How Effective Are Palm-Fiber-Based Erosion Control Blankets (ECB) against Natural Rainfall?

Abstract

:1. Introduction

1.1. Mechanical Properties of Sugar Palm Fibers

1.2. Properties of Common ECBs

2. Materials and Methodology

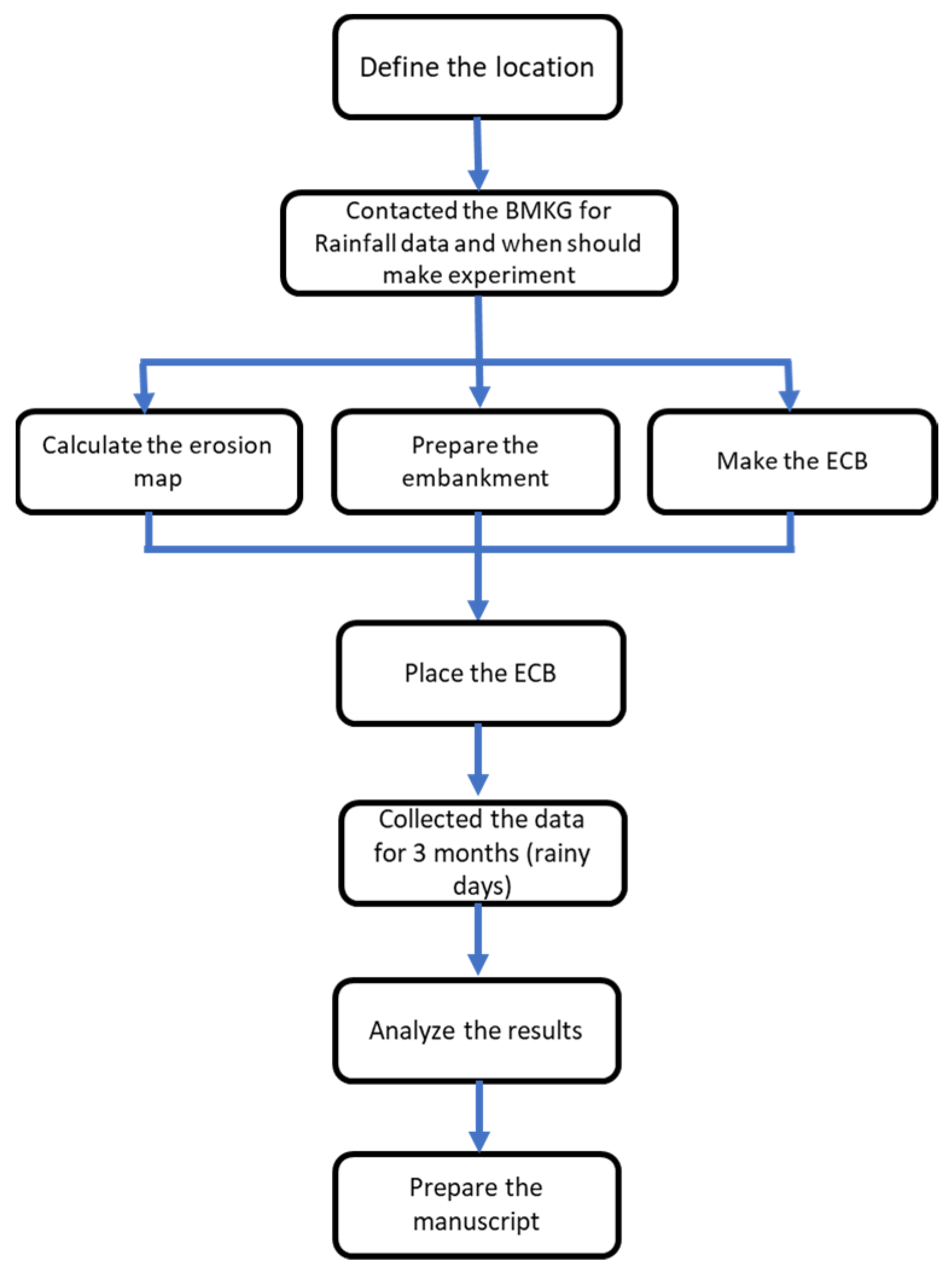

2.1. Research Methodology

2.2. Sugar Palm Fiber Net ECBs

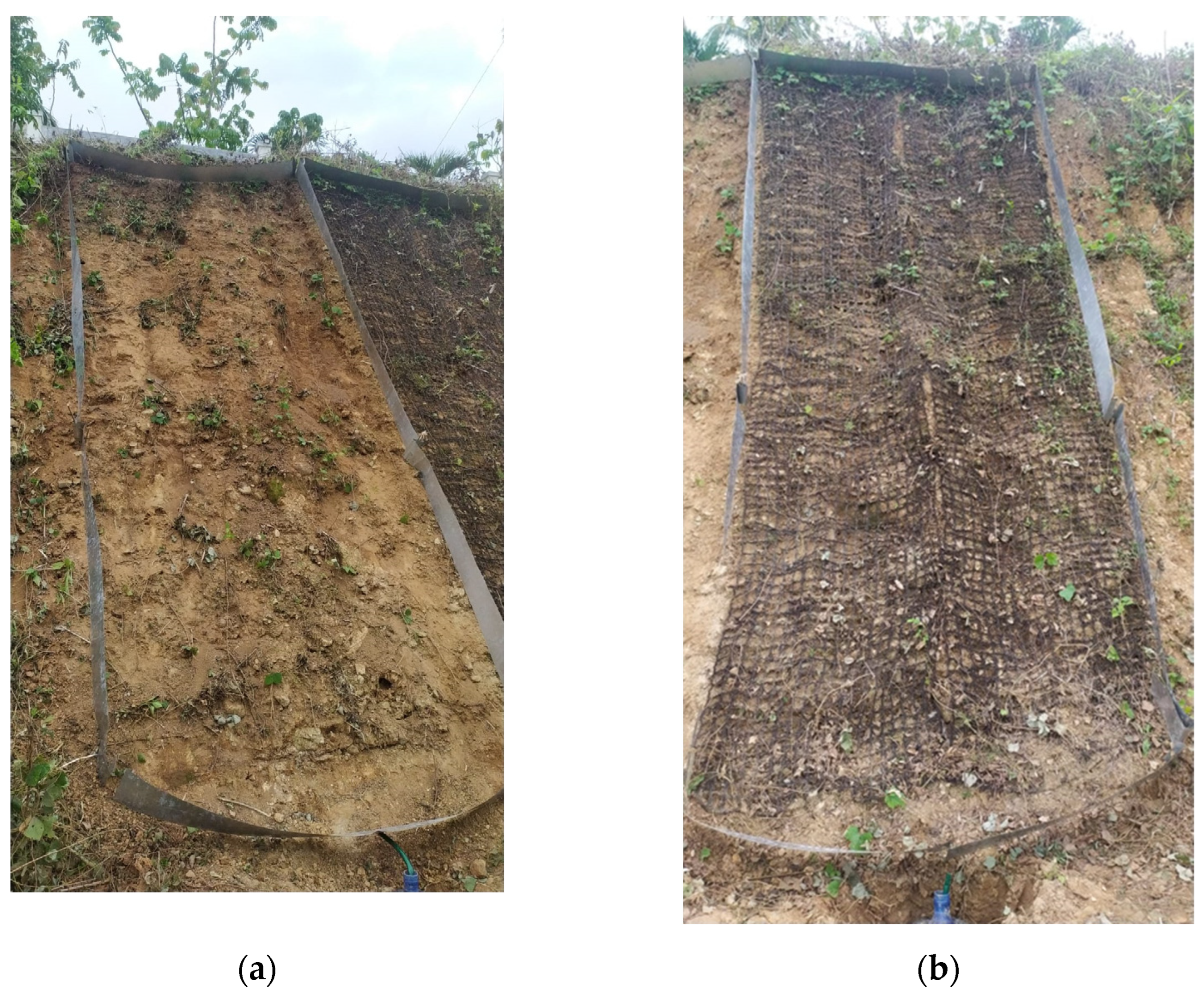

