A Formulation Model for Computations to Estimate the Lifecycle Cost of NiZn Batteries

Abstract

1. Introduction

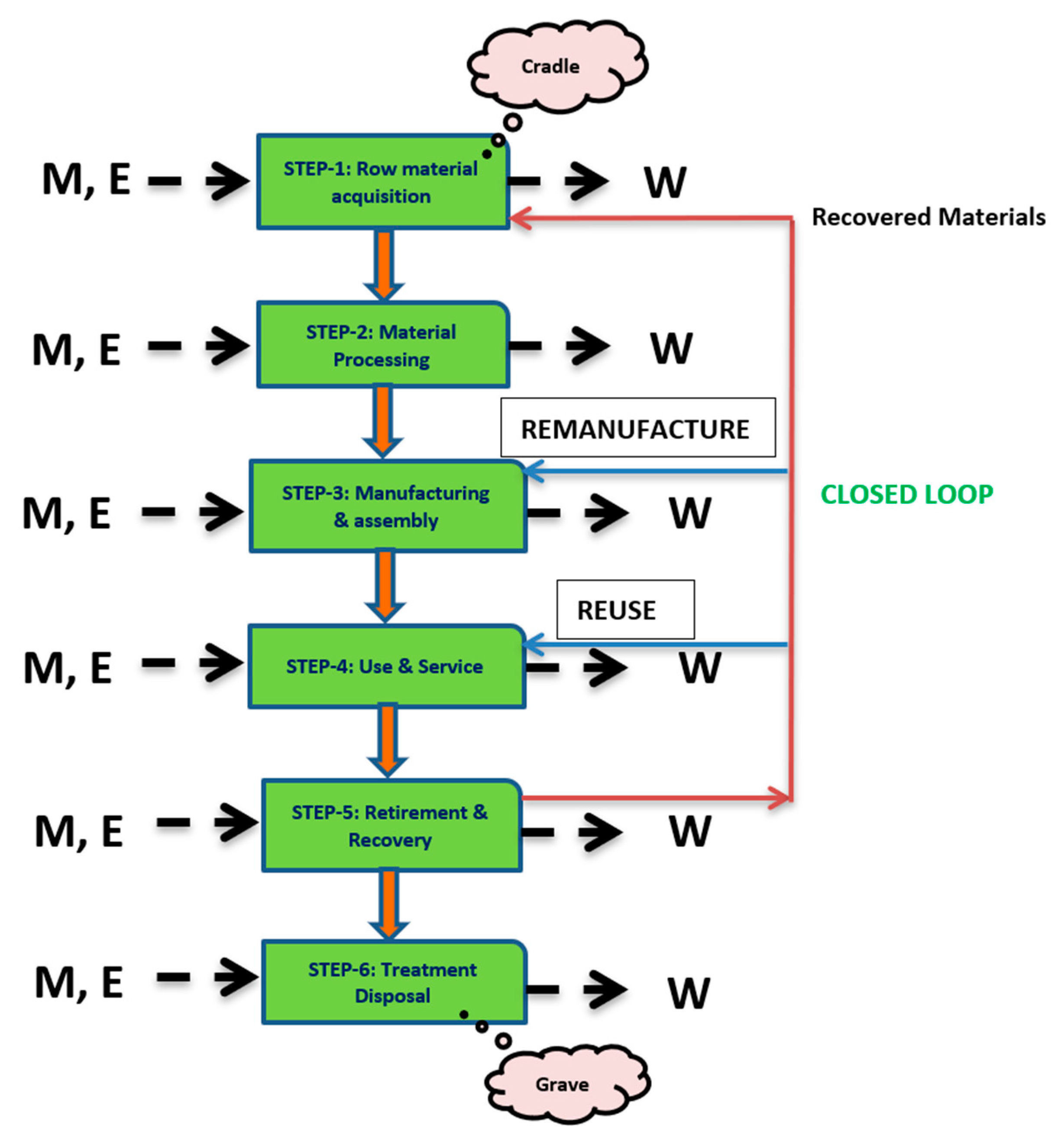

2. Methodology: Cost Function

3. Lifecycle Cost Modeling

- = acquisition or capitol or investment cost (€/kWh);

- = subsidy by the government (%);

- = operation and maintenance costs (€/kWh);

- = cost at the end of life (€/kWh);

- = energy stored in or discharged from the battery (kWh);

- Wp = wattage peak;

- = duration of the lifetime of the battery in years;

- = discount rate (%);

- = time in years.

