Emergency Logistics Facilities Location Dual-Objective Modeling in Uncertain Environments

Abstract

:1. Introduction

- 1.

- In previous research, most studies have established models from a risk-neutral perspective. Therefore, this paper considers the risk preferences of decision-makers based on the stochastic programming model, introducing CVaR to measure the impact of extreme situations on the objective function.

- 2.

- This paper uses both stochastic programming and robust optimization methods for modeling, and analyzes and compares the results of the two uncertainty methods for the case background proposed in this paper, to assist decision-makers with different risk preferences in making management decisions.

2. Literature Review

2.1. Concept of Emergency Logistics

2.2. Emergency Logistics Research Methodology

2.3. Risk Metrics Applications

3. Problem Formulation

3.1. Problem Description

- 1.

- Fixed costs: Emergency logistics facilities are assumed to have the functions of emergency material allocation and human resource scheduling. The construction scheduling, and storage costs of each emergency logistics facility are assumed to be known and remain constant throughout the period under consideration.

- 2.

- Constant transport speed: The speed of each transport unit is assumed to be constant, implying that the time taken between material demand points is directly proportional to the distance.

- 3.

- Uniform transportation cost: The cost of transporting emergency supplies is assumed to be uniform and known for all units.

- 4.

- Known distances: The distance from each emergency logistics facility to each emergency logistics demand point is assumed to be known and does not change over time.

- 5.

- Allocation and scheduling rules: It is assumed that each emergency logistics facility can provide materials and dispatch human resources to multiple emergency logistics demand points, as shown in Figure 1(1). Each emergency supply–demand point can be serviced by multiple emergency logistics facilities, as shown in Figure 1(2), allowing for a flexible and robust supply chain.

- 6.

- Demand relationship: The demand for supplies at emergency supply points is proportional to the demand for human resources. If a place has a large demand for supplies, it may be densely populated or severely affected by a disaster. Therefore, it will have more injured people and more affected groups, so it needs more emergency rescue human resources.

- I: The set of emergency supply–demand points, ;

- J: The set of emergency logistics alternative facility points, ;

- K: The set of emergency logistics rescue scenarios, .

- : Unit transportation cost between emergency supply–demand point i and emergency logistics facility j;

- : Transportation distance between emergency supply–demand point i and emergency logistics facility j;

- : Maximum service distance of emergency logistics facility;

- : Construction cost of emergency logistics facility j;

- : Storage cost of unit emergency supplies during pre-disaster emergency supplies reserve;

- : Storage capacity limit of emergency logistics facility;

- : The cost of dispatching a unit of professional emergency rescue human resources;

- : The cost of dispatching a unit of social emergency rescue human resources;

- : The cost of dispatching a unit of grassroots emergency rescue human resources;

- : Demand quantity of emergency supply–demand point i;

- V: Speed of emergency supply transport vehicle;

- : Transportation time between emergency supply–demand point i and emergency logistics facility j;

- : The ratio coefficient of the demand for one unit of emergency supplies to the demand for one unit of professional/social/grassroots emergency rescue human resources at the demand point;

- : Road congestion coefficient;

- : Road congestion coefficient under scenario k;

- P: Maximum number of emergency logistics facilities to be built.

- : 0–1 binary variable; if emergency logistics facility j is selected, the value is 1, otherwise it is 0;

- : 0–1 binary variable; if emergency logistics facility j provides supplies to demand point i, the value is 1, otherwise it is 0;

- : 0–1 binary variable, under scenario K; if the emergency logistics facility j provides supplies to the demand point i, the value is 1, otherwise it is 0;

- : The quantity of emergency supplies stored at emergency logistics facility j;

- : The amount of supplies allocated by emergency logistics facility j to emergency supply–demand point i;

- : The amount of material distributed by emergency logistics facility j to emergency material demand point i under scenario k;

- : The number of professional emergency rescue human resources dispatched from emergency logistics facility j to demand point i;

- : The number of social emergency rescue human resources dispatched from emergency logistics facility j to demand point i;

- : The number of grassroots emergency rescue human resources dispatched from emergency logistics facility j to demand point i;

- : The number of professional emergency rescue human resources dispatched from emergency logistics facility j to demand point i under scenario K;

- : The number of grassroots emergency rescue human resources dispatched from emergency logistics facility j to demand point i under scenario K;

- : The number of grassroots emergency rescue human resources dispatched from emergency logistics facility j to demand point i under scenario K.

