Research on Radiation Monitoring Strategy for Spent Fuel Reprocessing Plant Based on Coordination of Nuclear Security Risk and Facility Importance Evaluation

Abstract

1. Introduction

2. Importance Analysis of the Nuclear Security Radiation Incident at Spent Fuel Reprocessing Plants

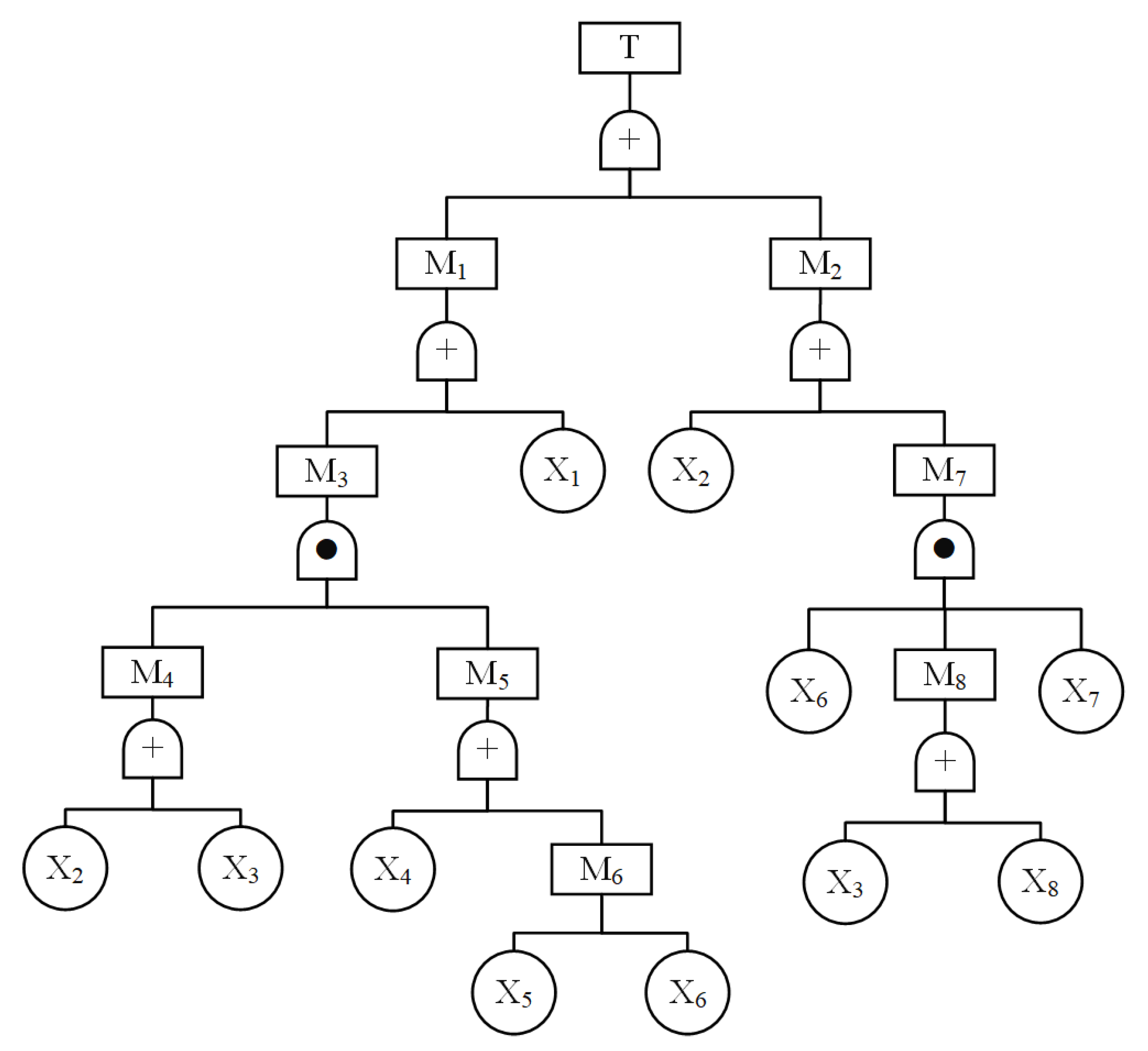

2.1. Establishment of Fault Tree

2.1.1. Minimum Cut Set

2.1.2. Structural Importance of Basic Events

2.2. Quantitative Analysis of Nuclear Security Radiation Fault Tree for Spent Fuel Reprocessing Plants

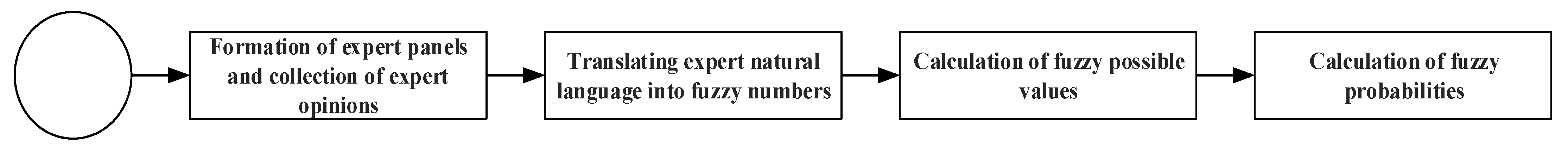

2.2.1. Obtaining the Probability of Occurrence of Basic Events

- (1)

- Expert scoring to judge probabilities of occurrence of basic events.

