3.1. Bamboo Housing in Latin America

There are many bamboo species in Latin America; the one predominantly used for construction purposes is guadua angustifolia. In Colombia, the traditional method of building with bamboo is known as “bahareque”, while in Peru and Ecuador, it is referred to as “quincha”. Similar techniques are also found in other countries such as Brazil and Venezuela. These ancient construction techniques typically involve using uprights of wood or bamboo and horizontal elements made of twigs or reeds. A braid can be single sided or double sided and is plastered with “mud” (loam), clay, gypsum (mixture of lime and water), or a combination of similar raw materials. The finishing of these walls always involves plastering with cement, lime, or earthen materials.

Due to the occurrence of earthquakes in many countries, the bahareque and quincha structures—when they were in poor condition—were often proved unable to withstand severe seismic activity, resulting in the collapse or damage of numerous houses. These techniques were therefore commonly referred to as “non-engineered”. Where the structures were in good condition (properly built, preserved, and maintained well), their physical behavior during earthquakes was acceptable. Consequently, a global search began for technically improved bamboo-based building constructions (or engineered bahareque). Today, the improved bahareque technique for walls is widely regarded as earthquake-resistant and aesthetically pleasing. The bahareque walls are normally called “engineered bahareque”, or “composite bamboo shear walls” (CBSW). The CBSW system is an effective way of creating low-carbon housing that provides excellent code-compliant strength, ductility, and durability, and has significant potential for affordable housing in highly seismic lower- and middle-income countries, where bamboo grows [

11].

In Colombia, the pioneering use of bahareque constructions, plastered with earth, dates back to early times. Since 2002, this guadua-based system has been included in the national building codes for seismic resistance. Following the devastating earthquake of 1999 in Colombia’s coffee region, which resulted in 1185 deaths and over 4000 injuries, it became evident that significant damage had occurred to many houses, particularly in the departments of Quindío and Risaralda. However, numerous houses were reconstructed using the improved bahareque technology. Engineer Luis Felipe López played an integral role in this process and later introduced the enhanced technology to the Philippines.

Colombian architect Simón Vélez has gained international recognition for his innovative designs in bamboo construction, making bamboo buildings widely renowned. As a result, Colombia has become a leading country in this field, with many bamboo experts being sent to other countries to share their knowledge and transfer bamboo techniques. In Colombia, there is a wealth of knowledge, and construction workers are extensively trained to work with bamboo. Currently, there are no known social housing plans of any size that incorporate the improved bahareque technique. However, ongoing studies are being conducted in the coffee region to explore the use of this new architecture for the construction of social housing.

In Costa Rica, the National Bamboo Project (NPB; 1986–1995) introduced a strategy to combat deforestation by replacing the use of wood with bamboo as a seismically sound and affordable building material. The project aimed to promote the use of bamboo in a housing program, the industrialization of bamboo, and the marketing of its by-products. Initially, 700 low-cost homes were constructed, and 200 hectares of bamboo was cultivated by 1989. Unfortunately, the NPB did not receive the intended large-scale follow-up. However, it did contribute to the improvement of construction techniques, such as using stone, bricks, and cement for foundations, bamboo piles for frames, and bamboo panels for plastered walls. The NPB demonstrated that the bamboo houses designed have the potential to be sustainable and seismically resilient alternatives to houses made of more “modern” building materials like stone, concrete, and steel. Consequently, well-designed homes using engineered bamboo have a higher chance of acceptance among local communities. In Costa Rica, bamboo can often be found in the buildings and homes of holiday resorts.