3.2. Basic Model

4. Stochastic Programming Model

TSP Model for Emergency Logistics Facility Location Based on Risk Preference

5. Robust Optimization Model

5.1. Robust Model for Emergency Logistics Facility Location Based on Box Uncertainty Set

5.2. Robust Model for Emergency Logistics Facility Location Based on Polyhedral Uncertainty Set

6. Numerical Analysis

6.1. Numerical Example

6.1.1. Pre-Locating of Emergency Logistics Facilities

6.1.2. Parameters of Model

6.2. Analysis of Location Results in Defined Environments

6.2.1. Comparative Analysis of Single Target Results

6.2.2. Comparative Analysis of Dual Objective Results

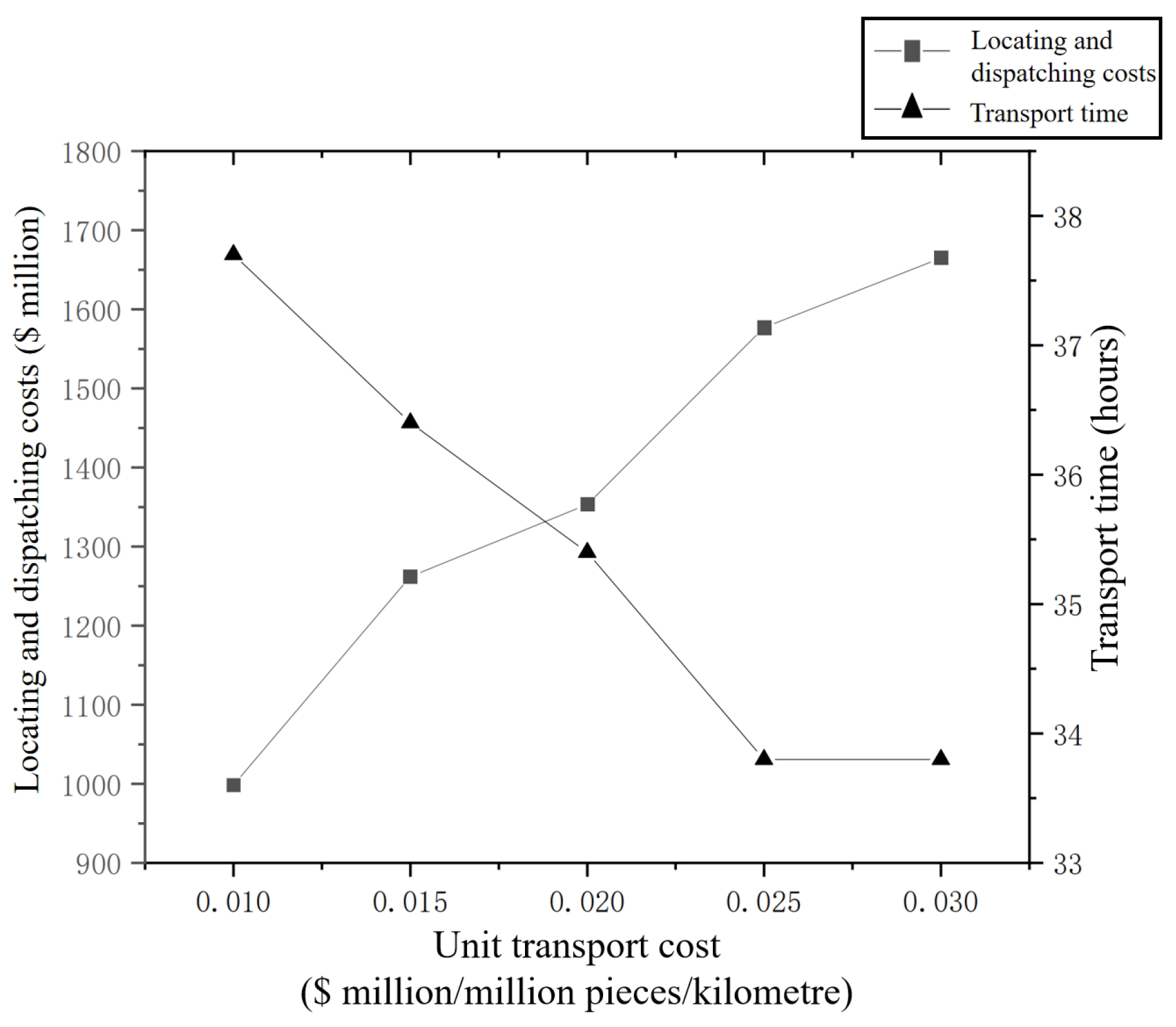

6.2.3. Sensitivity Analysis of Transportation Costs

6.3. Analysis of Location Results in Uncertain Environments

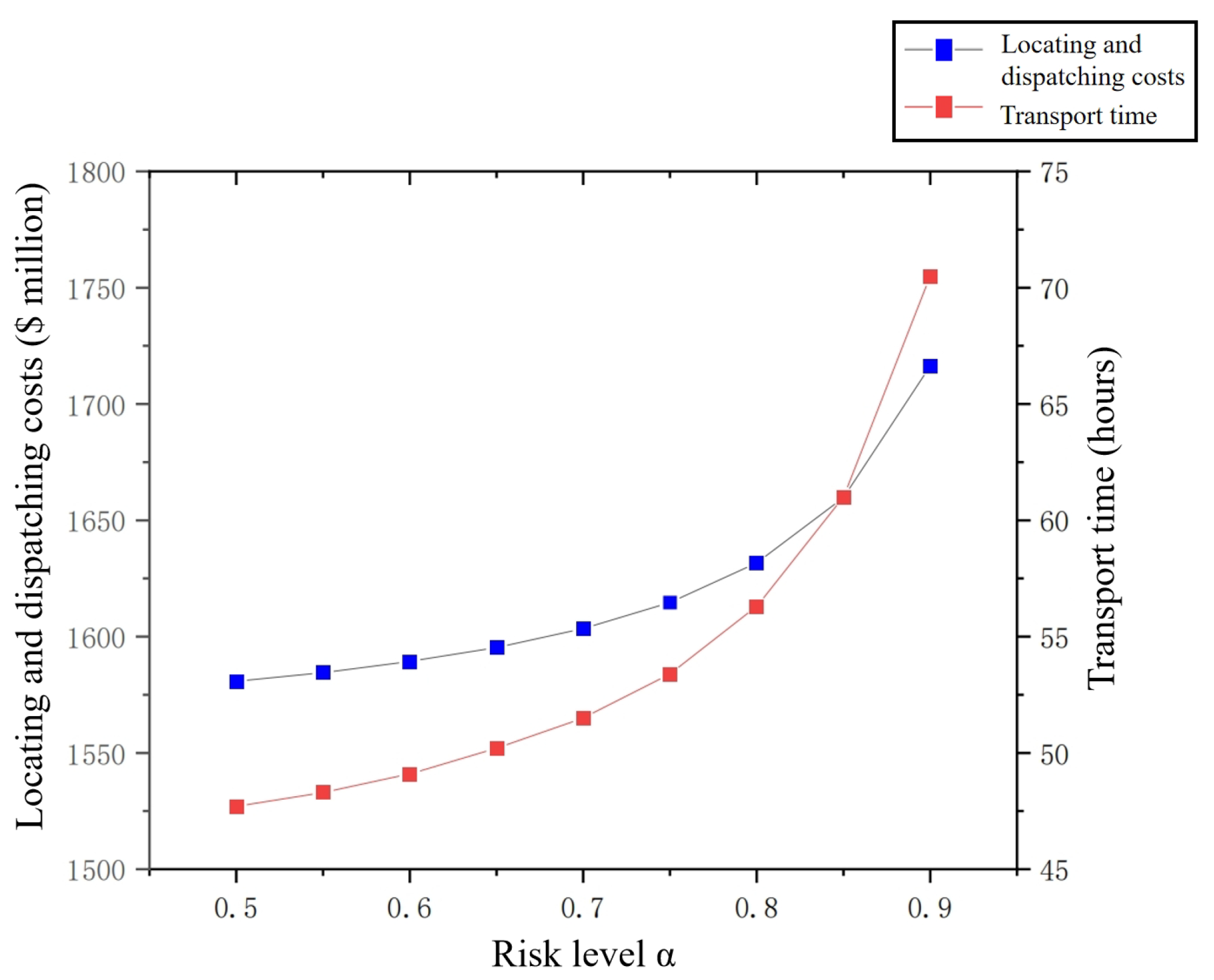

6.3.1. Location Results for Stochastic Programming Models

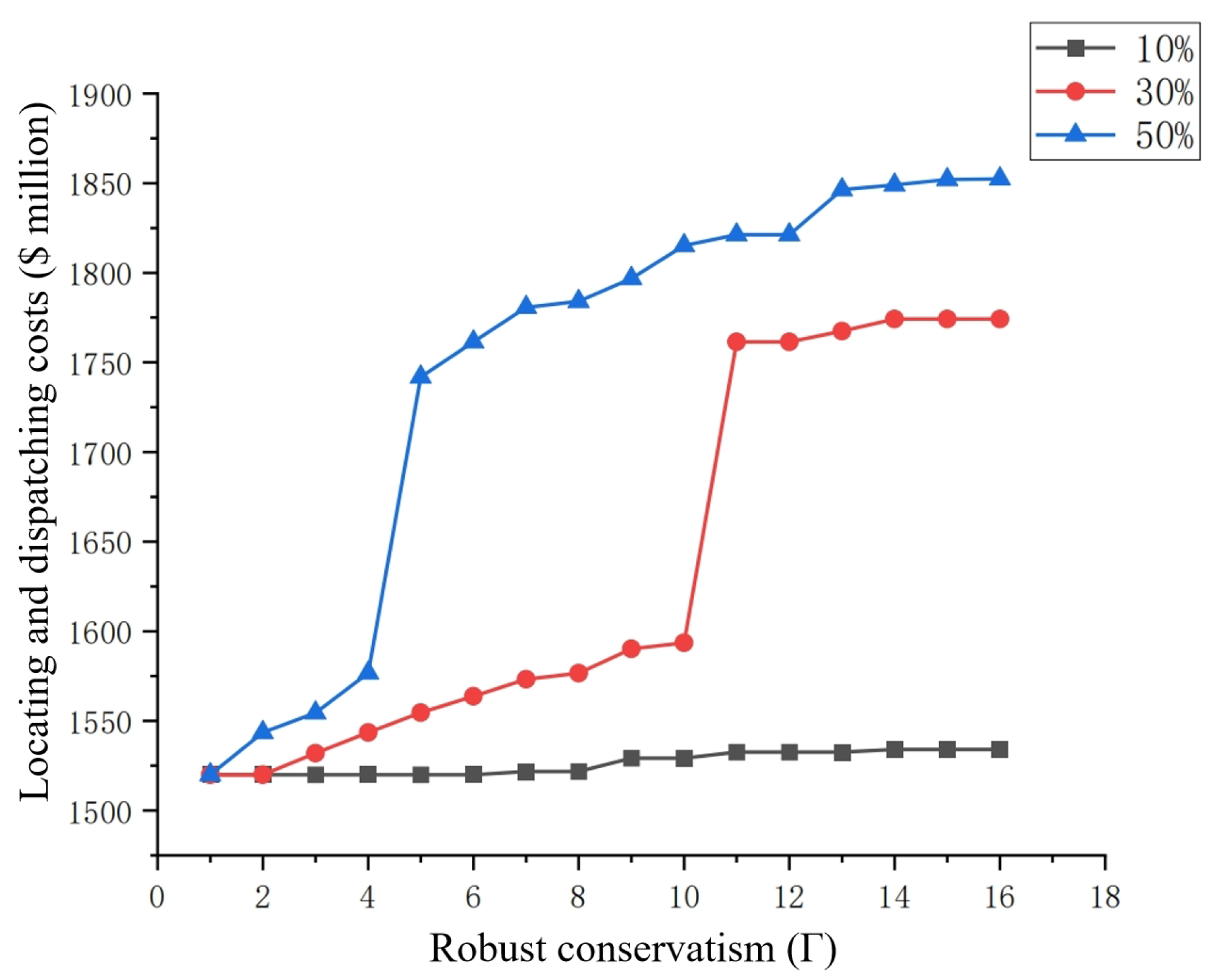

6.3.2. Location Results for Robust Optimization Models

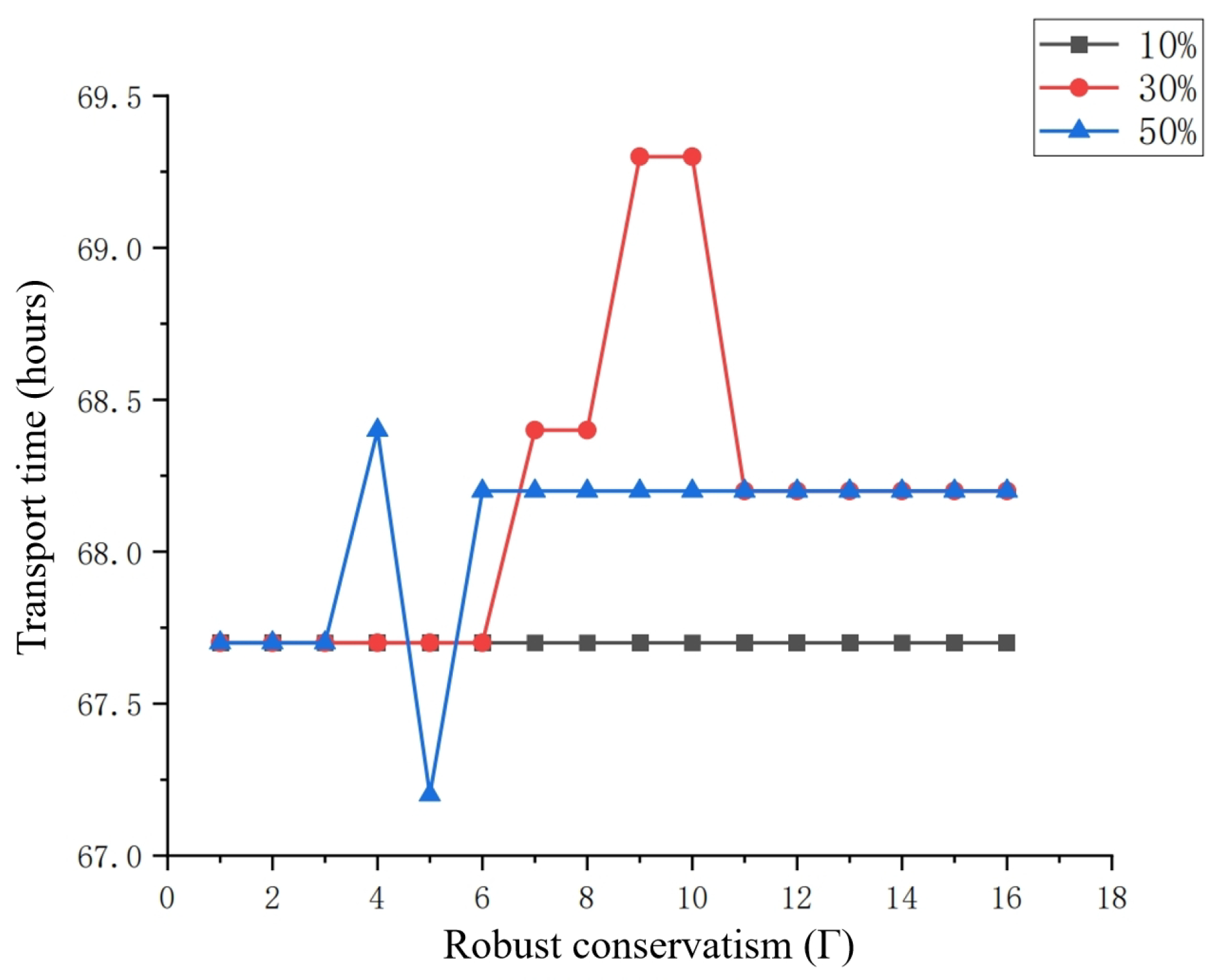

6.3.3. Sensitivity Analysis of Parameters in Uncertainty Models

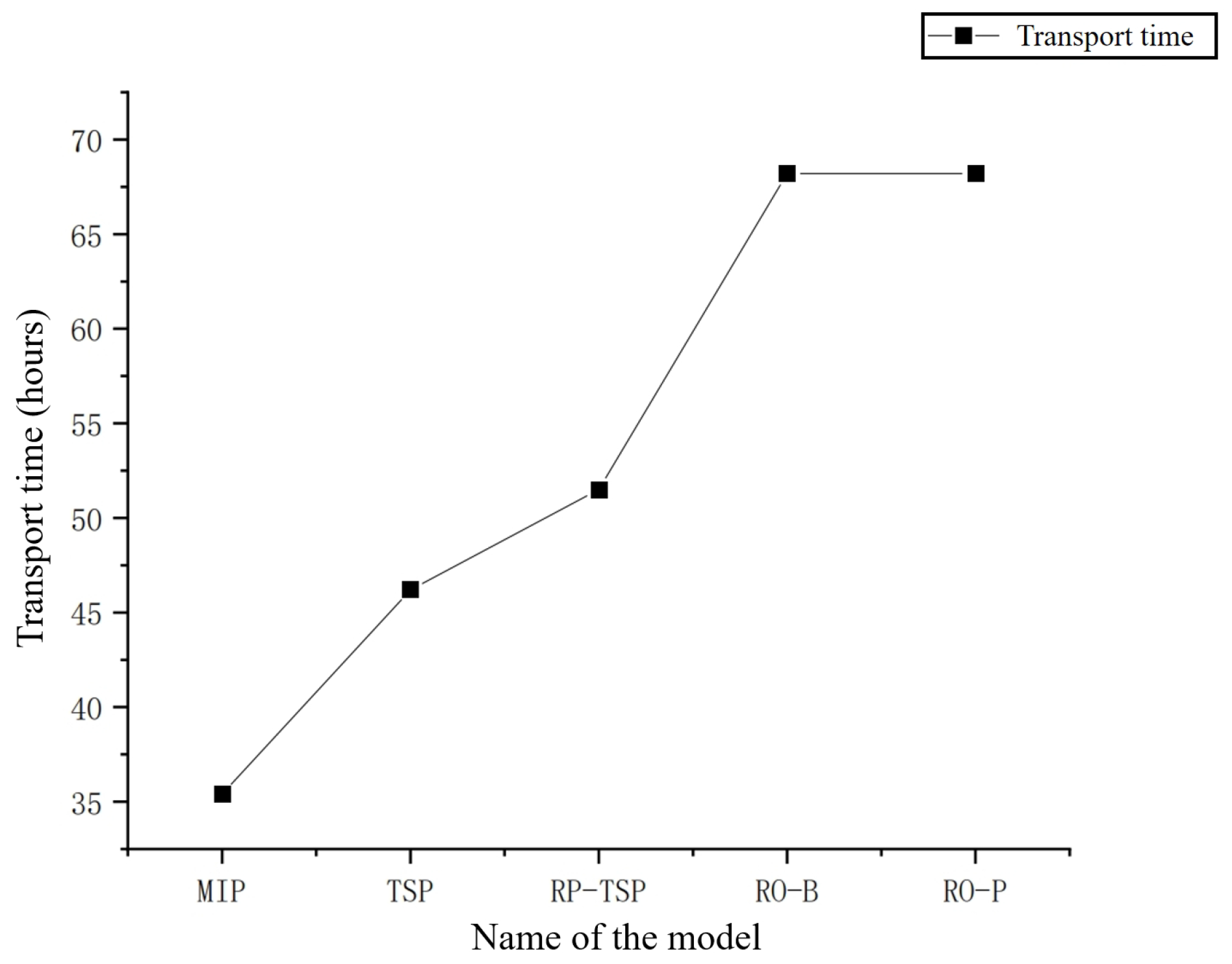

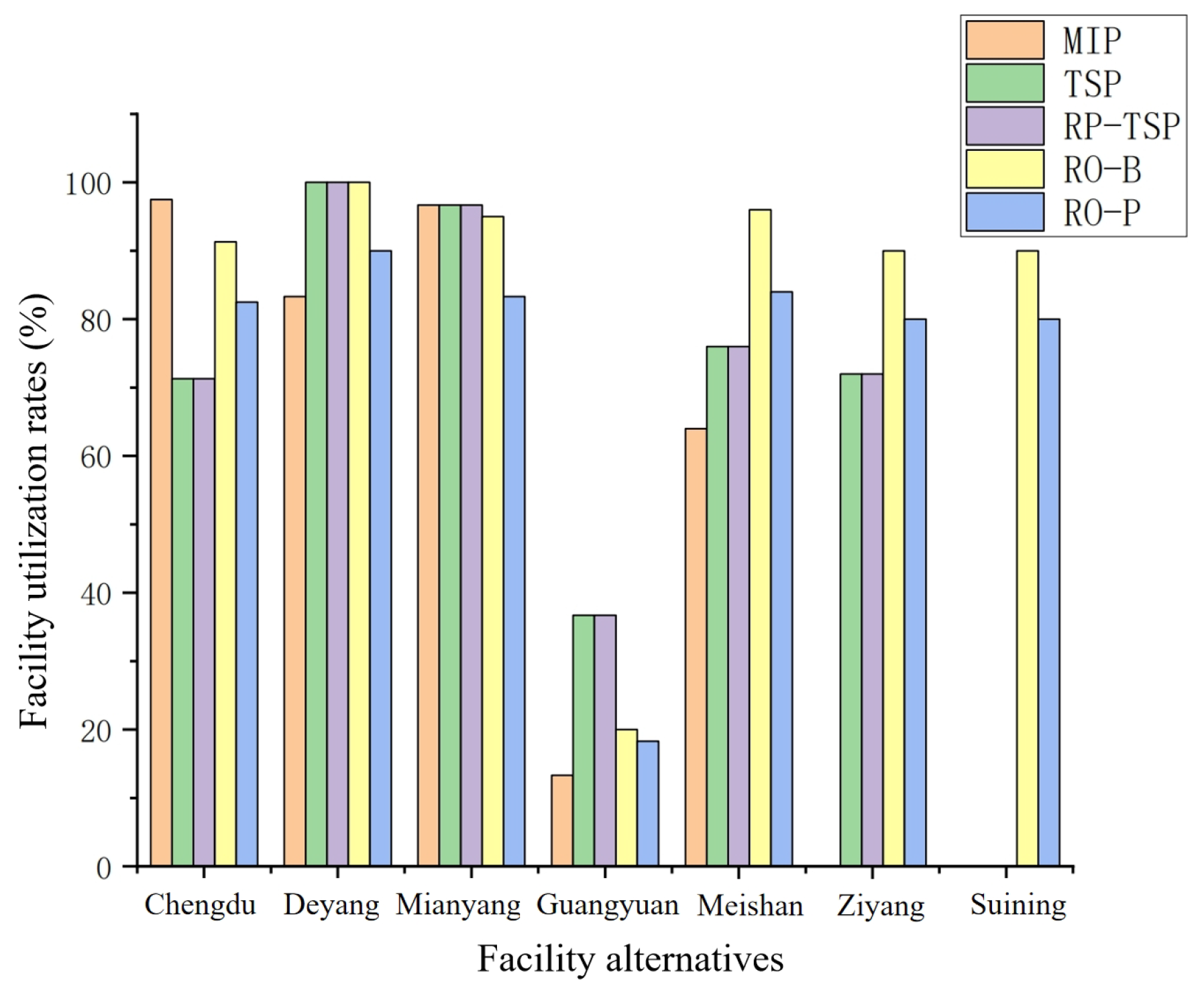

6.3.4. Comparative Analysis of Uncertainty Optimization Methods

6.4. Management Insights

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yaghmaei, N. Human Cost of Disasters: An Overview of the Last 20 Years, 2000–2019; UN Office for Disaster Risk Reduction: Geneva, Switzerland, 2020. [Google Scholar]

- OCHA. Global Humanitarian Overview 2022. 2021. Available online: https://2022.gho.unocha.org/ (accessed on 1 November 2021).

