Abstract

This paper presents a structured framework for implementing Industry 4.0 projects. The framework is developed through an extensive review of the existing literature, wherein potential challenges and success factors related to adopting disruptive technologies in such projects are systematically analyzed and categorized. Additionally, the authors introduce a semi-structured questionnaire tailored for interviews with key decision-makers in companies strategically pursuing digital transformation. This questionnaire is designed to elicit valuable insights based on the experiences and perspectives of these decision-makers. The resulting framework is synthesized from the interviews and literature review. It delineates the essential steps necessary for the effective implementation of Industry 4.0 projects, focusing on establishing strategic priorities as the foundational stage of the entire process.

1. Introduction

Today, we find ourselves amid the fourth industrial revolution, Industry 4.0. Coined in 2011 in Germany, Industry 4.0 has gained widespread recognition, with scholars positing its pivotal role in maintaining competitiveness in today’s industries [1]. Industry 4.0 catalyzes the emergence of new business models and avenues for enhancing product and service quality [2]. Manufacturing industries are transitioning from mass production to extensive product customization, with pervasive communication channels among humans, machines, and between machines [3], facilitating superior information management and decision-making [4].

Numerous scholars highlight that Industry 4.0 hinges on industrial components’ ability to communicate seamlessly [5]. Consequently, organizations must navigate a complex transformation process, addressing dimensions spanning organizations, finance, technology, operations, and sustainability. Achieving the envisioned goals of Industry 4.0 necessitates the meticulous selection and holistic management of projects, characterized by the inherent uncertainty and complexity stemming from the disruptive nature of the technologies involved and their impacts [6].

Integrating sustainability into Industry 4.0 practices presents another layer of complexity [7,8]. Although Industry 4.0 has the potential to significantly reduce waste and improve energy efficiency through optimized production processes, the initial high costs and complexity of Industry 4.0 eco-friendly technologies can be prohibitive for many organizations [9]. Furthermore, the focus on technological solutions sometimes overshadows the need for a holistic approach to sustainability, including both environmental and social and economic dimensions [10]. The challenge lies in aligning Industry 4.0 innovations with sustainability goals without compromising the economic viability of businesses [11,12].

This research investigates approaches organizations employ in their project implementations, spanning traditional best practices exemplified in the Project Management Body of Knowledge (PMBOK) by the Project Management Institute (PMI) to agile approaches like Scrum. The PMBOK, developed by PMI starting in the 1990s, serves as a compendium of project management knowledge, processes, skills, tools, and techniques deemed fundamental in enhancing the likelihood of success across various project types. Scrum, in use since the 1990s, provides a framework for managing complex product development and establishing roles, artifacts, and events for dealing with project uncertainty [13].

Despite the availability of project management guides, a void persists in methods for a more tailored approach addressing the definition, portfolio formation, and execution of projects in the context of Industry 4.0, particularly within organizations actively pursuing new technologies. Organizations across diverse industries engage in project implementations as a routine practice. However, when it comes to assimilating disruptive technologies such as Industry 4.0, the complexity and uncertainty are magnified, necessitating potentially specialized steps for project implementation. This research endeavors to define and delineate these steps, if they exist, by scrutinizing concrete cases and the available literature. The objective of this research is to systematize a comprehensive framework for managing the implementation of Industry 4.0 projects by (1) identifying the specific challenges attributed to the disruptive nature of these projects; (2) assessing the existence and relevance of distinct steps for managing Industry 4.0 project implementation; and (3) elaborating upon specific steps that may serve as facilitators in the management of Industry 4.0 projects, should they be discerned.

The following research questions will be addressed in this study:

- (1)

- What challenges are encountered when implementing Industry 4.0 projects?

- (2)

- What best practices can be gleaned from successful disruptive technology projects?

- (3)

- Are there specific, definable steps that should be integrated into a comprehensive framework for implementing Industry 4.0 projects?

In this study, the utilization of the PRINCE2 methodology was proposed as a structural foundation for the inclusion or exclusion of stages, owing to its business-centric focus and adherence to PMBOK best practices, thereby operationalizing them in various aspects. According to the PRINCE2 methodology, every project introduces change to the business environment. Projects are transient in nature, allowing the organization to revert to normal operations following adjustments. They involve integration across multiple domains, are fraught with inherent uncertainties, and, most notably, are unique in their execution, even when concurrent with other projects. PRINCE2, widely adopted in the UK, embodies a seven-process approach to effective project management: (1) starting a project; (2) directing a project; (3) initiating a project; (4) controlling a stage; (5) managing product delivery; (6) managing project boundaries; (7) closing a project [14].

Choosing PRINCE2 as the backbone of the proposed approach helps bridge gaps related to project actions and project uncertainties associated with the sustainability issues of adopting new technologies. Given the integrative nature of PRINCE2 and its incorporation of project management best practices, it helps treat these issues during project initiation, planning, execution, and closing. In this sense, technology adoption becomes more than a matter of business model innovation or efficiency but also of meeting triple-bottom-line concerns.

This paper follows this structure: Section 2 discusses the underlying concepts of Industry 4.0 and PRINCE2 related to this work. Section 3 presents the research approach that was adopted, which is composed of a systematic literature review and interviews with experts. Section 4 presents the results of the literature review and the interviews. Section 5 discusses the proposed framework and its implications. Lastly, Section 6 provides concluding remarks for this work.

2. Theoretical Background

2.1. Industry 4.0

Industry 4.0, characterized by integrating smart technologies like the Internet of Things (IoT), cyber-physical systems, and cloud computing into manufacturing, represents a significant shift towards more interconnected and intelligent production environments [15]. This revolution optimizes production processes and introduces flexibility and efficiency, allowing for real-time decision-making and reduced downtime. The core principles that guide the transformation toward Industry 4.0 include interoperability, virtualization, decentralization, real-time capability, service orientation, and modularity, which collectively enable the creation of smart factories. These factories can self-optimize and significantly enhance productivity by leveraging digital technologies to automate and improve manufacturing processes [16].

However, the implementation of Industry 4.0 comes with its set of challenges, particularly in technology adoption. One significant hurdle is the digital divide between large-scale enterprises and small- to medium-sized enterprises (SMEs). While larger companies may have the capital and infrastructure to invest in and deploy cutting-edge technologies, SMEs often struggle with limited resources, making it difficult to adopt and integrate these advanced systems into their operations. Additionally, the complexity of Industry 4.0 technologies demands a highly skilled workforce capable of managing and maintaining these sophisticated systems, posing a challenge in terms of training and skill development across industries [17,18,19,20,21].

Despite these obstacles, adopting Industry 4.0 technologies offers immense opportunities for businesses to become more efficient, agile, and customer-focused. The benefits extend beyond mere productivity gains, encompassing enhanced product quality, improved working conditions, and greater sustainability. By embracing digital transformation, companies can achieve superior operational performance and develop a competitive edge [22,23].

The path to a successful Industry 4.0 transition requires navigating challenges with strategic planning, investment in training and skills development, and a commitment to sustainability that goes beyond mere technological upgrades. Policymakers, industry leaders, and academic institutions must collaborate to create an ecosystem that supports technology adoption while ensuring that the benefits of Industry 4.0 are accessible to all stakeholders, including smaller enterprises, and are aligned with broader environmental and social objectives [22].

2.2. Projects in Controlled Environments (PRINCE2)

PRINCE2 (Projects in Controlled Environments) is a widely recognized project management approach used by organizations and governments to manage and control the execution of various types of projects. It provides a structured approach that covers project organization, management, and control, emphasizing dividing projects into manageable and controllable stages. PRINCE2 is built on seven principles, seven themes, and seven processes that guide project managers in executing projects effectively, ensuring that the project remains viable, and achieves its objectives within cost, time, and quality constraints [24,25].

One of the key benefits of PRINCE2 is its flexibility and adaptability to any type and size of project. This methodology ensures a high degree of control and organization over the project lifecycle, facilitating effective decision-making and risk management. PRINCE2 also emphasizes a product-focused approach, which helps to deliver projects that meet requirements and contribute value to the organization. Additionally, its well-defined framework supports clear communication among project stakeholders, fostering a common language and understanding that enhances project outcomes [26].

However, PRINCE2 is sometimes perceived as a rigid framework that can be daunting for organizations. The methodology requires significant investment in training and certification to be effectively implemented, which might be a barrier for smaller organizations or teams. Moreover, the emphasis on documentation and process can sometimes lead to bureaucratic overhead, potentially slowing down project progress if not managed carefully [26,27,28].