- (2)

- Expert evaluation results.

- (3)

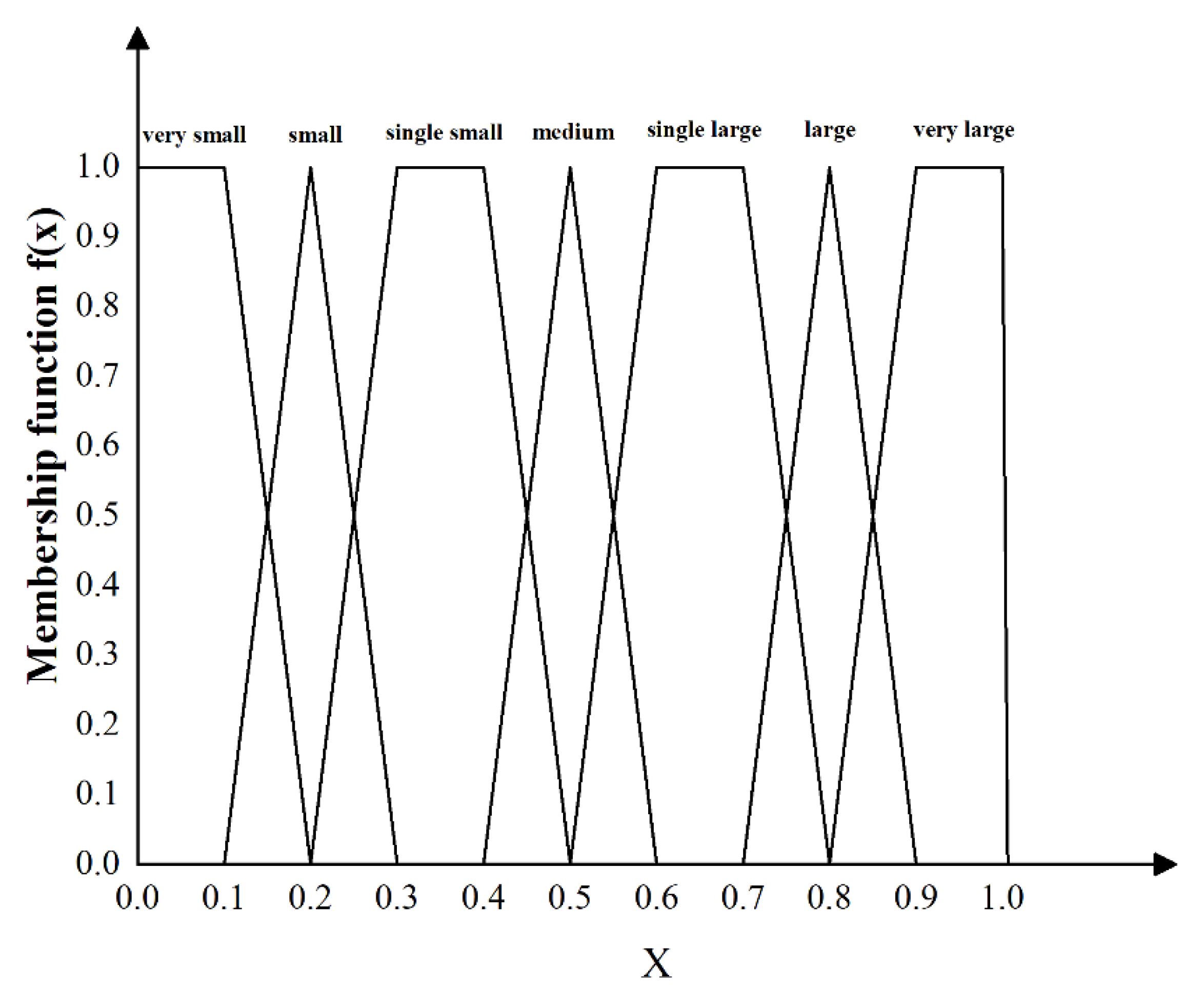

- Quantification of expert opinions based on the affiliation function

- (4)

- Calculation of the average fuzzy number.

- (5)

- Transformation of fuzzy numbers into fuzzy probabilities using the left-right fuzzy ranking method.