2.3. Embankment Preparation

2.4. Evaluation of Erosion Control Practices

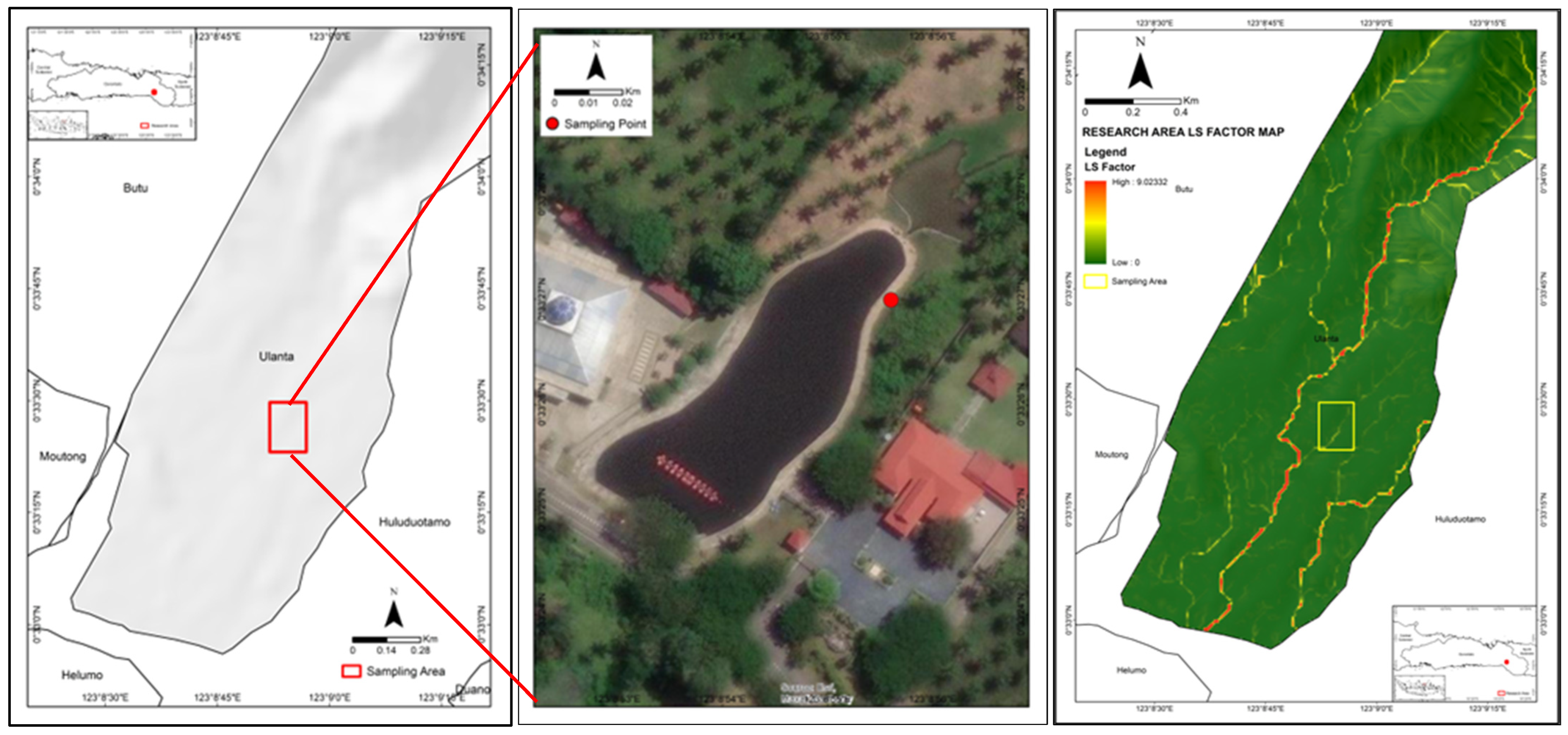

2.5. GIS Hazard Map

3. Results and Discussion

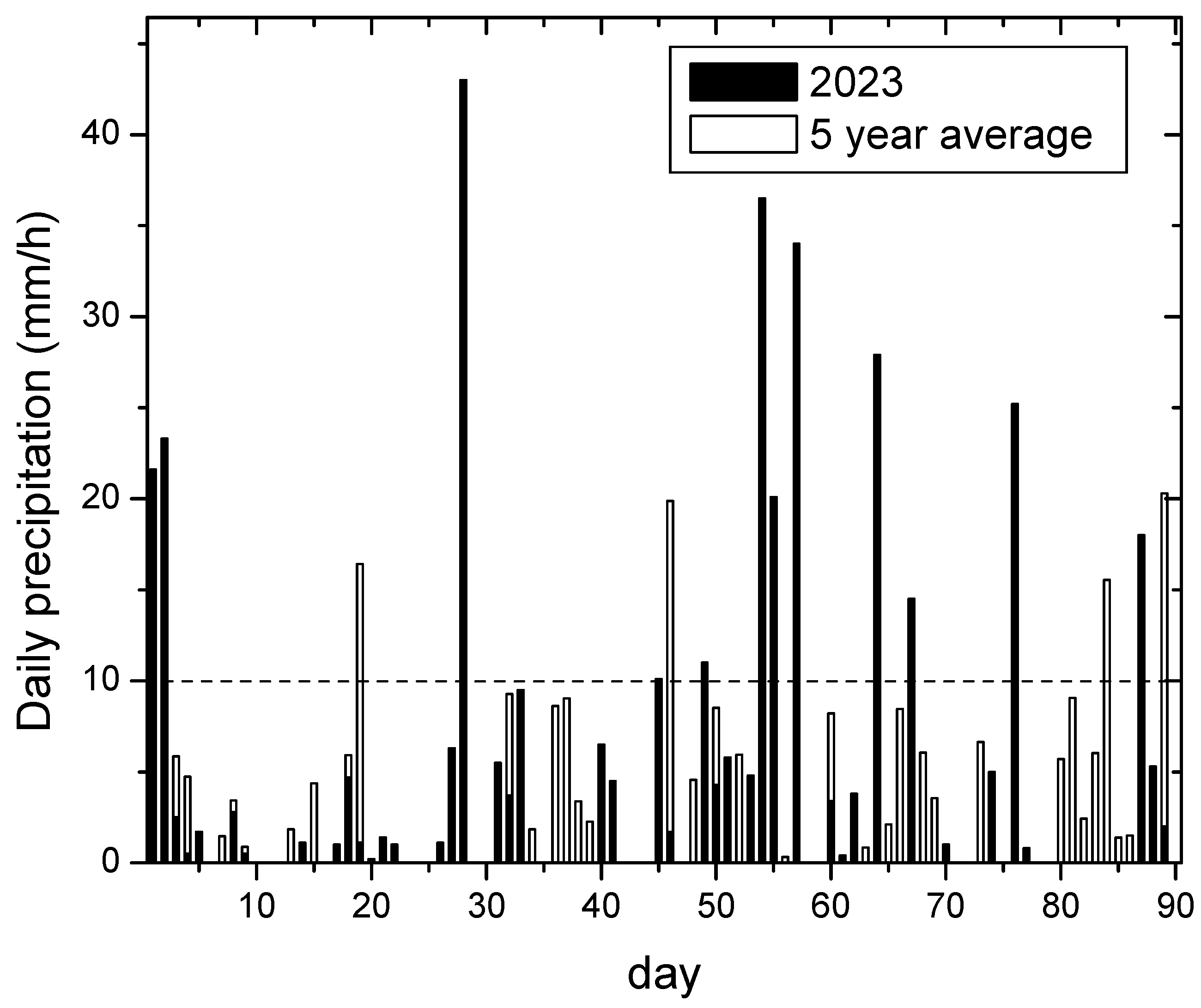

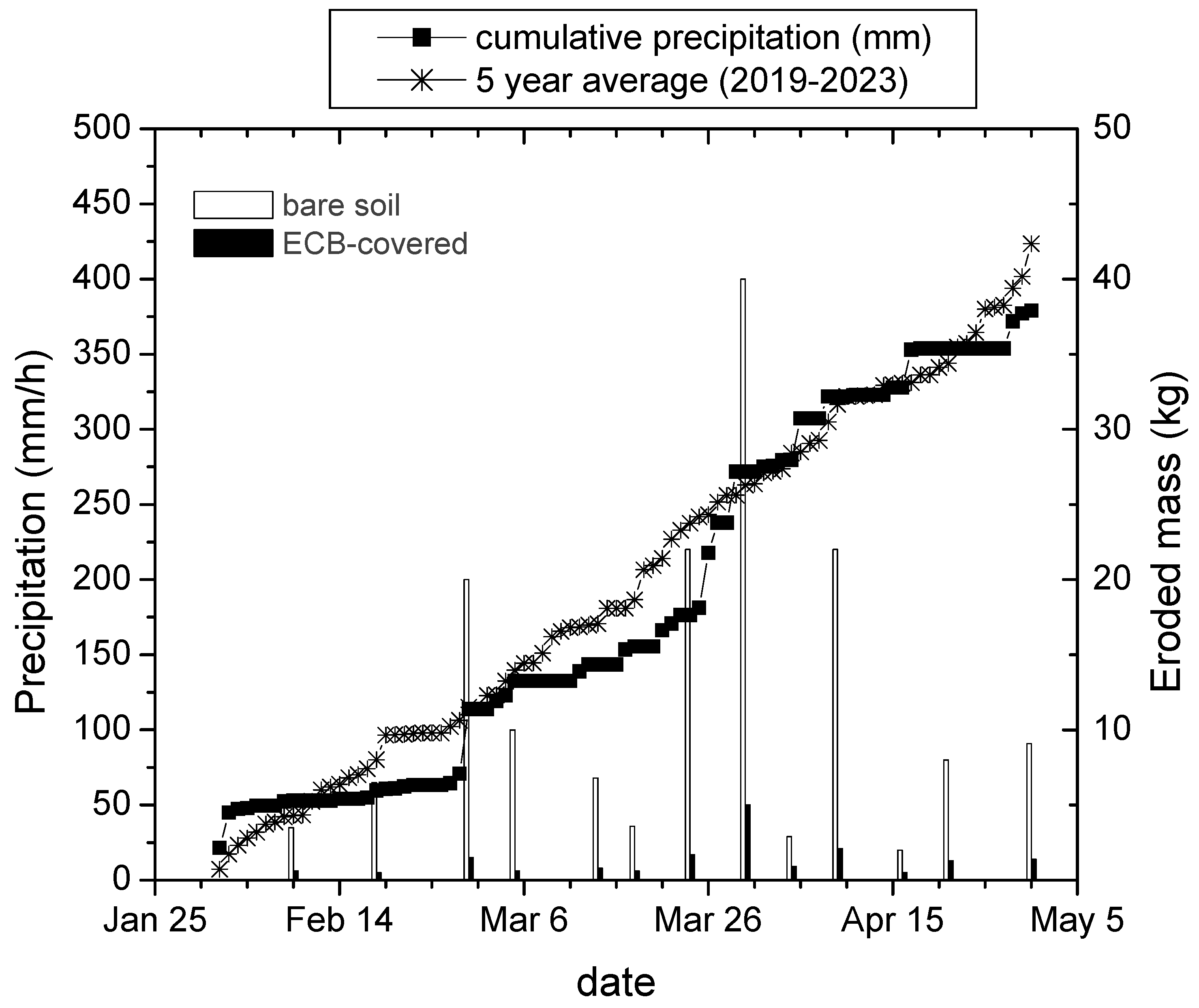

3.1. Precipitation and Erosion Map of the Location

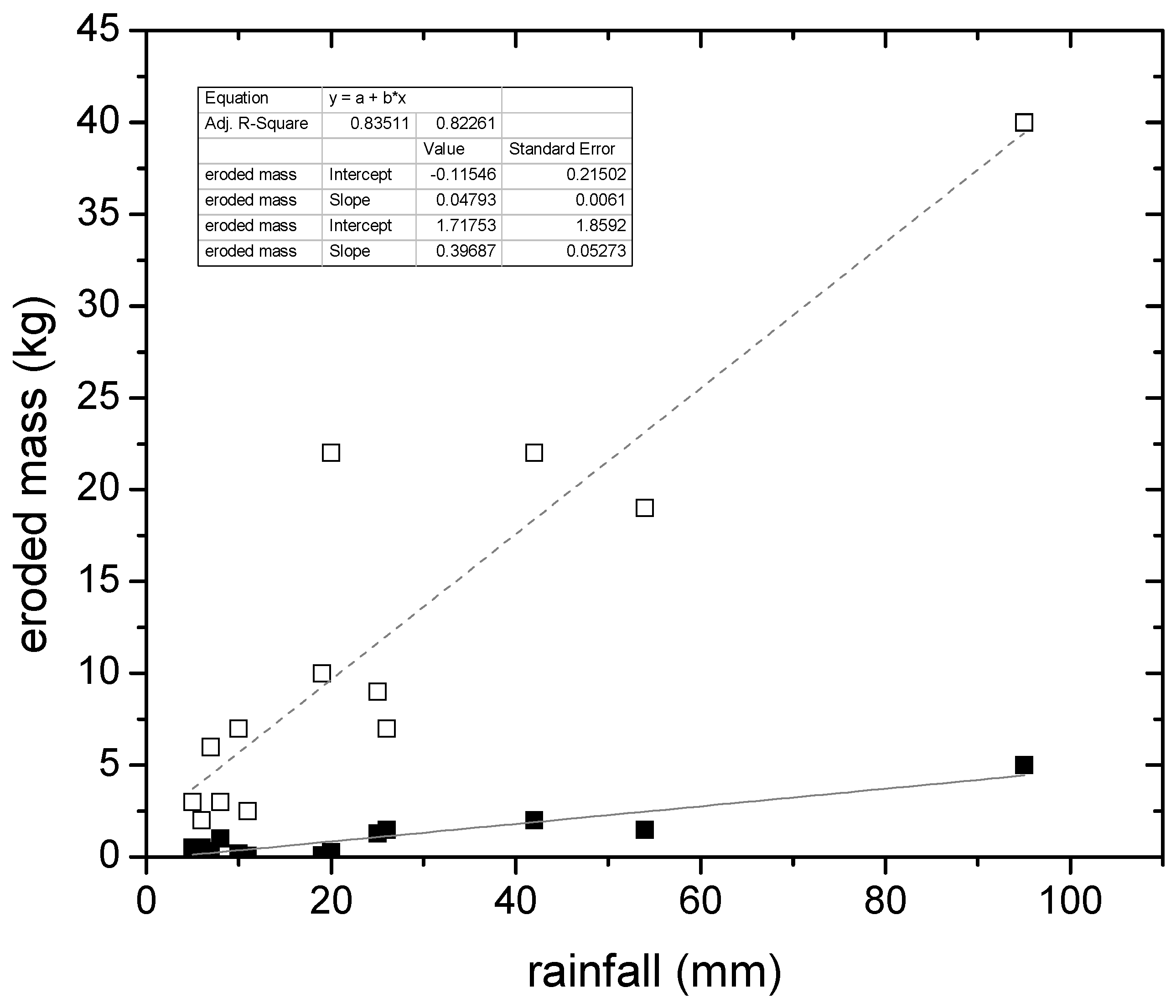

3.2. ECB Effects on Soil Erosion

3.3. Efficiency of ECB

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, G.-L.; Liu, Y.-F.; Cui, Z.; Liu, Y.; Shi, Z.-H.; Yin, R.; Kardol, P. Trade-off between Vegetation Type, Soil Erosion Control and Surface Water in Global Semi-Arid Regions: A Meta-Analysis. J. Appl. Ecol. 2020, 57, 875–885. [Google Scholar] [CrossRef]

- Evelpidou, N.; Cordier, S.; Merino, A.; de Figueiredo, T.; Centeri, C. Runoff Erosion; University of Athens: Athens, Greece, 2013. [Google Scholar]

- Borrelli, P.; Alewell, C.; Alvarez, P.; Anache, J.A.A.; Baartman, J.; Ballabio, C.; Bezak, N.; Biddoccu, M.; Cerdà, A.; Chalise, D.; et al. Soil Erosion Modelling: A Global Review and Statistical Analysis. Sci. Total Environ. 2021, 780, 146494. [Google Scholar] [CrossRef] [PubMed]