The application of PRINCE2 follows a process-based approach. Each process is designed to guide the project team through the development, execution, and delivery of the project, ensuring that objectives are clear, roles and responsibilities are defined, and risks are managed [28].

- (1)

- Starting Up a Project (SU): This involves the preliminary evaluation of the project to ensure it is viable before any significant resources are committed. Key activities include appointing the project team, defining the project brief, and creating an initial project plan. This phase sets the foundation by clarifying the project’s objectives, scope, constraints, and justification, ensuring a solid basis for the decision to proceed.

- (2)

- Directing a Project (DP): Spanning from the project’s initiation to closure, this step outlines the project board’s roles and responsibilities, including executive, senior user, and senior supplier roles. The board is responsible for providing overall direction and management, making key decisions, and ensuring the project remains aligned with organizational strategies and objectives. This step involves key decision points, notably project authorization, at various stages.

- (3)

- Initiating a Project (IP): Detailed planning ensures a strong foundation for project control and management in this phase. It includes developing Project Initiation Documentation (PID) encompassing the project’s approach and management strategies, and a detailed plan. This documentation serves as a reference point throughout the project lifecycle, outlining how the project will be executed, monitored, and controlled.

- (4)

- Controlling a Stage (CS): PRINCE2 projects are divided into stages, and this process governs the monitoring and control activities within each stage. Tasks include assigning work, monitoring progress, managing issues and risks, and ensuring stage boundaries are adhered to. This step is crucial for maintaining control over the project by ensuring regular reviews and assessments and facilitating timely decision-making and adjustments as needed.

- (5)

- Managing Product Delivery (MP): This process ensures that the project’s products are created and delivered according to the specified requirements, timeframes, and quality standards. It involves close communication between the project manager and the team members tasked with producing the project’s outputs. Activities include accepting, executing, and delivering work packages, along with quality checks to ensure that deliverables meet the predefined standards.

- (6)

- Managing a Stage Boundary (SB): This step focuses on reviewing the current stage and planning the next stage, ensuring the project remains on track and aligned with its objectives. It involves updating the project plan and business case based on the latest project performance and information, preparing for the next stage, and seeking approval from the project board to move forward. This process allows for reflection and learning, ensuring continuous improvement.

- (7)

- Closing a Project (CP): The final step involves formalizing the acceptance of the project’s product, disbanding the project team, and either closing the project or recommending it move to the next phase if it is part of a larger program. This process includes activities such as handing over deliverables, evaluating project performance against its objectives, identifying lessons learned, and ensuring all project documentation is completed and archived.

3. Research Approach

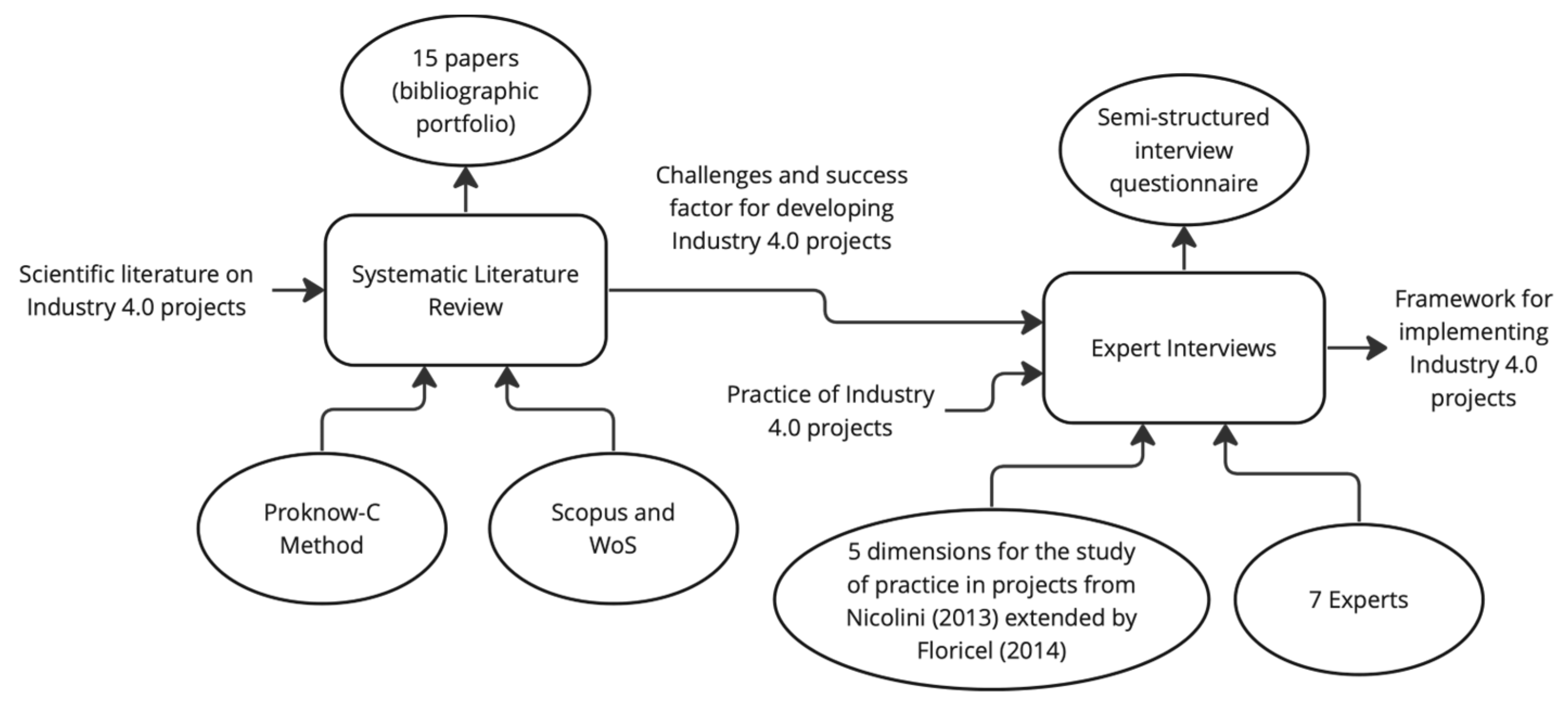

The research approach employed in this study encompasses two distinct sources of information, each contributing to a comprehensive understanding of the challenges and management aspects associated with Industry 4.0 projects towards the development of a comprehensive framework that helps address these issues. Figure 1 provides an overview of the research approach.

Figure 1.

Research approach adopted in this study, representing the steps, support elements (below steps), intermediate products (above steps), and information flow [29,30].

The two main methodological approaches employed are as follows:

- Systematic Literature Review: The first source of information involves a systematic literature review that encompasses the academic landscape surrounding the challenges, success factors, and failure factors pertinent to implementing and managing Industry 4.0 projects. This rigorous review serves as the foundational knowledge base for the development of the subsequent data collection instrument, a semi-structured questionnaire.

- Expert Interviews: The second source of information involves interviews with key industry practitioners through the application of semi-structured questionnaires. These interviews provide valuable, first-hand accounts of practical challenges and solutions related to the implementation of Industry 4.0 projects from real-world cases, aligning with the principles of Yin’s multiple case study method [31]. The choice of this method is driven by the dynamic and evolving nature of Industry 4.0, which exists within a real-world context that lacks clear boundaries between the phenomenon and its surrounding environment. Additionally, this method allows for the inclusion of qualitative and quantitative data, offering a holistic perspective on the subject matter. By incorporating these real-world perspectives, this research aims to bridge the gap between academic discourse and practical industry experiences.