2.2.2. Probabilistic Importance of Basic Events

2.2.3. Critical Importance of Basic Events

3. Fuzzy Comprehensive Decision Making

3.1. Factor Set

3.2. Weighting Set

3.3. Evaluation Set

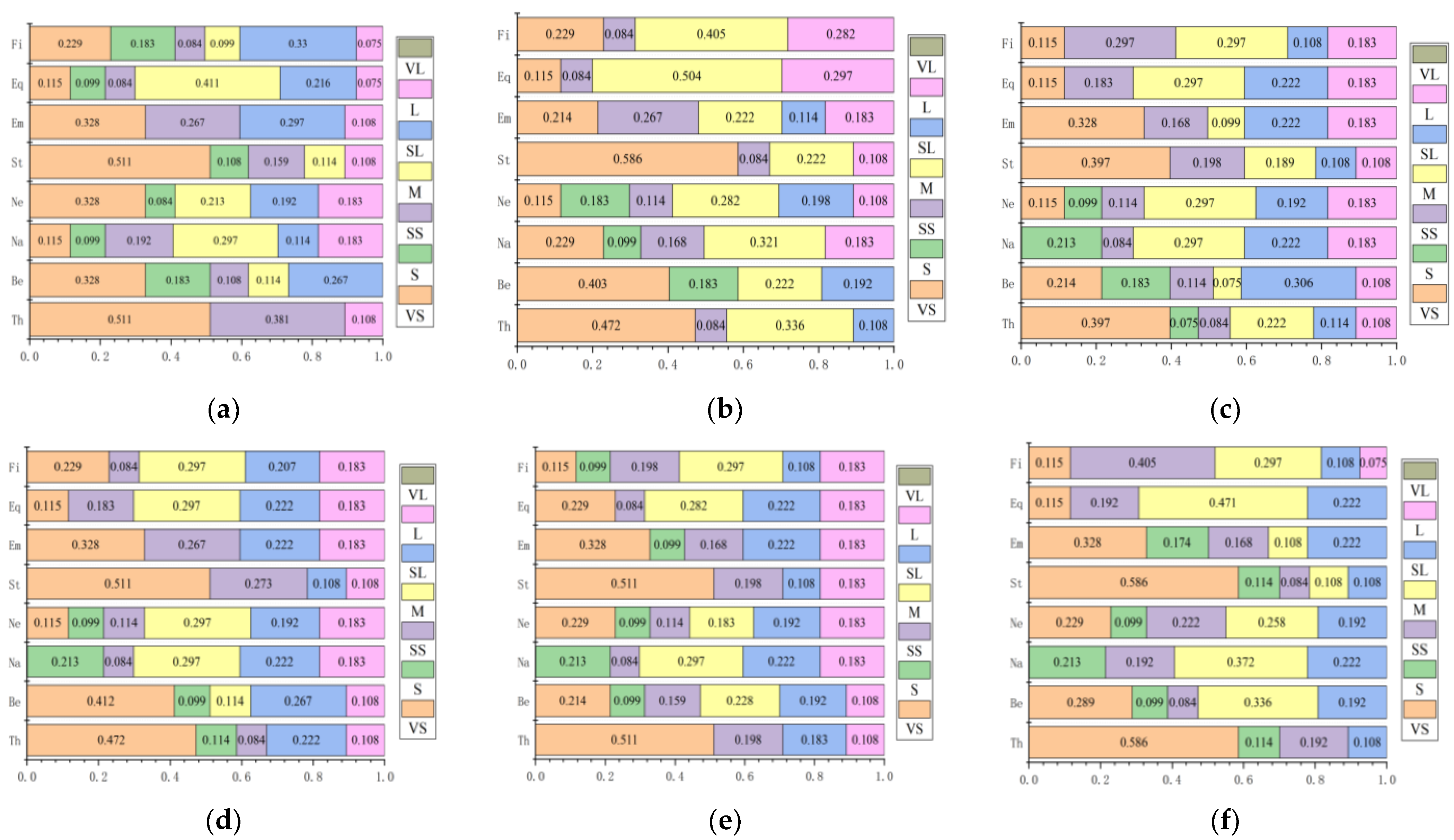

3.4. Single Factor Evaluation Matrix

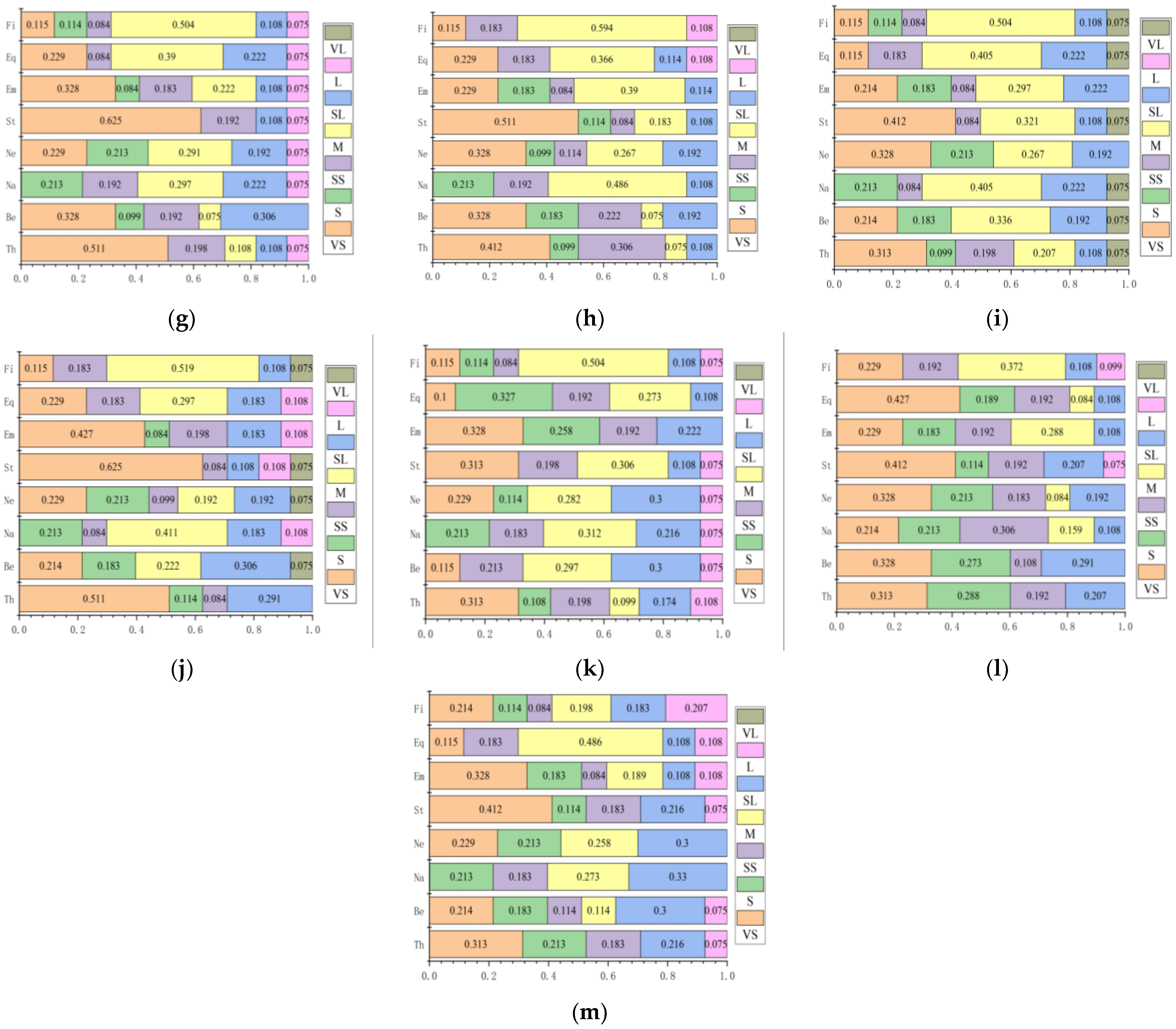

3.5. Fuzzy Synthesis Evaluation

- Spent Fuel Pool:

- Extraction Process Plant:

- Tail-End Conversion Plant:

- Waste Liquid Purification Plant:

- Curing Workshop:

- Discharge Workshop:

- Solid Waste Preparation Workshop:

- Equipment Room:

- Storehouse:

- Centralized Control Room:

- Office Area:

- Dormitory:

- Laboratory:

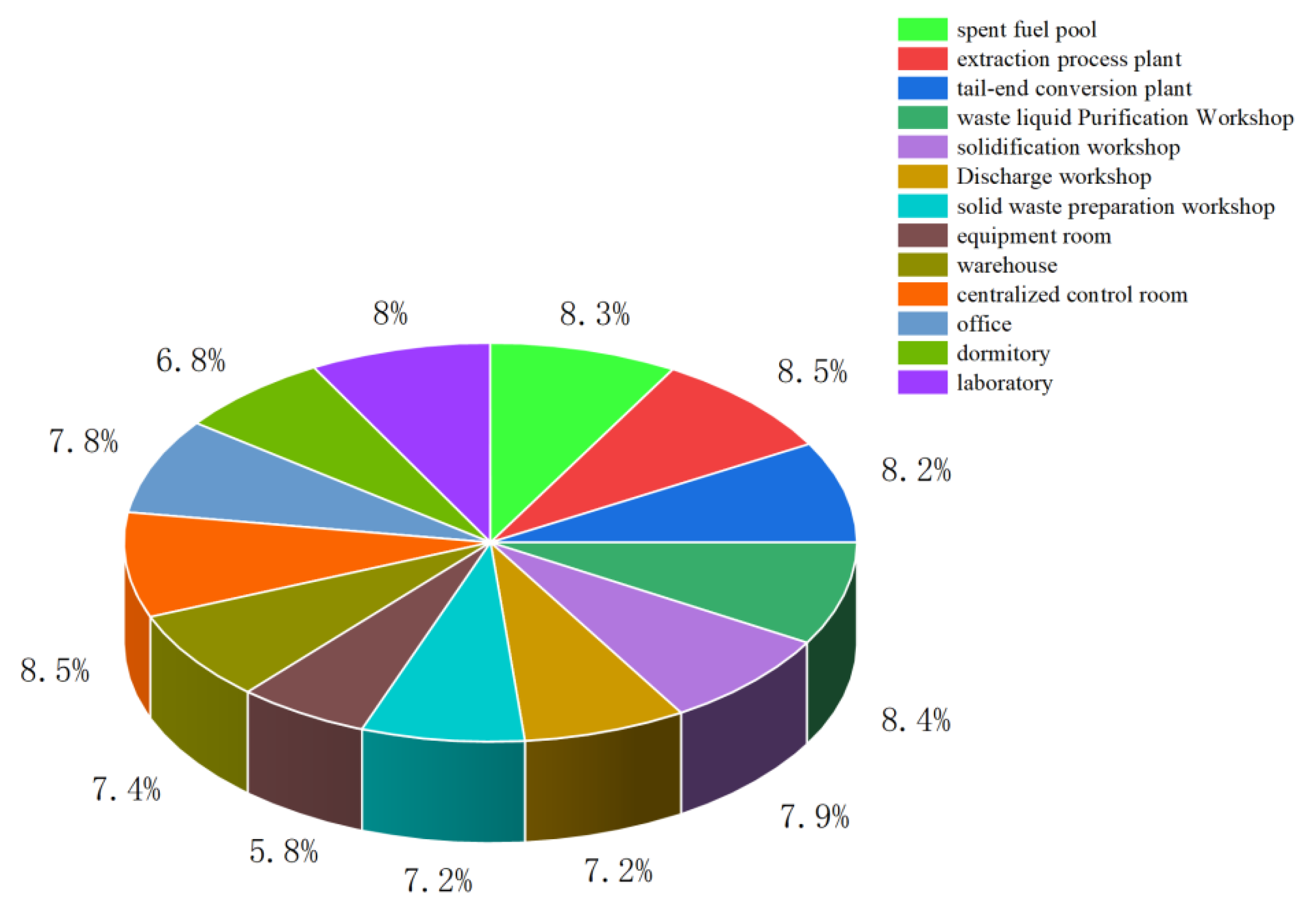

3.6. Fuzzy Comprehensive Evaluation

3.7. Comparison and Verification

4. Optimization of Radiation Source Monitoring for Radiation Events at Each Facility

4.1. Importance Grading

4.2. Monitoring Program

5. Conclusions and Future Works

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ibrahim, M.; Hamdan, S.N.; Haris, M.F.; Sulaiman, M.S.; Aris, S.N.M.; Hasan, M.H.B.; Ab Hamid, A.H. Big data analytics nuclear security framework. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1106, 012026. [Google Scholar] [CrossRef]

- Tolo, S.; Patelli, E.; Beer, M. Risk Assessment of spent nuclear fuel facilities considering climate change. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2017, 3, G4016003. [Google Scholar] [CrossRef]

- Dimitrov, D. Examples of nuclear security measures for nuclear facilities. Secur. Future 2021, 5, 51–54. [Google Scholar]

- Li, R.R. Application of Risk Assessment Grading Method in Accident Analysis of Nuclear Fuel Reprocessing Plant; University of South China: Hengyang, China, 2018. [Google Scholar]

- Rajakarunakaran, S.; Kumar, A.M.; Prabhu, V.A. Applications of fuzzy faulty tree analysis and expert elicitation for evaluation of risks in LPG refuelling station. J. Loss Prev. Process. Ind. 2015, 33, 109–123. [Google Scholar] [CrossRef]

- Wei, C.; Xu, S.; Zou, S.; Zhao, F.; Qin, Z.; Dong, H.; Hou, Z. Risk Analysis and Evaluation of Nuclear Security Radiation Events in Spent Fuel Reprocessing Plants. Sustainability 2022, 15, 781. [Google Scholar] [CrossRef]

- Wu, X.; Hu, F. Analysis of ecological carrying capacity using a fuzzy comprehensive evaluation method. Ecol. Indic. 2020, 113, 106243. [Google Scholar] [CrossRef]

- Sun, M.; Zheng, W.X.; Duan, X.B. Research on Deep Coal Seam Mining Floor Starta Water Bursting Influenced Factors Based on Analytic Hierachy Process. Appl. Mech. Mater. 2014, 608, 737–741. [Google Scholar]

- Xi, J.; Zhao, Y.; Ding, T.; Tian, J.; Li, L. Analysis Model of Risk Factors of Urban Bus Operation Based on FTA-CLR. Adv. Civ. Eng. 2021, 2021, 6657786. [Google Scholar] [CrossRef]

- Robati, M.; Rezaei, F. Evaluation and ranking of urban sustainability based on sustainability assessment by fuzzy evaluation model. Int. J. Environ. Sci. Technol. 2021, 19, 625–650. [Google Scholar] [CrossRef]