- Borrelli, P.; Robinson, D.A.; Fleischer, L.R.; Lugato, E.; Ballabio, C.; Alewell, C.; Meusburger, K.; Modugno, S.; Schütt, B.; Ferro, V.; et al. An Assessment of the Global Impact of 21st Century Land Use Change on Soil Erosion. Nat. Commun. 2017, 8, 2013. [Google Scholar] [CrossRef] [PubMed]

- Pribadi, D.O.; Vollmer, D.; Pauleit, S. Impact of Peri-Urban Agriculture on Runoff and Soil Erosion in the Rapidly Developing Metropolitan Area of Jakarta, Indonesia. Reg. Environ. Chang. 2018, 18, 2129–2143. [Google Scholar] [CrossRef]

- Rudiarto, I.; Doppler, W. Impact of Land Use Change in Accelerating Soil Erosion in Indonesian Upland Area: A Case of Dieng Plateau, Central Java-Indonesia. Int. J. Agrisci. 2013, 3, 558–576. [Google Scholar]

- Subehi, L.; Wibowo, H.; Jung, K. Characteristics of Rainfall-Discharge and Water Quality at Limboto Lake, Gorontalo, Indonesia; Bandung Institute of Technology: Bandung, Indonesia, 2016. [Google Scholar]

- Kimijima, S.; Sakakibara, M.; Amin, A.; Nagai, M.; Indriati Arifin, Y. Mechanism of the Rapid Shrinkage of Limboto Lake in Gorontalo, Indonesia. Sustainability 2020, 12, 9598. [Google Scholar] [CrossRef]

- Lihawa, F.S. The Effect of Watershed Environmental Conditions and Landuse of Sediment Yield Ini Alo-Pohu Watershed. Int. J. Geogr. IJG 2009, 41, 103–122. [Google Scholar]

- Arifin, Y.I.; Manyoe, I.N.; Napu, S.S.S. Geological Study of Pantai Indah for Geotourism Development Based on Geological Observation and Assessment of Science, Education, Tourism and the Risk Degradation. J. Phys. Conf. Ser. 2021, 1968, 012048. [Google Scholar] [CrossRef]

- Janus. FY2021 City-to-City Collaboration Programme for Zero-Carbon Society (Support Project for the Achievement of SDGs and Developing a Sustainable Decarbonized Society: City-to-City Collaboration between Ehime Prefecture and Gorontalo Province) Report March. 2022. Available online: https://www.env.go.jp/earth/coop/lowcarbon-asia/english/project/data/EN_IDN_2021_05.pdf (accessed on 15 October 2023).

- Sims, N.C.; Barger, N.N.; Metternicht, G.I.; England, J.R. A Land Degradation Interpretation Matrix for Reporting on UN SDG Indicator 15.3.1 and Land Degradation Neutrality. Environ. Sci. Policy 2020, 114, 1–6. [Google Scholar] [CrossRef]

- Smets, T.; Poesen, J.; Fullen, M.A.; Booth, C.A. Effectiveness of Palm and Simulated Geotextiles in Reducing Run-off and Inter-Rill Erosion on Medium and Steep Slopes. Soil. Use Manag. 2007, 23, 306–316. [Google Scholar] [CrossRef]

- Coelho, A.T.; Menezes, G.B.; de Brito Galvão, T.C.; Coelho, J.F.T. Performance of Rolled Erosion Control Products (RECPs) as Bioswale Revetments. Sustainability 2021, 13, 7731. [Google Scholar] [CrossRef]

- Kalibová, J.; Jačka, L.; Petrů, J. The Effectiveness of Jute and Coir Blankets for Erosion Control in Different Field and Laboratory Conditions. Solid Earth 2016, 7, 469–479. [Google Scholar] [CrossRef]

- Bhattacharyya, R.; Fullen, M.A.; Davies, K.; Booth, C.A. Use of Palm-Mat Geotextiles for Rainsplash Erosion Control. Geomorphology 2010, 119, 52–61. [Google Scholar] [CrossRef]

- Bachtiar, D.; Sapuan, S.M.; Zainudin, E.S.; Khalina, A.; Dahlan, K.Z.M. The Tensile Properties of Single Sugar Palm (Arenga pinnata) Fibre. IOP Conf. Ser. Mater. Sci. Eng. 2010, 11, 012012. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Ismarrubie, Z.N.; Rahman, M.Z.A. Physical and Chemical Properties of Different Morphological Parts of Sugar Palm Fibres. Fibres Text. East. Eur. 2012, 2, 21–24. [Google Scholar]

- Jahja, M.; Dihuma, K.; Setiawan, D.G.E.; Yamaguchi, T.; Metaragakusuma, A.P.; Sakakibara, M. Mechanical Properties of Sugar Palm (Arenga pinnata) Ropes and Nets for Agricultural Purposes. Jambura Phys. J. 2023, 5, 57–66. [Google Scholar] [CrossRef]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K. Characterization of Sugar Palm (Arenga Pinnata) Fibres Tensile and Thermal Properties. J. Therm. Anal. Calorim. 2012, 109, 981–989. [Google Scholar] [CrossRef]

- Poletto, M.; Ornaghi, H.L., Jr.; Zattera, A.J. Native Cellulose: Structure, Characterization and Thermal Properties. Materials 2014, 7, 6105–6119. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Amaral Da Silva, I.L.; Da Costa, L.L. Natural Lignocellulosic Fibers as Engineering Materials-An Overview. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2011, 42, 2963–2974. [Google Scholar] [CrossRef]

- Petroudy, S.R.D. Physical and Mechanical Properties of Natural Fibers. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier: Amsterdam, The Netherlands, 2017; pp. 59–83. [Google Scholar]

- Chanliaud, E.; Burrows, K.M.; Jeronimidis, G.; Gidley, M.J. Mechanical Properties of Primary Plant Cell Wall Analogues. Planta 2002, 215, 989–996. [Google Scholar] [CrossRef]

- Suryanto, H.; Marsyahyo, E.; Irawan, Y.S.; Soenoko, R. Morphology, Structure, and Mechanical Properties of Natural Cellulose Fiber from Mendong Grass (Fimbristylis globulosa). J. Nat. Fibers 2014, 11, 333–351. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A State-of-the-Art Review on Soil Reinforcement Technology Using Natural Plant Fiber Materials: Past Findings, Present Trends and Future Directions. Materials 2018, 11, 553. [Google Scholar] [CrossRef] [PubMed]

- Fangueiro, R.; Rana, S. Natural Fibres: Advances in Science and Technology towards Industrial Applications: From Science to Market; Springer: Dordrecht, The Netherlands, 2016; Volume 12, ISBN 9789401775137. [Google Scholar]

- Metaragakusuma, A.P.; Meutia, A. Research institute for Humanity and Nature Newsletter. Kyoto January 2023. pp. 1–16.

