Abstract

Nanomaterials enhance the performance of both asphalt binders and asphalt mixtures. They also improve asphalt durability, which reduces resource consumption and environmental impact in the long term associated with the production and transportation of asphalt materials. Thus, this paper studies the effectiveness of Nano Calcium Carbonate (Nano CaCO3) and Nano Hydrated Lime (NHL) as modifiers and examines their impact on ranges from 0% to 10% through comprehensive laboratory tests. Softening point, penetration, storage stability, viscosity, and mass loss due to short-term aging using the Rolling Thin Film Oven Test (RTFO) were performed on asphalt binders. Results indicated a significant improvement in binder stiffness, particularly at 4% Nano CaCO3 and 6% NHL content by weight. Dynamic Shear Rheometer (DSR) tests further revealed substantial improvements in rutting resistance, with NHL exhibiting superior high-temperature stability and a notable increase in the rutting factor. Marshall stability tests on asphalt concrete (AC) mixtures showed a 22.3% increase in stability with 6% NHL by weight, surpassing the 20.2% improvement observed with Nano CaCO3 and indicating enhanced load-bearing capacity. The resilient modulus of the mixtures consistently increased with the addition of NHL, suggesting improved durability in rutting. Moisture susceptibility tests revealed that NHL significantly enhances moisture resistance, exceeding the 80% TSR benchmark at just 2% content by weight and reaching an impressive 94.6% at 10% content by weight. In contrast, Nano CaCO3 demonstrated a more gradual improvement, achieving an 88.2% TSR at 10% content. Furthermore, permanent deformation analysis indicated a 68.64% improvement in rutting resistance with 10% NHL content by weight, exceeding Nano CaCO3’s improvement rate. Optimal fatigue resistance was achieved at 4% for Nano CaCO3 and 6% for NHL by weight, with respective CT index improvements of 30% and 35.4%, showing NHL’s consistent benefits across various nanomaterial contents. Overall, the study suggests that both Nano CaCO3 and NHL positively impact asphalt performance, with NHL offering more pronounced benefits across a range of properties. These findings provide valuable insights for pavement engineers and underscore NHL’s potential as an effective additive in asphalt mixture design. Real-world applications and validations are essential for a comprehensive understanding of these nanomaterials in practical pavement engineering scenarios.

1. Introduction

The integration of nanotechnology in pavement engineering, specifically through nano-modifiers like Nano Calcium Carbonate (Nano CaCO3) and Nano Hydrated Lime (NHL), represents a significant advancement in the field [1,2,3]. These nanomaterials have shown potential in addressing key distresses in asphalt pavement concrete, such as moisture damage, rutting, and fatigue cracking. However, despite these advancements, the existing literature reveals a notable gap in fully understanding the impacts of these nanomaterials, especially considering a broad range of dosages and their comprehensive effects on diverse asphalt properties.

While Nano CaCO3 enhances the thermal and mechanical properties of asphalt binders, research efforts like those by [4,5,6,7] predominantly focus on specific improvements in the stiffness and stability of asphalt mixtures. These studies underscore the benefits of Nano CaCO3 in augmenting resistance to deformation and moisture damage. However, they do not extensively explore the optimal range of Nano CaCO3 dosages that would maximize these benefits across various asphalt properties. This gap in understanding the dosage-response relationship limits the potential to fully leverage Nano CaCO3’s capabilities in pavement applications. Additionally, the incorporation of nanomaterials as additives in asphalt mixtures represents a significant innovation in engineering, offering flexible applications for enhancing pavement performance [8,9,10,11].

Similarly, the use of NHL, known for its high surface area and unique particle morphology, has been thoroughly studied in works such as those by [12,13,14,15,16]. These studies highlight the effectiveness of NHL in enhancing moisture resistance and reducing stripping in asphalt mixtures. Additionally, NHL’s role in improving asphalt aging resistance is well-documented, a crucial factor for long-term pavement performance. Despite this, there is a lack of comprehensive analysis in the literature regarding the range of percentage of NHL dosages and their overall impact on both asphalt binders and mixtures. Understanding how varying concentrations of NHL affect multiple aspects of asphalt performance remains an area that needs more exploration. Further, the use of nanomaterials in asphalt mixtures has been increasing in recent years due to their ability to reduce deformations, moisture damage, and low-temperature cracking [17,18].

Moreover, even though Nazari et al. [19] and Shafabakhsh et al. [20] have indicated that Nano CaCO3 and NHL positively influence the rheological properties of asphalt mixtures, a detailed correlation between these rheological changes and field performance is yet to be established. Aljbouri and Albayati [21] research, which extends to a variety of nanomaterials (nano silica, nano clay, nano platelet hydroxyapatite, and nano carbonate calcium), broadens the perspective but also indicates the need for more in-depth study of the Marshall properties and durability of asphalt concrete (AC) mixtures with nanomaterials.

Thus, the current study presents a comprehensive investigation into the effectiveness of Nano CaCO3 and NHL as modifiers. It explores their impact across a wide dosage range (0% to 10%) and encompasses a variety of laboratory tests for both asphalt binders and mixtures. This includes evaluations of penetration, softening point, storage stability, viscosity, and mass loss due to short-term aging using the Rolling Thin Film Oven Test (RTFO) for binders. Additionally, it involves assessments of Marshall properties, resilient modulus, moisture susceptibility, permanent deformation, and fatigue resistance for mixtures.

2. Materials

2.1. Asphalt Cement

The asphalt cement used in the research was obtained from the Dora oil refinery southwest of Baghdad. Its properties are presented in Table 1. The asphalt cement’s performance was evaluated per the Superpave performance grade (PG) requirement. The tests conducted following AASHTO M 320 [22] affirmed that the asphalt cement satisfactorily met the requirements for a PG 64-16.

Table 1.

Physical Properties of Asphalt Cement.

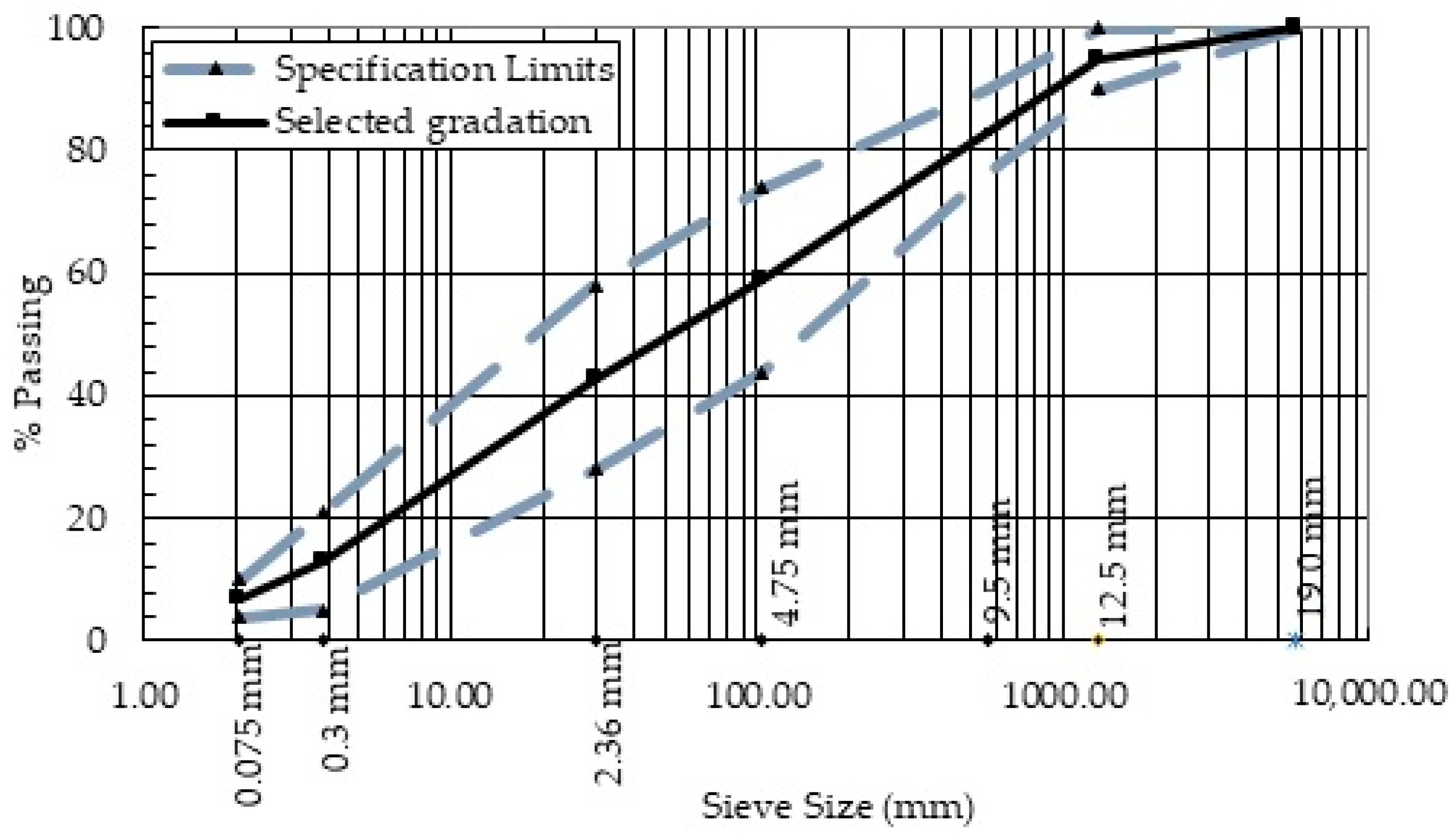

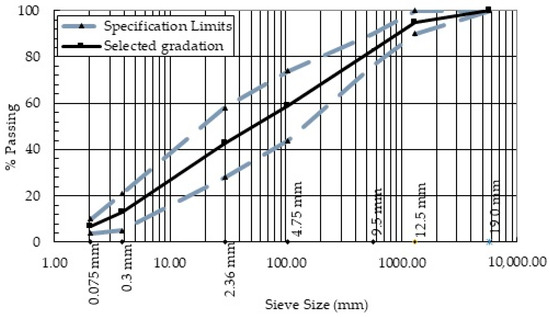

2.2. Aggregates

Crushed quartz aggregates from the Amanat Baghdad AC mix plant in the north of Baghdad were used. Table 2 presents the physical properties of the coarse and fine aggregate fractions and the mineral filler. These components were combined to fulfill the specifications of mix type D-5, as per the ASTM D3515-96 [23] standard for aggregate gradation in bituminous mixtures (Figure 1), commonly used in asphalt surface courses with a nominal maximum aggregate size of 12.5 mm (0.5 inch).

Table 2.

Aggregates physical properties.

Figure 1.

Aggregate gradation.

2.3. Asphalt Cement Modifier

Two calcium-based nanomaterials, Nano CaCO3 and NHL, were utilized to modify asphalt cement. Their properties are detailed in Table 3. Five different content levels were investigated for each modifier, in addition to a control mix (0% modifier): 2%, 4%, 6%, 8%, and 10% by weight of the asphalt binder. To achieve a homogeneous blend of the modified binder, the pre-heated asphalt cement (to 140 °C) was added to the nanomaterial and thoroughly mixed with a shear mixer at 3000 rpm for 15 min.

Table 3.

Chemical composition and physical properties of Nano CaCO3 and NHL.

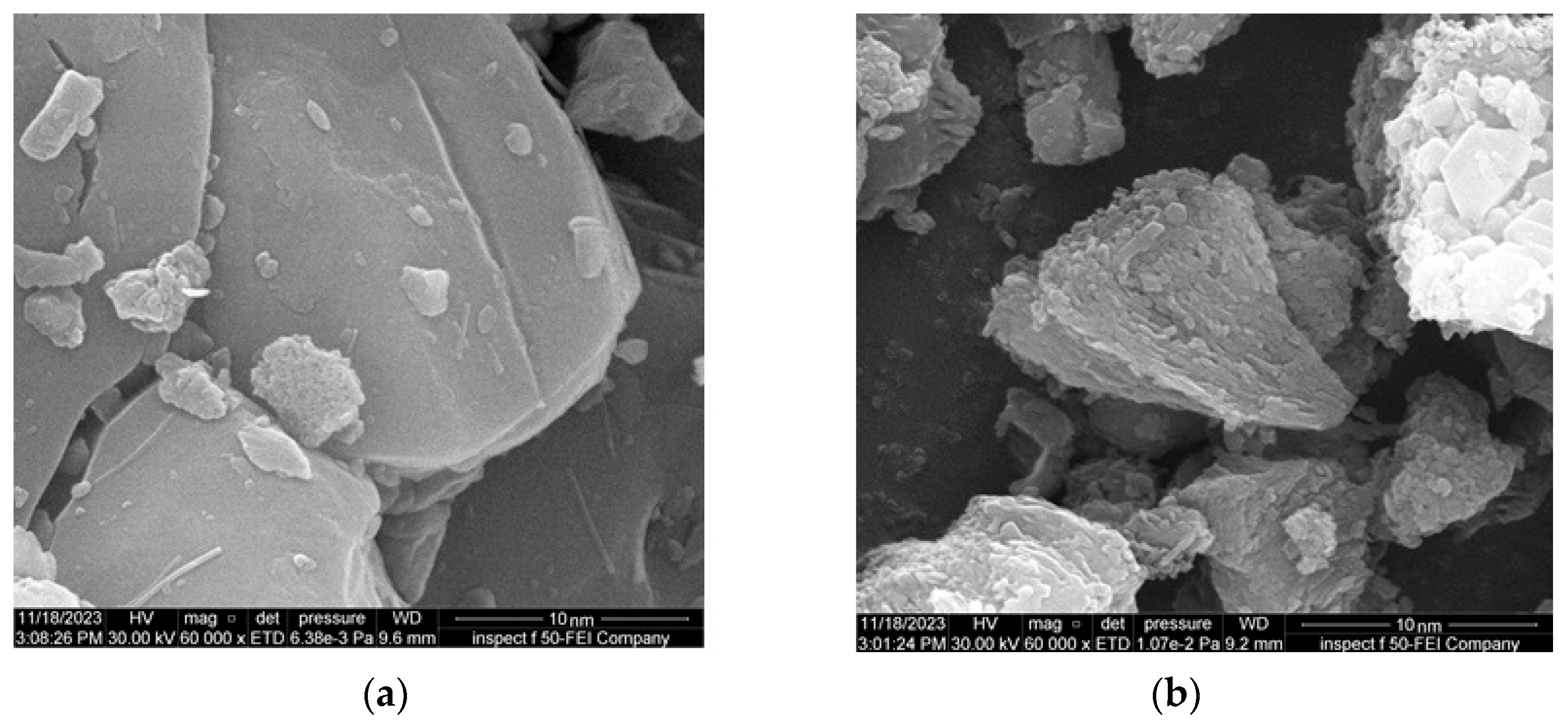

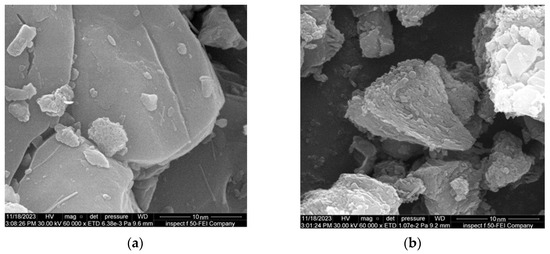

Scanning Electron Microscope (SEM) images at 60,000× magnification, depicted in Figure 2, distinctly highlight the morphological and crystalline differences between Nano CaCO3 and NHL. Nano CaCO3 particles manifest as well-defined, angular shapes with sharp edges and smooth surfaces, reflecting their crystalline mineralogy. Contrastingly, NHL particles appear notably smaller than Nano CaCO3, with surfaces that are rougher and more irregular, featuring visible pits and crevices that suggest a high porosity. The less uniform crystalline form of NHL, typical for calcium hydroxide, potentially offers a greater surface area, thereby increasing its reactivity for various applications. The marked differences in size and structure between these two materials are likely to have significant implications for their interaction and performance when incorporated as modifiers in asphalt cement.