3.1. Systematic Literature Review

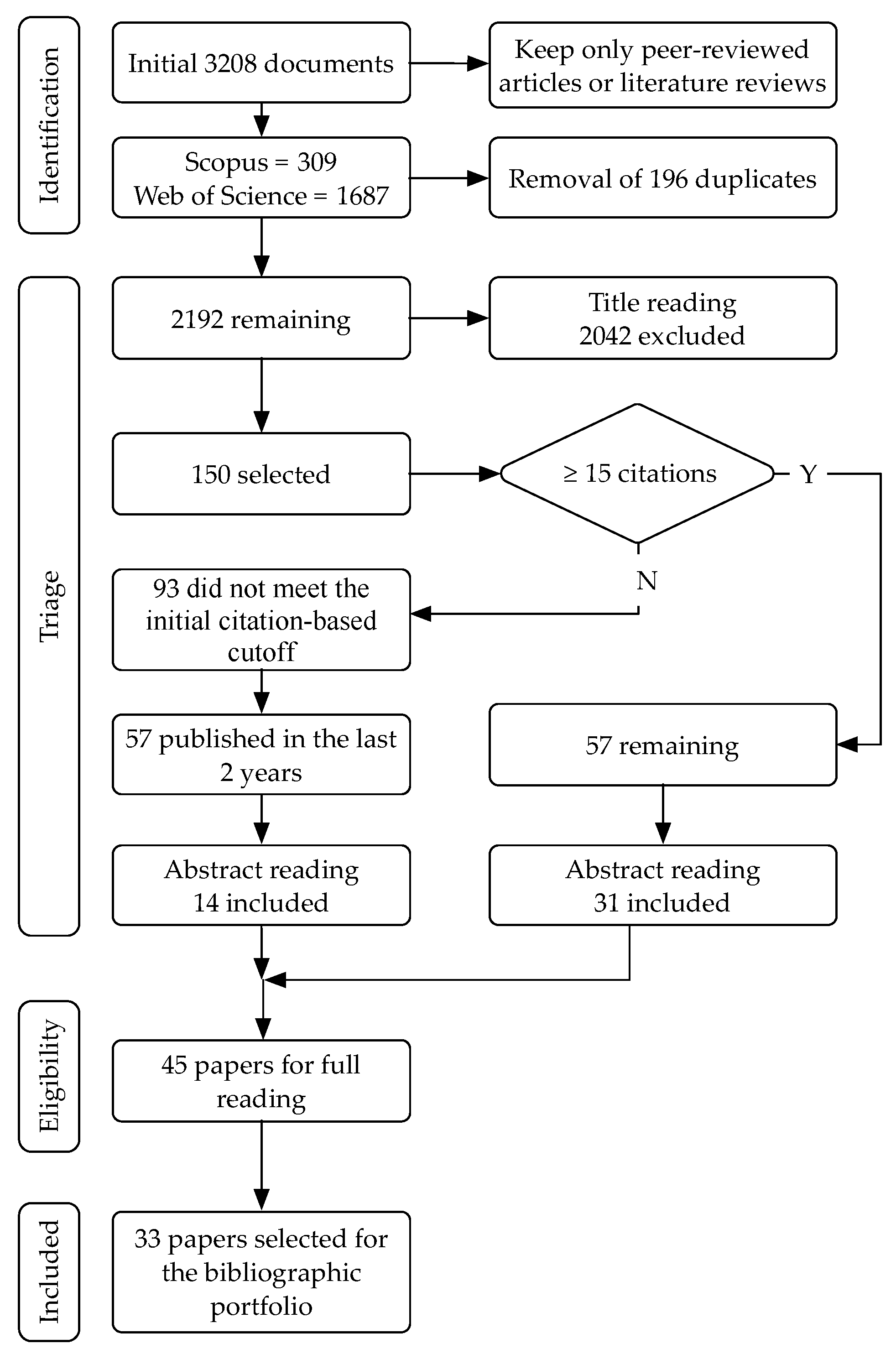

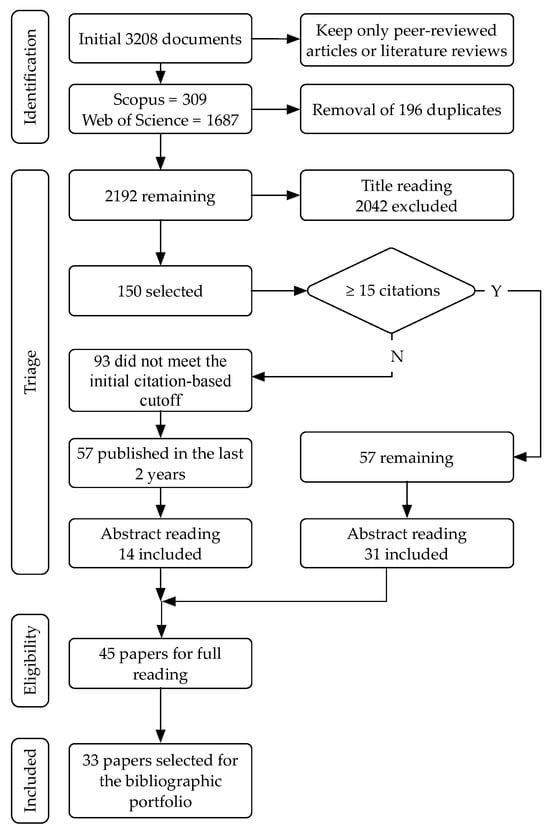

The establishment of a solid theoretical foundation for this study commenced with applying the Knowledge Development Process—Constructivist approach, also known as Proknow-C [32,33]. This method was the guiding framework for constructing the bibliographic portfolio essential for the subsequent literature review. The process involved several distinct steps, depicted in Figure 2, to ensure a comprehensive and well-informed exploration of the chosen research area:

Figure 2.

PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) from [34] drill-down for the systematic literature review performed in this study.

- Defining Research Axes and Search Terms: The initial step involved defining specific research axes and selecting pertinent search terms to guide the exploration of the literature. Two primary axes were identified: “Industry 4.0” and “project implementation”. For these axes, the following search terms were established: “4.0”, “indust*”, “project*”, and “implement*”. These terms were meticulously selected to capture a broad spectrum of relevant articles in the field.

- Combining Search Terms: To refine the search process, combined the selected search terms were combined in two distinct ways: (1) “4.0 AND implement* AND project* AND indust*”; (2) “implementation” AND “industry 4.0”.

- Databases Selection: To access a comprehensive pool of scholarly resources, two prominent databases were chosen: Scopus and Web of Science. These databases collectively yielded a total of 3208 documents published from January 2015 to February 2024. Filtering them by peer-reviewed articles or literature reviews yielded a total of 2388 articles; 309 were indexed in Scopus, and 1687 were sourced from Web of Science. After removing duplicate titles (196), we were left with 2192 articles for further evaluation and alignment with the research theme.

- Title Screening and Alignment: In the initial phase of screening, we scrutinized the titles of the 2192 articles and kept 150. The remainder were excluded due to misalignment with the research objectives. These exclusions were primarily based on the articles’ failure to address the research focus adequately.

- Citation-Based Filtering: The next step involved filtering the remaining 150 articles based on the number of citations they had received. A cutoff criterion of 15 citations was applied, resulting in 57 articles meeting this criterion, accounting for 83.8% of the citations up to the search date.

- Abstract Reading and Refinement: Following the citation-based filtering, we proceeded to read the abstracts of the 57 selected articles. After careful consideration, 31 articles were retained as they aligned closely with the research theme. These 31 articles became a foundational part of the study’s bibliographic portfolio.

- Author Analysis: Additionally, we examined the authors contributing to these 31 articles, aiming to expand the potential portfolio further. However, when we extended our search to locate these authors in the papers published more than two years ago, the abstracts did not align with the research theme.

- Further Abstract-Based Selection: To augment our portfolio, we broadened our search to include 93 papers that did not meet the initial citation-based cutoff criterion. Notably, 57 of these papers had been published in the last two years, and 14 of them featured abstracts that were closely aligned with the research theme. Nevertheless, the same stringent filtering criteria were applied, eliminating articles that focused on specific technologies, lacked a comprehensive analysis, did not address management issues, or concentrated solely on specific industry niches.

- Final Bibliographic Portfolio: The culmination of these selection processes resulted in a bibliographic portfolio comprising 45 articles, all with abstracts closely aligned with the research theme. These articles were selected for comprehensive reading and analysis, providing a solid foundation for the subsequent phases of this study. Notably, 33 of these articles were instrumental in shaping the bibliographic references for this research, enriching the framework with relevant insights, and expanding the scope of the study. These papers were selected because they directly explored either potential challenges or critical success factors for the adoption of Industry 4.0 technologies. Challenges were directly addressed and discussed, not only mentioned as a side-effect or something to be further examined.

3.2. Expert Interviews

For the expert interviews, a semi-structured questionnaire was created, designed to facilitate the evaluation and refinement of the initial research model. This questionnaire aligns with the five dimensions for the study of practice, outlined by [29] and elaborated upon by [30]:

- Work and Effort: This dimension seeks to elucidate the unique challenges and steps involved in the implementation of Industry 4.0 projects, differentiating them from traditional project implementations. Key questions include the following:

- ∘

- Are there distinct steps for the implementation of Industry 4.0 projects not found in traditional project implementations?

- ∘

- Does the company employ specific methodologies or frameworks for managing Industry 4.0 projects?

- Materiality: Focusing on the material aspects of projects and their business connection, this dimension explores questions such as the following:

- ∘

- Was there a tangible problem that necessitated the project?

- ∘

- How are the projects interconnected, and what is their impact on the organization?