3.1. Capital Cost ()

3.1.1. Cost of Raw-Material Acquisition

- ;

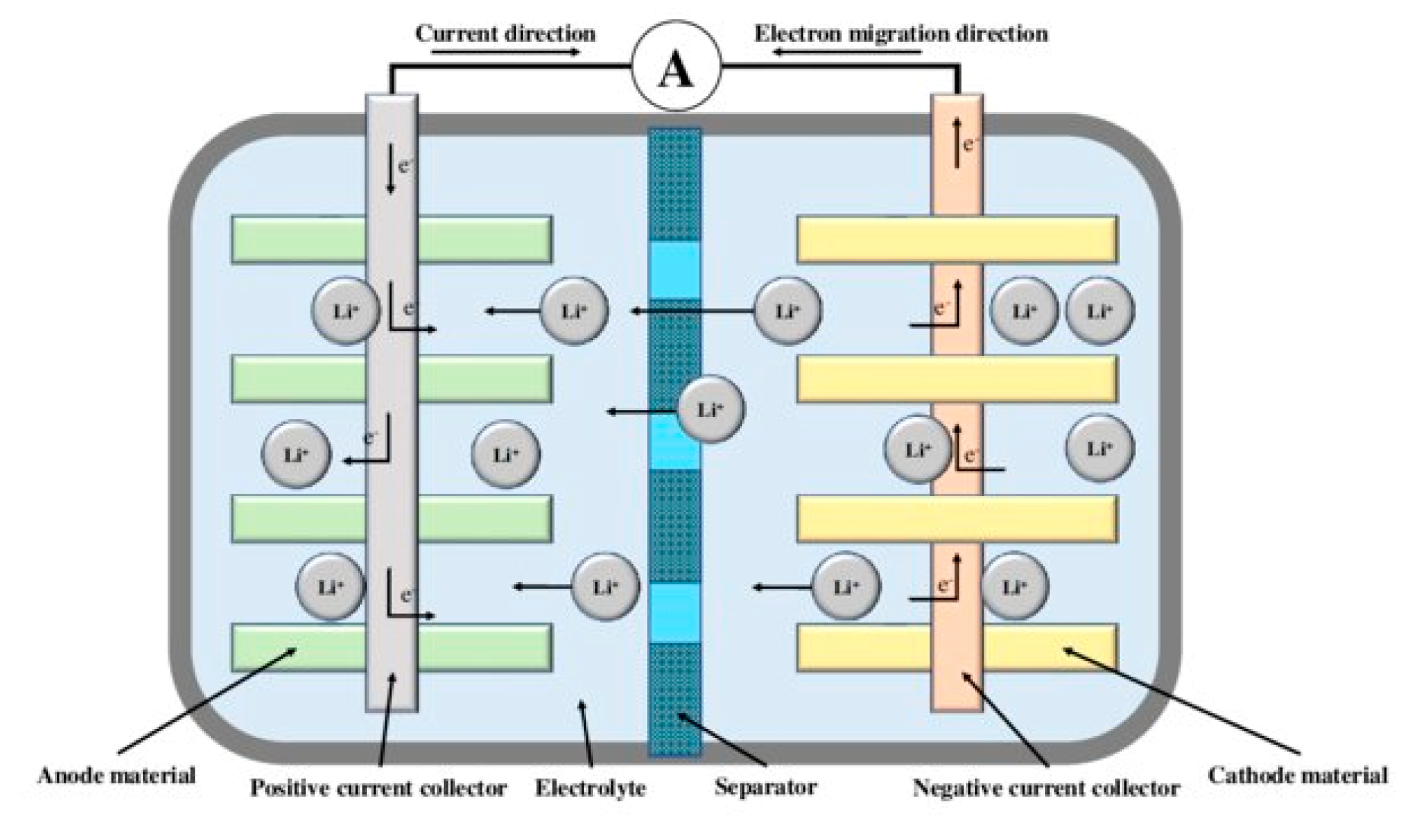

3.1.2. Cost of Manufacturing ()

3.2. Cost of Use and Service ()

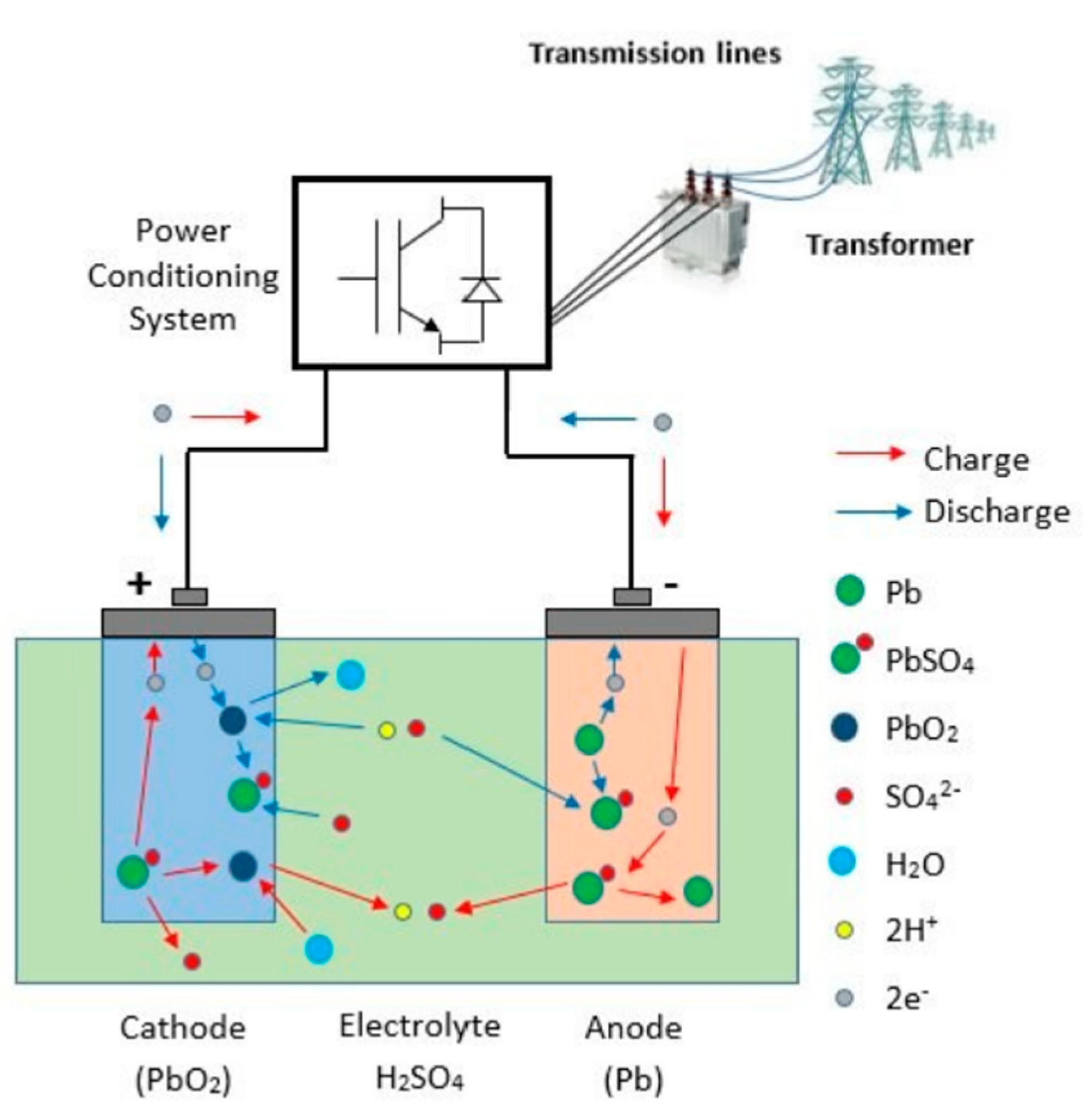

3.3. End-of-Life Cost ()

4. Results and Discussion

4.1. Costs Based on Formula Calculations

4.2. Costs Based on Energy Units Released

4.3. Costs Based on openLCA Calculations

5. Limitations and Assumptions

6. Conclusions

- Formula modeling and openLCA v. 1.11 software operations have the lowest costs and the lowest cost per unit of emitted energy. As previously stated, this is based on comparisons between lead–acid and lithium-ion NMC and LFP batteries;