Figure 2.

SEM images of (a) Nano CaCO3 and (b) NHL.

3. Mixing and Testing Methods

3.1. Mixing

Aggregates (gradation depicted in Figure 1) and mineral filler were heated for 6 h in an oven at 150 °C before mixing. Asphalt cement was also heated to 150 °C for 2 h. After heating, aggregates, filler, and asphalt cement were mixed for 2 min using an asphalt mixer. The hot mix was then transferred immediately into the compaction mold and compacted. Prior to compaction, the mold and compaction equipment were pre-heated for 10 min at 110 °C and 140 °C following the Marshall mix design specifications.

3.2. Testing Methods

3.2.1. Binders

Numerous tests were conducted on asphalt binders to assess their performance, adhering to standardized procedures. The Penetration Test (ASTM D5-06, [32]) evaluated the binder’s consistency, while the Softening Point Test (ASTM D36-06, [33]) was a crucial indicator of the binder’s thermal susceptibility. The Rolling Thin Film Oven Test (ASTM D2872-22, [34]) provided an understanding of the volatile content in the binder. The storage stability was assessed as per ASTM D7173-20 [35], examining consistency after storage. Furthermore, the Rotational Viscosity Test (ASTM D4402 [36]) was used to assess the binder’s viscosity at specific temperatures. Finally, the Dynamic Shear Rheometer (DSR) Test (AASHTO T315, [37]) was employed to examine the viscoelastic behavior of both original and nano-modified asphalt. The above tests collectively offer a detailed profile of the asphalt binder’s performance, from workability and aging resistance to thermal and mechanical stability, ensuring the development of high-quality, durable asphalt mixtures.

3.2.2. AC Mixtures

In assessing the performance of AC mixtures, a range of tests was conducted as per established ASTM standards. The Marshall Test (ASTM D6927, [38]) was utilized to evaluate the performance and volumetric properties (%AV, %VMA and %VFA) of AC samples. The theoretical specific gravity of mixtures was assessed per ASTM D2041 [39], and moisture susceptibility was determined per ASTM D4867 [40].

The indirect tensile strength (ITS) test and tensile strength ratio (TSR) testing were conducted at room temperature in cylindrical specimens of 101.6 mm in height and 63 mm in diameter. The air void content of samples ranged from 6% to 8%. They were divided into two sets: ‘dry’ or unconditioned, tested at room temperature (~25 °C), and ‘wet’ or conditioned, submerged in water in a vacuum pressure of 70 kPa or 525 mm Hg for 5 min. Following a freeze–thaw cycle, all samples were subjected to the indirect tensile strength (ITS) test and tensile strength ratio (TSR) testing at room temperature.

Resilient modulus and permanent deformation of cylindrical samples, 101.6 mm (4 in.) in diameter and 203.2 mm (8 in.) in height, were conducted at 20 °C and 40 °C, respectively, following Albayati [41].

Finally, samples of 101.6 mm (4 in.) in height and 63 mm (2.5 in.) in diameter at an air void level of around 7% were subjected to Indirect Tensile Cracking Test (IDEAL-CT) (ASTM D8225, [42]). Each test was performed in triplicate at a constant temperature of 20 °C. The results are presented in a typical load-displacement graph.

4. Mix Design

The optimum asphalt binder content (OABC) for the mixes with neat asphalt was determined using the Marshall mix design method. Five different asphalt contents were tested, between 4.0% and 6.0%, in increments of 0.5% by weight of the total mix. The OABC was determined as the average of three asphalt contents that achieved peak stability, maximum density, and a target %AV of 4%. The Marshall test results for each mix are summarized in Table 4.

Table 4.

Mix design results via the Marshall method.

The calculated OABC was found to be 5.0%. At this content, all other properties, such as flow, VMA, and VFA, were within acceptable limits: flow (2–4 mm), VMA (more than 14%), and VFA (70–85%). It is important to note that the primary objective of this study is to investigate the effects of Nano CaCO3 and NHL on the performance properties of AC mixes. Therefore, a constant optimum asphalt content of 5.0%, as calculated for mixes with neat asphalt cement, was maintained across all mixes rather than optimizing the mix design for each type and percentage of nanomaterial.

5. Results and Discussion

5.1. Binder Properties

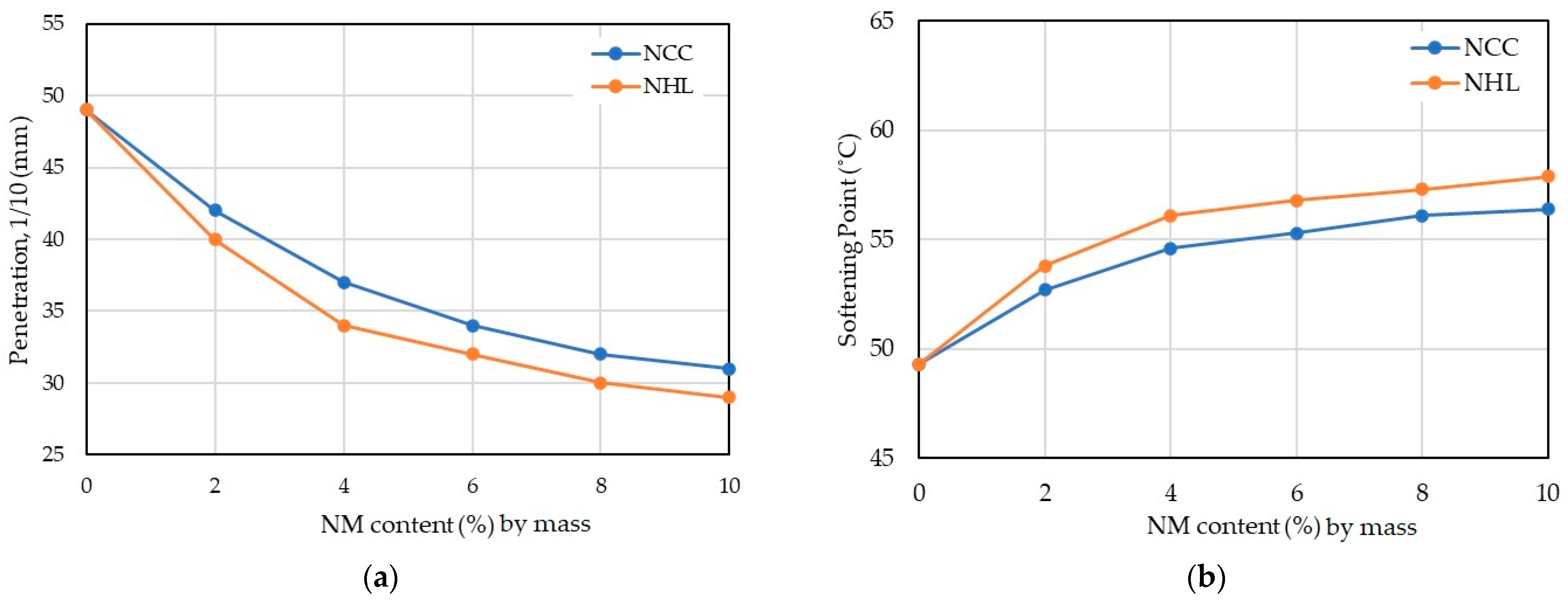

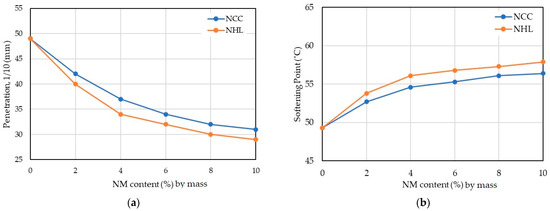

Figure 3 illustrates the effect of Nano CaCO3 and NHL on the basic physical properties, penetration, and softening point. The addition of Nano CaCO3 and NHL significantly affects these fundamental properties. The slope of the line from 0% to 4% for both Nano CaCO3 and NHL appears steeper than from 4% to 10%. This suggests that the initial additions of up to 4% contribute to a faster rate of stiffening in the asphalt binder. The rate of change in penetration decreases beyond 4%, indicating a reduced effectiveness of additional nanomaterial in increasing the binder’s stiffness. With Nano CaCO3, in comparison to neat asphalt cement, the penetration value sees a substantial decrease of approximately 24.49% at a 4% inclusion rate, reducing further to 16.22% as the content increases to 10%. This stiffening effect is even more pronounced with NHL, which reduces the penetration by 30.61% at 4% content and by 14.71% at 10%.

Figure 3.

Effect of Nano CaCO3 and NHL on (a) penetration and (b) softening point.

The softening point exhibits a similar pattern. With Nano CaCO3, there is a 10.75% increase from 0% to 4% content, followed by a moderate 3.30% increase from 4% to 10%. NHL leads to a more considerable softening point rise of 13.79% up to 4% content, with a subsequent 3.21% increase to 10%. The more pronounced effect of NHL on the binder properties could be attributed to its finer particle size and stronger potential for interfacial bonding within the asphalt matrix due to rough surface texture. Similar trends in the modification of asphalt binder properties have been observed in other studies. Azarhoosha and Hamedi [43] noted the effectiveness of NHL in enhancing the physical properties of asphalt binders. Additionally, Mohammed and Abed’s [7] research highlighted the substantial impact of Nano CaCO3 in altering the consistency properties of asphalt cement. These findings align with our observations regarding the pronounced stiffening and alteration in physical properties imparted by NHL and Nano CaCO3, reinforcing the potential of these nanomaterials in asphalt binder modification. The phenomenon of capturing part of the binder by the free spaces in the nanomaterials and the division into ‘free’ and ‘bound’ binders also defines the stiffening of the mixture.

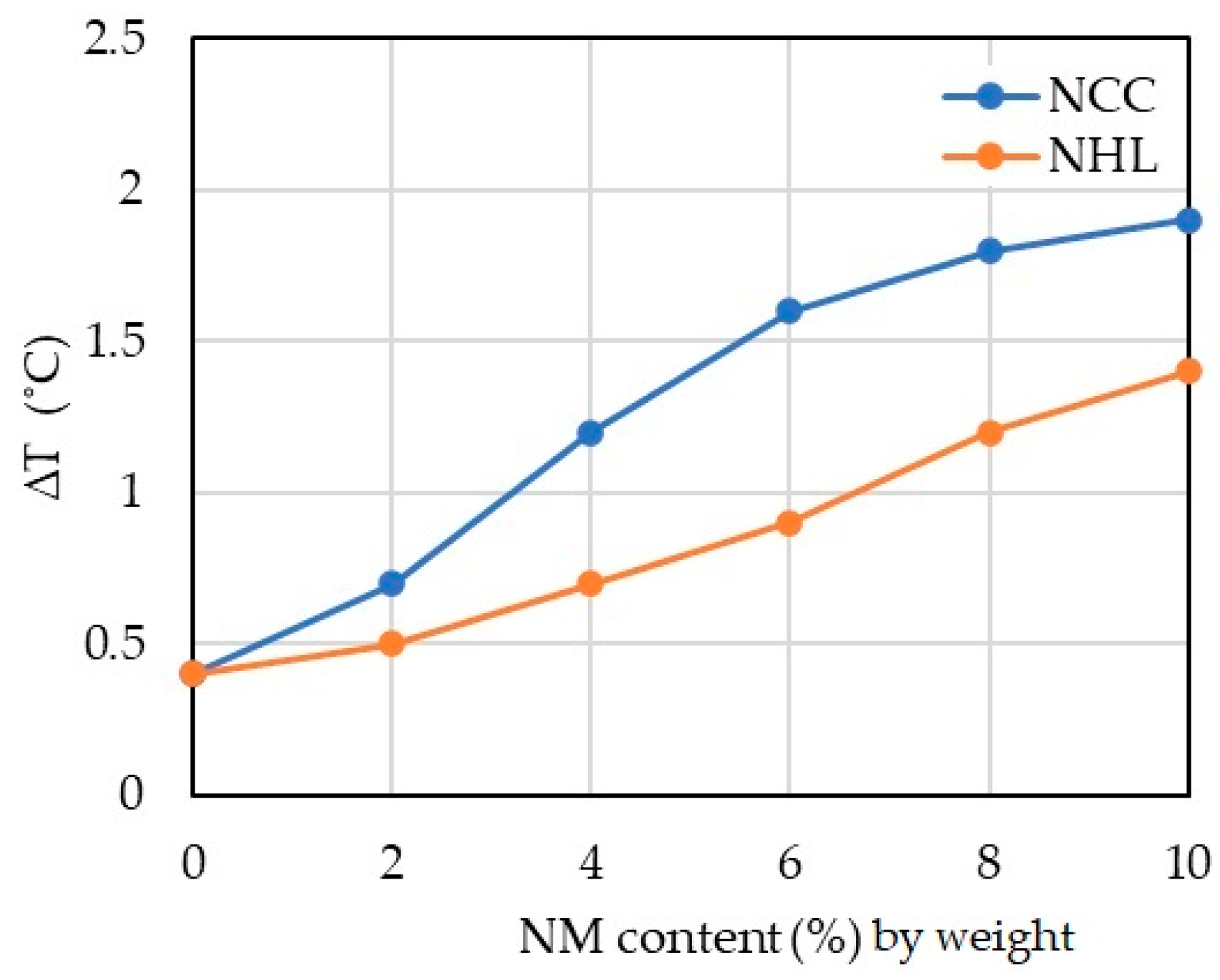

5.2. Compatibility of Modifier

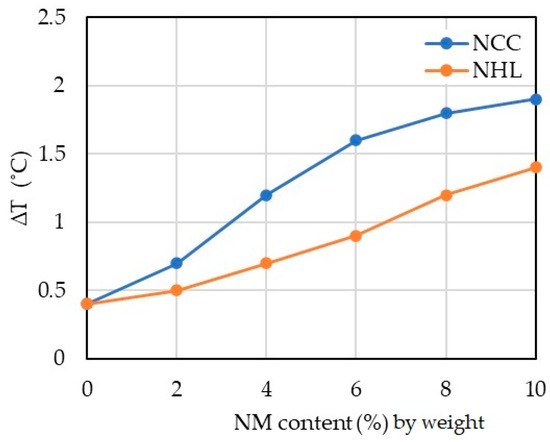

Figure 4 illustrates the results from the storage stability test, reflecting the compatibility of asphalt binders modified with Nano CaCO3 and NHL. The data show that with an increase in NM content, there is a corresponding rise in ΔT values for both modifiers. Notably, the Nano CaCO3-modified asphalt binder exhibits a higher ΔT compared to the NHL-modified binder, suggesting less homogeneity with increasing Nano CaCO3 content. This could be linked to the higher density of Nano CaCO3 (0.67 gm/cm3) in comparison to NHL (0.45 gm/cm3). The greater density of Nano CaCO3 particles may lead to more pronounced settling over time, which could contribute to the observed differences in softening point throughout the binder material. Despite this, the ΔT values, even at higher concentrations of Nano CaCO3, are still within the acceptable range (less than 2.2 °C) for compatibility with the asphalt binder. However, the lower ΔT values associated with NHL suggest better storage stability, indicating that NHL may be a more compatible nanomaterial for maintaining the homogeneity of the asphalt binder during storage in tanks at the mixing plant. The findings regarding the storage stability of Nano CaCO3-modified asphalt binders, as indicated by the rise in ΔT values, align with the trends observed in the studies conducted by Mohammed and Abed [7] and Aljbouri and Albayati [21]. However, it’s noteworthy that there appears to be a lack of similar studies focusing on NHL in the available literature, which suggests that the results on NHL’s storage stability values could offer a new perspective to the field.