- Creativity: Given the disruptive nature of Industry 4.0 technologies, this dimension delves into the need for ongoing innovation within related projects, examining factors such as the following:

- ∘

- How disruptive are the technologies involved?

- ∘

- How does the company foster creativity and proactivity among project participants?

- Knowledge: This dimension aims to understand how lessons and best practices are developed, shared, and absorbed within the organization:

- ∘

- What best practices have been observed for successful projects involving disruptive technologies?

- ∘

- How are these best practices shared, and is there a mechanism for confirming their adoption?

- Interests and Power: The final set of questions investigates the organizational hierarchy, power dynamics, and decision-making agility within the company, as well as the barriers and challenges faced in implementing Industry 4.0 projects:

- ∘

- Is there executive support for executing Industry 4.0 projects?

- ∘

- How are project themes selected, and who is involved in these decisions?

- ∘

- What critical barriers have been encountered during project implementation?

This study comprises interviews with seven key decision-makers representing six companies, spanning both industrial and service sectors. These companies have actively implemented projects involving Industry 4.0 technologies, providing diverse perspectives and insights into the challenges and management approaches associated with such initiatives. A profile of the interviewees can be seen in Table 1. All interviewees have experience with Industry 4.0 initiatives, either at a portfolio or program level, project planning level, or project execution level, and had, at the time of the interviews, over five years of experience with such initiatives.

Table 1.

Profile of the interviewees, with the industry they belong to, and remarks on the interviews.

4. Results

4.1. Systematic Literature Review

Through a meticulous examination of the papers in the bibliographic portfolio, the systematic review unearthed both potential challenges (outlined in Section 3.1) and success factors (detailed in Section 3.2).

4.1.1. Potential Challenges

The following challenges associated with the implementation of Industry 4.0 projects have been identified within the existing body of literature:

- Integration of Projects: The integration of novel technologies with existing systems has emerged as a critical challenge. This process entails a thorough analysis of the current operational landscape, often leveraging modernization or expansion efforts as a foundation [35]. Ref. [36] presents four cases illustrating companies’ procedures to introduce digital elements in their operations. Using a multi-case methodology, they analyze projects’ documentation and interviews to describe the organizational path to digitalization. The authors propose a five-step common path: (1) customer orientation and operational efficiency, (2) understanding the operation, (3) developing solutions with technology, if necessary, (4) solution implementation and integration, and (5) reviewing and looking after new improvements.

- Human Resources: Several multifaceted challenges related to human resources have been underscored. These challenges encompass team attitudes towards Industry 4.0, the scarcity of specialized experts, the deficiency in management skills, gaps in technological knowledge, and time constraints. The impact of Industry 4.0 on employment remains a topic of debate, with routine or simplistic job roles potentially decreasing, necessitating additional training and reskilling—an aspect that presents a broader societal challenge. Professional development and training have emerged as pivotal factors for the successful implementation of Industry 4.0 [37,38,39]. Ref. [40] focuses on the challenges associated with adopting Industry 4.0 technologies in manufacturing, identifying the “Lack of employee skills” and “lack of technological infrastructure” as the topmost challenges in adopting Industry 4.0. Ref. [41] From the literature review, the authors sum up 35 key organizational challenges to implementing Industry 4.0 technology, the top one being the lack of a skilled workforce.

- Communications: In the realm of communication, the transition from linear communication models to decentralized and less controllable forms has introduced notable complexities. The rise of social networks has democratized information sharing among stakeholders and communication participants. Electronic media has been recognized as a primary means of disseminating information regarding the adoption of new technologies. Additionally, challenges in this domain encompass communication standards, agile data collection on factory floors, network infrastructure, and data security [2,42]. Ref. [43] reports the challenges encountered during the transformation process from a traditional food manufacturer to adopting Industry 4.0 technologies. For each technology, from data collection and real-time big data to a cloud-based dashboard and security, the authors describe the challenges and how they overcame them.

- Cost: The substantial cost associated with implementing Industry 4.0 initiatives represents a significant hurdle. Demonstrating a tangible return on investment can prove challenging, as noted by [44,45]. The dynamic nature of technology introduces an element of risk, further complicating investment decisions. While financial resources are often available, particularly within organizations strategically oriented toward digital transformation, careful evaluation and allocation of these resources within the project portfolio remain essential [45]. Ref. [46] analyzes barriers to fully implementing Industry 4.0 vision, identifying areas in which decision support is vital. Among them are the lack of interoperability or standards, security concerns, and uncertain ROI. Ref. [47] carried out research using a sample of 114 manufacturing enterprises to determine and analyze the critical success factors in project management and their relation to Industry 4.0 and sustainability. They found that finance was a critical success factor for evaluating the benefits of sustainability and environmental protection benefits in Industry 4.0 projects.

- Acquisition for Projects: Technology companies engaged in implementing Industry 4.0 projects may gain profound insights into clients’ business operations, potentially leading to competition in the market [48].

- Top Management Support: A critical prerequisite for the successful implementation of Industry 4.0 projects and the overarching adoption of Industry 4.0 principles is unwavering support from top management. Such support fosters a culture of innovation and encourages employees to seek novel solutions to challenges, including the utilization of Industry 4.0 technologies [49]. Ref. [50] studies the drivers and barriers to the adoption of Artificial Intelligence (AI). The drivers include support from top management and organizational readiness.

Additionally to these challenges, ref. [51] analyzes the impact of Industry 4.0 implementation on supply chains and develops an implementation framework by considering as barriers financial constraints, a lack of management support, resistance to change, a lack of expertise, and legal issues. Ref. [52] empirically investigates and comparatively analyzes the benefits, challenges, and critical success factors (CSFs) of Industry 4.0 across four continents and developing and developed economies. The main finding is that the challenges change across continents; for example, in Africa, “Employee’s resistance to change” is the biggest challenge, and in Europe and North America, it is “Lack of I 4.0 skills and know-how”. Ref. [53] aimed to identify Industry 4.0 approaches (technologies, projected benefits, and barriers to Industry 4.0) and its main applicability in the broiler meat production chain in the poultry sector. The main barriers to Industry 4.0, also known as inhibiting factors, are high investments, the lack of knowledge, uncertainties in results, and challenges in qualifying human capital.

4.1.2. Implementation Success Factors

The key internal factors influencing the implementation of Industry 4.0 projects derived from scholarly research are outlined as follows:

- Perception of Implementation Benefits: The perceived benefits of implementation, particularly in terms of operational flexibility and efficiency, stand out as a critical factor. This aspect, emphasized by [1], serves as both an enabling and pivotal determinant in the context of smart manufacturing implementation. However, it is noteworthy that the perception of value addition to the consumer market remains somewhat underdeveloped among managerial stakeholders. Nevertheless, substantial improvements in industrial process monitoring have been observed [48]. Ref. [54] presents the critical components of the framework of Industry 4.0 and the basic stage of implementing the concept in enterprises. Their framework begins with the internal preparation of the company for Industry 4.0 projects, including production 4.0 as a strategic goal, pilot projects in production 4.0, the launch of smart production systems, and improving production-related activities (e.g., internal and external logistics), and finishes with cyber-physical systems.

- Strategic Alignment: Strategic alignment emerges as a focal point for Industry 4.0 initiatives. Ref. [55] underscores the importance of aligning 4.0 initiatives with the overarching organizational strategy—a fundamental cornerstone of successful implementation. This strategic alignment guides macro-level decisions within the company, substantially enhancing the likelihood of successful implementation. The active sponsorship of 4.0 initiatives by management, especially senior executives, is identified as a critical success factor by [55]. This entails a structural transformation aimed at fostering vertical integration within hierarchical subsystems within a factory. Additionally, it aims to create a flexible and configurable system and encourages horizontal integration through value networks, promoting collaboration among corporations.

- IT Infrastructure Maturity: The maturity of the IT infrastructure assumes a central role in the successful implementation of Industry 4.0 initiatives. This maturity is distinguished by several key attributes, including openness, flexibility, and the capacity for seamless integration with emerging technologies. Ref. [56] underpins the significance of cultivating a technologically advanced infrastructure as the foremost challenge in the entire implementation journey. This imperative underscores the need for organizations to invest in cutting-edge technology and foster an environment where these technologies can harmoniously coexist and evolve. The extent to which an organization’s IT infrastructure can readily embrace and adapt to new technological paradigms can significantly impact the effectiveness and efficiency of Industry 4.0 projects. Thus, it becomes imperative for entities to meticulously evaluate and enhance their IT landscapes to align with the dynamic demands of Industry 4.0.