- The location is critical for infrastructure (material extraction area, manufacturing plant, usage area, recycling plant, etc.). This can have a substantial long-term impact on battery costs;

- Other aspects to consider include machinery prices, storage, raw-material providers, and shipment numbers. The value of battery-recycling materials is very significant. These aspects have a substantial impact on the battery’s lifetime cost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lehmusto, M.; Santasalo-aarnio, A. Mathematical framework for total cost of ownership analysis of marine electrical energy storage inspired by circular economy. J. Power Sources 2022, 528, 231164. [Google Scholar] [CrossRef]

- Martínez-Fernández, P.; Villalba-Sanchís, I.; Yepes, V.; Insa-Franco, R. A review of modelling and optimisation methods applied to railways energy consumption. J. Clean. Prod. 2019, 222, 153–162. [Google Scholar] [CrossRef]

- Battke, B.; Schmidt, T.S.; Grosspietsch, D.; Hoffmann, V.H. A review and probabilistic model of lifecycle costs of stationary batteries in multiple applications. Renew. Sustain. Energy Rev. 2013, 25, 240–250. [Google Scholar] [CrossRef]

- EDP Labelec. Long Lasting Batteries; EDP Labelec: Sacavém, Portugal, 2021. [Google Scholar]

- Chang, D.; Kim, Y.; Jung, S. Comprehensive study of the performance of alkaline organic redox flow batteries as large-scale energy storage systems. Int. J. Energy Res. 2019, 43, 4449–4458. [Google Scholar] [CrossRef]

- Spataru, C.; Bouffaron, P. Off-Grid Energy Storage. In Storing Energy; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Wei, L.; Zeng, L.; Wu, M.C.; Jiang, H.R.; Zhao, T.S. An aqueous manganese-copper battery for large-scale energy storage applications. J. Power Sources 2019, 423, 203–210. [Google Scholar] [CrossRef]

- Yousif, M.; Ai, Q.; Wattoo, W.A.; Jiang, Z.; Hao, R.; Gao, Y. Least cost combinations of solar power, wind power, and energy storage system for powering large-scale grid. J. Power Sources 2019, 412, 710–716. [Google Scholar] [CrossRef]

- Lai, S.B.; Jamesh, M.I.; Wu, X.C.; Dong, Y.L.; Wang, J.H.; Gao, M.; Liu, J.F.; Sun, X.M. A promising energy storage system: Rechargeable Ni–Zn battery. Rare Met. 2017, 36, 381–396. [Google Scholar] [CrossRef]

- IEC 60300-3-3:2017; Dependability Management—Part 3-3: Application Guide—Life Cycle Costing. International Electrotechnical Commission: London, UK, 2017.

- Zhou, Z.; Alcalá, J.; Yepes, V. Environmental, economic and social impact assessment: Study of bridges in china’s five major economic regions. Int. J. Environ. Res. Public Health 2021, 18, 122. [Google Scholar] [CrossRef]

- ISO 604 61010-1:2001; International Standard International Standard. ISO: Geneva, Switzerland, 2003; Volume 2003, p. 13.

- He, G.; Ciez, R.; Moutis, P.; Kar, S.; Whitacre, J.F. The economic end of life of electrochemical energy storage. Appl. Energy 2020, 273, 115151. [Google Scholar] [CrossRef]

- Johnson, M.R.; McCarthy, I.P. Product recovery decisions within the context of Extended Producer Responsibility. J. Eng. Technol. Manag.—JET-M 2014, 34, 9–28. [Google Scholar] [CrossRef]

- Kampker, A.; Wessel, S.; Fiedler, F.; Maltoni, F. Battery pack remanufacturing process up to cell level with sorting and repurposing of battery cells. J. Remanufacturing 2021, 11, 1–23. [Google Scholar] [CrossRef]