In Ecuador, the NGO Hogar de Cristo (HdC) built approximately 265,000 traditional bamboo houses for and with local communities until 2012. These housing types were designed to be built quickly. One of the prototypes, known as the “MACAHO” model, utilizes timber frames and preserved bamboo for wall panels. This particular model is often designed as an expandable home, which keeps the cost of the basic module relatively low and affordable for a large number of low-income households. According to the HdC brochure from 2020, the purchase price for the “Salomé” housing model is USD 2684 [

12]. This is, however, a temporary home with a limited lifespan. The brochure also includes models that can be expanded on the ground floor with walls made of concrete blocks, as well as final housing models with concrete block walls and metal frames. Bamboo is only used for partitions in these instances, while the house frames are constructed from wood. In 2022, the Ecuadorian government initiated a new program focused on bamboo houses, which will be implemented by the Ministry of Urban Development and Public Housing. The first type of bamboo house was constructed in the canton of Omedo, located in the province of Manabí. The local vocational training institution ”Escuela Taller Manabí”, specializing in bamboo constructions, was involved in the project, with assistance provided by INBAR and the Spanish aid organization AECID. However, the cost of a single home is USD 18,700, which is relatively high for low-income households. Nevertheless, the government has pledged to finance the construction of 220 homes as part of this project.

In Nicaragua, bamboo housing is not yet widespread. However, the National University of Engineers in Managua, UNI, has developed a prototype for use in social housing in the country. This project serves as a research center for safe building in Nicaragua, a volcanic country prone to frequent earthquakes. Moreover, young architects and engineers have designed a hurricane-resistant bamboo house in the city of El Rama, located in Nicaragua’s Caribbean region. Architect Jorge Bonilla’s start-up, “Bambuksa”, assists local communities in constructing bamboo houses. The organization EcoPlanet Bamboo owns and operates three bamboo plantations in the El Rama region, which collectively cover more than 4000 hectares of restored forest landscapes [

13].

El Salvador, another volcanic country susceptible to frequent earthquakes, explored the improved bahareque technique in 2002 through a collaborative study involving the NGOs Fundasal, Misereor, and CRATerre-EAG. The study aimed to develop a low-cost, seismic-resistant house for rural areas using bamboo and timber. Around 2015, a consultancy firm called ARUP, the Salvadoran NGO REDES, and the University of Cambridge collaborated to develop an innovative model house using bamboo, timber, and cement mortar. The resulting house was low-cost, seismically resistant, and sustainable. Technical testing was conducted at the University of Cambridge, and the authors concluded that this type of housing could be suitable for highly seismic areas [

14]. Fundasal completed an improved bahareque model house for Mrs. Bersaides Ramirez in 2022 [

15]. The development of bamboo houses in El Salvador is still at a small-scale level, but there is significant potential for growth.

In Peru, bamboo grows in the northeastern provinces of Cajamarca, Lambayeque, Piura, and Amazonas. Bamboo material is also imported from Ecuador. In the Piura region, bamboo is traditionally used by lower-income families. However, during earthquakes, many building structures using the old quincha wood and bamboo techniques were destroyed. Currently, there are pilot projects being set up in the country to construct earthquake-resistant bamboo houses. But sometimes, initiators did not prove, using calculations, that houses would become earthquake resistant. The IVUC housing institute of the University of San Martín de Porres in Lima prepared a valuable guidebook for building houses with bamboo in Peru [

16]. The architects Yann Barnet and Faouzi Jabrane from IVUC developed a small temporary house made of bamboo for the victims of the 2007 earthquake. A total of 50 growth houses consisting of prefabricated panels were built. The residents themselves assembled the houses under the technical supervision of IVUC [

17]. Later, two other housing models were developed (IVUC 2 and 3), both with an additional floor. The IVUC’s work is innovative in several ways: the houses are constructed quickly, they can be individually expanded, an extra floor can be added, and the architecture is modern and colorful. Architect Tania Cerrón also has experience in designing structures with bamboo, including rural dwellings [

18]. In the region around the city of Piura, which is often affected by floods and tropical storms, the “Mesa Técnica Regional del Bambú” was established by the regional government. Its purpose is to enhance the value of bamboo crops and improve stock management to promote Guayaquil’s bamboo production for the construction sector. With the support of the European Union, 400 construction workers will receive training in the construction of climate change-resilient bamboo houses in the Piura region. Additionally, some model homes will be built in low-income communities [

19].