- Kovacs, G.; Moshtari, M. A roadmap for higher research quality in humanitarian operations: A methodological perspective. Eur. J. Oper. Res. 2019, 276, 395–408. [Google Scholar] [CrossRef]

- Trunick, P. Special report: Delivering relief to tsunami victims. Logist. Today 2005, 46, 1–3. [Google Scholar]

- Van Wassenhove, L. Humanitarian aid logistics: Supply chain management in high gear. J. Oper. Res. Soc. 2006, 57, 475–489. [Google Scholar] [CrossRef]

- Sahebjamnia, N.; Torabi, S.; Mansouri, S. A hybrid decision support system for managing humanitarian relief chains. Decis. Support Syst. 2017, 95, 12–26. [Google Scholar] [CrossRef]

- Kundu, T.; Sheu, B.; Kuo, H. Emergency logistics management—Review and propositions for future research. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102789. [Google Scholar] [CrossRef]

- Kovács, G.; Spens, K. Humanitarian logistics in disaster relief operations. Int. J. Phys. Distrib. Logist. Manag. 2006, 37, 99–114. [Google Scholar] [CrossRef]

- Knott, R. Humanitarian aid logistics: Supply chain management in high gear. Disasters 1987, 11, 113–115. [Google Scholar] [CrossRef]

- Barbarosoglu, G.; Arda, Y. A two-stage stochastic programming framework for transportation programming in disaster response. J. Oper. Res. Soc. 2004, 55, 43–53. [Google Scholar] [CrossRef]

- Beamon, B.; Kotleba, S. Inventory modeling for complex emergencies in humanitarian relief operations. Int. J. Logist. Res. Appl. 2006, 9, 1–18. [Google Scholar] [CrossRef]