- Mathew, M.; Kong, Q.H.; McGrory, J.; Fowler, M. Simulation of lithium ion battery replacement in a battery pack for application in electric vehicles. J. Power Sources 2017, 349, 94–104. [Google Scholar] [CrossRef]

- Nagapurkar, P.; Smith, J.D. Techno-economic optimization and environmental Life Cycle Assessment (LCA) of microgrids located in the US using genetic algorithm. Energy Convers. Manag. 2019, 181, 272–291. [Google Scholar] [CrossRef]

- Larsson, P.; Borjesson, P. Cost models for battery energy storage systems. Bachelor’s Thesis, KTH School of Industrial Engineering and Management, Stockholm, Sweeden, 2018; p. 31. [Google Scholar]

- Mehdijev, S. Dimensioning and Life Cycle Costing of Battery Storage System in residential housing—A case study of Local System Operator Concept. 2017. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2:1130036 (accessed on 30 January 2024).

- Žižlavský, O. Net Present Value Approach: Method for Economic Assessment of Innovation Projects. Procedia Soc. Behav. Sci. 2014, 156, 506–512. [Google Scholar] [CrossRef]

- Santarremigia, F.E.; Poveda-Reyes, S.; Hervás-Peralta, M.; Molero, G.D. A Decision-Making Method for Boosting New Digitalization Technologies. Int. J. Inf. Technol. Decis. Mak. 2021, 20, 635–669. [Google Scholar] [CrossRef]

- Schmidt, O.; Melchior, S.; Hawkes, A.; Staffell, I. Projecting the Future Levelized Cost of Electricity Storage Technologies. Joule 2019, 3, 81–100. [Google Scholar] [CrossRef]

- Poonpun, P.; Jewell, W.T. Analysis of the cost per kilowatt hour to store electricity. IEEE Trans. Energy Convers. 2008, 23, 529–534. [Google Scholar] [CrossRef]

- Mongird, K.; Viswanathan, V.; Balducci, P.; Alam, J.; Fotedar, V.; Koritarov, V.; Hadjerioua, B. An Evaluation of Energy Storage Cost and Performance Characteristics. Energies 2020, 13, 3307. [Google Scholar] [CrossRef]

- Mathur, N.; Sutherland, J.W.; Singh, S. A study on end of life photovoltaics as a model for developing industrial synergistic networks. J. Remanufacturing 2022, 12, 281–301. [Google Scholar] [CrossRef]

- Dai, Q.; Spangenberger, J.; Ahmed, S.; Gaines, L.; Kelly, J.C.; Wang, M. EverBatt: A Closed-Loop Battery Recycling Cost and Environmental Impacts Model; Argonne National Laboratory: Argonne, IL, USA, 2019; pp. 1–88.

- Peters, M.S.; Timmerhaus, K.D. PDandEforC Engineers.pdf. In Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Seuring, S.; Schmidt, W.-P.; Ciroth, A.; Rebitzer, G.; Huppes, G.; Lichtenvort, K. Modeling for Life Cycle Costing. In Environmental Life Cycle Costing; CRC Press: Boca Raton, FL, USA, 2008; pp. 17–34. [Google Scholar] [CrossRef]

- Navarro, I.J.; Yepes, V.; Martí, J.V. A review of multicriteria assessment techniques applied to sustainable infrastructures design. Adv. Civ. Eng. 2019, 2019, 6134803. [Google Scholar] [CrossRef]

- Rahman, M.M.; Oni, A.O.; Gemechu, E.; Kumar, A. The development of techno-economic models for the assessment of utility-scale electro-chemical battery storage systems. Appl. Energy 2021, 283, 116343. [Google Scholar] [CrossRef]

- Schoenung, S.M.; Hassenzahl, W. Long vs. Short-Term Energy Storage: Sensitivity Analysis A Study for the DOE Energy Storage Systems Program; Sandia National Laboratories (SNL): Albuquerque, NM, USA; Livermore, CA, USA, 2007; p. 42.