In Mexico, attempts have been made in certain states to promote housing construction using bamboo and improved bahareque techniques. North of the city of Puebla, a project was initiated to construct model houses utilizing prefabricated bamboo elements. The “Comunal Taller de Arquitectura” in Mexico City collaborated with local communities to develop housing designs. However, the initial building plan, which included domestic bamboo as well as local wood and stone, was rejected for a first home due to regulatory constraints imposed by CONAVI (2016), the National Housing Commission. As a result, government funding was not yet possible. Undeterred, the construction group proceeded to design a second prototype for social housing in a mountain village, utilizing a prefabricated bamboo frame. To circumvent the use of local bamboo species, bamboo was imported from abroad. Eventually, a model house was successfully constructed through collaboration with local residents, and it was subsequently recognized and awarded by CONAVI. In addition to these government initiatives, there are also private ventures focused on bamboo housing in Mexico. One such example is the ecological bamboo house called “Casa Milpa”, which was created by Cooperativa Las Cañadas in Huatusco, Veracruz [

20]. Another noteworthy project is the “Crece tu Casa”, a bamboo structure designed by architect Lucila Aguilar in Tuzantán. This design received the second prize in the World Design Awards 2021, organized by The Architecture Community. “Crece tu Casa” is an adaptable model house with walls made from various materials [

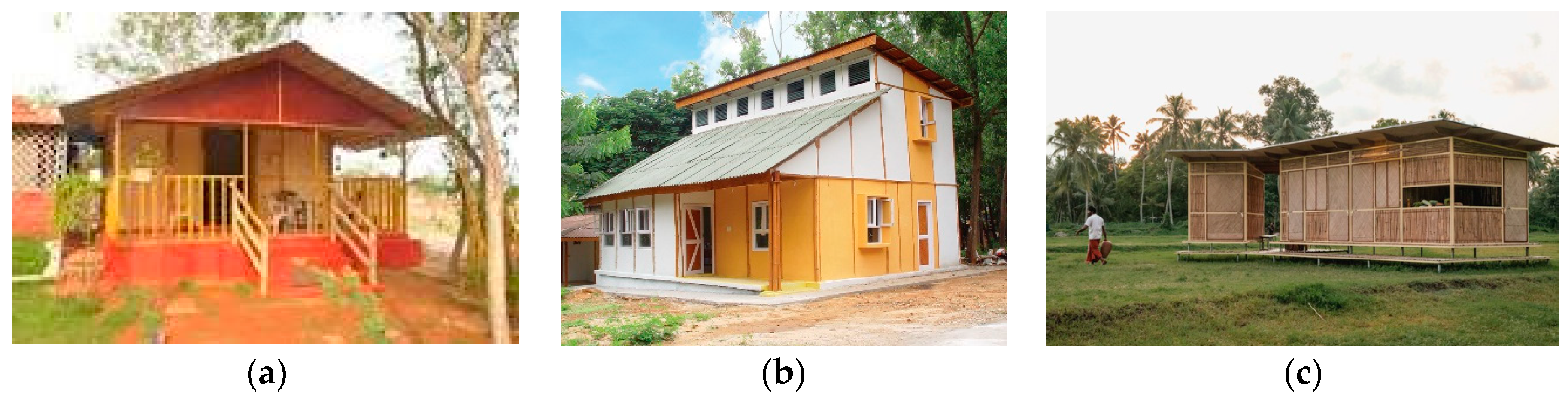

21]. Currently, Mexico is actively working on establishing a new standard (NMX) for the design and construction of bamboo structures. Exemplary bamboo dwellings in some Latin-America countries are shown in

Figure 3.

3.2. Bamboo Housing in Asia

In various Asian countries, bamboo is abundantly available for use in various applications. Traditionally, bamboo has been extensively used in agricultural areas and rural villages. It continues to be a cost-effective material for many families who construct their homes, either individually or collectively. Examples of countries known for their bamboo resources include Bangladesh, China, the Philippines, India, Indonesia, Japan, Nepal, and Thailand.