- Development of Internal Knowledge and Skills: The internal development of knowledge and skills related to the transition to Industry 4.0 assumes paramount importance. Ref. [57] highlights the significance of behavioral skills and social intelligence as determinants in mitigating the risks associated with workplace displacement due to the introduction of new technologies. Ref. [58] investigates the relevant antecedents of essential capability for digital transformation, identifying three micro-foundations for digital capability: digital-savvy skills, digital intensity, and context for action and interaction. The authors used Structural Equation Modeling to link these micro-foundations with business performance. They tested the model in 427 large companies from different sectors.

- Lean Experience: Previous experience with lean methodologies represents a noteworthy precursor that augments the prospects of fruitful Industry 4.0 implementation. Organizations well versed in the principles of lean management bring a valuable reservoir of knowledge to the table. This familiarity with lean practices, characterized by an emphasis on efficiency, waste reduction, and continuous improvement, provides a solid foundation for transitioning into the intricacies of Industry 4.0. Such experience not only fosters a culture of operational excellence but also instills a mindset attuned to optimizing processes. As a result, these organizations are better positioned to navigate the challenges and complexities that often accompany the adoption of Industry 4.0 technologies, potentially increasing the likelihood of successful implementation.

- Occupational Health and Safety: The integration of Industry 4.0 technologies into the workplace may introduce transformative changes with implications for occupational health and safety. As traditional manufacturing processes evolve into digitally driven and automated systems, the risk landscape within industrial environments may undergo alterations. These changes necessitate careful consideration and evaluation. While Industry 4.0 has the potential to enhance workplace safety through real-time monitoring and predictive maintenance, it may also introduce novel challenges related to cybersecurity and the safe interaction of humans with advanced machinery. Consequently, it is essential for organizations embarking on Industry 4.0 initiatives to proactively assess and manage these evolving risk levels to ensure that occupational health and safety standards are not compromised in the pursuit of technological advancement.

Additionally to these critical success factors, ref. [51] states that the drivers for implementing Industry 4.0 projects they found in their study were agility, customization, accuracy, and efficiency. Ref. [59] identifies engineering and production management requirements in an I4.0 setting using a literature review of 130 articles. The principles identified were interconnection/connectivity, information transparency, decentralized decision-making, technical assistance, the human factor, technology, intelligence/awareness, knowledge, and interoperability. The authors of Ref. [52] establish in their work that the critical success factors are the same across continents: “Aligning the I 4.0 initiatives with organizational strategy”, “Top management support to I 4.0 initiatives”, and “Employees will be important for the success of I 4.0”.

4.2. Interviews

Based on the insights garnered from the conducted interviews and informed by pertinent literature, several crucial determinants for the digital transformation of the examined companies can be elucidated:

- Company Strategy for Digital Transformation/C-Level Support: A fundamental prerequisite for digital transformation is the presence of a well-defined organizational strategy aligned with this transformative endeavor. Such strategic alignment necessitates unequivocal sponsorship from the C-level leadership. The absence of such support can severely impede the effectiveness of digital transformation initiatives, as underscored by [55,60].

- Human-Centric Transformation: Effecting a successful digital transformation often entails a cultural shift within organizations. This shift involves empowering teams, fostering an environment conducive to active listening, encouraging participation, and stimulating creativity. While technology and processes are pivotal, their ultimate utility hinges on their enthusiastic adoption and utilization by people. A pivotal aspect of this human-centric approach is instilling an innate curiosity to learn about new technologies and the acquisition of requisite skills for navigating the digital transformation landscape. As identified by [39], essential competencies for professionals in the Industry 4.0 milieu encompass the ability to navigate complexity, resolve intricate challenges, and adapt adeptly to novel circumstances.

- Problem Relevance: The existence of a genuine and pertinent problem to be solved serves as a linchpin for the success and sustainability of any project. Assessing the problem’s significance and weighing the cost of its potential solution against the anticipated financial returns are critical considerations. Some projects may falter during this phase if they fail to address a problem that the organization genuinely recognizes or if the solution’s cost outweighs the expected returns. Ref. [35] underscores the importance of evaluating whether the integration of new and existing technologies augments process value. An in-depth analysis of the current operational landscape, often drawing from modernization or expansion efforts, forms a foundational aspect of this assessment.

- Alignment of Technology Selection with the Problem: It is common for the allure of technology to lead users to seek problems that align with a particular solution. However, the recommended approach is to commence with the identification of the problem and subsequently seek the technology that best addresses it. Initiating with technology, and then, seeking a problem can heighten the risk of fabricating a problem that does not inherently exist. Ref. [61] accentuates the significance of accurately selecting project portfolios—an intricate endeavor that harmonizes the contradictory and diverse objectives within the organization.

- Fostering Creativity in Proposing Diverse Solutions: Creativity assumes a pivotal role in Industry 4.0 projects, where the same problem may harbor multiple potential solutions. Encouraging creativity represents both a task and a challenge for managers overseeing Industry 4.0 initiatives. It entails the open-minded consideration of ideas, even if they do not pertain to the most salient problems, as this encouragement of creativity can transform seemingly minor issues into significant opportunities if appropriately developed.

- Necessity for Knowledge Homogenization among Stakeholders: The traditional compartmentalized working model imposes limits on the responsibilities of individual departments. In the Industry 4.0 paradigm, interdepartmental collaboration becomes imperative. This necessitates cross-functional teams that comprehend the interconnectedness of projects and domains. An interviewee highlighted this novel modus operandi as a principal challenge, especially concerning IT, which must now handle data not solely confined to departmental cloud repositories but also data directly sourced from the factory floor. To operate effectively in this new milieu, team members must attain a comprehensive understanding of this transformed landscape. Ref. [21] pinpoints the lack of skills, knowledge, training, and harmonization of knowledge as potential obstacles to successful implementations.

- Familiarity with Available Technologies: Through benchmarking, collaboration with consultants, engagement with established industry suppliers, or the support of innovative startups, it is essential to explore multiple solutions for the same problem. A broad and creative analysis of available options enhances the likelihood of successful implementation. Ref. [44] identifies a lack of technological knowledge as a challenge to successful implementation, underscoring the importance of staying well versed in available technologies.