- SRIREP Natural Fiber Research Group. Available online: https://srirep.org/ (accessed on 15 September 2023).

- Davies, K.; Fullen, M.A.; Booth, C.A. A Pilot Project on the Potential Contribution of Palm-Mat Geotextiles to Soil Conservation. Earth Surf. Process Landf. 2006, 31, 561–569. [Google Scholar] [CrossRef]

- Echo-Friendly-Jute-Coir-Geotextiles-700_10000010324187. Available online: www.alibaba.com (accessed on 20 January 2024).

- Bhattacharyya, R.; Fullen, M.A.; Davies, K.; Booth, C.A. Utilizing Palm-Leaf Geotextile Mats to Conserve Loamy Sand Soil in the United Kingdom. Agric. Ecosyst. Environ. 2009, 130, 50–58. [Google Scholar] [CrossRef]

- Bhattacharyya, R.; Davies, K.; Fullen, M.A.; Booth, C.A. Effects of Palm-Mat Geotextiles on the Conservation of Loamy Sand Soils in East Shropshire, UK; Catena Verlag: Reiskirchen, Germany, 2008. [Google Scholar]

- Artidteang, S.; Tanchaisawat, T.; Bergado, D.T.; Chaiyaput, S. Natural Fibers in Reinforcement and Erosion Control Applications with Limited Life Geosynthetics. In Ground Improvement Case Histories: Compaction, Grouting and Geosynthetics; Elsevier: Amsterdam, The Netherlands, 2015; pp. 717–740. [Google Scholar]

- Tanchaisawat, T.; Bergado, D.T.; Artidteang, S. Large-Scale Soil Erosion Performance Test of Water Hyacinth Limited Life Geosynthetics Combined with Ruzi Grasses. Int. J. Geotech. Eng. 2014, 8, 315–327. [Google Scholar] [CrossRef]

- Artidteang, S.; Bergado, D.T.; Tanchaisawat, T.; Saowapakpiboon, J. Investigation of Tensile and Soil-Geotextile Interface Strength of Kenaf Woven Limited Life Geotextiles (LLGS). Lowl. Technol. Int. 2012, 14, 1–8. [Google Scholar]

- Hrabĕl, P.; Mizera Herák, D.; Kabutey, A. Mechanical Behaviour of Sugar Palm (Arenga pinnata) Fibres. Agron. Res. 2018, 16, 1046–1051. [Google Scholar] [CrossRef]

- Mogea, J.; Seibert, B.; Smits, W. Multipurpose Palms: The Sugar Palm (Arenga pinnata (Wurmb) Merr.). Agrofor. Syst. 1991, 13, 111–129. [Google Scholar] [CrossRef]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K.; Siregar, J.P. Sugar Palm (Arenga pinnata): Its Fibres, Polymers and Composites. Carbohydr. Polym. 2013, 91, 699–710. [Google Scholar] [CrossRef]

- Artidteang, S.; DT, B.; Chaiyaput, S.; Tanchaisawat, T.; LG, L. Performance of Ruzi Grass Combined with Woven Limited Life Geotextiles (LLGS) for Soil Erosion Control. Lowl. Technol. Int. 2016, 18, 1–8. [Google Scholar] [CrossRef]

- Jahja, M.; Arifin, Y.I.; Gafur, N.A.; Masulili, F.; Kusuma, A.P.M.; Sakakibara, M. Performances of Erosion Control Blanket Made From Palm Fiber On Reducing Erosion In The Slopes Of Lake Limboto Basin. E3S Web Conf. 2023, 400, 01019. [Google Scholar] [CrossRef]

- Meng, X.; Zhu, Y.; Yin, M.; Liu, D. The Impact of Land Use and Rainfall Patterns on the Soil Loss of the Hillslope. Sci. Rep. 2021, 11, 16341. [Google Scholar] [CrossRef] [PubMed]

- Santos, R.; Fonseca, F.; Baptista, P.; Paz-Gonzalez, A.; de Figueiredo, T. Erosion Control Perfromance of Improved Soil Management in Olive Groves: A Field Experimental Study in NE Portugal. Land 2023, 12, 1700. [Google Scholar] [CrossRef]

- Olii, M.R.; Olii, A.; Pakaya, R.; Olii, M.Y.U.P. GIS-Based Analytic Hierarchy Process (AHP) for Soil Erosion-Prone Areas Mapping in the Bone Watershed, Gorontalo, Indonesia. Environ. Earth Sci. 2023, 82, 225. [Google Scholar] [CrossRef]

- Schad, P. The International Soil Classification System WRB, 3rd ed.; FAO: Rome, Italy, 2016; ISBN 9789251083697. [Google Scholar]

- Kuhn, N.J.; Greenwood, P.; Fister, W. Use of Field Experiments in Soil Erosion Research. In Developments in Earth Surface Processes; Elsevier: Amsterdam, The Netherlands, 2014; Volume 18, pp. 175–200. [Google Scholar]

- Sensoy, H.; Kara, Ö. Slope Shape Effect on Runoff and Soil Erosion under Natural Rainfall Conditions. iForest-Biogeosciences For. 2014, 7, 110. [Google Scholar] [CrossRef]

- Marzen, M.; Iserloh, T.; De Lima, J.L.M.P.; Fister, W.; Ries, J.B. Impact of Severe Rain Storms on Soil Erosion: Experimental Evaluation of Wind-Driven Rain and Its Implications for Natural Hazard Management. Sci. Total Environ. 2017, 590, 502–513. [Google Scholar] [CrossRef]