Figure 4.

Storage stability test results.

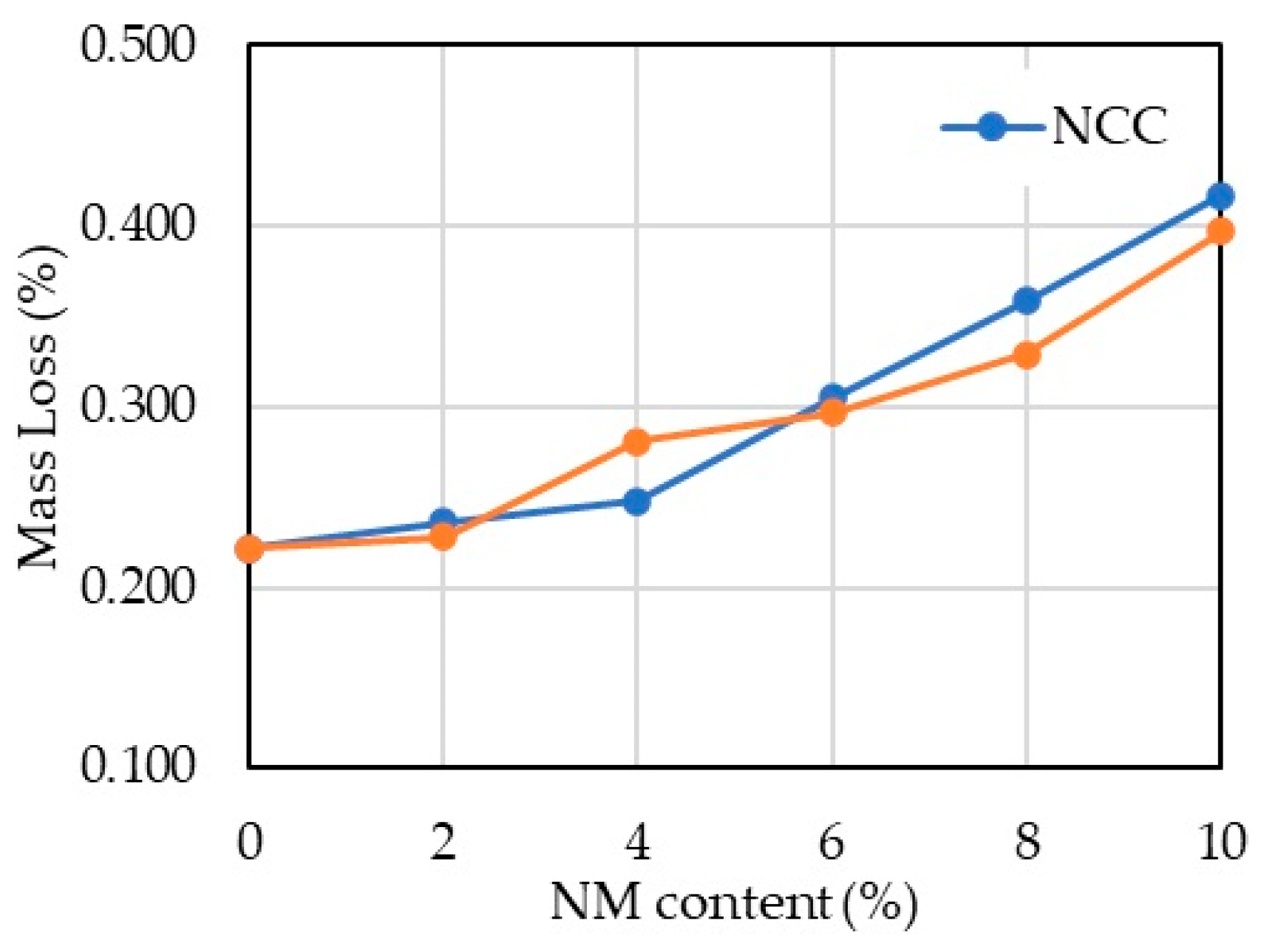

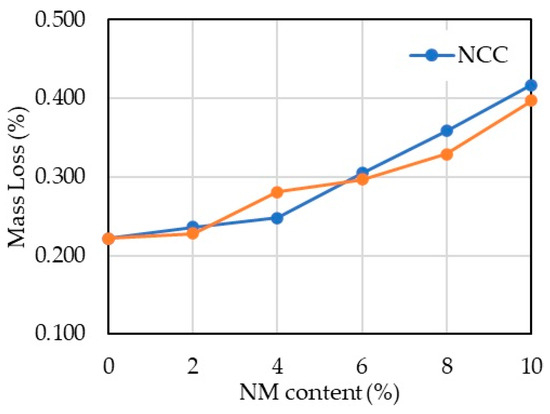

5.3. Mass Loss Due to Ageing

Figure 5 presents the results of mass loss from the Rolling Thin Film Oven (RTFO) test, which evaluates the aging characteristics of asphalt binders modified with Nano CaCO3, and this test simulates the short-term aging process that binders undergo during the production and application of hot mix asphalt. The data depicted in the graph indicate an incremental increase in mass loss as the percentage of nanomaterial (NM) content increases. Starting with no NM, the mass loss of the binder is 0.222%, which rises to 0.417% as Nano CaCO3 content reaches 10%. NHL-modified binders exhibit a similar trend, with mass loss peaking at 0.397% at the same NM content. This rising trend suggests that the inclusion of Nano CaCO3 and NHL affects the binder’s thermal stability, with Nano CaCO3 showing a slightly higher mass loss than NHL at equivalent NM contents (except at 4%), indicating a greater release of volatile substances. Although several pieces of research exist on the addition of Nano CaCO3 and NHL to asphalt binders, results related to mass loss due to RTFO in this literature are limited.

Figure 5.

Results of mass loss due to RTFO.

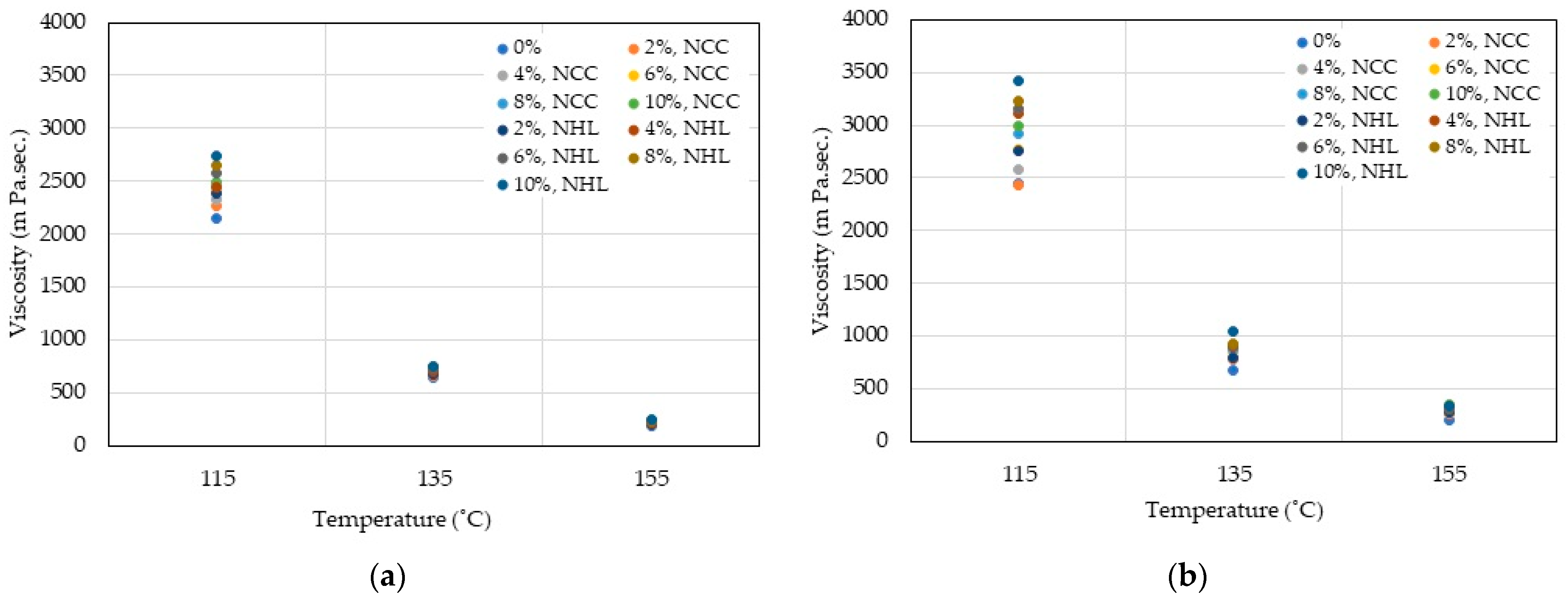

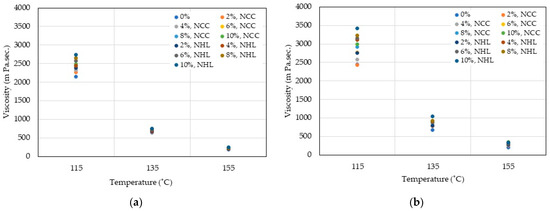

5.4. Binder Workability

Figure 6 depicts the outcomes of evaluating the workability of asphalt binders, as measured by rotational viscosity, both in their original state and after undergoing the Rolling Thin Film Oven (RTFO) test to assess short-term aging effects. These figures demonstrate how the incorporation of nanomaterials—Nano CaCO3 and NHL—affects the viscosity of the binders at three different temperatures: 115 °C, 135 °C, and 155 °C. In the original, unaged state (Figure 6a), a clear increase in viscosity with the addition of Nano CaCO3 and NHL is observed. The viscosity at 115 °C starts at 2154.4 mPa·s for the neat binder and progressively climbs with higher percentages of nanomaterials, reaching up to 2495.3 mPa·s for Nano CaCO3 and 2741.5 mPa·s for NHL at a 10% addition. This pattern is consistent at the highest temperatures, though overall viscosity decreases as temperature increases, demonstrating typical thermodynamic behavior where heat reduces viscosity, enhancing flow.

Figure 6.

Results of rotational viscosity for (a) original binder and (b) after RTFO.

Upon RTFO aging (Figure 6b), the viscosity of all binders increases, reflecting the stiffening effect of short-term thermal exposure. This aging escalates the viscosity values significantly, but even at the highest NM content post-aging, the viscosity remains below the 3000 mPa·s threshold at 135 °C recommended by the Strategic Highway Research Program (SHRP). This suggests that despite the increase in viscosity due to NM addition and aging, all asphalt types retain sufficient flow characteristics at high temperatures, ensuring they can be effectively worked during paving operations.

The workability of the original and aged binders, as indicated by their viscosity, implies an improvement in high-temperature stability with the incorporation of Nano CaCO3 and NHL. Nonetheless, the consistent decrease in viscosity with rising temperatures across all mixes affirms that these binders, even when modified and aged, should maintain adequate workability for typical hot mix asphalt processes. This observation aligns with findings reported by Nazari et al. [19] regarding Nano CaCO3 and Diab and You [44], who noted increased viscosity with high dosages of NHL (up to 20%) used to modify asphalt cement.