5. Discussion and Framework Presentation

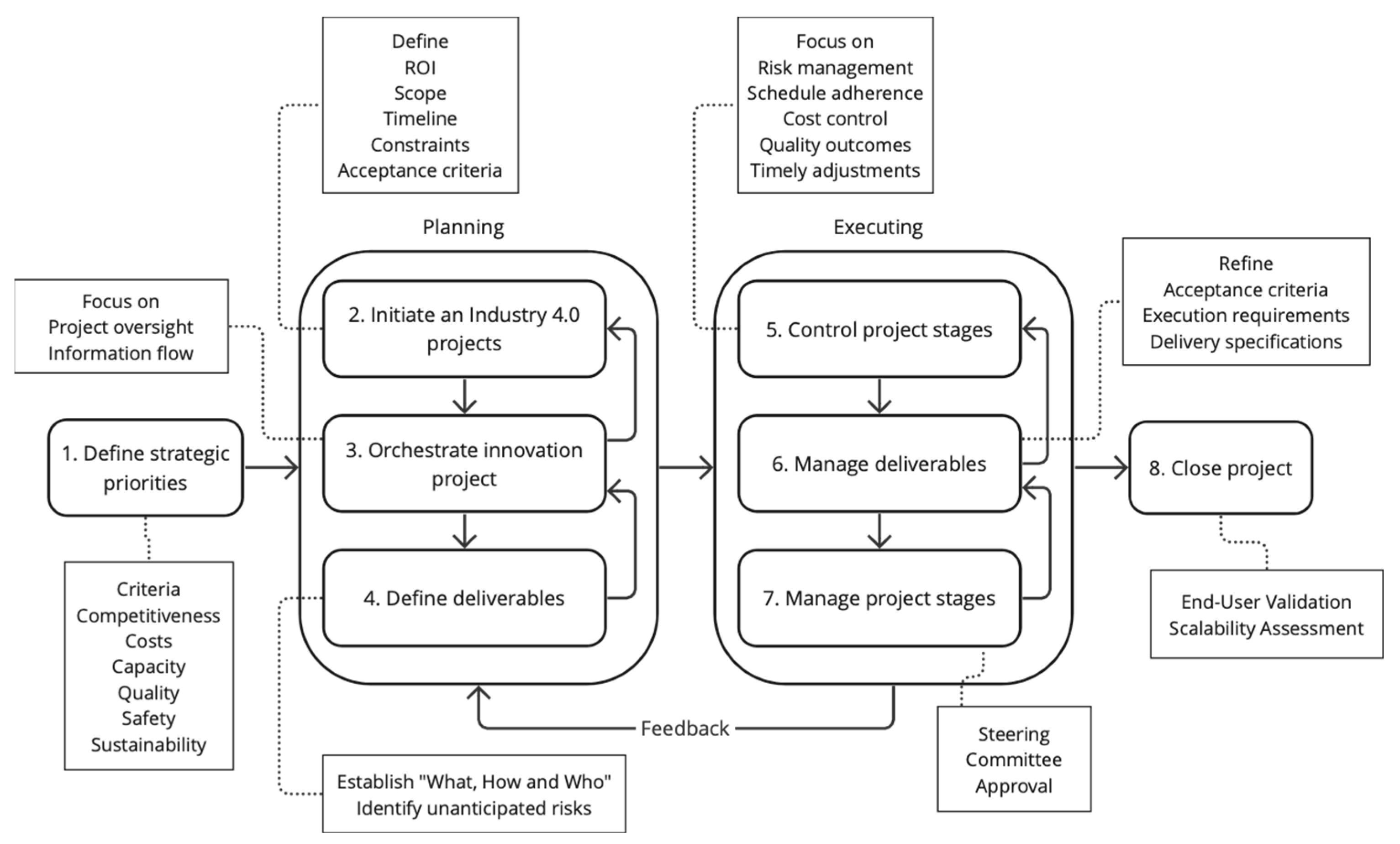

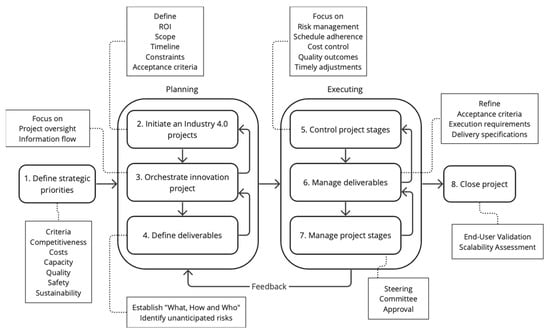

In an effort to streamline the implementation of Industry 4.0 projects, and given the inherently disruptive nature of Industry 4.0-related technologies, tailored augmentation of the existing PRINCE2 framework is suggested, according to Figure 3. Within specific contexts, such as the adoption of RFID, big data, or other Industry 4.0 disruptive technologies, project sponsors or executors may recommend the utilization of a specialized model grounded in innovation principles.

Figure 3.

Framework for implementing Industry 4.0 projects (extended from PRINCE2).

Figure 3 highlights, beyond the main steps of the PRINCE2 extended framework, numbered in the Figure 3, the relationships among them, establishing feedback loops among steps that may be revisited for improving what has already been done, and the main concerns of each step (connected to them by a dotted line), which may include criteria, activities, or other elements necessary for each one.

Leveraging the PRINCE2 framework as the foundational structure, owing to its business-oriented focus and structured product delivery stages, and drawing upon insights from extensive literature analysis and interviews, the ensuing steps are proposed for the effective implementation of Industry 4.0 projects:

- (1)

- Define Strategic Priorities: To establish robust and successful implementation, it is imperative to predefine the company’s strategic priorities. These priorities serve as a pivotal compass guiding project decisions. Prioritization may encompass augmenting competitiveness, reducing costs, increasing production capacity, enhancing product quality, fortifying safety, and fostering sustainability, among other considerations. This strategic alignment with the array of challenges and objectives enables a more coherent analysis of relevant technologies.

- (2)

- Initiate an Industry 4.0 Project: The inception phase marks the initial stride toward future realization. During this phase, the project’s feasibility is meticulously examined, often involving a return on investment (ROI) analysis. Ideas undergo a filtration process, with emphasis placed on the most salient, prioritized, and viable concepts. Essential parameters such as scope assumptions, timelines, constraints, and acceptance criteria are meticulously defined.

- Company Strategy for Innovation: Highlighting the organization’s readiness across all dimensions—including top management, middle management, value chains, digitalization, and employees—is pivotal for successful project implementation. The organization’s maturity stage should be assessed comprehensively.

- Central Oversight Body for Project Monitoring: Establishing a dedicated entity within the organization to oversee all projects, endowed with the autonomy to scrutinize and potentially interconnect them, is critical.

- Resource Management and Capital Procurement: Efficiently managing the initial investment and securing necessary resources, especially in instances where the initial investment is not internally sourced, requires astute financial planning. Specific credit lines designed to promote industrial initiatives may be explored.

- (3)

- Orchestrate Innovation Project: This phase delineates crucial decisions necessary for the project’s successful and controlled execution. Given the dynamic nature of Industry 4.0 technologies, it is vital to exercise strategic oversight to ensure that the project remains on course without undue constraints on its evolution. Project managers play a pivotal role in executive guidance, ensuring clear and unimpeded information flow.

- Team with a Learning Orientation: Cultivating a team with a continuous learning bias is essential. This predisposition fosters adaptability in navigating the evolving landscape of Industry 4.0 technologies.

- Familiarity with Available Technologies: A comprehensive understanding of the spectrum of available technologies is essential for informed decision-making.

- (4)

- Define Deliverables: This process lays the groundwork for comprehending the effort required to deliver the project’s objectives. It aims to enhance transparency and facilitate information sharing to reduce the risk of project failure. Unanticipated risks that surface during this stage can be identified and addressed promptly, potentially averting project derailment. The “What, How, and Who” aspects are central to this endeavor.

- (5)

- Control Project Stages: This stage entails the execution of the project manager’s duties, focusing on risk management, schedule adherence, cost control, and the delivery of quality outcomes. Real-time data provided by project management technologies empowers agile decision-making, enabling timely adjustments and checkpoint assessments at shorter intervals.

- (6)

- Manage Deliverables: The specialist team manager assumes responsibility for ensuring that deliverables are aligned with project objectives. A more refined definition of acceptance criteria, execution requirements, and delivery specifications is imperative.

- Competitive Advantage through Agility: Swift adaptation to uncertainties inherent in innovative product development can confer a competitive edge. The organization’s responsiveness to change influences its competitive positioning.

- (7)

- Manage project stages: Each project stage concludes with a milestone or boundary that delineates its conclusion, enabling the transition to the subsequent stage. In agile models, these stage-to-stage transitions are often termed increments. Before progressing to subsequent stages, the Steering Committee (as introduced in step two) must grant approval based on an evaluation of the project’s continued alignment with business objectives and its risk profile.

- (8)

- Close Project: This phase aims to affirm the project’s final acceptance, confirming that established objectives have been met or that the project no longer holds potential value for the business. Final acceptance entails end-user validation and scalability assessment. In the context of innovation projects related to Industry 4.0, formalizing lessons learned is of paramount importance. This repository of insights serves as a valuable resource for all stakeholders involved in future initiatives.

Table 2 depicts the relationship between the identified challenges and success factors from Section 4 and the project steps of the proposed model in Figure 3. A single “+” denotes a relationship, whereas a “++” denotes a very strong relationship. This table aims to show that all challenges and success factors are considered in this framework. A strong relationship means that the step, as previously described, directly addresses the challenge, or takes into account the success factor, whereas a simple relationship means that the challenge is either partially or indirectly addressed and that the critical success factor is partially or indirectly taken into account.

Table 2.

Relationships of framework steps and Industry 4.0 project challenges and success factors.

Table 3 depicts the relationship between the insights from the cases and each one of the steps of the framework in the same sense as Table 2.

Table 3.

Relationships of framework steps and Industry 4.0 insights from the cases.

5.1. Implications for Researchers

The proposed framework, by adapting PRINCE2 to guide Industry 4.0 technology adoption projects, introduces a multidisciplinary research opportunity. It invites exploration into how traditional project management methodologies can evolve to address the complexity, agility, and innovation required in Industry 4.0 environments. This adaptation could involve investigating new risk management strategies, stakeholder engagement processes, and the integration of digital transformation frameworks within PRINCE2. Researchers are tasked with identifying the modifications necessary to make PRINCE2 applicable and effective in the context of smart manufacturing, automation, and data-driven decision-making, thereby enhancing its relevance for future technological landscapes.

This involves developing methodologies that assess the environmental impact of new technologies, ensuring projects contribute positively to sustainability goals. Researchers might also explore how such a framework can promote economic and social sustainability, encouraging projects that not only innovate but also enhance community well-being and ensure long-term viability. This interdisciplinary approach expands the scope of project management research to include sustainability metrics, encouraging a balance between innovation and environmental stewardship.