- Paul, J.; MacDonald, L. Optimal location, capacity and timing of stockpiles for improved hurricane preparedness. Int. J. Prod. Econ. 2016, 174, 11–28. [Google Scholar] [CrossRef]

- Paul, J.; Wang, X. Robust location-allocation network design for earthquake preparedness. Transp. Res. Part B Methodol. 2019, 119, 139–155. [Google Scholar] [CrossRef]

- Shen, L.; Tao, F.; Shi, Y. Optimization of location-routing problem in emergency logistics considering carbon emissions. Int. J. Environ. Res. Public Health 2019, 16, 2982. [Google Scholar] [CrossRef]

- Du, J.; Wu, P.; Wang, Y.; Yang, D. Multi-stage humanitarian emergency logistics: Robust decisions in uncertain environment. Nat. Hazards 2023, 115, 899–922. [Google Scholar] [CrossRef]

- Altay, N.; Kovács, G.; Spens, K. The evolution of humanitarian logistics as a discipline through a crystal ball. J. Humanit. Logist. Supply Chain Manag. 2021, 11, 577–584. [Google Scholar] [CrossRef]

- Kovacs, G.; Spens, K.M. (Eds.) Relief Supply Chain Management for Disasters: Humanitarian Aid and Emergency Logistics; Information Science Reference: Hershey, PA, USA, 2011. [Google Scholar]

- Basharat, M.; Riaz, M.; Jan, M.; Xu, C.; Riaz, S. A review of landslides related to the 2005 Kashmir Earthquake: Implication and future challenges. Nat. Hazards 2021, 108, 1–30. [Google Scholar] [CrossRef]

- Huang, K.; Jiang, Y.; Yuan, Y.; Zhao, L. Modeling multiple humanitarian objectives in emergency response to large-scale disasters. Transp. Res. Part E Logist. Transp. Rev. 2015, 75, 1–17. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, N.; Zhang, J. Integrated temporary facility location and casualty allocation planning for post-disaster humanitarian medical service. Transp. Res. Part E Logist. Transp. Rev. 2019, 128, 1–16. [Google Scholar] [CrossRef]