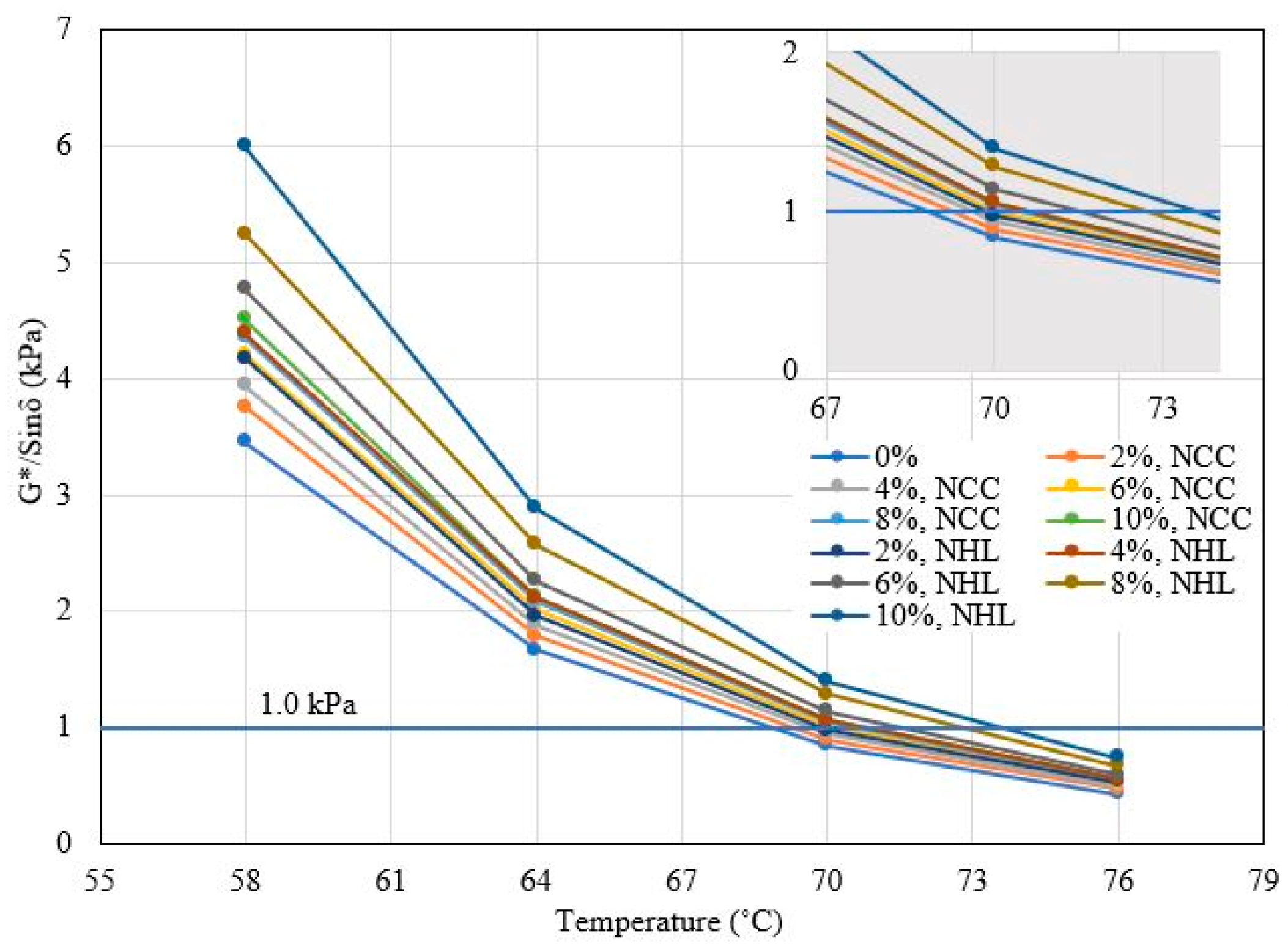

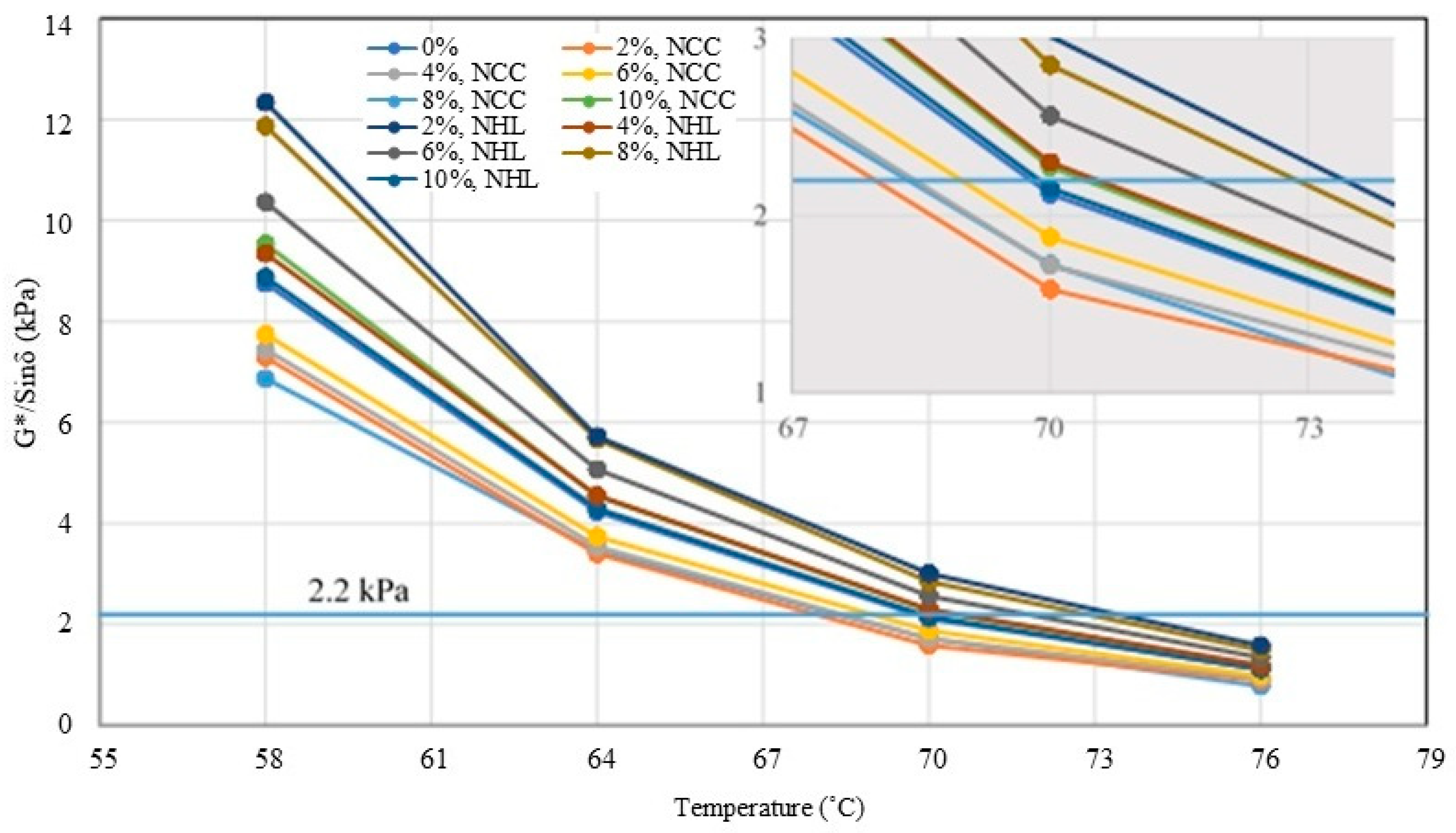

5.5. Binder Rheology

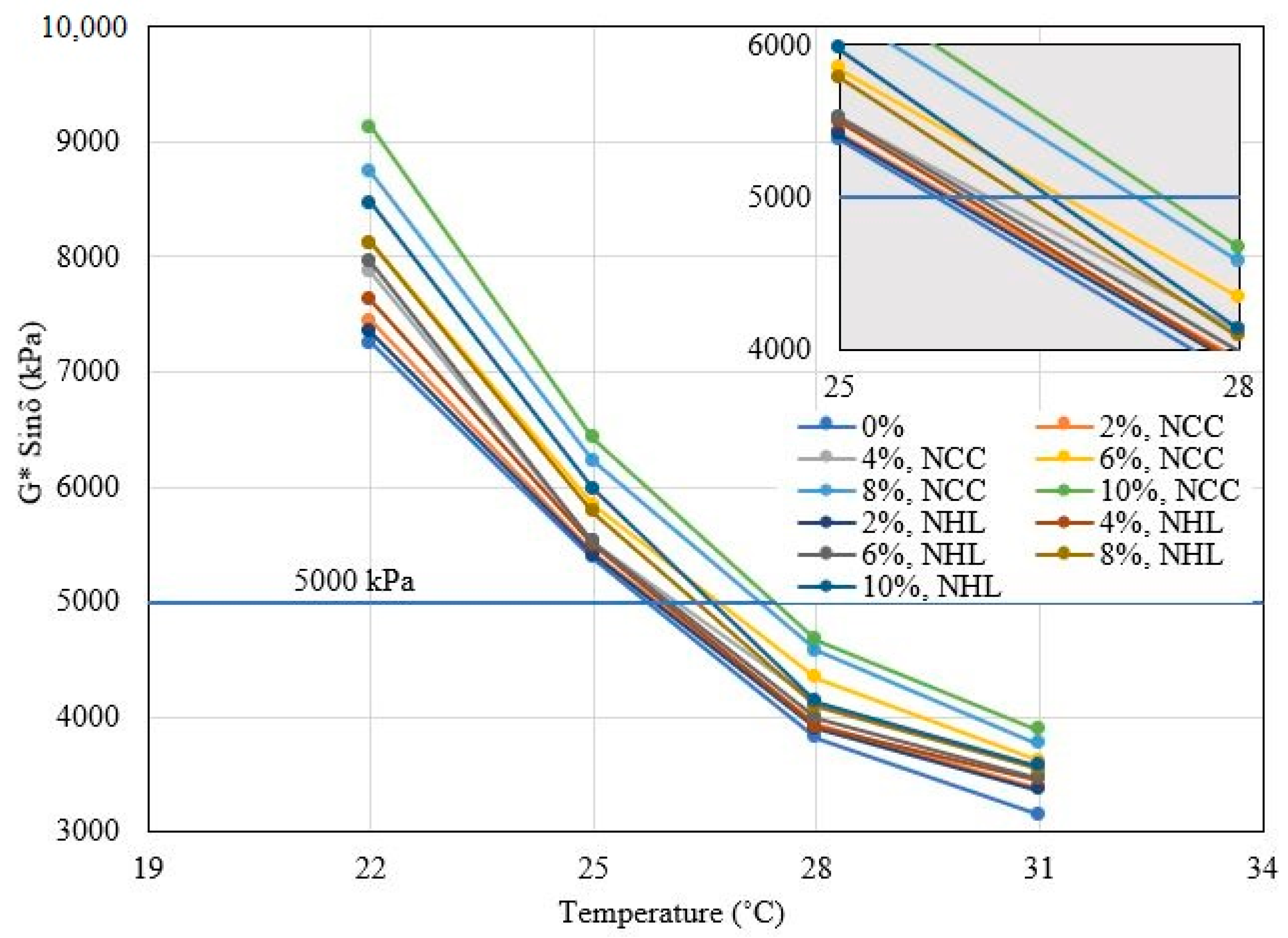

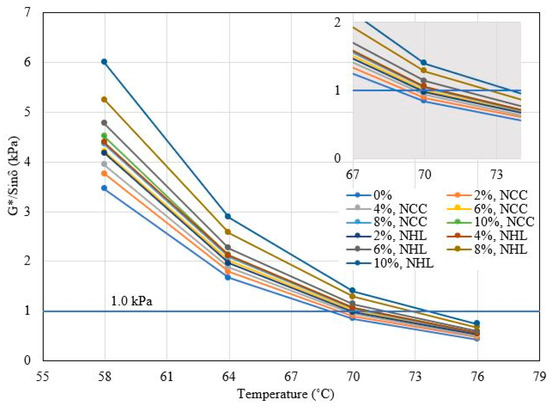

Figure 7, Figure 8 and Figure 9 present the rheological properties of asphalt binders by the conducted Dynamic Shear Rheometer (DSR) tests. As stated in previous sections, the DSR test evaluates the binder’s performance in terms of rutting potential, represented by the rutting factor (G*/sin δ) for the original and RTFO-aged samples, and fatigue resistance, denoted by the fatigue factor (G*/sin δ) after Pressure Aging Vessel (PAV) conditioning. Figure 10 reveals an increase in the rutting parameter G*/sin δ for original binders with Nano CaCO3, where the value rises by approximately 38% at 58 °C when modified with 10% Nano CaCO3. However, NHL shows an even more significant improvement, with a 73% increase under the same conditions, indicating enhanced resistance to permanent deformation. On the other hand, considering the limit of rutting factor with a minimum of 1 kPa, it is obvious the 10% Nano CaCO3 and NHL can extend the failure temperature from 69 °C (for neat asphalt) to 71 °C and 74 °C, respectively.

Figure 7.

Results of DSR of the original binder.

Figure 8.

Results of DSR after RTFO.

Figure 9.

Results of DSR after PAV.

Figure 10.

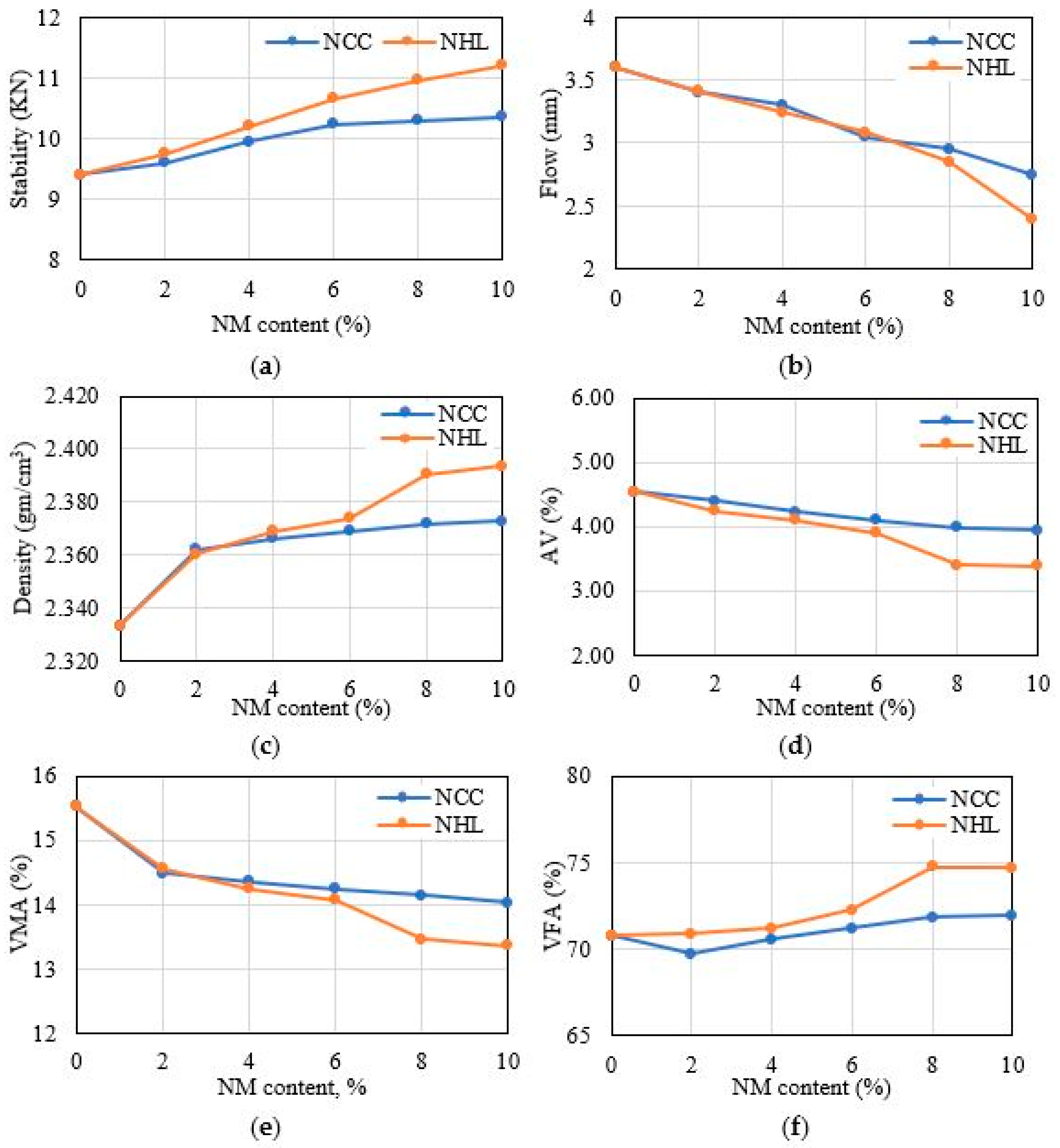

Effect of Nano CaCO3 and NHL on Marshall Properties. (a) Stability. (b) Flow. (c) Density. (d) AV. (e) VMA. (f) VFA.

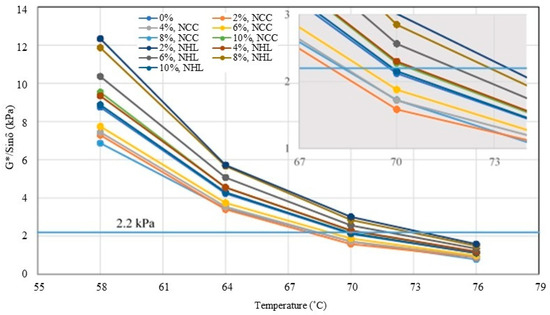

After RTFO aging, as depicted in Figure 8, both Nano CaCO3 and NHL show increased rutting resistance, but NHL-modified binders exhibit a more robust response. For instance, at 58 °C, binders with 10% NHL show an increase in G*/sin δ by nearly 80% compared to the unmodified binder, signifying a substantial improvement in high-temperature stability and a potential for better performance in resisting traffic-induced rutting.