- Anache, J.A.A.; Wendland, E.C.; Oliveira, P.T.S.; Flanagan, D.C.; Nearing, M.A. Runoff and Soil Erosion Plot-Scale Studies under Natural Rainfall: A Meta-Analysis of the Brazilian Experience. Catena 2017, 152, 29–39. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Shi, W. Seismic Control of Adaptive Variable Stiffness Intelligent Structures Using Fuzzy Control Strategy Combined with LSTM. J. Build. Eng. 2023, 78, 107549. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, Y.; Nagarajaiah, S.; Shi, W. Bi-Directional Semi-Active Tuned Mass Damper for Torsional Asymmetric Structural Seismic Response Control. Eng. Struct. 2023, 294, 116744. [Google Scholar] [CrossRef]

- Apollonio, C.; Petroselli, A.; Tauro, F.; Cecconi, M.; Biscarini, C.; Zarotti, C.; Grimaldi, S. Hillslope Erosion Mitigation: An Experimental Proof of a Nature-Based Solution. Sustainability 2021, 13, 6058. [Google Scholar] [CrossRef]

- Chen, S.C.; Chang, K.T.; Wang, S.H.; Lin, J.Y. The Efficiency of Artificial Materials Used for Erosion Control on Steep Slopes. Environ. Earth Sci. 2011, 62, 197–206. [Google Scholar] [CrossRef]

- Climate Hazard Center CHIRPS: Rainfall Estimates from Rain Gauge and Satellite Observations. Available online: https://www.chc.ucsb.edu/data/chirps (accessed on 15 November 2023).

- Badan Informasi Geospasial Satu Data Indonesia. Available online: https://tanahair.indonesia.go.id/portal-web (accessed on 15 November 2023).

- López-Vicente, M.; Guzmán, G. Measuring Soil Erosion and Sediment Connectivity at Distinct Scales. In Precipitation; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780128226995. [Google Scholar]

- Li, P.; Tariq, A.; Li, Q.; Ghaffar, B.; Farhan, M.; Jamil, A.; Soufan, W.; El Sabagh, A.; Freeshah, M. Soil Erosion Assessment by RUSLE Model Using Remote Sensing and GIS in an Arid Zone. Int. J. Digit Earth 2023, 16, 3105–3124. [Google Scholar] [CrossRef]

- Ramdhan Olii, M.; Ichsan, I. Assessment of Critical Land Using Geographic Information Systems—A Case Study of Limboto Watershed, Gorontalo. IOP Conf. Ser. Earth Environ. Sci. 2020, 437, 012053. [Google Scholar] [CrossRef]

- Takal, K.M.; Mittal, S.K.; Sarup, J. Estimation of Soil Erosion and Net Sediment Trapped of Upper-Helmand Catchment in Kajaki Reservoir Using USLE Model and Remote Sensing & GIS Technique. Int. J. Adv. Eng. Res. Sci. 2017, 4, 150–156. [Google Scholar] [CrossRef]

- Hamed, M.M.; Nashwan, M.S.; Shahid, S.; Wang, X.J.; Ismail, T.B.; Dewan, A.; Asaduzzaman, M. Future Köppen-Geiger Climate Zones over Southeast Asia Using CMIP6 Multimodel Ensemble. Atmos. Res. 2023, 283, 106560. [Google Scholar] [CrossRef]

- Nicknish, P.A.; Chiang, J.C.H.; Hu, A.; Boos, W.R. Regional Tropical Rainfall Shifts under Global Warming: An Energetic Perspective OPEN ACCESS Regional Tropical Rainfall Shifts under Global Warming: An Energetic Perspective. Environ. Res. Clim. 2023, 2, 015007. [Google Scholar] [CrossRef]

- Mamalakis, A.; Randerson, J.T.; Yu, J.-Y.; Pritchard, M.S.; Magnusdottir, G.; Smyth, P.; Levine, P.A.; Yu, S.; Foufoula-Georgiou, E. Zonally Contrasting Shifts of the Tropical Rain Belt in Response to Climate Change. Nat. Clim. Chang. 2021, 11, 143–151. [Google Scholar] [CrossRef]

- Salles, C.; Poesen, J.; Sempere-Torres, D. Kinetic Energy of Rain and Its Functional Relationship with Intensity. J. Hydrol. 2002, 257, 256–270. [Google Scholar] [CrossRef]

- Mineo, C.; Ridolfi, E.; Moccia, B.; Russo, F.; Napolitano, F. Assessment of Rainfall Kinetic-Energy–Intensity Relationships. Water 2019, 11, 1994. [Google Scholar] [CrossRef]

- Shin, S.S.; Park, S.D.; Choi, B.K. Universal Power Law for Relationship between Rainfall Kinetic Energy and Rainfall Intensity. Adv. Meteorol. 2016, 2016, 2494681. [Google Scholar] [CrossRef]

- Rachman, A. La Nina 3 Tahun Berakhir, Ancaman Baru Intai RI Di 2023. Available online: https://www.cnbcindonesia.com/news/20221229190500-4-401309/la-nina-3-tahun-berakhir-ancaman-baru-intai-ri-di-2023 (accessed on 15 November 2023).

- Chadwick, R.; Good, P.; Martin, G.; Rowell, D.P. Large Rainfall Changes Consistently Projected over Substantial Areas of Tropical Land. Nat. Clim. Chang. 2016, 6, 177–181. [Google Scholar] [CrossRef]

- Mohamadi, M.A.; Kavian, A. Effects of Rainfall Patterns on Runoff and Soil Erosion in Field Plots. Int. Soil Water Conserv. Res. 2015, 3, 273–281. [Google Scholar] [CrossRef]

- Chang, J.-M.; Chen, H.; Jou, B.J.-D.; Tsou, N.-C.; Lin, G.-W. Characteristics of Rainfall Intensity, Duration, and Kinetic Energy for Landslide Triggering in Taiwan. Eng. Geol. 2017, 231, 81–87. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Indraratna, B. Natural Fibre for Geotechnical Applications: Concepts, Achievements and Challenges. Sustainability 2023, 15, 8603. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Asrofi, M.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; et al. Sugar Palm (Arenga pinnata (Wurmb.) Merr) Cellulosic Fibre Hierarchy: A Comprehensive Approach from Macro to Nano Scale. J. Mater. Res. Technol. 2019, 8, 2753–2766. [Google Scholar] [CrossRef]