- Sun, H.; Li, Y.; Zhang, J. Collaboration-based reliable optimal casualty evacuation network design for large-scale emergency preparedness. Socio-Econ. Program. Sci. 2022, 81, 101192. [Google Scholar] [CrossRef]

- Ghasemi, P.; Khalili-Damghani, K.; Hafezalkotob, A.; Raissi, S. Stochastic optimization model for distribution and evacuation programming (A case study of Tehran earthquake). Socio-Econ. Program. Sci. 2022, 71, 100745. [Google Scholar]

- Paul, J.; Zhang, M. Supply location and transportation programming for hurricanes: A two-stage stochastic programming framework. Eur. J. Oper. Res. 2019, 274, 108–125. [Google Scholar] [CrossRef]

- Wang, L. A two-stage stochastic programming framework for evacuation programming in disaster responses. Comput. Ind. Eng. 2020, 145, 106458. [Google Scholar] [CrossRef]

- Oksuz, M.; Satoglu, S. A two-stage stochastic model for location planning of temporary medical centers for disaster response. Int. J. Disaster Risk Reduct. 2020, 44, 101426. [Google Scholar] [CrossRef]

- Aydin, N. A stochastic mathematical model to locate field hospitals under disruption uncertainty for large-scale disaster preparedness. Int. J. Optim. Control 2016, 6, 85–102. [Google Scholar] [CrossRef]

- Manopiniwes, W.; Irohara, T. Stochastic optimisation model for integrated decisions on relief supply chains: Preparedness for disaster response. Int. J. Prod. Res. 2017, 55, 979–996. [Google Scholar] [CrossRef]