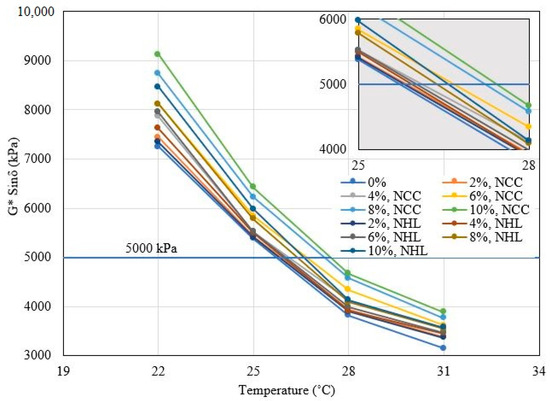

Figure 9’s post-PAV aging DSR results suggest that binders modified with Nano CaCO3 and NHL have a marginally lower resistance to fatigue cracking compared to the neat asphalt binder due to their increased stiffness, as indicated by higher G* sin δ values. The fatigue factor for the unmodified binder crosses the critical 5000 kPa threshold at approximately 25.5 °C. For binders with 10% Nano CaCO3 and NHL, the intersection with this limit occurs at higher temperatures, around 26 °C and 27 °C, respectively, which implies a slightly elevated risk of fatigue cracking. Yet, these findings, when viewed in the context of binder behavior alone. The characteristics of the mixture, including aggregate interlock, binder distribution, and voids in the mineral aggregate, might offset the effects of increased binder stiffness. Within the complex matrix of an asphalt mixture, these properties can interact to potentially neutralize the risk of fatigue cracking suggested by binder tests. In terms of rutting resistance, these findings align with those of Nazari et al. [19], who investigated the use of Nano CaCO3, and Diab and You [44], who focused on NHL. Both studies also reported an inverse effect on fatigue resistance. However, our results contrast with those of Azarhoosha and Hamedi [43], who examined NHL and observed different fatigue behaviors. While there is a consensus on improved rutting resistance with both Nano CaCO3 and NHL, the varying impacts on fatigue resistance underscore the complex influence of these nanomaterials on asphalt binder rheology.

5.6. Mixture Performance with Modified Binder

5.6.1. Marshall Properties

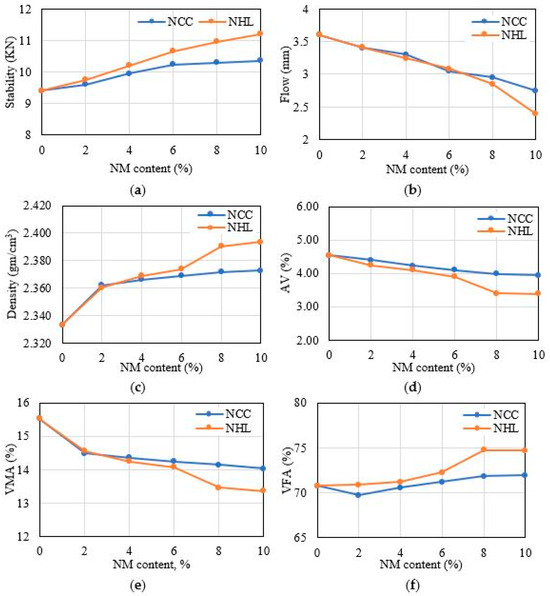

The Marshall properties of AC mixtures incorporating Nano CaCO3 and NHL reveal distinctive trends in performance as the nanomaterial content increases, as displayed in Figure 10. Analysis at a 6% nanomaterial inclusion level reveals that Nano CaCO3 enhances the stability of the mix by approximately 8.83%, while NHL provides a more substantial increase of 13.3% relative to mixtures without any nanomaterials. Upon increasing the nanomaterial content to 10%, the stability improvements for Nano CaCO3 and NHL are 10.11% and 19.15%, respectively.

The flow values, indicative of the mixture’s resistance to deformation, decrease with the addition of nanomaterials, suggesting a rise in binder stiffness. However, this decrease does not compromise the mix’s workability, as the flow remains within the acceptable range of 2–4 mm. Density trends upward for both Nano CaCO3 and NHL, with a marked increase for NHL at and beyond 6% content, pointing to better compaction and cohesion within the mixture.

The inclusion of Nano CaCO3 and NHL also leads to a reduction in air voids (AV), with NHL showing a more significant decline. However, with a 6% inclusion of NHL, voids in mineral aggregate (VMA) drop below the preferred threshold of 14%, potentially indicating over-compaction. In contrast, NHL markedly betters the voids filled with asphalt (VFA) more than Nano CaCO3, underscoring its superior ability to ensure that the binder permeates the aggregate voids effectively. The increased VFA and reduced AV at higher nanomaterial contents suggest that NHL is especially adept at replacing air with a binder in the mixture, thus enhancing the potential for improved durability of AC pavement.

5.6.2. Resilient Modulus Results

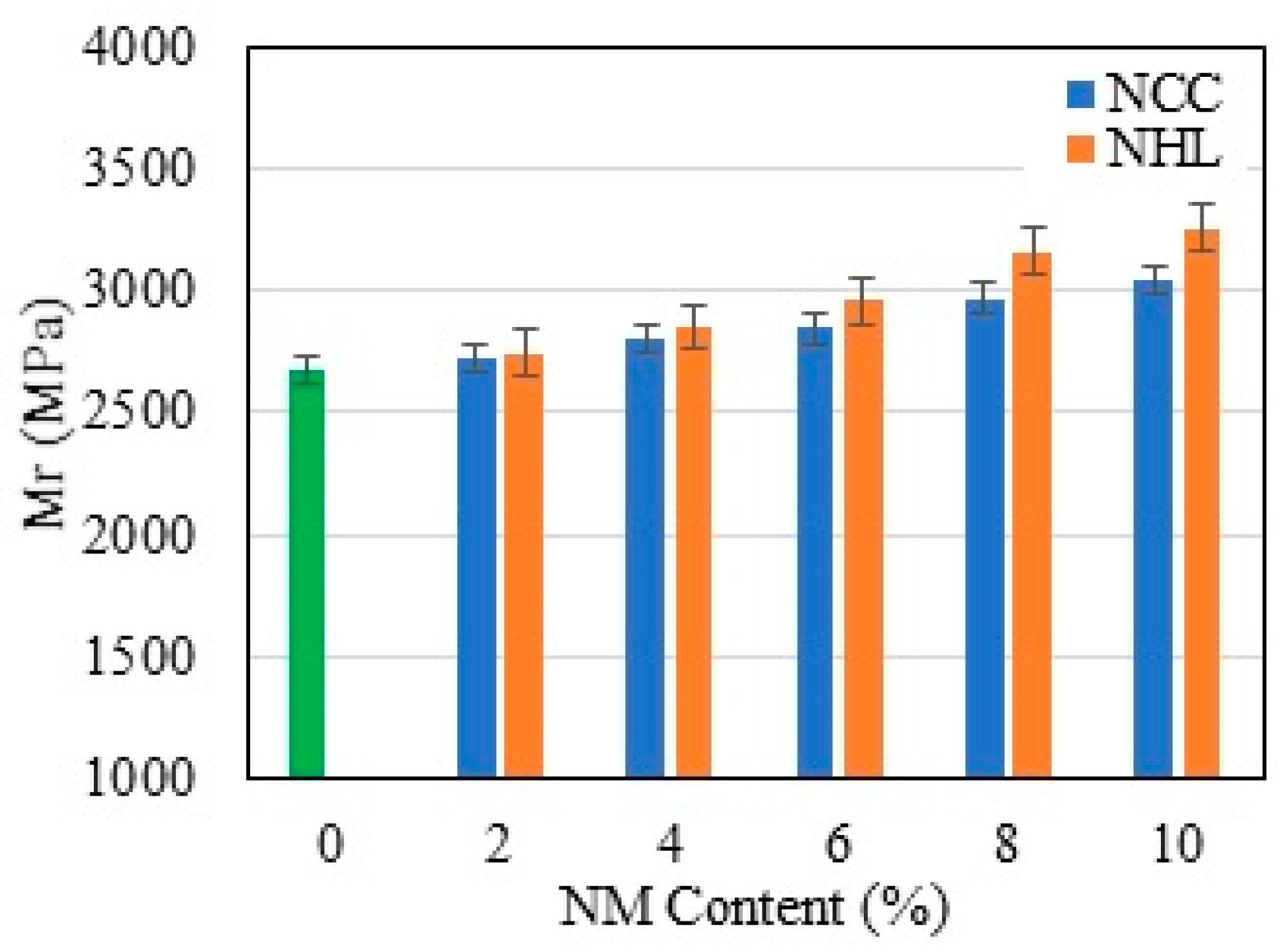

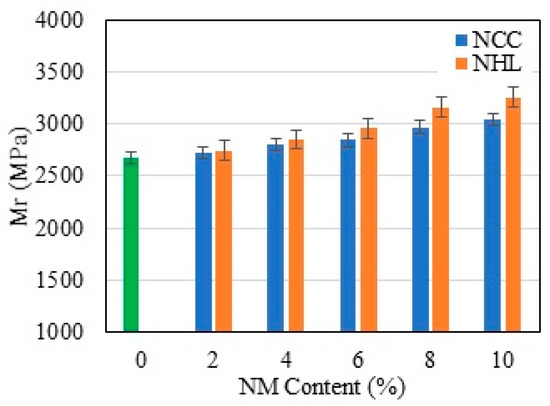

The data presented in Figure 11 reflect the effect of Nano CaCO3 and NHL on the resilient modulus (Mr) of asphalt mixtures at 20 °C. Starting with baseline Mr of 2680.28 MPa without any nanomaterial content. Upon the addition of Nano CaCO3, there is a moderate rise in Mr, reaching 3048.33 MPa at a 10% inclusion rate. This increment represents a gradual strengthening effect of Nano CaCO3 on the asphalt mix, pointing to a mixture that can better recover from deformation due to traffic loading.

Figure 11.

Effect of Nano CaCO3 and NHL on resilient modulus at 20 °C.

Similarly, NHL exhibits a more pronounced influence on the resilient modulus. Starting at the same base Mr, NHL-modified mixtures show an enhanced modulus at each level of content, surpassing Nano CaCO3 at 6% content and beyond. The NHL mixtures reach an Mr of 3254.37 MPa at a 10% inclusion rate, demonstrating a more substantial stiffening effect than Nano CaCO3. This increasing trend in Mr with the addition of nanomaterials indicates that both Nano CaCO3 and NHL enhance the elastic response of the asphalt mixtures. Notably, NHL-modified mixtures show a more significant increase in Mr, suggesting that NHL offers superior performance in terms of increased stiffness and durability.