- Yucesan, M.; Gul, M. Hospital service quality evaluation: An integrated model based on Pythagorean fuzzy AHP and fuzzy TOPSIS. Soft Comput. 2020, 24, 3237–3255. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, L.; Pan, X.; Wang, Z.; Xu, X. Comprehensive evaluation of cloud manufacturing service based on fuzzy theory. Int. J. Fuzzy Syst. 2021, 23, 1755–1764. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, M. Probabilistic fuzzy comprehensive evaluation method for high-rise building fire risk. China Saf. Sci. J. 2004, 14, 99–103. [Google Scholar]

- Ni, S.; Zou, S.; Chen, J. Evolutionary Game Model of Internal Threats to Nuclear Security in Spent Fuel Reprocessing Plants Based on RDEU Theory. Sustainability 2022, 14, 2163. [Google Scholar] [CrossRef]

- Majewski, M.; Nestler, K.; Veit, D.A.; Diekmeyer, B.; Waldeck, S.; Port, M.; Becker, B.V. Detection of embedded low-level radioactive shrapnel after the explosion of a radiological dispersal device in radiological emergency imaging. Health Phys. 2020, 119, 95–100. [Google Scholar] [CrossRef]

- Hileman, B. Nuclear theft poses growing security threat. Chem. Eng. News 2010, 73, 24–25. [Google Scholar] [CrossRef]

- Cho, H.S.; Woo, T.H. Cyber security in nuclear industry—Analytic study from the terror incident in nuclear power plants (NPPs). Ann. Nucl. Energy 2017, 99, 47–53. [Google Scholar] [CrossRef]

- Solodov, A.; Williams, A.; Al Hanaei, S.; Goddard, B. Analyzing the threat of unmanned aerial vehicles (UAV) to nuclear facilities. Secur. J. 2018, 31, 305–324. [Google Scholar] [CrossRef]

- Busch, N. Risks of Nuclear Terror: Vulnerabilities to Theft and Sabotage at Nuclear Weapons Facilities. Contemp. Secur. Policy 2002, 23, 19–60. [Google Scholar] [CrossRef]

- Wang, F.; Wang, J.; Wang, J.; Li, Y.; Hu, L.; Wu, Y. Risk monitor riskangel for risk-informed applications in nuclear power plants. Ann. Nucl. Energy 2016, 91, 142–147. [Google Scholar] [CrossRef]

- Pękala, B. Uncertainty data in interval-valued fuzzy set theory. In Properties, Algorithms and Applications, Studies in Fuzziness and Soft Computing; Springer: Berlin/Heidelberg, Germany, 2019; Volume 367. [Google Scholar]

- Wan, S.P.; Li, D.F. Fuzzy mathematical programming approach to heterogeneous multiattribute decision-making with inter-val-valued intuitionistic fuzzy truth degrees. Inf. Sci. 2015, 325, 484–503. [Google Scholar] [CrossRef]

- Krejčí, J.; Krejčí, J. Fuzzy set theory. In Pairwise Comparison Matrices and Their Fuzzy Extension: Multi-Criteria Decision Making with a New Fuzzy Approach; Springer: Berlin/Heidelberg, Germany, 2018; pp. 57–84. [Google Scholar]

- Tseng, T.L.; Konada, U.; Kwon, Y. A novel approach to predict surface roughness in machining operations using fuzzy set theory. J. Comput. Des. Eng. 2016, 3, 1–13. [Google Scholar] [CrossRef]

- Dombi, J. Membership function as an evaluation. Fuzzy Sets Syst. 1990, 35, 1–21. [Google Scholar] [CrossRef]

- Chen, S.J.; Hwang, C.L. Fuzzy multiple attribute decision making methods. In Fuzzy Multiple Attribute Decision Making: Methods and Applications; Springer: Berlin/Heidelberg, Germany, 1992; pp. 289–486. [Google Scholar]

| Symbols | Events | Symbols | Events |

|---|---|---|---|

| Nuclear Security Radiation Incidents | Employee Theft | ||

| Loss of Radioactive Sources | Attack | ||

| Radiation Source Leakage | Natural Disaster | ||

| Failure of Regulatory Facilities | Internet Information Events | ||

| Failure of Auxiliary Equipment | Stealing | ||

| Failure of Support Equipment | Employee Injury | ||

| Failure of Monitoring Instruments | Equipment Failure | ||

| Highly Radioactive Liquid Leakage | Fire | ||

| Emergency Response Failure |

| Events/Possibility | Very Small | Small | Single Small | Medium | Single Large | Large | Very Large |