- Marchi, B.; Pasetti, M.; Zanoni, S. Life Cycle Cost Analysis for BESS Optimal Sizing. Energy Procedia 2017, 113, 127–134. [Google Scholar] [CrossRef]

- Xu, Y.; Pei, J.; Cui, L.; Liu, P.; Ma, T. The Levelized Cost of Storage of Electrochemical Energy Storage Technologies in China. Front. Energy Res. 2022, 10, 873800. [Google Scholar] [CrossRef]

- McCarthy, L.; Delbosc, A.; Currie, G.; Molloy, A. Factors influencing travel mode choice among families with young children (aged 0–4): A review of the literature. Transp. Rev. 2017, 37, 767–781. [Google Scholar] [CrossRef]

- Lima, M.C.C.; Pontes, L.P.; Vasconcelos, A.S.M.; de Araujo Silva Junior, W.; Wu, K. Economic Aspects for Recycling of Used Lithium-Ion Batteries from Electric Vehicles. Energies 2022, 15, 2203. [Google Scholar] [CrossRef]

- Alfaro-Algaba, M.; Ramirez, F.J. Techno-economic and environmental disassembly planning of lithium-ion electric vehicle battery packs for remanufacturing. Resour. Conserv. Recycl. 2020, 154, 104461. [Google Scholar] [CrossRef]

- Lander, L.; Cleaver, T.; Rajaeifar, M.A.; Nguyen-Tien, V.; Elliott, R.J.; Heidrich, O.; Kendrick, E.; Edge, J.S.; Offer, G. Financial viability of electric vehicle lithium-ion battery recycling. iScience 2021, 24. [Google Scholar] [CrossRef]

- Squiller, D.; Brody, R. Nickel-zinc batteries for hybrid electric vehicles and stationary storage. In Technical Proceedings of the 2011 NSTI Nanotechnology Conference and Expo, NSTI-Nanotech 2011; 2011; Volume 1, pp. 690–693. Available online: http://www.scopus.com/inward/record.url?eid=2-s2.0-81455133603&partnerID=40&md5=0f751a82e007f50374d0a933362d2ab7 (accessed on 30 January 2024).

- Poullikkas, A.; Nikolaidis, P. A comparative review of electrical energy storage systems for better sustainability. J. Power Technol. 2017, 97, 220–245. [Google Scholar]

- Halleux, V. New EU Regulatory Framework for Batteries. 2021. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2021/689337/EPRS_BRI(2021)689337_EN.pdf (accessed on 7 July 2021).

- Sundén, B. Battery technologies. In Hydrogen, Batteries and Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2019; pp. 57–79. [Google Scholar] [CrossRef]

- Institute of Electrical and Electronics Engineers. Nickel Metal Life Cycle Data. In Proceedings of the 2019 18th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Las Vegas, NV, USA, 28–31 May 2019. [Google Scholar]

| Cost Criteria | Assumptions of the Equations |

|---|---|

| A. Total Cost of Variable | A.1 + A.2 +A.3 |

| 1. Cost of Materials | The sum of the cost of the materials |

| 2. Cost of Direct Labor | Total direct labor-hour requirement * hourly labor rate |

| 3. Variable Overhead | 40% of A.2 + 20% of C.1 |

| B. Total Investment | B.1 + B.2 + B.3 + B.4 |

| 1. Cost of Launch | 5% of A.1 + 10% of A.2 + 10% of A.3 |

| 2. Working Capital | 15% of A.2 + 15% of A.3 |

| 3. Capital Equipment | The sum of the costs of the capital equipment |

| 4. Cost of Building | Total building area * per-square-meter building cost |

| C. Fixed Expenses | C.1 + C.2 + C.3 |

| 1. Depreciation | 16.7% of B.3 + 5% of B.4 |

| 2. GSA Cost | 25% of A.2 + 25% of A.3 + 25% of C.l |

| 3. R&D Cost | 40% of C.1 |

| D. Profit | 5% of B |

| E. Warranty | 5.6% of A + 5.6% of C + 5.6% of D |

| F. Total Cost | A + C + D + E |

| Final Battery Cost Calculations from Formulas | |||||

|---|---|---|---|---|---|

| Number | Type of Battery | Production (Includes Cost of Raw Materials) | Use Scenario: Generic Use | EoL (End-of-Life) | Total (€/kg of Battery Mass) |