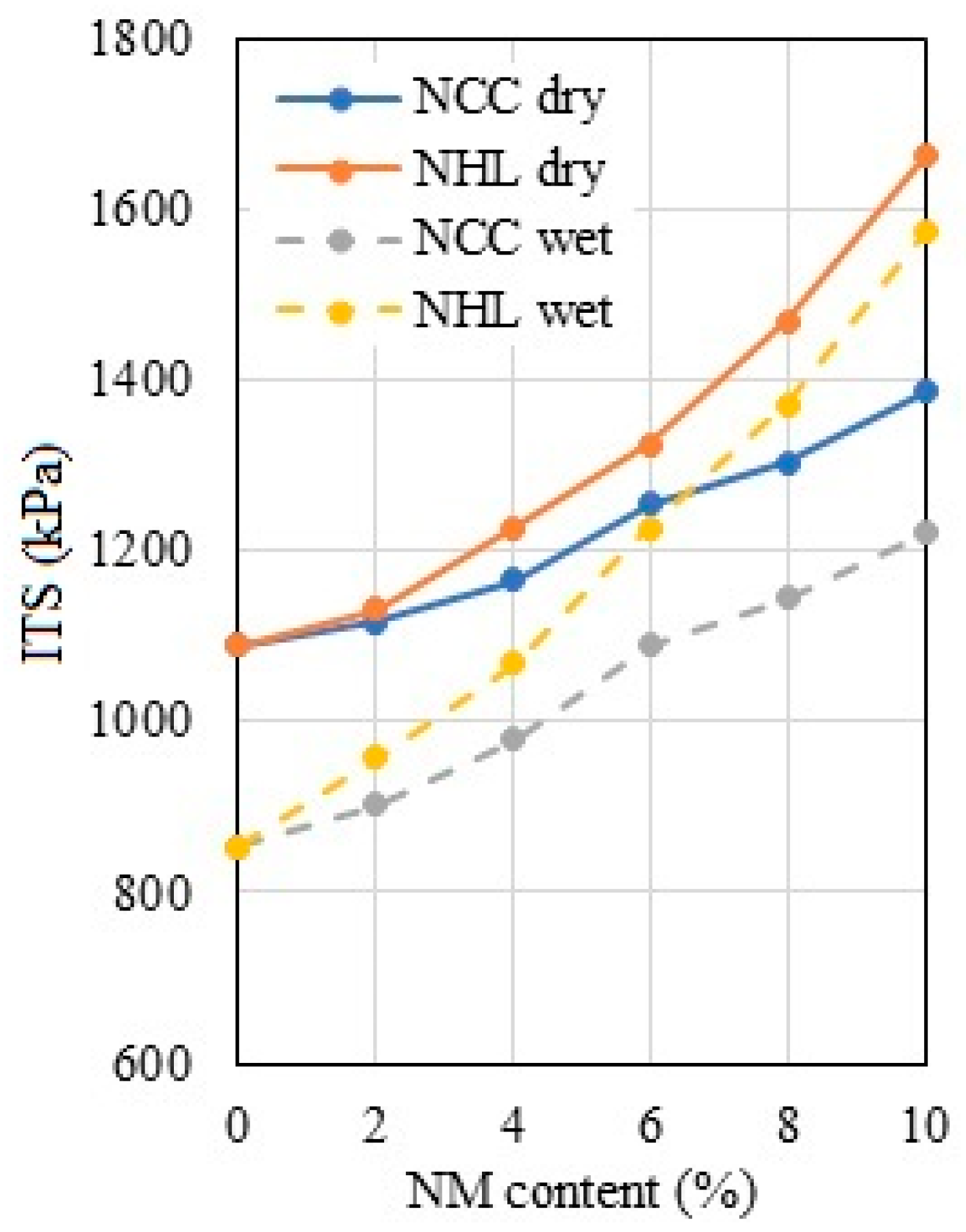

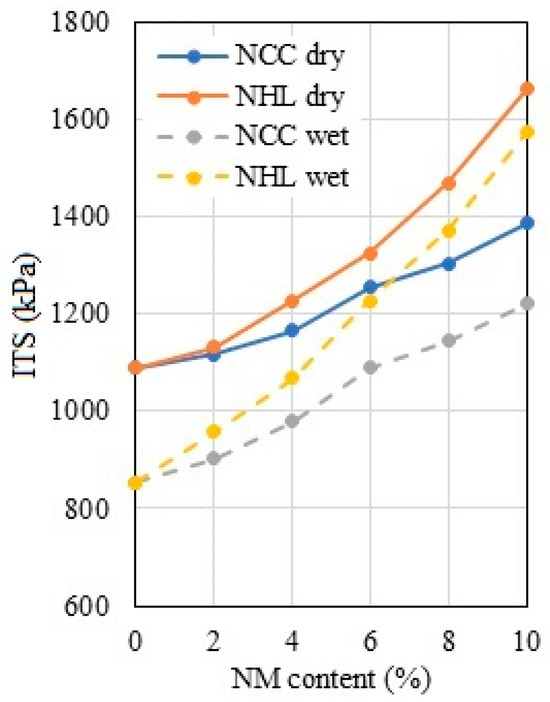

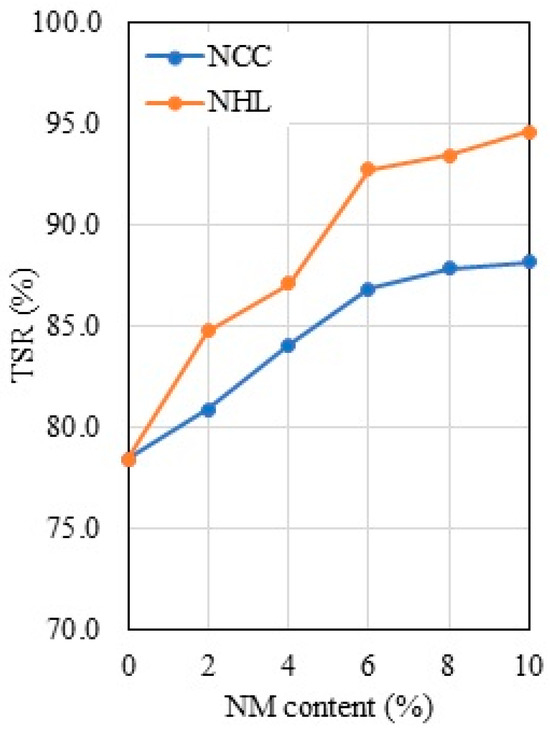

5.6.3. Moisture Susceptibility Results

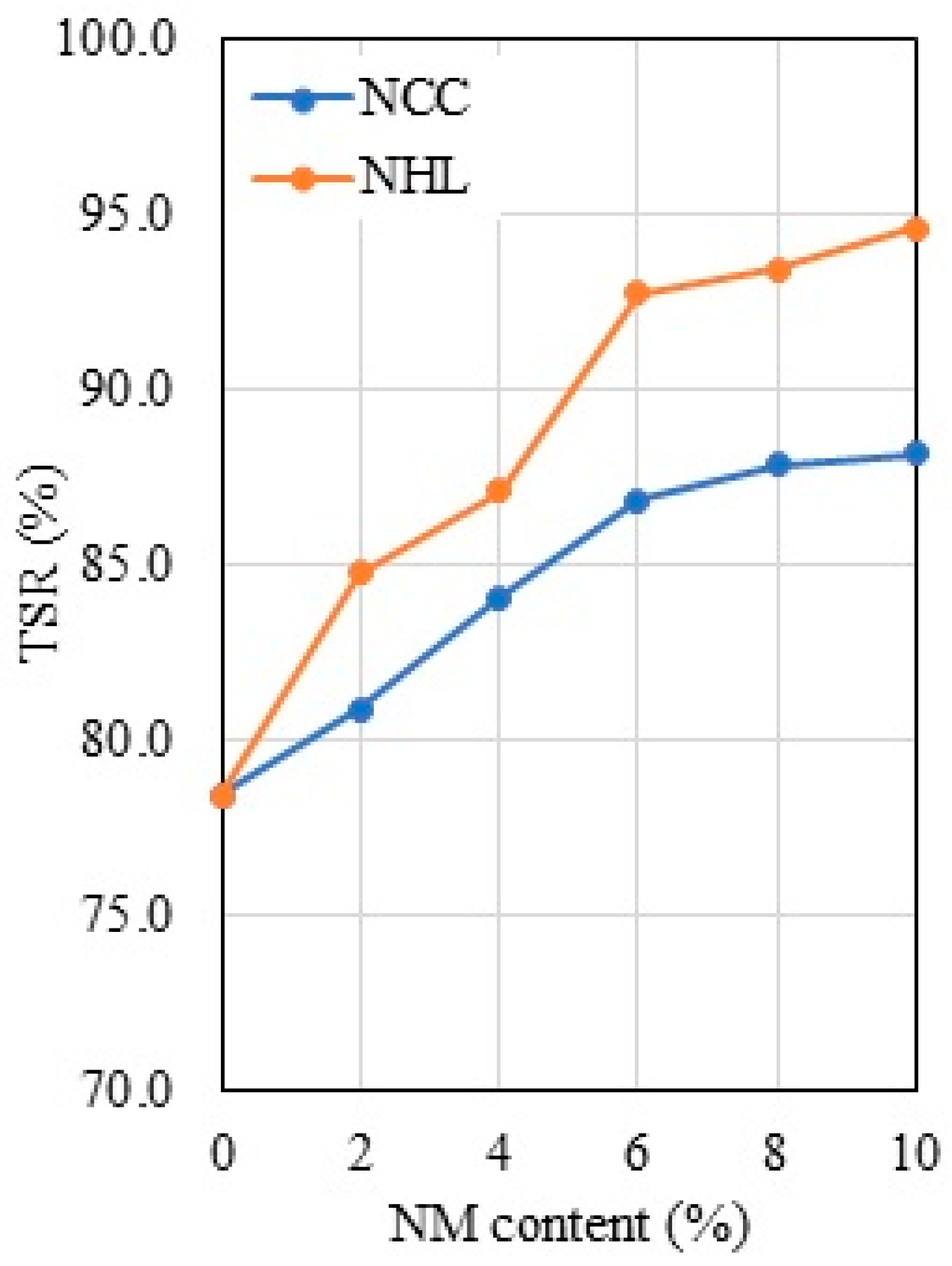

The use of Nano CaCO3 and NHL improves the moisture resistance of AC, as shown in Figure 12 and Figure 13. NHL significantly increases both the dry and wet indirect tensile strength (ITS), with notable improvements up to 6% NM content. Beyond this point, the rate of ITS increase for Nano CaCO3 begins to stabilize while NHL continues to strengthen the mix. Compared to mixes with neat asphalt, the ITS dry improvement rates for Nano CaCO3 mix at 6% and 10% are 15.1% and 27.2%, respectively, while for NHL, they are 21.5% and 52.5%. For ITS wet, the improvements are 27.5% and 43% for Nano CaCO3 and 43.6% and 84% for NHL, respectively. Regarding moisture damage resistance, NHL exceeds the 80% tensile strength ratio (TSR) threshold at just 2% NM content, indicating superior moisture resistance, whereas Nano CaCO3 progresses more slowly in reaching this standard. Overall, NHL proves to be more effective in enhancing the moisture damage resistance of AC mixtures, likely due to its increased binder stiffness, which in turn may improve binders’ cohesion and adhesion properties.

Figure 12.

Effect of NM on ITS.

Figure 13.

Effect of NM on TSR.

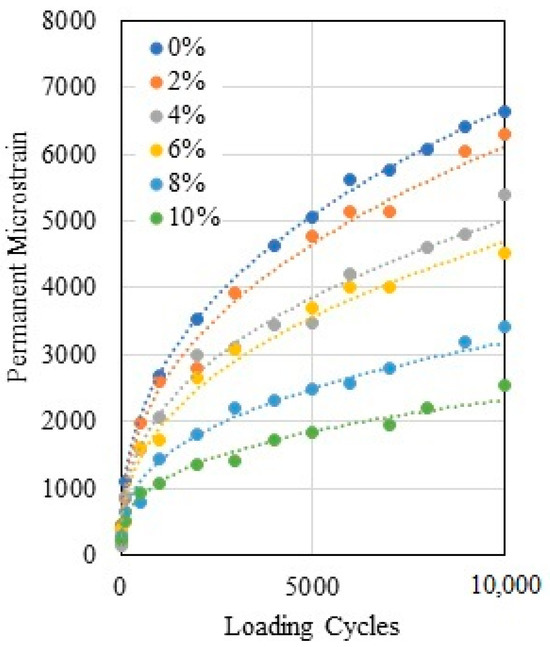

5.6.4. Permanent Deformation Results

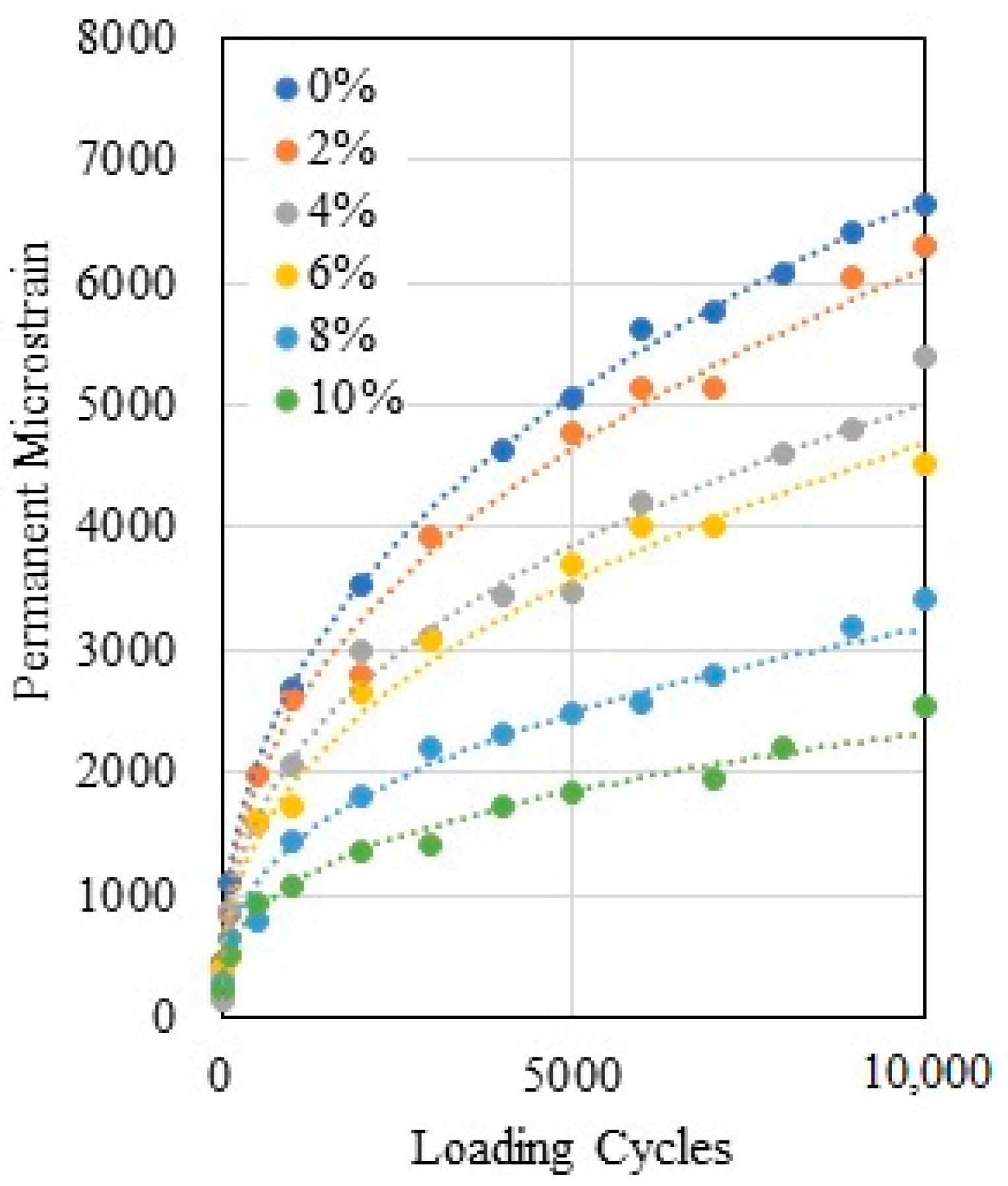

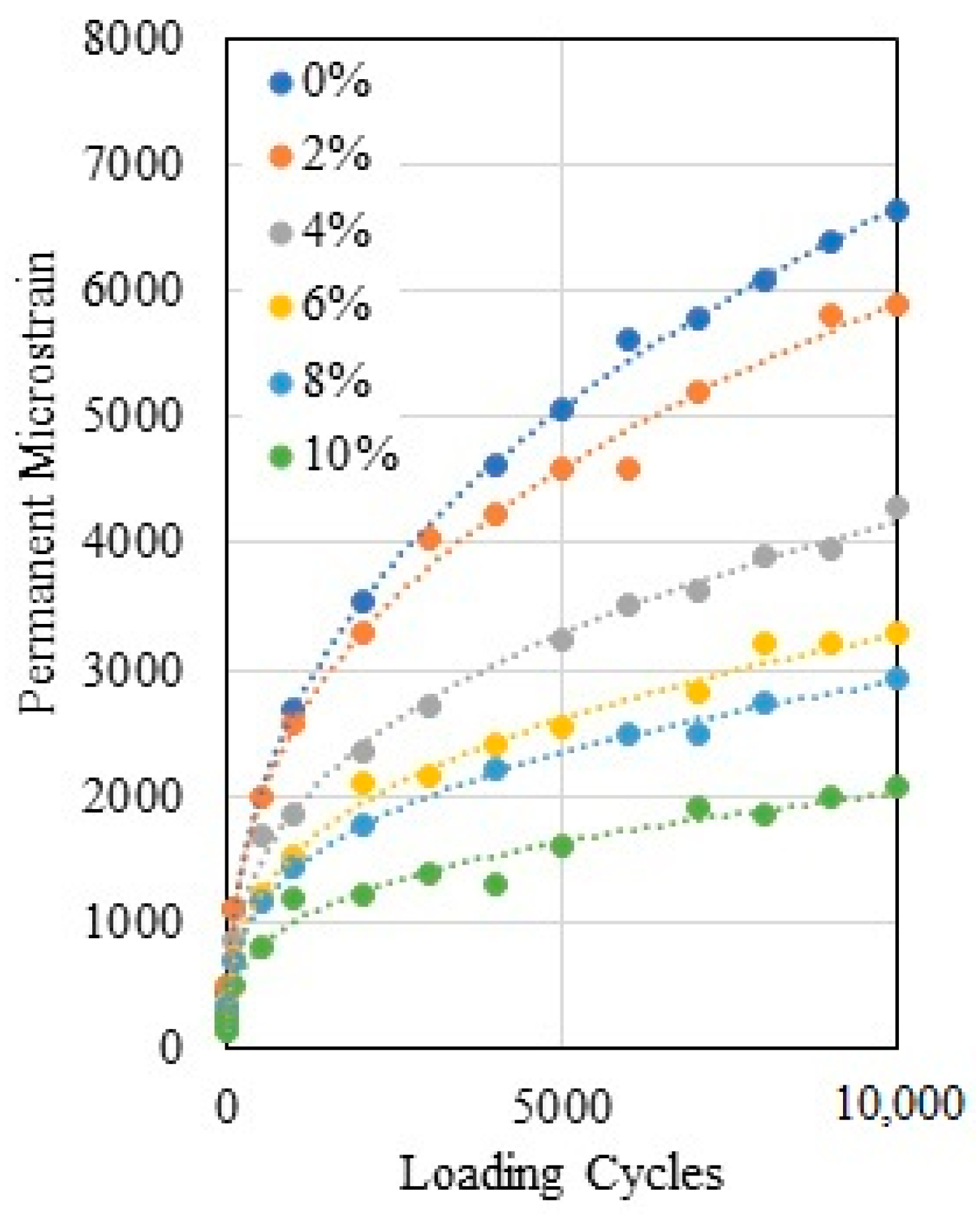

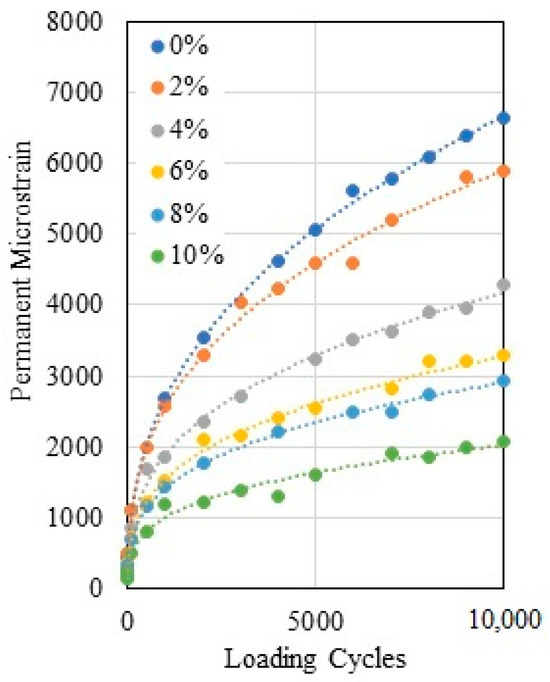

The performance of AC mixtures modified with Nano CaCO3 and NHL in terms of permanent deformation is illustrated in Figure 14 and Figure 15, respectively. A comparison of permanent strain against loading cycles for various nanomaterial (NM) contents shows that permanent deformation decreases with the increasing content of both Nano CaCO3 and NHL. For a clear numerical comparison, power fitting on a logarithmic scale delineates the data with straight lines characterized by an intercept (a), indicating the initial permanent strain, and a slope (b), representing the rate of strain accumulation through successive load applications. The parameters ‘a’ and ‘b’, along with the permanent strain (εp) at the 1000th load cycle, measure the mixture’s resistance to permanent deformation; lower values indicate enhanced rutting resistance. All parameters are exhibited in Table 5. The analyzed data reveal that both Nano CaCO3 and NHL contribute to a decrease in permanent deformation parameters. For Nano CaCO3, the intercept ‘a’ drops from 198 at 0% NM to 110 at 10% NM content, and the slope ‘b’ from 0.3916 to 0.331, reflecting a decrease in the strain accumulation rate. Similarly, NHL shows a reduction in intercept from 198 to 125 and in slope from 0.3622 to 0.3001 over the same NM range. At 6% NM, NHL shows an improvement rate in (εp) of 50.24%, indicating a significant increase in rutting resistance. This improvement is more pronounced at 10% NM, where NHL achieves an (εp) improvement rate of 68.64%. On the other hand, Nano CaCO3’s improvement rates are 31.8% at 6% NM and 61.8% at 10% NM. These findings highlight that the added NHL to AC mixtures not only reduces the rate of permanent deformation but also improves the mix’s overall structural stability more effectively than Nano CaCO3. The results underscore NHL’s potential as a superior modifier for enhancing the durability of pavement structures.