Bangladesh has an extensive delta area and is frequently affected by river flooding, as well as rising sea levels. The climate in Bangladesh is greatly influenced by its long, tropical rainy season. There is a high demand for affordable housing, with a large portion of the population relying on traditional building materials like bamboo for their homes. However, there is a shortage in the bamboo supply due to poor management, even though bamboo is still abundant. The most commonly used bamboo species is Melocanna Baccifera (muli). In areas like the Chittahong Hill Tracks, houses are constructed using bamboo, wood, and rammed earth. In flood-prone areas, homes are often raised on stilts, which can be vulnerable. In new constructions, the foundations of the dwellings must be made of concrete or stone, with wooden or bamboo structures built on top. It is preferable for elevated houses to be supported by concrete piles. Homes not only need to withstand rising water levels but also cyclones, placing additional demands on the building structures. Therefore, there is a pressing need for climate-resistant housing to tackle the consequences of climate change.

Nearly 1 million Rohingya refugees from Myanmar have found temporary shelter in Bangladesh, where they are forced to live in camps in very poor circumstances. Many temporary shelters are made of bamboo and are very fragile. Aid organizations are trying to improve the technical conditions of the bamboo houses with measures to counteract the worst problems [

22]. Heavy rainfall and severe flooding can damage shelters or completely destroy them. The temporary shelters showed in

Figure 4 can be improved but are not durable in a technical sense in the case of flooding and heavy storms.

In the Philippines, bamboo naturally grows in backyards, riverbanks, forest areas, and sometimes on private lands. The archipelago provides an excellent climate for various bamboo species. The bamboo industry in the Philippines is steadily growing and gaining recognition as a sustainable source of income for farmers. The country’s climate, with abundant rainfall and fertile soil, is conducive to bamboo cultivation. Houses located on the coast or riverbanks are constructed on stilts, as the country frequently experiences typhoons, necessitating improved construction techniques. The Cement Bamboo Frame Technology in the Philippines [

23], developed by the Base Bahay Foundation (BBF), is an enhancement of the traditional “wattle and daub” technique, known locally as “tabique Pampango”. This method involves using vertically placed wooden posts and horizontally woven branches covered in clay or loam. The BBF frame is covered with a mesh to hold cement mortar plaster, resulting in smooth outer walls that maintain an ordinary appearance. The BBF has successfully built over 1000 small homes in 12 municipalities in the Philippines. The BBF states that their “Cement Bamboo Frame Homes” are resistant to typhoons, earthquakes, fires, and termite attacks. Similar homes are also being constructed in Nepal through a partnership with the NGO Habitat for Humanity. Furthermore, the Forest Products Research and Development Institute (FPRDI), an agency under the Ministry of Science and Technology, is working on a low-cost, DIY bamboo shelter for the impoverished. This ready-made house designed by FPRDI can be assembled in just 2 days [

24]. Some exemplary dwellings in Bangladesh and the Philippines are shown in

Figure 4.

Figure 4.

(

a,

b) Temporary shelters in Bangladesh and the Philippines. (

c–

f) Cement bamboo frame homes in the Philippines. (

a) Bangladesh. Typical NGO-led bamboo shelter in Cox’s Bazar. Refugee camp. Source: S. Kaminski [

22]. (

b) The Philippines. Do-it-yourself bamboo shelter for low-income families. Source: FPRDI [

24]. (

c) The Philippines. Base Bahay Innovation Center. Source: Base Bahay Foundation [

23]. (

d) The Philippines. Neighborhood bamboo houses. Source: Base Bahay Foundation [

23]. (

e) The Philippines. Housing project with plastered houses. Source: Base Bahay Foundation [

23]. (

f) the Philippines. Social housing of Base-Bahay and Habitat for Humanity in Negros Occidental. Source: Hilti Foundation [

23].

Figure 4.