| 1 | NiZn Formulation 1 | 4.63 | 0.1 | 0.88 | 5.61 |

| 2 | NiZn Formulation 2 | 5.41 | 0.1 | 0.91 | 6.42 |

| 3 | Lead–Acid Battery | 2.37 | 0.1 | 4.26 | 6.73 |

| 4 | Lithium-Ion Battery LFP | 19.25 | 0.01 | 11.64 | 30.9 |

| 5 | Lithium-Ion Battery NMC 532 | 74 | 1.16 | 11.64 | 86.8 |

| 6 | Lithium-Ion Battery NMC 622 | 108.81 | 0.1 | 11.6 | 120.55 |

| Cost for Releasing 1 kWh of Energy | ||||

|---|---|---|---|---|

| Number | Battery Name | Mass to Release 1 kWh of Energy (kg/kWh) | Final Battery Cost (€/kg Battery) | Cost per Energy Unit Released (€/kWh) |

| 1 | NiZn Formulation 1 | 0.0067 | 5.61 | 0.0376 |

| 2 | NiZn Formulation 2 | 0.0067 | 6.42 | 0.0430 |

| 3 | Lead–Acid Battery | 0.0948 | 6.73 | 0.6380 |

| 4 | Lithium-Ion Battery LFP | 0.00513 | 30.0 | 0.15852 |

| 5 | Lithium-Ion Battery NMC 532 | 0.00513 | 86.8 | 0.44528 |

| 6 | Lithium-Ion Battery NMC 622 | 0.00513 | 120.55 | 0.61842 |

| Cost Elements | Cost Breakdown by Life Stage | ||||

|---|---|---|---|---|---|

| Cost of the Raw-Material Acquisition | Cost in the Manufacturing Stage | Cost in the Installation Phase | Cost in the Installation, Operation, and Maintenance Phases | Cost in the Disposal/Recycling Stage | |

| NiZn Formulation 1 | |||||

| Cost for purchasing raw materials or subproducts (€/kg) | 4.62 | 4.62 | |||

| Energy cost (kWh/kg) | 0.01 | 0.01 | 0.01 | 0.01 | |

| Labor cost (€/month * person) | 2500 | 2500 | 2500 | 2500 | |

| Machinery cost | 0 | 49,300.4 | |||

| Safety/quality tests | |||||

| Packaging | |||||

| Transportation cost (€/kg * km) | 0.00003 | ||||

| Storage cost (€/kg) (https://www.osti.gov/servlets/purl/7300200 (accessed on 30 January 2024)) | 4.62 | ||||

| Software/hardware development | |||||

| Income from recycling (sale of recycled parts) | |||||

| NiZn Formulation 2 | |||||

| Cost for purchasing raw materials or subproducts (€/kg) | 5.41 | 5.41 | |||

| Energy cost (kWh/kg) | 0.01 | 0.01 | 0.01 | 0.01 | |

| Labor cost (€/month * person) | 2500 | 2500 | 2500 | 2500 | |

| Machinery cost | 0 | 49,300.4 | |||

| Safety/quality tests | |||||

| Packaging | |||||

| Transportation cost (€/kg * km) | 0.00003 | ||||

| Storage cost (€/kg) (https://www.osti.gov/servlets/purl/7300200 (accessed on 30 January 2024)) | 5.41 | ||||

| Software/hardware development | |||||

| Income from recycling (sale of recycled parts) | |||||

| Lead–Acid Battery | |||||

| Cost for purchasing raw materials or subproducts (€/kg) | 2.36 | 2.36 | |||

| Energy cost (kWh/kg) | 0.01 | 0.01 | 0.01 | 0.01 | |

| Labor cost (€/month * person) | 2500 | 2500 | 2500 | 2500 | |

| Machinery cost | 0 | 89,500 | |||

| Safety/quality tests | |||||

| Packaging | |||||

| Transportation cost (€/kg * km) | 0.00003 | ||||

| Storage cost (€/kg) (https://www.osti.gov/servlets/purl/7300200 (accessed on 30 January 2024)) | 2.36 | ||||