- Ben-tal, A.; Nemirovski, A. Robust Convex Optimization. Math. Oper. Res. 1998, 23, 769–805. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Yu, G. A scenario-based hybrid robust and stochastic approach for joint programming of relief logistics and casualty distribution considering secondary disasters. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 102029. [Google Scholar] [CrossRef]

- Najafi, M.; Eshghi, K.; Dullaert, W. A multi-objective robust optimization model for logistics planning in the earthquake response phase. Transp. Res. Part E Logist. Transp. Rev. 2013, 49, 217–249. [Google Scholar] [CrossRef]

- Ni, W.; Shu, J.; Song, M. Location and emergency inventory pre-positioning for disaster response operations: Min-max robust model and a case study of Yushu earthquake. Prod. Oper. Manag. 2018, 27, 160–183. [Google Scholar] [CrossRef]

- Balcik, B.; Yanikoglu, I. A robust optimization approach for humanitarian needs assessment planning under travel time uncertainty. Eur. J. Oper. Res. 2020, 282, 40–57. [Google Scholar] [CrossRef]

- Ke, G. Managing reliable emergency logistics for hazardous materials: A two-stage robust optimization approach. Comput. Oper. Res. 2022, 138, 105557. [Google Scholar] [CrossRef]

- Basak, S.; Shapiro, A. Value-at-risk-based risk management: Optimal policies and asset prices. Rev. Financ. Stud. 2001, 14, 371–405. [Google Scholar] [CrossRef]

- Jin, T.; Yang, X. Monotonicity theorem for the uncertain fractional differential equation and application to uncertain financial market. Math. Comput. Simul. 2021, 190, 203–221. [Google Scholar] [CrossRef]

- Rockafellar, R.; Wets, R. Stochastic variational inequalities: Single-stage to multistage. Math. Program. 2017, 165, 331–360. [Google Scholar] [CrossRef]

- Jin, T.; Xia, H. Lookback option pricing models based on the uncertain fractional-order differential equation with Caputo type. J. Ambient Intell. Humaniz. Comput. 2023, 14, 6435–6448. [Google Scholar] [CrossRef]

- Qu, S.; Li, S. A supply chain finance game model with order-to-factoring under blockchain. Syst. Eng. Theory Pract. 2023, 41, 1–16. [Google Scholar]

- Ji, Y.; Ma, Y. The robust maximum expert consensus model with risk aversion. Math. Program. 2023, 99, 101866. [Google Scholar] [CrossRef]

- Ahmed, S. Convexity and decomposition of mean-risk stochastic programs. Math. Program. 2006, 106, 433–446. [Google Scholar] [CrossRef]

- Miller, N.; Ruszczyński, A. Risk-averse two-stage stochastic linear programming: Modeling and decomposition. Oper. Res. 2011, 59, 125–132. [Google Scholar] [CrossRef]

- Xu, X.; Yan, Z.; Shahidehpour, M.; Li, Z.; Yan, M.; Kong, X. Data-Driven Risk-Averse Two-Stage Optimal Stochastic Scheduling of Energy and Reserve With Correlated Wind Power. IEEE Trans. Sustain. Energy 2020, 11, 436–447. [Google Scholar] [CrossRef]

- Das, D.; Verma, P.; Tanksale, A. Designing a closed-loop supply chain for reusable packaging materials: A risk-averse two-stage stochastic programming model using CVaR. Comput. Ind. Eng. 2022, 167, 108004. [Google Scholar] [CrossRef]

- Lewis, C. Linear Programming: Theory and Applications. 2008, pp. 1–66. Available online: https://www.whitman.edu/documents/Academics/Mathematics/lewis.pdf (accessed on 11 May 2008).

- Meyer, R. On the existence of optimal solutions to integer and mixed-integer programming problems. Math. Program. 1974, 7, 223–235. [Google Scholar] [CrossRef]

- Martínez-Legaz, J. On Weierstrass extreme value theorem. Optimization Letters. J. Risk 2014, 8, 391–393. [Google Scholar]

- Huang, M.; Huang, L.; Zhong, Y.; Yang, H.; Chen, X.; Huo, W.; Shi, L. MILP Acceleration: A Survey from Perspectives of Simplex Initialization and Learning-Based Branch and Bound. J. Oper. Res. Soc. China 2023, 1, 1–42. [Google Scholar] [CrossRef]

- Rockafellar, R.; Uryasev, S. Optimization of conditional value-at-risk. J. Risk 2000, 2, 21–42. [Google Scholar] [CrossRef]

- Soyster, A.L. Convex programming with set-inclusive constraints, and application to inexact LP. Oper. Res. 1973, 21, 1154–1157. [Google Scholar] [CrossRef]

- Feng, J.; Gai, W.; Li, J.; Xu, M. Location selection of emergency supplies repositories for emergency logistics management: A variable weighted algorithm. J. Loss Prev. Process Ind. 2020, 63, 104032. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, X.; Jiang, S.; Yan, J.; Han, Y. Emergency logistics scheduling with multiple supply-demand points based on grey interval. J. Saf. Sci. Resil. 2022, 3, 179–188. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Fan, J.; Wang, Z.; Zhen, L. Emergency logistics network optimization with time window assignment. Expert Syst. Appl. 2023, 214, 119145. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Yuan, Y. International Journal of Environmental Research and Public Health. Expert Syst. Appl. 2019, 16, 779. [Google Scholar]

- Jiang, Y.; Yuan, Y.; Huang, K.; Zhao, L. Logistics for Large-Scale Disaster Response: Achievements and Challenges. In Proceedings of the 2012 45th Hawaii International Conference on System Sciences, Maui, HI, USA, 4–7 January 2012; pp. 1277–1285. [Google Scholar]

- Wang, F.; Ge, X.; Li, Y.; Zheng, J.; Zheng, W. Optimising the Distribution of Multi-Cycle Emergency Supplies after a Disaster. Sustainability 2023, 15, 902. [Google Scholar] [CrossRef]

- Ghasemi, P.; Goodarzian, F.; Abraham, A. A new humanitarian relief logistic network for multi-objective optimization under stochastic programming. Appl. Intell. 2022, 52, 13729–13762. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Zhou, H. Robust dual sourcing inventory routing optimization for disaster relief. PLoS ONE 2023, 18, e0284971. [Google Scholar] [CrossRef] [PubMed]