(

a,

b) Temporary shelters in Bangladesh and the Philippines. (

c–

f) Cement bamboo frame homes in the Philippines. (

a) Bangladesh. Typical NGO-led bamboo shelter in Cox’s Bazar. Refugee camp. Source: S. Kaminski [

22]. (

b) The Philippines. Do-it-yourself bamboo shelter for low-income families. Source: FPRDI [

24]. (

c) The Philippines. Base Bahay Innovation Center. Source: Base Bahay Foundation [

23]. (

d) The Philippines. Neighborhood bamboo houses. Source: Base Bahay Foundation [

23]. (

e) The Philippines. Housing project with plastered houses. Source: Base Bahay Foundation [

23]. (

f) the Philippines. Social housing of Base-Bahay and Habitat for Humanity in Negros Occidental. Source: Hilti Foundation [

23].

India is a major producer of bamboo and has a rich history of indigenous bamboo construction. India is home to more than 135 different species, 50 percent of which are cultivated in the eastern/northeastern states of India. Bamboo has been historically and economically important in India for cookware, food, and construction purposes. In the colder and cloudier climate of northeast India, the “wattle and daub” construction technique, also known as “Ikara”, is used. This technique involves wooden or bamboo frames with split bamboo fabrics that are covered with “mud” (soil/earth) to form the wall elements. The bamboo or wood frame is smothered with soil mixed with a slurry and allowed to dry. The foundation of the dwelling is elevated and consists of tamped earth, and more recently, cement mortar has also been used.

Today, improved techniques are employed using wooden or bamboo frames filled with split bamboo fabrics as wall panels. These panels can be prefabricated, and the house frames are often made of metal. Social enterprise Bamboo House India offers such homes in the market. Their metal construction frames are relatively lightweight and easy to assemble [

25].

In October 2022, the Indian Plywood Industries Research and Training Institute (IPIRTI) in Bangalore merged with the Institute of Wood Science and Technology. They have developed an earthquake-resistant bamboo house that combines traditional methods with modern construction techniques. Their research has demonstrated that bamboo can be utilized to create earthquake-resistant frames and wall panels. This system is suitable for prefabrication or in situ fabrication [

26].

According to architect Harikrishnan Sasidharan from NO Architects, the Kerala region in southern India has recently faced heavy rainfall and flooding. The floods in 2018 resulted in significant devastation. In response to these challenges, NO Architects has been researching reusable construction methods, leading to the development of a pilot project. The main structure of this project can serve multiple purposes, such as a residential unit, clinic, aid station, shelter, library, or even toilets. The infill panels can be easily modified depending on the specific use. To avoid the need for concrete foundations, a set of screw piles has been employed as the structural system. The metal construction frame consists of standardized components that can be assembled without the need for skilled labor. An estimated cost for completing a two-bedroom structure, including sanitary facilities, ranges from EUR 5500 to 6600 [

27]. Three exemplary bamboo dwellings are shown in

Figure 5.