5.2. Implications for Managers

For managers, this framework helps navigate through the complexities of integrating advanced technologies with traditional project management frameworks. Managers must adapt to a rapidly changing environment, requiring them to be agile and technologically innovative. This necessitates a continuous learning approach and the ability to lead cross-functional teams effectively, ensuring that projects not only meet their objectives but also align with the broader strategic goals of embracing Industry 4.0 technologies.

This framework might also be used to prioritize environmental conservation, economic efficiency, and social equity, balancing innovation with sustainability goals and leading teams toward outcomes that are not just technologically advanced but also socially responsible and environmentally friendly. This approach requires a new set of skills and a deep understanding of sustainable development principles in the context of Industry 4.0.

6. Conclusions

A framework for managing Industry 4.0 projects has been systematically presented in this study. However, it is crucial to acknowledge that the findings are rooted in specific industries, necessitating further validation for broader applicability. The intricacies of implementing Industry 4.0 projects are deeply entwined with a company’s overarching strategy, rendering a comprehensive analysis of all transformative facets a challenging endeavor within the scope of this research. While the current study may not exhaustively cover every facet of organizational change or provide an all-encompassing framework to navigate the complexity inherent in Industry 4.0 implementations, it aims to make a valuable contribution to academia and business practices. By delineating steps that, if diligently followed, promise a discernible enhancement in project management, this research endeavors to provide practical insights for stakeholders engaging in Industry 4.0 endeavors.

PRINCE2’s comprehensive nature, with its focus on principles, themes, and processes, becomes instrumental in navigating the multifaceted challenges of sustainable technology integration, from stakeholder engagement to benefit realization, ultimately leading to sustainable competitive advantages and corporate responsibility.

It is imperative to emphasize that this research does not aspire to encapsulate the entirety of organizational change or depict every organizational stage during the Industry 4.0 journey. Instead, it concentrates on offering a set of guidelines and considerations that are pertinent to facilitating the nuanced and challenging landscape of Industry 4.0 project implementations. This study underscores the evolutionary nature of the journey towards Industry 4.0, where the inherently disruptive characteristics of technologies introduce heightened risks to investments, necessitating an unwavering commitment to continuous learning. In this dynamic landscape, the adaptation to new products, services, and markets is not merely an option but an essential component of the transformative process.

The proposed framework aims to encapsulate key requisites vital for navigating this evolutionary journey, fostering more streamlined and effective implementation of Industry 4.0 projects. This research has not only highlighted pertinent challenges but also shed light on success factors and shared practical implementation experiences, contributing to the collective understanding of Industry 4.0 dynamics in contemporary business landscapes.

Finally, in the context of this study, Industry 5.0 [62] is highly pertinent, representing a shift towards a more human-centric, resilient, and sustainable industrial paradigm. As this study aims to extend the PRINCE2 framework to support Industry 4.0 technology adoption projects, incorporating Industry 5.0 ideals means emphasizing personalized production, the collaboration between humans and machines, and the well-being of workers. This evolution underscores the necessity for a project management approach that not only drives technological innovation but also fosters an environment where technology augments human capabilities and operates within the limits of ecological sustainability. Thus, this study’s framework must be adaptable to not only the current technological landscape but also the forthcoming advancements that Industry 5.0 promises.

Limitations of the Study

This study may face limitations such as a potential bias from the selected literature, which might not fully represent the diverse perspectives within Industry 4.0 contexts. Additionally, the rapid evolution of Industry 4.0 technologies could outpace this study’s findings, leading to recommendations that might become quickly outdated. The generalizability of the developed framework could also be limited if the study samples are not sufficiently diverse or large enough to capture the wide range of Industry 4.0 applications and organizational contexts.

This study might also struggle with incorporating the full range of stakeholder perspectives within Industry 4.0, leading to a framework that might not fully address all user needs or industry standards. Furthermore, the dynamic nature of Industry 4.0 could introduce challenges in establishing long-term applicability for the framework, necessitating regular updates to keep pace with technological advancements. Lastly, the reliance on interviews might introduce subjective biases, affecting the objectivity and reproducibility of the study’s outcomes, thus impacting the framework’s credibility and wider acceptance.

Author Contributions

Conceptualization, J.E.P.J. and F.D.; Methodology, L.H.R.-M. and F.D.; Validation, J.E.P.J.; Formal analysis, L.H.R.-M.; Investigation, L.H.R.-M.; Writing—review & editing, J.E.P.J. and F.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A Brief Discussion on the Trends of Habilitating Technologies for Industry 4.0 and Smart Manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Kumar, S.; Suhaib, M.; Asjad, M. Analyzing the Barriers to Industry 4.0 through Best-Worst Method. Int. J. Perform. Eng. 2020, 16, 27. [Google Scholar] [CrossRef]

- Ślusarczyk, B. Industry 4.0–Are We Ready? Pol. J. Manag. Stud. 2018, 17, 232–248. [Google Scholar] [CrossRef]

- Pan, M.; Sikorski, J.; Kastner, C.A.; Akroyd, J.; Mosbach, S.; Lau, R.; Kraft, M. Applying Industry 4.0 to the Jurong Island Eco-Industrial Park. Energy Procedia 2015, 75, 1536–1541. [Google Scholar] [CrossRef]

- Demircan Keskin, F. A Two-stage Fuzzy Approach for Industry 4.0 Project Portfolio Selection within Criteria and Project Interdependencies Context. J. Multi-Criteria Decis. Anal. 2020, 27, 65–83. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Determinants of Information and Digital Technology Implementation for Smart Manufacturing. Int. J. Prod. Res. 2020, 58, 2384–2405. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Kluczek, A. Impact of Industry 4.0 on Sustainability-Bibliometric Literature Review. Sustainability 2020, 12, 5650. [Google Scholar] [CrossRef]

- Furstenau, L.B.; Sott, M.K.; Kipper, L.M.; Machado, E.L.; López-Robles, J.R.; Dohan, M.S.; Cobo, M.J.; Zahid, A.; Abbasi, Q.H.; Imran, M.A. Link Between Sustainability and Industry 4.0: Trends, Challenges and New Perspectives. IEEE Access 2020, 8, 140079–140096. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Gonzalez, E.S. Understanding the Adoption of Industry 4.0 Technologies in Improving Environmental Sustainability. Sustain. Oper. Comput. 2022, 3, 203–217. [Google Scholar] [CrossRef]

- Schwaber, K.; Sutherland, J. The Scrum Guide, The Definitive Guide to Scrum: The Rules of the Game. Pub. Scrum.org 2020. Available online: https://www.scrum.org/resources/scrum-guide (accessed on 12 February 2024).

- De Melo, J.L.; dos Santos, C.P.; Rosamilha, N.; Ribeiro, M.C.T.; Macedo, J.; de Oliveira, A.V. Guia Preparatório Para a Certificação Prince2 Foundation. Gerenciamento de Projetos Em Ambiente Controlado, 1st ed.; Editora NovaTerra: Rio De Janeiro, Brazil, 2015; ISBN 978-8561893606. [Google Scholar]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the Definition of Industry 4.0: Analysis and Open Questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Ing, T.S.; Lee, T.C.; Chan, S.W.; Alipal, J.; Hamid, N.A. An Overview of the Rising Challenges in Implementing Industry 4.0. Int. J. Supply Chain Manag. 2019, 8, 1181–1188. [Google Scholar]

- Kumar, R.; Singh, R.K.; Dwivedi, Y.K. Application of Industry 4.0 Technologies in SMEs for Ethical and Sustainable Operations: Analysis of Challenges. J. Clean. Prod. 2020, 275, 124063. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, M. Challenges and Benefits of Industry 4.0: An Overview. Int. J. Supply Oper. Manag. 2018, 5, 256–265. [Google Scholar]

- Prause, M. Challenges of Industry 4.0 Technology Adoption for SMEs: The Case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef]

- Vuksanović Herceg, I.; Kuč, V.; Mijušković, V.M.; Herceg, T. Challenges and Driving Forces for Industry 4.0 Implementation. Sustainability 2020, 12, 4208. [Google Scholar] [CrossRef]

- Bajic, B.; Rikalovic, A.; Suzic, N.; Piuri, V. Industry 4.0 Implementation Challenges and Opportunities: A Managerial Perspective. IEEE Syst. J. 2021, 15, 546–559. [Google Scholar] [CrossRef]

- Muller, J.M.; Kiel, D.; Voigt, K.I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Barker, S. Brilliant PRINCE2: What You Really Need to Know about PRINCE2; Pearson: London, UK, 2013; ISBN 0273750550. [Google Scholar]