- Sarma, D.; Bera, U.; Singh, A.; Maiti, M. A multi-objective post-disaster relief logistic model. In Proceedings of the 2017 IEEE Region 10 Humanitarian Technology Conference (R10-HTC), Dhaka, Bangladesh, 21–23 December 2017; pp. 205–208. [Google Scholar]

| Author | Multi-Objective | Problem | Uncertainty | Method | ||||

|---|---|---|---|---|---|---|---|---|

| LC | HRSC | TT | RO | SP | CVaR | |||

| Huang et al. [19] | √ | √ | √ | EVIA | ||||

| Liu et al. [20] | -constraint method | |||||||

| Sun et al. [21] | √ | √ | Gurobi | |||||

| Ghasemi et al. [22] | √ | √ | √ | √ | NSGAII | |||

| Paul and Zhang [23] | √ | √ | √ | Cplex | ||||

| Oksuz and Satoglu [25] | √ | √ | √ | Cplex | ||||

| Aydin [26] | √ | √ | Cplex | |||||

| Manopiniwes and Irohara [27] | √ | √ | √ | √ | Matlab | |||

| Li et al. [29] | √ | √ | √ | √ | √ | Matlab | ||

| Ke [33] | √ | √ | Gurobi | |||||

| Du et al. [15] | √ | √ | Algorithm and Cplex | |||||

| Barbarosoglu and Arda [10] | √ | √ | Cplex | |||||

| Paul and MacDonald [12] | √ | √ | √ | √ | EV | |||

| Paul and Wang [13] | √ | √ | √ | Cplex | ||||

| Shen et al. [14] | √ | √ | √ | Cplex | ||||

| Jin and Xia [37] | √ | √ | Gurobi | |||||

| Qu and Li [38] | √ | √ | Cplex | |||||

| Ji and Ma [39] | √ | √ | Matlab | |||||

| Miller and Ruszczyński [41] | √ | √ | DA | |||||

| Wang [24] | √ | √ | √ | √ | LRA | |||

| Xu et al. [42] | √ | √ | Matlab | |||||

| Das et al. [43] | √ | √ | √ | Gurobi | ||||

| Najafi [30] | √ | √ | SMSRM | |||||

| Ni et al. [31] | √ | √ | √ | BDA | ||||

| Balcik and Yanikoglu [32] | √ | √ | √ | TSHA | ||||

| Our paper | √ | √ | √ | √ | √ | √ | √ | Gurobi |

| Alternative | ||||||

|---|---|---|---|---|---|---|

| Locations | (USD 10,000) | (USD 10,000/10,000 Units) | (10,000 Units) | (USD 10,000/10,000 Units) | (USD 10,000/10,000 Units) | (USD 10,000/10,000 Units) |

| Chengdu | 240 | 0.3 | 80 | 260 | 180 | 40 |

| Deyang | 180 | 0.25 | 60 | 340 | 230 | 50 |

| Mianyang | 180 | 0.25 | 60 | 400 | 260 | 65 |

| Guangyuan | 180 | 0.25 | 60 | 480 | 310 | 80 |

| Meishan | 150 | 0.2 | 50 | 340 | 230 | 50 |

| Ziyang | 150 | 0.2 | 50 | 340 | 230 | 50 |

| Suining | 150 | 0.2 | 50 | 400 | 260 | 65 |

| Alternative Locations | Chengdu | Deyang | Mianyang | Guangyuan | Meishan | Ziyang | Suining |

|---|---|---|---|---|---|---|---|

| Wenchuan County | 144 | 162 | 198 | 328 | 202 | 225 | 297 |

| Beichuan County | 215 | 134 | 92 | 231 | 223 | 207 | 187 |

| Mianzhu | 116 | 35 | 60 | 221 | 180 | 180 | 185 |

| Qingchuan County | 300 | 218 | 174 | 92 | 389 | 353 | 313 |

| Mao County | 183 | 114 | 122 | 288 | 242 | 256 | 270 |

| Dujiangyan | 71 | 105 | 123 | 290 | 130 | 169 | 226 |

| Pingwu County | 293 | 212 | 160 | 167 | 360 | 347 | 302 |

| Pengzhou | 69 | 74 | 95 | 261 | 135 | 140 | 195 |

| Santai County | 138 | 106 | 72 | 222 | 207 | 160 | 99 |

| Lezhi County | 115 | 150 | 185 | 332 | 141 | 58 | 83 |

| Zhongjiang County | 97 | 39 | 59 | 235 | 165 | 120 | 141 |

| Renshou County | 78 | 152 | 200 | 367 | 34 | 65 | 179 |

| Zitong County | 201 | 122 | 60 | 150 | 268 | 258 | 194 |

| Yanting County | 174 | 135 | 126 | 222 | 243 | 196 | 94 |

| Hongya County | 123 | 208 | 255 | 438 | 63 | 139 | 253 |

| Ya’an City | 131 | 210 | 248 | 421 | 101 | 177 | 294 |

| Alternative Locations | Chengdu | Deyang | Mianyang | Guangyuan | Meishan | Ziyang | Suining |

|---|---|---|---|---|---|---|---|

| Wenchuan County | 3.6 | 4.1 | 5 | 8.2 | 5.1 | 5.6 | 7.4 |

| Beichuan County | 5.4 | 3.4 | 2.3 | 5.8 | 5.6 | 5.2 | 4.7 |

| Mianzhu | 2.9 | 0.9 | 1.5 | 5.5 | 4.5 | 4.5 | 4.6 |

| Qingchuan County | 7.5 | 5.5 | 4.4 | 2.3 | 9.7 | 8.8 | 7.8 |

| Mao County | 4.6 | 2.9 | 3.1 | 7.2 | 6.1 | 6.4 | 6.8 |

| Dujiangyan | 1.8 | 2.6 | 3.1 | 7.3 | 3.3 | 4.2 | 5.7 |

| Pingwu County | 7.3 | 5.3 | 4 | 4.2 | 9 | 8.7 | 7.6 |

| Pengzhou | 1.7 | 1.9 | 2.4 | 6.5 | 3.4 | 3.5 | 4.9 |

| Santai County | 3.5 | 2.7 | 1.8 | 5.6 | 5.2 | 4 | 2.5 |

| Lezhi County | 2.9 | 3.8 | 4.6 | 8.3 | 3.5 | 1.5 | 2.1 |

| Zhongjiang County | 2.4 | 1 | 1.5 | 5.9 | 4.1 | 3 | 3.5 |

| Renshou County | 2 | 3.8 | 5 | 9.2 | 0.9 | 1.6 | 4.5 |

| Zitong County | 5 | 3.1 | 1.5 | 3.8 | 6.7 | 6.5 | 4.9 |

| Yanting County | 4.4 | 3.4 | 3.2 | 5.6 | 6.1 | 4.9 | 2.4 |

| Hongya County | 3.1 | 5.2 | 6.4 | 11 | 1.6 | 3.5 | 6.3 |

| Ya’an City | 3.3 | 5.3 | 6.2 | 10.5 | 2.5 | 4.4 | 7.4 |

| Cities/Towns | Demand | Cities/Towns | Demand |

|---|---|---|---|

| (10,000 Units) | (10,000 Units) | ||

| Wenchuan County | 8 | Santai County | 20 |

| Beichuan County | 10 | Lezhi County | 10 |

| Mianzhu | 20 | Zhongjiang County | 20 |

| Qingchuan County | 8 | Renshou County | 20 |

| Mao County | 10 | Zitong County | 8 |

| Dujiangyan | 25 | Yanting County | 10 |

| Pingwu County | 10 | Hongya County | 12 |

| Pengzhou | 15 | Ya’an City | 20 |

| Alternative Locations | Chengdu | Deyang | Mianyang | Meishan |

|---|---|---|---|---|

| Wenchuan County | 8 | |||

| Beichuan County | 10 | |||

| Mianzhu | 20 | |||

| Qingchuan County | 8 | |||

| Mao County | 10 | |||

| Dujiangyan | 25 | |||

| Pingwu County | 10 | |||

| Pengzhou | 15 | |||

| Santai County | 6 | 14 | ||

| Lezhi County | 10 | |||

| Zhongjiang County | 20 | |||

| Renshou County | 20 | |||

| Zitong County | 8 | |||

| Yanting County | 10 | |||

| Hongya County | 12 | |||

| Ya’an City | 2 | 18 |

| Alternative Locations | Chengdu | Deyang | Mianyang | Guangyuan | Meishan | Ziyang | Suining |