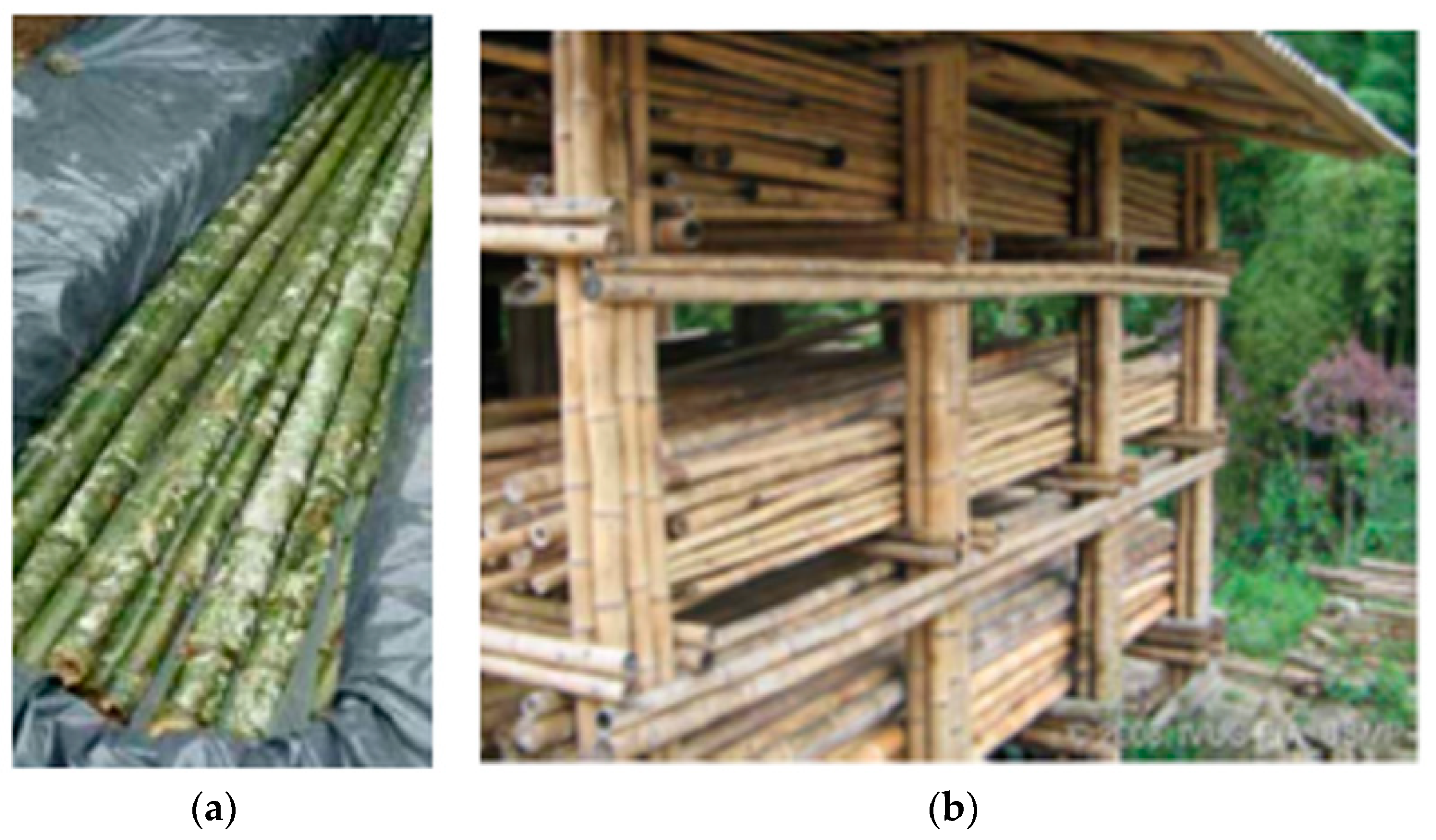

Indonesia is a country that is abundantly rich in various bamboo species, which are used for a wide range of purposes. Advanced bamboo constructions have been utilized in various sectors, including hotels, restaurants, and buildings in the tourism industry. These structures are always designed by architects. Another segment of buildings comprises affordable bamboo houses, constructed by families or local communities. The Indonesian government expects that families and communities take responsibility for building their own homes. Bamboo houses are often elevated and designed to promote proper ventilation. Improved bamboo houses are made using “plastered bamboo”, a novel construction technique in Indonesia that resembles the improved bahareque techniques seen in Latin America. Private companies like PT Karisma in Depok, West Java, provide simple homes, either as ready-to-assemble kits or fully constructed. The architects from Institut Teknologi Bandung (ITB) have developed a new concept called “Mabuter”, which involves plastered bamboo houses that are affordable and of a decent quality. According to architect Akhmad Gunawan, this concept is both environmentally friendly and resistant to earthquakes. In 2000, a plaster bamboo house was built in Sukabumi, West Java, for earthquake victims. Remarkably, it remained in good condition until 2023. Recognizing the importance of disaster relief, especially in earthquake-prone areas, ITB and Universitas Mataram established a joint knowledge center in North Lombok in 2018 [

28]. The aim is to initiate learning projects focused on bamboo houses for local communities residing in rural areas. Example homes constructed with plastered bamboo in Indonesia are shown in

Figure 6.