|---|---|---|---|---|---|---|---|

| Employee Theft | 12 | 0 | 3 | 6 | 6 | 0 | 3 |

| Attack | 12 | 3 | 3 | 9 | 3 | 0 | 0 |

| Natural Disaster | 0 | 6 | 6 | 6 | 9 | 3 | 0 |

| Internet Information Events | 3 | 3 | 0 | 6 | 12 | 3 | 3 |

| Stealing | 9 | 0 | 12 | 3 | 6 | 0 | 0 |

| Employee Injury | 3 | 0 | 9 | 6 | 9 | 3 | 0 |

| Equipment Failure | 3 | 0 | 6 | 6 | 6 | 9 | 0 |

| Fire | 6 | 3 | 3 | 6 | 6 | 6 | 0 |

| Basic Events and Their Symbols | Probability | Weight |

|---|---|---|

| Employee Theft (X1) | 2.228 × 10−3 | 0.068 |

| Attack (X2) | 1.033 × 10−3 | 0.032 |

| Natural Disaster (X3) | 4.560 × 10−3 | 0.142 |

| Internet information events (X4) | 7.834 × 10−3 | 0.242 |

| Stealing (X5) | 1.542 × 10−3 | 0.048 |

| Employee Injury (X6) | 4.592 × 10−3 | 0.142 |

| Equipment Failure (X7) | 6.730 × 10−3 | 0.208 |

| Fire (X8) | 3.819 × 10−3 | 0.118 |

| Basic Events and Their Symbols | Probability Importance |

|---|---|

| Employee Theft X1 | 0.998967 |

| Attack X2 | 0.997772 |

| Natural Disaster X3 | 0.000078 |

| Internet information events X4 | 0.000027 |

| Stealing X5 | 0.000035 |

| Employee Injury X6 | 0.000091 |

| Equipment Failure X7 | 0.000038 |

| Fire i | 0.000030 |

| Basic Events and Their Symbols | Critical Importance |

|---|---|

| Employee Theft X1 | 0.682902 |

| Attack X2 | 0.316245 |

| Natural Disaster X3 | 0.000110 |

| Internet Information Events X4 | 0.000067 |

| Stealing X5 | 0.000017 |

| Employee Injury X6 | 0.000129 |

| Equipment Failure X7 | 0.000079 |

| Fire X8 | 0.000036 |

| Number | Evaluation (V) | Fuzzy Possibility Value (S) |

|---|---|---|

| 1 | VS | 0.091 |

| 2 | S | 0.227 |

| 3 | SS | 0.363 |

| 4 | M | 0.500 |

| 5 | SL | 0.636 |

| 6 | L | 0.773 |

| 7 | VL | 0.909 |

| Number | Number of People | Qualification | Length of Service | Education | Score | Weight |

|---|---|---|---|---|---|---|

| 1 | 9 | 5 (Senior Engineers) | 4 (20~30) | 5 (Doctor) | 14 | 0.347 |

| 2 | 6 | 5 (Professor) | 3 (10~20) | 5 (Doctor) | 13 | 0.215 |

| 3 | 6 | 4 (Researcher) | 3 (10~20) | 5 (Doctor) | 12 | 0.198 |

| 4 | 6 | 4 (Intermediate Engineer) | 2 (5~10) | 4 (Doctor) | 10 | 0.165 |

| 5 | 3 | 3 (Assistant Engineer) | 2 (5~10) | 4 (Doctor) | 9 | 0.075 |

| Evaluation Modules | Spent Fuel Pool | Extraction Process Plant | Tail-End Conversion Plant | Waste Liquid Purification Plant | Curing Workshop | Discharge Workshop | Solid Waste Preparation Workshop |

|---|---|---|---|---|---|---|---|

| Result | 0.283 | 0.290 | 0.301 | 0.295 | 0.299 | 0.292 | 0.289 |

| Normalized results | 0.077 | 0.079 | 0.082 | 0.080 | 0.081 | 0.079 | 0.078 |

| Evaluation Modules | Equipment Room | Storehouse | Centralized Control Room | Office Area | Dormitory | Laboratory | |

| Result | 0.342 | 0.276 | 0.201 | 0.262 | 0.301 | 0.262 | |

| Normalized results | 0.092 | 0.075 | 0.054 | 0.071 | 0.082 | 0.070 |

| Importance Interval | (0, 0.070] | (0.070, 0.080] | (0.080, 1] |

|---|---|---|---|

| Monitoring Grades | Grade I | Grade II | Grade III |

| Evaluation Modules | Spent Fuel Pool | Extraction Process Plant | Tail-End Conversion Plant | Waste Liquid Purification Plant | Curing Workshop | Discharge Workshop | Solid Waste Preparation Workshop |

|---|---|---|---|---|---|---|---|

| Grade | III | III | III | III | II | II | II |

| Evaluation Modules | Equipment Room | Storehouse | Centralized Control Room | Office Area | Dormitory | Laboratory | |

| Grade | I | II | III | II | I | III |

| Equipment Types | Reference Models |

|---|---|

| Monitoring of α and β Radiation Surface Contamination | Como170 (Nuvia SEA, Dlmen, Germany) |

| X, γ radiation Surface Contamination Monitoring | FH40G, FHZ672E-10 (Thermo Fisher, Waltham, MA, USA) |