|---|---|---|---|---|---|---|---|

| Wenchuan County | 8 | ||||||

| Beichuan County | 10 | ||||||

| Mianzhu | 20 | ||||||

| Qingchuan County | 8 | ||||||

| Mao County | 10 | ||||||

| Dujiangyan | 25 | ||||||

| Pingwu County | 10 | ||||||

| Pengzhou | 15 | ||||||

| Santai County | 20 | ||||||

| Lezhi County | 10 | ||||||

| Zhongjiang County | 20 | ||||||

| Renshou County | 8 | ||||||

| Zitong County | 10 | ||||||

| Yanting County | 10 | ||||||

| Hongya County | 12 | ||||||

| Ya’an City | 20 |

| Cost Weight | Time Weight | Locating and Dispatching | Emergency Transport |

|---|---|---|---|

| Cost (USD 10,000) | Time (h) | ||

| 0.1 | 0.9 | 228.75 | 33.2 |

| 0.2 | 0.8 | 208.45 | 33.8 |

| 0.3 | 0.7 | 189.46 | 35.4 |

| 0.4 | 0.6 | 166.35 | 37.7 |

| 0.5 | 0.5 | 166.35 | 37.7 |

| Cost Weighting | Transport Cost | Locating and Dispatching | Emergency Transport |

|---|---|---|---|

| (USD Million/Million Units/km) | Cost (USD 10,000) | Time (h) | |

| 0.3 | 0.0014 | 139.79 | 37.7 |

| 0.3 | 0.0021 | 176.71 | 36.4 |

| 0.3 | 0.0028 | 189.45 | 35.4 |

| 0.3 | 0.0035 | 220.77 | 33.8 |

| 0.3 | 0.0042 | 233.07 | 33.8 |

| Road Conditions | Demand Scenarios | ||

|---|---|---|---|

| (0.25) | (0.15) | (0.1) | |

| (0.15) | (0.09) | (0.06) | |

| (0.1) | (0.06) | (0.04) |

| Alternative Locations | Chengdu | Deyang | Mianyang | Guangyuan | Meishan | Ziyang |

|---|---|---|---|---|---|---|

| Wenchuan County | 10 | |||||

| Beichuan County | 12 | |||||

| Mianzhu | 24 | |||||

| Qingchuan County | 10 | |||||

| Mao County | 12 | |||||

| Dujiangyan | 29 | |||||

| Pingwu County | 12 | |||||

| Pengzhou | 18 | |||||

| Santai County | 24 | |||||

| Lezhi County | 12 | |||||

| Zhongjiang County | 24 | |||||

| Renshou County | 24 | |||||

| Zitong County | 10 | |||||

| Yanting County | 12 | |||||

| Hongya County | 14 | |||||

| Ya’an City | 24 |

| Alternative Locations | Chengdu | Deyang | Mianyang | Guangyuan | Meishan | Ziyang |

|---|---|---|---|---|---|---|

| Wenchuan County | 10 | |||||

| Beichuan County | 12 | |||||

| Mianzhu | 24 | |||||

| Qingchuan County | 10 | |||||

| Mao County | 12 | |||||

| Dujiangyan | 29 | |||||

| Pingwu County | 12 | |||||

| Pengzhou | 18 | |||||

| Santai County | 24 | |||||

| Lezhi County | 12 | |||||

| Zhongjiang County | 24 | |||||

| Renshou County | 24 | |||||

| Zitong County | 10 | |||||

| Yanting County | 12 | |||||

| Hongya County | 14 | |||||

| Ya’an City | 24 |

| Alternative Locations | Chengdu | Deyang | Mianyang | Guangyuan | Meishan | Ziyang | Suining |

|---|---|---|---|---|---|---|---|

| Wenchuan County | 12 | ||||||

| Beichuan County | 15 | ||||||

| Mianzhu | 30 | ||||||

| Qingchuan County | 12 | ||||||

| Mao County | 15 | ||||||

| Dujiangyan | 38 | ||||||

| Pingwu County | 15 | ||||||

| Pengzhou | 23 | ||||||

| Santai County | 30 | ||||||

| Lezhi County | 15 | ||||||

| Zhongjiang County | 30 | ||||||

| Renshou County | 30 | ||||||

| Zitong County | |||||||

| Yanting County | 12 | 15 | |||||

| Hongya County | 18 | ||||||

| Ya’an City | 30 |

| Alternative Locations | Chengdu | Deyang | Mianyang | Guangyuan | Meishan | Ziyang | Suining |

|---|---|---|---|---|---|---|---|

| Wenchuan County | 11 | ||||||

| Beichuan County | 13 | ||||||

| Mianzhu | 27 | ||||||

| Qingchuan County | 11 | ||||||

| Mao County | 13 | ||||||

| Dujiangyan | 35 | ||||||

| Pingwu County | 13 | ||||||

| Pengzhou | 20 | ||||||

| Santai County | 27 | ||||||

| Lezhi County | 13 | ||||||

| Zhongjiang County | 27 | ||||||

| Renshou County | 27 | ||||||

| Zitong County | 11 | ||||||

| Yanting County | 13 | ||||||

| Hongya County | 15 | ||||||

| Ya’an City | 27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Ma, Y.; Liu, C.; Ji, Y. Emergency Logistics Facilities Location Dual-Objective Modeling in Uncertain Environments. Sustainability 2024, 16, 1361. https://doi.org/10.3390/su16041361

Xu F, Ma Y, Liu C, Ji Y. Emergency Logistics Facilities Location Dual-Objective Modeling in Uncertain Environments. Sustainability. 2024; 16(4):1361. https://doi.org/10.3390/su16041361

Chicago/Turabian StyleXu, Fang, Yifan Ma, Chang Liu, and Ying Ji. 2024. "Emergency Logistics Facilities Location Dual-Objective Modeling in Uncertain Environments" Sustainability 16, no. 4: 1361. https://doi.org/10.3390/su16041361