hydration and fractal analysis on Low-heat Portland cement pastes by thermodynamic-based methods. Fractal Fract. 2023, 7, 606–633. [Google Scholar] [CrossRef]

- Peng, Y.; Tang, S.; Huang, J.; Tang, C.; Wang, L.; Liu, Y. Fractal analysis on pore structure and modeling of hydration of magnesium phosphate cement paste. Fractal Fract. 2022, 6, 337–355. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Huang, M.; Yin, H.; Jiang, K.; Xiao, K.; Tang, S. Influence of different alkali sulfates on the shrinkage, hydration, pore structure, fractal dimension and microstructure of low-heat Portland cement, medium-heat Portland cement and ordinary Portland cement. Fractal Fract. 2021, 5, 79–106. [Google Scholar] [CrossRef]

- Xiong, H.; Yuan, K.; Wen, M.; Yu, A.; Xu, J. Influence of pore structure on the moisture transport property of external thermal insulation composite system as studied by NMR. Constr. Build. Mater. 2019, 228, 116815. [Google Scholar] [CrossRef]

- Lu, Y. Effect of Ultra-Fine Fly Ash on Mechanical Properties and Microstructure of Cement-Based Materials. Master's Thesis, Chang’an University, Xi’an, China, 2022. [Google Scholar]

- Wu, Z. Discussion on the recent development direction of concrete science and technology. J. Chin. Ceram. Soc. 1979, 3, 262–270. [Google Scholar]

| Name of Indicator | Average Degree of Polymerization | Alcoholysis Degree | Sodium Oxide | Chloride | Sulfate | |

|---|---|---|---|---|---|---|

| Name of Sample | ||||||

| Polyvinyl alcohol (PVA) | 1750 ± 50 | ≥87.0% | 19.3–22.8% | ≤0.01% | ≤0.01% | |

| Type | Apparent Density (kg/m3) | Water Absorption (%) | Crushing Index (%) |

|---|---|---|---|

| RB | 2527.9 | 21.4 | 21.8 |

| Modified RB | 2589.2 | 18.9 | 16.2 |

| RC | 2586.3 | 6.4 | 13.1 |

| Modified RC | 2660.5 | 4.7 | 10.1 |

| Groups. | C | O | Fe | Na | Mg | Al | Si | Ca | |

|---|---|---|---|---|---|---|---|---|---|

| RB | 1 | 30.20 | 26.68 | 0.14 | 0.74 | 1.61 | 6.11 | 30.79 | 3.73 |

| 2 | 29.02 | 29.45 | 0.07 | 2.09 | 0.79 | 9.76 | 26.80 | 2.02 | |

| 3 | 19.56 | 33.71 | 0.76 | 1.09 | 2.04 | 7.19 | 27.10 | 8.55 | |

| Modified RB | 1 | 65.32 | 16.61 | 0.44 | 1.15 | 1.01 | 3.28 | 11.04 | 1.16 |

| 2 | 60.30 | 16.96 | 0.04 | 0.73 | 1.29 | 7.30 | 13.06 | 0.31 | |

| 3 | 41.31 | 24.92 | 0.42 | 1.65 | 1.85 | 6.14 | 21.72 | 1.99 | |

| RC | 1 | 12.47 | 27.86 | 0.09 | 0.30 | 1.97 | 17.38 | 31.69 | 8.24 |

| 2 | 15.02 | 24.42 | 0.04 | 0.75 | 1.84 | 20.11 | 32.20 | 5.62 | |

| 3 | 13.91 | 24.09 | 0.00 | 1.95 | 0.05 | 18.24 | 34.61 | 7.16 | |

| Modified RC | 1 | 29.57 | 24.95 | 0.13 | 1.93 | 1.08 | 7.81 | 27.73 | 6.80 |

| 2 | 48.58 | 15.16 | 0.11 | 1.86 | 3.00 | 6.82 | 19.69 | 4.78 | |

| 3 | 52.33 | 23.55 | 1.03 | 1.84 | 1.05 | 3.43 | 11.50 | 5.25 | |

| Cement | Specific Surface Area/m2·kg−1 | Setting Time/min | Stability | Burning Vector/% | 3d Strength/MPa | 28d Strength/MPa | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | Bending | Compressive | Bending | Compressive | ||||

| P·O42.5 | 365 | 186 | 235 | Qualified | 3.22 | 5.8 | 23.1 | 8.2 | 45.7 |

| Groups | Water | Cement | Sand | Stone | RB | RC | Water Reducing Admixture |

|---|---|---|---|---|---|---|---|

| RAC1, P-RAC1 | 154 | 342 | 666 | 867 | 0 | 372 | 1.71 |

| RAC2, P-RAC2 | 154 | 342 | 666 | 867 | 112 | 260 | 1.71 |

| RAC3, P-RAC3 | 154 | 342 | 666 | 867 | 186 | 186 | 1.71 |

| Groups | Water | Cement | Sand | Stone | RB | RC | Water Reducing Admixture |

| RAC4, P-RAC4 | 154 | 342 | 666 | 867 | 260 | 112 | 1.71 |

| RAC5, P-RAC5 | 154 | 342 | 666 | 867 | 372 | 0 | 1.71 |

| Groups | Peak Area | Peak Ratio/% | |||

|---|---|---|---|---|---|

| The First Peak | The Second Peak | The Third Peak | The Fourth Peak | ||

| RAC3 | 3598.187 | 70.754 | 14.052 | 9.219 | 5.975 |

| P-RAC3 | 3346.589 | 86.497 | 6.018 | 5.358 | 2.127 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiu, J.; Zhang, Y.; Qin, Q.; Xiao, Z.; Lei, T.; Li, L. Study on Mechanical Properties and Microscopic Mechanism of PVA-Modified Recycled Brick Aggregate Concrete. Sustainability 2024, 16, 1292. https://doi.org/10.3390/su16031292

Qiu J, Zhang Y, Qin Q, Xiao Z, Lei T, Li L. Study on Mechanical Properties and Microscopic Mechanism of PVA-Modified Recycled Brick Aggregate Concrete. Sustainability. 2024; 16(3):1292. https://doi.org/10.3390/su16031292

Chicago/Turabian StyleQiu, Jisheng, Yuqing Zhang, Qing Qin, Zhijie Xiao, Tiantian Lei, and Le Li. 2024. "Study on Mechanical Properties and Microscopic Mechanism of PVA-Modified Recycled Brick Aggregate Concrete" Sustainability 16, no. 3: 1292. https://doi.org/10.3390/su16031292

APA StyleQiu, J., Zhang, Y., Qin, Q., Xiao, Z., Lei, T., & Li, L. (2024). Study on Mechanical Properties and Microscopic Mechanism of PVA-Modified Recycled Brick Aggregate Concrete. Sustainability, 16(3), 1292. https://doi.org/10.3390/su16031292