| Pyroelectric Dosimeter | TLD-469 (NAYOU, Shanghai, China) |

| Electronic Dosimeter | GHZ1300 (Xiangting, Hangzhou, China) |

| Individual Dose Class | FN-2000B (FEINUOFEI, Shenzhen, China) |

| TLD-2000B (FEINUOFEI, Shenzhen, China) |

| Monitoring Grade | Test Items | Instrumentation | Monitoring Method |

|---|---|---|---|

| Grade I | Searching for radioactive sources | Mobile Monitoring Vehicle | Patrol along the suspicious path and forward to the designated center through the communication network system. |

| NaI (TI) Roving Spectrometer | |||

| Delineation of pollution control zones | Portable γ Dose Rate Meter | Search measurements are taken in suspicious areas and calculated using the prediction system. When an increase in the dose rate is detected, the location of the radioactive source is determined using methods such as the center of the circle. | |

| Nuclide analysis | Neutron Detector | The boundaries of the contamination control zone are delineated on the basis of radiation exposure | |

| Portable γ Spectrometer | Portable γ-spectrometers and high-performance scintillation neutron detectors have been used for nuclide identification. | ||

| Neutron Detector | |||

| Surface pollution monitoring | Monitoring of α and β Radiation Surface Contamination | Surface contamination meters are used to detect the surface activity on suspected contaminated persons, and surfaces within the contaminated area calculated by the prediction system, as well as on decontaminated surfaces. | |

| X, γ Radiation Surface Contamination Monitoring | |||

| Grade II | Searching for radioactive sources | Mobile Monitoring Vehicle | Patrol along the suspicious path and forward to the designated center through the communication network system. |

| NaI (TI) Roving Spectrometer | |||

| Delineation of pollution control zones | Portable γ Dose Rate Meter | Search measurements are taken in suspicious areas and calculated using the prediction system. When an increase in the dose rate is detected, the location of the radioactive source is determined using methods such as the center of the circle. | |

| Nuclide analysis | Neutron Detector | The boundaries of the contamination control zone are delineated on the basis of radiation exposure. | |

| Portable γ Spectrometer | Portable γ spectrometers and high-performance scintillation neutron detectors have been used for nuclide identification. | ||

| Neutron Detector | |||

| Surface pollution monitoring | Monitoring of α and β Radiation Surface Contamination | Surface contamination meters are used to detect the surface activity on suspected contaminated persons, and surfaces within the contaminated area calculated by the prediction system, as well as on decontaminated surfaces. | |

| X, γ Radiation Surface Contamination Monitoring | |||

| Grade III | Searching for radioactive sources | Mobile Monitoring Vehicle | Patrol along the suspicious path and forward to the designated center through the communication network system. |

| NaI (TI) Roving Spectrometer | |||

| Delineation of pollution control zones | Portable γ Dose Rate Meter | Search measurements are taken in suspicious areas and calculated using the prediction system. When an increase in the dose rate is detected, the location of the radioactive source is determined using methods such as the center of the circle. | |

| Nuclide analysis | Neutron Detector | The boundaries of the contamination control zone are delineated on the basis of radiation exposure. | |

| Portable γ Spectrometer | Portable γ-spectrometers and high-performance scintillation neutron detectors have been used for nuclide identification. | ||

| Neutron Detector | |||

| Surface pollution monitoring | Monitoring of α and β Radiation Surface Contamination | Surface contamination meters are used to detect the surface activity on suspected contaminated persons, and surfaces within the contaminated area calculated by the prediction system, as well as on decontaminated surfaces. | |

| X, γ Radiation Surface Contamination Monitoring |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Li, Q.; Wei, C.; Xu, S.; Zou, S.; Huang, Y.; Lei, Y. Research on Radiation Monitoring Strategy for Spent Fuel Reprocessing Plant Based on Coordination of Nuclear Security Risk and Facility Importance Evaluation. Sustainability 2024, 16, 1495. https://doi.org/10.3390/su16041495

Sun M, Li Q, Wei C, Xu S, Zou S, Huang Y, Lei Y. Research on Radiation Monitoring Strategy for Spent Fuel Reprocessing Plant Based on Coordination of Nuclear Security Risk and Facility Importance Evaluation. Sustainability. 2024; 16(4):1495. https://doi.org/10.3390/su16041495

Chicago/Turabian StyleSun, Meilan, Qingxin Li, Cuiyue Wei, Shoulong Xu, Shuliang Zou, Youjun Huang, and Yang Lei. 2024. "Research on Radiation Monitoring Strategy for Spent Fuel Reprocessing Plant Based on Coordination of Nuclear Security Risk and Facility Importance Evaluation" Sustainability 16, no. 4: 1495. https://doi.org/10.3390/su16041495

APA StyleSun, M., Li, Q., Wei, C., Xu, S., Zou, S., Huang, Y., & Lei, Y. (2024). Research on Radiation Monitoring Strategy for Spent Fuel Reprocessing Plant Based on Coordination of Nuclear Security Risk and Facility Importance Evaluation. Sustainability, 16(4), 1495. https://doi.org/10.3390/su16041495