- Abdul Gafur, N.; Sakakibara, M.; Sera, K.; Indriati Arifin, Y. Toxic Metal Concentrations of Human Hair in Downstream of ASGM Sites in Bone Bolango Regency, Gorontalo Province, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2020, 536, 012006. [Google Scholar] [CrossRef]

- Arifin, Y.I.; Sakakibara, M.; Sera, K.; Fenty Usman, P.; Lihawa, F. Mercury Exposure from Small Scale Gold Mining Activities and Neurological Symptoms on Inhabitants and Miners: A Case Study in Bolaang Mongondow, North Sulawesi Province, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2020, 589, 012013. [Google Scholar] [CrossRef]

- Kasamatsu, H.; Shimagami, M.; Manovita Pateda, S.; Muziatun; Pongoliu, Y.; Tamu, Y.; Bumulo, S. Transdisciplinary Approach for Solving Problems in an Artisanal and Small-Scale Gold Mining in Gorontalo, Indonesia. World Futures 2023, 79, 593–609. [Google Scholar]

| Key Aspects | Natural Fibers | |||||

|---|---|---|---|---|---|---|

| Mechanical Properties | Coir | Hemp | Jute | Sisal | Buriti | Sugar Palm |

| Diameter (µm) | 90–500 | 33 | 10–85 | 180–470 | 240–370 | |

| Density (kg/m3) | 870–1520 | 1140–1500 | 1100–1500 | 700–1450 | 630–1120 | 1160 |

| Tensile strength (MPa) | 100–225 | 270–920 | 250–860 | 280–750 | 129–254 | 222–286 |

| Young modulus (GPa) | 3–6 | 30–70 | 10–30 | 9–56 | 22–32 | 4–12 |

| Elongation at break (%) | 15–50 | 240–370 | 222–286 | 4–12 | 2.3–3.1 | 2.2–6.1 |

| Chemical (%) | ||||||

| Cellulose | 32–51 | 67–78 | 56–71 | 57–71 | 65–71 | 43.88 |

| Hemi-cellulose | 29–35 | 5.5–16.1 | 29–35 | 16 | 7.24 | |

| Lignin | 31–35 | 2.2–3.7 | 11–24 | 11 | 21–27 | 33.24 |

| Water absorption | 95–180 | 8–9 | 12–105 | 56–230 | 9.1 | 8.36 |

| Dimensions and Properties | Natural Fibers | |||||

|---|---|---|---|---|---|---|

| Borassus | Buriti | Jute * | Coir * | Water Hyacinth | Sugar Palm | |

| Mat thickness (mm) | 20 | 10 | 6 | 9 | 6.96 | 6 |

| Strip thickness (mm) | 22.5 | 12.5 | 6 | 9 | 7.0 | 7.5 |

| Density (kg/m2) | 1.091 | 0.413 | 0.5 | 0.4 | 0.854 | 0.29 |

| Percentage of open area | 22.9 | 55.8 | 70–75 | 65 | 58.78 | 77.44 |

| Mesh size (mm) | 50 × 50 | 40 × 40 | 11 × 18 | - | 30 × 30 | 50 × 50 |

| Lifespan (yr.) | NA | NA | Up to 1 | 4–6 | NA | >5 |

| Erosion Event Date | Precipitation Characteristics | Soil Loss (kg) | |||

|---|---|---|---|---|---|

| P 1 | P Peak 2 | NDP 3 | Bare Soil | ECB | |

| 9 February 2023 | 52.9 | 23.6 | 2 | 3.5 | 0.6 |

| 18 February 2023 | 6.8 | 4.7 | 0 | 6.5 | 0.5 |

| 28 February 2023 | 54.1 | 43 | 1 | 20 | 1.5 |

| 5 March 2023 | 18.7 | 9.5 | 1 | 10 | 0.6 |

| 14 March 2023 | 11 | 6.5 | 0 | 6.8 | 0.8 |

| 18 March 2023 | 11.8 | 10.1 | 1 | 3.6 | 0.6 |

| 24 March 2023 | 21.1 | 5.8 | 0 | 22 | 1.7 |

| 30 March 2023 | 95.4 | 36.5 | 3 | 40 | 5.0 |

| 4 April 2023 | 7.6 | 3.8 | 0 | 2.9 | 0.9 |

| 9 April 2023 | 41.6 | 27.9 | 2 | 22 | 2.1 |

| 16 April 2023 | 6 | 5 | 0 | 2 | 0.5 |

| 21 April 2023 | 26 | 25.2 | 1 | 8 | 1.3 |

| 30 April 2023 | 25.3 | 18 | 1 | 9.1 | 1.4 |

| TOTAL | 379.1 | 154.6 | 16.7 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jahja, M.; Mudatstsir, A.; Supu, I.; Arifin, Y.I.; Rauf, J.; Sakakibara, M.; Yamaguchi, T.; Metaragakusuma, A.P.; Butolo, I. How Effective Are Palm-Fiber-Based Erosion Control Blankets (ECB) against Natural Rainfall? Sustainability 2024, 16, 1655. https://doi.org/10.3390/su16041655

Jahja M, Mudatstsir A, Supu I, Arifin YI, Rauf J, Sakakibara M, Yamaguchi T, Metaragakusuma AP, Butolo I. How Effective Are Palm-Fiber-Based Erosion Control Blankets (ECB) against Natural Rainfall? Sustainability. 2024; 16(4):1655. https://doi.org/10.3390/su16041655

Chicago/Turabian StyleJahja, Mohamad, Ali Mudatstsir, Idawati Supu, Yayu Indriati Arifin, Jayanti Rauf, Masayuki Sakakibara, Tsutomu Yamaguchi, Andi Patiware Metaragakusuma, and Ivana Butolo. 2024. "How Effective Are Palm-Fiber-Based Erosion Control Blankets (ECB) against Natural Rainfall?" Sustainability 16, no. 4: 1655. https://doi.org/10.3390/su16041655