China is a leader in the production of bamboo products and building materials. It has established industrial processes for manufacturing, assembling, and exporting high-quality bamboo products, including prefabricated elements for model homes. China is renowned as one of the most significant bamboo-producing countries, where various new techniques have been developed and implemented. Traditional Chinese bamboo houses, such as the Galan bamboo house and those belonging to the Dai group in Xishuangbanna, are well known. These bamboo houses are designed with a double-layer structure to prevent moisture, with the Dai people residing upstairs while keeping cattle and poultry below [

29]. Dai housing is shown in

Figure 7a.

The focus of the industry is on producing prefabricated elements for housing. In Kathmandu, Nepal, and Addis Ababa, Ethiopia, a demonstration house measuring 40 m

2 was constructed using Chinese bamboo and structural parts. Such applications have great potential, particularly for temporary housing in the aftermath of natural disasters. The production of laminated bamboo is a key aspect of the bamboo industry, with various shapes and dimensions being produced for housing and building applications [

30]. Industrially constructed demonstration house is shown in

Figure 7b.

3.3. Bamboo Housing in Africa

Large-scale logging is taking place in Africa, partly due to the economic value of tropical timber as an export product. Wood is frequently used as a construction material, as well as for firewood and charcoal. Although bamboo grows naturally in 36 out of the 54 African countries, its utilization is not yet widespread. Expanding the cultivation and use of bamboo could help mitigate deforestation. The economic potential of bamboo is substantial, making the establishment of numerous bamboo plantations viable. However, there is still a lack of or limited presence of a bamboo processing industry. From an economic standpoint, there is potential for expanding bamboo cultivation in Africa. Planting bamboo forests in areas at risk of desertification could yield positive and rapid results. Various initiatives focus on commercializing bamboo, primarily for furniture production and other consumer goods, creating an income source for small-scale entrepreneurs. However, large-scale purchases of bamboo raw materials by industrial players could sideline local residents.

Africa possesses vast natural bamboo forests ranging from sea level to mountainous regions. Approximately 4 percent of the continent’s forests consist of bamboo. In Kenya, many bamboo species are solid rather than hollow. It has versatile uses in manufacturing consumer items and can be employed in public housing as well. If bamboo is utilized and applied locally, fostering a strong collaboration with local communities, a win–win situation can be achieved for the local economy and the environment (by preventing desertification). Oxytenanthera abyssinica is a native species found in East Africa, thriving at altitudes between 1200 and 1800 m. Through international agreements facilitated by the UN, opportunities exist to enhance farmers’ and their organizations’ expertise in bamboo cultivation in countries like Ethiopia, Uganda, and Kenya.

In Uganda, the government has initiated the implementation of the National Bamboo Strategy and Action Plan for the period of 2019 to 2029. This strategic plan aims to maximize the utilization of the country’s bamboo resources. The implementation of this plan is being facilitated by INBAR, the Ministry of Water and Environment, and the National Forestry Authority (NFA). Currently, there are around 67,000 hectares of bamboo in protected areas. Additionally, there is a plan to expand the bamboo acreage outside of protected areas by an additional 375,000 hectares. The entrepreneur Fred Ijjo from FOB Consult Ltd., a social enterprise that collaborates with local communities for housing projects, has successfully developed model homes using bamboo.

There are many opportunities for utilizing bamboo as a sustainable building material in Ethiopia. The country boasts numerous bamboo forests in certain regions. With an impressive 1 million hectares of native bamboo, Ethiopia is one of the largest bamboo producers in Africa, hosting 67 percent of all African bamboo species. Two main species, yushania alpina and oxytenanthera abyssinica, are commonly found in the country’s highlands and lowlands, respectively. Despite the vast natural bamboo resources, Ethiopia has only recently started harnessing its potential. Efforts are currently being made to develop innovative housing designs using bamboo.