Figure 14.

Effect of Nano CaCO3 on permanent deformation at 40 °C.

Figure 15.

Effect of NHL on permanent deformation at 40 °C.

Table 5.

Effect of NM on Permanent Deformation Parameters.

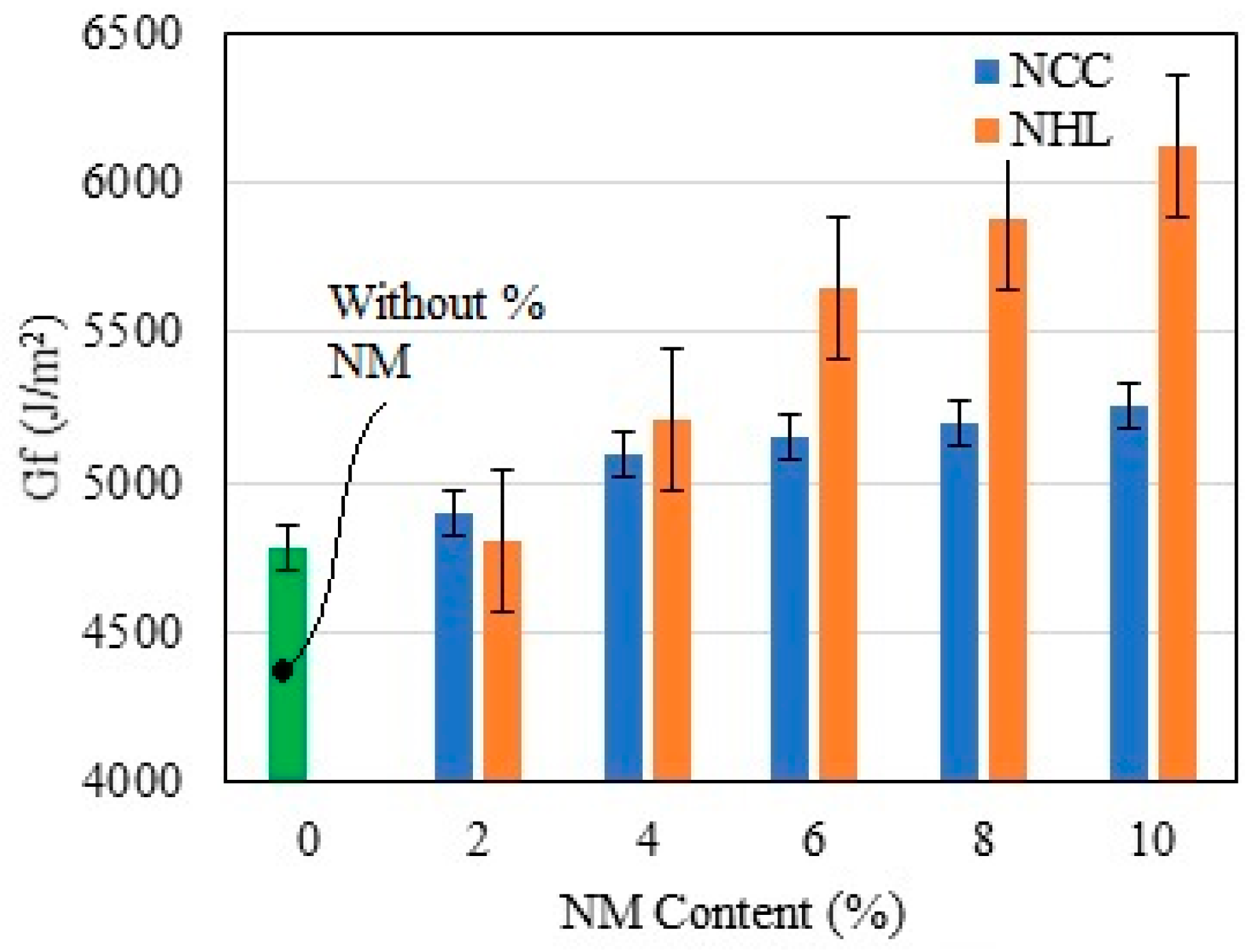

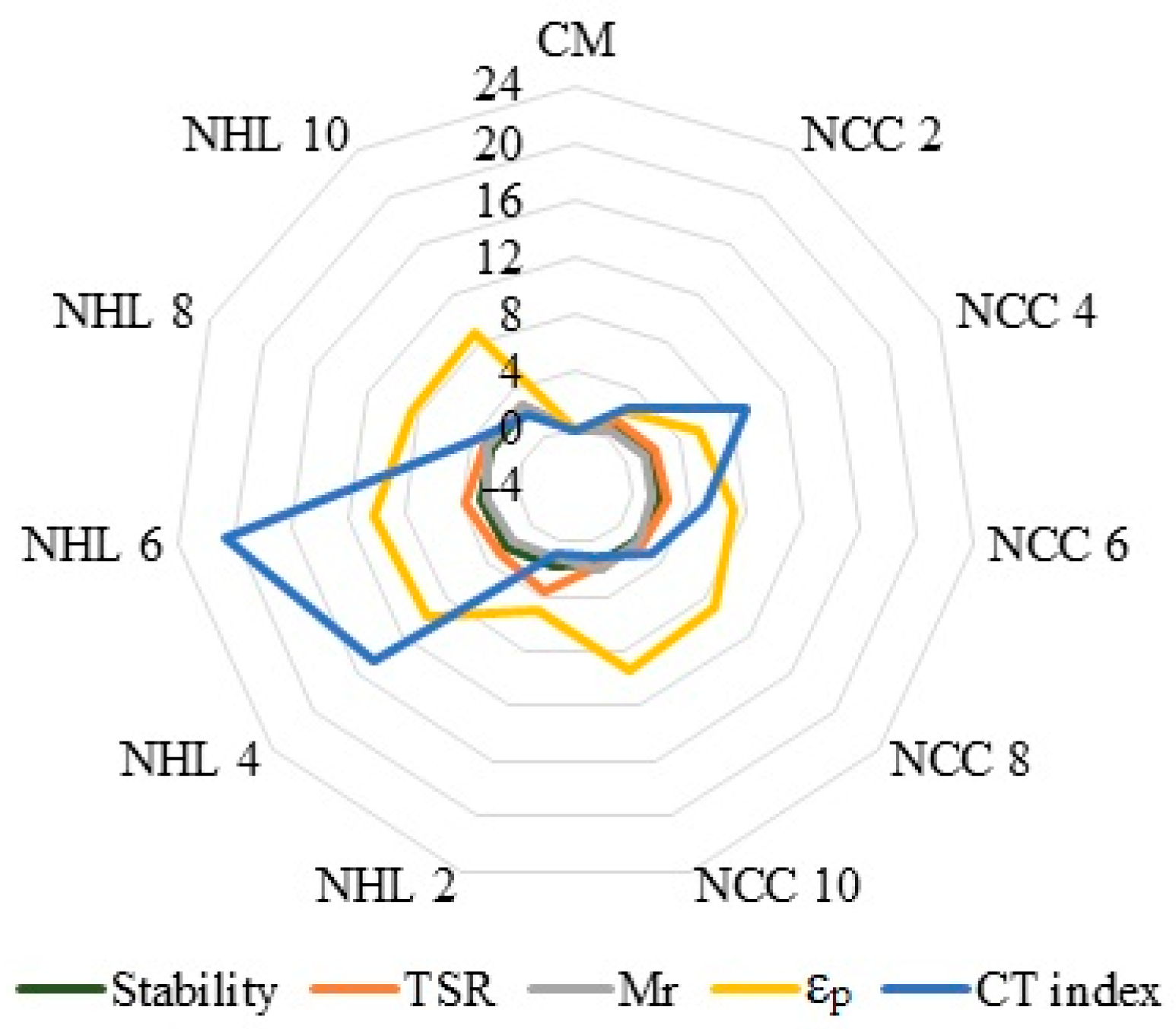

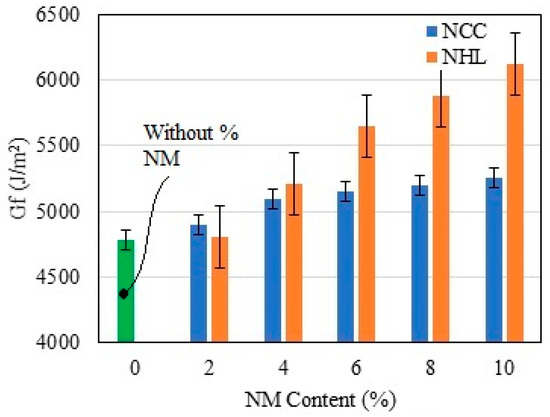

5.6.5. Fatigue Performance

In examining the effects of Nano CaCO3 and NHL on the fatigue resistance of AC mixtures presented in Figure 16, the fracture energy (Gf) is a critical factor indicative of the material’s ability to resist the initiation of cracking. The Gf values reveal a consistent rise with the increasing content of NHL, maintaining a steady rate of improvement through to a 10% addition. This suggests that NHL continuously enhances the mixture’s resilience against the beginnings of fatigue cracking over the evaluated range of nanomaterial content. In contrast, Nano CaCO3 demonstrates a significant increase in Gf up to a 4% inclusion level, indicating a strong initial enhancement in resisting crack initiation. However, beyond this point, the growth rate in Gf values for Nano CaCO3 begins to plateau, suggesting a diminishing return with higher concentrations of Nano CaCO3 in terms of resisting the onset of fatigue cracks.

Figure 16.

Effect of NM on fatigue cracking results.

This contrast is further elucidated when considering the m75 values, which reflect the rate of crack propagation. Nano CaCO3 exhibits the most substantial reduction in crack growth at a 4% content, marking an optimal concentration for halting the spread of cracks. Meanwhile, NHL displays its lowest m75 values at a 6% content, signaling a superior capability to slow down crack progression compared to Nano CaCO3. Additionally, the CT index, which measures the overall resistance to fatigue, finds its best values at 4% for Nano CaCO3 and 6% for NHL. Specifically, Nano CaCO3 and NHL at these respective contents show improvement rates of 30% and 35.4% over mixes with neat asphalt cement. Remarkably, NHL-enhanced mixtures at 6% reach the highest CT index value (75.25), reflecting formidable fatigue resistance. These results suggest that while both Nano CaCO3 and NHL improve fatigue performance, NHL provides a more consistent and extended benefit across a broader range of nanomaterial content.

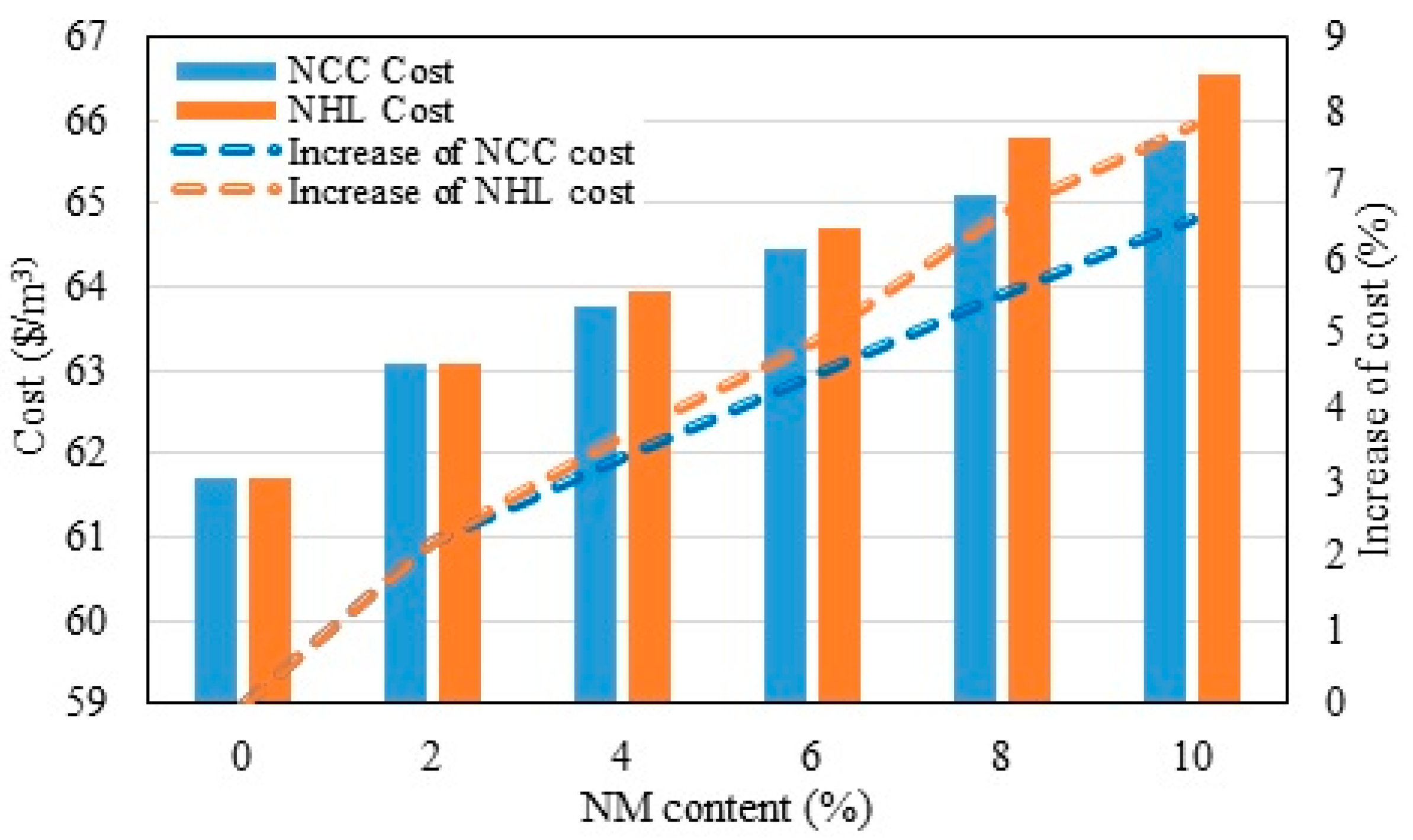

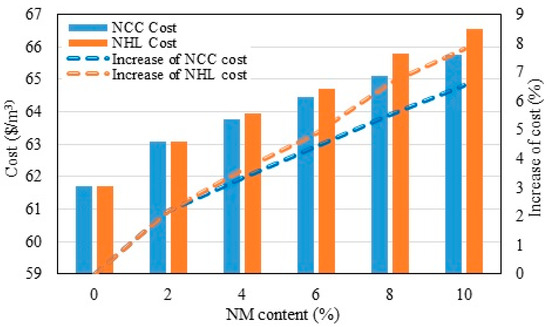

6. Cost Analysis

Table 6 shows the cost of materials used in this research. The total cost per cubic meter for each mix, derived from the shown costs, along with the corresponding percentage increase in cost compared to the control mix (0% NM content), are presented in Figure 17.