| Software/hardware development | |||||

| Income from recycling (sale of recycled parts) | |||||

| Lithium-Ion Battery LFP | |||||

| Cost for purchasing raw materials or subproducts (€/kg) | 32.54 | 19.25 | |||

| Energy cost (kWh/kg) | 0 | 1.17 | 0.01 | 0.01 | |

| Labor cost (€/month * person) | 2500 | 2500 | 2500 | 2500 | |

| Machinery cost | 0 | 108,954 | |||

| Safety/quality tests | |||||

| Packaging | 4.75 | ||||

| Transportation cost (€/kg * km) | 0.00001 | ||||

| Storage cost (€/kg) (https://www.osti.gov/servlets/purl/7300200 (accessed on 30 January 2024)) | 32.54 | ||||

| Software/hardware development | |||||

| Income from recycling (sale of recycled parts) | |||||

| Lithium-Ion Battery NMC 532 | |||||

| Cost for purchasing raw materials or subproducts (€/kg) | 24.27 | 74 | |||

| Energy cost (kWh/kg) | 0 | 1.86 | 0.01 | 0.01 | |

| Labor cost (€/month * person) | 2500 | 2500 | 2500 | 2500 | |

| Machinery cost | 0 | 108,954 | |||

| Safety/quality tests | |||||

| Packaging | 5.55 | ||||

| Transportation cost (€/kg * km) | 0.00001 | ||||

| Storage cost (€/kg) (https://www.osti.gov/servlets/purl/7300200 (accessed on 30 January 2024)) | 24.27 | ||||

| Software/hardware development | |||||

| Income from recycling (sale of recycled parts) | |||||

| Lithium-Ion Battery NMC 622 | |||||

| Cost for purchasing raw materials or subproducts (€/kg) | 25.57 | 108.4 | |||

| Energy cost (kWh/kg) | 0 | 1.86 | 0.01 | 0.01 | |

| Labor cost (€/month * person) | 2500 | 2500 | 2500 | 2500 | |

| Machinery cost | 0 | 108,954 | |||

| Safety/quality tests | |||||

| Packaging | 5.02 | ||||

| Transportation cost (€/kg * km) | 0.00001 | ||||

| Storage cost (€/kg) (https://www.osti.gov/servlets/purl/7300200 (accessed on 30 January 2024)) | 25.57 | ||||

| Software/hardware development | |||||

| Income from recycling (sale of recycled parts) | |||||

| Type of Battery | Battery Pack Production Cost Calculated by the Model (€/kg of Battery Mass) | Battery Pack Production Cost Calculated by the Software openLCA v. 1.11 (€/kg of Battery Mass) | Percentage Deviation |

|---|---|---|---|

| Ni Zn Formulation 2 | 6.42 | 6.30 | 1.90 |

| Lead–Acid Battery | 6.73 | 6.62 | 1.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malviya, A.K.; Zarehparast Malekzadeh, M.; Santarremigia, F.E.; Molero, G.D.; Villalba-Sanchis, I.; Yepes, V. A Formulation Model for Computations to Estimate the Lifecycle Cost of NiZn Batteries. Sustainability 2024, 16, 1965. https://doi.org/10.3390/su16051965

Malviya AK, Zarehparast Malekzadeh M, Santarremigia FE, Molero GD, Villalba-Sanchis I, Yepes V. A Formulation Model for Computations to Estimate the Lifecycle Cost of NiZn Batteries. Sustainability. 2024; 16(5):1965. https://doi.org/10.3390/su16051965

Chicago/Turabian StyleMalviya, Ashwani Kumar, Mehdi Zarehparast Malekzadeh, Francisco Enrique Santarremigia, Gemma Dolores Molero, Ignacio Villalba-Sanchis, and Victor Yepes. 2024. "A Formulation Model for Computations to Estimate the Lifecycle Cost of NiZn Batteries" Sustainability 16, no. 5: 1965. https://doi.org/10.3390/su16051965

APA StyleMalviya, A. K., Zarehparast Malekzadeh, M., Santarremigia, F. E., Molero, G. D., Villalba-Sanchis, I., & Yepes, V. (2024). A Formulation Model for Computations to Estimate the Lifecycle Cost of NiZn Batteries. Sustainability, 16(5), 1965. https://doi.org/10.3390/su16051965