In Tanzania, the adoption of bamboo houses is still in its early stages. The National Housing and Building Research Agency is currently investigating the potential use of bamboo for the production of doors, windows, and roofing materials. The primary focus of this research is to identify building materials that can enable families to construct more modern homes at a lower cost. If found feasible, families will be encouraged to invest in bamboo cultivation for the production of these materials. A common construction technique in Tanzania is known as “wattle and daub”, which involves using earth (or mud) for walls. However, these structures often need to be restored after the rainy season. Tanzanians are growing more concerned about the health issues associated with houses built using earthen walls, such as insufficient ventilation and the risk of infestation by insects and fungi. In

Figure 8, two bamboo houses in Uganda and one in Ethiopia are shown.

In other sub-Saharan African countries, despite their warm and humid climate, bamboo is still not widely used as a material for housing. Traditionally, homes were constructed with earthen walls, known as wattle and daub. These houses mostly consist of a single floor, with a tamped earth or cement floor and walls that are plastered with earth. Nowadays, these walls are often replaced with bricks. However, there is tremendous potential for the utilization of bamboo in Africa, especially if governments take measures to encourage the cultivation of bamboo for (public) housing and mitigate the effects of desiccation and desertification.

3.4. Discussions on Results of Housing Construction with Bamboo

Latin America: Improved bahareque techniques for housing can be found in several countries. In 2013, Kaminski provided a general overview [

31]. However, some of these developments are still in their early stages and have not yet resulted in large-scale bamboo housing construction. In some cases, government regulations have posed obstacles to the construction of homes with local bamboo, as seen in Mexico. Nevertheless, educational and research institutions are carrying out various pilot projects, with NGOs also actively participating in these efforts. Governments recognize the importance of promoting bamboo cultivation in the context of new climate and environmental policies, as well as for enhancing sustainability in the construction sector. There is a growing recognition that improved bahareque techniques can enable the construction of social and affordable housing that is resistant to earthquakes and storms. Thanks to the longstanding efforts of Hogar de Cristo in Ecuador, many homes have been built using wood and bamboo, particularly those designed for individual growth potential. Numerous families have transitioned from their original homes to ones built with more “modern” materials like bricks and concrete blocks. NGOs have played a crucial role in making bamboo construction accessible to low-income families, such as Habitat for Humanity did in several countries, as well as Progreso in Piura, Peru. To ensure an adequate supply of bamboo in the future, the organization and management of bamboo forests are often incorporated into national policies for forest and agricultural management, as well as nature development.

Asia: In the countries mentioned, bamboo houses are traditionally widespread, particularly in rural areas and small villages. Natural disasters and climate change heavily impact large parts of Bangladesh, India, the Philippines, and Indonesia. Bangladesh is facing severe challenges due to floods and tropical storms. The most significant threats in Indonesia are earthquakes and volcanic eruptions, given its geographic location along the “Ring of Fire”. Therefore, attention is focused on constructing earthquake-resistant buildings. In Bangladesh, homes in vulnerable areas are often built on stilts, and foundation piles are preferably made of concrete, despite the higher cost. The Philippines has made progress in adopting the Cement Bamboo Frame Technology, thanks to initiatives by aid organizations, which serve as important exemplary projects. Floods, severe storms, and typhoons pose specific demands on building structures in the Philippines, similar to Bangladesh. Coastal areas in both countries have numerous stilt houses that require reinforcement. India has four distinct climate regions, each with unique housing construction requirements. Among the challenges faced in India are heavy flooding, necessitating waterproof foundations, as well as the need for earthquake-resistant construction in other regions. China, with its vast industrial potential, is the largest exporter of bamboo and plays a significant role in supplying the construction sector. India and Japan hold the second and third positions, respectively.

Africa: This continent has numerous bamboo reserves in the countries located south of the Sahara. People traditionally used the “mud-wall” (earth) technique to construct their homes. Whenever a village is established, all members of the community, irrespective of age or gender, come together to support each other. By embracing modern technology and increasing awareness about the advantageous properties of bamboo materials and constructions, sustainable development can be initiated. If villagers utilize communal aid, it is hoped that an affordable, low-tech bamboo building technique can be employed. However, it is crucial for the improved bamboo techniques to reach the local communities. Some governments aim to harness the potential of bamboo to benefit local economies and combat land desiccation and degradation.