Table 6.

Materials Cost.

Figure 17.

Cost per cubic meter of individual mix type and % increase in cost.

The cost analysis reveals that both NCC and NHL lead to increased expenditures in asphalt mixture preparation. Notably, the increment in cost is consistent with the rise in NM content; however, the rate of cost increase varies between the two nanomaterials. For instance, the cost for NCC-modified mixtures exhibits a lower increase rate compared to NHL, with a significant difference at higher NM contents.

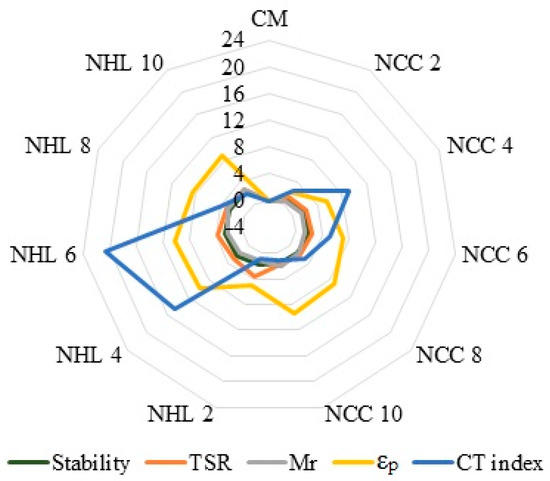

To assess the economic efficiency and identify the optimal quantity of modifier that maximizes performance at minimal cost, this study employs a ‘Gain’ index. This index is a comparative ratio that evaluates the percentage enhancement in key properties of the modified mixtures over the control mix (CM) against the percentage rise in mixture cost. Figure 18 details the gain values in various mechanical properties for asphalt mixes modified with NCC and NHL at different dosages. To discern the optimal dosages for NCC and NHL, one can analyze the percentage gain across all considered mechanical properties: Stability, TSR, Mr, εp (permanent deformation), and CT index (fatigue resistance). For NCC, a 4% content shows a balanced and high percentage gain across most properties, particularly in TSR, Mr, and CT index, with gains being 2.15%, 1.31%, and 9.02%, respectively. These gains are substantial when compared to the control mix. The percentage gain begins to taper off or decrease beyond the 4% content, especially noted in the CT index, where it drops significantly at 10% NCC content. On the other hand, NHL, at a 6% content, exhibits the highest percentage gains, with substantial improvements in all properties. The TSR shows a 3.74% gain, Mr a 2.11% gain, and the CT index a remarkable 20.61% gain, which is the peak across all NHL contents. Beyond 6%, the gains either level off or reduce, as seen with the CT index dropping to 3.72% at 8% NHL content and even lower at 10%. Therefore, the optimal dosage for NCC is 4%, while it is 6% for NHL. These concentrations provide considerable enhancement in pavement performance, suggesting they are the most cost-effective choices for improving the long-term durability and resistance of asphalt concrete mixtures against various types of distress.

Figure 18.

Gain index values per mix.

7. Conclusions

Based on the experimental evaluations of asphalt binders and AC mixes modified with Nano CaCO3 and NHL at various dosages ranging from 0% to 10%, the following key findings can be concluded:

- Nano CaCO3 and NHL enhance binder stiffness, with pronounced effects up to 4% content (24.49% reduction in penetration for Nano CaCO3, 30.61% for NHL; 10.75% increase in softening point for Nano CaCO3, 13.79% for NHL). Beyond this, stiffening effects plateau;

- DSR tests show substantial rutting resistance improvements in Nano CaCO3 and NHL-modified binders, especially with NHL exhibiting increases of 73% and 80% in rutting factor after original and RTFO aging, respectively. However, post-PAV aging results reveal marginally lower fatigue resistance for both Nano CaCO3 and NHL compared to neat asphalt;

- Marshall stability increased by 22.3% with the addition of 6% NHL, surpassing the 20.2% improvement observed with Nano CaCO3, indicating a higher load-bearing capacity for NHL-modified mixes;

- NHL consistently enhances the resilient modulus up to 21.4% at 10% content, while Nano CaCO3′s benefits level off beyond 4%;

- Compared to neat asphalt, which fails to meet the 80% TSR benchmark for moisture resistance, NHL significantly enhances this aspect. It exceeds the 80% TSR threshold at only 2% content and reaches an impressive 94.6% at 10%. While Nano CaCO3 also improves moisture resistance, its performance is more gradual, achieving an 88.2% TSR at 10%. This indicates NHL’s superior effectiveness in enhancing the moisture durability of asphalt mixtures;

- Nano CaCO3 and NHL significantly reduce permanent deformation in asphalt mixtures. At a 10% dosage, compared to 0% NM mixes, NHL significantly reduces permanent deformation in asphalt mixtures, showing a notable 68.64% improvement in rutting resistance (measured by εp at N = 10,000), which is higher than Nano CaCO3′s 61.88% improvement in the same terms;

- Optimal fatigue resistance is achieved at 4% for Nano CaCO3 and 6% for NHL, with respective CT index improvements of 30% and 35.4%, respectively. NHL shows a more consistent benefit across various nanomaterial contents.

In summary, this study suggests that for optimal performance, practitioners should consider using Nano CaCO3 and NHL at recommended dosages of 4% and 6%, respectively, as asphalt binder additives. NHL-modified mixes were more effective than Nano CaCO3-modified mixes. However, further field testing and evaluations are recommended to ensure enhanced pavement performance and confirm the technical viability and practical applicability of Nano CaCO3 and NHL in practical pavement applications. The experimental results of this study for some key properties of asphalt mixes with the resulting two dosages, as well as the control mix (0% NM), are summarized in Table 7.

Table 7.

Summary of key results for unmodified and modified asphalt mixes with Nano CaCO3 and NHL.

Author Contributions

Methodology, A.H.A. and A.F.A.-A.; Formal analysis, A.H.A. and A.F.A.-A.; Investigation, A.H.A. and A.F.A.-A.; Resources, A.H.A.; Writing—original draft, A.H.A. and A.F.A.-A.; Writing—review & editing, J.B., M.A.-K. and M.R.; Supervision, A.H.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Razavi, S.-H.; Kavussi, A. The role of nanomaterials in reducing moisture damage of asphalt mixes. Constr. Build. Mater. 2020, 239, 117827. [Google Scholar] [CrossRef]

- Karahancer, S.; Enieb, M.; Saltan, M.; Terzi, S.; Eriskin, E.; Cengizhan, A.; Akbas, M.Y. Evaluating Mechanical Properties of Bitumen and Hot Mix Asphalt Modified with Nano Ferric Oxide. Constr. Build. Mater. 2020, 234, 117381. [Google Scholar] [CrossRef]

- Amini, A.; Ziari, H.; Saadatjoo, S.A.; Hashemifar, N.S.; Goli, A. Rutting Resistance, Fatigue Properties and Temperature Susceptibility of Nano Clay Modified Asphalt Rubber Binder. Constr. Build. Mater. 2021, 267, 120946. [Google Scholar] [CrossRef]

- Moghadas Nejad, F.; Geraee, E.; Azarhoosh, A.R. The Effect of Nano Calcium Carbonate on the Dynamic Behaviour of Asphalt Concrete Mixture. Eur. J. Environ. Civ. Eng. 2020, 24, 1219–1228. [Google Scholar] [CrossRef]

- Yarahmadi, A.M.; Shafabakhsh, G.; Asakereh, A. Laboratory Investigation of the Effect of Nano Caco3 on Rutting and Fatigue of Stone Mastic Asphalt Mixtures. Constr. Build. Mater. 2022, 317, 126127. [Google Scholar] [CrossRef]

- Wang, Z.H.; Bai, E.L.; Xu, J.Y.; Du, Y.H.; Zhu, J.S. Effect of Nano-SiO2 and Nano-CaCO3 on the Static and Dynamic Properties of Concrete. Sci. Rep. 2022, 12, 907. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.M.; Abed, A.H. Enhancing Asphalt Binder Performance through Nano-SiO2 and Nano-CaCO3 Additives: Rheological and Physical Insights. Case Stud. Constr. Mater. 2023, 19, e02492. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Xu, G.; Wu, C. Investigation of the Aging Behaviors of Multi-Dimensional Nanomaterials Modified Different Bitumens by Fourier Transform Infrared Spectroscopy. Constr. Build. Mater. 2018, 167, 536–542. [Google Scholar] [CrossRef]

- Tanzadeh, R.; Shafabakhsh, G. Surface Free Energy and Adhesion Energy Evaluation of Modified Bitumen with Recycled Carbon Black (Micro-Nano) from Gases and Petrochemical Waste. Constr. Build. Mater. 2020, 245, 118361. [Google Scholar] [CrossRef]

- Ashish, P.K.; Singh, D. Use of Nanomaterial for Asphalt Binder and Mixtures: A Comprehensive Review on Development, Prospect, and Challenges. Road Mater. Pavement Des. 2021, 22, 492–538. [Google Scholar] [CrossRef]

- Debbarma, K.; Debnath, B.; Sarkar, P.P. A Comprehensive Review on the Usage of Nanomaterials in Asphalt Mixes. Constr. Build. Mater. 2022, 361, 129634. [Google Scholar] [CrossRef]

- Nataadmadja, A.D.; Prahara, E.; Setyandito, O. The effect of hydrated lime addition in improving the moisture resistance of hot mix asphalt (HMA). InIOP Conf. Ser. Earth Environ. Sci. 2020, 426, 012023. [Google Scholar] [CrossRef]

- Taherkhani, H.; Tajdini, M. Comparing the Effects of Nano-Silica and Hydrated Lime on the Properties of Asphalt Concrete. Constr. Build. Mater. 2019, 218, 308–315. [Google Scholar] [CrossRef]

- Sebaaly, P.E.; Little, D.N.; Epps, J.A. The Benefits of Hydrated lime in Hot Mix Asphalt; University of Nevada: Reno, NV, USA, 2006. [Google Scholar]

- Preti, F.; Accardo, C.; Gouveia, B.C.S.; Romeo, E.; Tebaldi, G. Influence of High-Surface-Area Hydrated Lime on Cracking Performance of Open-Graded Asphalt Mixtures. Road Mater. Pavement Des. 2021, 22, 2654–2660. [Google Scholar] [CrossRef]

- Han, S.; Dong, S.; Yin, Y.; Liu, M.; Liu, Y. Study on the effect of hydrated lime content and fineness on asphalt properties. Constr. Build. Mater. 2020, 244, 118379. [Google Scholar] [CrossRef]

- Kim, S.; Sholar, G.A.; Byron, T.; Kim, J. Performance of Polymer-Modified Asphalt Mixture with Reclaimed Asphalt Pavement. Transp. Res. Rec. 2009, 2126, 109–114. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; van de Ven, M.; Erkens, S.; Skarpas, A. Effect of Laboratory Aging on Chemistry and Rheology of Crumb Rubber Modified Bitumen. Mater. Struct. 2020, 53, 26. [Google Scholar] [CrossRef]

- Nazari, H.; Naderi, K.; Nejad, F.M. Improving Aging Resistance and Fatigue Performance of Asphalt Binders Using Inorganic Nanoparticles. Constr. Build. Mater. 2018, 170, 591–602. [Google Scholar] [CrossRef]

- Shafabakhsh, G.A.; Sadeghnejad, M.; Alizadeh, S. Engineering the Effect of Nanomaterials on Bitumen and Asphalt Mixture Properties. A Review. Balt. J. Road Bridge Eng. 2023, 18, 1–31. [Google Scholar] [CrossRef]

- Aljbouri, H.J.; Albayati, A.H. Effect of Nanomaterials on the Durability of Hot Mix Asphalt. Transp. Eng. 2023, 11, 100165. [Google Scholar] [CrossRef]

- AASHTO M 320; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013; Volume 33.

- ASTM D3515-96; Standard Specification for Hot-Mixed, Hot-Laid Bituminous Paving Mixtures. ASTM International: West Conshohocken, PA, USA, 2021; Volume 04-03.

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015; Volume 04-02.

- ASTM C88/C88M-18; Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. ASTM International: West Conshohocken, PA, USA, 2018; Volume 04-02.

- ASTM C131/C131M-20; Standard Test Method for Resistance to Degradation of Small-Size Coarse. Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020; Volume 04-02.

- ASTM D4791-19(2023); Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2023; Volume 04-03.

- ASTM D5821-13(2017); Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2017; Volume 04-03.

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2023; Volume 04-02.

- ASTM C142/C142M-17(2023); Standard Test Method for Clay Lumps and Friable Particles in Aggregates. ASTM International: West Conshohocken, PA, USA, 2023; Volume 04-02.

- ASTM D2419-22; Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022; Volume 04-03.

- ASTM D5-06; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2006; Volume 04-03.

- ASTM D36-06; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2006; Volume 04-04.

- ASTM D2872-22; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2022; Volume 04-03.

- ASTM D7173-20; Standard Practice for Determining the Separation Tendency of Polymer from Polymer Modified Asphalt. ASTM International: West Conshohocken, PA, USA, 2020; Volume 04-03.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2015; Volume 04-03.

- AASHTO T315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- ASTM D6927; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2015; Volume 04-03, pp. 1–7.

- ASTM D2041; Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures. ASTM International: West Conshohocken, PA, USA, 2011; Volume 04-03.

- ASTM D4867; Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures. ASTM International: West Conshohocken, PA, USA, 2009; Volume 04-03.

- Albayati, A.H. Performance Evaluation of Plant Produced Warm Mix Asphalt. J. Eng. 2018, 24, 145–164. [Google Scholar] [CrossRef]

- ASTM D8225; ASTM International, Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. ASTM International: West Conshohocken, PA, USA, 2019.

- Azarhoosha, A.; Hamedi, G.H. Investigation of the Rheological Behavior and Properties of Modified Asphalt Binder with Nano Hydrated Lime. AUT J. Civ. Eng. 2019, 3, 187–192. [Google Scholar] [CrossRef]

- Diab, A.; You, Z. Rheological characteristics of nano-sized hydrated lime-modified foamed warm mix Asphalt. In Pavement Materials, Structures, and Performance; American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 79–89. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).