- Tuttle, S. PRINCE2 in Action: Project Management in Real Terms; IT Governance Publishing: Ely, UK, 2018; ISBN 1849283273. [Google Scholar]

- Abdullah, A.A.; Abdul-Samad, Z.; Abdul-Rahman, H.; Salleh, H. Project Management Standards, Guides and Methods: A Critical Overview. J. Proj. Manag. Pract. 2021, 1, 35–51. [Google Scholar] [CrossRef]

- Albert, M.; Balve, P.; Spang, K. Evaluation of Project Success: A Structured Literature Review. Int. J. Manag. Proj. Bus. 2017, 10, 796–821. [Google Scholar] [CrossRef]

- AXELOS. Managing Successful Projects with PRINCE2, 6th ed.; The Stationery Office: Norwich, UK, 2017. [Google Scholar]

- Nicolini, D. Practice Theory, Work, and Organization: An Introduction; OUP: Oxford, UK, 2012; ISBN 0191644625. [Google Scholar]

- Floricel, S.; Bonneau, C.; Aubry, M.; Sergi, V. Extending Project Management Research: Insights from Social Theories. Int. J. Proj. Manag. 2014, 32, 1091–1107. [Google Scholar] [CrossRef]

- Yin, R.K. Estudo de Caso-: Planejamento e Métodos; Bookman Editora: Porto Alegre, Brazil, 2015; ISBN 8582602324. [Google Scholar]

- Ensslin, L.; Ensslin, S.R.; Lacerda, R.T.D.O.; Tasca, J.E. ProKnow-C, Knowledge Development Process—Constructivist. Process. Técnico Pat. Regist. Pendente INPI Bras. 2010, 10. [Google Scholar]

- de Carvalho, G.D.G.; Sokulski, C.C.; da Silva, W.V.; de Carvalho, H.G.; de Moura, R.V.; de Francisco, A.C.; Da Veiga, C.P. Bibliometrics and Systematic Reviews: A Comparison between the Proknow-C and the Methodi Ordinatio. J. Informetr. 2020, 14, 101043. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef]

- Veile, J.W.; Kiel, D.; Müller, J.M.; Voigt, K.-I. Lessons Learned from Industry 4.0 Implementation in the German Manufacturing Industry. J. Manuf. Technol. Manag. 2020, 31, 977–997. [Google Scholar] [CrossRef]

- Martinez, F. Process Excellence the Key for Digitalisation. Bus. Process Manag. J. 2019, 25, 1716–1733. [Google Scholar] [CrossRef]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- Wilkesmann, M.; Wilkesmann, U. Industry 4.0–Organizing Routines or Innovations? VINE J. Inf. Knowl. Manag. Syst. 2018, 48, 238–254. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ozkan-Ozen, Y.D. Analyzing Workforce 4.0 in the Fourth Industrial Revolution and Proposing a Road Map from Operations Management Perspective with Fuzzy DEMATEL. J. Enterp. Inf. Manag. 2018, 31, 891–907. [Google Scholar] [CrossRef]

- Alsaadi, N. Modeling and Analysis of Industry 4.0 Adoption Challenges in the Manufacturing Industry. Processes 2022, 10, 2150. [Google Scholar] [CrossRef]

- Dieste, M.; Sauer, P.C.; Orzes, G. Organizational Tensions in Industry 4.0 Implementation: A Paradox Theory Approach. Int. J. Prod. Econ. 2022, 251, 108532. [Google Scholar] [CrossRef]

- Kovaitė, K.; Šūmakaris, P.; Stankevičienė, J. Digital Communication Channels in Industry 4.0 Implementation: The Role of Internal Communication. Manag. J. Contemp. Manag. Issues 2020, 25, 171–191. [Google Scholar] [CrossRef]

- Konur, S.; Lan, Y.; Thakker, D.; Morkyani, G.; Polovina, N.; Sharp, J. Towards Design and Implementation of Industry 4.0 for Food Manufacturing. Neural Comput. Appl. 2023, 35, 23753–23765. [Google Scholar] [CrossRef]

- Pollak, A.; Hilarowicz, A.; Walczak, M.; Gąsiorek, D. A Framework of Action for Implementation of Industry 4.0. an Empirically Based Research. Sustainability 2020, 12, 5789. [Google Scholar] [CrossRef]

- Schneider, P. Managerial Challenges of Industry 4.0: An Empirically Backed Research Agenda for a Nascent Field. Rev. Manag. Sci. 2018, 12, 803–848. [Google Scholar] [CrossRef]

- Marques, M.; Agostinho, C.; Zacharewicz, G.; Jardim-Gonçalves, R. Decentralized Decision Support for Intelligent Manufacturing in Industry 4.0. J. Ambient. Intell. Smart Environ. 2017, 9, 299–313. [Google Scholar] [CrossRef]

- Vrchota, J.; Rehor, P.; Maríková, M.; Pech, M. Critical Success Factors of the Project Management in Relation to Industry 4.0 for Sustainability of Projects. Sustainability 2021, 13, 281. [Google Scholar] [CrossRef]

- Calabrese, A.; Levialdi Ghiron, N.; Tiburzi, L. ‘Evolutions’ and ‘Revolutions’ in Manufacturers’ Implementation of Industry 4.0: A Literature Review, a Multiple Case Study, and a Conceptual Framework. Prod. Plan. Control 2021, 32, 213–227. [Google Scholar] [CrossRef]

- Lenart-Gansiniec, R. Organizational Learning in Industry 4.0. Probl. Zarządzania 2019, 17, 96–108. [Google Scholar] [CrossRef]

- Shang, G.; Low, S.P.; Lim, X.Y. V Prospects, Drivers of and Barriers to Artificial Intelligence Adoption in Project Management. Built Environ. Proj. Asset Manag. 2023, 13, 629–645. [Google Scholar] [CrossRef]

- Ghadge, A.; Kara, M.E.; Moradlou, H.; Goswami, M. The Impact of Industry 4.0 Implementation on Supply Chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Antony, J.; Sony, M.; Garza-Reyes, J.A.; McDermott, O.; Tortorella, G.; Jayaraman, R.; Sucharitha, R.S.; Salentijin, W.; Maalouf, M. Industry 4.0 Benefits, Challenges and Critical Success Factors: A Comparative Analysis through the Lens of Resource Dependence Theory across Continents and Economies. J. Manuf. Technol. Manag. 2023, 34, 1073–1097. [Google Scholar] [CrossRef]

- da Silva, V.; Kovaleski, J.L.; Pagani, R.N.; Gomes, M.A.S. Industry 4.0 Implementations: A Systematic Review of Approaches and Main Applicabilities in the Broiler Meat Production Chain. World’s Poult. Sci. J. 2023, 79, 563–579. [Google Scholar] [CrossRef]

- Gajdzik, B.; Grabowska, S.; Saniuk, S. A Theoretical Framework for Industry 4.0 and Its Implementation with Selected Practical Schedules. Energies 2021, 14, 940. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical Factors for the Successful Implementation of Industry 4.0: A Review and Future Research Direction. Prod. Plan. Control 2020, 31, 799–815. [Google Scholar] [CrossRef]

- Contador, J.C.; Satyro, W.C.; Contador, J.L.; de Mesquita Spinola, M. Flexibility in the Brazilian Industry 4.0: Challenges and Opportunities. Glob. J. Flex. Syst. Manag. 2020, 21, 15–31. [Google Scholar] [CrossRef]

- Hirsch-Kreinsen, H. Digitization of Industrial Work: Development Paths and Prospects. J. Labour Mark. Res. 2016, 49, 1–14. [Google Scholar] [CrossRef]

- Sousa-Zomer, T.T.; Neely, A.; Martinez, V. Digital Transforming Capability and Performance: A Microfoundational Perspective. Int. J. Oper. Prod. Manag. 2020, 40, 1095–1128. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Díaz-Madroñero, M.; Campuzano-Bolarín, F. Implementing Industry 4.0 Principles. Comput. Ind. Eng. 2021, 158, 107379. [Google Scholar] [CrossRef]

- Hoyer, C.; Gunawan, I.; Reaiche, C.H. The Implementation of Industry 4.0—A Systematic Literature Review of the Key Factors. Syst. Res. Behav. Sci. 2020, 37, 557–578. [Google Scholar] [CrossRef]

- Ghasemzadeh, F.; Archer, N.P. Project Portfolio Selection through Decision Support. Decis. Support Syst. 2000, 29, 73–88. [Google Scholar] [CrossRef]

- Leng, J.W.; Sha, W.N.; Wang, B.C.; Zheng, P.; Zhuang, C.B.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L.H. Industry 5.0: Prospect and Retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).